Composite electrocatalyst material used for Li-air batteries and preparation method thereof

A lithium-air battery and electrocatalyst technology, applied in the field of electrochemistry, can solve problems such as poor conductivity of transition metal oxides, ineffective reduction of charging voltage, uneven distribution of manganese oxide and silver, etc., to improve electrocatalytic performance , promote the effect of stability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

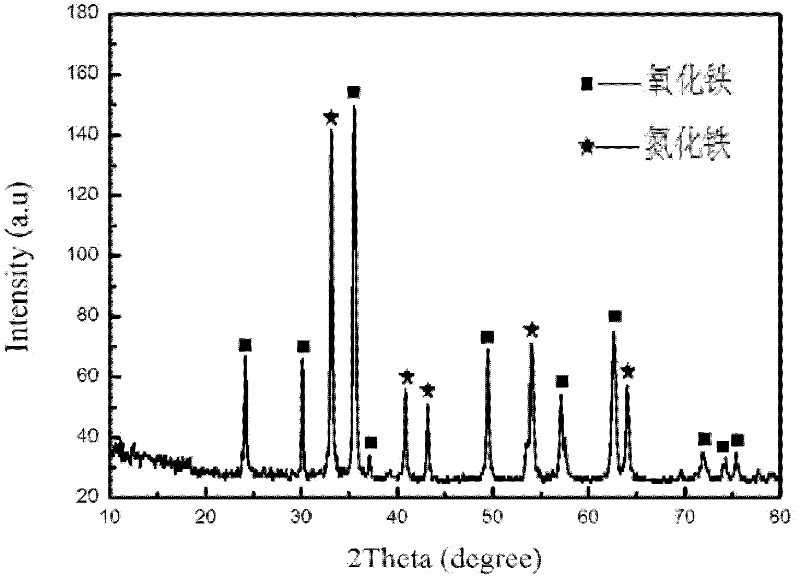

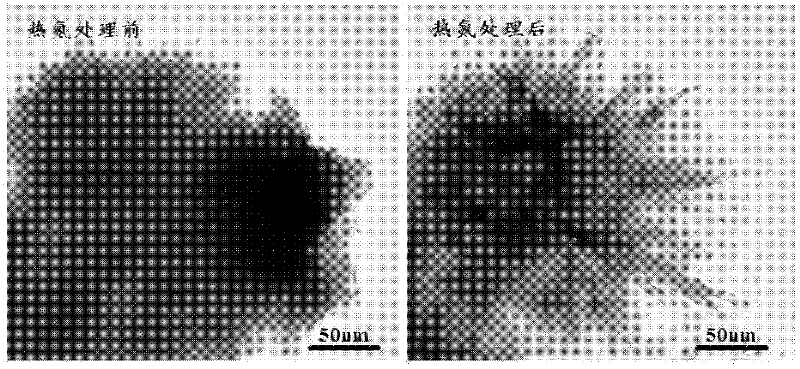

[0038] Disperse 3.0g of iron oxide nanoparticles with a diameter of 300nm and 0.5g of urea in an aqueous solution, ultrasonically oscillate for 2h, and dry the obtained slurry at 100°C to obtain nitrogen-pretreated iron oxide powder, which is placed in a vacuum tube furnace In the process, vacuumize the tube furnace, and then feed the mixed gas of ammonia and argon with a molar ratio of 3:4. After the furnace is filled with gas, keep the gas flow rate at 300ml / min; The temperature was raised to 350°C at a rate of °C / min, kept at a temperature of 1h, and then cooled with the furnace to obtain an iron oxide composite electrocatalyst material with a diameter of 300nm and a surface iron nitride modification.

[0039] Material performance characterization:

[0040] The crystal structure of the material was analyzed with a Rigaku 3014 X-ray diffractometer in Japan, and the morphology of the material was observed with a transmission electron microscope TEM (PhilipsCM12).

[0041] El...

Embodiment 2

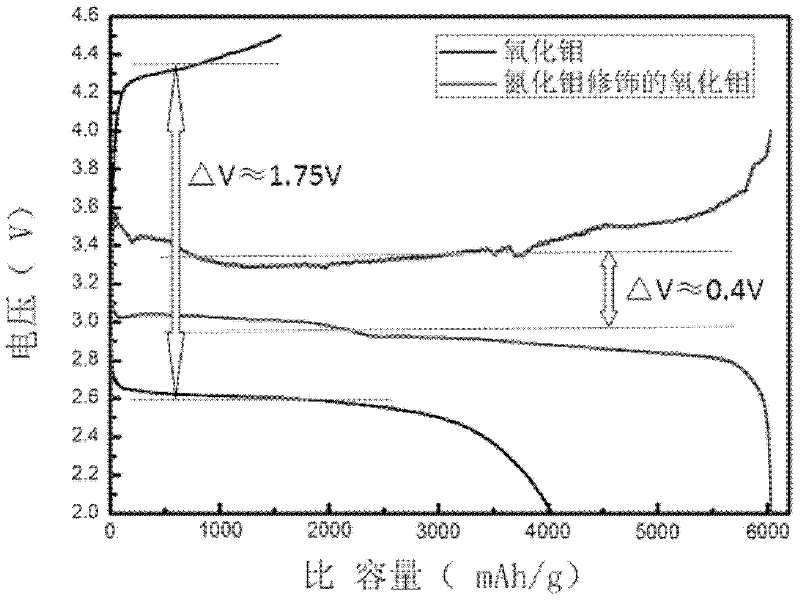

[0045] Disperse 2.0g of molybdenum oxide nanoparticles with a diameter of 100nm and 0.5g of urea in an aqueous solution, ultrasonically oscillate for 2 hours, and dry the obtained slurry at 100°C to obtain nitrogen-pretreated molybdenum oxide powder, which is placed in a vacuum tube furnace In the process, vacuumize the tube furnace, and then feed the mixed gas of ammonia and argon with a molar ratio of 4:4. After the furnace is filled with gas, keep the gas flow rate at 350ml / min; The temperature was raised to 550°C at a rate of °C / min, held for 1.5h, and then cooled with the furnace to obtain a molybdenum oxide composite electrocatalyst material with a diameter of 100nm and a molybdenum nitride-modified surface.

[0046] The electrochemical performance test is the same as in Example 1.

[0047] According to the composite electrocatalyst material prepared in Example 2, the assembled battery has good electrocatalytic performance, the first discharge specific capacity is 6000mA...

Embodiment 3

[0049] Put 2.0g of cobalt trioxide nanoparticles with a diameter of 200nm into a vacuum tube furnace, vacuumize the tube furnace, and then feed a mixed gas of ammonia and argon with a molar ratio of 2:4, and wait for the furnace to be filled with gas. Keep the gas flow rate at 300ml / min; raise the temperature of the tube furnace to 450°C at a rate of 5°C / min, keep it warm for 30min, and then cool with the furnace to obtain a composite electrocatalyst material of cobalt nitride-modified cobalt tetroxide with a diameter of 200nm .

[0050] The electrochemical performance test is the same as in Example 1.

[0051] The composite electrocatalyst material prepared according to Example 3 has uniform particle dispersion and good electrical conductivity. The initial discharge capacity is 5500mAh / g, the discharge voltage platform is 2.75V, and the charging platform is 3.6V. The battery performance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com