Patents

Literature

149 results about "Ferrous disulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(II) sulfide or ferrous sulfide (Br.E. sulphide) is one of a family chemical compounds and minerals with the approximate formula FeS. Iron sulfides are often iron-deficient non-stoichiometric.

High discharge capacity lithium battery

InactiveUS20050277023A1High capacityLong storage lifeElectrode manufacturing processesFinal product manufactureScavengerCycloaliphatic epoxy

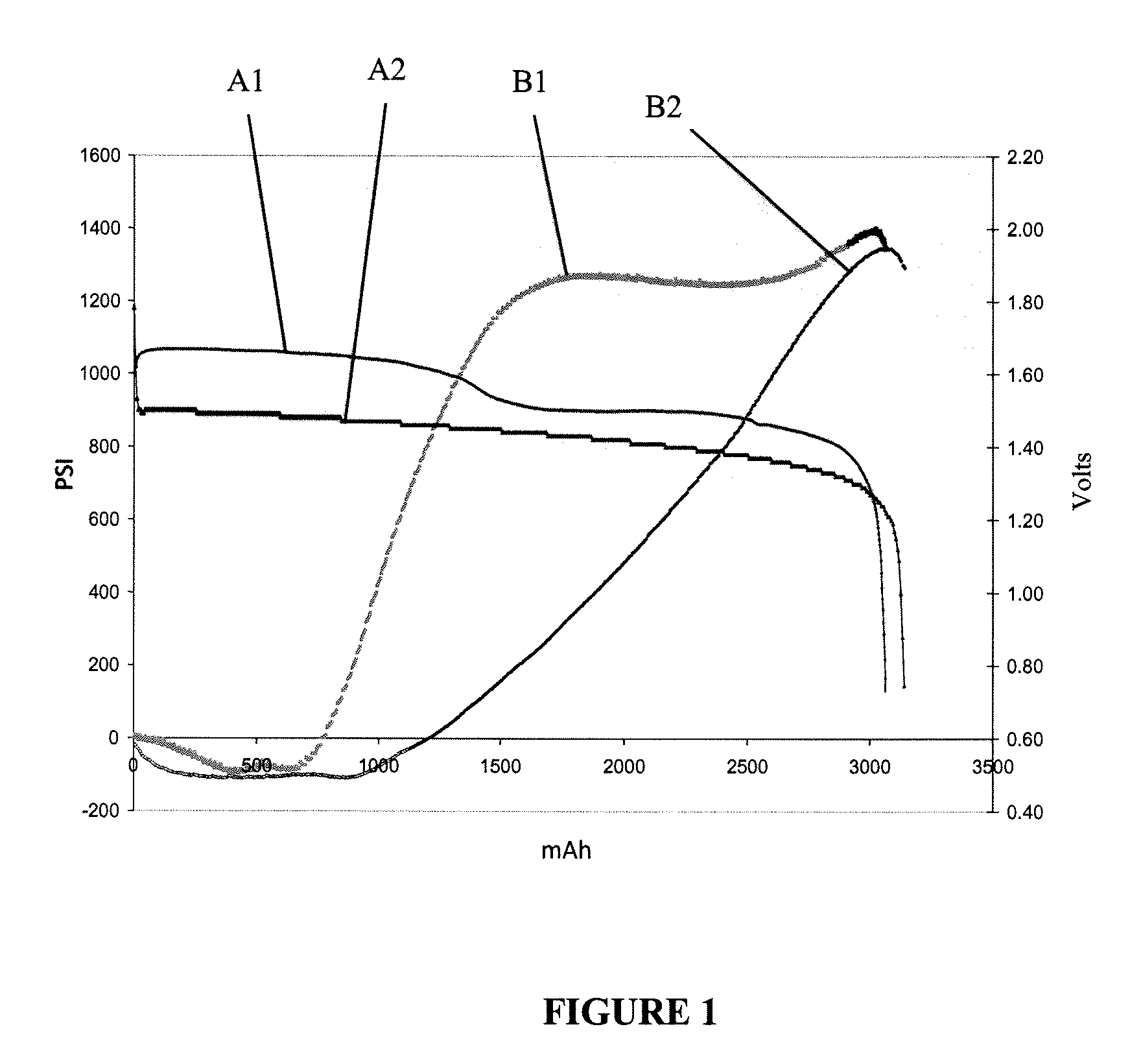

Electrochemical battery cells, and more particularly, to cells comprising a lithium negative electrode and an iron disulfide positive electrode. Before use in the cell, the iron disulfide has an inherent pH, or a mixture of iron disulfide and an pH raising additive compound have a calculated pH, of at least a predetermined minimum pH value. In a preferred embodiment, the pH raising additive compound comprises a Group IIA element of the Periodic Table of the Elements, or an acid scavenger or pH control agent such as an organic amine, cycloaliphatic epoxy, amino alcohol or overbased calcium sulfonate. In one embodiment, the iron disulfide particles utilized in the cell have a specific reduced average particle size range. Methods for preparing cathodes and electrochemical battery cells comprising such cathodes including (a) iron disulfide or (b) a mixture of iron disulfide and the pH raising additive compound, having (a) an inherent pH or (b) a calculated pH greater than or equal to a predetermined minimum value are disclosed.

Owner:ENERGIZER BRANDS

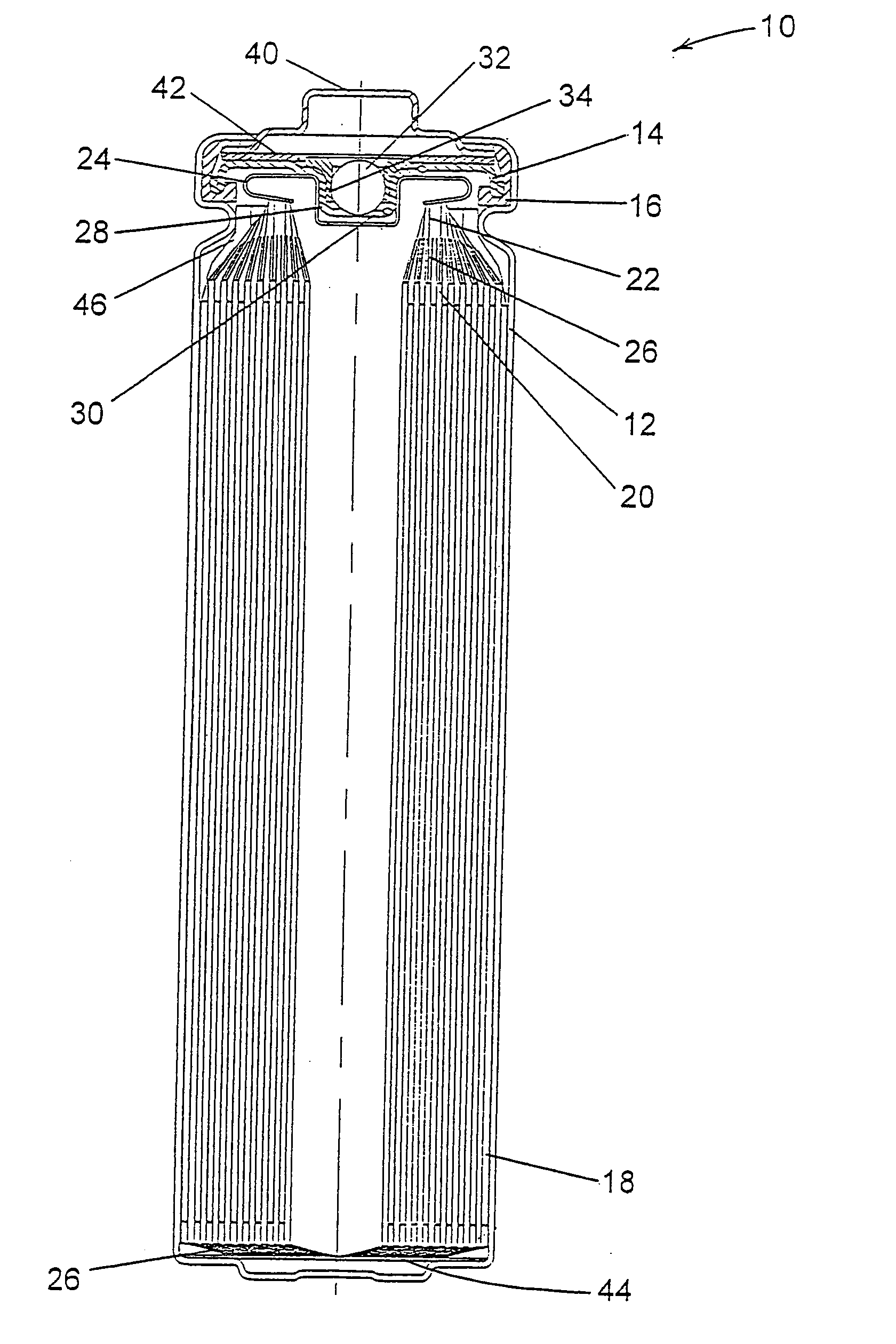

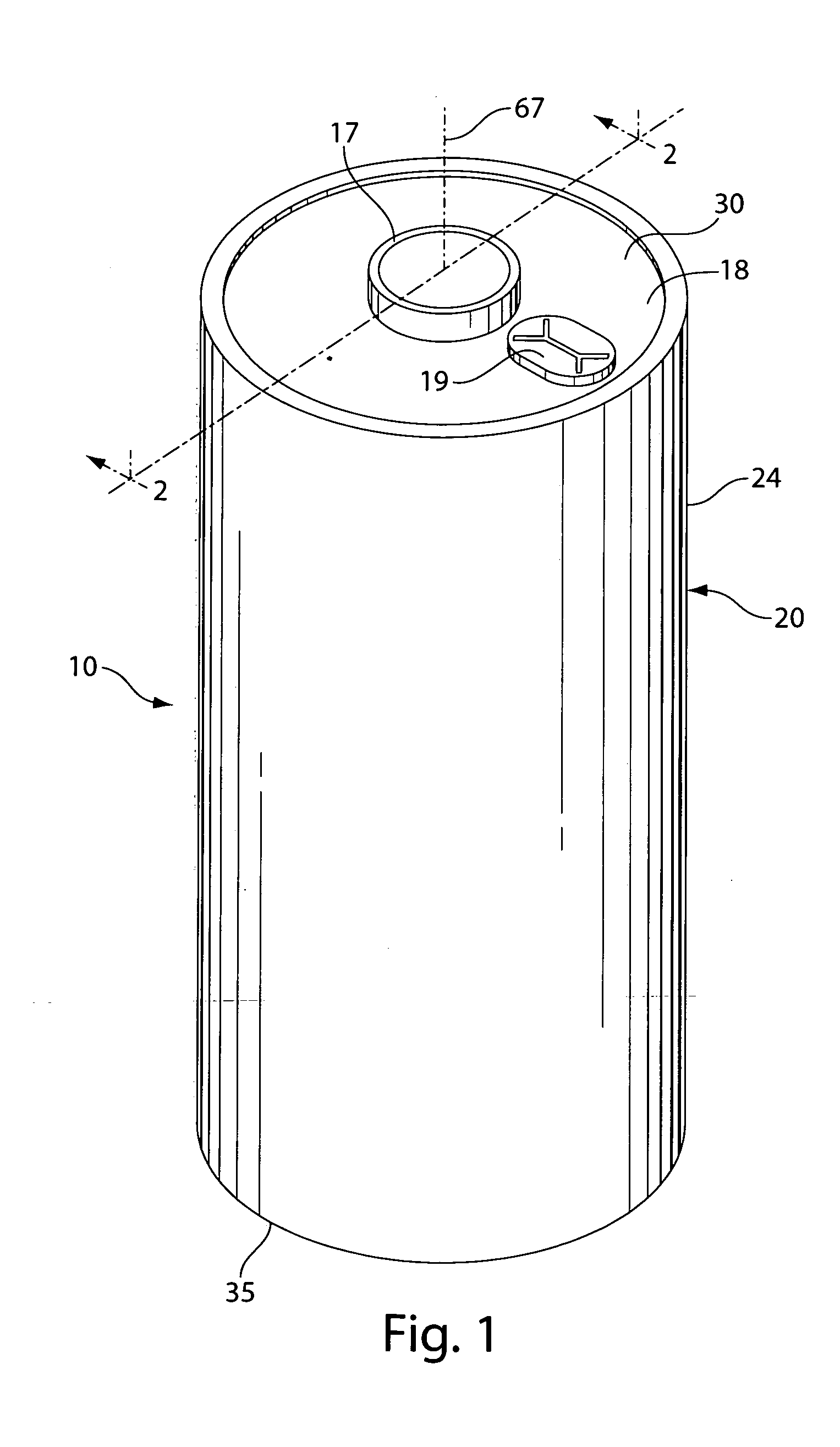

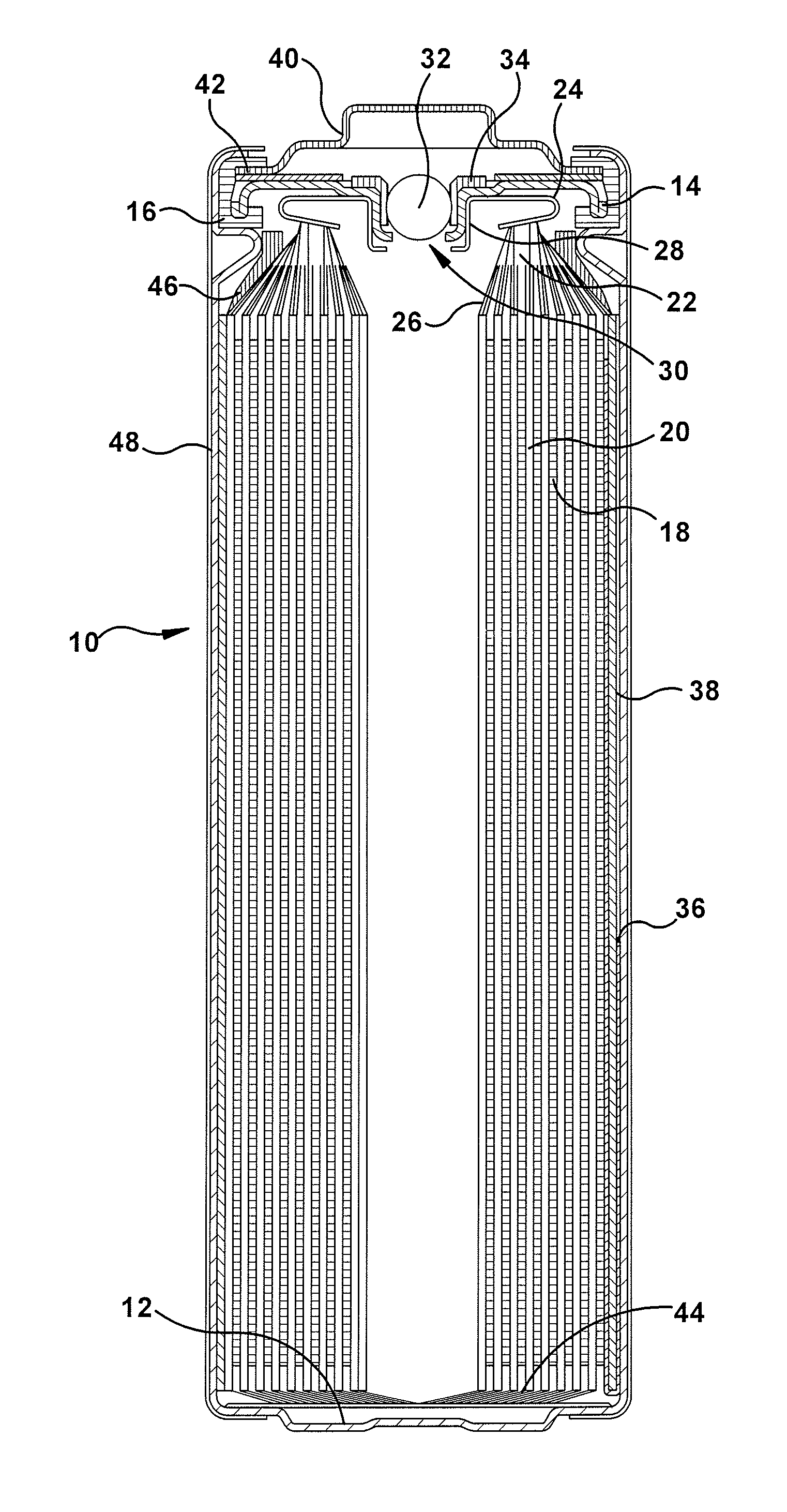

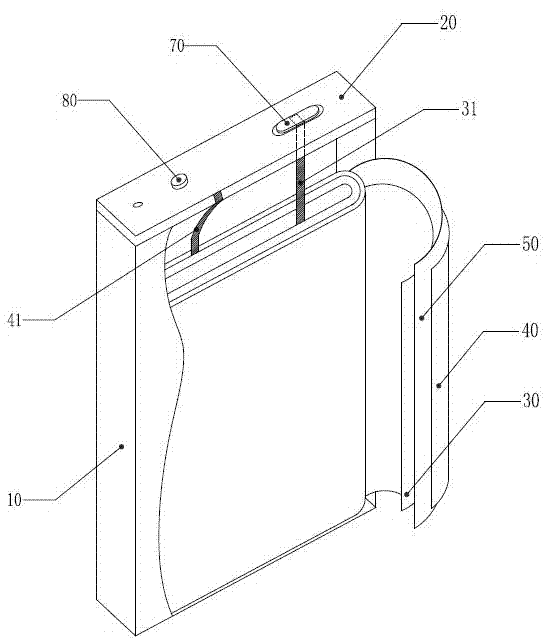

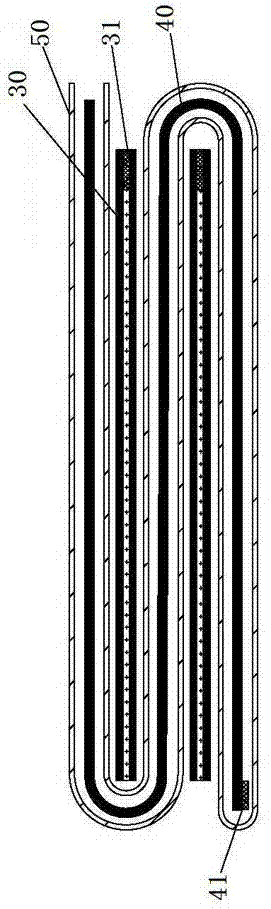

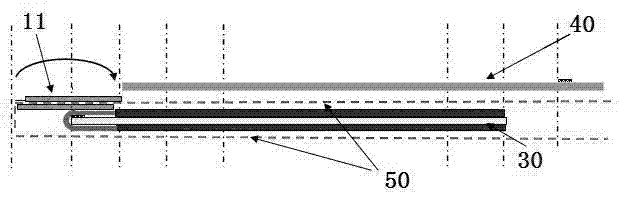

Lithium-Iron Disulfide Cell Design

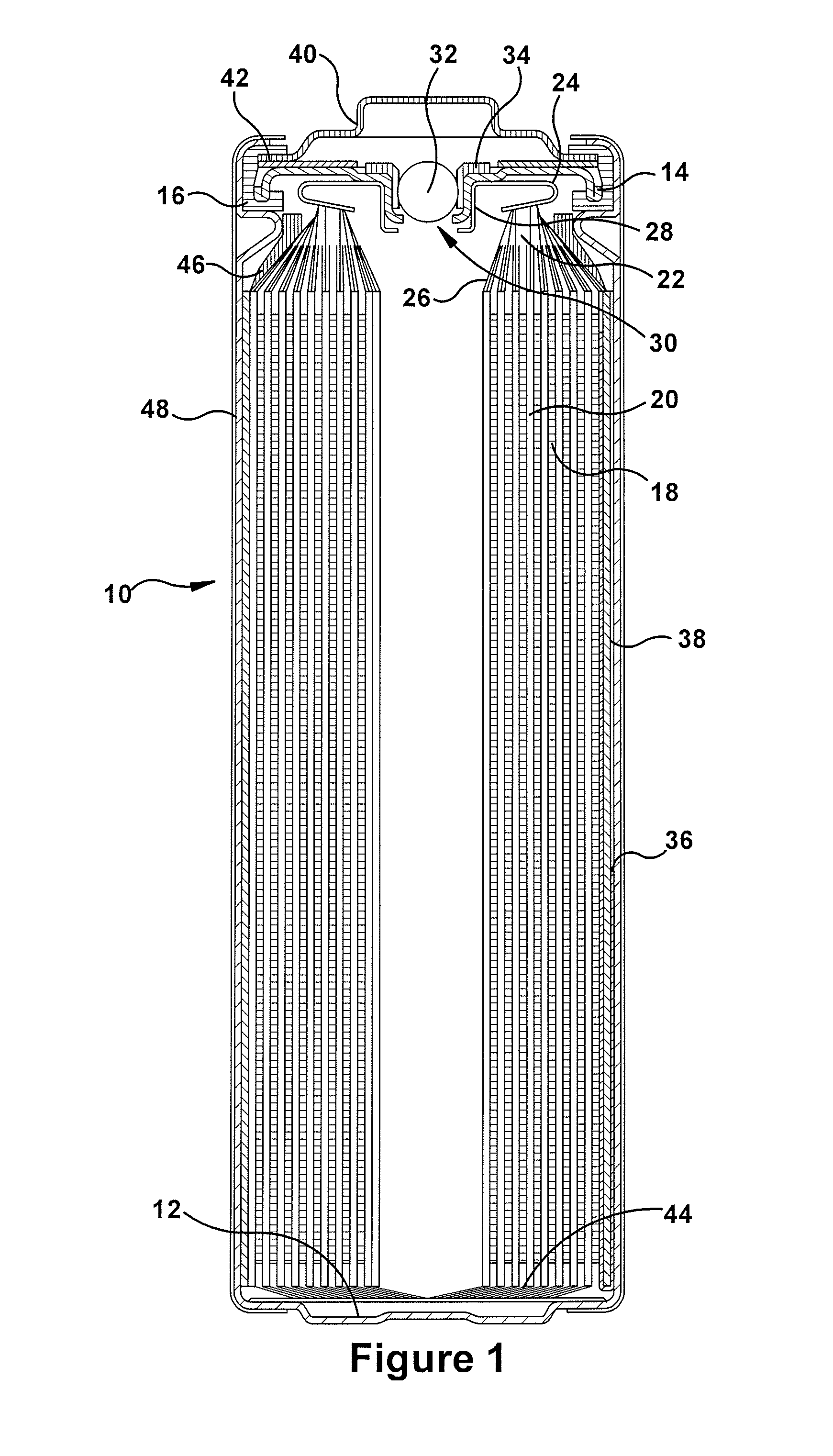

ActiveUS20090104520A1Large capacityIncrease capacityCell seperators/membranes/diaphragms/spacersSmall-sized cells cases/jacketsCell designEngineering

Owner:ENERGIZER BRANDS

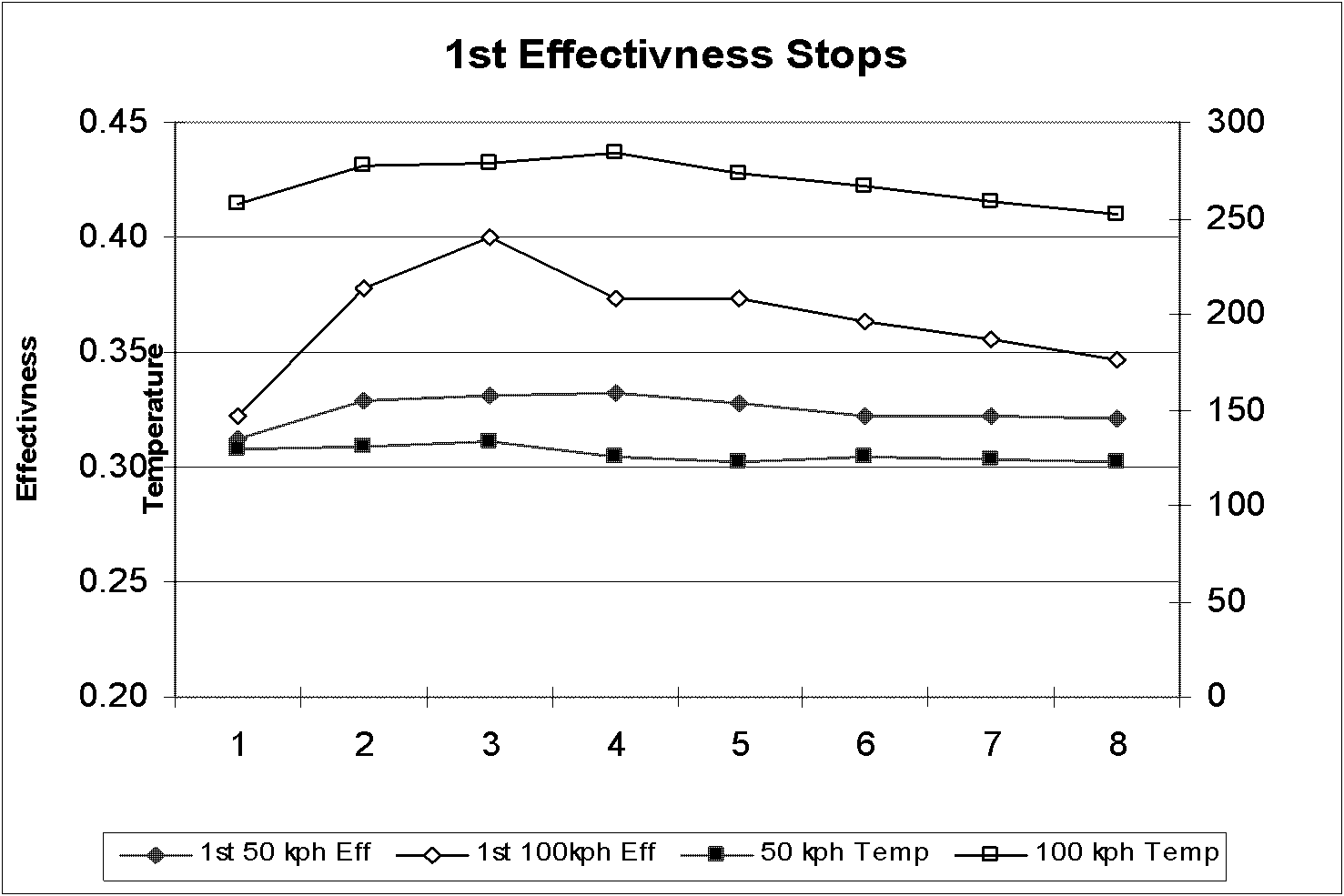

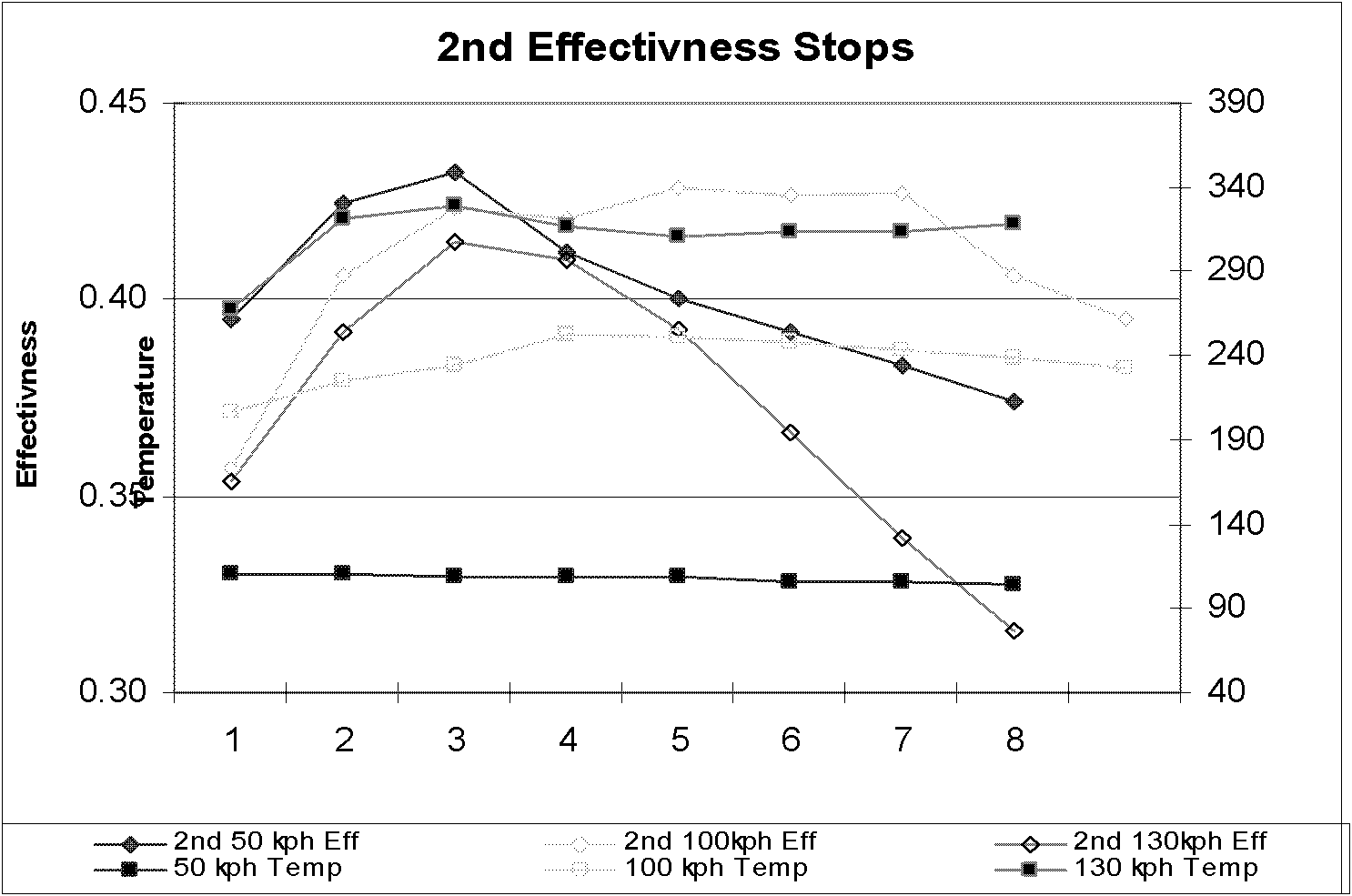

Copper-free ceramic friction material with little falling ash and preparation method thereof

InactiveCN101823856AAvoid secondary pollutionMeet the requirements of environmental protectionBraking membersFriction liningAdhesiveAramid

The invention discloses a copper-free ceramic friction material with little falling ash and a preparation method thereof. The copper-free ceramic friction material with little falling ash is prepared by mixing, shaping and thermally processing the following raw materials in percentage by weight: 5 to 14 percent of adhesive, 20 to 45 percent of reinforcing material, 10 to 40 percent of ceramic material, 10 to 18 percent of lubricant and the balance of filler, wherein nitrile rubber modified phenolic resin and nitrile rubber powder are used as the adhesive; the reinforcing material is one or a mixture of more of aramid fiber, carbon fiber, steel fiber, foam iron powder and aluminum oxide fiber; the ceramic material is one or a combination of more of molybdenum disulfide, magnesium oxide andferrous disulphide; the lubricant is the mixture of graphite and mica; and the filler is the mixture of composite filler, barite, friction powder and aluminum powder. The material has high friction performance, low brake noise and high heat fading resistance, and particularly shows high performance in aspects of wear resistance, long life and great reduction in the falling ash of a wheel hub; therefore, the material can meet both the requirement of a modern automobile braking system on operating conditions and the requirement on economy and environment friendliness when an automobile is used.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

Method of preparing cathode containing Iron disulfide for a lithium cell

ActiveUS20090291366A1Improve discharge efficiencyUseful electrical energyFinal product manufactureOrganic electrolyte cellsPrimary cellAlloy

A primary cell having an anode comprising lithium or lithium alloy and a cathode comprising iron disulfide (FeS2) or a mixture of iron disulfide (FeS2) and iron sulfide (FeS) and conductive carbon particles. A cathode slurry is prepared comprising the FeS2 or FeS2 plus FeS powder, conductive carbon, binder, and a solvent. The binder is preferably a styrene-ethylene / butylene-styrene (SEBS) block copolymer. There is an advantage discovered in utilizing a hydronaphthalene solvent to form the cathode slurry. The preferred solvent is 1,2,3,4-tetrahydronaphthalene or decahydronaphthalene and mixtures thereof. The slurry mixture is coated onto a conductive substrate and the solvent evaporated leaving a dry cathode coating on the substrate. Higher drying temperature may be used resulting in a dry cathode coating which resists cracking. The anode and cathode can be spirally wound with separator therebetween and inserted into the cell casing with electrolyte then added.

Owner:DURACELL U S OPERATIONS

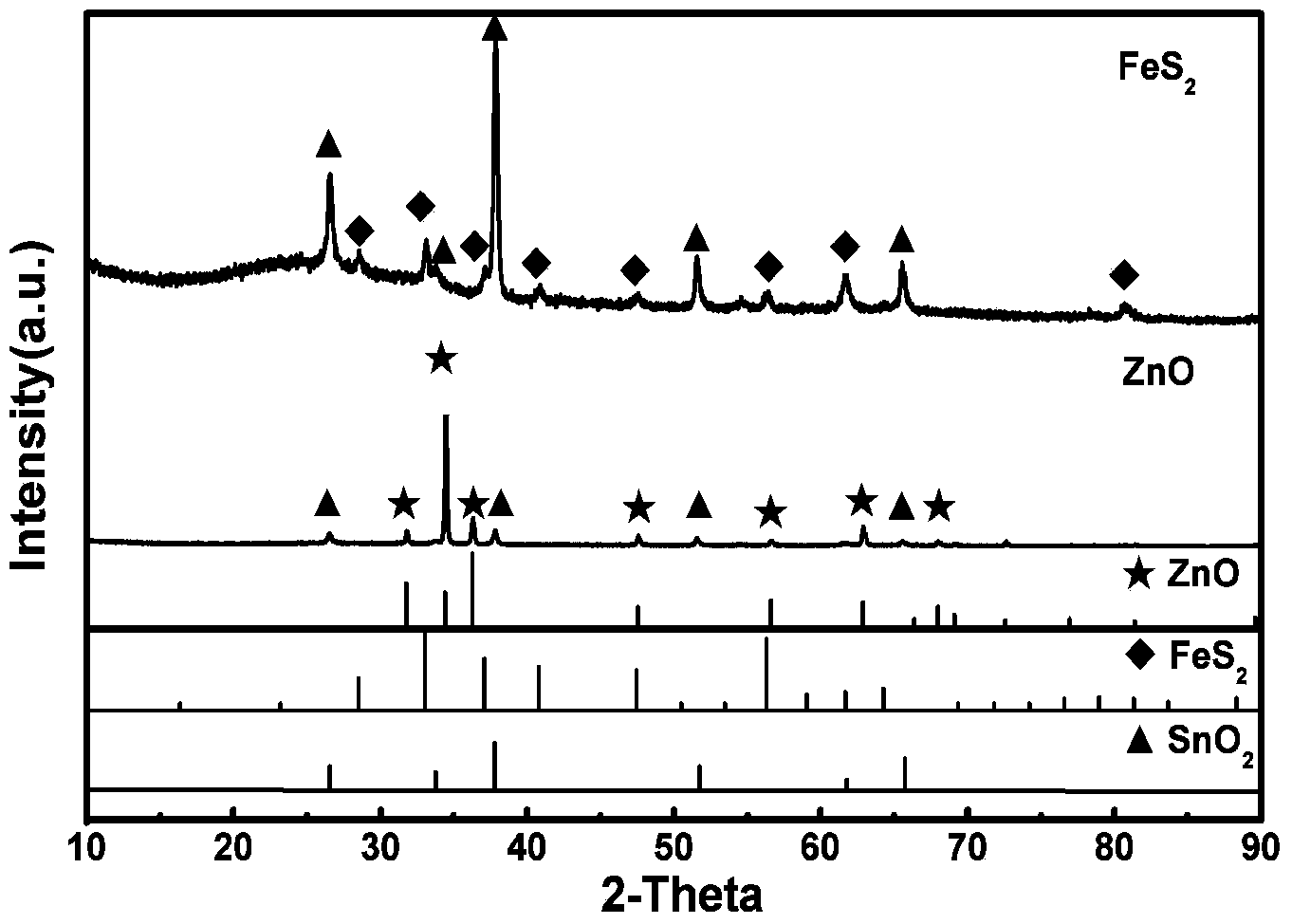

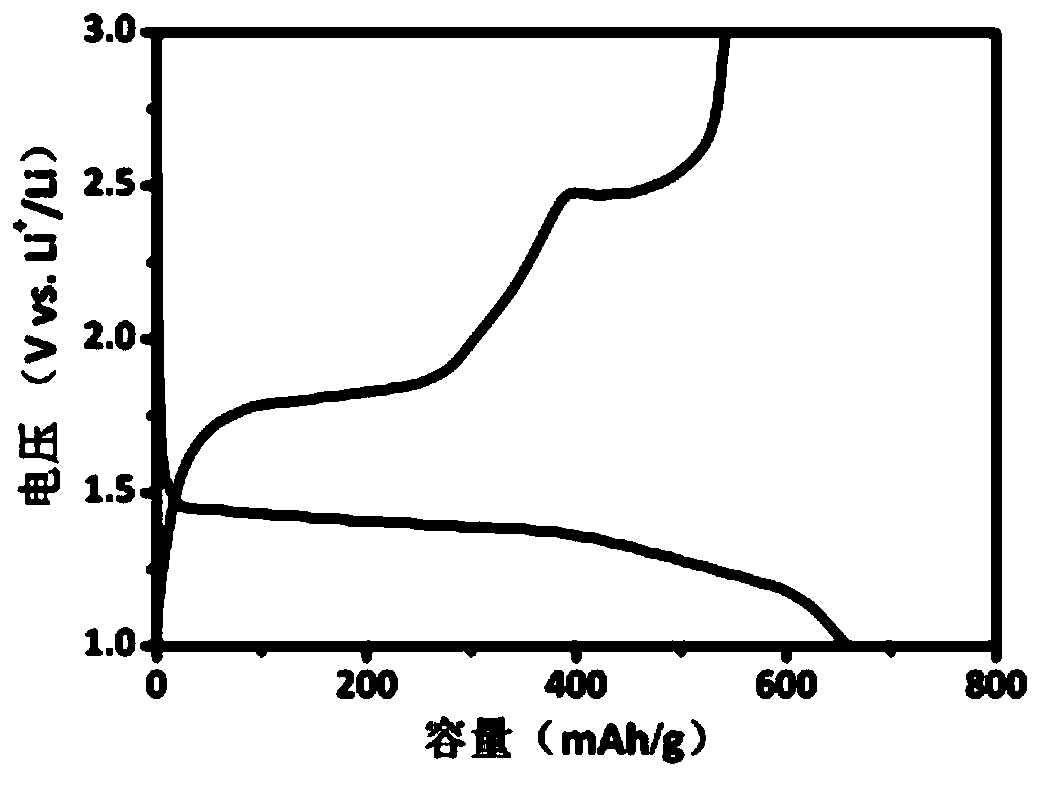

Preparation method of flaky nanometer FeS2/C negative electrode material

ActiveCN107611409AImprove ionic conductivityFast ion conductivityMaterial nanotechnologyCell electrodesMass ratioSolvent

The invention discloses a preparation method of a flaky nanometer FeS2 / C negative electrode material. The preparation method comprises the following steps: (1) dissolving an iron source and an organicligand into a solvent I, and stirring uniformly to obtain a homogeneous solution; (2) performing a hydrothermal reaction on the homogeneous solution obtained in the step (1), naturally cooling to room temperature, filtering, washing, depositing and drying to obtain yellow or red powder; (3) dispersing the yellow or red powder obtained in the step (2) and a sulfur source compound in a solvent II in the mass ratio of 1:(3 to 4), performing a hydrothermal reaction on mixed solution, natural cooling to room temperature, filtering, washing, precipitating and drying to obtain black powder; and (4)calcining the black powder obtained in the step (3) in a protective atmosphere, and cooling to room temperature to obtain the flaky nanometer FeS2 / C negative electrode material. The obtained flaky nanometer FeS2 / C negative electrode material is uniform in shape and size. A carbon material can be effectively compounded with ferrous sulfide, so that the ionic conductivity and electronic conductivityof the material are increased. The two-dimensional structure has the characteristics of shorter diffusion distance of lithium ions, high transmission rate, high specific surface area, high conductivity, high ion transmission speed and the like.

Owner:CENT SOUTH UNIV

Non-aqueous solution lithium-ferrous disulfide primary cell

ActiveCN1845364AHigh magnificationOrganic electrolyte cellsPrimary cell electrodesMetal foilAdhesive

The disclosed non-aqueous Li-FeS2 one-time cell comprises: coating porous anode active material composed by FeS2 with average size less than 40 mum, the conductive material and adhesive on metal foil of collecting-current body; using Li and high-pure PE membrane or PE / PP composite membrane with specific surface area as 0.8-10m2 / g as the cathode active material and cell membrane respectively. This production has well discharge performance.

Owner:FUJIAN NANPING NANFU BATTERY

Preparation method of graphene and ferrous disulfide composite positive electrode material

The invention relates to a preparation method of a graphene and ferrous disulfide composite positive electrode material. The method comprises the following steps of: (1) ultrasonically peeling graphite oxide to oxidized graphene to obtain an oxidized graphene colloid liquor, and reducing the oxidized graphene to graphene by a reducing agent; etching and washing to obtain graphene powder, and dispersing the graphene powder in acetone to obtain a graphene dispersion liquid; (2) preparing high purity ferrous disulfide nanocrystals by FeSO4, (NH2)2CS and PVP (Polyvinyl Pyrrolidone); (3) adding the ferrous disulfide nanocrystals into the graphene dispersion liquid, and mechanically stirring and mixing paste, heating, cooling and ball-milling and sieving the obtained mixed paste to obtain the graphene and ferrous disulfide composite positive electrode material. According to the composite positive electrode material prepared by the invention, high purity ferrous disulfide is prepared by a wet method to ensure the high energy density of ferrous disulfide. The material is covered by high purity graphene, so that the electric conductivity and ionic mobility of the material are improved.

Owner:SHENGZHOU ELECTRIC POWER +3

Preparation method of graphene oxide/iron disulfide composite nano particles

InactiveCN102910615AUniform particle sizeGood dispersionMaterial nanotechnologyCarbon compoundsHydration reactionPolyvinyl alcohol

The invention relates to nano FeS2 materials, and particularly relates to a preparation method of graphene oxide / iron disulfide composite nano particles. According to the preparation method of the graphene oxide / iron disulfide composite nano particles, ferrous chloride tetrahydrate (FeCl2.4H2O) and sulfur powder are used as raw materials, are dissolved in water together with surfactant polyvinyl alcohol (PVA) and polyvinylpyrrolidone (PVP), and then mixed with graphene oxide under a certain pH (potential of hydrogen) condition; the obtained mixed solution is arranged in a reaction kettle and sealed, is held for 12 hours to 24 hours in a constant-temperature box at 180 DEG C to 200 DEG C by using a hydrothermal method, is cooled to normal temperature, stood and separated, centrifugally washed and dried, finally the graphene oxide / iron disulfide composite nano particles can be obtained.

Owner:JIANGSU UNIV

Method for preparing sulfuric acid by reducing and decomposing gypsum with pyrite

InactiveCN102530889AReduce the temperatureReduce energy consumptionSulfur compoundsMoistureMaterials science

The invention discloses a method for preparing sulfuric acid by reducing and decomposing gypsum with pyrite. The method is characterized by comprising the following steps of: grinding the semi-hydrated gypsum with moisture content of 0.1-10% or anhydrous gypsum and pyrite with moisture content of 0.1-15% until the average particle size is 1-500 microns, wherein the molar ratio of the effective component ferrous disulfide in pyrite to the effective component calcium sulfate in gypsum is (0.5-5):10; adding the mixture into a reactor at a temperature of 800-1300 DEG C; baking for 0.1-4 hours in an inertia, weak-oxidizing or reducing atmosphere; and preparing sulfuric acid from the produced sulfur dioxide tail gas. According to the invention, the gypsum reducing and decomposing rate is high, the reducing and decomposing temperature and energy consumption are low, the technology is simple, the production cycle is short, and the method is easy to control and convenient to popularize.

Owner:SICHUAN UNIV

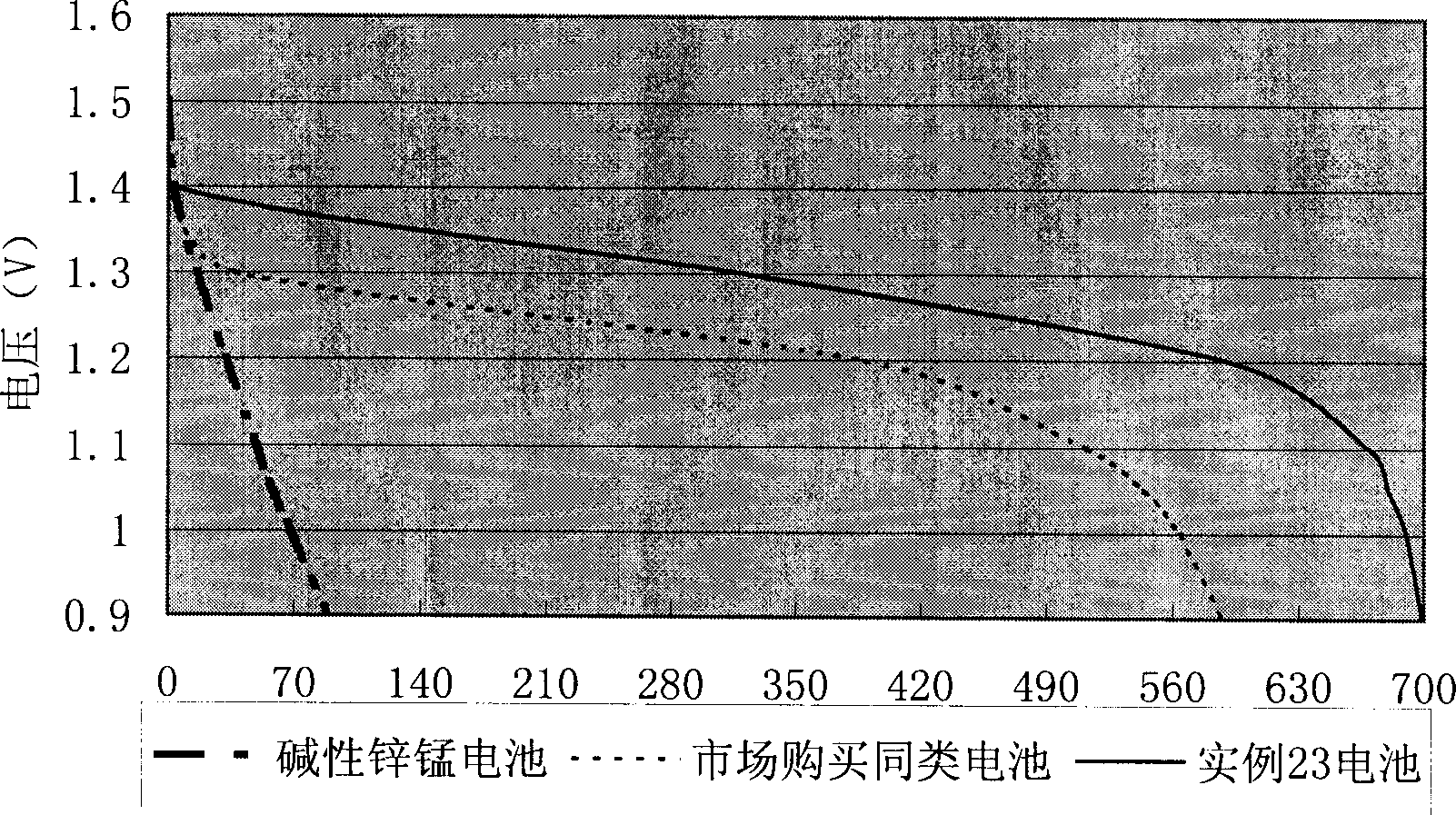

Anode material of Li-ferrous disulfide battery and battery

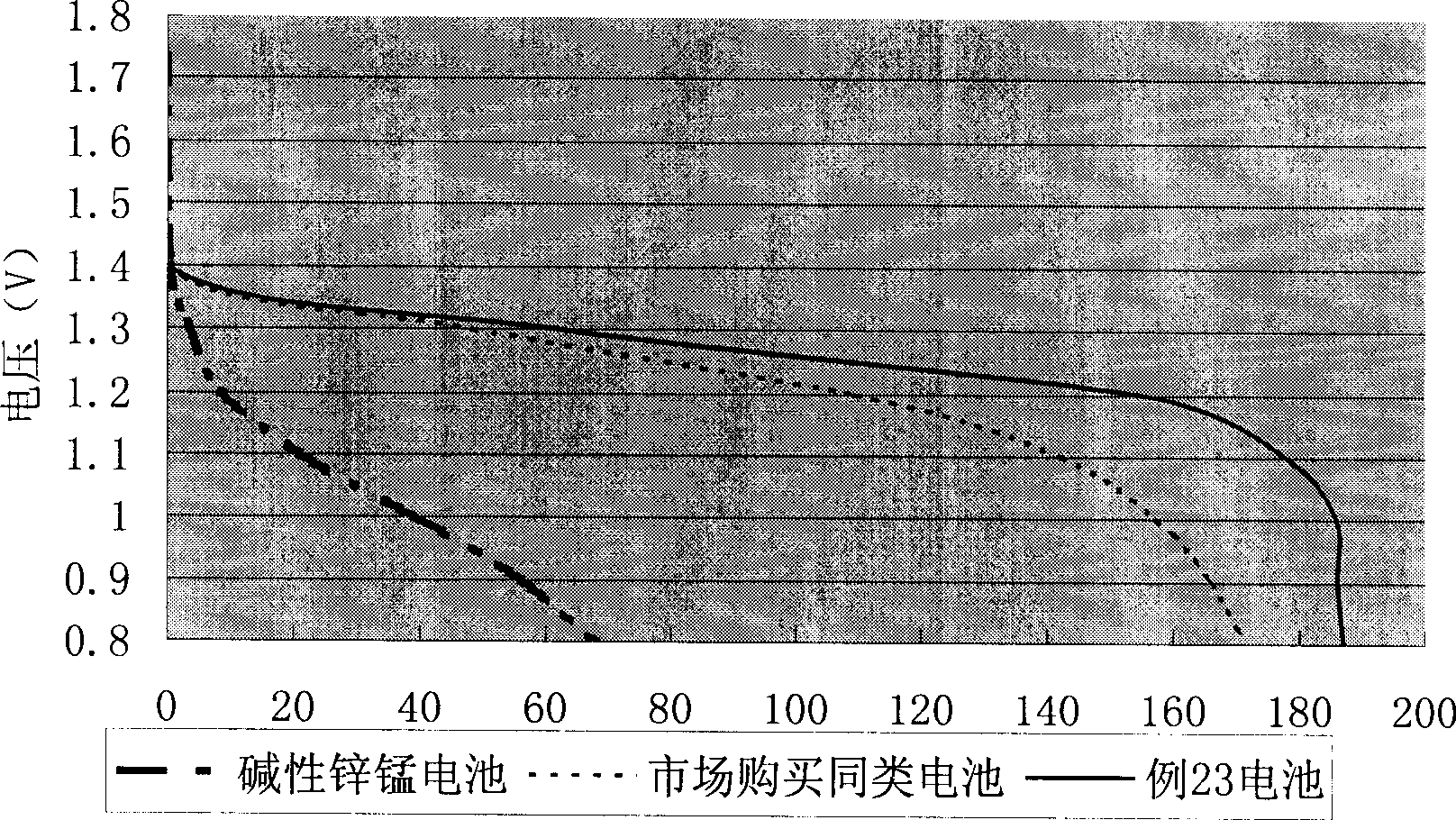

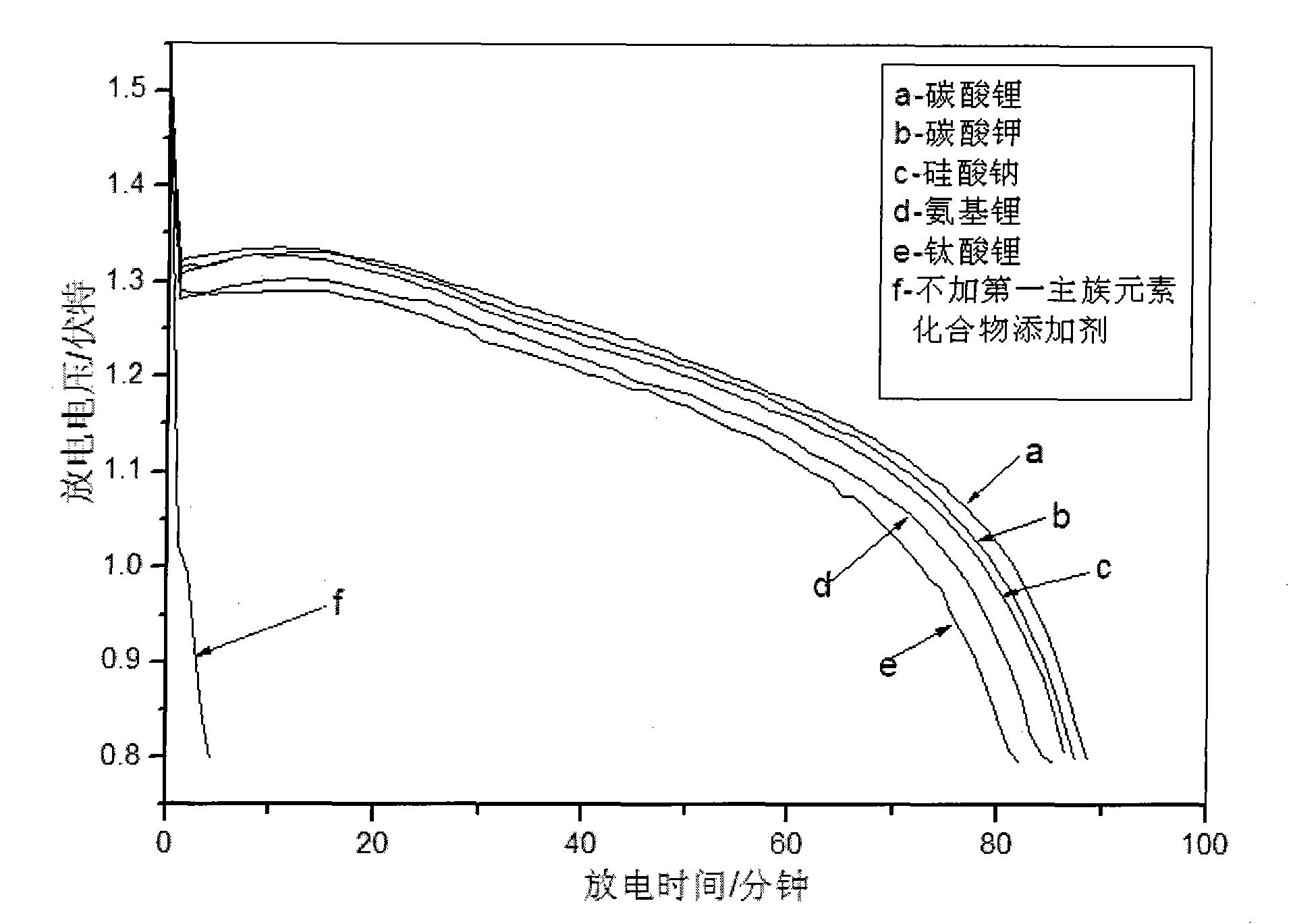

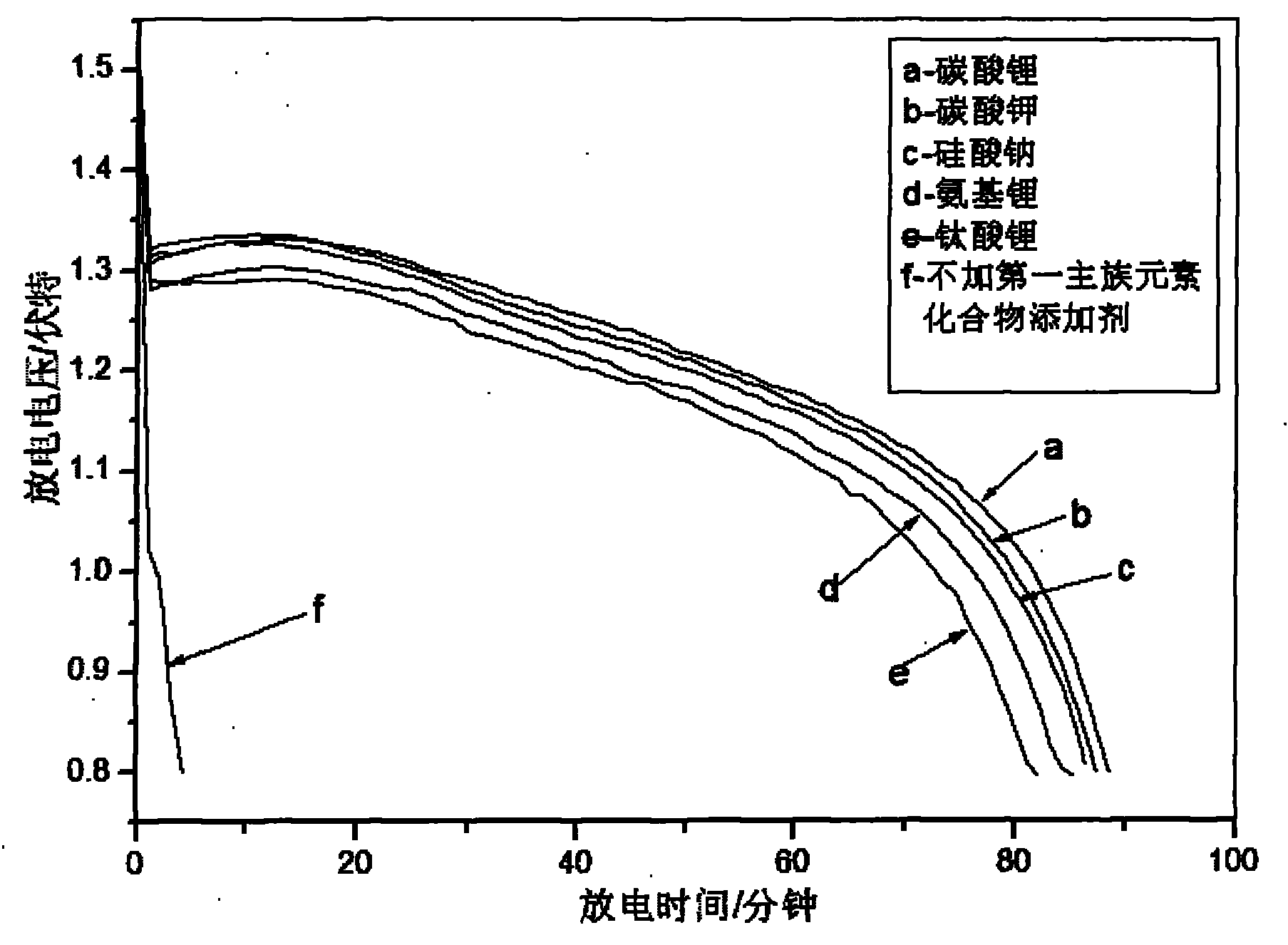

InactiveCN102024953AExtend discharge timeImprove discharge capacityFinal product manufactureCell electrodesAluminateMain group element

The invention relates to an anode material of a Li-ferrous disulfide battery and the Li-ferrous disulfide battery, belonging to the battery field. The anode material of the Li-ferrous disulfide battery comprises the following ingredients by weight percentage: 50-99.5 percent of ferrous disulfide powder, 0.25-25 percent of bonder, 0.25-25 percent of conductive agent and the balance first main group element compounds accounting for 0.4-10 percent of the quality of the ferrous disulfide powder; the first main group element compounds comprise one ore more o carbonate, bicarbonate, silicate, germanate, acetate, phosphate, aluminate, titanate and amino salts. In the invention, the added first main group element compounds greatly improve the discharging platform and discharging performance of the battery, the discharging platform of the battery is high, the discharging time is long, the discharge capacity is large, the heavy-current discharging property is good and the storage life is long.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

Preparation method of calcium ferrite

The invention relates to a preparation methodof calcium ferrite, which belongs to the technical field of metallurgy. The method comprises the following steps of: (a) mixing gypsum, pyrite and iron supplements to obtain a mixed material, wherein the molar ratio of calcium sulphate in gypsum to ferrous disulfide in pyrite to iron element in the iron supplements is 1: (0.1-2.5): (0-2), the molar ratio of calcium element to the iron element in the mixed material is 1: (1-2.5), the water content of the gypsum is less than 10wt%, and the water content of the pyrite is 0.1-15wt%; and (b) roasting the mixed material for 0.1-4 hours at a roasting temperature of 900-1500 DEG C under a protective atmosphere, and after the roasting is finished, cooling to obtain calcium ferrite, wherein the protective atmosphere is an inert atmosphere or a reductive atmosphere or an oxidative atmosphere with an oxygen content of less than 5 wt%.

Owner:SICHUAN UNIV +1

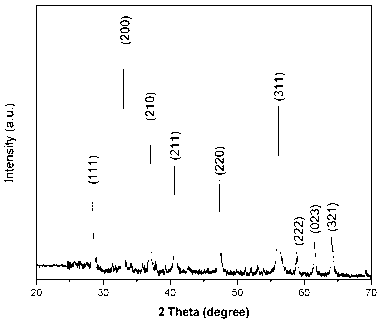

Anode material and anode plate of lithium-iron disulfide battery and method for preparing same

InactiveCN101521279ALower open circuit voltageHigh conductivityElectrode manufacturing processesActive material electrodesIron disulfideBattery cell

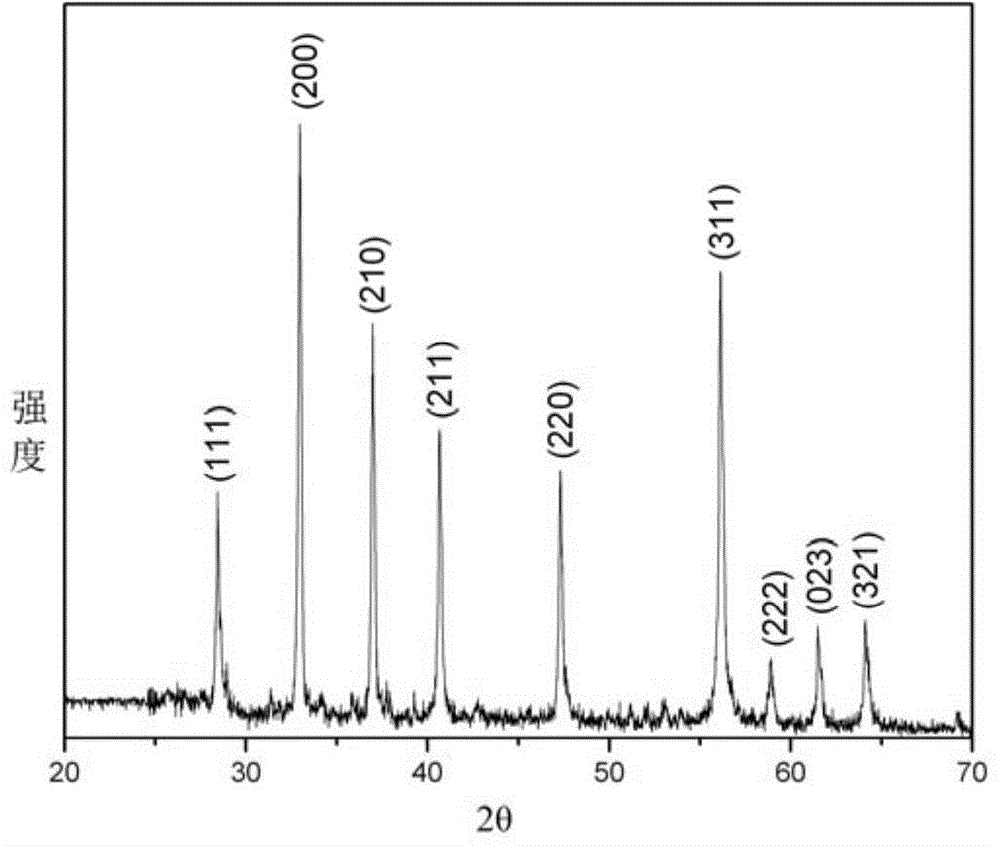

The invention discloses an anode material and an anode plate of a lithium-iron disulfide battery and a method for preparing the same, wherein the anode material comprises iron disulfide which is an iron disulfide nanometer crystal, and FeSO4, (NH2)2CS and S taken as reaction raw materials and PVP taken as a dispersing agent react under the acid or alkali condition to prepare the iron disulfide. The obtained iron disulfide is an N-shaped crystal, of which the purity is as high as 100 percent; compared with the iron disulfide used in the prior art, the iron disulfide of the invention can greatly reduce the open circuit voltage of the lithium-iron disulfide battery, make the voltage platform more stable, improve the conductive activity of the battery, improve the discharging performance of heavy current, improve the discharging depth of the battery and make the lithium-iron disulfide battery have higher actual values.

Owner:广州市天球实业有限公司 +1

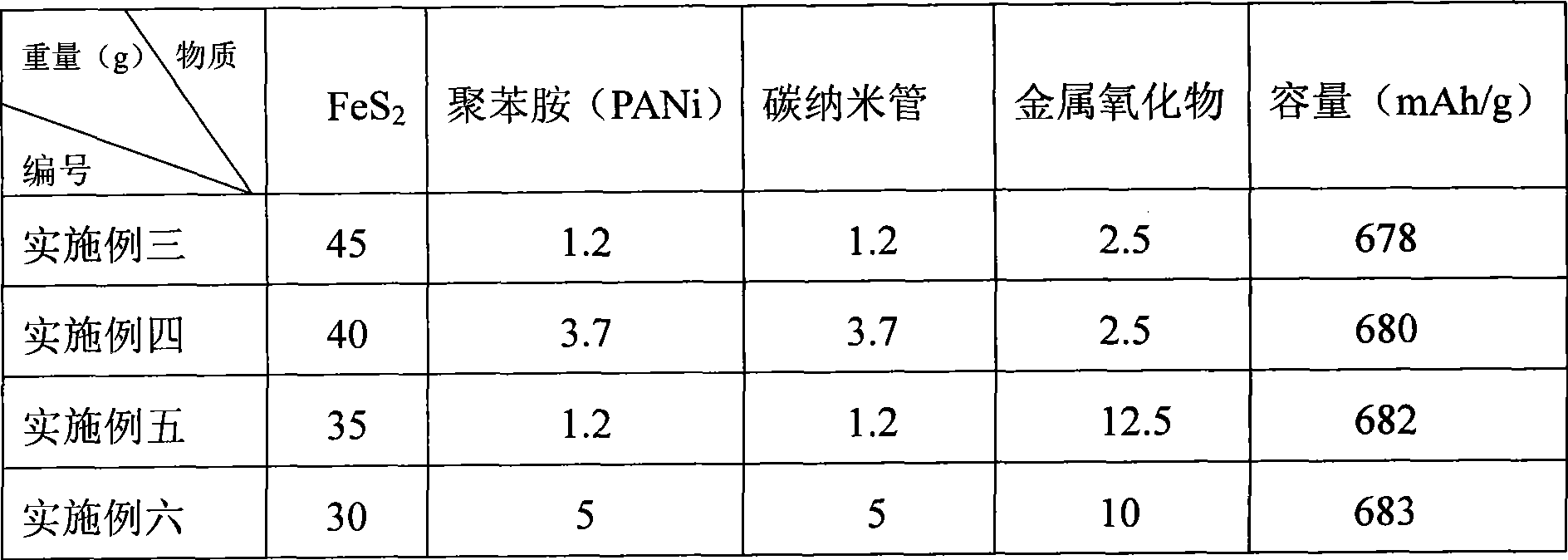

Lithium-ferrous disulfide battery and manufacturing method thereof

ActiveCN102751499AImprove discharge performanceImprove low temperature discharge performanceCell electrodesFinal product manufactureFiberCarbon fibers

The invention relates to a lithium-ferrous disulfide battery. The lithium-ferrous disulfide battery comprises a housing, an anode, a cathode, an isolating membrane for isolating the anode from the cathode, and an electrolytic solution, wherein the anode and the cathode are arranged in the housing, the anode contains 80-95% of ferrous disulfide (FeS2) by mass ratio, the cathode is a lithium tablet, solvents for the electrolytic solution comprise 1,3-dioxolane and glycol dimethyl ether, and electrolyte for the electrolytic solution comprises lithium iodide. A manufacturing method for the lithium-ferrous disulfide battery is as follows: adding a proper amount of carbon nanotube, vapor growth carbon fibers, conductive graphite and / or super conductive carbon into the anode, and adding a proper amount of additives such as N,N-dimethyl trifluoroacetamide and the like into the electrolytic solution. The lithium-ferrous disulfide battery manufactured by the manufacturing method is good in discharge performance in wider high and low temperature environments.

Owner:EVE ENERGY CO LTD

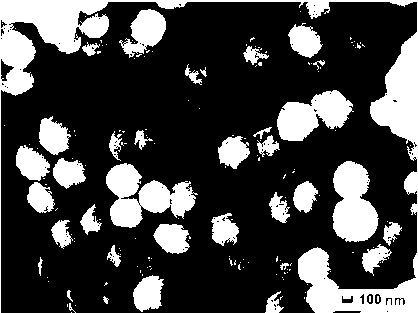

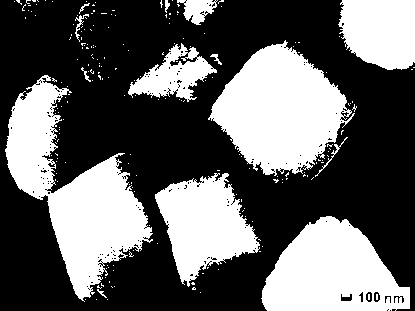

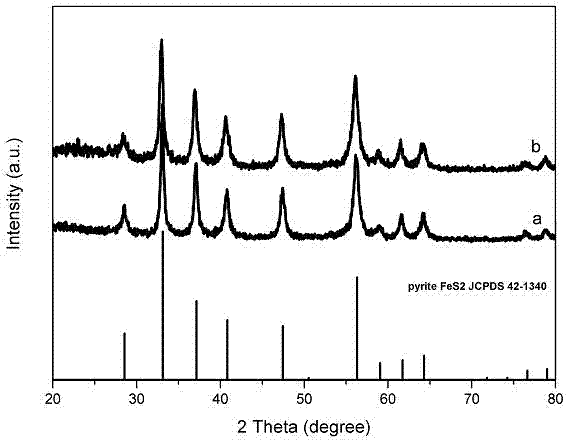

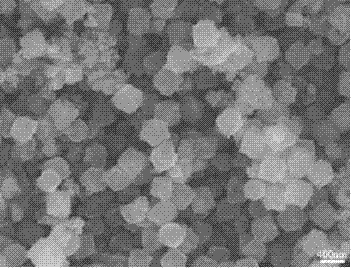

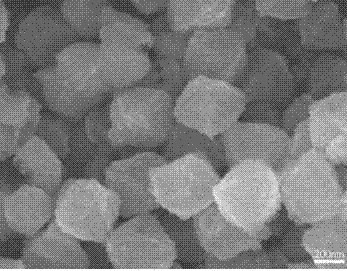

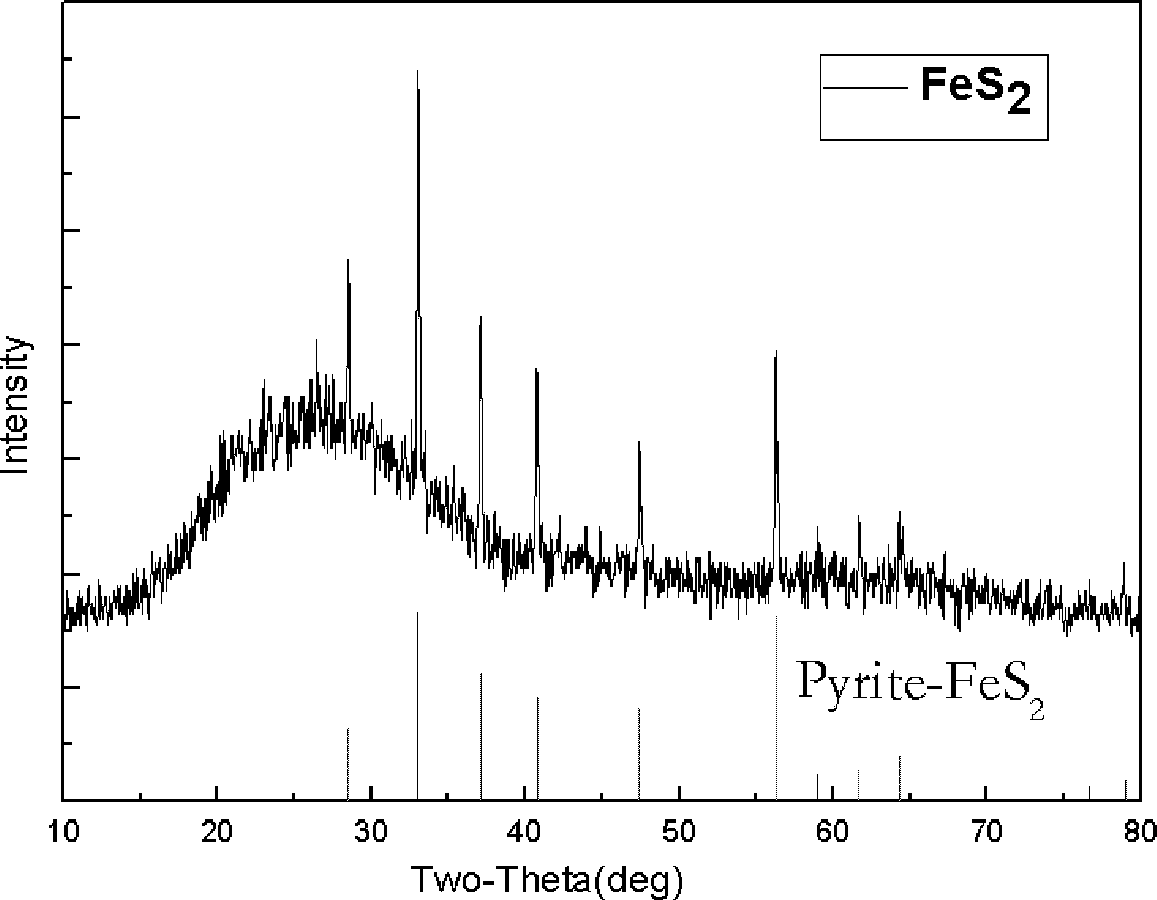

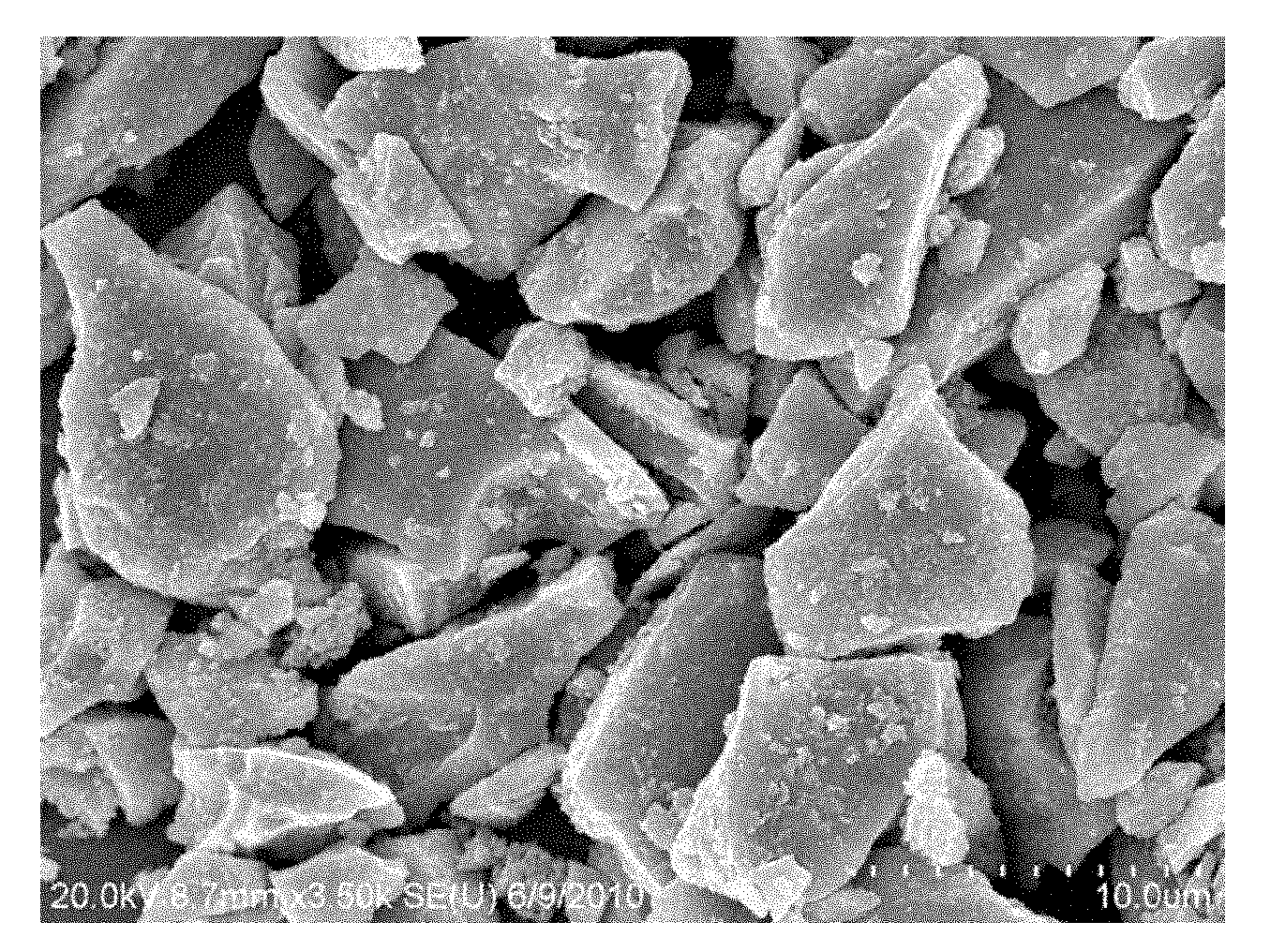

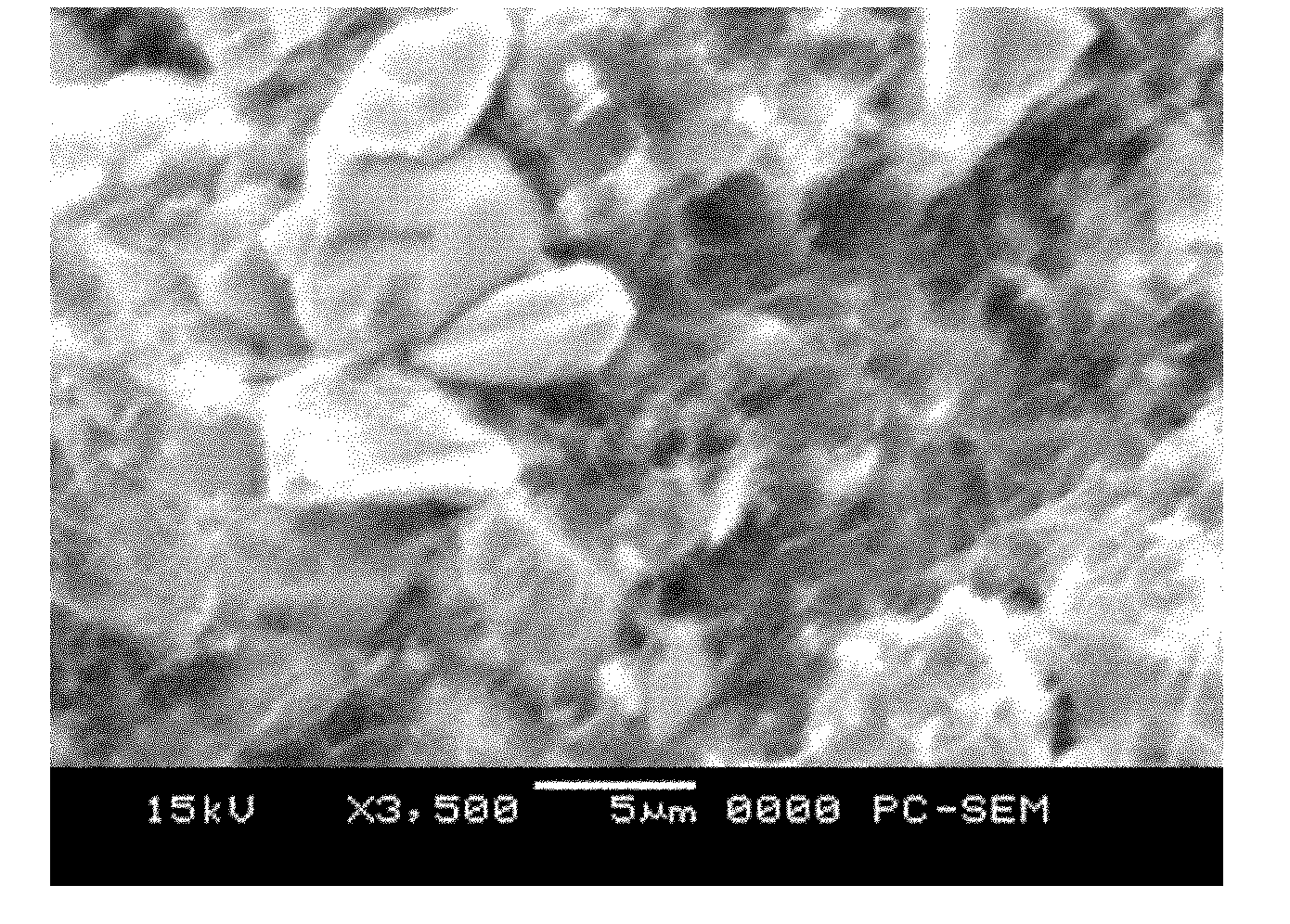

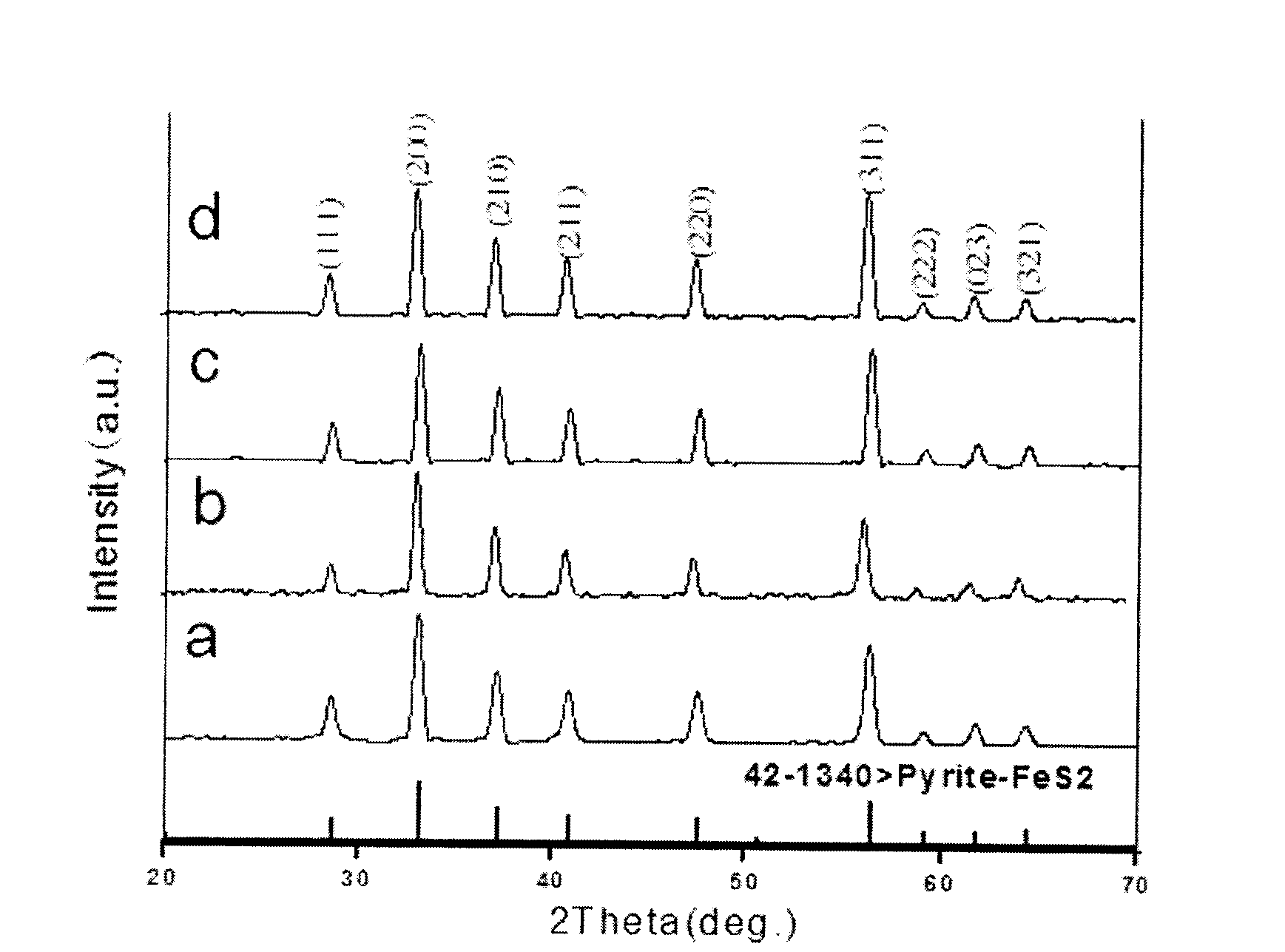

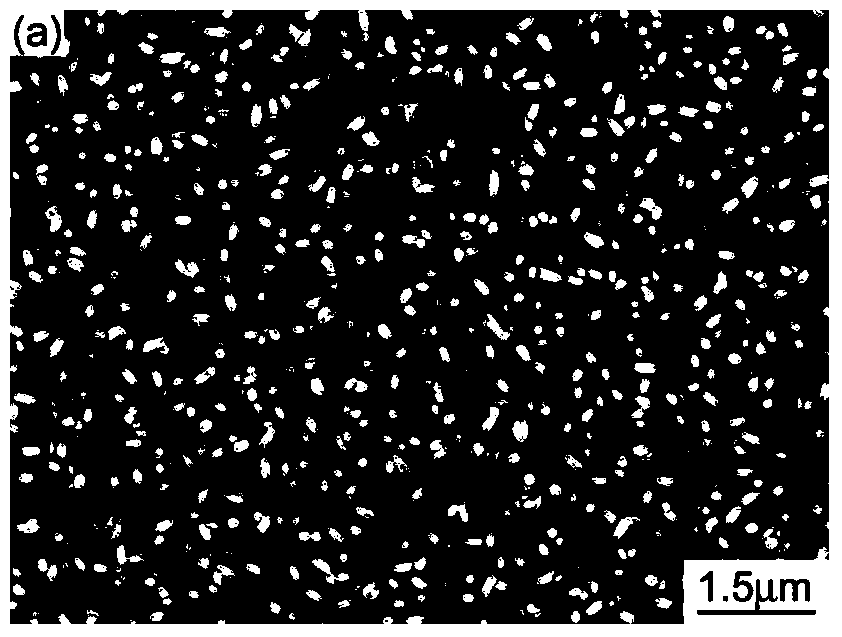

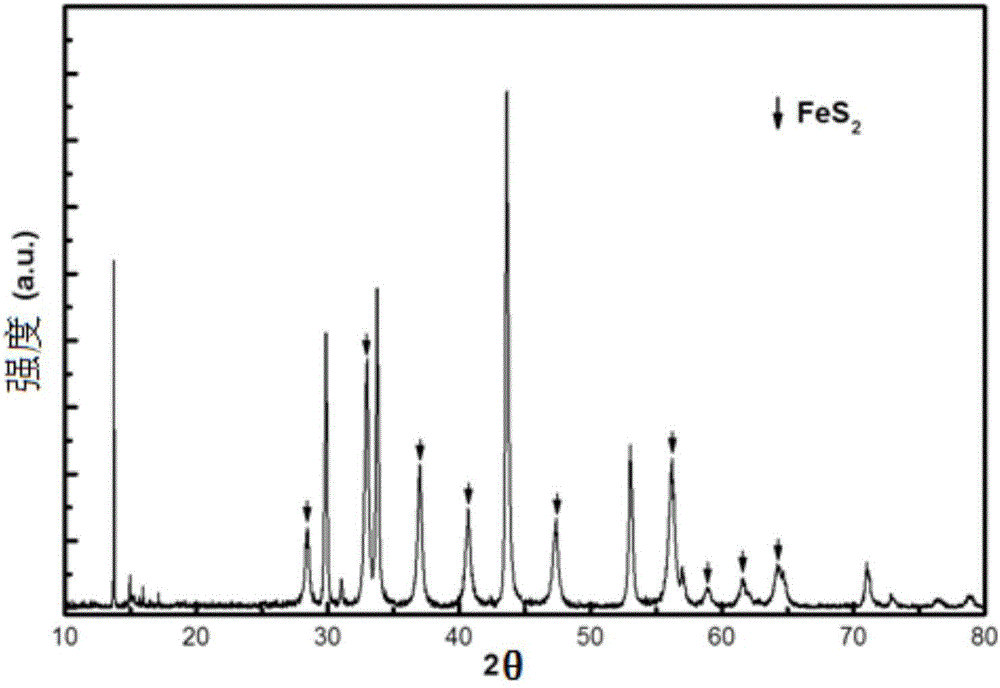

Preparation method of pyrite-type ferrous disulfide micron/nano crystalline material with controllable morphology

InactiveCN102786098AEffective particle size controlEffective control of morphologyMaterial nanotechnologyIron sulfidesThio-Active agent

The invention relates to a preparation method of a pyrite-type ferrous disulfide micron / nano crystalline material with a controllable morphology. The method comprises the following steps of: (1) respectively adding solvent dimethyl sulfoxide into compounding agent thioglycolic acid and surfactant polyvinylpyrrolidone under the condition of agitating and leading in nitrogen or argon, and obtaining a solution A by mixing and agitating; (2) orderly adding an iron source and a sodium thiosulfate water solution into the solution A, leading in the nitrogen or argon and vigorously stirring to obtain a solution B; (3) transferring the solution B into a reaction kettle and reacting for 4-12 hours at 120-180 DEG C after uniformly agitating, to obtain pyrite-type ferrous disulfide suspension liquid; (4) centrifugally separating, washing for a plurality of times and drying the pyrite-type ferrous disulfide suspension liquid in vacuum to constant weight to obtain the pyrite-type ferrous disulfide micron / nano crystalline material. The product obtained by the method has controllable particle size and morphology, good process repeatability and stable quality, and is expected to be applied to the fields such as photovoltaic conversion and lithium ion battery materials.

Owner:LANZHOU UNIVERSITY

Ferrous disulfide semiconductor film preparation method

ActiveCN102642874AThickness is easy to controlEasy for large-scale continuous productionIron sulfidesVulcanizationIron(II) chloride

The invention discloses a ferrous disulfide semiconductor film preparation method, which relates to the field of preparation of compound semiconductor films for solar cells and the like. The method includes: by an aqueous solution deposition method, using ferrous sulfate or ferrous chloride aqueous solution as cation precursor solution, and using sodium polysulfide aqueous solution as anion precursor solution; controlling immersion time of a substrate in the precursor solution and circulation times to deposit a ferrous disulfide film premade layer; and subjecting the premade layer to vulcanization heat treatment at the high temperature to obtain a ferrous disulfide film. The ferrous disulfide semiconductor film preparation method is short in procedure, low in cost, high in reproducibilityand easy in massive continuous production, and the film is controllable in component and suitable for large-area growth. The deposition substrate can be normal soda lime glass, conductive glass, flexible stainless steel plates, titanium plates, molybdenum plates or plastic plates. The film prepared by the method is controllable in thickness and component, compact and uniform in appearance, high in crystallizing performance and photoelectric property and applicable to thin film solar cells.

Owner:CENT SOUTH UNIV

Electrolyte solution and lithium-ferrous disulfide battery containing same

ActiveCN103456970AOvercoming power failureOvercoming the problem of low discharge capacityOrganic electrolyte cellsPhysical chemistryPropylene carbonate

The invention discloses electrolyte solution used for a lithium-ferrous disulfide battery. The electrolyte solution comprises electrolyte and an electrolyte solvent, wherein the electrolyte comprises bistrifluoromethanesulfonimide lithium salt, the electrolyte solvent comprises at least one of 1, 3-dioxolame, glycol dimethyl ether and propylene carbonate. The electrolyte solution provided by the invention is formed by the combination of the specific electrolyte and the electrolyte solvent, is mainly used in the lithium-ferrous disulfide battery, is low in cost and can solve the problem that the existing lithium-ferrous disulfide battery cannot discharge electricity or has low discharge capacity at below 40 DEG C, so as to remarkably improve the discharge performance of the lithium-ferrous disulfide battery at below 40 DEG C. Furthermore, the invention also discloses the lithium-ferrous disulfide battery containing the lithium-ferrous disulfide battery, and the lithium-ferrous disulfide battery has good discharge performance.

Owner:EVE ENERGY CO LTD

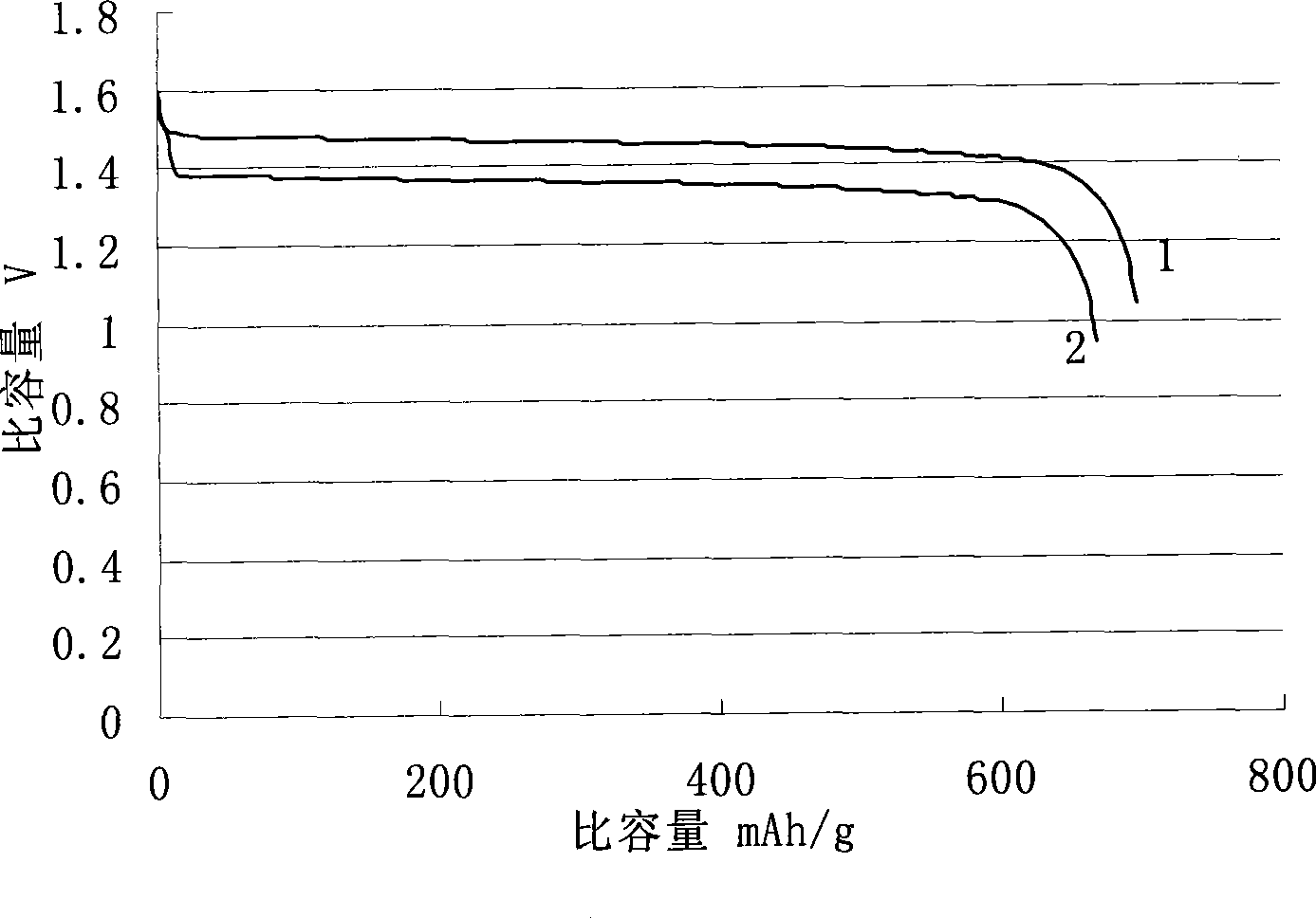

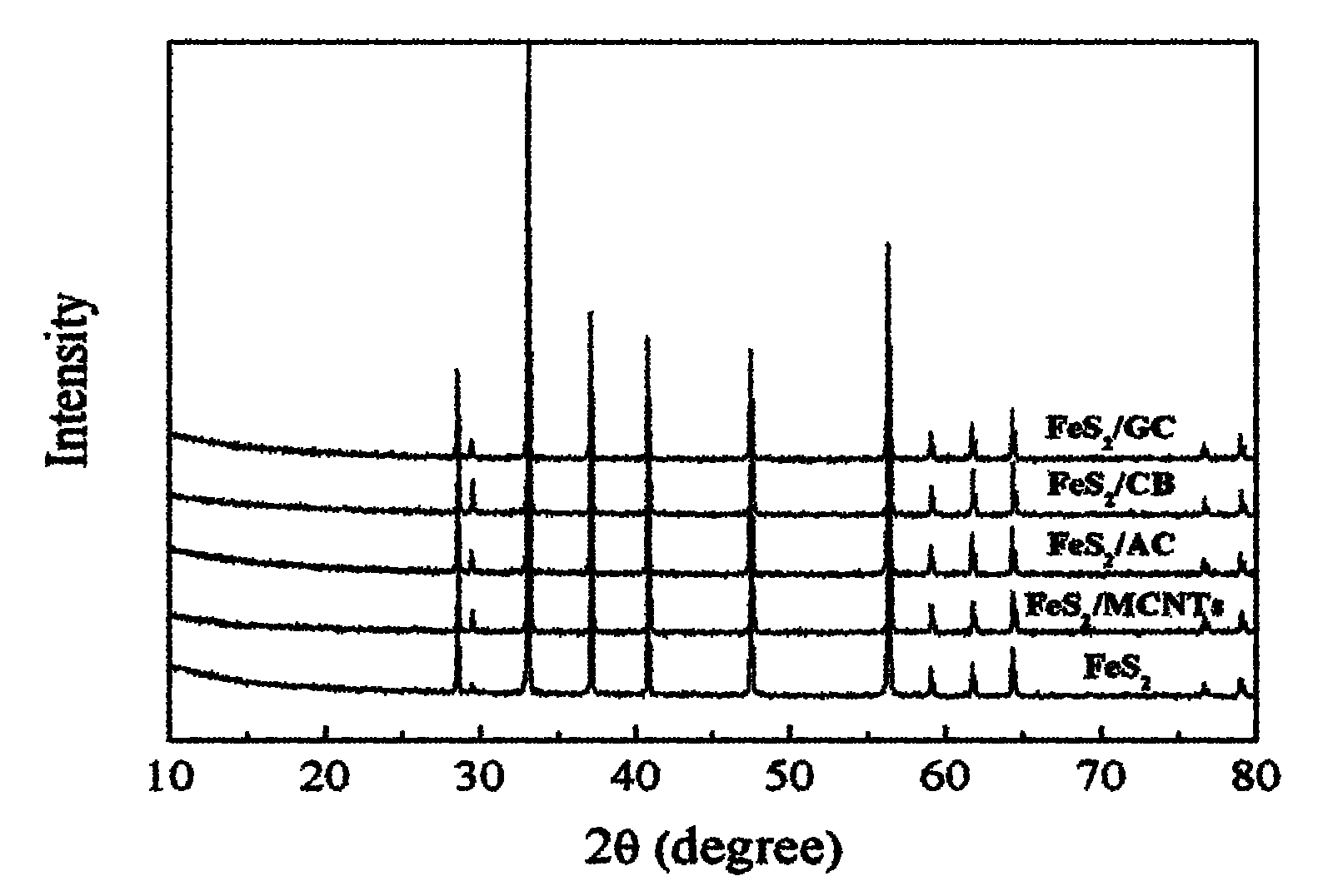

Ferrous disulfide/carbon composite cathode material of primary lithium battery and preparation method and application thereof

InactiveCN102157736AImprove liquid absorption capacityImprove conductivityCell electrodesSecondary cellsCarbon compositesMass ratio

The invention discloses a ferrous disulfide / carbon composite cathode material of primary lithium battery, wherein the mass percentage of ferrous disulfide is 50-99.5 percent, and the mass percentage of carbon is 0.5-50 percent. The preparation method comprises the steps of: (1) mixing a carbon source material with dispersant in mass ratio of 1:(20-120) to obtain suspension; adding pyrite to the suspension, wherein the mass ratio of the pyrite to the carbon source is (90-99.5):(0.5-10), then mixing for 1-10h to obtain mixed paste; and (2), heating the mixed paste obtained from the step 1 to reach the temperature of 50-150 DEG C under the protection of an inert gas, keeping the temperature for 1-40h, then heating to reaching the temperature of 250-400 DEG C, keeping the temperature for 1-20h, then cooling to the room temperature, and obtaining granular ferrous disulfide / carbon composite cathode material of the primary lithium battery through ball-milling and sieving. The invention has the advantage that the battery prepared by the composite cathode material has higher large-current discharge performance and remarkably improved discharge plateau potential.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

Preparation method of lithium battery electrolyte

InactiveCN103943882APrevent slow polymerizationLow viscosityFinal product manufacturePrimary cellsAlkalinityOrganic solvent

The invention discloses a preparation method of a lithium battery electrolyte, belonging to the technical field of lithium batteries. The preparation method is characterized by comprising the steps of adding an organic amine or metal oxide additive which accounts for 0.1-5 percent by weight of an organic solvent in the organic solvent forming an electrolyte; and reducing the temperature of the organic solvent to be 0 DEG C, then adding lithium salt in the organic solvent of the electrolyte under the stirring state, and controlling the temperature of the organic solvent to be 0-10 DEG C in an adding process. According to the preparation method, a defined amount of organic amine or metal oxide is added in a nonaqueous electrolyte, and has alkalinity and a certain inhibition effect; the temperature when lithium salt is added is strictly controlled, the electrolyte is effectively prevented from a polymerization reaction during production and transportation and after injection of a battery, and effects of stabilizing the viscosity of the lithium iodide nonaqueous electrolyte and reducing the internal resistance of a lithium-ferrous disulfide battery are realized.

Owner:BEIJING INST OF CHEM REAGENTS

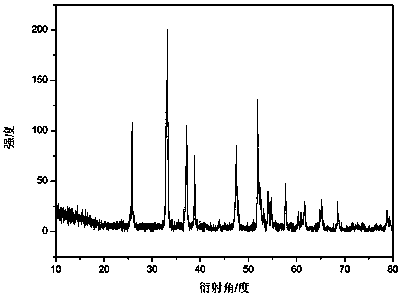

Method for synthesizing pyrite type ferrous disulfide by hydro-thermal method

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

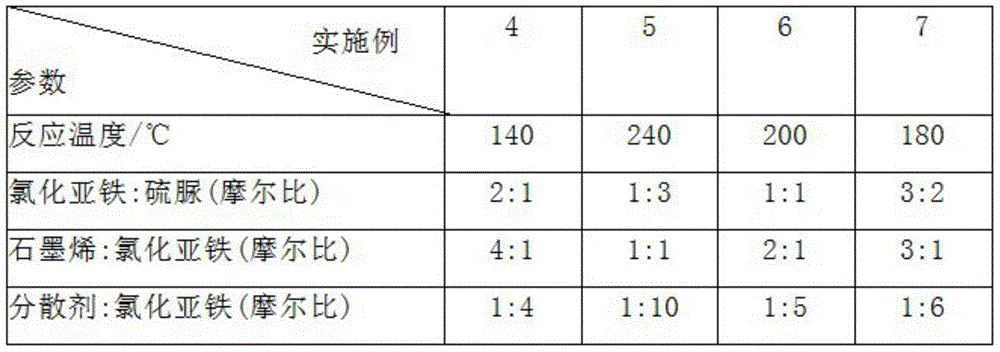

Preparation method of ferrous disulfide-graphene composite nano lubricant

ActiveCN103602362AHigh purityUniform sizeMaterial nanotechnologyInorganic pigment treatmentAlcoholThiourea

The invention discloses a preparation method of a ferrous disulfide-graphene composite nano lubricant. The preparation method is characterized by comprising the following steps: (1), adding matrix graphene, an iron source ferrous chloride and a dispersing agent into water to prepare liquor, regulating pH value to be alkaline, adding a vulcanizing agent thiourea, and uniformly mixing the liquor for future use; and (2), transferring the liquor into a stainless steel reaction kettle, sealing, cooling to the room temperature after carrying out hydrothermal reaction for 16 hours at 140 DEG C-240 DEG C, cleaning products by using deionized water, repeatedly cleaning by using absolute ethyl alcohol, carrying out vacuum drying to obtain black powder, wherein the structure of the black powder is that an FeS2 nanosphere coats on a graphene sheet layer, and dimension is 450 nm-800 nm. According to the preparation method, materials are easily available, price is low, preparation process is simple, parameters are easy to control, production process is safe and environment-friendly, and therefore, the preparation method is especially suitable for large-scale industrial production.

Owner:ZHENJIANG COLLEGE

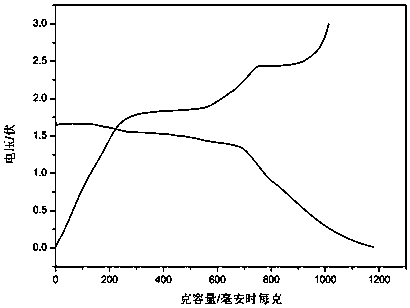

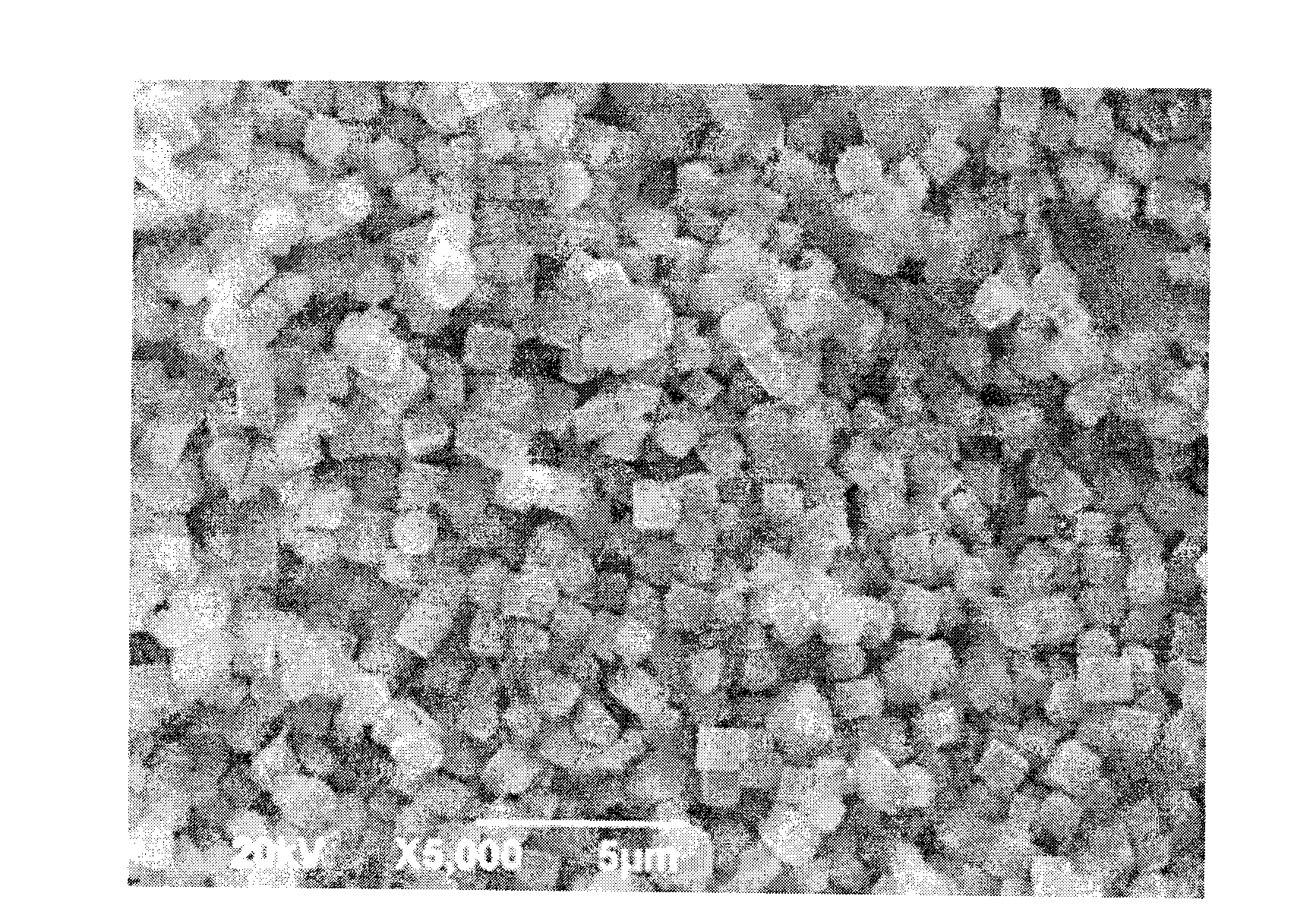

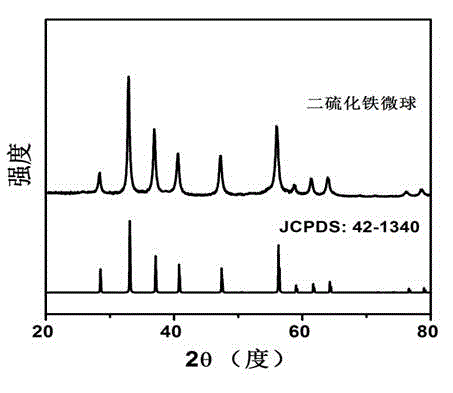

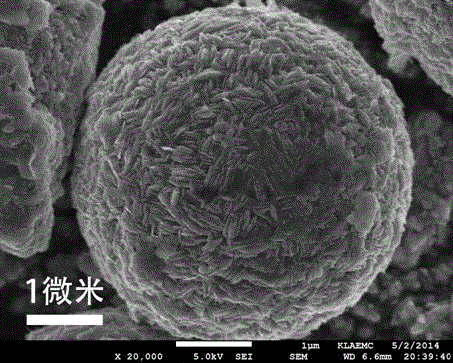

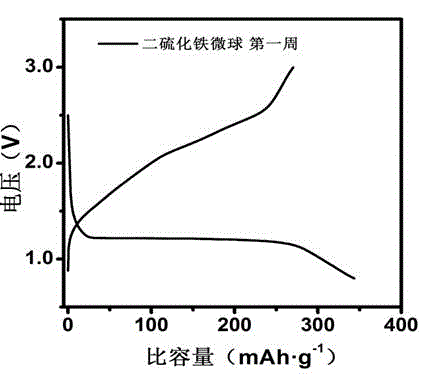

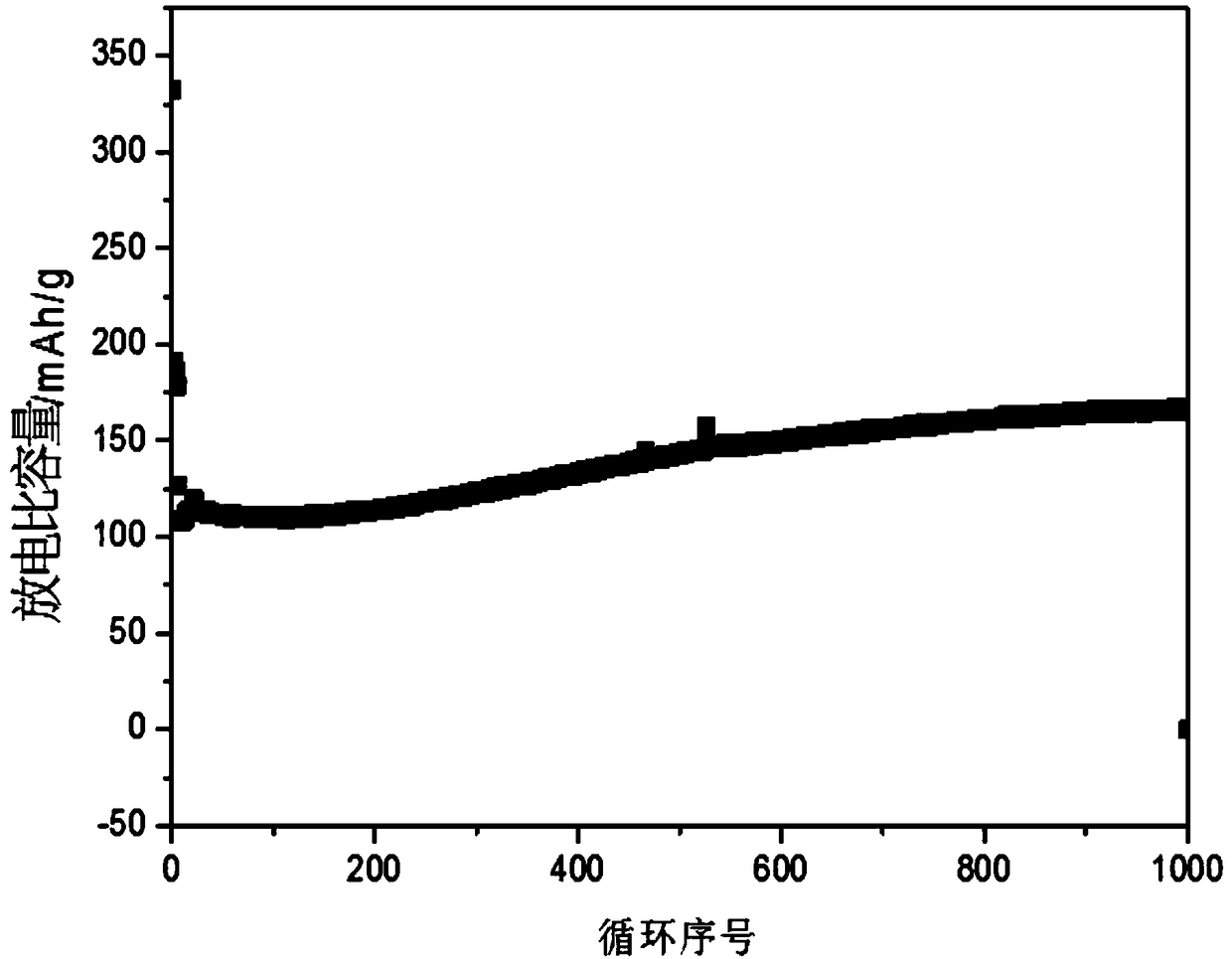

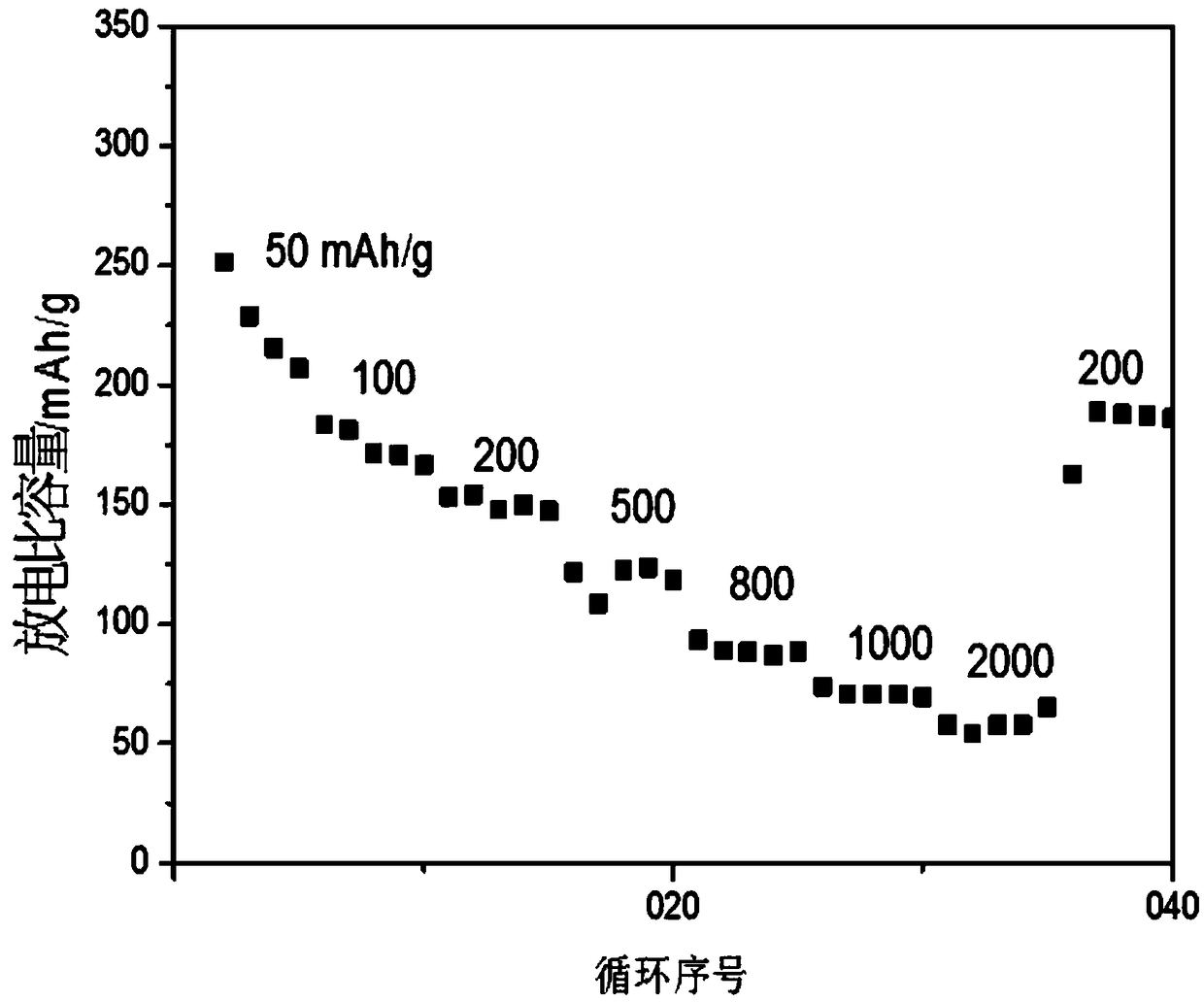

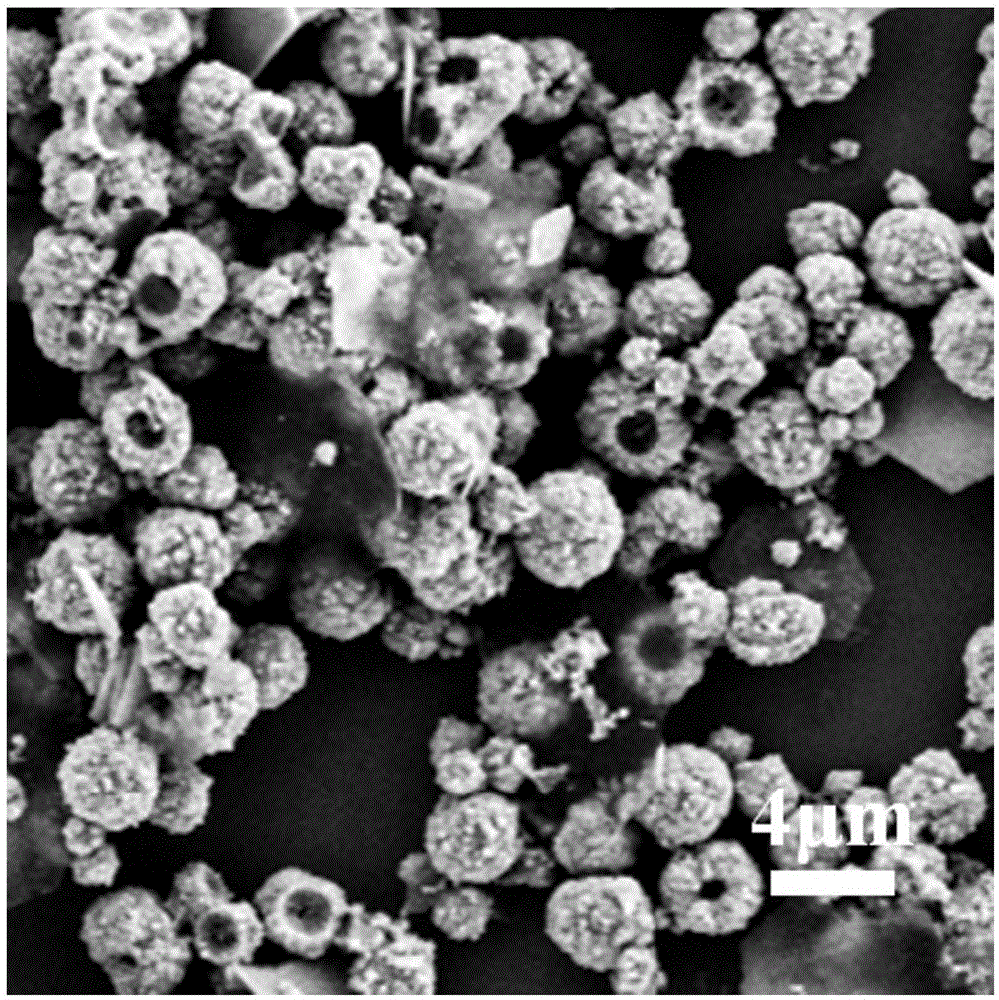

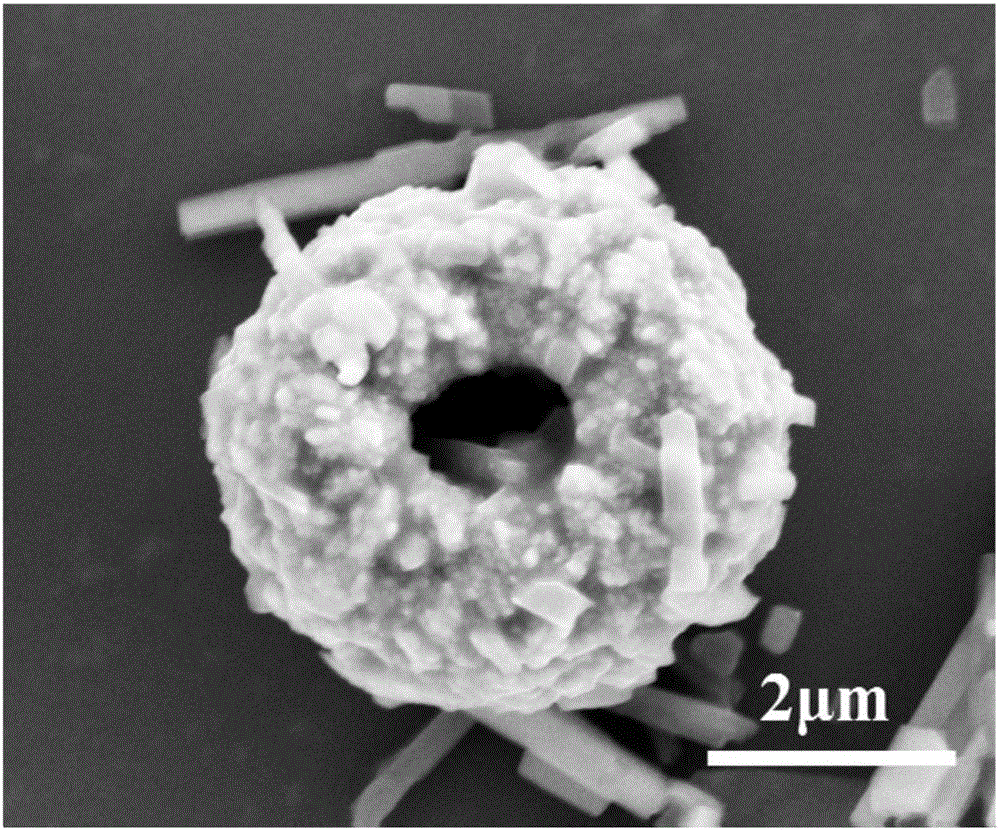

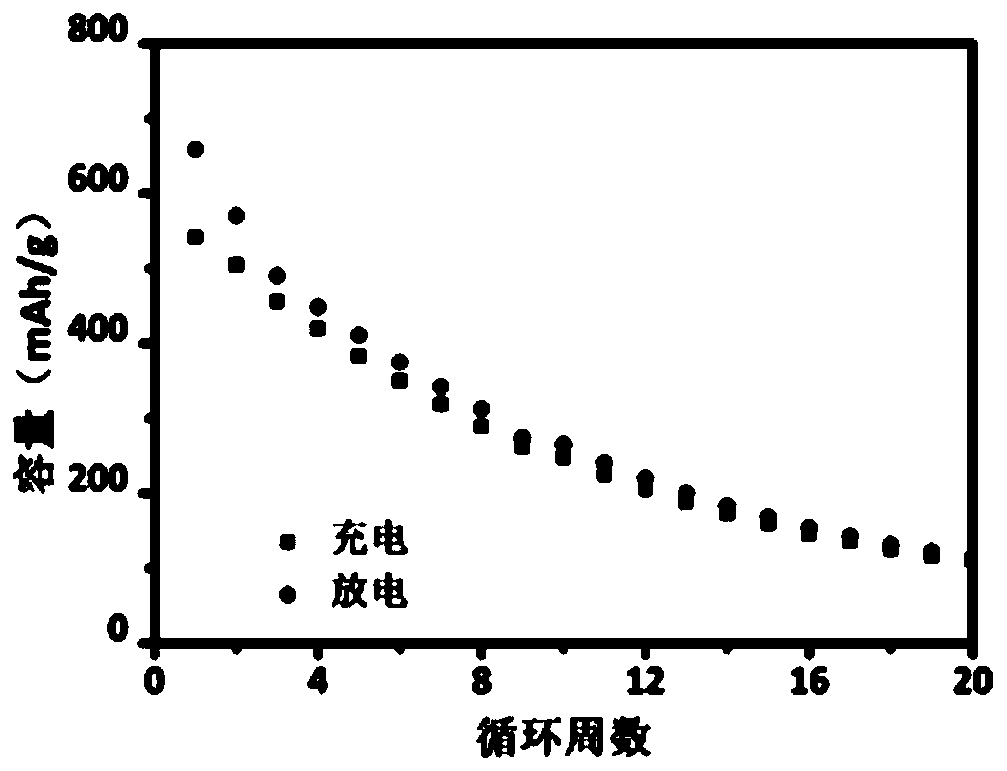

High-magnification and long-service-life rechargeable room-temperature sodium battery and preparation method thereof

ActiveCN104393353AHigh specific capacityExcellent rate performanceMaterial nanotechnologyCell electrodesCarbon nanotubePetroleum coke

The invention discloses a preparation method of a high-magnification and long-service-life rechargeable room-temperature sodium battery. A ferrous disulfide microsphere is used as a cathode material, a sodium sheet is used as an anode, a diaphragm is a three-layer membrane formed by polyethylene, polypropylene and polyethylene, or glass fiber paper, an electrolyte is an ether type electrolyte containing a sodium salt; a conductive agent used by coating a cathode plate is formed from one or more of acetylene black, Super P, KS-6, a carbon nano tube, graphene, petroleum coke and the like; a binder is polyvinylidene fluoride or sodium carboxymethylcellulose; a solvent is N-methyl pyrrolidone or water; a current collector is foamed nickel, a copper sheet, foamed copper or an aluminum sheet. The preparation method has the advantages that the ferrous disulfide microsphere is simply and conveniently prepared, and the purity is high. Meanwhile, due to a morphologic advantage of a micro-nanometer structure, the high-magnification and long-service-life rechargeable room-temperature sodium battery is relatively high in specific capacity and cyclic stability and excellent in magnification performance. Therefore, a ferrous / sodium disulfide secondary battery is expected to be in commercialized production, and becomes the next-generation large-scale energy storage battery.

Owner:NANKAI UNIV

Production process of lithium-ferrous disulfide battery anode

The invention provides a production process of a lithium-ferrous disulfide battery anode, comprising the following steps of: (a) integrally punching a metal strap to form a metal mesh; (b) cleaning and drying the metal mesh; (c) preparing half-dry sizing and coating the sizing on the meta mesh, wherein the half-dry sizing is prepared from ferrous disulfide, a conductive agent and a caking agent; (d) drying the coated metal mesh; and (e) cutting, rolling and welding the dried metal mesh by using electrode lugs. By using the metal mesh as anode matrix and coating the prepared half-dry sizing on the metal mesh to obtain an anode plate, the production process of the lithium-ferrous disulfide battery anode solves the problem that strap breaking easily generates in the coating process; the coating on the anode plate has favorable adhering performance; powder of the anode plate is not easy to fall in the preparation and winding process; the consumption of solvent for stirring the sizing is less; the filling quantity of active substances is high; and the capacity of batteries is larger.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

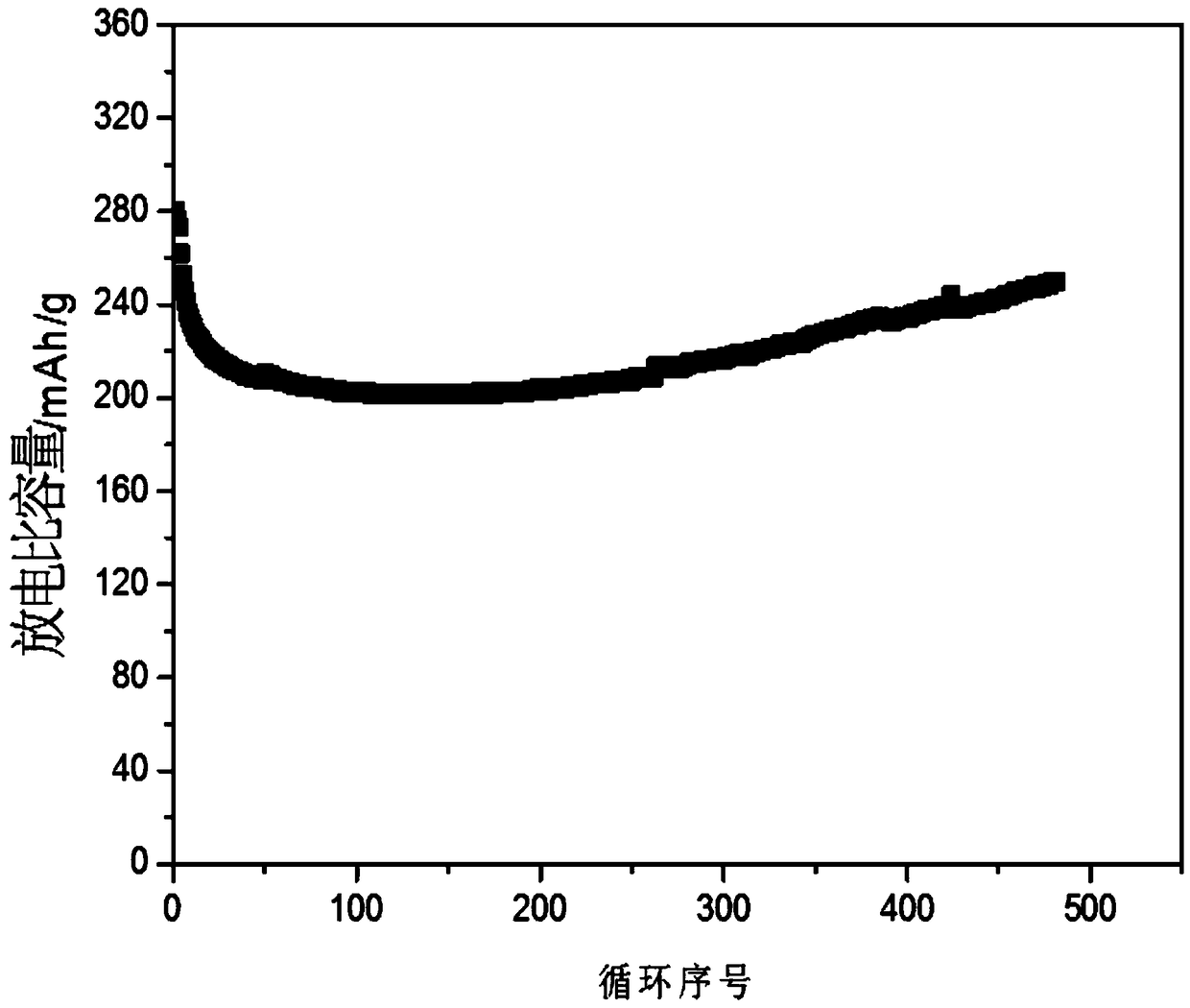

Selenium-doped ferrous disulfide carbon-coated composite material and preparation and application methods thereof

ActiveCN109437123AHigh activityImprove electrochemical activityCell electrodesSecondary cellsSodium-ion batteryCarbon coated

The invention discloses a selenium-doped ferrous disulfide carbon-coated composite material. The composition of the selenium-doped ferrous disulfide carbon-coated composite material is FeSe*S2-*@C, wherein x is 0.1-1.9. When applied to sodium ion batteries, the selenium-doped ferrous disulfide carbon-coated composite material can effectively inhibit volume expansion effects and increase actual specific capacity, rate capability and cycling performance. The invention also discloses preparation and application methods of the selenium-doped ferrous disulfide carbon-coated composite material.

Owner:中山高容新能源科技有限公司

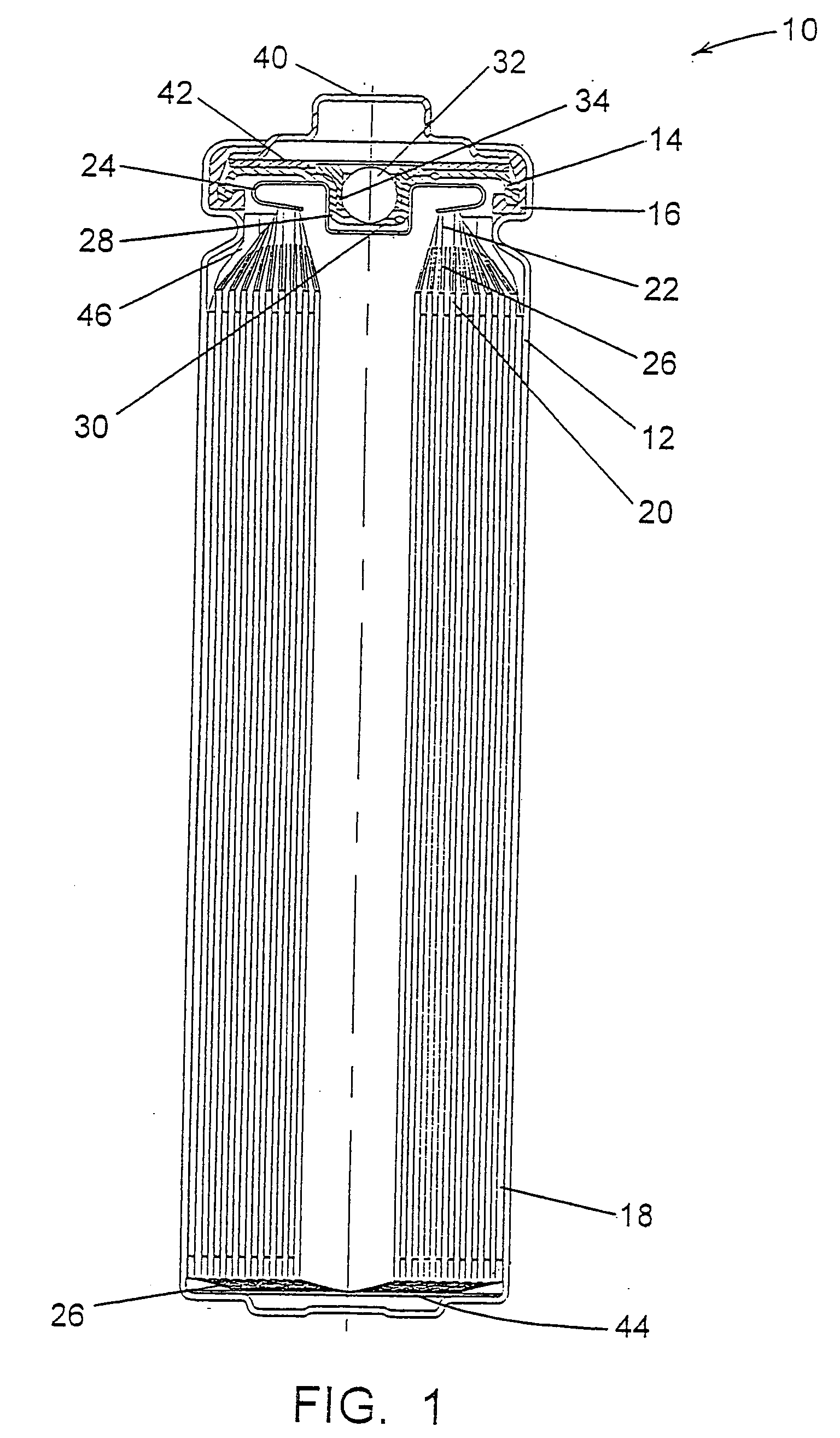

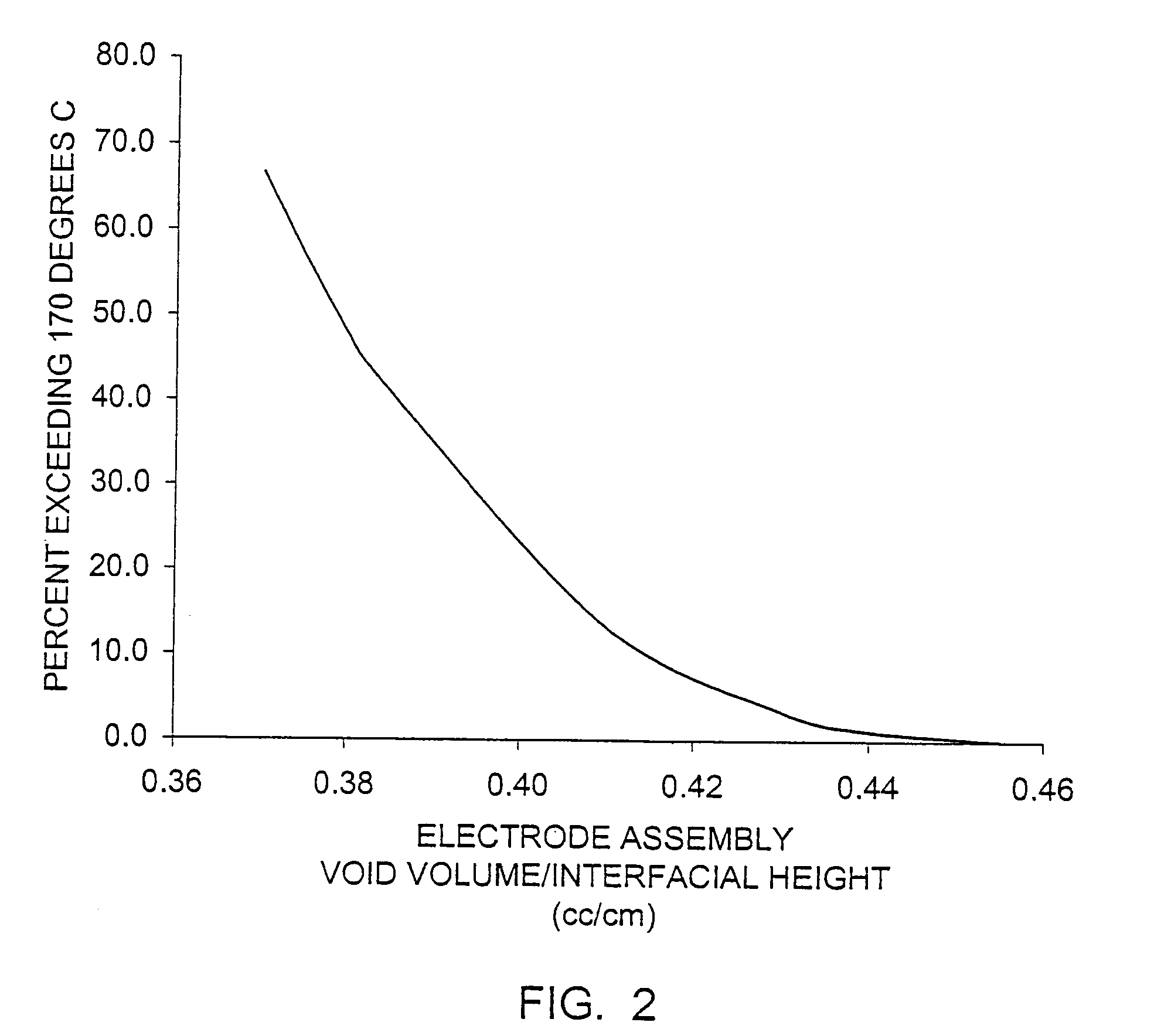

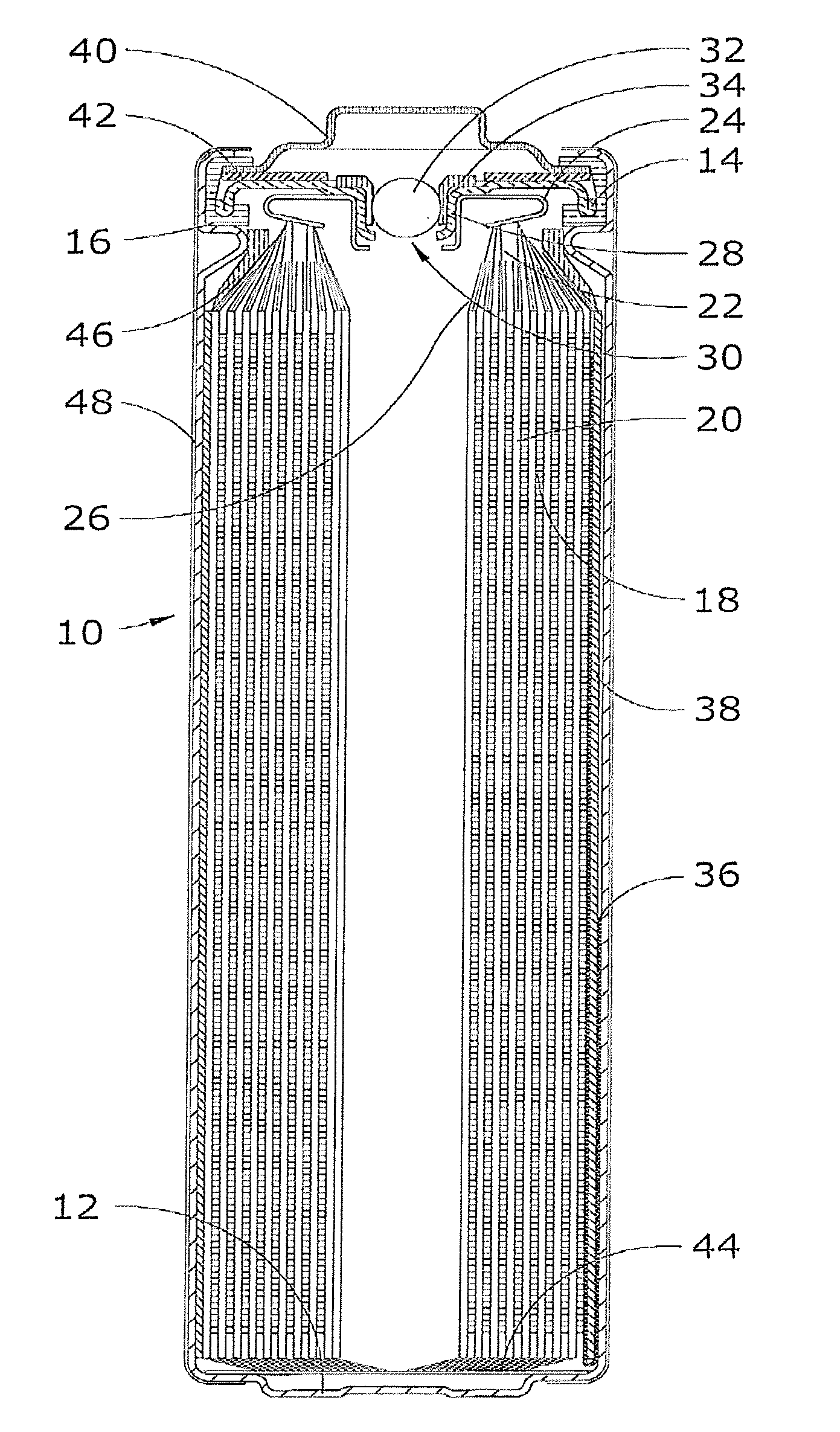

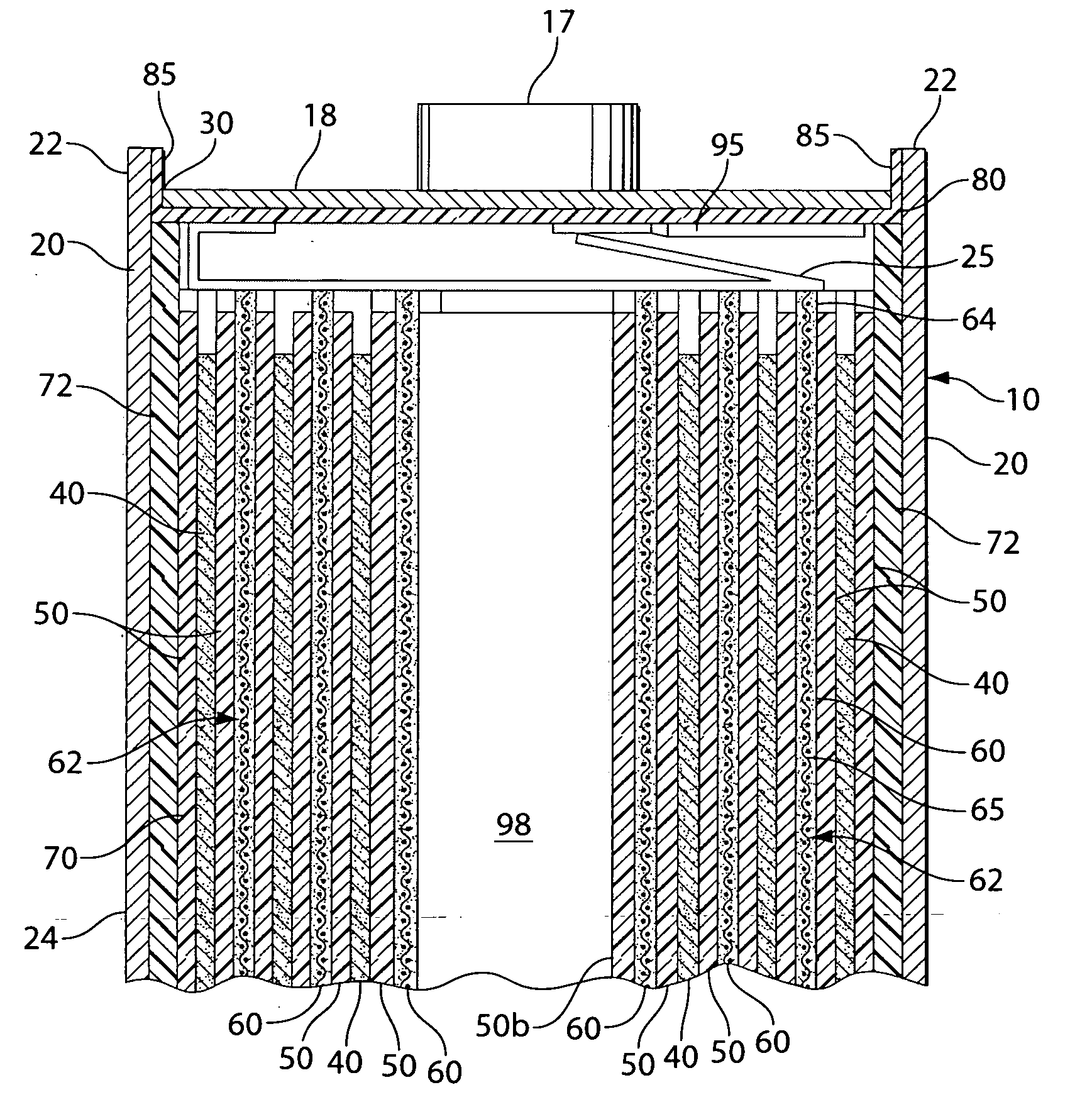

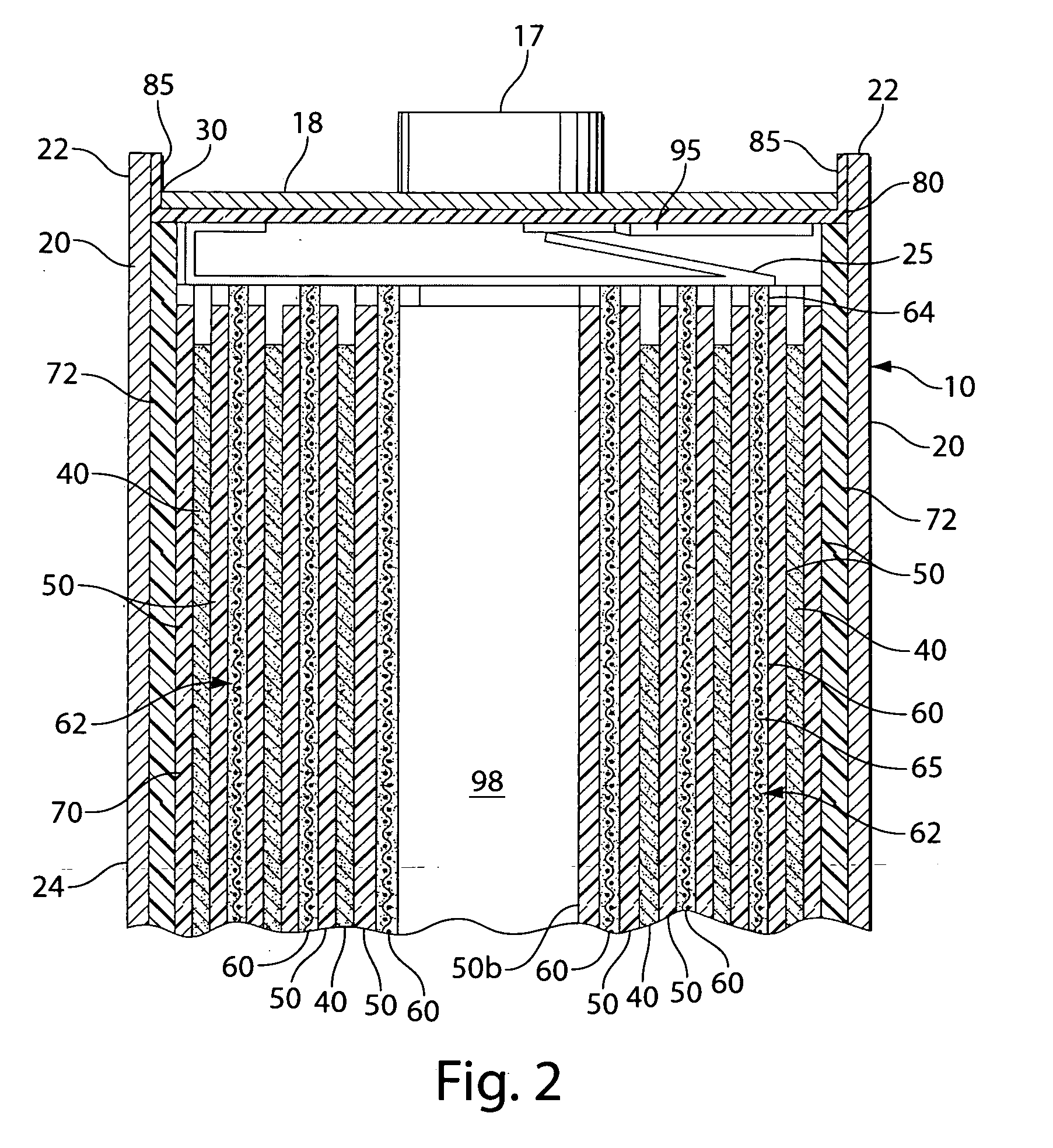

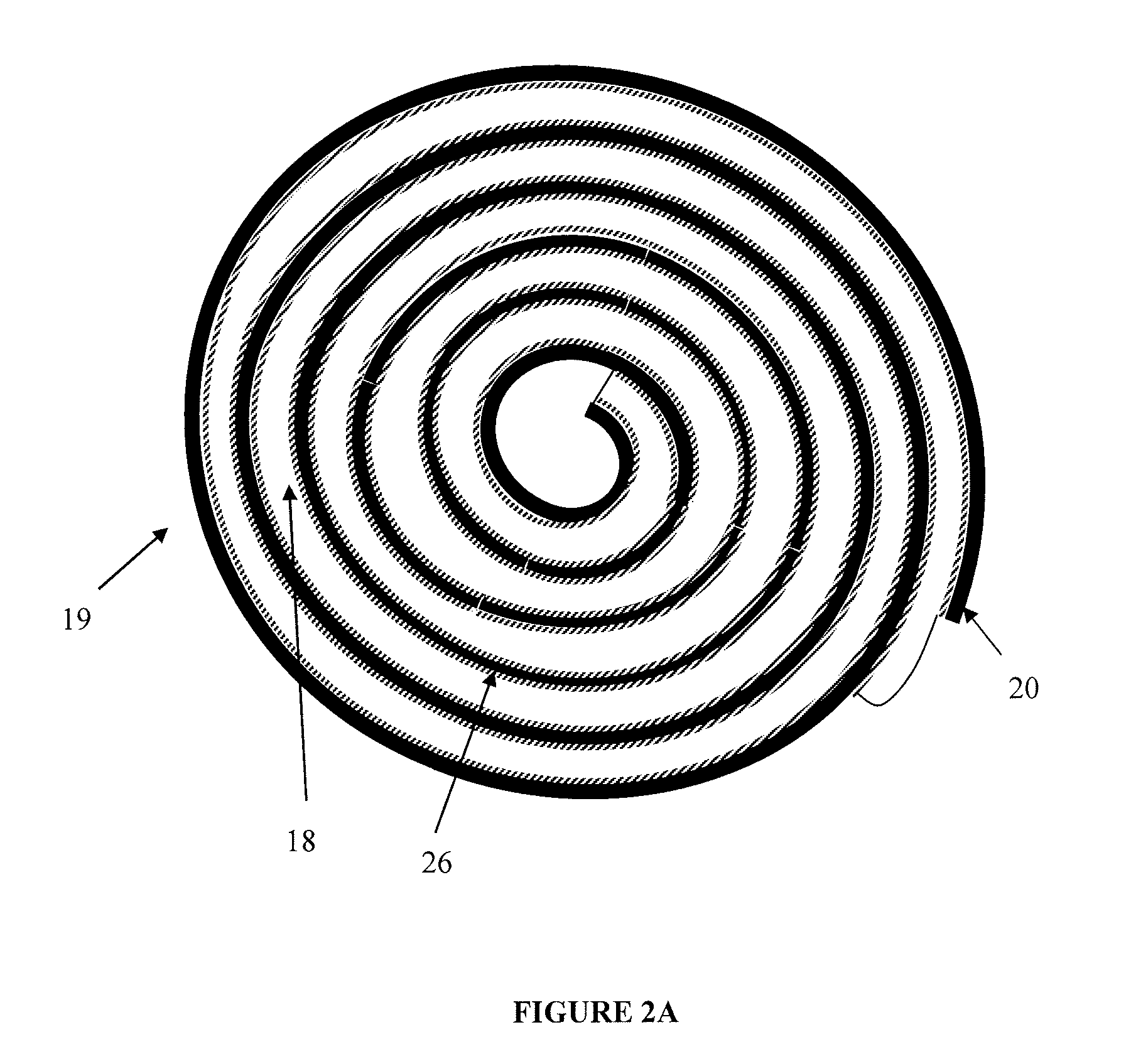

Lithium-Iron Disulfide Cell Design

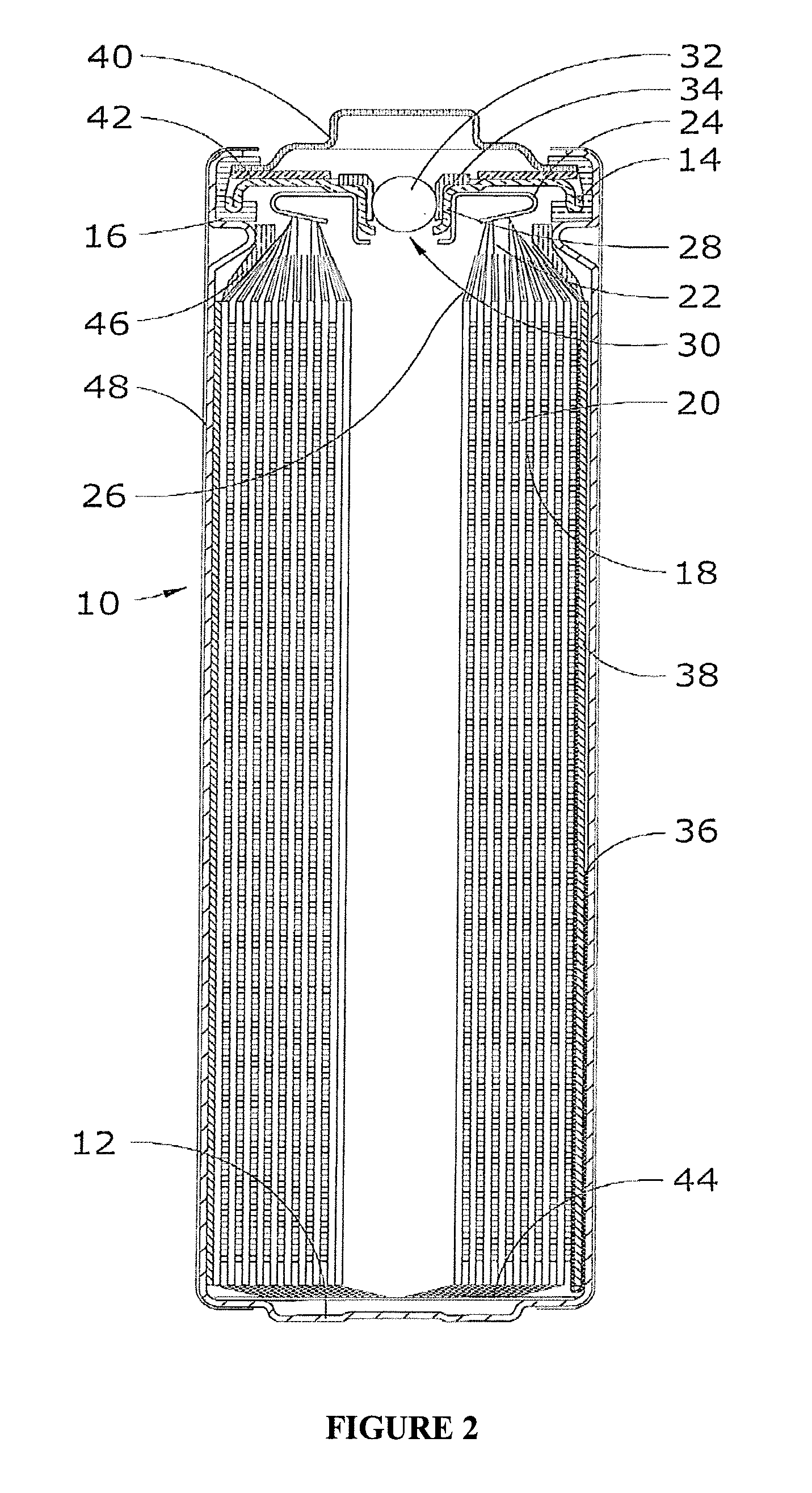

ActiveUS20120251860A1Improve discharge performanceReduce the amount requiredFinal product manufactureElectrode carriers/collectorsElectrochemical responseElectrical battery

The invention relates to primary electrochemical cells, in addition to methods for manufacturing and discharging the same, having a jellyroll electrode assembly that includes a positive electrode with a coating comprising iron disulfide deposited on a current collector situated on the outermost circumference of the jellyroll, a lithium-based negative electrode and a polymeric separator. More particularly, the invention relates to a cell design which optimizes cell capacity and substantially eliminates premature voltage drop-off on intermittent service testing by eliminating the edge effect through, for example, deliberately relieving stack pressure and / or extending the distance lithium ions proximate to the terminal end of the positive electrode must travel to undergo an electrochemical reaction in that region.

Owner:ENERGIZER BRANDS

FeS2 film and preparation method thereof

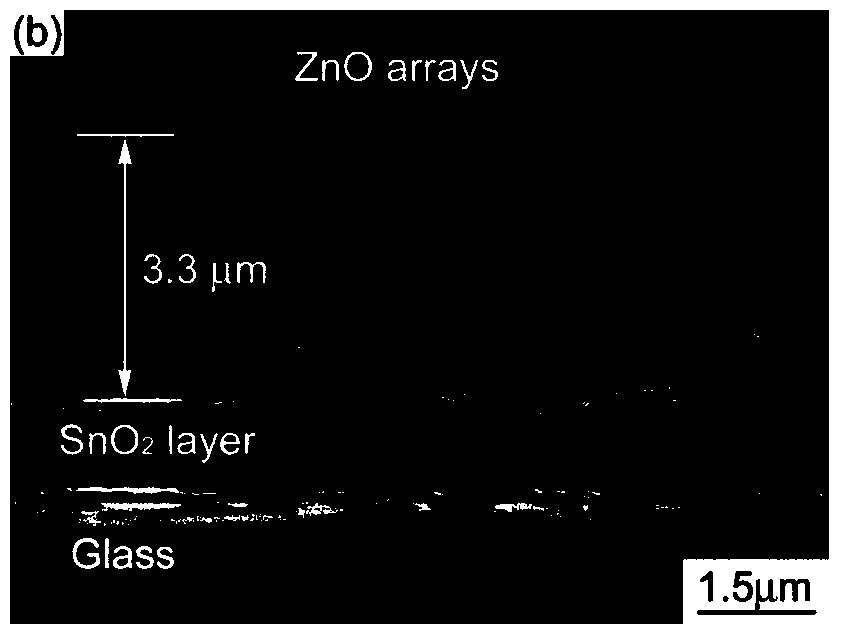

InactiveCN103824902AIncrease the effective light absorption areaEnhanced light absorptionFinal product manufacturePhotovoltaic energy generationRoom temperatureNanorod

The invention discloses a preparation method of a FeS2 film. The method comprises the following steps: using FTO conductive glass as a base; configuring a seed layer solution; soaking the base into the seed layer solution to coat in a pulling manner at room temperature; forming a layer of even ZnO nanocrystalline seed on the surface of the base; preparing a precursor solution; forming an even and compact ZnO nano rod array film on the surface of the base; covering the surface of the base with a Fe(OH)3 nano rod array by the ZnO nano rod array film at room temperature; carrying out vulcanizing treatment, and converting the Fe(OH)3 nano rod array into an FeS2 nano rod array. The FeS2 film comprises the base made of the FTO conductive glass; the base is covered with the FeS2 nano rod array; each FeS2 nano rod is formed by stacking FeS2 nano particles. The FeS2 film has the advantages that the optical absorption properties and the photoelectric conversion efficiency are improved by increasing the effective optical absorption area of a ferrous disulfide film.

Owner:ZHEJIANG UNIV

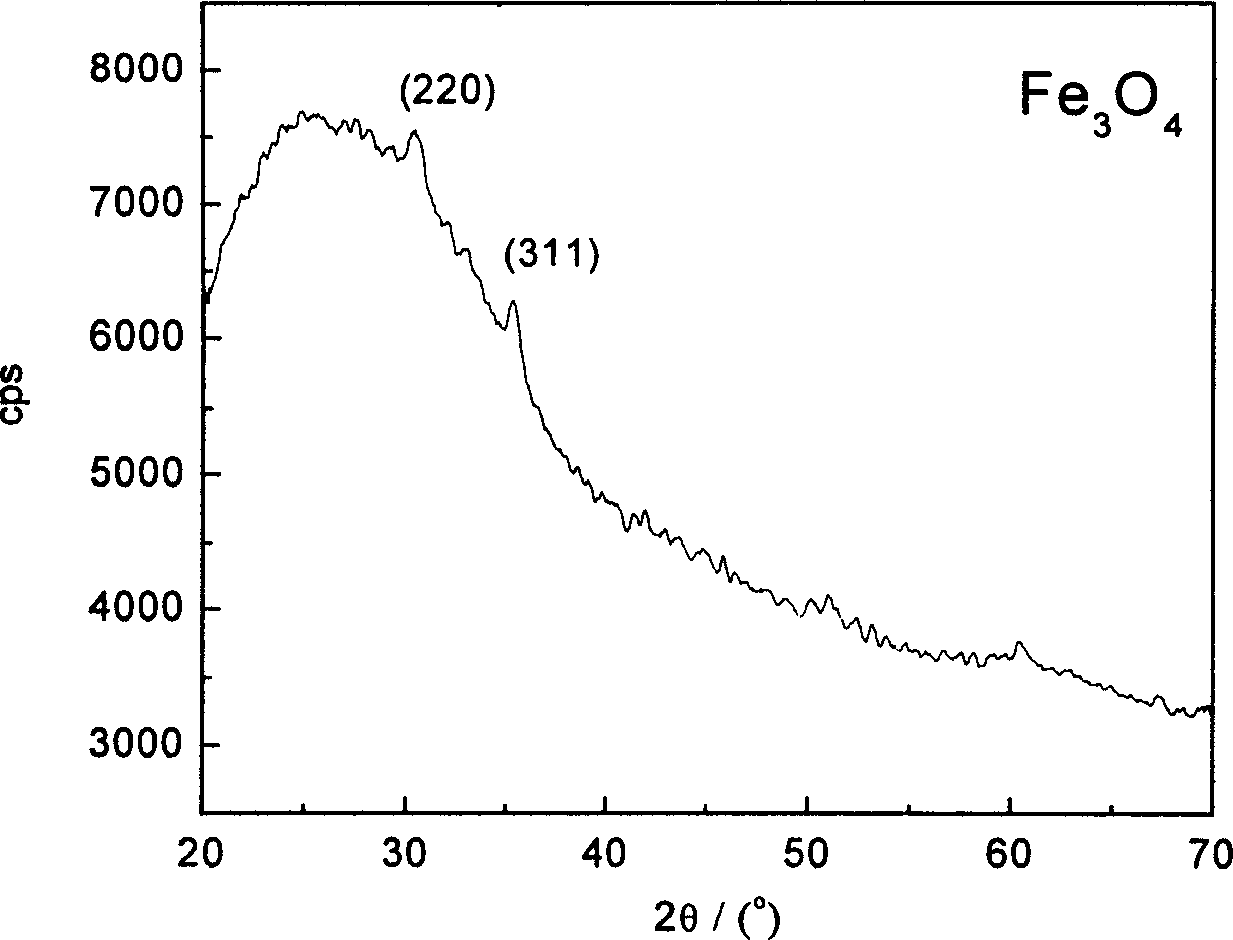

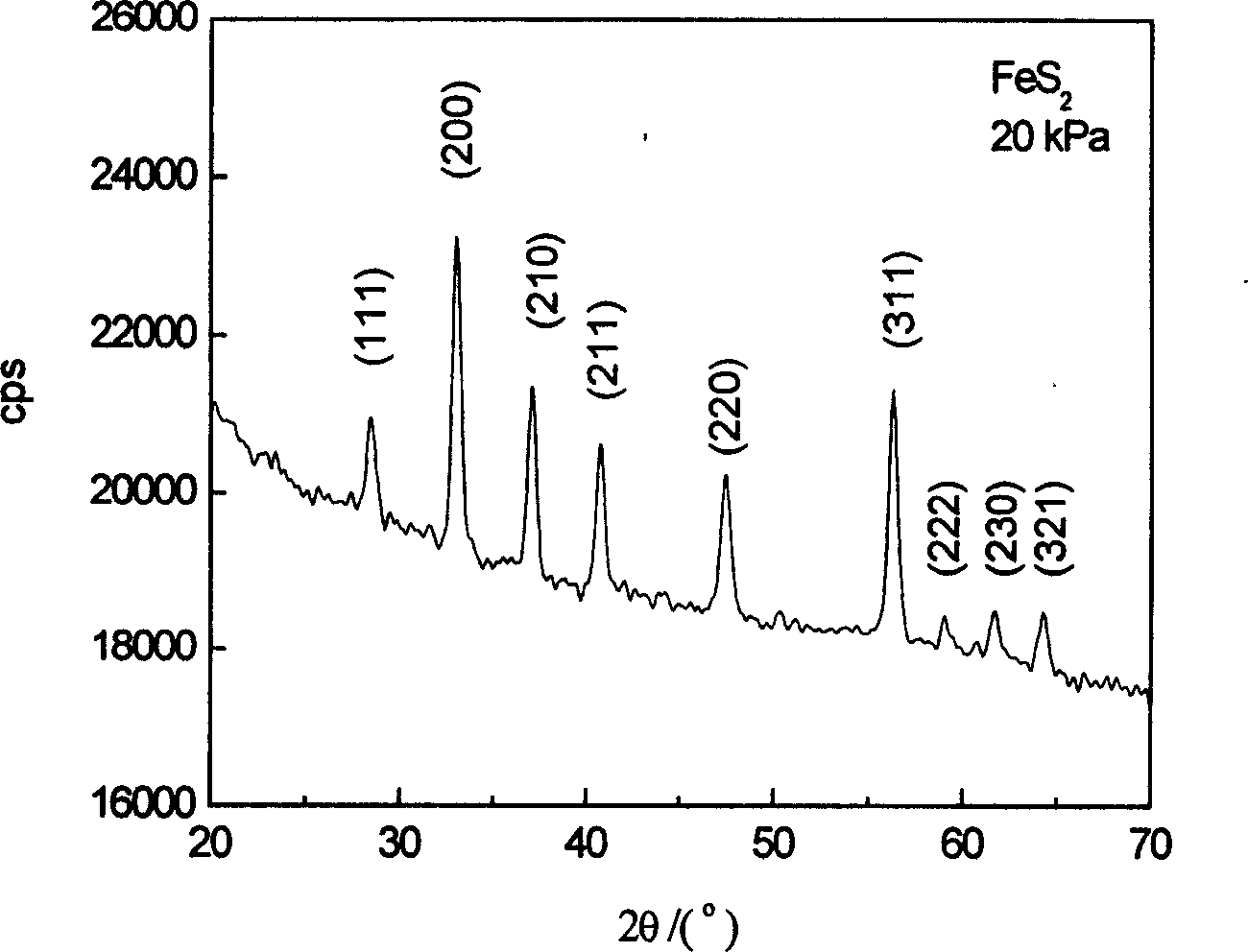

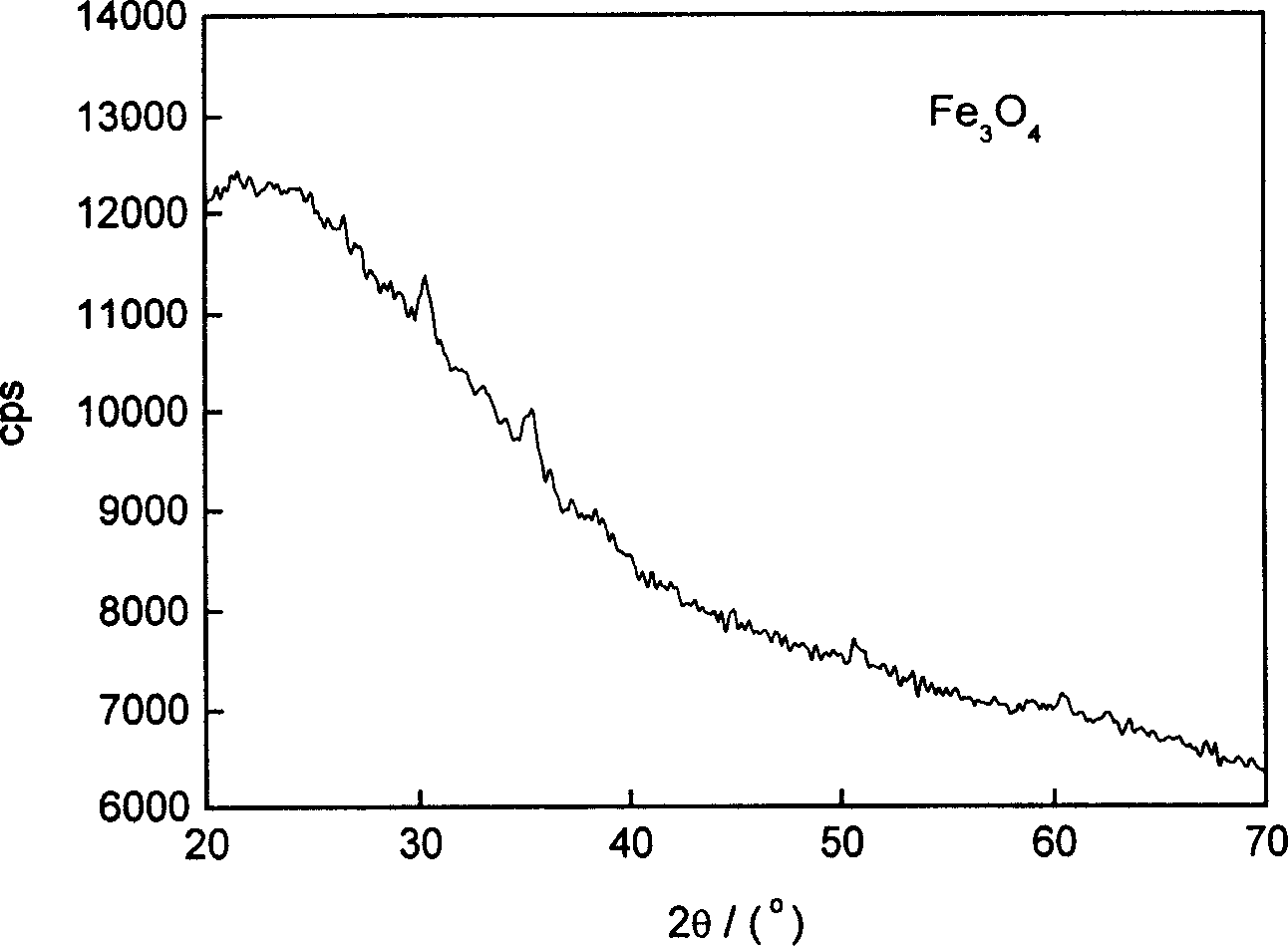

Method of synthesizing ferrous disulfide film by electro deposition oxidation and hot sulfurization

InactiveCN1624196AAvoid residueAvoid barrier effectMetallic material coating processesAqueous solutionMetal

A process for preparing the cubic crystal type FeS2 film by electric deposition, oxidizing and thermal sulfurizing includes such steps as electrically depositing Fe-S compound film on the electrically conductive glass subtrate in the aqueous solution of FeSO4 and Na2S2O3, oxidizing to obtain the precurse Fe3O4 film, and isothermal treating at 350-450 deg.C of sulfurizing temp to obtain cubic crystal type FeS2 film.

Owner:ZHEJIANG UNIV

Method for preparing electrolyte for lithium-ferrous disulfide battery by one-step method

The invention belongs to the technical field of primary lithium batteries, and discloses a method for preparing electrolyte for a lithium-ferrous disulfide battery by a one-step method. The method comprises the following steps: in inert atmosphere, adding elemental iodine into an organic solvent and stirring the organic solvent evenly at 0-5 DEG C; adding lithium aluminum hydride or lithium hydride and carrying out stirring reaction for 1-2 hours; heating the mixture to 40-60 DEG C and carrying out stirring reaction for 1-2 hours; and centrifuging and filtering the mixture to obtain the electrolyte for the lithium-ferrous disulfide battery. According to the preparation method, the electrolyte for the lithium-ferrous disulfide battery is synthesized by the one-step method; and no water is introduced in the entire preparation process, so that the cost is relatively low; and the lithium-ferrous disulfide battery prepared from the electrolyte prepared by the method is good in property.

Owner:EVE ENERGY CO LTD

Square lithium-ferrous disulfide battery and its preparation method

ActiveCN102738418AEasy to prepareEase of mass productionOrganic electrolyte cellsPrimary cell electrodesElectrical batteryMusic player

Owner:EVE ENERGY CO LTD

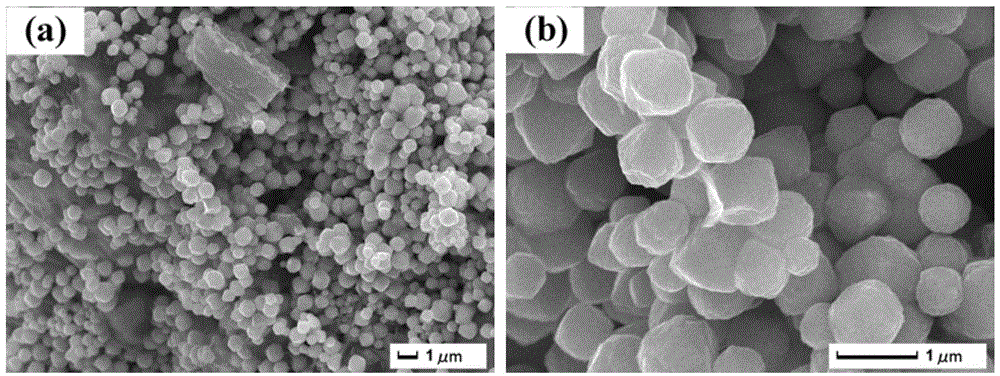

Ferrous disulfide microspheres and preparation method thereof

The invention relates to ferrous disulfide microspheres and a preparation method thereof. The ferrous disulfide microspheres are microspheres with single hole structures and are formed by clustering ferrous disulfide nano particles. The preparation method comprises the following steps: (1) dissolving ferric salt or ferrite into deionized water to obtain a solution; (2) adding thiourea into the solution, and carrying out stirring to dissolve the thiourea to obtain a mixed solution; (3) adding polyvinylpyrrolidone into the mixed solution, and carrying out ultrasonic stirring to obtain reaction liquid; (4) putting the reaction liquid into a reaction kettle, and after the reaction is completed, carrying out cooling, washing and centrifugating to obtain the ferrous disulfide microspheres. Compared with the prior art, the ferrous disulfide microspheres and the preparation method thereof which are disclosed by the invention have the advantages that the microspheres are uniform in particle size, the synthesis process is simple, a few of types of raw materials are needed, and the requirement on equipment is relatively low.

Owner:SHANGHAI JIAO TONG UNIV

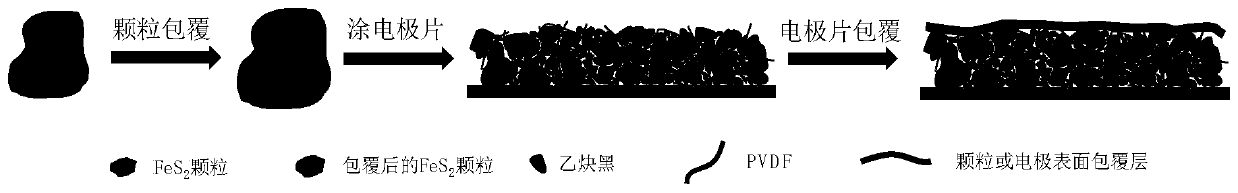

Iron disulfide positive electrode material, preparation method thereof and alkali metal ion battery

InactiveCN109935779AImprove conductivityIncrease capacityElectrode manufacturing processesLi-accumulatorsSodium-ion batteryDissolution

The invention discloses an iron disulfide positive electrode material, a preparation method thereof and an alkali metal ion battery, and belongs to the technical field of battery electrode materials.The preparation method comprises the following steps: firstly, coating the surfaces of iron disulfide particles with a conductive polymer in a chemical polymerization manner; uniformly coating the prepared material on a current collector; and coating the surface of an electrode piece with the conductive polymer. According to the invention, the method can remarkably improve the conductivity of theactive substance, alleviates the volume effect during lithium intercalation and deintercalation of iron disulfide, inhibits the problem of dissolution of the active substance in the charging and discharging process, and improves the cycle performance and the rate capability of the battery. The material is suitable for lithium, sodium and potassium ion batteries.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com