Ferrous disulfide microspheres and preparation method thereof

A technology of ferrous disulfide and microspheres, applied in iron sulfide and other directions, can solve the problems of non-cubic phase pyrite impurities, difficult process control, uneven morphology, etc., to achieve uniform morphology and size, low cost, The effect of large binding reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Weigh 2.7g FeCl 3 ·6H 2 O, fully dissolved in 40mL deionized water, stirred to obtain a homogeneous solution;

[0037] (2) Add 0.76g of thiourea to the above solution, fully stir and dissolve;

[0038] (3) Add 10g of polyvinylpyrrolidone (PVP) into the above solution by weighing again, and stir while ultrasonically to obtain a homogeneous transparent solution;

[0039] (4) Transfer the final solution into a polytetrafluoroethylene-lined stainless steel sealed high-temperature and high-pressure reactor, heat it to 240 ° C, and react at constant temperature for 12 hours. After the reaction is completed, cool it, and then wash it with deionized water and absolute ethanol. Centrifuge three times, and finally the target product can be obtained.

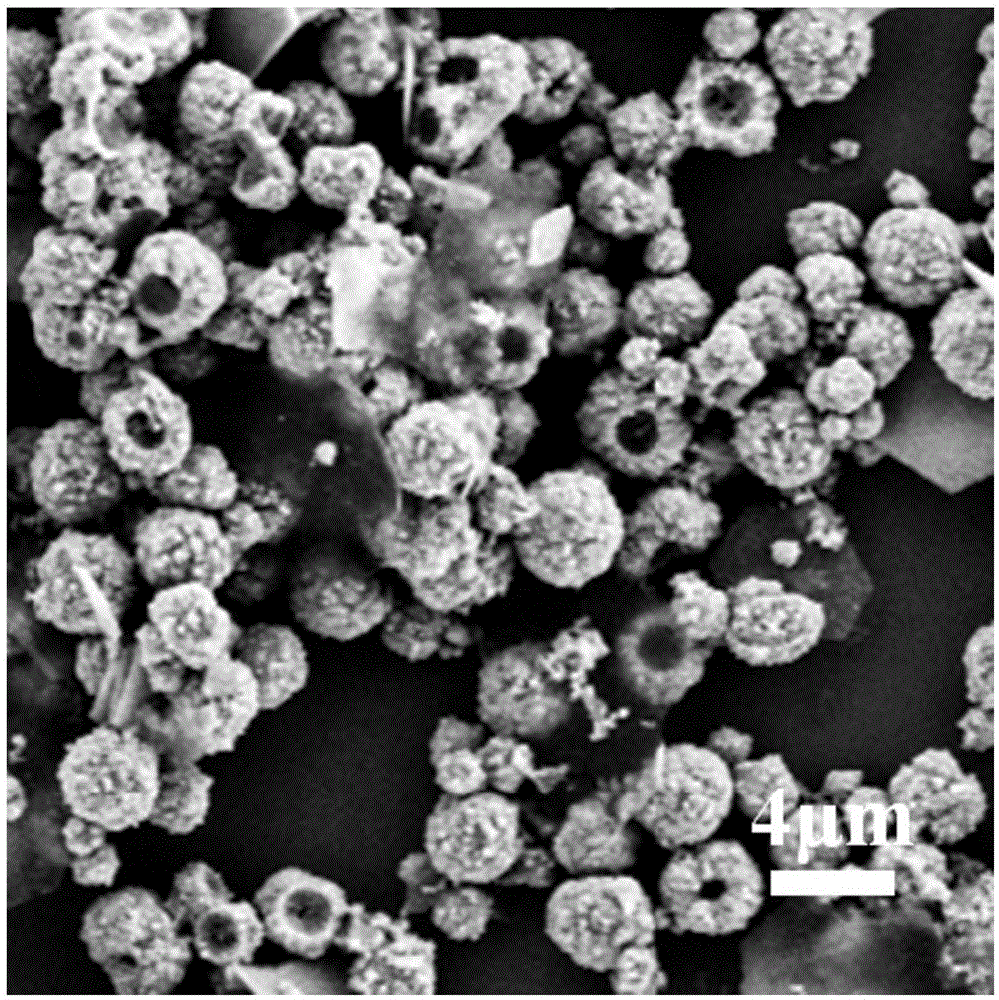

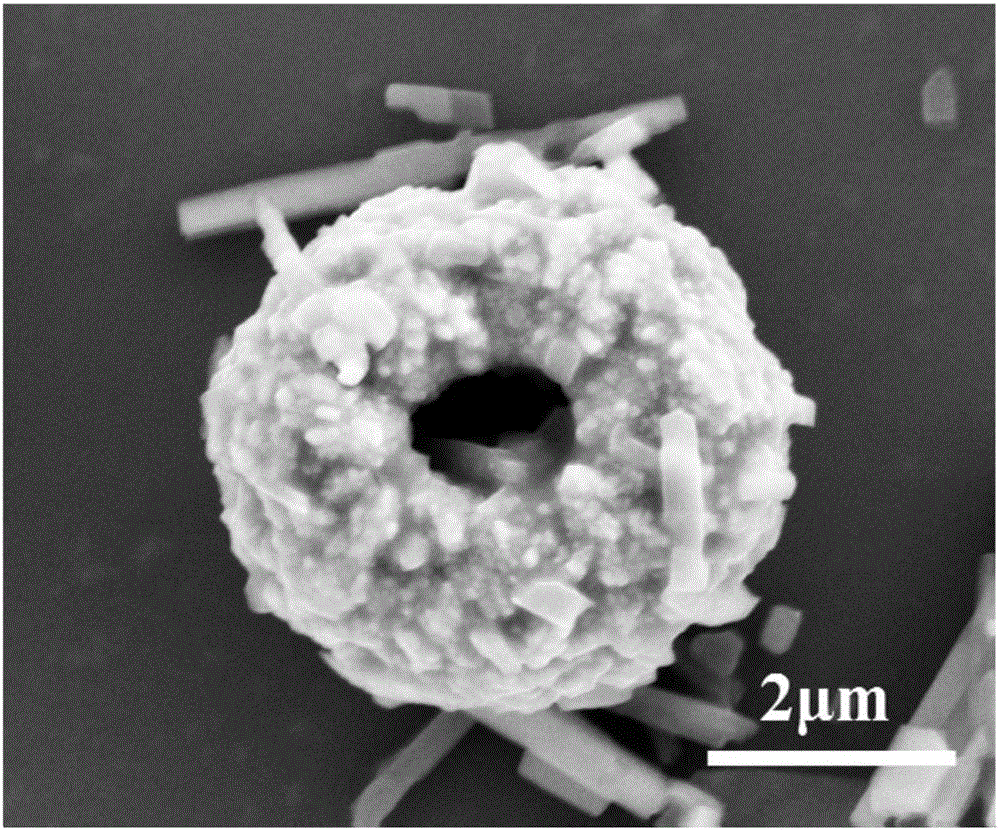

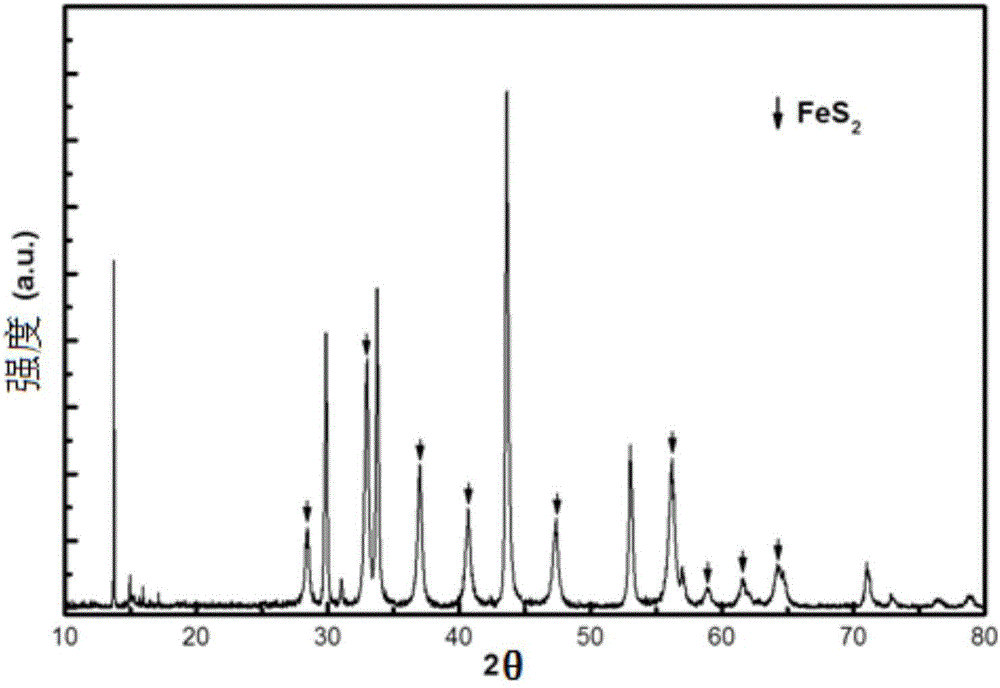

[0040] For the FeS prepared above 2 microspheres for detection, figure 1 , figure 2 FeS prepared for this example 2 The scanning electron micrograph of the microsphere shows that the FeS 2 The microspheres are uniformly...

Embodiment 2

[0042] (1) Weigh 2.0g FeCl 3 ·6H 2 O, fully dissolved in 40mL deionized water, stirred to obtain a homogeneous solution;

[0043] (2) Add 0.76g of thiourea to the above solution, fully stir and dissolve;

[0044] (3) Add 10g of polyvinylpyrrolidone (PVP) into the above solution by weighing again, and stir while ultrasonically to obtain a homogeneous transparent solution;

[0045] (4) Transfer the final solution into a polytetrafluoroethylene-lined stainless steel sealed high-temperature and high-pressure reactor, heat it to 240 ° C, and react at constant temperature for 12 hours. After the reaction is completed, cool it, and then wash it with deionized water and absolute ethanol. Centrifuge three times, and finally the target product can be obtained.

Embodiment 3

[0047] (1) Weigh 3.4g FeCl 3 ·6H 2 O, fully dissolved in 40mL deionized water, stirred to obtain a homogeneous solution;

[0048] (2) Add 0.76g of thiourea to the above solution, fully stir and dissolve;

[0049] (3) Add 10g of polyvinylpyrrolidone (PVP) into the above solution by weighing again, and stir while ultrasonically to obtain a homogeneous transparent solution;

[0050] (4) Transfer the final solution into a polytetrafluoroethylene-lined stainless steel sealed high-temperature and high-pressure reactor, heat it to 240 ° C, and react at constant temperature for 12 hours. After the reaction is completed, cool it, and then wash it with deionized water and absolute ethanol. Centrifuge three times, and finally the target product can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com