Method of synthesizing ferrous disulfide film by electro deposition oxidation and hot sulfurization

An iron disulfide and electrodeposition technology, applied in metal material coating process, coating and other directions, can solve the problems of weak bonding between film and substrate, complex equipment, low efficiency, etc., to avoid blocking effect, high efficiency, and preparation Simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The ITO conductive glass with a size of 20×15mm2 is used as the substrate of the carrier film, and the conductive film composition is In 2 o 3 :SnO 2 =9:1, ultrasonic cleaning in acetone solution for 15 minutes, then ultrasonic cleaning in ethanol solution for 15 minutes, after ultrasonic cleaning, thoroughly rinse with ionized water to remove residual organic solution.

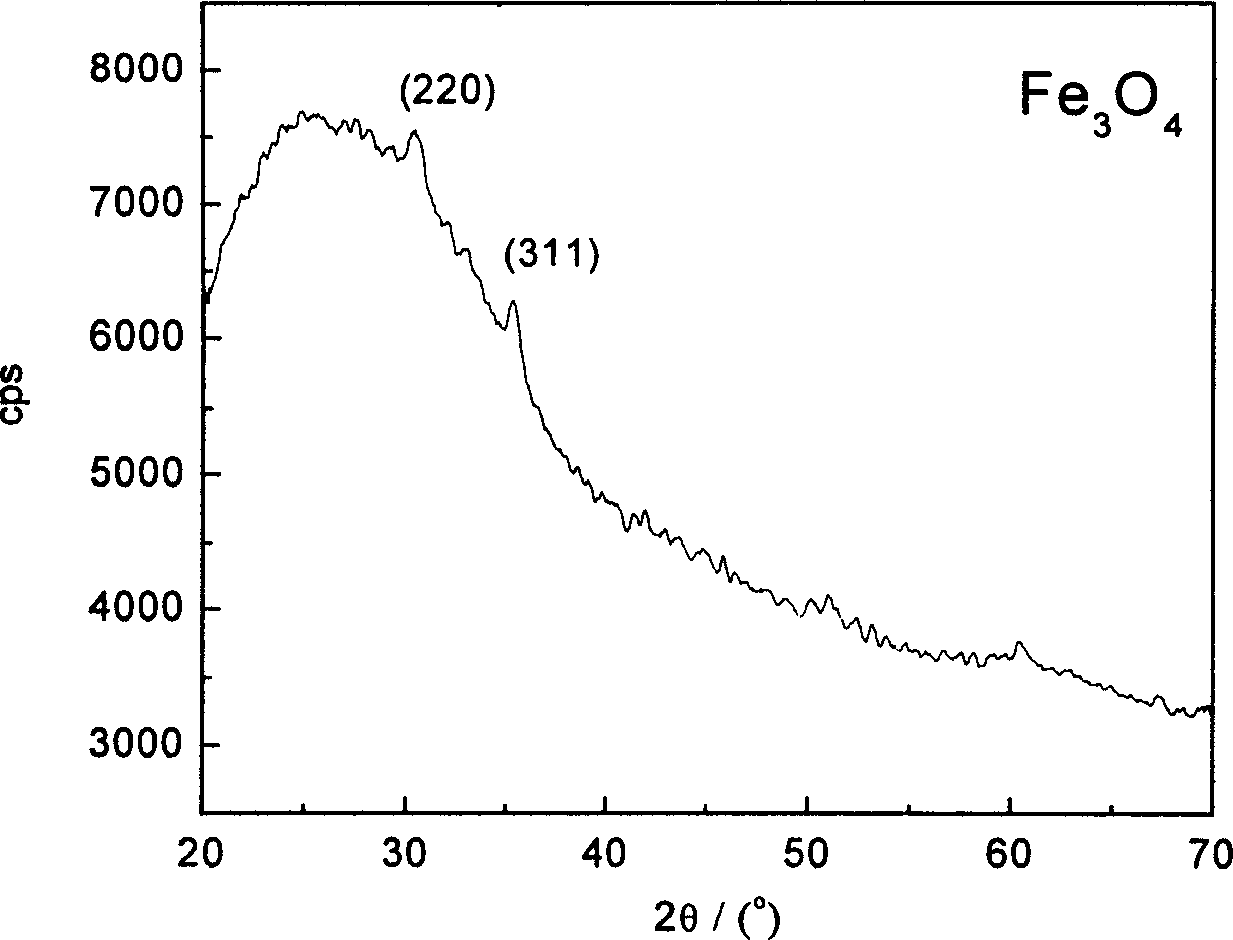

[0033] Prepare FeSO with a molar concentration ratio of 1:5 4 and Na 2 S 2 o 3 aqueous solution with diluted H 2 SO 4 Adjust the pH of the solution to 5.0. A Pt sheet was used as a counter electrode to deposit a Fe-S compound film on the substrate, maintaining a constant current of 0.75mA, and the deposition time was 20min. The deposited sample was rinsed with deionized water, soaked in absolute ethanol for 1 h, and then placed in an oven with dry air at 180 °C for 2 h for oxidation treatment, and the crystal structure was obtained as follows: figure 1 Shown Fe 3 o 4 Prefabricated film.

[...

Embodiment 2

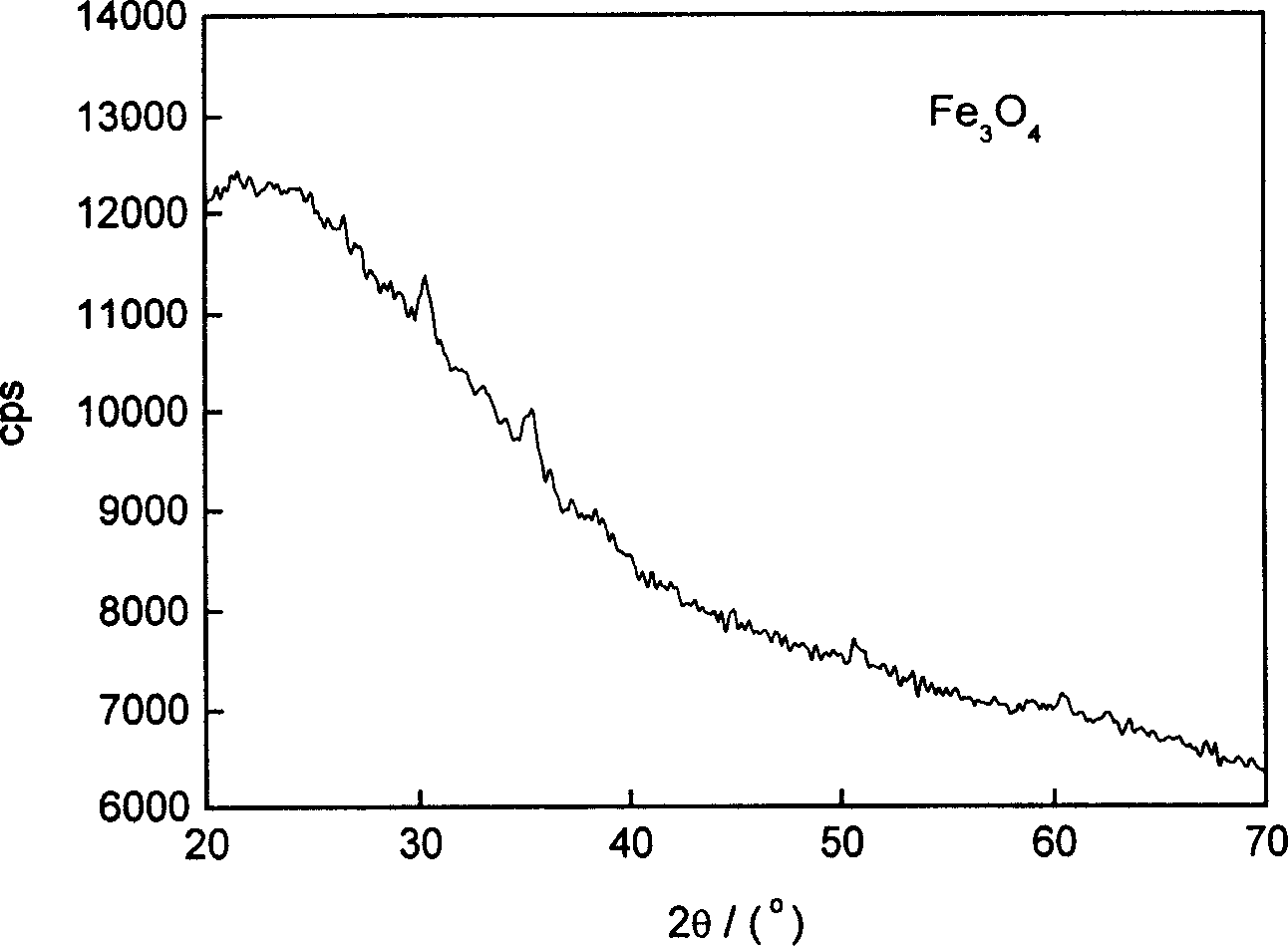

[0036] Prepare the Fe-S compound film according to the method of Example 1, place the electrodeposited film in an oven with dry air at 220°C for 2 hours for oxidation treatment to obtain Fe 3 o 4 Prefabricated membranes with crystal structures such as image 3 shown.

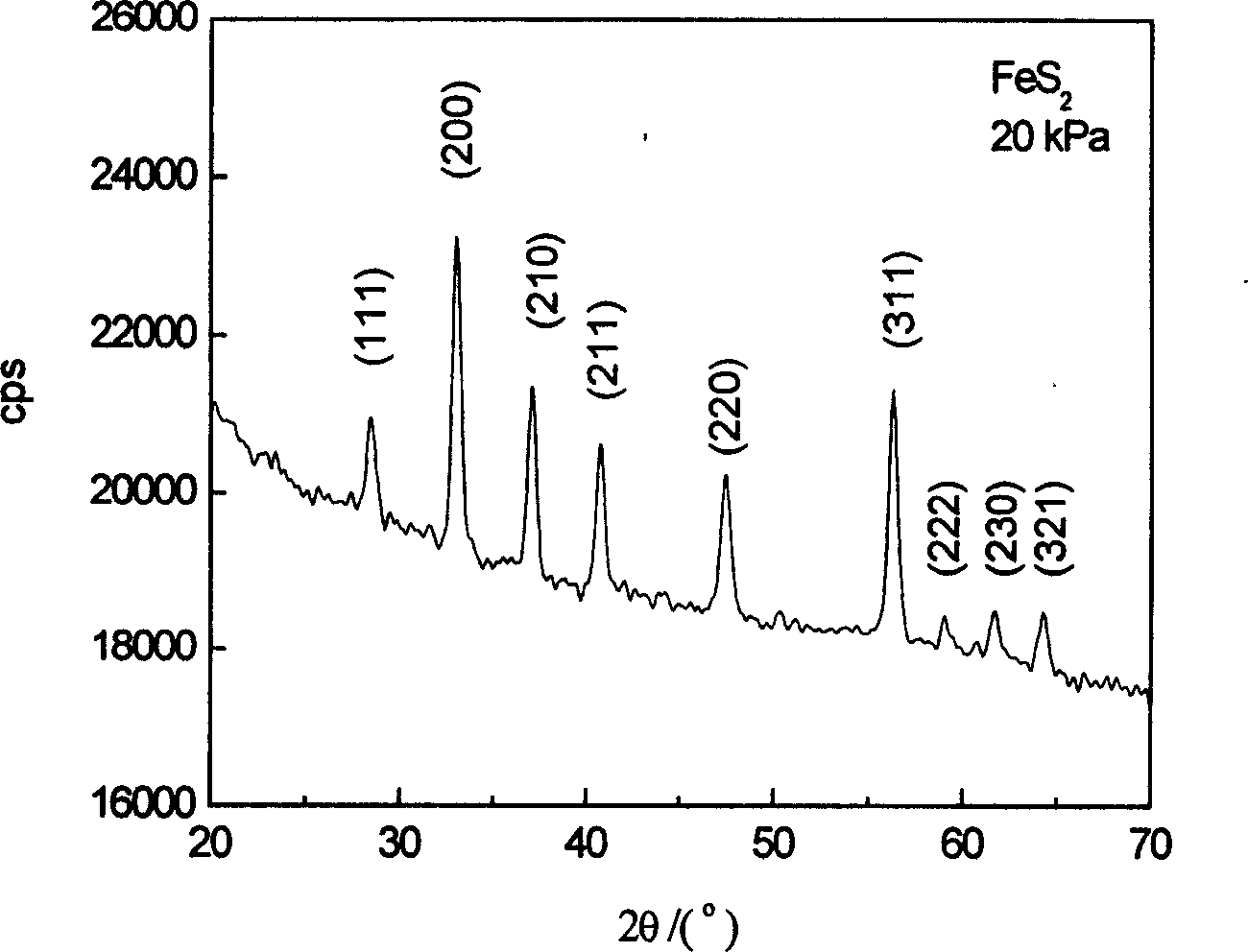

[0037] Calculate the mass required to produce 40kPa nominal sulfur pressure sublimation sulfur powder (purity is 99.5%) under the condition of 450°C, and then convert the prefabricated membrane into FeS according to the method in Example 1 at 450°C for 5h 2 Thin film (vacuumization and argon replacement repeated 8 times before the quartz tube is packaged), the crystal structure is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com