Patents

Literature

59results about How to "Lower open circuit voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

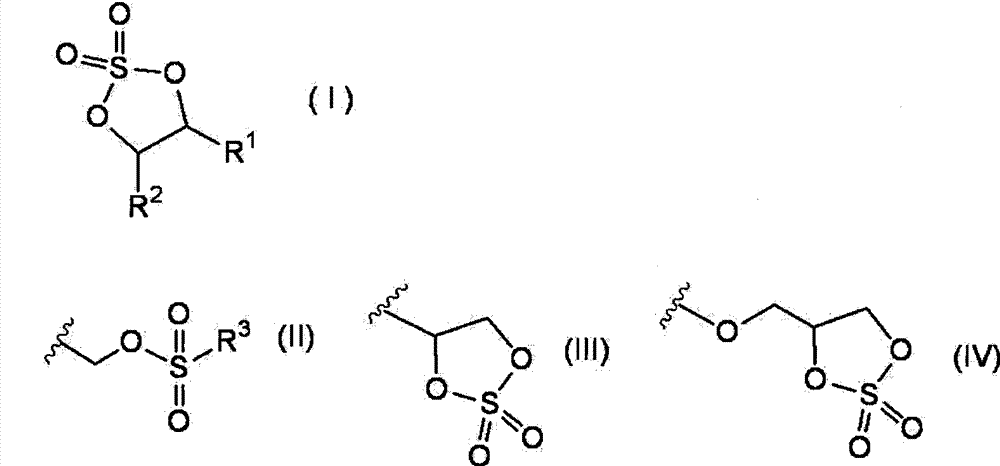

Cyclic sulfate compound, non-aqueous electrolyte solution containing same, and lithium secondary battery

ActiveCN103098290AGood capacity retentionLower open circuit voltageOrganic chemistryFinal product manufactureHydrogen atomHalogen

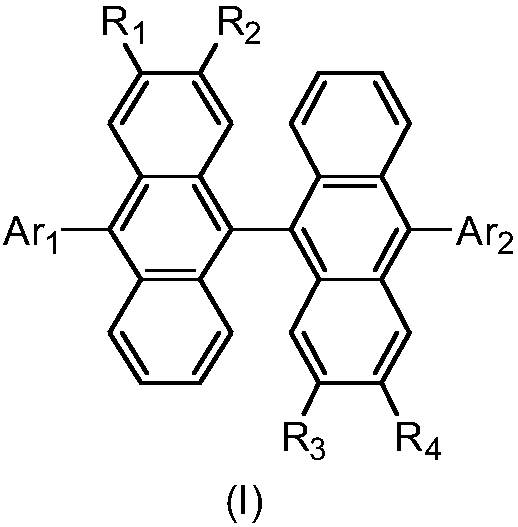

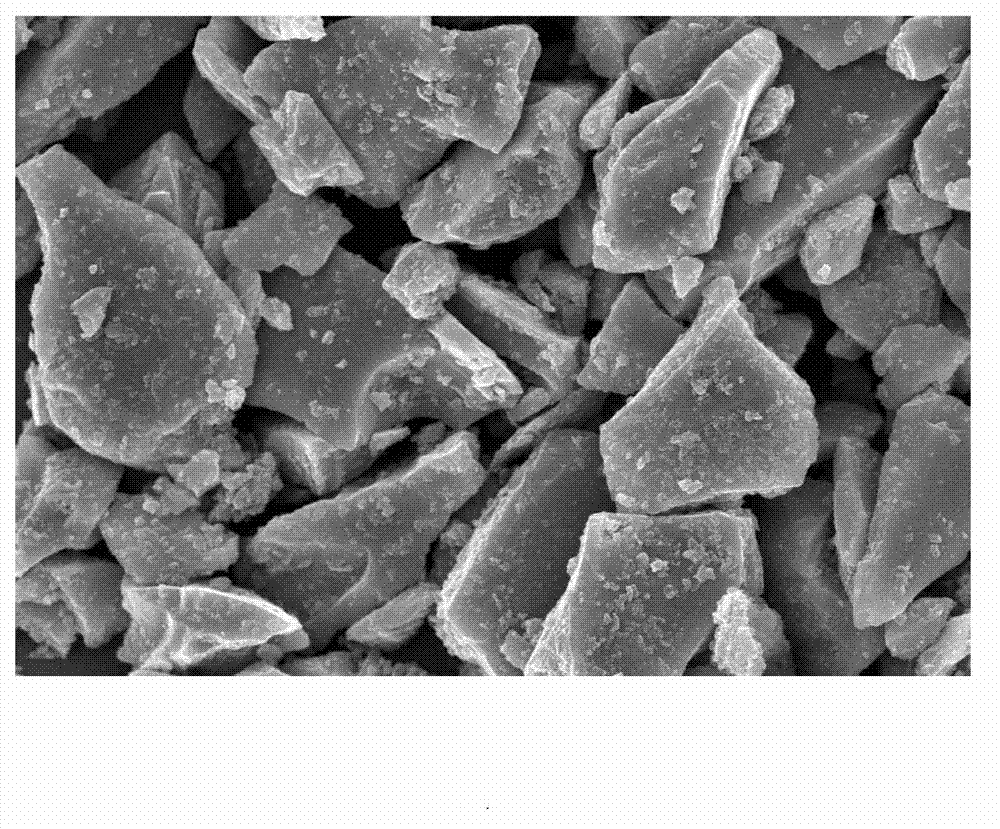

A non-aqueous electrolyte solution containing a cyclic sulfate compound represented by formula (I) is provided, wherein in formula (I), R1 represents a group represented by formula (II) or a group represented by formula (III); R2 represents a hydrogen atom, an alkyl group having from 1 to 6 carbon atoms, a group represented by formula (II), or a group represented by formula (III); and in formula (II), R3 represents a halogen atom, an alkyl group having from 1 to 6 carbon atoms, a halogenated alkyl group having from 1 to 6 carbon atoms, an alkoxy group having from 1 to 6 carbon atoms, or a group represented by formula (IV).

Owner:MITSUI CHEM INC

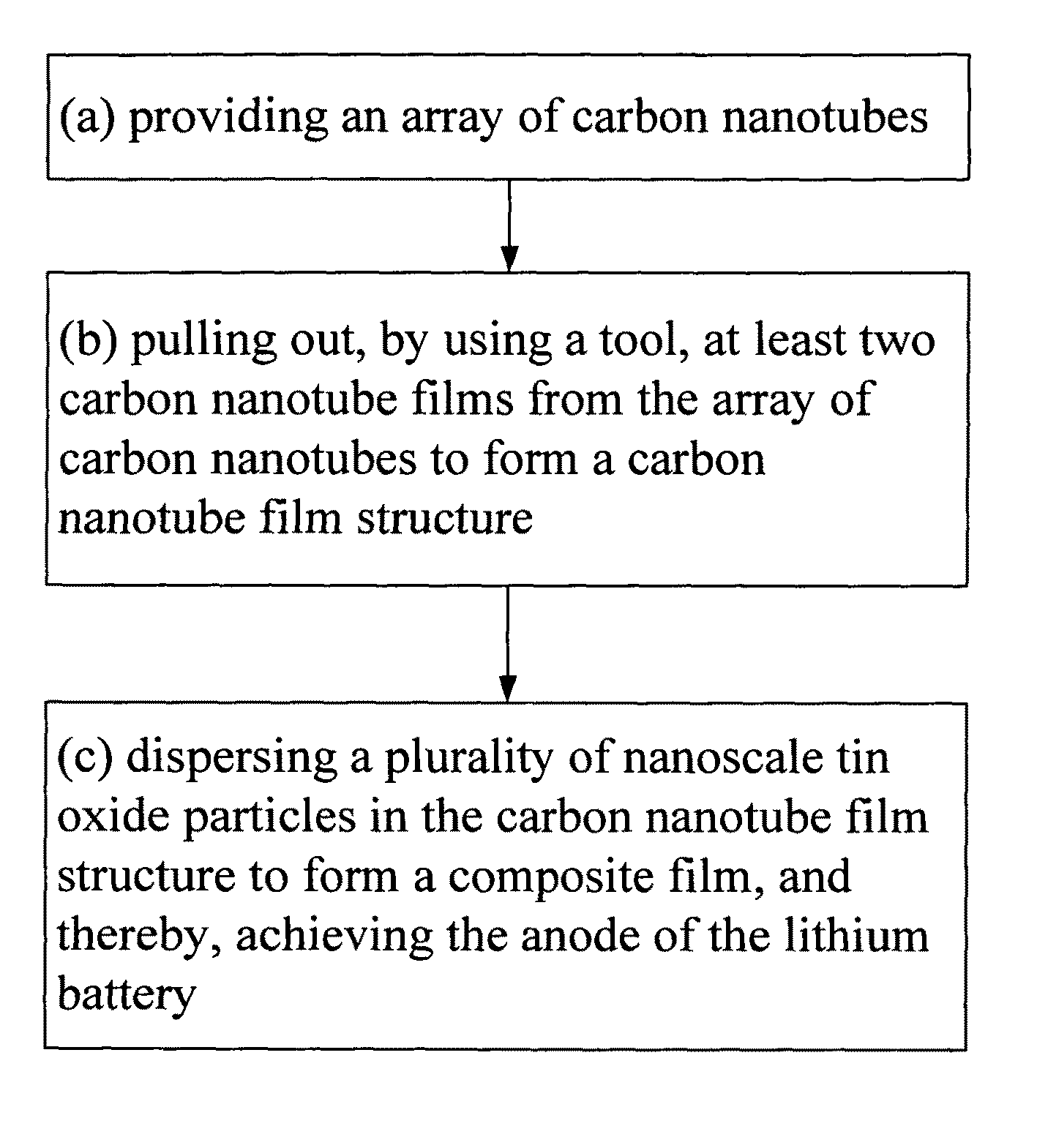

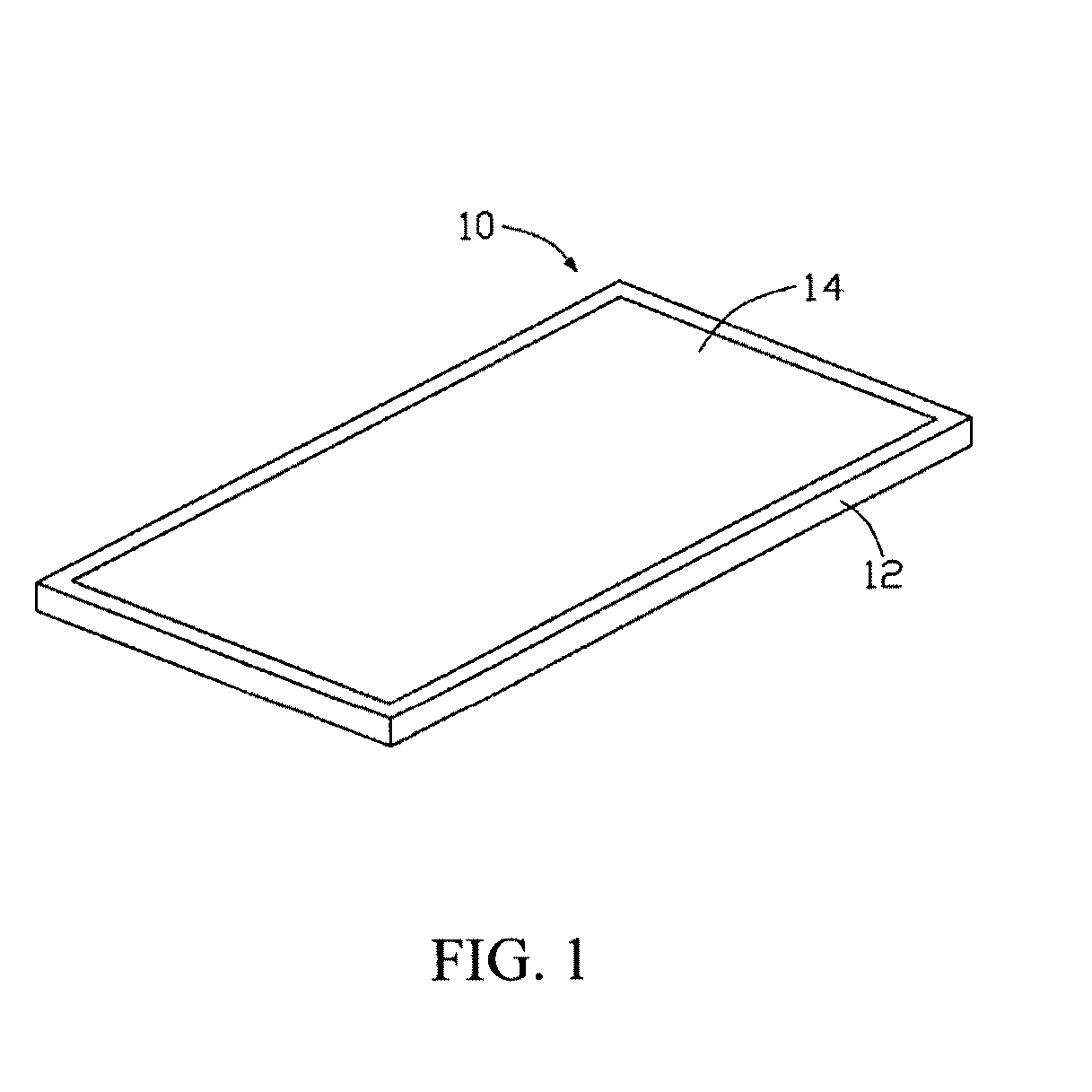

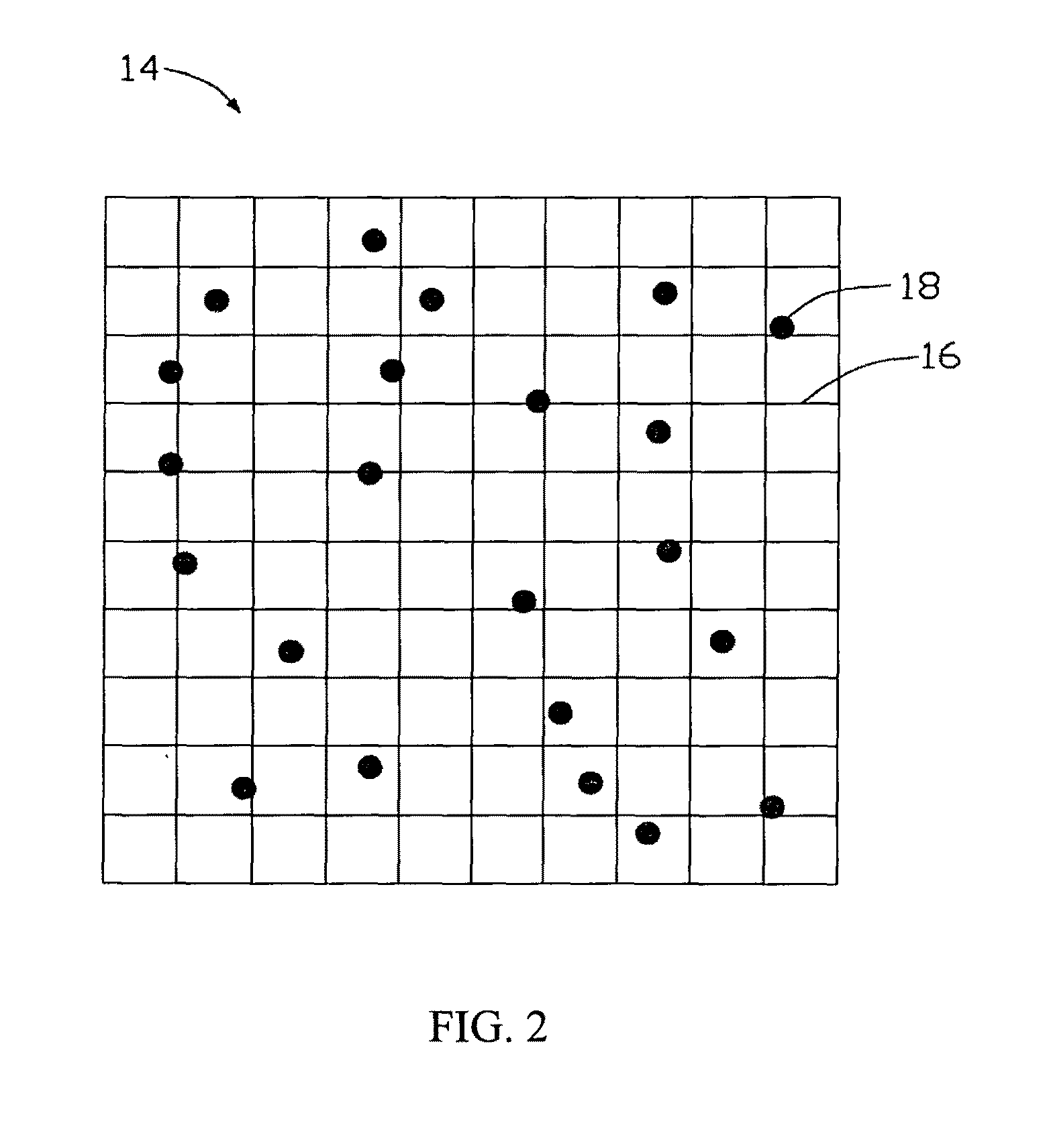

Anode of a lithium battery and method for fabricating the same

ActiveUS20090075171A1Increase energy densityLarge capacityConductive materialActive material electrodesThin membraneCarbon nanotube

An anode of a lithium battery includes a composite film, the composite film comprising a carbon nanotube film structure and a plurality of nanoscale tin oxide particles dispersed therein. A method for fabricating an anode of a lithium battery, the method includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, by using a tool, at least two carbon nanotube films from the array of carbon nanotubes to form a carbon nanotube film structure; and (c) dispersing a plurality of nanoscale tin oxide particles in the carbon nanotube film structure to form a composite film, and thereby, achieving the anode of the lithium battery.

Owner:TSINGHUA UNIV +1

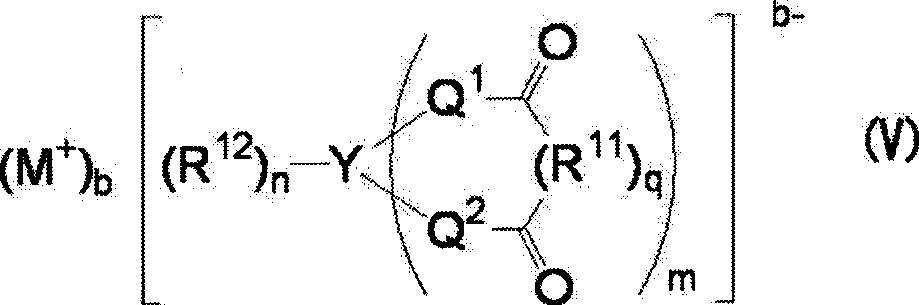

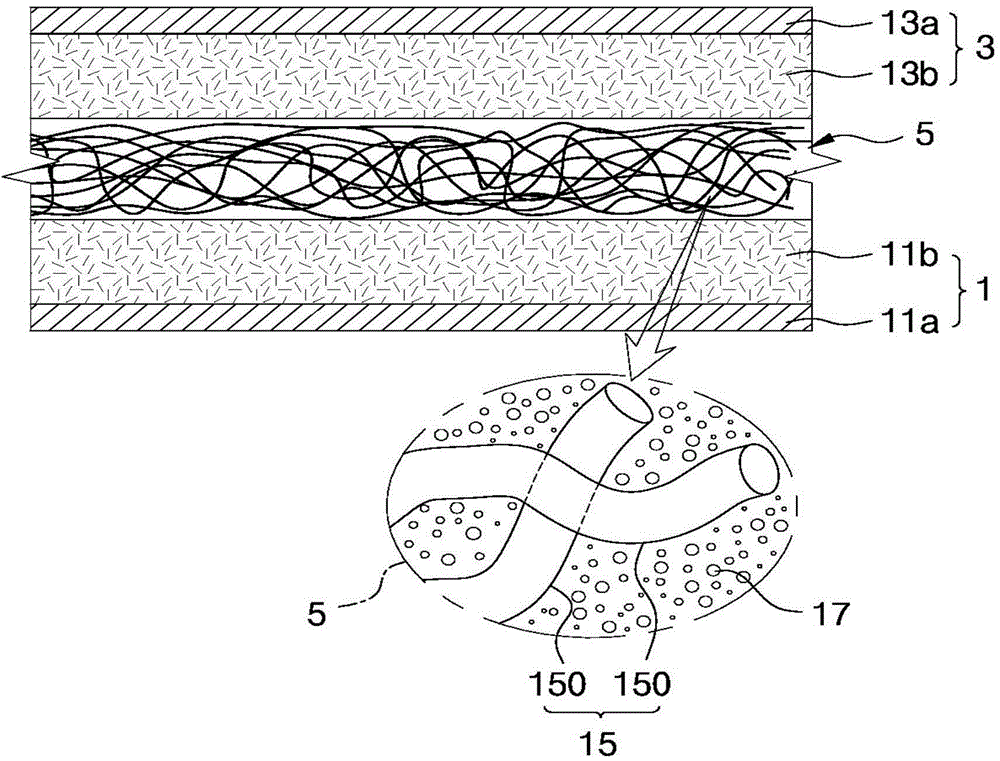

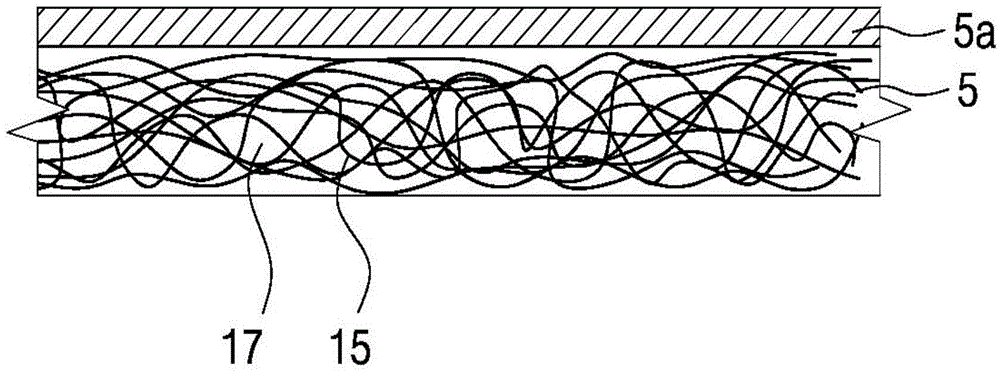

Polymer electrolyte, lithium secondary battery using same, and method for manufacturing lithium secondary battery

ActiveCN104919639AAvoid short circuitAchieve securityFinal product manufactureConductive materialPolymer electrolytesLithium

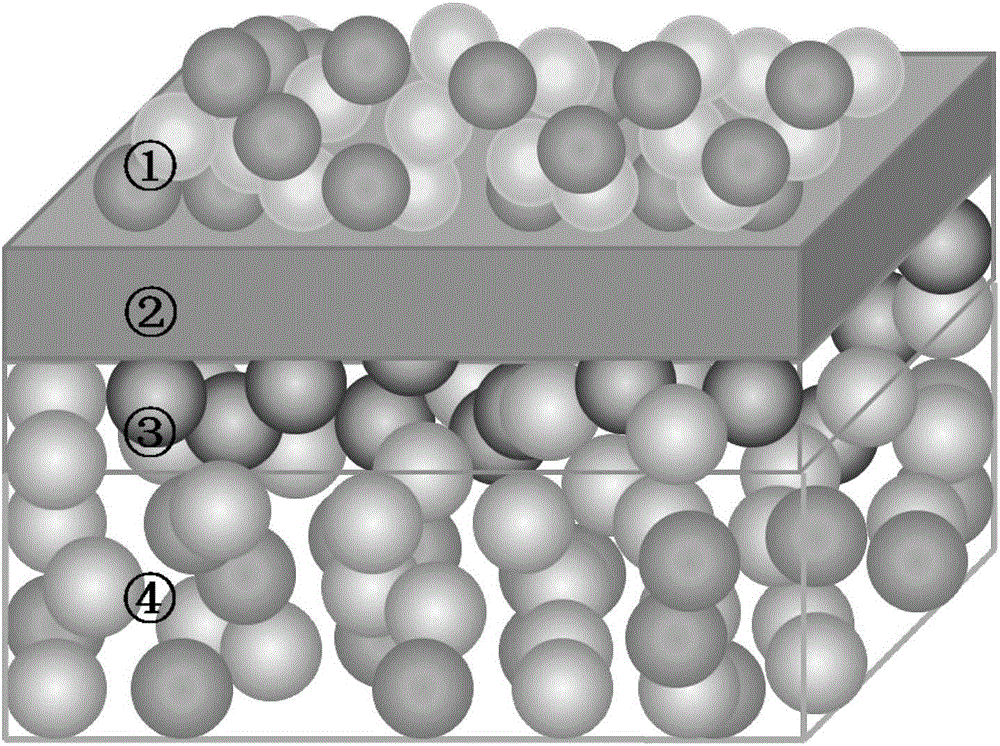

The present invention relates to a polymer electrolyte, a lithium secondary battery using the same, and a method for manufacturing the lithium secondary battery, wherein: an electrode assembly is formed by using a porous nanofiber web as an electrolyte matrix; an organic electrolyte having a mixture of a gel polymer-forming monomer and a polymerization initiator is injected, and a gel polymer electrolyte is formed by polymerization; and the porous nanofiber web is maintained in a web form such that stability can be increased by preventing a short circuit between a cathode and an anode. The polymer electrolyte, according to the present invention, comprises: the porous nanofiber web which is provided with a plurality of nanofibers; and a gel polymer portion which is impregnated into the porous nanofiber web, wherein the gel polymer portion is formed by polymerizing the gel polymer-forming monomer after a non-aqueous organic solvent, a solute of lithium salt, and the organic electrolyte having the gel polymer-forming monomer and the polymerization initiator have been impregnated into the porous nanofiber web.

Owner:AMOGREENTECH CO LTD

Anode of a lithium battery and method for fabricating the same

ActiveUS8017272B2Increase energy densityLarge capacityNon-metal conductorsConductive materialComposite filmCarbon nanotube

An anode of a lithium battery includes a composite film, the composite film comprising a carbon nanotube film structure and a plurality of nanoscale tin oxide particles dispersed therein. A method for fabricating an anode of a lithium battery, the method includes the steps of: (a) providing an array of carbon nanotubes; (b) pulling out, by using a tool, at least two carbon nanotube films from the array of carbon nanotubes to form a carbon nanotube film structure; and (c) dispersing a plurality of nanoscale tin oxide particles in the carbon nanotube film structure to form a composite film, and thereby, achieving the anode of the lithium battery.

Owner:TSINGHUA UNIV +1

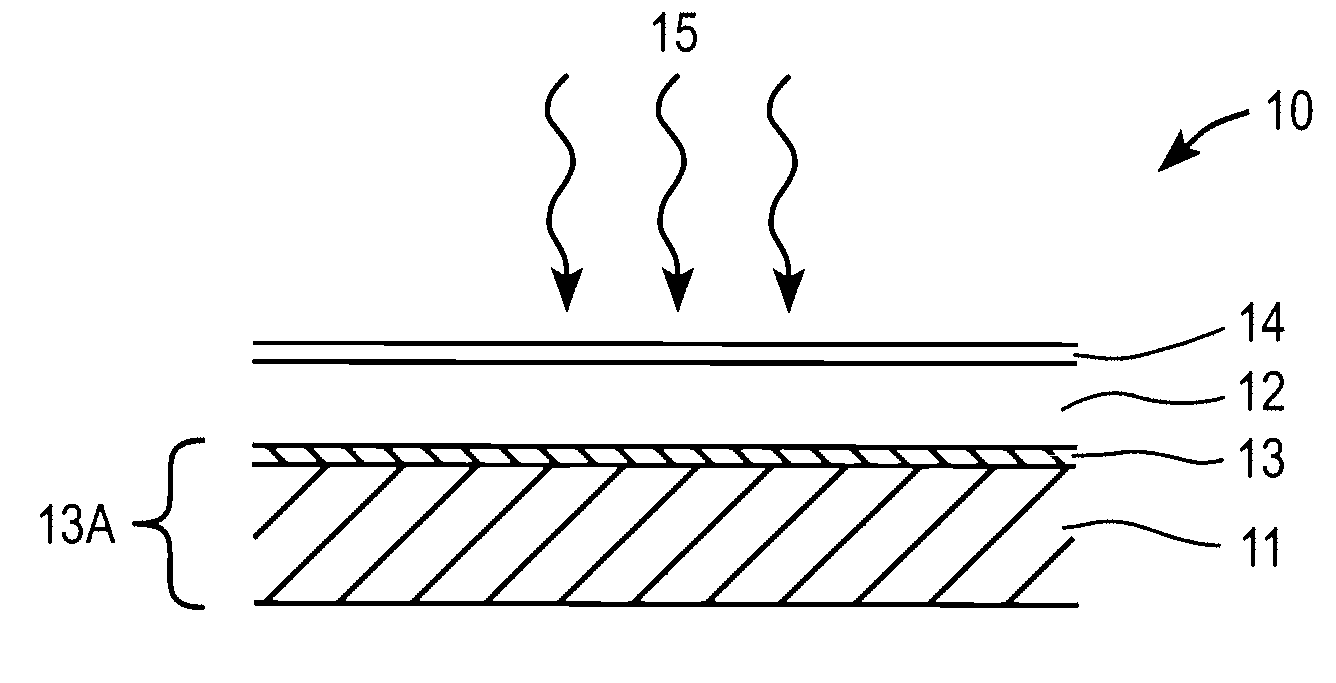

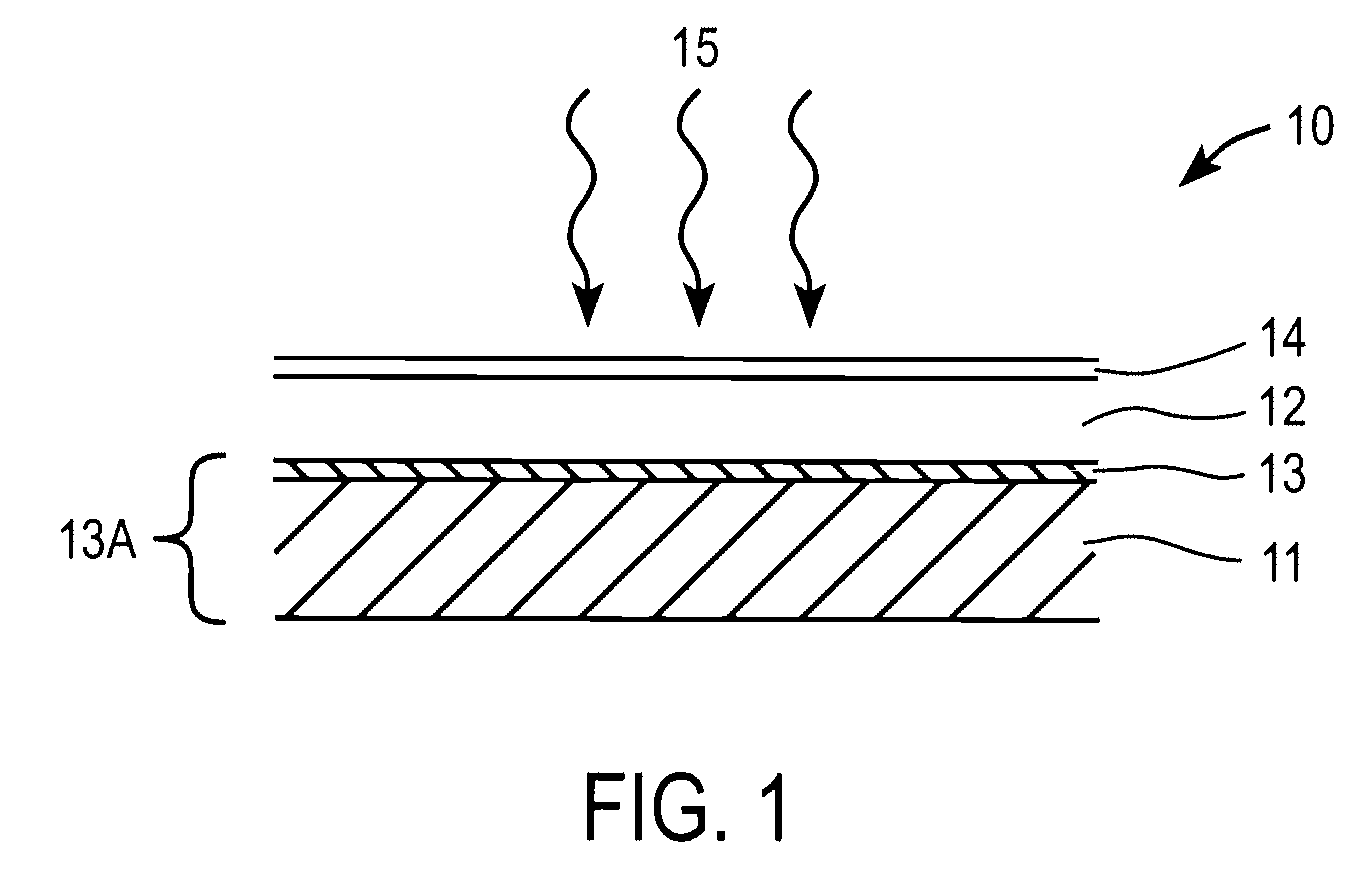

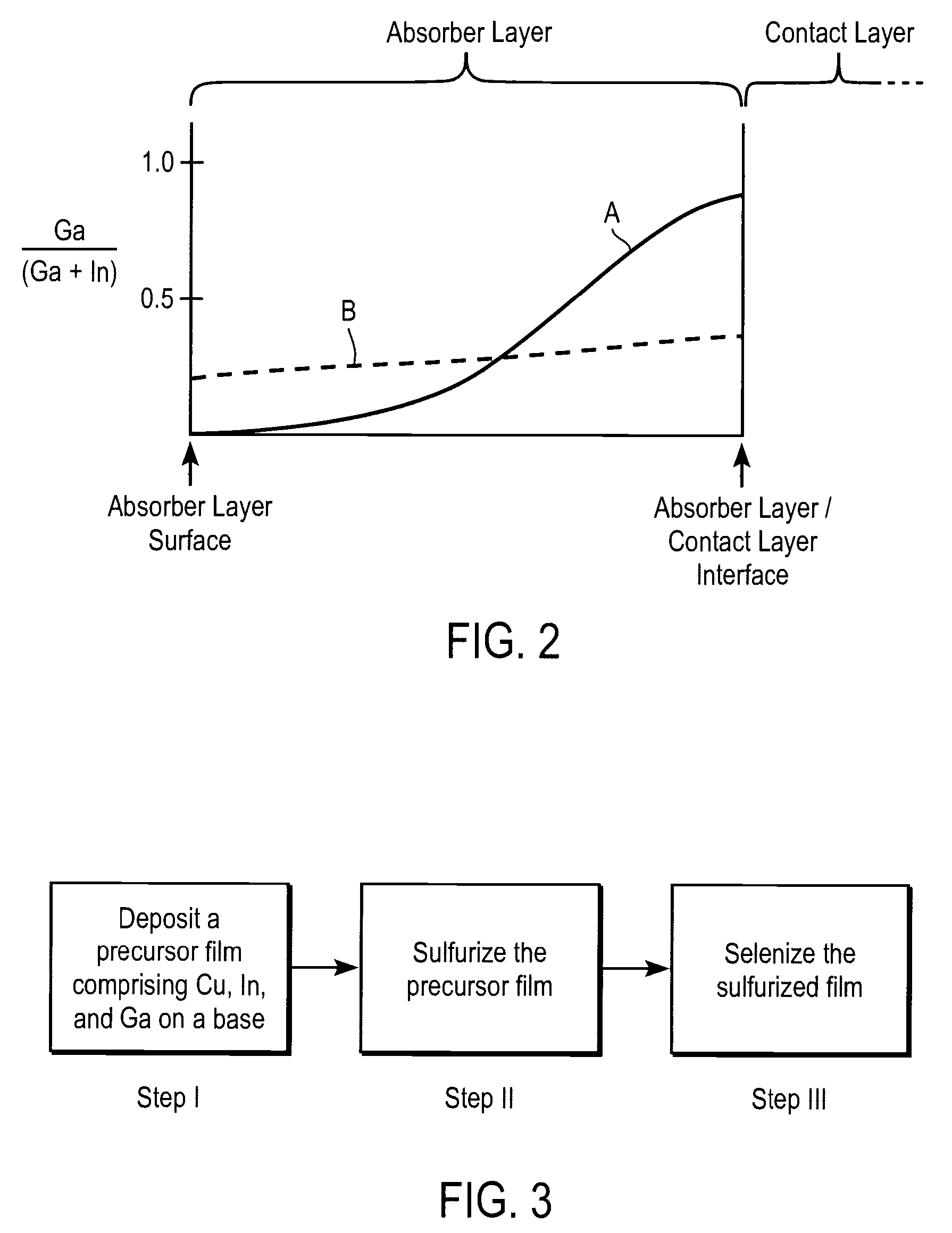

Method and apparatus for controlling composition profile of copper indium gallium chalcogenide layers

InactiveUS20080096307A1Improve performanceLow efficiencyVacuum evaporation coatingPretreated surfacesIndiumSulfur

The present invention relates to method and apparatus for preparing thin films of semiconductor films for radiation detector and photovoltaic applications. In one aspect, the present invention is directed to a method of forming a Cu(In,Ga)(S,Se)2 layer with substantially uniform Ga distribution. In a particular aspect, the method includes depositing a precursor film on the base, the precursor film including Cu, In and Ga, sulfurizing the precursor film thus forming a sulfurized precursor layer with a substantially uniform Ga distribution, and selenizing the sulfurized precursor layer to reduce the sulfur concentration therein and obtain the Cu(In,Ga)(S,Se)2 layer with substantially uniform Ga distribution. In a further aspect, the method also includes the step of selenizing the precursor film.

Owner:SOLOPOWER

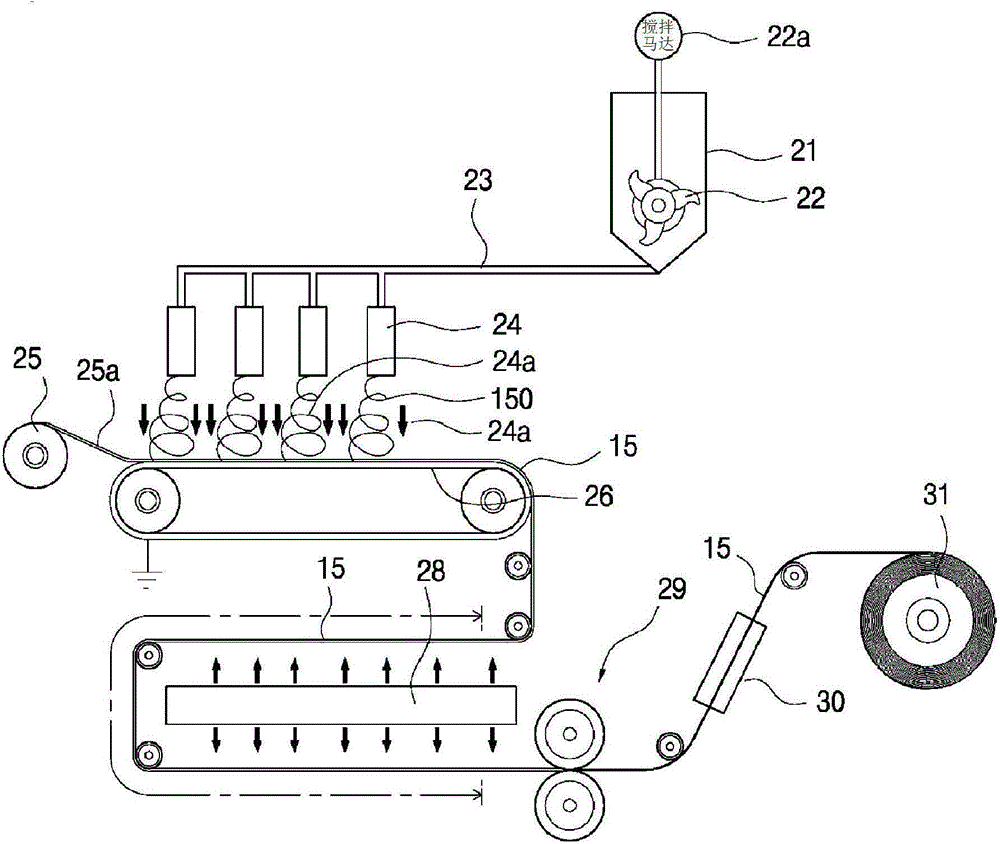

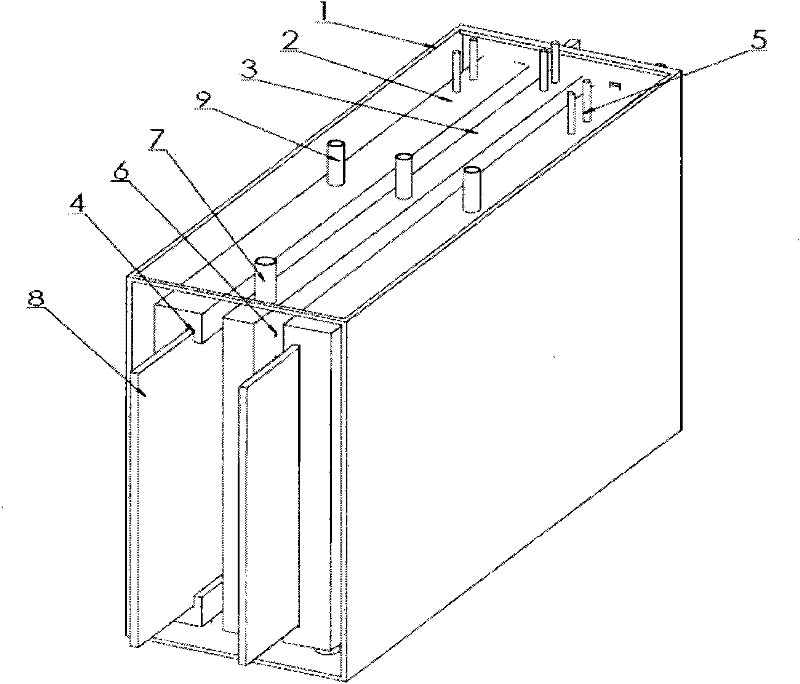

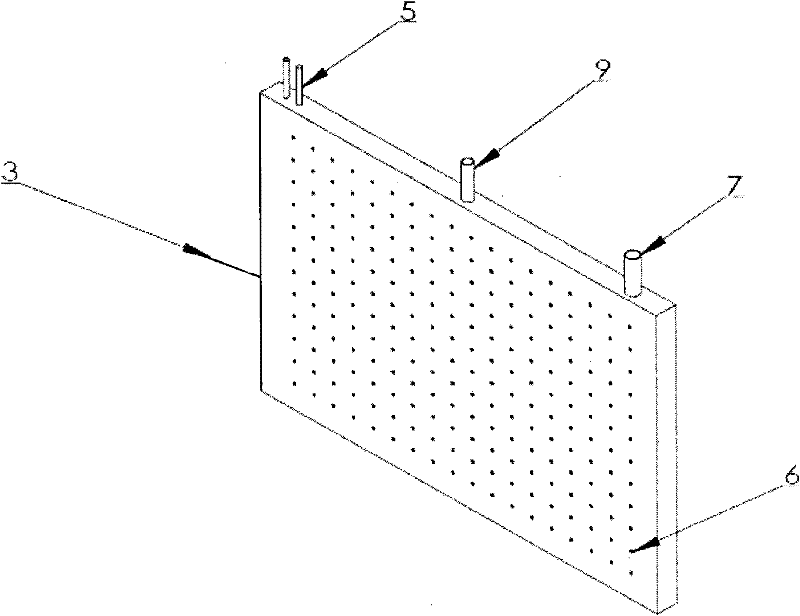

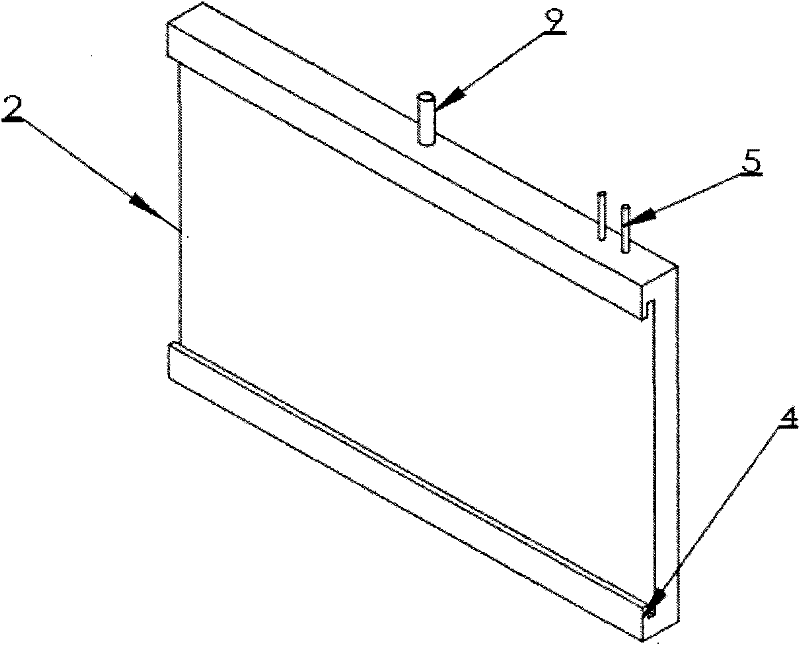

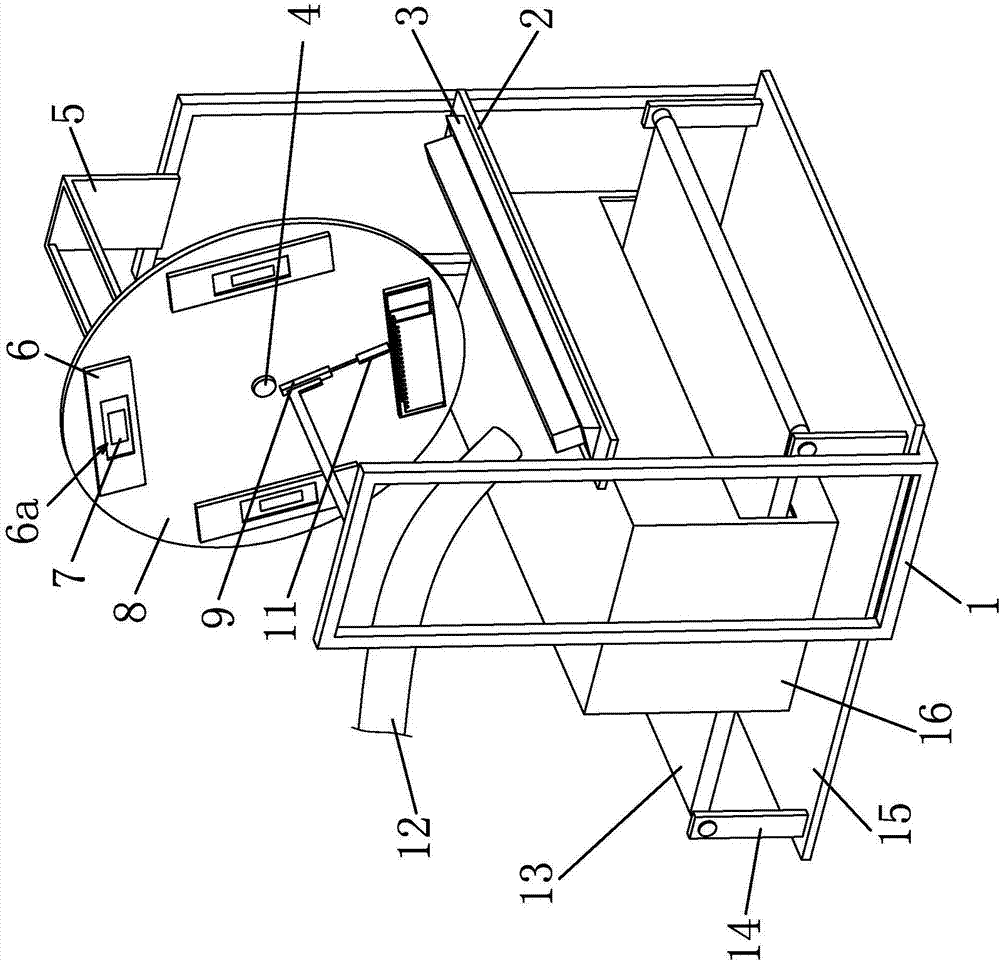

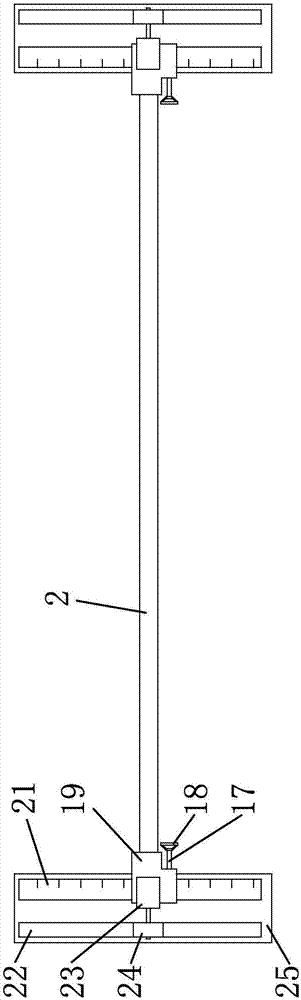

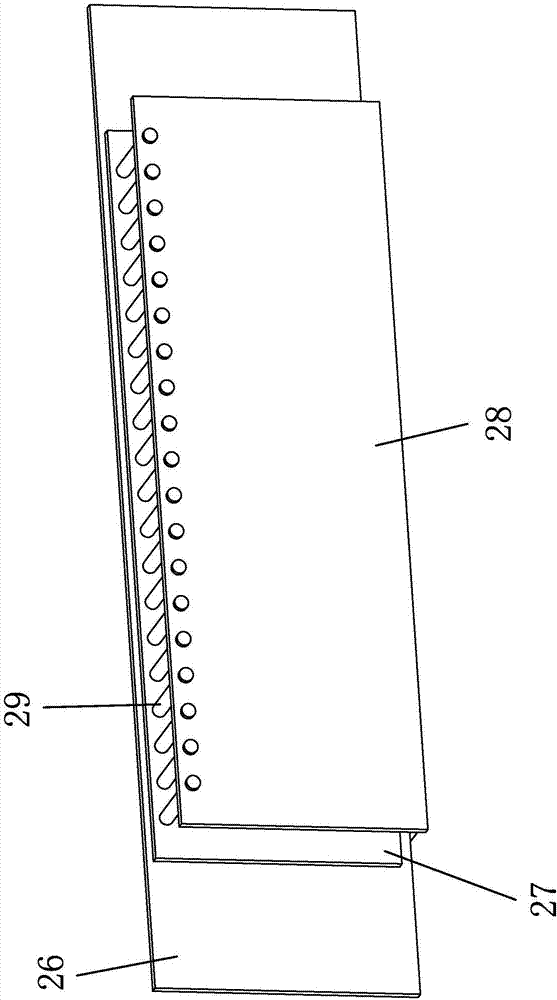

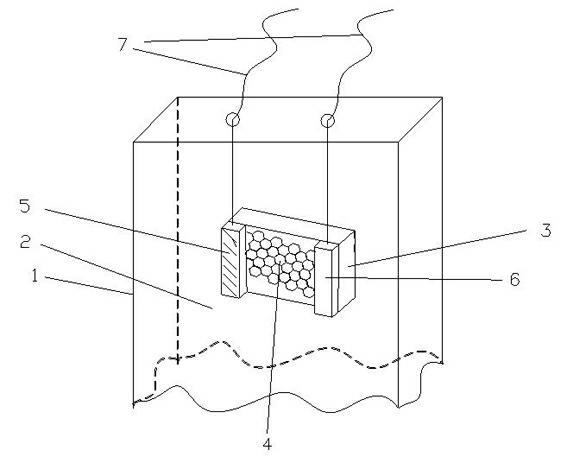

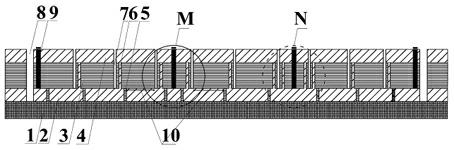

Plasm-aided selenium sulfuration treatment device and process

InactiveCN102051603ALow heating temperatureImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingFilm materialVacuum chamber

The invention relates to a plasm-aided selenium sulfuration treatment device arranged in a vacuum chamber. The plasm-aided selenium sulfuration treatment device comprises a shell, a cathode plate and an anode plate, wherein the cathode plate and the anode plate are alternately stacked to form a plasm generator, the cathode plate is provided with a groove for fixing a semiconductor film substrate, and small holes are uniformly distributed on the surface of the anode plate which is provided with a gas pipe, an independent internal heating electrode and an anode temperature-measuring point. The process based on the treatment device comprises the following steps of: (1) precasting a metal layer on the semiconductor film material according to the proportions of a chemical formula and then putting in the groove of the cathode plate; and (2) putting in the vacuum chamber to vacuumize, switching on a power supply to heat the cathode plate and the anode plate, switching on a power supply of the plasm generator and adding the mixed gases of selenium or sulfur, hydrogen and argon. The invention has the advantages that selenium ions have high reaction activity, the selenizing reaction of the metal precast layer is complete, the photoelectric conversion efficiency is high, and the substrate has lower heating temperature and is hardly deformed. An electronic mode is adopted to monitor the change of capacitive reactance between the two electrodes, know the conversion development and reduce the defective index of the industrial production.

Owner:NANKAI UNIV

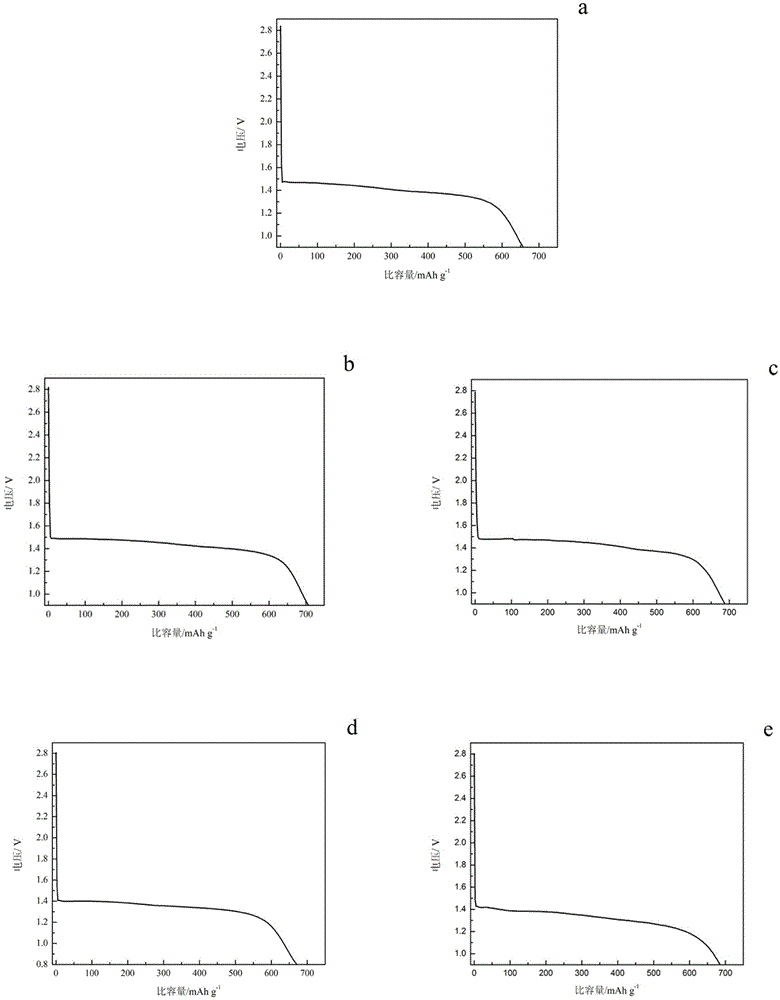

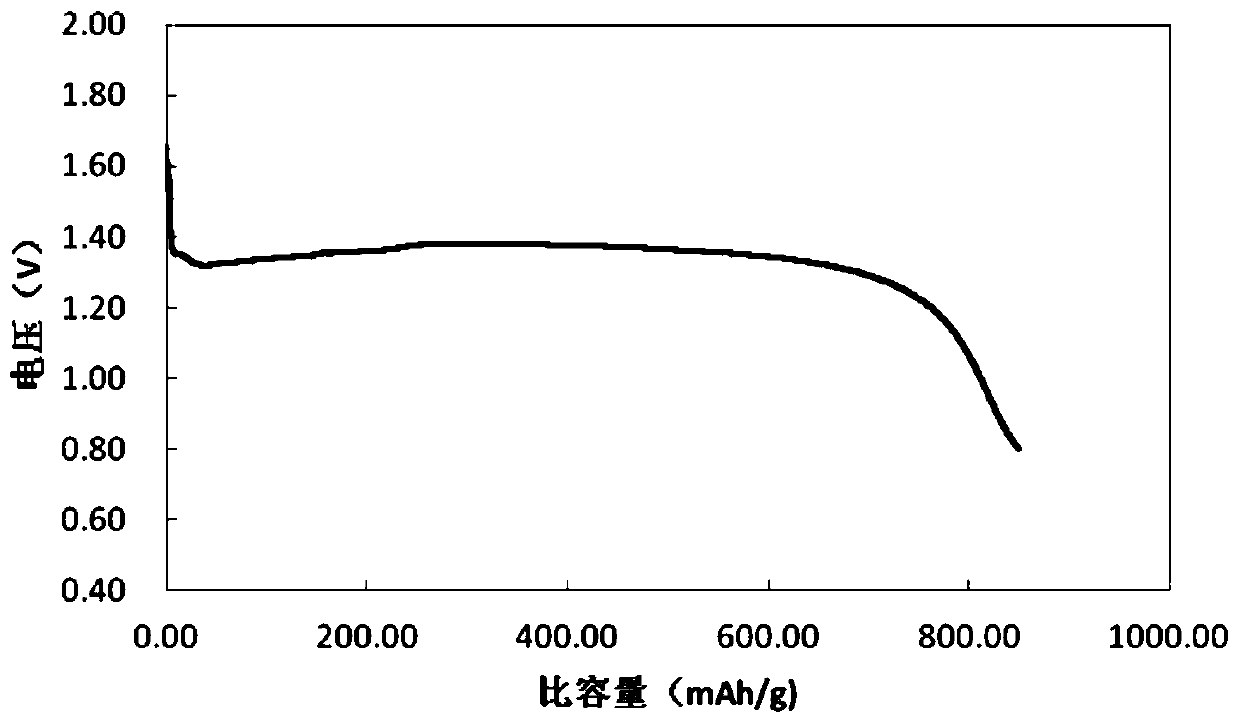

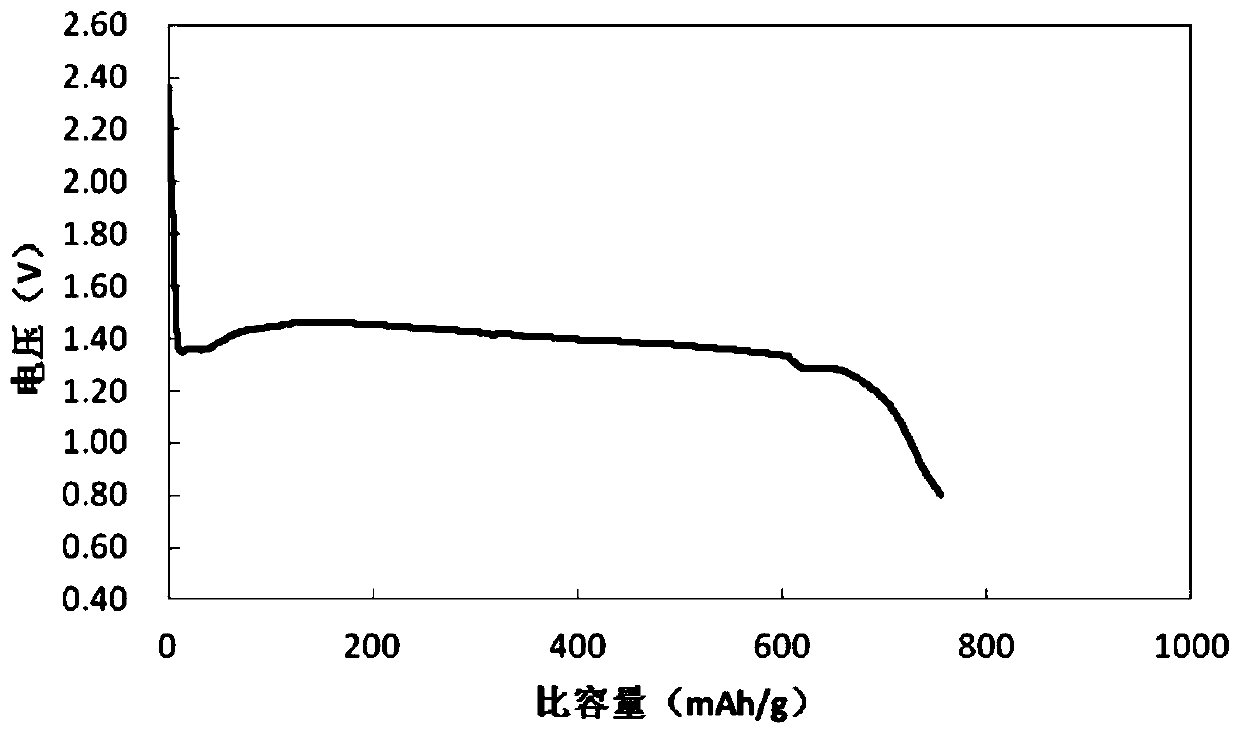

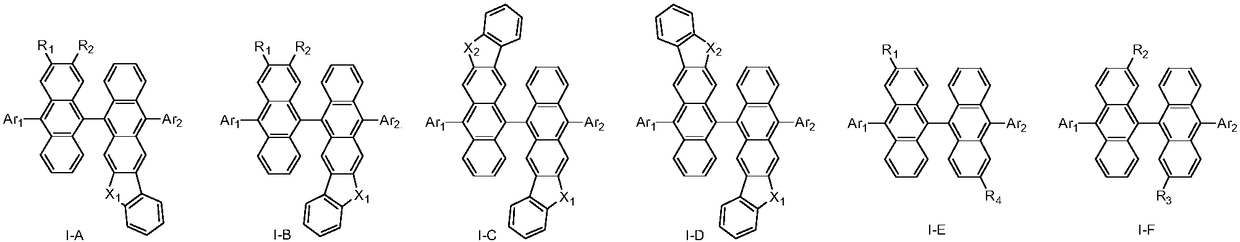

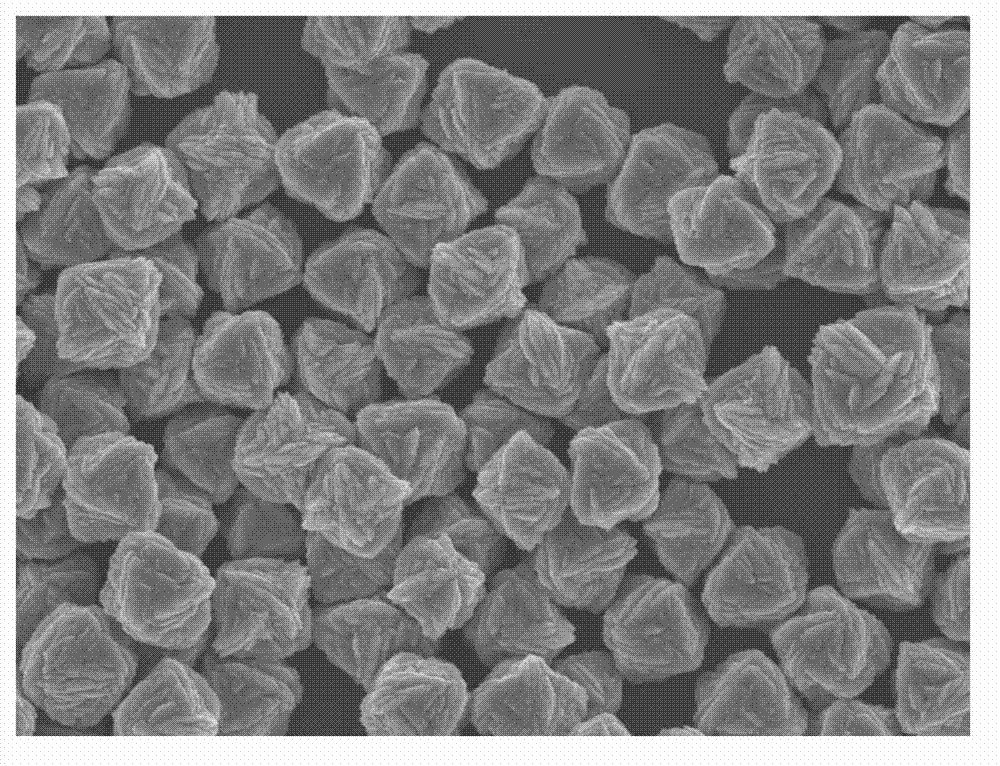

Method for preparing iron disulfide/carbon composite positive electrode material for disposable lithium battery and method for assembling button battery by using positive electrode material

The invention relates to a method for preparing an iron disulfide / carbon composite positive electrode material for a disposable lithium battery. According to the method, carbon covers the surfaces of iron disulfide particles, the mass percentage of iron disulfide is 75-99.5%, and the mass percentage of carbon is 0.5-25%. The method comprises the following specific steps: mixing pyrite and a carbon source substance according to the mass ratio of (75-95): (5-60), dispersing into a dispersing agent, and carrying out ball milling for 1-10 hours, so as to obtain a mixed paste material; drying the obtained mixed paste material for 1-10 hours in a vacuum drying oven at the temperature of 80-150 DEG C, heating the dried precursor material to the temperature of 300-500 DEG C under the protection of inert gas, maintaining for 1-8 hours, then, cooling to room temperature, and sifting, thereby obtaining the iron disulfide / carbon composite positive electrode material for the disposable lithium battery.

Owner:SHANDONG SHENGONGHAITE ELECTRONICS TECH

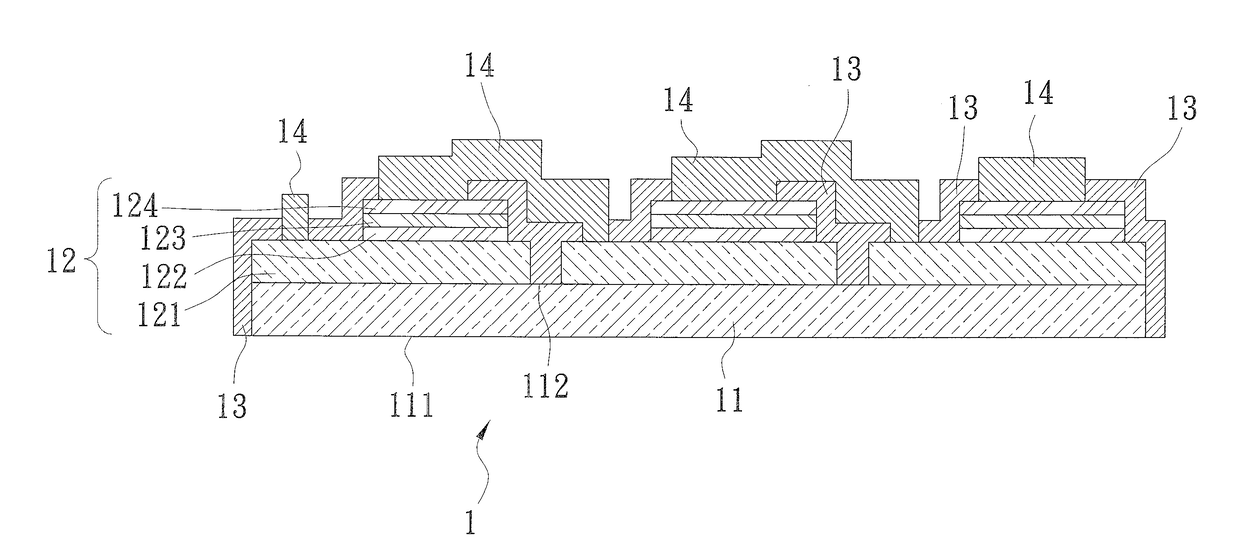

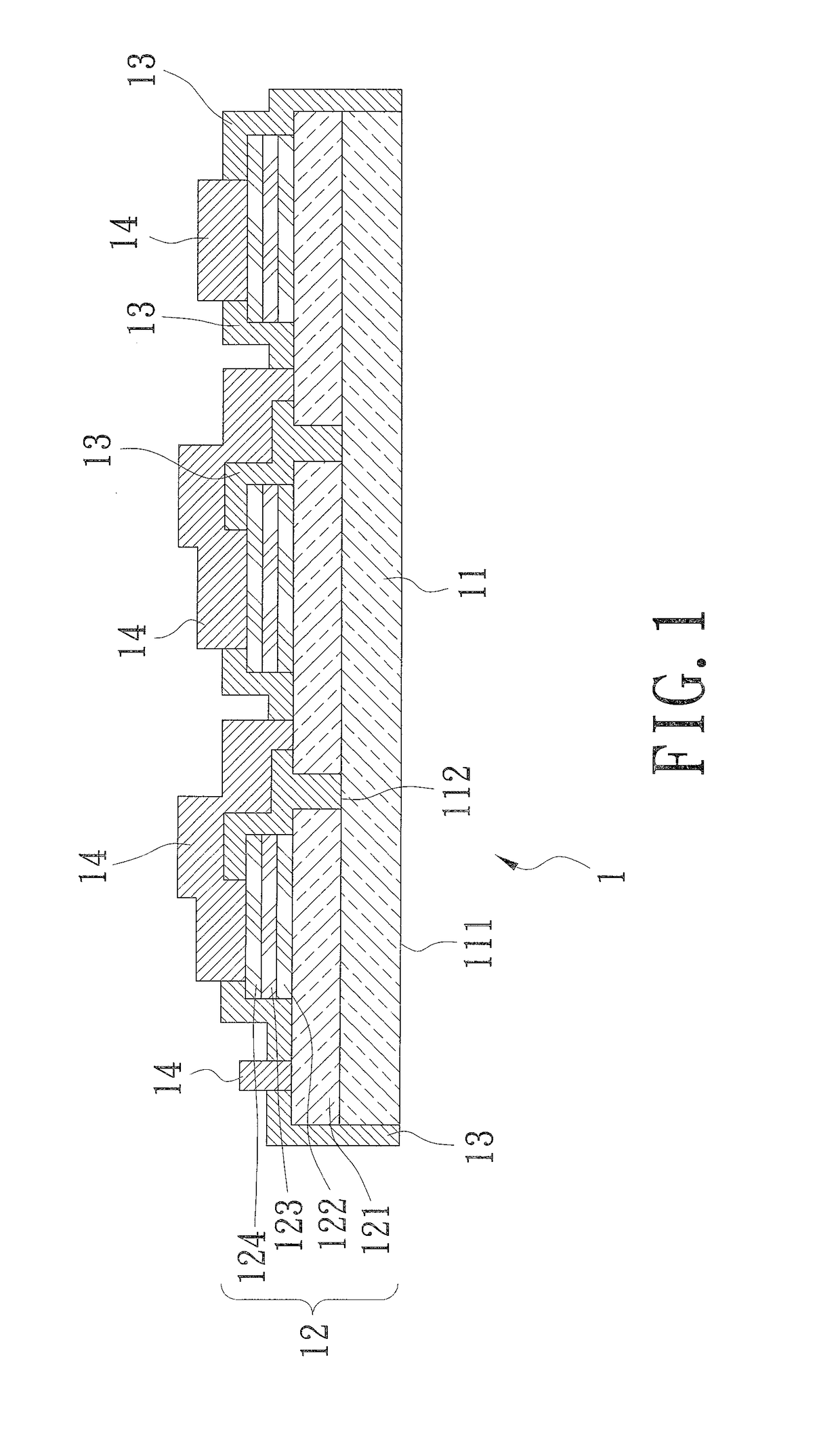

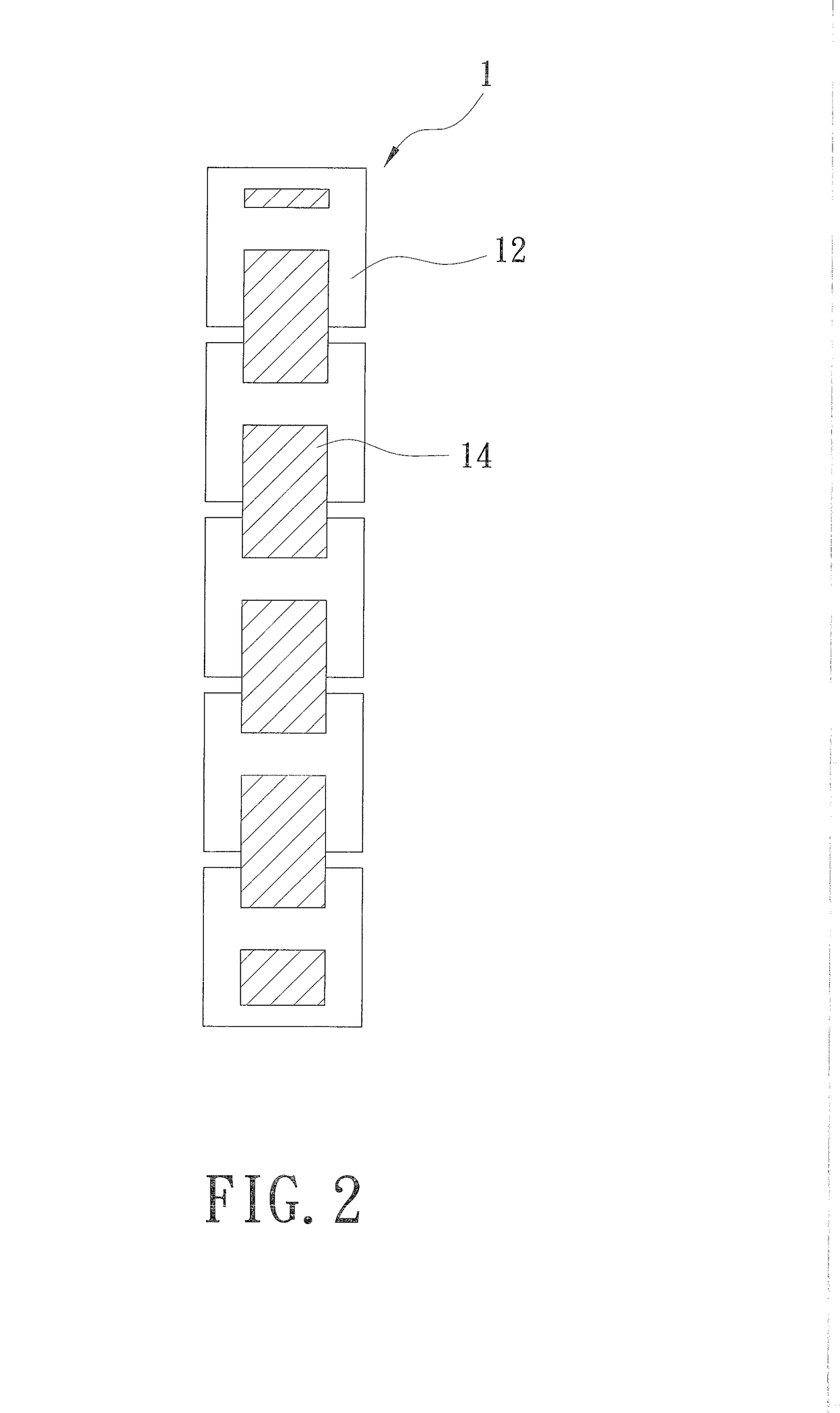

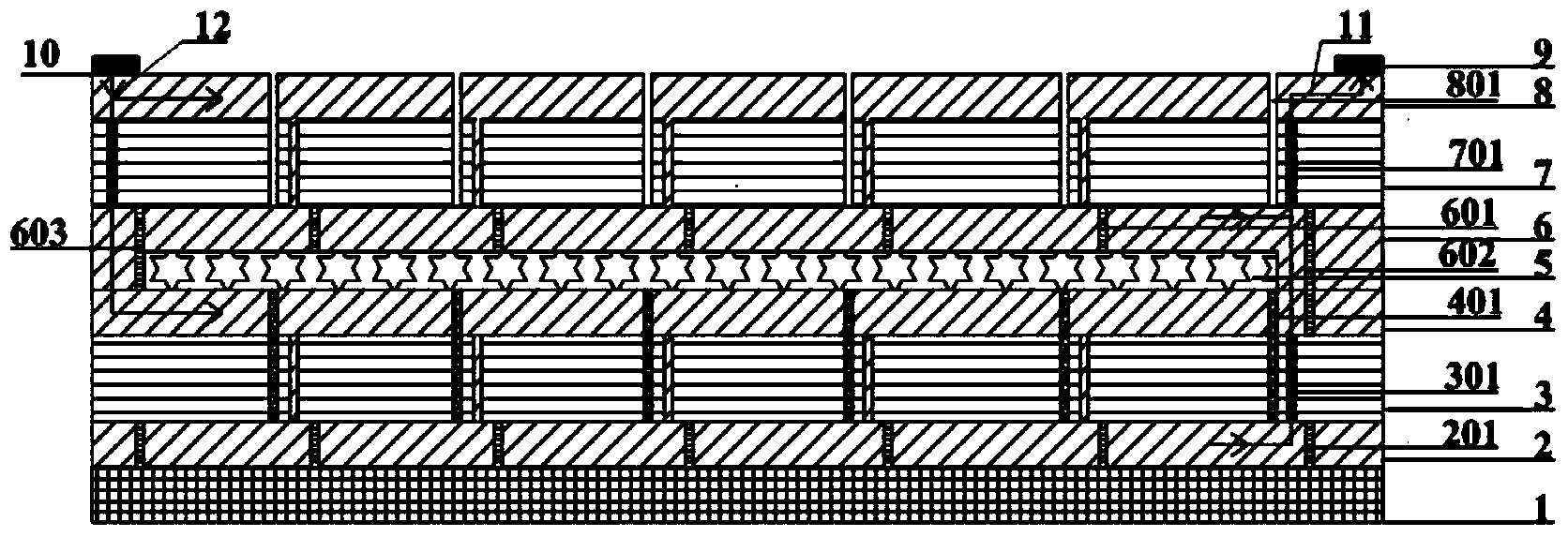

Solar cell module with perovskite layer

InactiveUS20170194102A1Avoid decompositionImprove instabilityLight-sensitive devicesSolid-state devicesElectrical conductorTransport layer

A solar cell module with a perovskite layer is revealed. The solar cell module includes a transparent substrate with a light incident surface and a surface opposite to the light incident surface. A plurality of solar cell units is disposed on the surface and each solar cell includes a transparent conductive layer, a first carrier transport layer, a perovskite layer and a second carrier transport layer. An insulation layer is not only located between the adjacent solar cell units but also covered over the solar cell units. A plurality of conductors is used for electrical connection of the plurality of solar cell units in series. Thus the solar cell module has better open circuit voltage and higher stability owing to connection way of the solar cell units in series and the insulation layer.

Owner:CPC CORPORATION

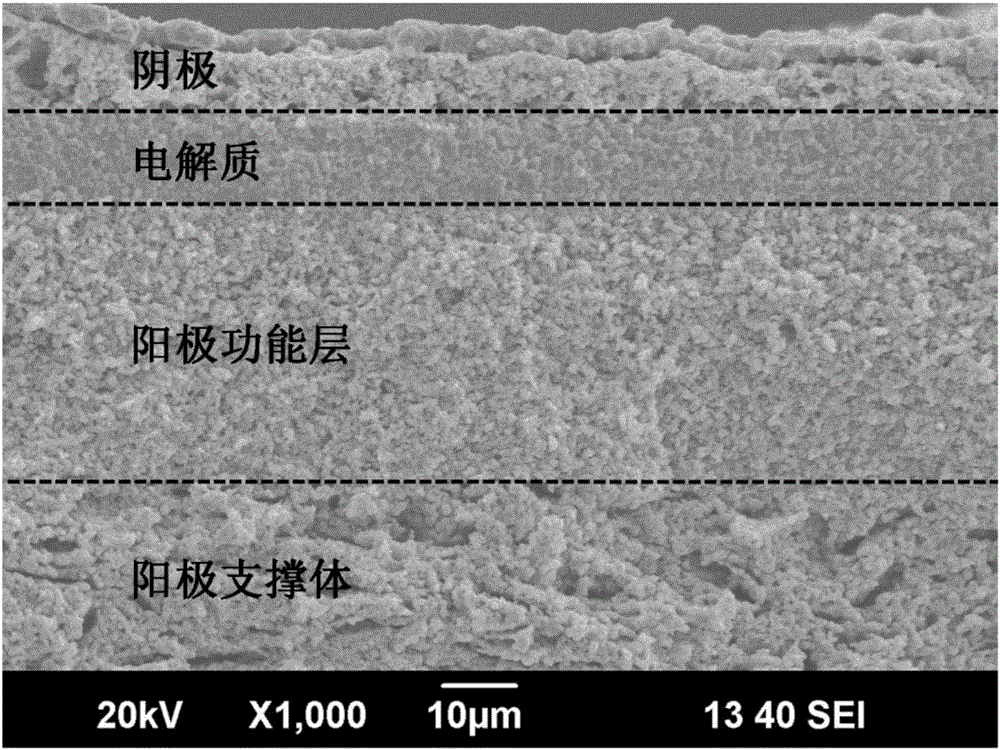

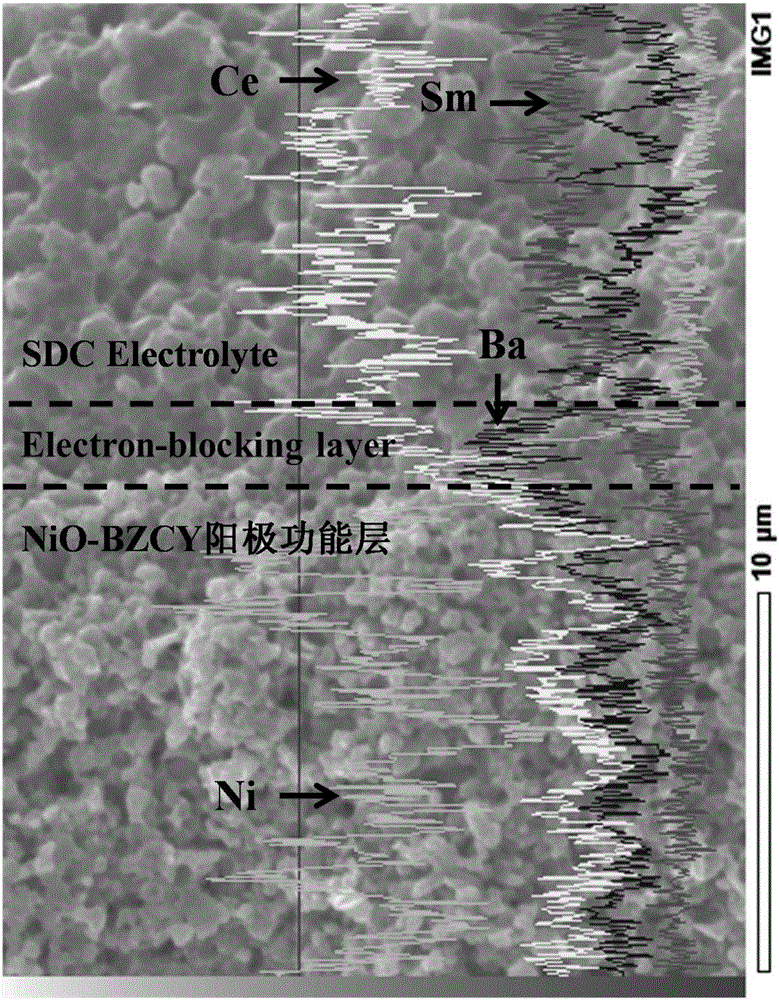

Doped cerium oxide-based solid oxide fuel cell and preparation method thereof

ActiveCN106848358AIncrease the open circuit voltageStable and efficient workFuel cellsComposite electrolyteFuel cells

The invention provides a doped cerium oxide-based solid oxide fuel cell. The fuel cell comprises an anode support, an anode functional layer containing Ba and / or Sr, an electron blocking layer, an electrolyte layer doped with cerium oxide and a cathode layer, and the above parts orderly contact. The electron blocking layer is formed by co-sintering the anode functional layer and the electrolyte layer. The elements in the anode functional layer are diffused at a high temperature and react with the electrolyte layer in situ at the interface to form the electron blocking layer, which effectively improves the open circuit voltage of the cell, so that the cell can work efficiently and stably in the middle-low temperature range. Compared with the conventional method using the double-layer electrolyte and composite electrolyte, method provided by the invention is simple and effective and realizes superior cell performances. The doped cerium oxide-based solid oxide fuel cell provides a novel idea for promoting the development of middle-low-temperature solid oxide fuel cells.

Owner:UNIV OF SCI & TECH OF CHINA

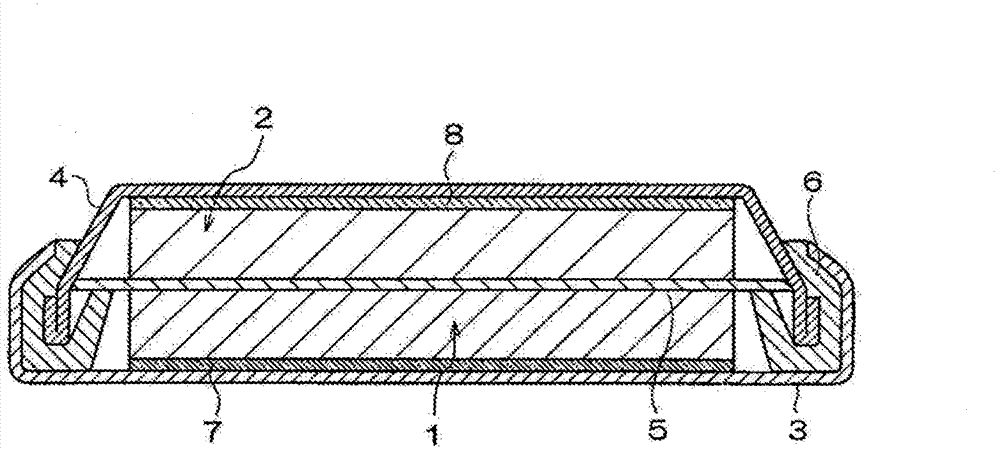

Composite battery

ActiveCN102651491AExtend your lifeSimple structureElectrochemical generatorsElectrode carriers/collectorsLithium iron phosphateElectrical battery

The invention discloses a composite battery. The composite battery comprises at least one lead-acid battery pack and at least one lithium ion battery pack connected in parallel with the lead-acid battery pack, wherein single lead-acid batteries in the lead-acid battery pack have electrolytes with the density of 1.29-1.33g / ml, and / or, the positive poles / negative poles of single lithium ion batteries in the lithium ion battery pack contain an active substance, the active substance at the positive poles of the single lithium ion batteries is at least one of lithium iron phosphate, lithium manganate, lithium cobalt oxide, a ternary material and the like, and the active substance at the negative poles is at least one of graphite, mesocarbon microbeads, lithium titanate and the like; and the proportion of the total open-circuit voltage of branch circuits of the lead-acid battery pack and that of branch circuits of the lithium ion battery pack is 0.99-1.01:1. By adopting the composite battery provided by the invention, the total open-circuit voltage of the lithium ion battery pack is matched with that of the lead-acid battery pack, so that the lead-acid batteries are prevented from damage, and the service life of the lead-acid batteries is prolonged; and meanwhile, the composite battery has the advantages of simple structure, easiness in implementation and low cost.

Owner:SHENZHEN CENT POWER TECH

Texturing technology and diffusion technology of diamond wire solar cell pieces

InactiveCN107195706AHigh reactivityReduce reflectivityAfter-treatment detailsFinal product manufactureHydrofluoric acidDiffusion

The invention provides a texturing technology and a diffusion technology of diamond wire solar cell pieces. The technical problems that the antireflection effect of an existing conventional chemical method is not obvious, the cost is increased by more than ten times after the whole set of a black silicon technology is matched and an existing diffusion technology is not matched with a texturing technology of diamond wires are solved. The texturing technology of the diamond wire solar cell pieces provided by the invention comprises the following steps: a, texturing; b, silicon wafer surface washing with ultrapure water; c, alkaline washing; d, silicon wafer surface washing with ultrapure water; e, mixed acid solution washing of hydrofluoric acid and hydrochloric acid; and f, ultrapure water washing and drying. The texturing technology has the advantage of low polycrystalline silicon reflectivity.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

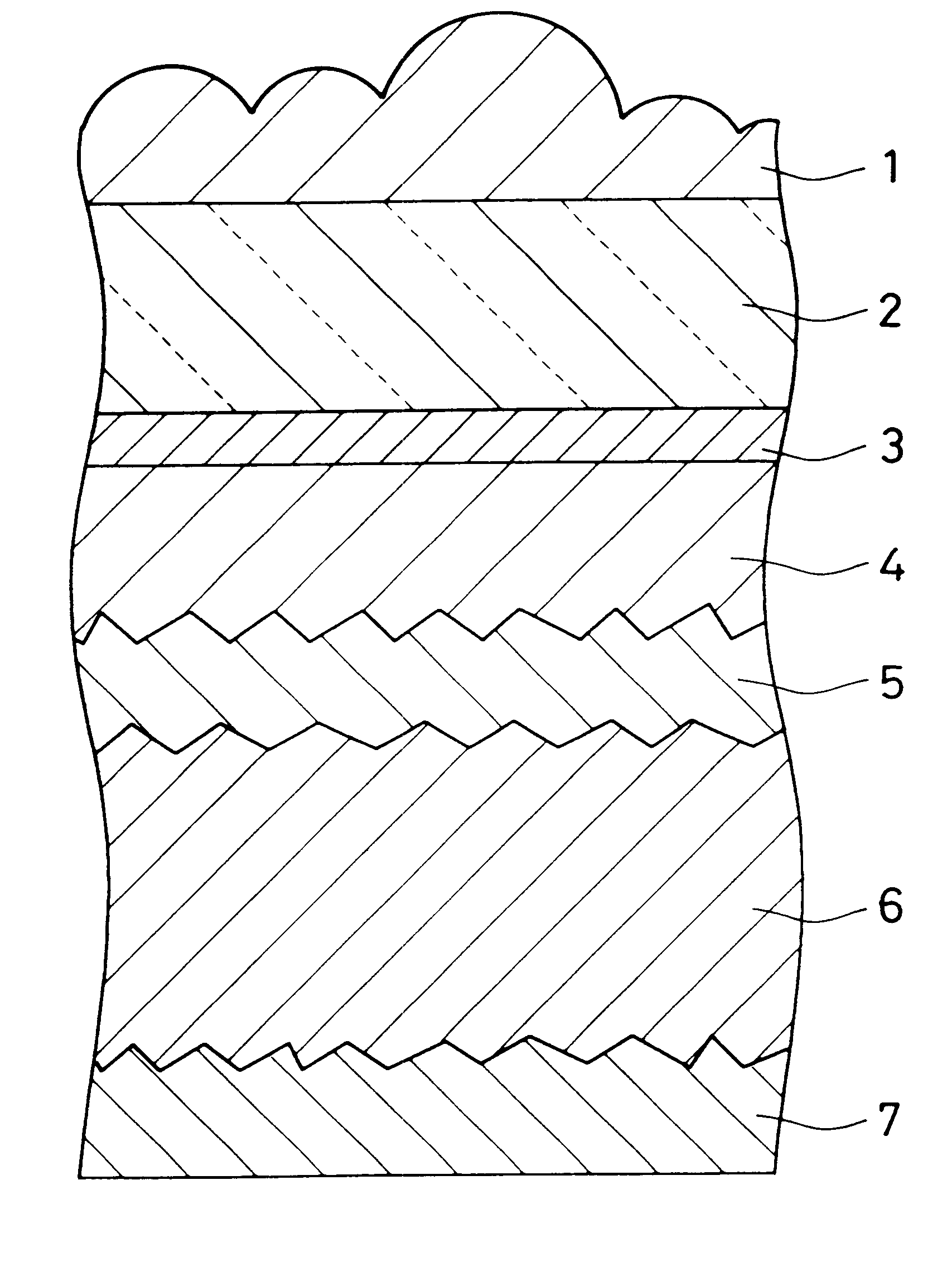

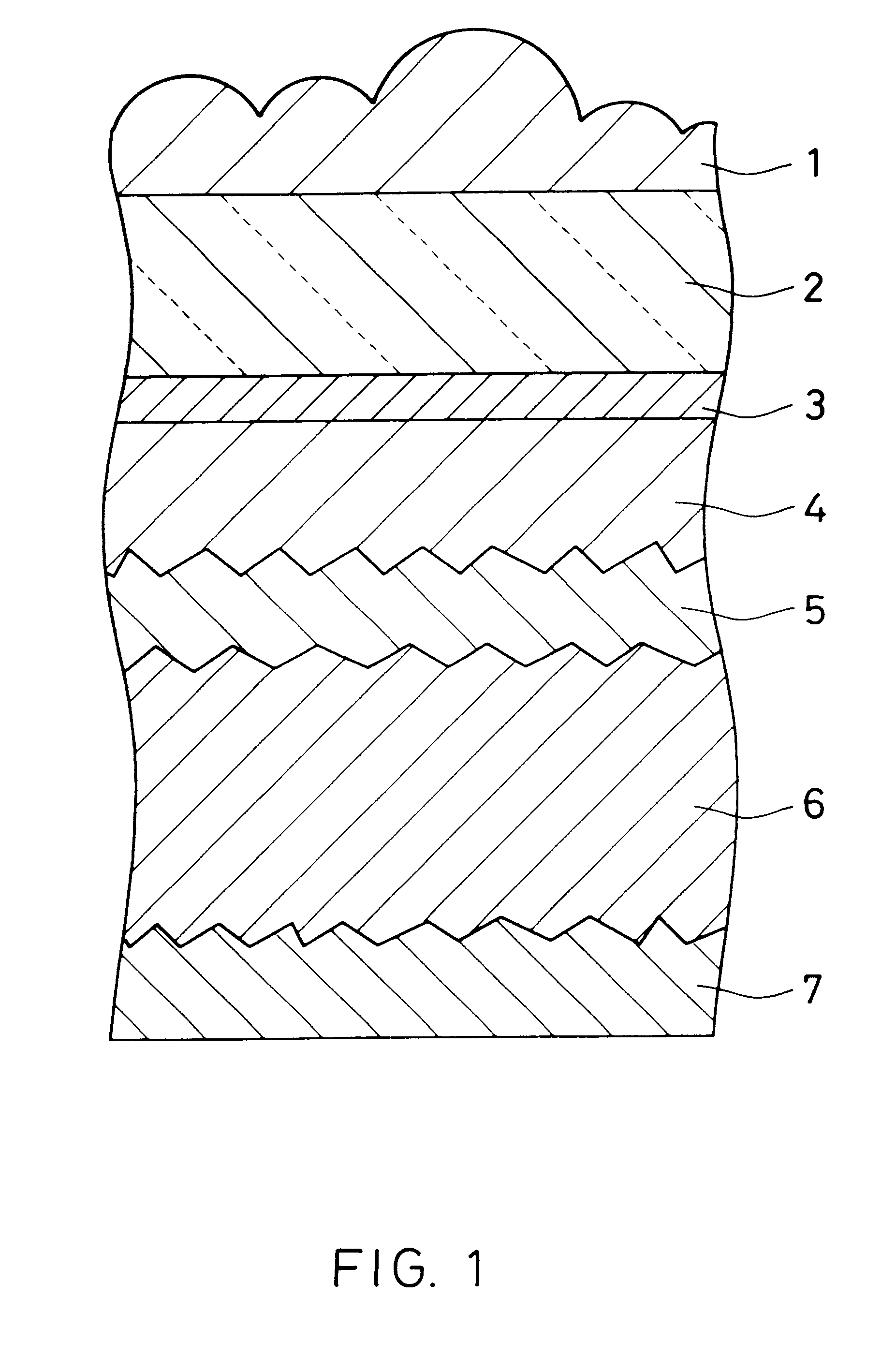

Photoelectric conversion device

InactiveUS6512170B1Improve photoelectric conversion efficiencyAvoid large gapsPV power plantsSemiconductor/solid-state device manufacturingTransmittanceTransparent conducting film

The present invention provides a photoelectric conversion device that improves photoelectric conversion efficiency with the interaction between a transparent substrate with a transparent conductive film, an antireflection film, and a photoelectric conversion unit. The antireflection film contains fine particles having an average particle diameter of 0.01 to 1.0 mum and has an uneven surface derived from the fine particles. The glass sheet with a transparent conductive film has a light transmittance of 75% or more in the wavelength region of 800 nm to 900 nm. The photoelectric conversion unit includes at least a photoelectric conversion unit including a photoelectric conversion layer having a band gap of 1.85 eV or less.

Owner:NIPPON SHEET GLASS CO LTD

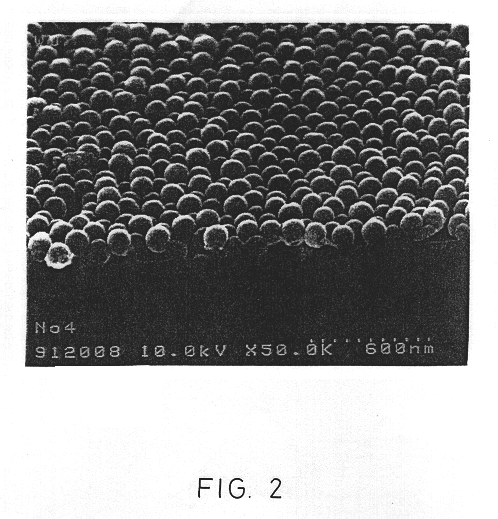

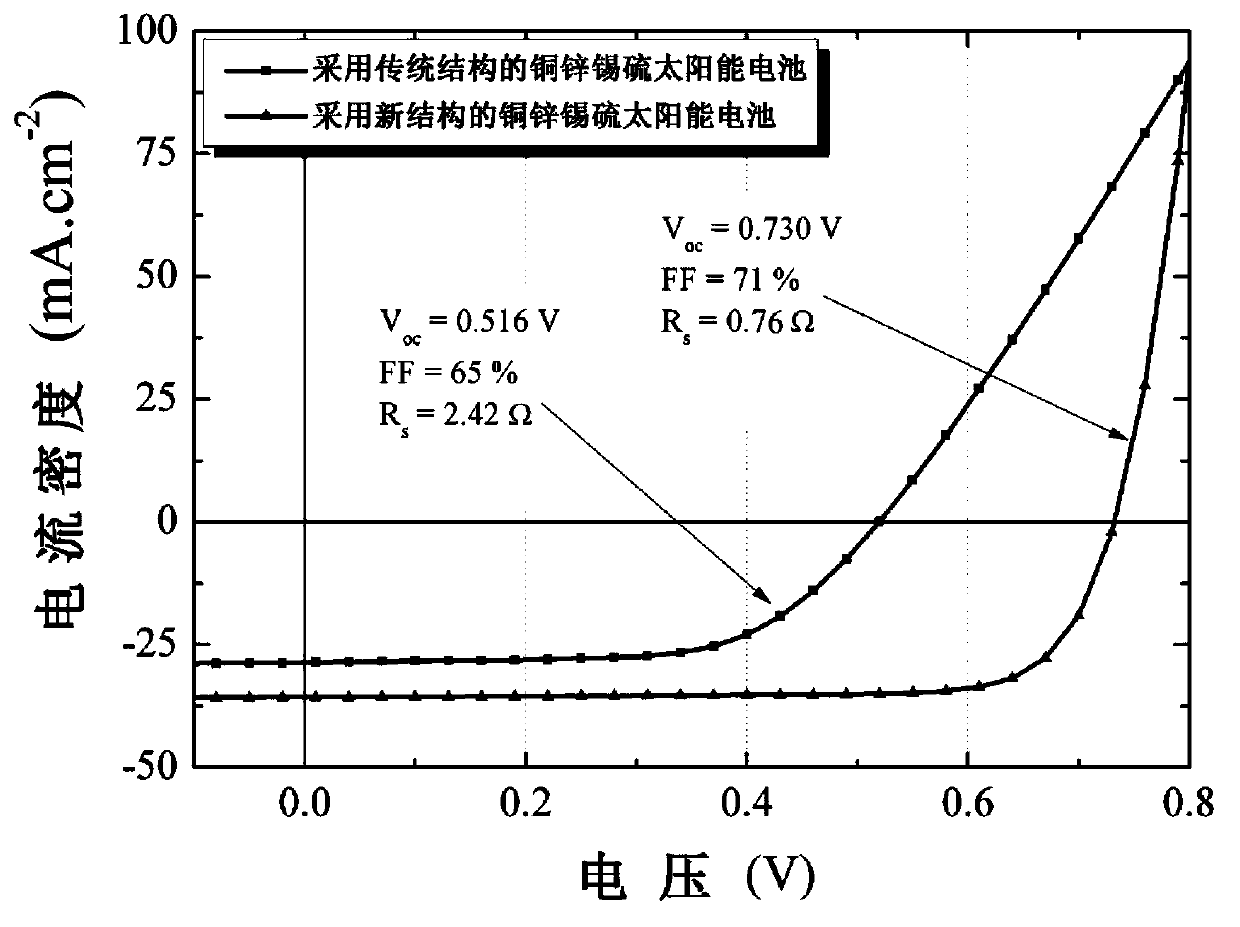

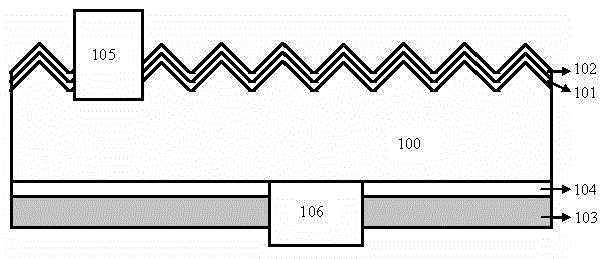

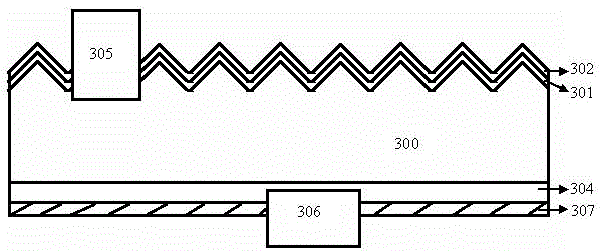

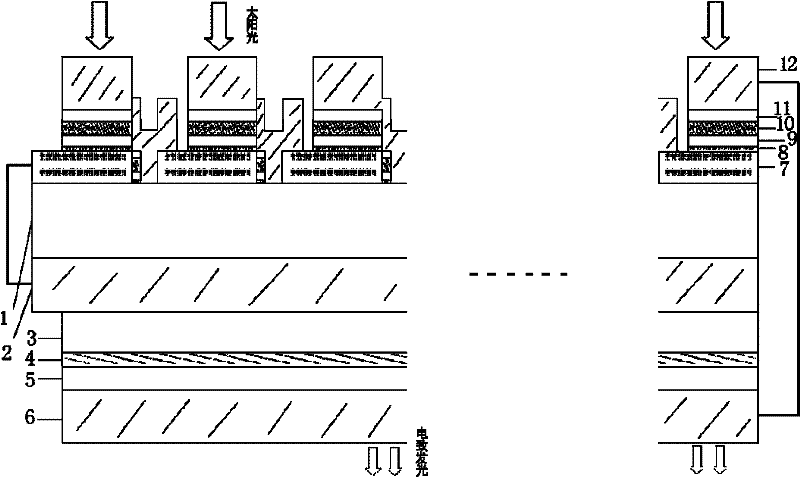

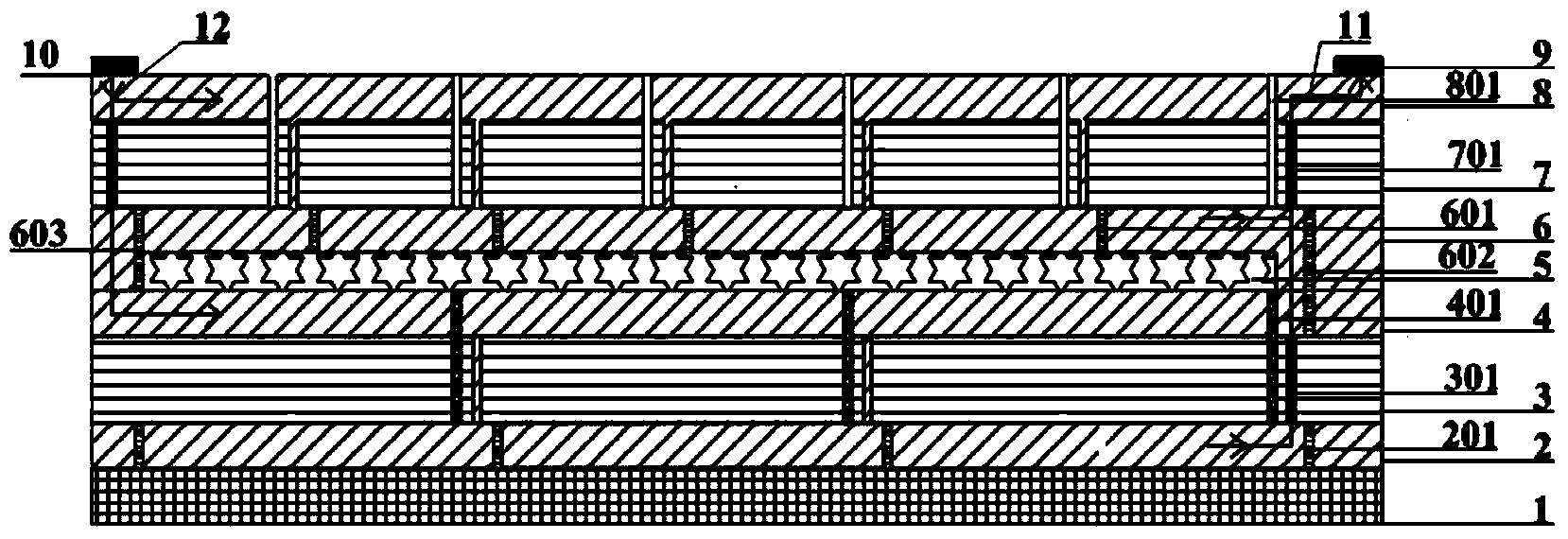

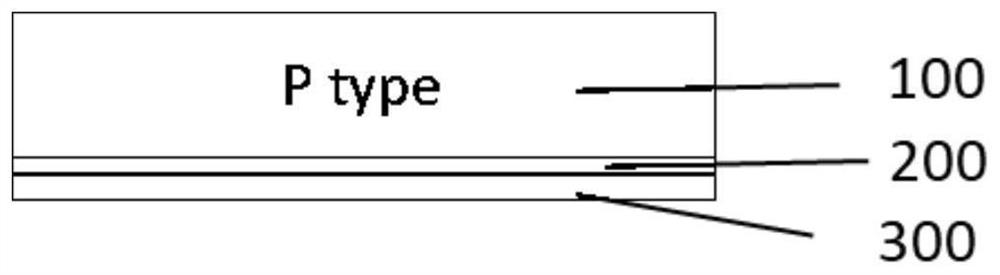

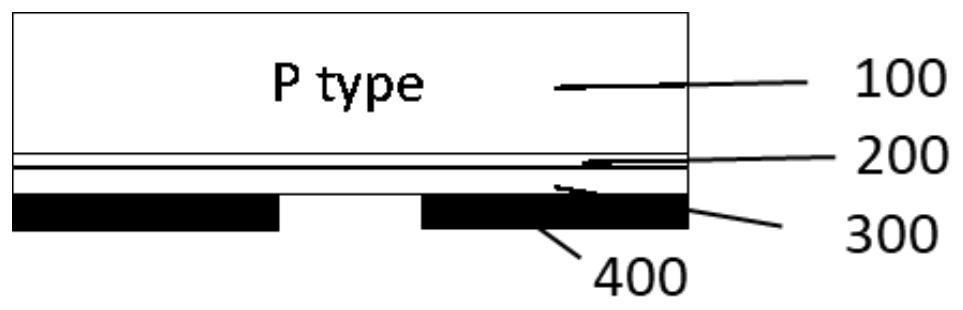

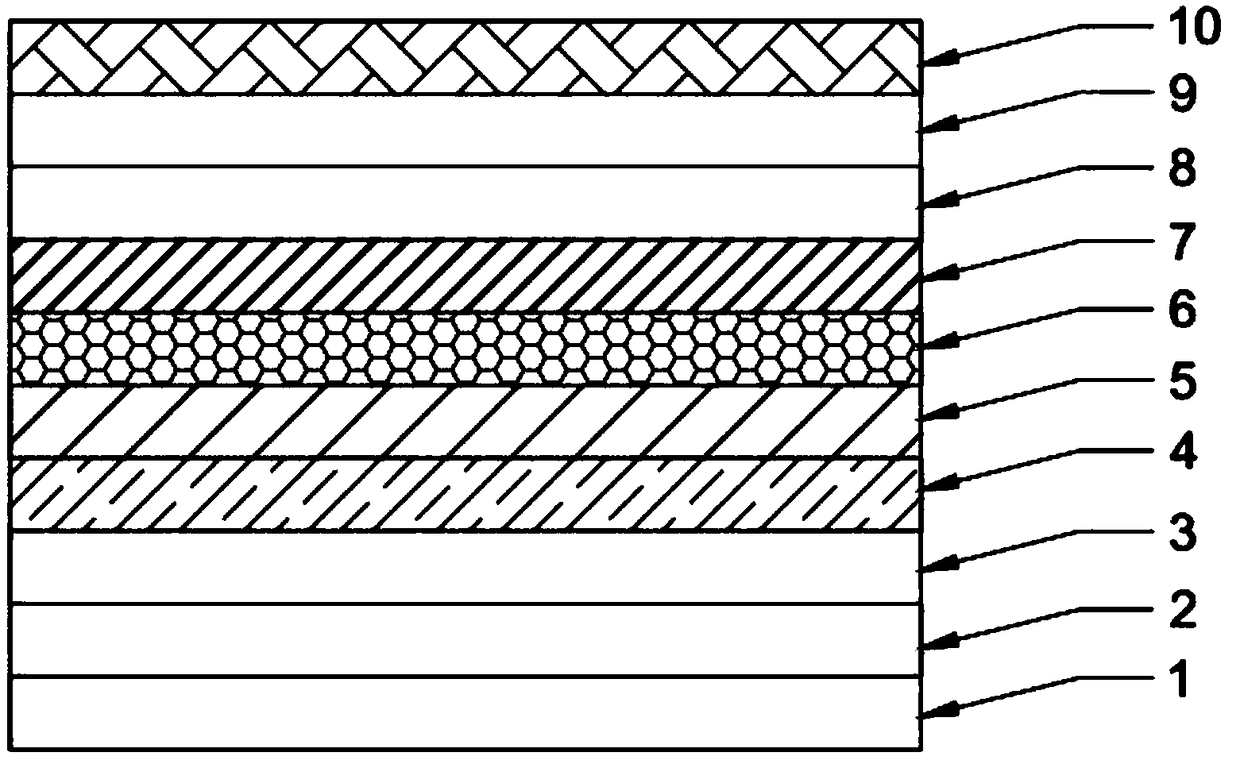

Laminated structure of copper-zinc-tin-sulfur film solar cell and preparation method thereof

ActiveCN103426943ALower open circuit voltageAdd series resistanceFinal product manufactureSemiconductor devicesSulfurInterface layer

A laminated structure of a copper-zinc-tin-sulfur film solar cell and a preparation method thereof are disclosed. The laminated structure of the copper-zinc-tin-sulfur film solar cell comprises substrate glass, a transparent conductive layer deposited on the substrate glass, an n-type buffer layer deposited on the transparent conductive layer, a p-type copper-zinc-tin-sulfur absorbing layer deposited on the n-type buffer layer, a molybdenum sulfide interface layer deposited on a p-type copper-zinc-tin-sulfur absorbing layer, and a metal back electrode layer deposited on the molybdenum sulfide interface layer.

Owner:SHAANXI COAL & CHEM TECH INST

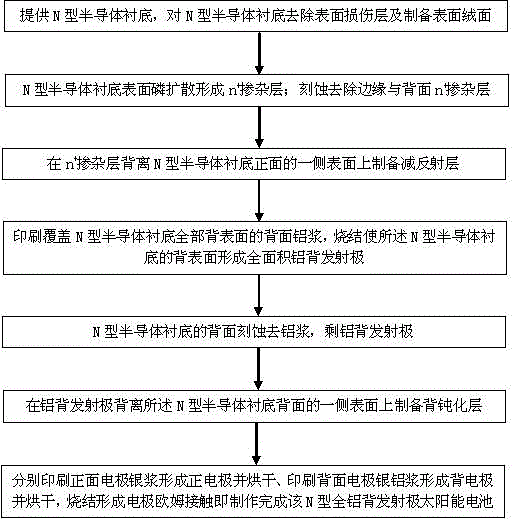

Manufacturing method of N type all-aluminum back emitter solar cell and solar cell prepared by the same

InactiveCN104868011AAvoid leakage currentImprove energy conversion efficiencyFinal product manufacturePhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a manufacturing method of an N type all-aluminum back emitter solar cell and a solar cell prepared by the same. The manufacturing method comprises: providing an N type semiconductor substrate, removing a surface damage layer, and preparing a surface pile face; carrying out phosphorus diffusion to form an n<+> doping layer and etching and removing the parts, formed at the edge and the back, of the n<+> doping layer; preparing an antireflection layer at the front side; printing a back aluminium paste and carrying out sintering to form a full-area aluminum back emitter; carrying out etching at the back and removing the aluminium paste and keeping the aluminum back emitter; preparing a back passivation layer at the back; printing a front electrode silver paste and carrying out drying, printing a back electrode silver-aluminium paste and carrying out drying, and carrying out sintering to form electrode ohmic contact. According to the invention, a problem of leak current existence at the boundary of the local back aluminium emitter and the back silver electrode can be solved; the solar cell quality is improved; and the conversion efficiency is improved by increasing the effective area of the PN node. With the back passivation layer, the open-circuit voltage and short-circuit current of the cell are increased. Moreover, the dual-face solar cell can be manufactured, so that the cell energy output is enhanced and the conversion efficiency is improved.

Owner:DK ELECTRONICS MATERIALS INC

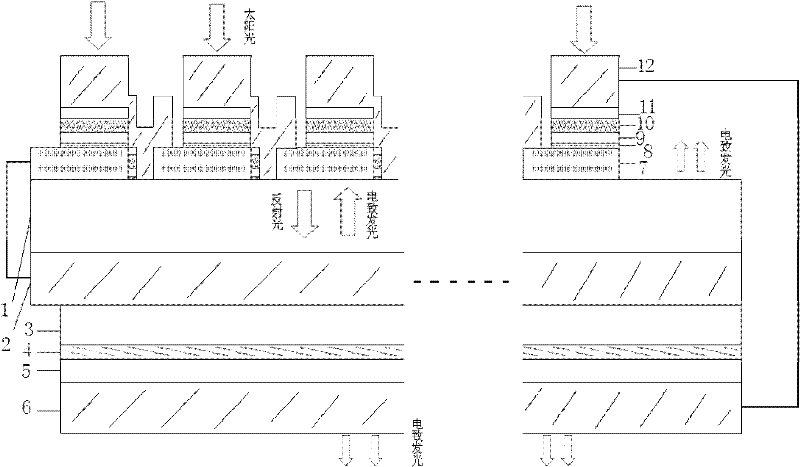

Organic photovoltaic and electroluminescent combined display device and production method thereof

InactiveCN102542926AIncrease brightnessLower open circuit voltageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention discloses an organic photovoltaic and electroluminescent combined display device and a production method thereof. The display device comprises an organic photovoltaic component and an organic electroluminescent component which are arranged on two sides of the same glass substrate. A metallic cathode of the organic photovoltaic component is connected with an ITO (indium tin oxide) conductive layer of the organic electroluminescent component, and an ITO conductive layer of an anode of the organic photovoltaic component is connected with an ITO conductive layer of the organic electroluminescent component. The organic photovoltaic component is used as a direct-current power source supplying direct-current voltage driving for luminescent devices, the open circuit voltage generated from the organic photovoltaic component is lower, and the driving voltage for the luminescent device is met by a series battery structure formed of multiple blocks. An electronic injection layer of the organic electroluminescent component is a polycrystal LaB6 which is transparent and has lower power function, both top emission and bottom emission of the luminescent devices can be realized, and light emitted from the bottoms of the luminescent devices permeates an Ag electrode layer on the other surface of the glass to be further reflected so that the brightness of light emitted from the tops of the luminescent devices can be enhanced.

Owner:IRICO

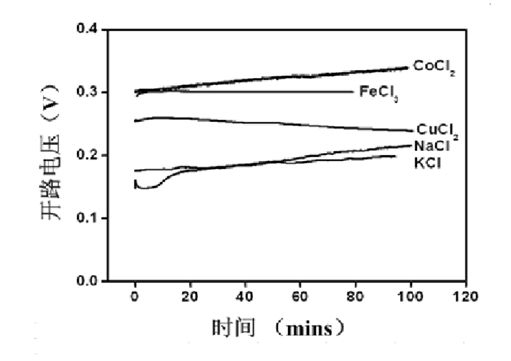

Power generation method adopting ionic thermal motion principle and graphene battery manufactured by power generation method

InactiveCN102496675AReduce security risksReduce performanceThermoelectric device detailsElectricityWork function

The invention discloses a power generating method adopting an ionic thermal motion principle. The power generating method comprises the following steps of: firstly, transferring graphene to a substrate and bonding a graphene film on the substrate; secondly, depositing a conducting material with a work function higher than that of the graphene at one end of the graphene film to obtain a first electrode and depositing a conducting material with a work function lower than that of the graphene at the other end of the graphene film to obtain a second electrode; thirdly, leading out the first electrode and the second electrode at two ends of the graphene film by using two metal wires; and fourthly, holding an ionic salt solution in a container casing, integrally immersing the substrate, the graphene film, the first electrode, the second electrode and the two metal wires in the ionic salt solution and leading the metal wires to the outside of the container casing. The invention also provides a graphene battery manufactured by using the power generating method. The power generating method adopting the ionic thermal motion principle and the graphene battery manufactured by the power generation method have the advantages of safety, reliability, no need of using power for charging, long service life of the graphene battery and no harm to a human body and environment.

Owner:SHENZHEN NATAN TECH

Organic sulfur compound anode material, and aluminum ion battery and anode piece for aluminum ion battery

ActiveCN106159230AImprove cycle performanceGood compatibilityCell electrodesSecondary cellsAluminum IonSulfur

The invention discloses an organic sulfur compound anode material, and an aluminum ion battery and an anode piece for the aluminum ion battery. The compound anode material is prepared according to the method comprising the following steps: dissolving a high-molecular polymer into a carbonic ester solvent, thereby obtaining a polymer solution; mixing organic sulfur powder with the polymer solution; filtering and taking filter residue; washing and drying, thereby obtaining the organic sulfur compound anode material. The mass ratio of high-molecular polymer to organic sulfur powder is (10-50):(5-20); the high-molecular polymer is any one or combination of polypropylene carbonate, polydiethylsiloxane, polymethyl acrylate and polymethyl methacrylate; the high-molecular polymer is covered on the organic sulfur surface, so that the stability of organic sulfur of the core is increased and the product yield of the pole piece processing is increased; the material is taken as the anode material for preparing the aluminum ion battery and the coating layer of the high-molecular polymer is dissolved in the organic electrolyte, so that the characteristic of high specific capacity of the organic sulfur is fully exerted.

Owner:深圳博磊达新能源科技有限公司

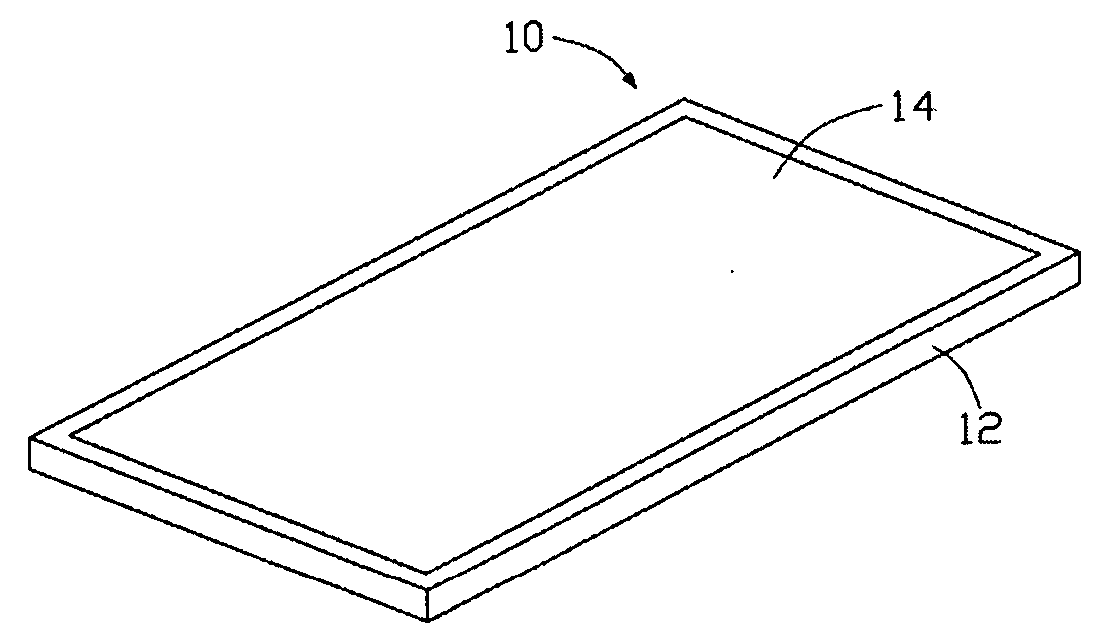

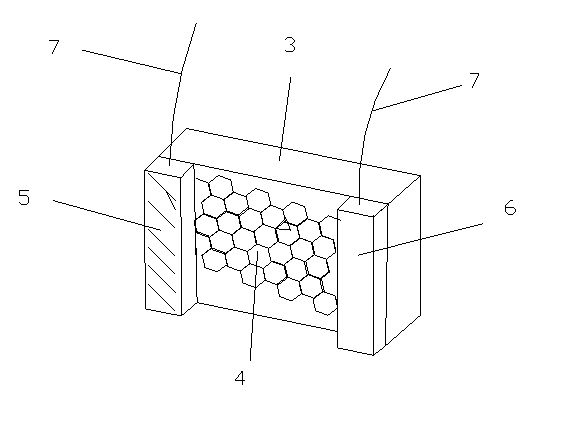

Thin film solar cell assembly and preparation method thereof

ActiveCN103715182AAchieve absorptionImprove conversion efficiencyFinal product manufactureSolid-state devicesEngineeringThin film solar cell

The invention discloses a thin film solar cell assembly comprising a substrate, a first unit cell deposited on the substrate and a second unit cell arranged on the first unit cell. The thin film solar cell assembly further comprises an insulation film layer arranged between the first unit cell and the second unit cell and used for enabling the first unit cell and the second unit cell to be insulated, a first isolation channel and a second isolation channel which are arranged at the two sides of the edge of the insulation film layer respectively and are used for enabling the first unit cell and the second unit cell to be connected in parallel. The invention also discloses a preparation method of the thin film solar cell assembly. Through the design of the invention, a high-efficiency film solar cell can be obtained.

Owner:紫石能源有限公司

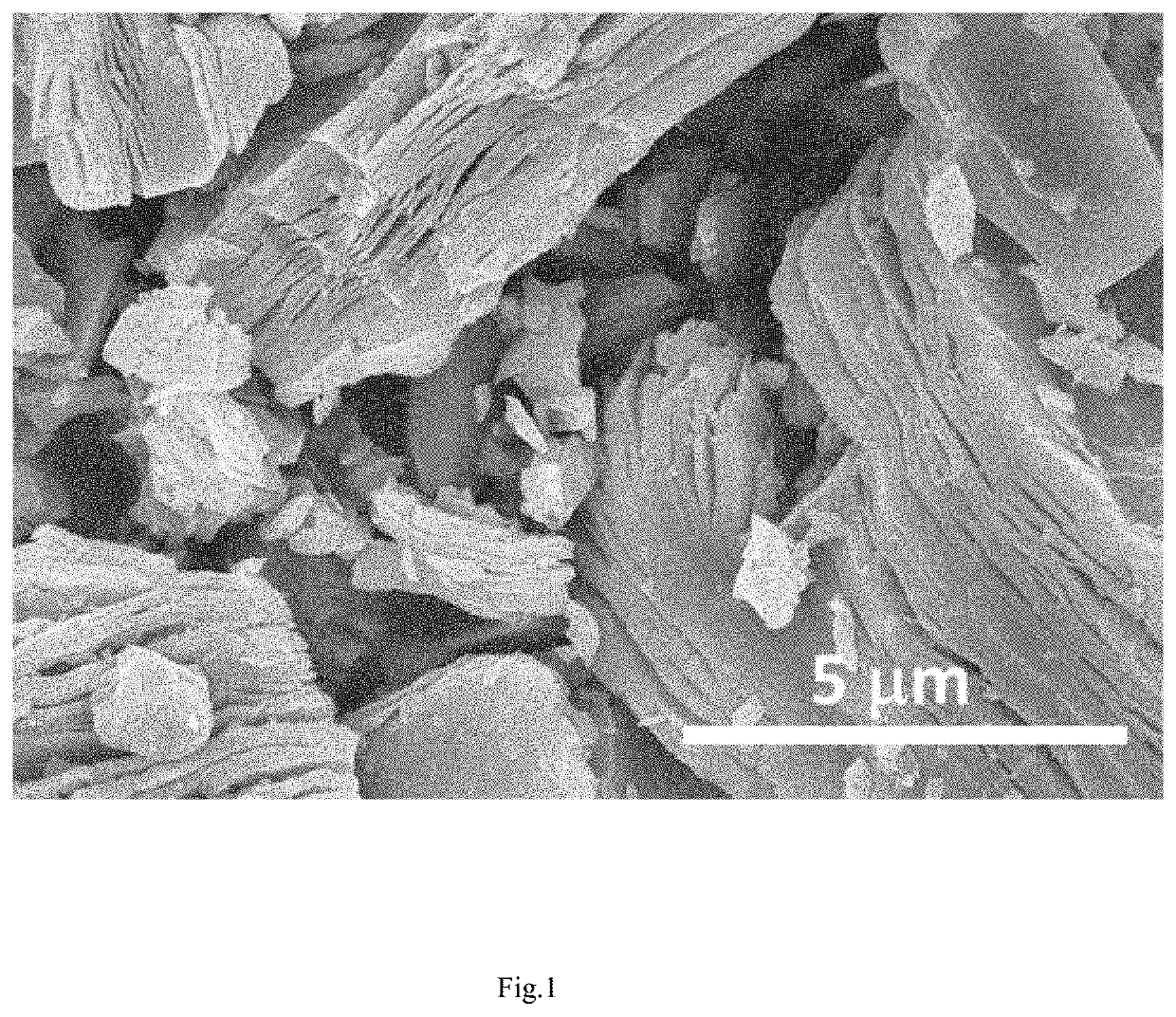

Selenium-doped mxene material, and preparation method and use thereof

ActiveUS20200227744A1Simple processReadily availableSecondary cellsPositive electrodesCleansing AgentsCyclic stability

The present invention discloses a selenium-doped MXene material and a preparation method thereof, comprising the following steps: (1) adding MXene and an organic selenium source into a dispersant, and stirring to prepare a dispersion with a concentration of 10 mg / ml to 100 mg / ml, wherein a mass ratio of MXene and an organic selenium source is 0.1 to 1:1; (2) transferring the dispersion into a reaction kettle, heating to 110° C. to 230° C., reacting for 10 h to 30 h, and then naturally cooling to a room temperature; and (3) washing the product obtained in the step (2) with a cleaning agent, centrifuging to collect a precipitate, and drying the precipitate under vacuum to obtain the selenium-doped MXene material. The composite material prepared by the present invention has high specific surface area, good electrical conductivity, cycle stability performance, rate performance and high theoretical specific capacity.

Owner:WUYI UNIV

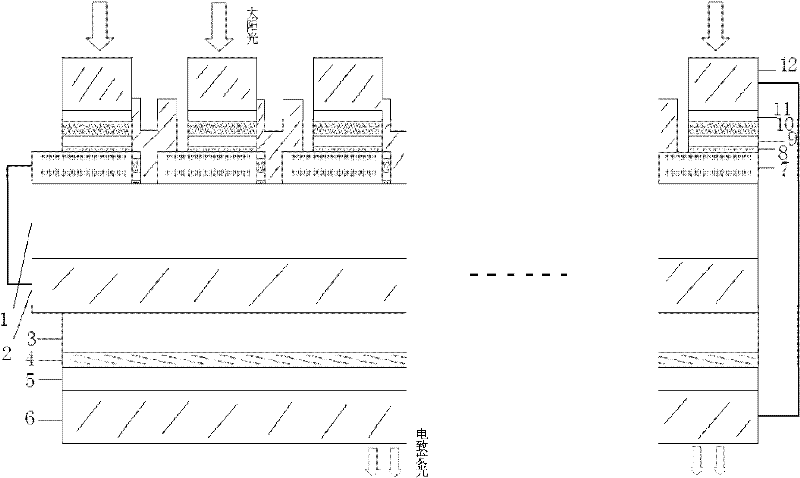

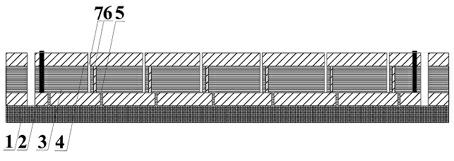

High-efficiency thin-film solar component battery structure and implementation method thereof

InactiveCN102222712ALower open circuit voltageIncrease flexibilityFinal product manufacturePhotovoltaic energy generationElectrical batteryEngineering

The invention relates to a high-efficiency thin-film solar component battery structure and an implementation method thereof, and belongs to the technical field of solar battery application. The technical scheme is as follows: the high-efficiency thin-film solar component battery structure comprises a piece of substrate glass, a front electrode film, a photoelectric absorption layer, a back electrode film, a packaging film and a back board; each photoelectric unit is connected in series to form two or more sets of photoelectric battery parts and then each photoelectric battery part is connected in parallel to form an integral thin-film component structure by adjusting etching times and etching positions of laser isolation channels, namely, each photoelectric unit is connected in series and then connected in parallel to form the integral component battery structure. In the invention, under the precondition that the power is basically not weakened, output voltage of the component can be efficiently reduced by adjusting the series and parallel connection structure among the photoelectric units in the thin-film solar battery component, and the matching flexibility of the thin-film battery component and fittings of a photovoltaic power generation system, such as an inverter, a controller and a storage battery; moreover, the BOS (basic operation system) cost of the system is reduced, and simultaneously the shading resistance performance of the component is efficiently improved.

Owner:BAODING TIANWEI GRP CO LTD +1

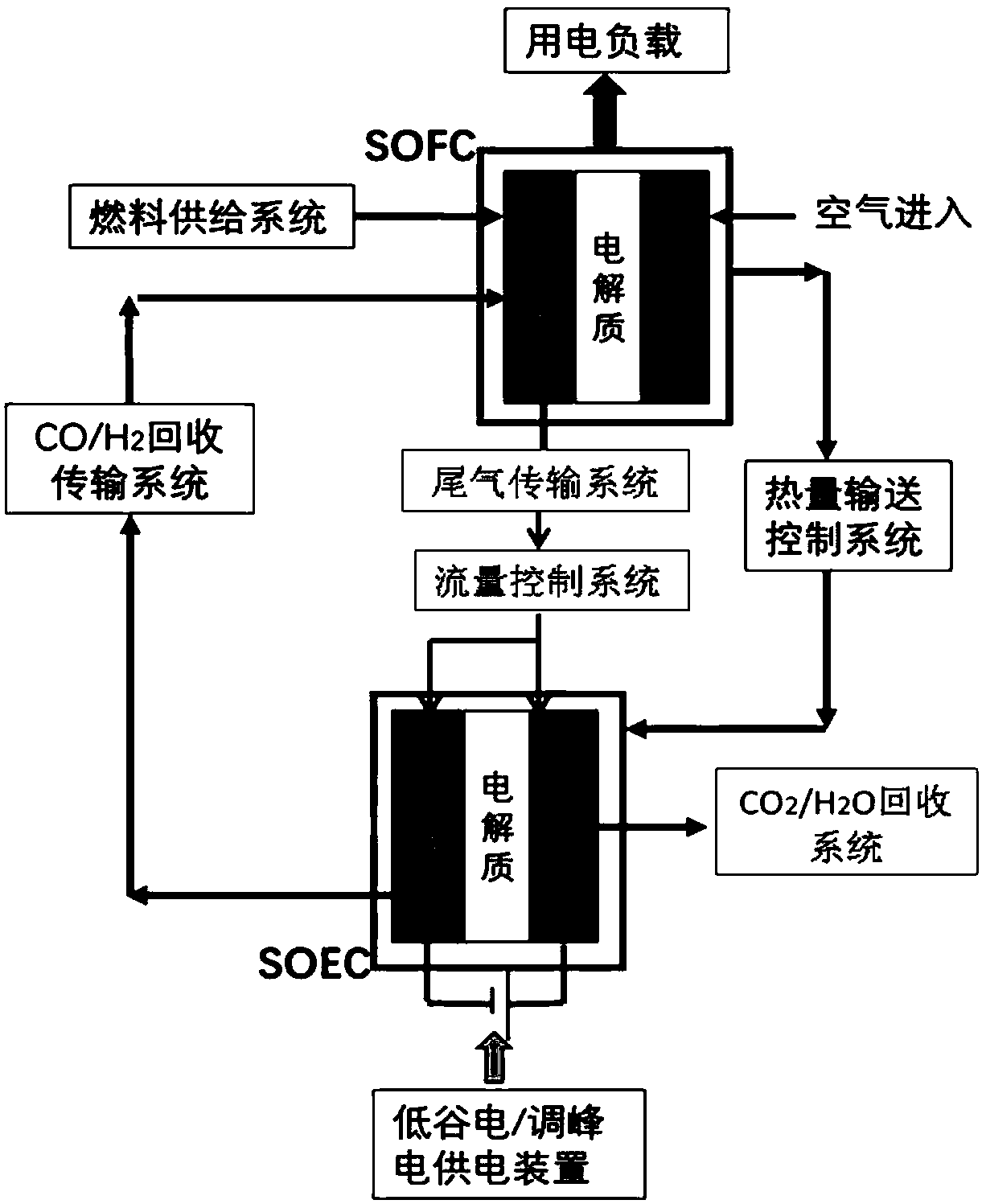

Solid oxide fuel cell tail gas treatment system and treatment method

PendingCN109473702ALower open circuit voltageReduce power consumptionFuel cellsNuclear engineeringFuel supply

The invention discloses a solid oxide fuel cell tail gas treatment system and a treatment method therefore. The system comprises a solid oxide fuel cell, a solid oxide electrolytic tank, a heat transfer control system, a tail gas transmission system, a flow control system, a CO / H2 recycling transmission system, a CO2 / H2O recycling system, a fuel supply system, and power utilization load and off-peak electricity / peak-regulation power supply device. The system utilizes the tail gas and heat produced by the solid oxide fuel cell, not only provides the heat for the solid oxide electrolytic tank, but also can convert the tail gas; the fuel energy utilization rate of the solid oxide fuel cell is improved, the pollutant emission is reduced, and an open-circuit voltage of the solid oxide electrolytic tank is reduced, and the power consumption of the solid oxide electrolytic tank is reduced.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +1

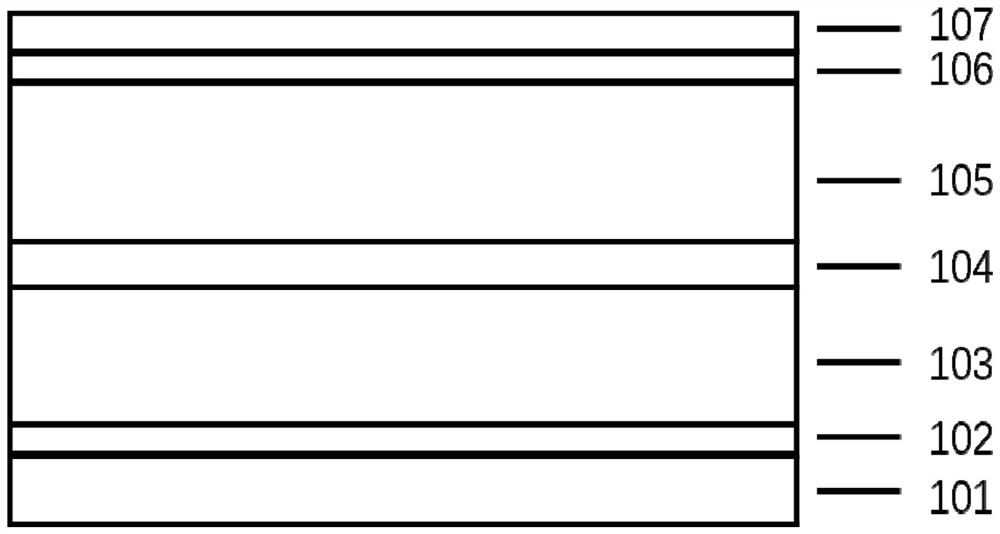

Local passivation contact IBC battery structure and preparation method thereof

PendingCN113611755AAvoid blockingAvoid blocking efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batterySolar battery

The invention discloses a local back passivation contact IBC solar cell, which comprises a P-type crystalline silicon substrate, and the back surface of the P-type crystalline silicon substrate sequentially comprises a tunneling oxide layer, back surface n + doped polycrystalline silicon regions, back surface slotting p + doped regions, a back surface passivation film and a back surface metal electrode from inside to outside, wherein the back surface n + doped polycrystalline silicon regions and the back surface slotting p + doped regions are alternately arranged; the front surface of the P-type crystalline silicon substrate is of a pyramid suede structure and sequentially comprises a front surface passivation film and an antireflection film; an emitter region on the back surface of the P-type crystalline silicon substrate adopts a tunneling oxide layer and an n + doped polycrystalline silicon passivation layer, the surface of the emitter region is passivated by an aluminum oxide and silicon nitride composite film or a silicon oxynitride film, a receiver region adopts local boron doping, and the surface of the receiver region is passivated by an aluminum oxide and silicon nitride composite film or a silicon oxynitride film; and according to the invention, the front electrode can be prevented from blocking light, the recombination rate of the back surface of the cell can be greatly reduced, the open-circuit voltage and the short-circuit current are improved, and the manufacturing cost of the solar cell is further reduced.

Owner:无锡琨圣智能装备股份有限公司

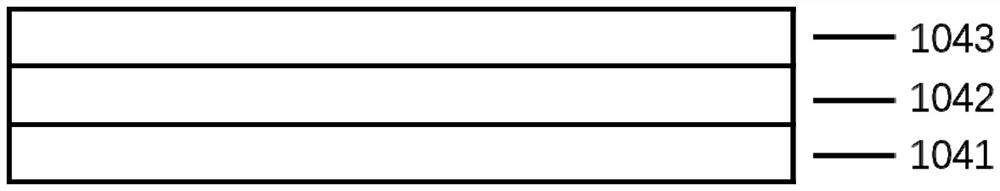

Intermediate layer suitable for laminated solar cell, cell and preparation method

ActiveCN112599675AGood electrical propertiesExcellent optical propertiesFinal product manufactureSolid-state devicesElectrical batteryPerovskite (structure)

The invention discloses an intermediate layer suitable for a laminated solar cell, a cell and a preparation method. MXene is adopted as a composite layer of the intermediate layer, good optical transmittance can be achieved while good electrical properties are ensured, and the intermediate layer is provided with a p type selective contact layer / MXene / n type selective contact layer structure. The intermediate layer can be used as an intermediate layer of a perovskite lamination device. According to the invention, the problem of electrical or optical loss of the middle layer of the prepared perovskite / perovskite two-end laminated solar cell can be solved, and the open-circuit voltage and the short-circuit current loss of the laminated device are reduced.

Owner:HUANENG NEW ENERGY CO LTD +1

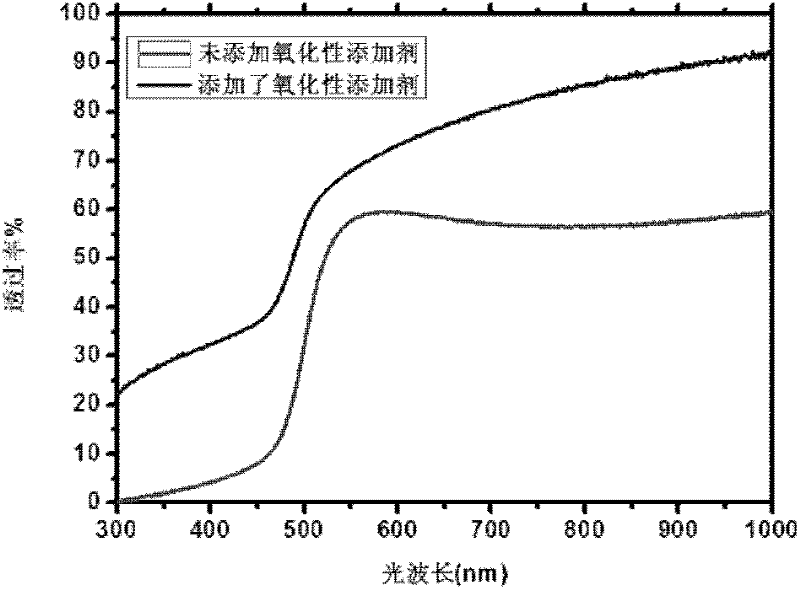

Method for preparing wide bandgap nanometer cadmium sulfide thin film

The invention relates to a method for preparing a wide bandgap nanometer cadmium sulfide thin film, which comprises the following steps that: indium tin oxide (ITO) glass using as substrates is placed in a reaction container after organic solvent soaking, ultrasonic cleaning and drying, and oxidbillity additives are added into reaction solution; in the reaction solution preparation stage, cadmiumsalt and the same acid radical ammonium salt are added into the container, de-ionized water is then added, when the temperature is heated to 40 to 70 DEG C, the proper amount of weak base aqueous solution (ammonia solution) is added for producing cadmium complex compounds, and the reaction solution in the first step is formed; and the weak base solution is added, simultaneously, the oxidbillity additives are added, the additives are organic peroxide (ROOH), organic peroxyacetic acid (RCOOOH) and 2 percent to 30 percent of oxyful, and the addition quantity of the oxidbillity additives is 1 percent to 10 percent of the mol number of the cadmium salt. At the time, thiourea is then added, the light transmittance and the energy gap of the wide bandgap nanometer cadmium sulfide thin film are obviously improved, and window materials of copper indium gallium selenium batteries or cadmium telluride batteries can be more favorably manufactured.

Owner:NANJING UNIV

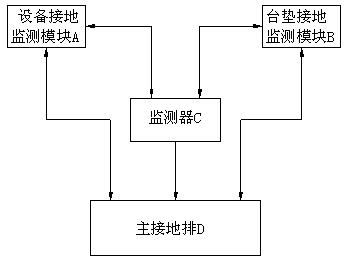

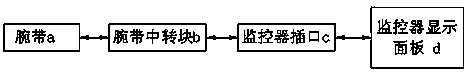

Online monitor for ESD grounding system

InactiveCN103353567AMonitor wearing statusMonitor ground statusElectrical testingIntegrated monitoringGround system

The invention discloses an online monitor for an ESD grounding system. The online monitor comprises an equipment grounding monitoring module (A), a cushion grounding monitor module (B), a monitor (C) and a main grounding bar (D). The equipment grounding monitoring module (A) and the cushion grounding monitor module (B) are respectively in mutual connection with the monitor (C) and the main grounding bar (D). The monitor (C) is connected with the main grounding bar (D). Monitor jacks (c) in the monitor (C) are respectively in mutual connection with a wrist belt transfer block (b) and a monitor display panel (d). The wrist belt transfer block (b) and a wrist belt (a) are connected with each other. Through unique design, the online monitor for the ESD grounding system realizes integrated monitoring of multiple parameters, has an acoustic-optical-electrical alarm function in case of a fault state, and fulfills a networking monitoring function.

Owner:SUZHOU TA&A ULTRA CLEAN TECH CO LTD

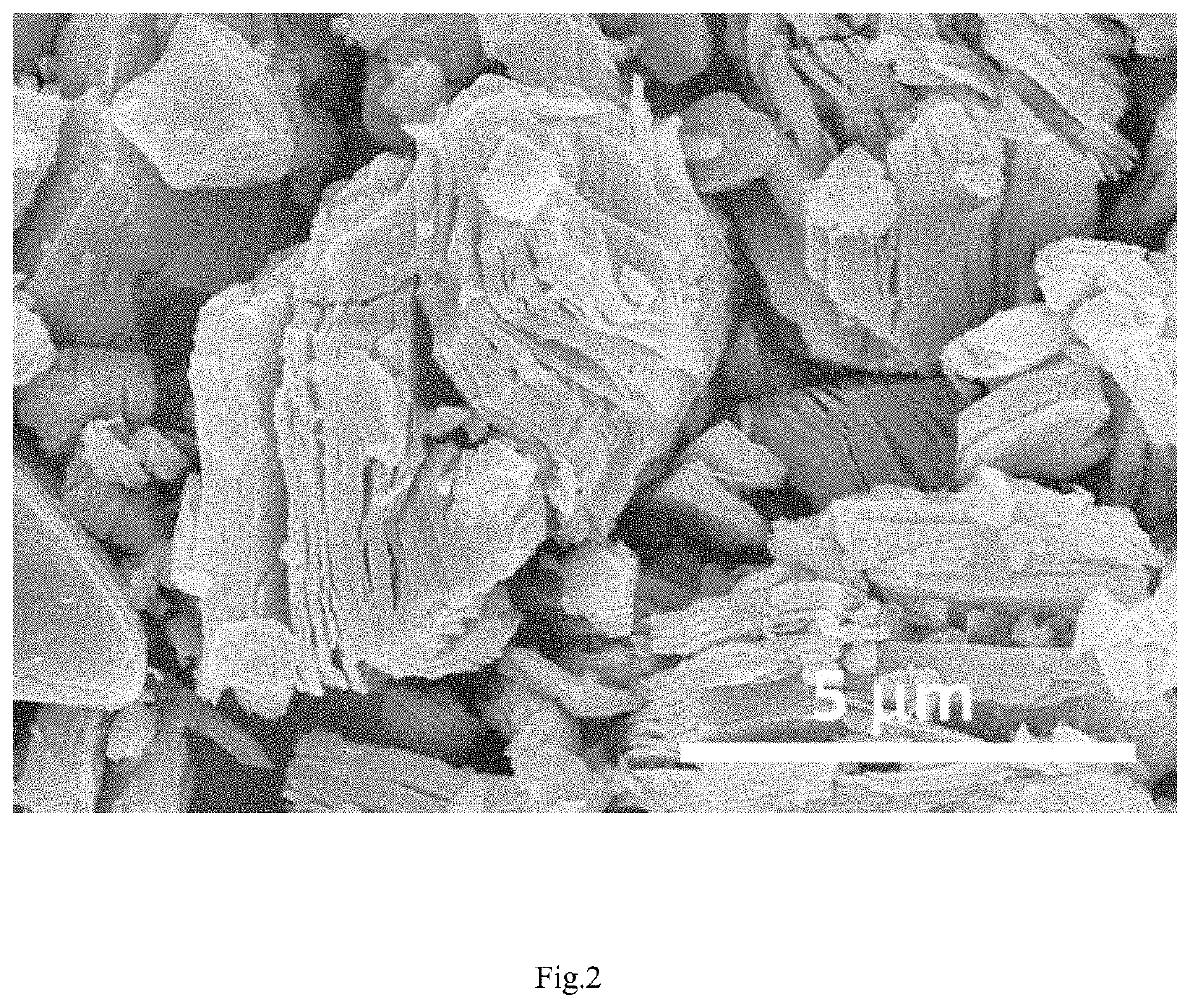

Iron disulfide positive electrode material and preparation method thereof

PendingCN111430714ALower open circuit voltageImprove conductivityMaterial nanotechnologyNon-aqueous electrolyte cellsElectrically conductiveIron disulfide

The invention discloses an iron disulfide positive electrode material and a preparation method thereof. The iron disulfide positive electrode material comprises iron disulfide, the surface of the irondisulfide is coated with a metal oxide, and a conductive agent is mixed in the iron disulfide, wherein the mass percent of the iron disulfide is 88%-95%, the mass percent of the conductive agent is 3%-8%, and the mass percent of the metal oxide is 0.5%-4%; the metal oxide is at least one of MgO, ZnO, CuO or TiO2, and the conductive agent is at least one of graphene and carbon nanotubes. The irondisulfide positive electrode material provided by the invention solves the problem that the open-circuit voltage of a battery assembled by the natural iron disulfide is too high.

Owner:东莞市天球实业有限公司

Organic electroluminescent device

InactiveCN108565345AImprove luminous efficiencyExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerOrganic electroluminescence

The invention provides an organic electroluminescent device, and relates to the technical field of organic photoelectrics. The organic electroluminescent device comprises a substrate, an anode, a cathode, and organic matter layers, wherein each organic matter layer includes at least one of an anode modification layer, a hole injection layer, a hole transmission layer, a light emitting layer, an electron transmission layer, an electron injection layer and a cathode modification layer, interposed between the anode and the cathode. By designing a reasonable device structure, by means of combinedusage of the subject and object of the lighting emitting layer, the organic electroluminescent device reduces the open circuit voltage, and improves the generation and utilization rate of excitons, thus improving the light emitting efficiency and the service life of the device. The organic electroluminescent device is excellent in performance and can be widely applied to the field of display and illumination.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

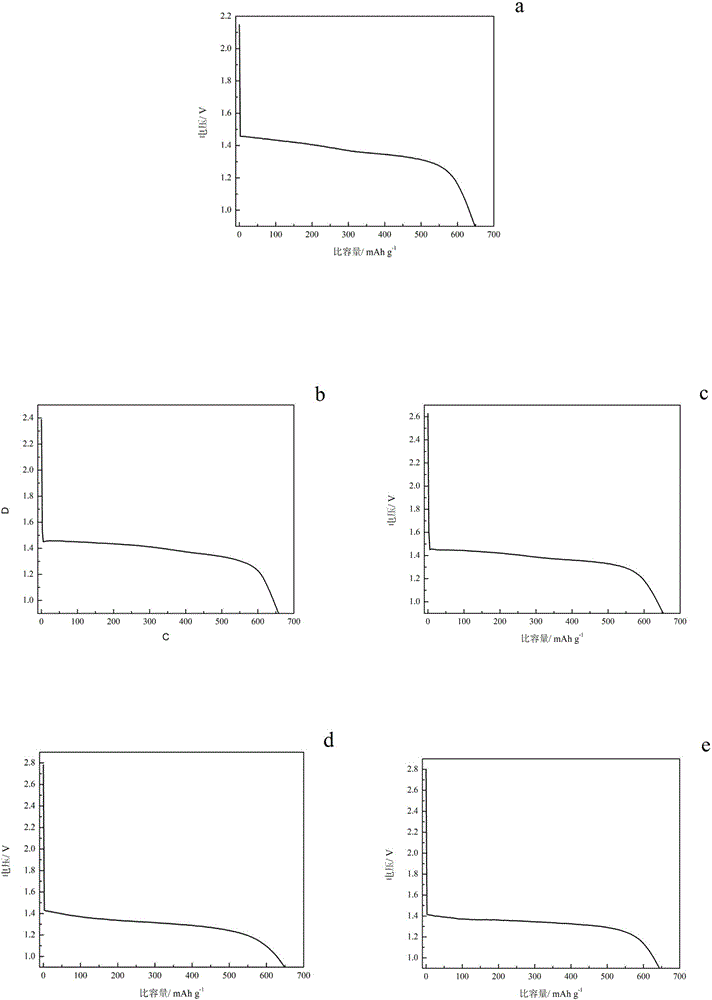

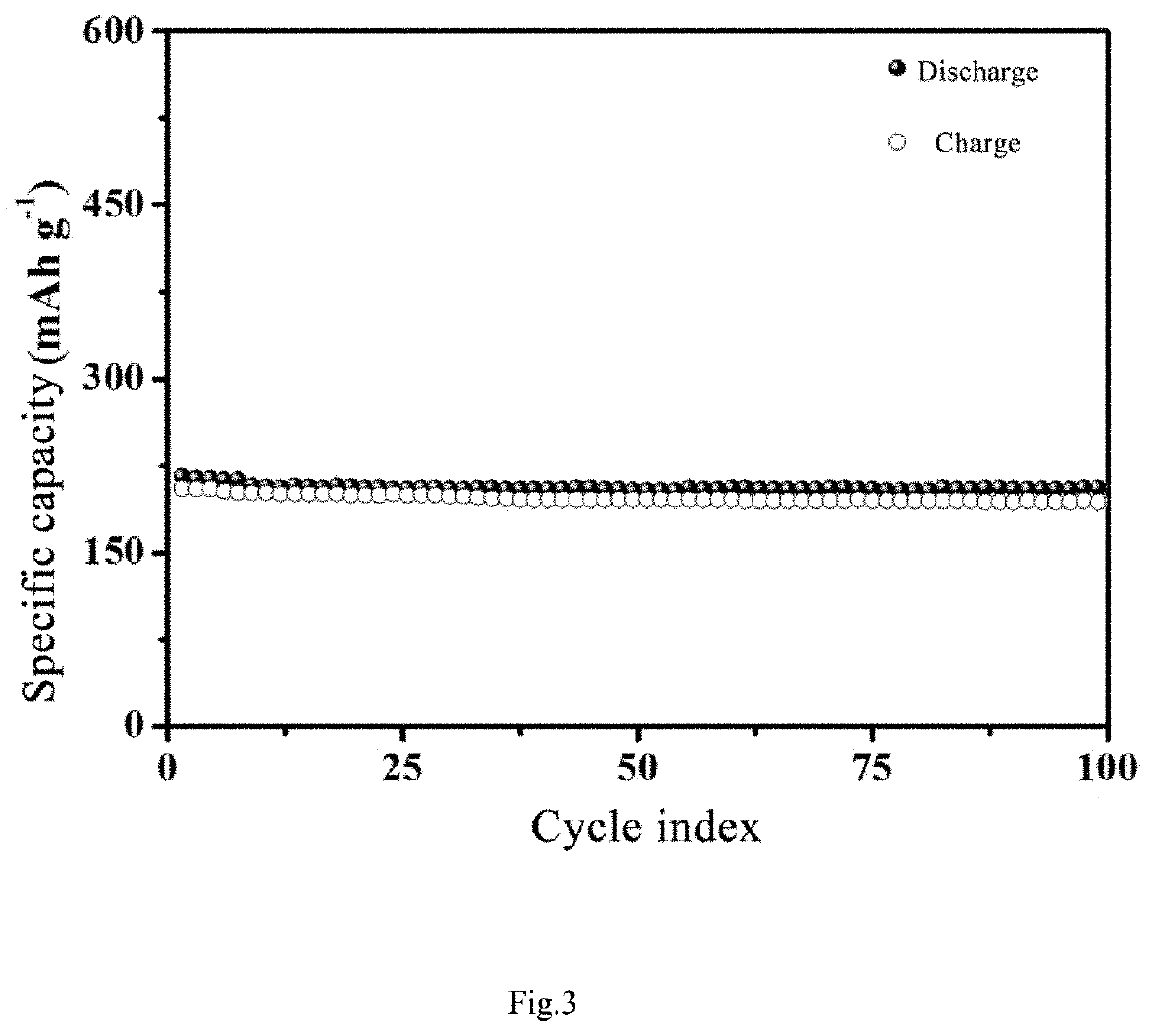

Method for preparing lithium-iron disulfide battery anode piece

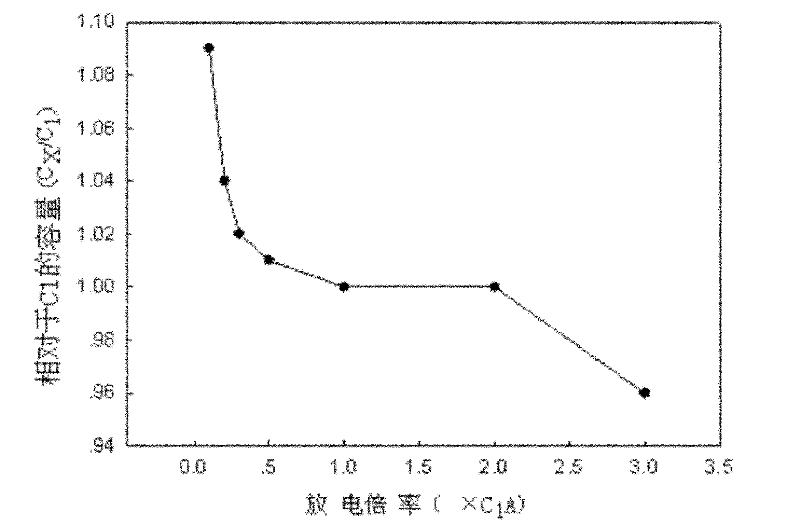

ActiveCN103050660ALower open circuit voltageHigh discharge platformPrimary cell electrodesMass ratioGranularity

The invention provides a method for preparing a lithium-iron disulfide battery anode piece. The method comprises the steps that FeS2 is taken as an active anode material, the size distribution of FeS2 respectively ranges from 0.1um to 1 um and from 10 um to 60 um, and firstly FeS2 is subjected to heat treatment in an inert gas at the temperature from 200 DEG C to 300 DEG C until elemental sulfur content in FeS2 is not higher than 0.3%; then FeS2 with fine granularity is subjected to ultrasonic dispersion at the temperature from 20 DEG C to 40 DEG C with power in a range from 300 W to 800 W; the obtained turbid liquid is added into a binding agent solution, and then the solution is integrally transferred to a mixture of FeS2 with coarse granularity and a conductive agent, and the mixture is uniformly stirred; and finally the anode piece is formed by the obtained anode paste according to working procedures of coating, press rolling and piece making, and then a lithium-iron disulfide battery is further prepared. A mass ratio of the FeS2 with fine granularity to the FeS2 with coarse granularity ranges from 1:99 to 1:4. According to the lithium-iron disulfide battery prepared by the method, the open-circuit voltage of the battery is reduced, the discharge platform is lifted, and the high-power discharge performance is improved.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

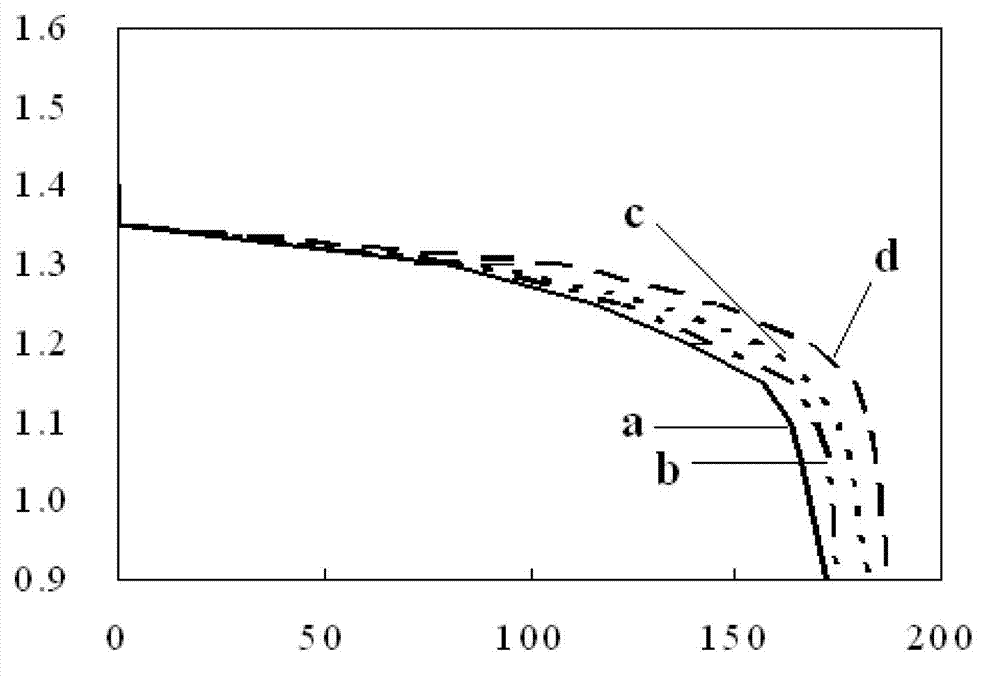

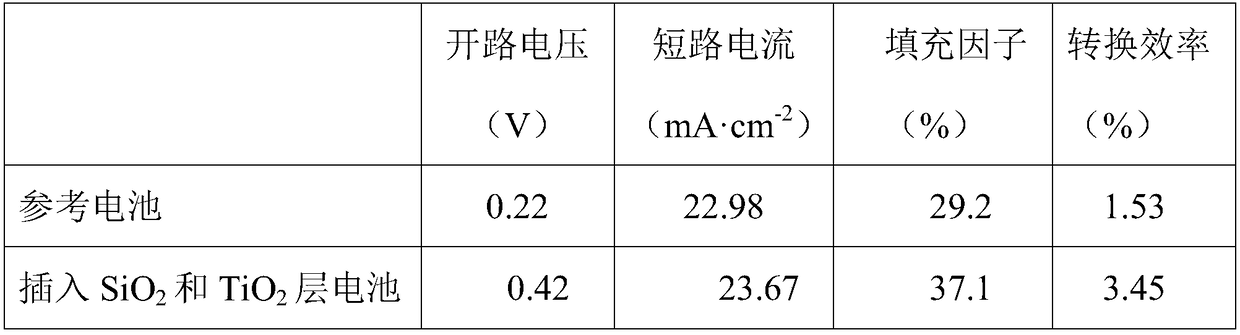

A novel undoped monocrystalline silicon heterojunction solar cell and a preparation method thereof

InactiveCN108987501ALower open circuit voltageIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationMonocrystalline siliconPower flow

The invention discloses a novel undoped monocrystalline silicon heterojunction solar cell and a preparation method thereof. The solar cell has the following structure: Ag / ITO / MoO3 / SiO2 / c-Si / TiO2 / Al; During the preparation, the silicon wafer is washed first, then the SiO2 passivation layer is deposited successively, the MoO3 is deposited, the TiO2 is deposited on the back side, the aluminum back side is deposited, the ITO is sputtered, and finally the gate line electrode is fabricated. SiO2 is inserted into MoO3 / c-Si interfacial layer, and TiO2 is inserted between c-Si / Al. The open-circuit voltage, short-circuit current and conversion efficiency of the device are higher than those of the reference battery.

Owner:ZHEJIANG NORMAL UNIVERSITY

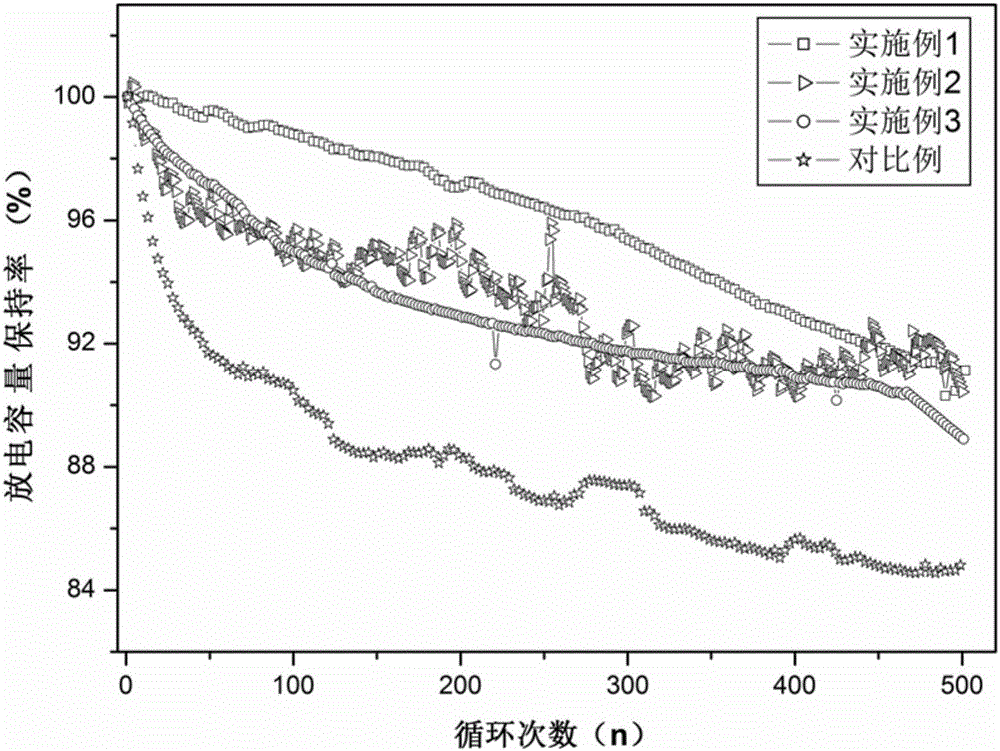

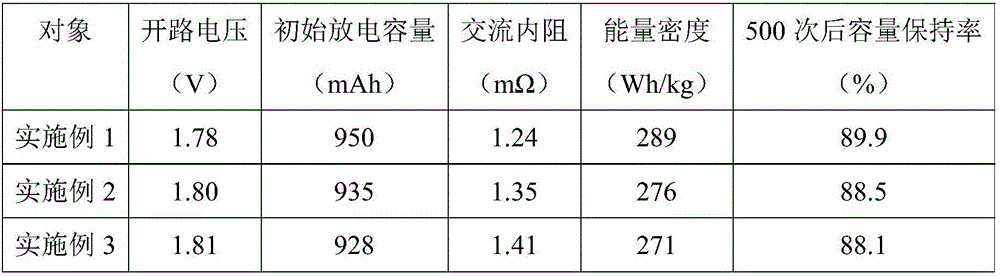

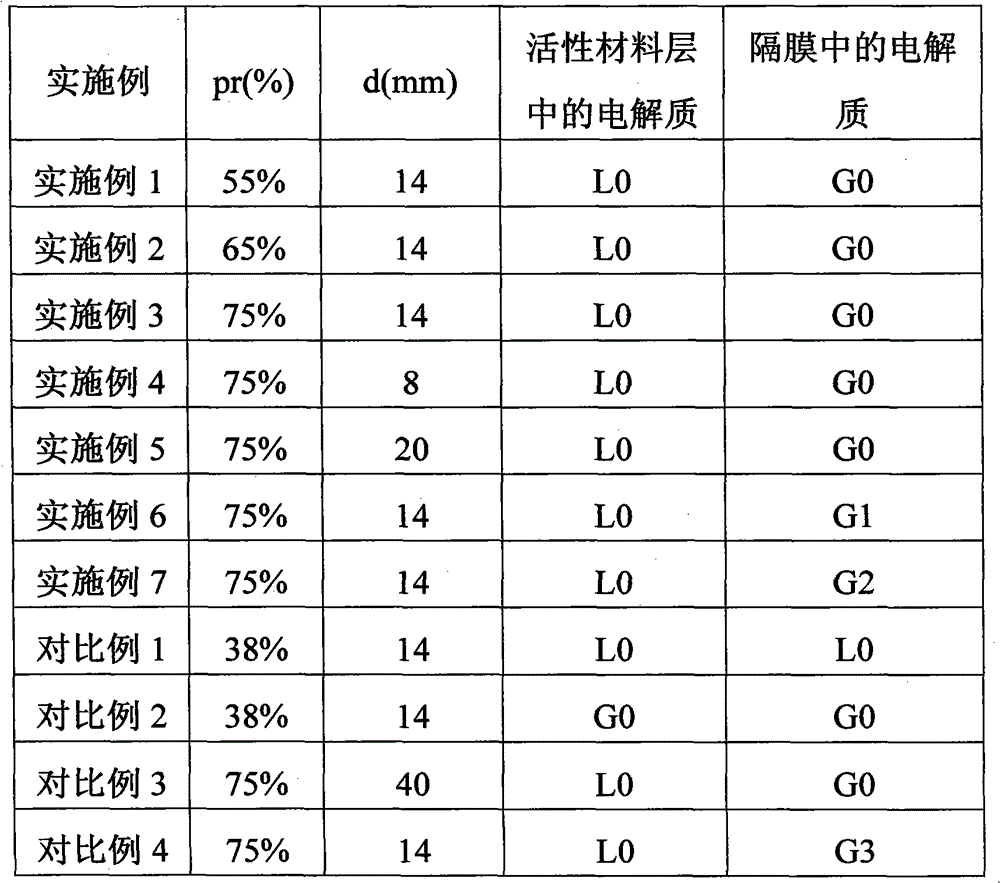

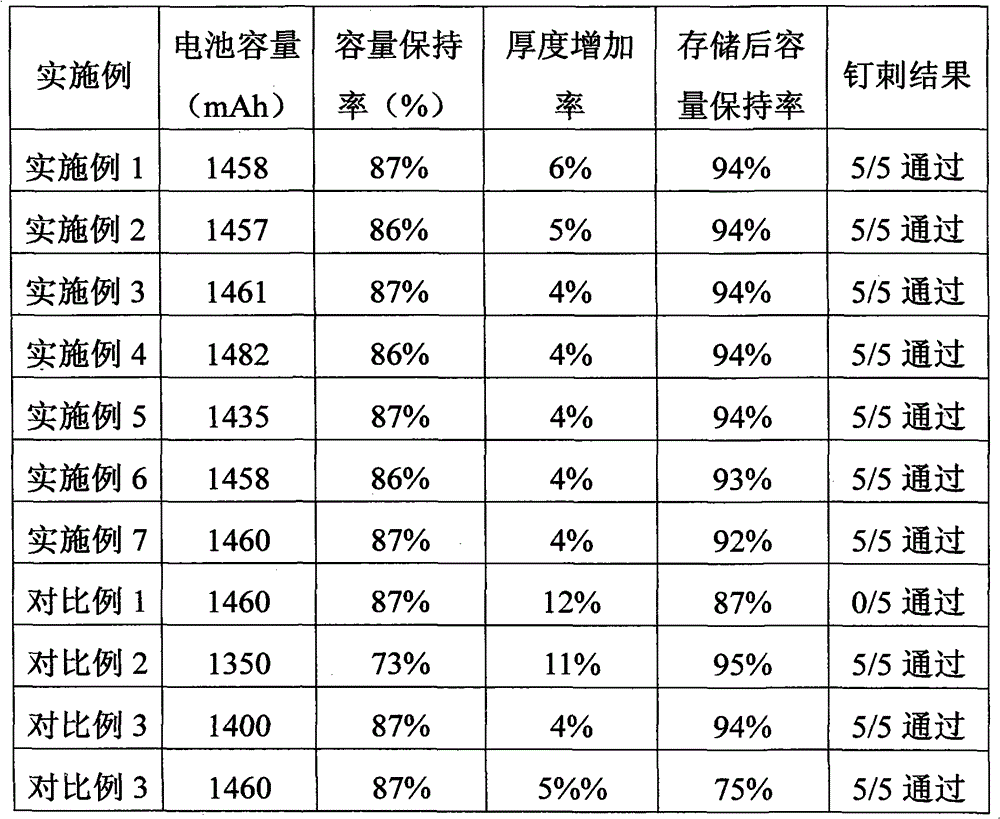

A lithium ion battery

ActiveCN102368562BHigh porosityIncreasing the thicknessSecondary cellsCell component detailsPorosityAluminum Ion

The invention discloses a lithium ion battery. A liquid electrolyte is filled in apertures of positive and negative pole active material layers of the lithium ion battery. A gel state electrolyte is filled in apertures of a separation film. The porosity pr of the separation film is great than or equal to 50% and is less than or equal to 78%. The elastic modulus of the gel state electrolyte is greater than that of a common separation film material. When pole pieces swell in lithium ion battery charging, the gel state electrolyte is easy to be compressed so that a space needed by pole piece thickness increase is obtained, and thus thickness increase of the whole lithium ion battery is reduced in lithium ion battery charging. In addition, the lithium ion battery provided by the invention has good short circuit safety and good electrochemical properties.

Owner:DONGGUAN AMPEREX TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com