Polymer electrolyte, lithium secondary battery using same, and method for manufacturing lithium secondary battery

一种锂二次电池、聚合物的技术,应用在电解质蓄电池制造、非水电解质蓄电池、二次电池等方向,能够解决离子传导度下降、气孔度低、厚度厚等问题,达到提高离子传导度、抑制界面电阻的增加、机械特性优秀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] By referring to the detailed description below with reference to the accompanying drawings, the above-mentioned purpose, features, and advantages can be clarified more clearly, so that those skilled in the art to which the present invention pertains can more easily implement the technical idea of the present invention.

[0040] In addition, in describing the present invention, if it is judged that the detailed description of known technologies related to the present invention may unnecessarily obscure the gist of the present invention, the detailed description will be omitted.

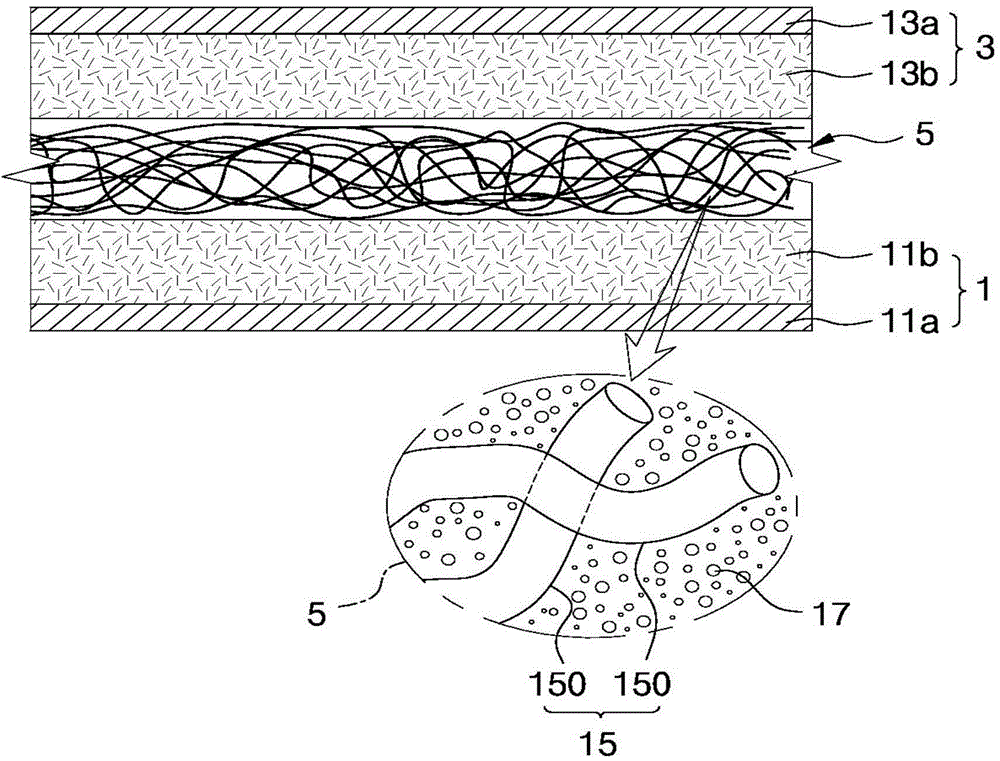

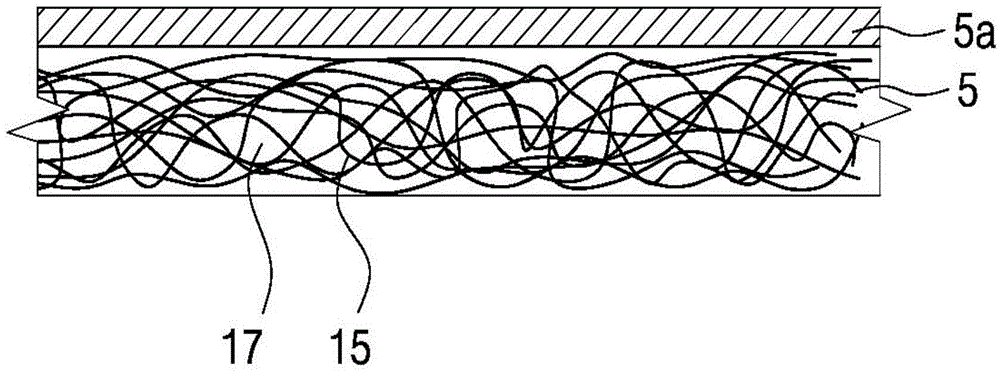

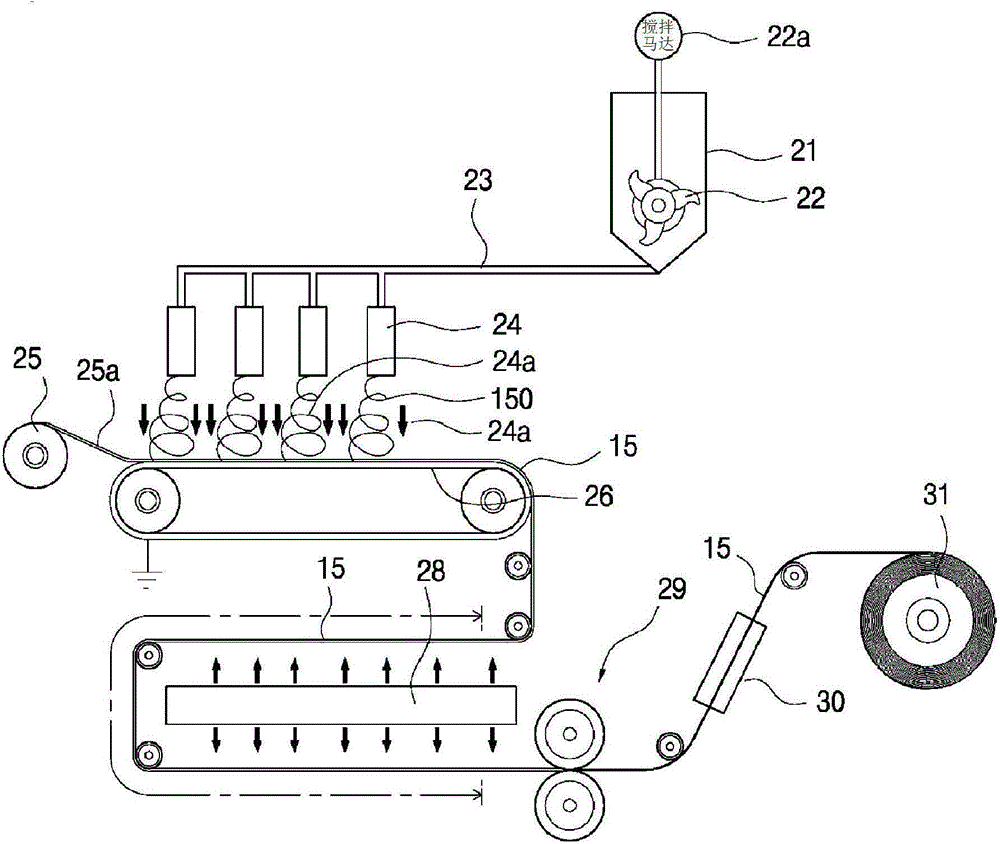

[0041] Hereinafter, in this specification, a polymer electrolyte means that a porous nanofibrous web (electrolyte matrix) as a porous separation membrane is assembled inside a casing together with a positive electrode and a negative electrode, and a gel-forming polymer is injected into the casing. The organic electrolyte solution of the monomer and the polymerization initiator is used to carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com