A lithium ion battery

A technology of lithium-ion batteries and separators, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of increased battery thickness, damage to electronic devices, and influence on normal operation, etc., to reduce calorific value and improve Effects of safety performance and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

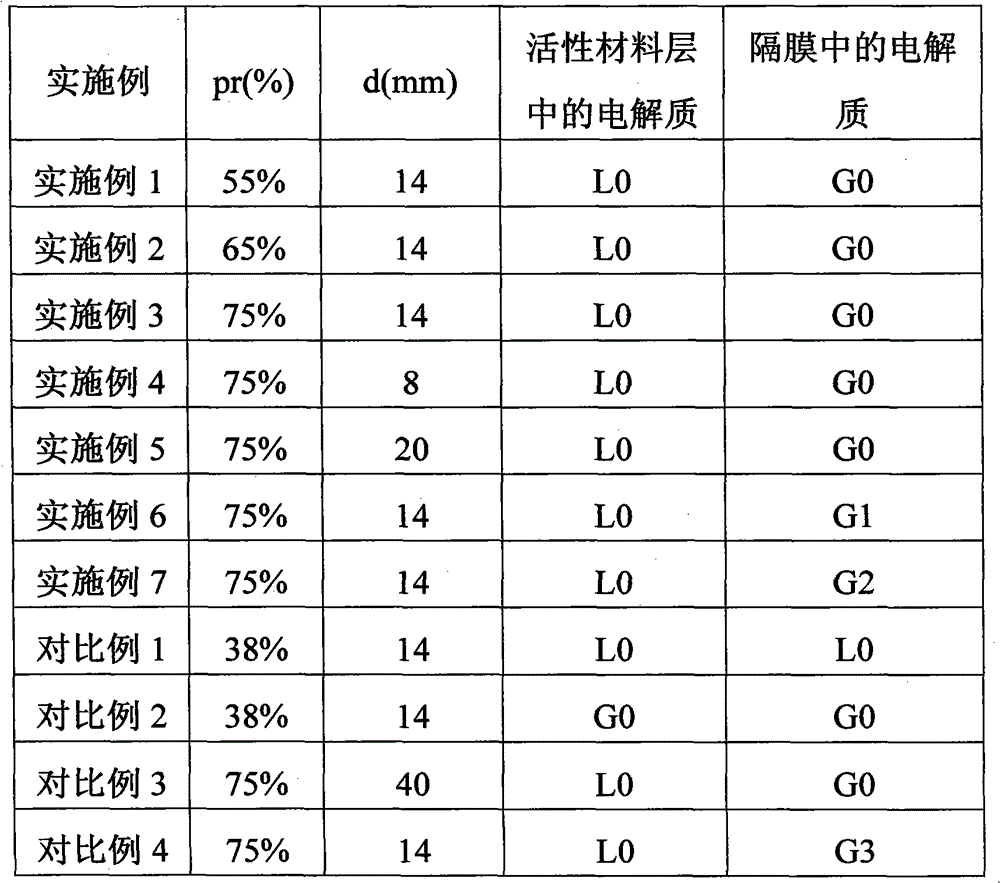

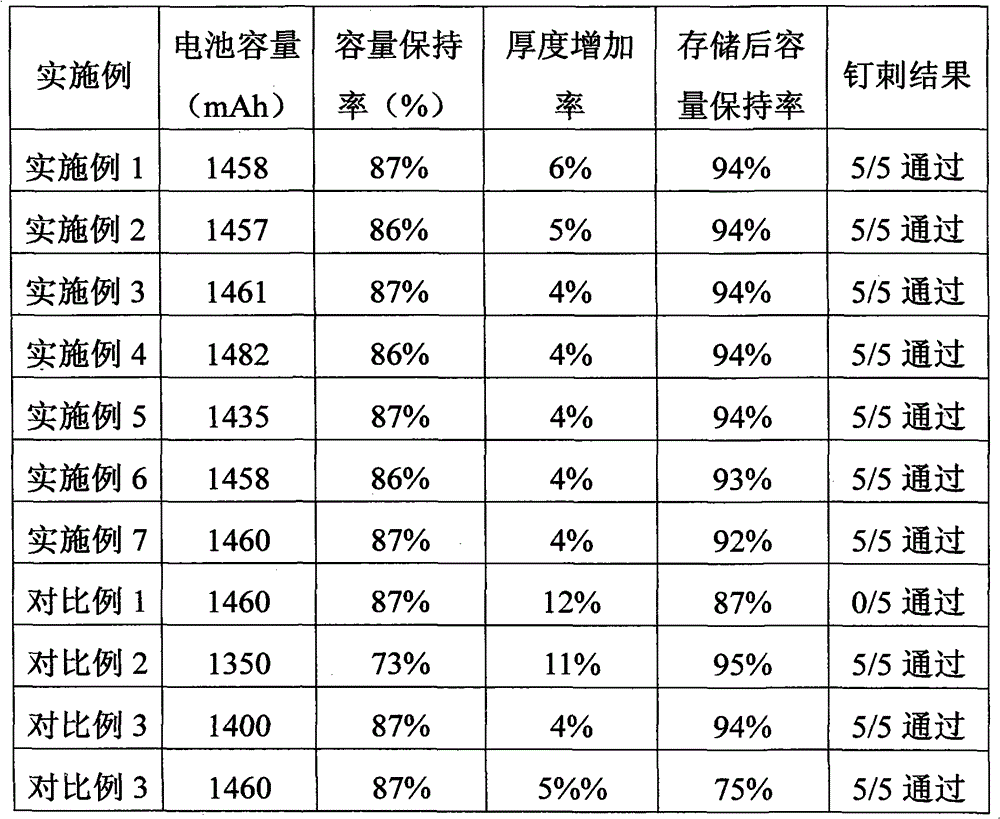

Examples

preparation example Construction

[0035] 1. Preparation of positive electrode sheet

[0036] The structure and composition of the positive electrode sheet: the positive electrode sheet includes a positive electrode current collector and a positive electrode diaphragm attached to both sides of the current collector. The positive electrode diaphragm includes a positive electrode active material, a binder, and a conductive agent. The present invention has no special limitation on the positive electrode active material. Existing positive electrode active materials for lithium ion batteries such as: LiCoO2, LiNiO2, LiMn2O4, LiNiMnCoO2, LiFePO4, etc. can be used to prepare the lithium ion battery disclosed by the present invention. The bonding agent and the conductive agent are not particularly limited, and the present invention can use all the positive current collectors, adhesives, and conductive agents that can be used in existing lithium-ion batteries. Considering the degree of maturity of the process, the prese...

Embodiment 1

[0050] Preparation of the negative electrode sheet: mix the negative electrode active material graphite, the thickener sodium carboxymethyl cellulose (CMC), the conductive agent (Super-P) and the binder styrene-butadiene rubber emulsion (SBR) with deionized water to obtain Negative slurry. The negative electrode slurry was evenly coated on a copper foil with a thickness of 9 μm by a coating process, and the negative electrode sheet was obtained after drying, rolling and slitting.

[0051] Preparation of positive electrode sheet: uniformly mix LiCoO2 powder, binder polyvinylidene fluoride, conductive agent (Super-P) and N-methylpyrrolidone to obtain positive electrode slurry. The positive electrode slurry was uniformly coated on an aluminum foil with a thickness of 14 μm by a coating process, and the positive electrode sheet was obtained after drying, rolling, and slitting.

[0052] Liquid electrolyte: the organic solvent and its weight ratio are EC / PC / EMC=1:1:1, the lithium s...

Embodiment 2

[0056] Except for using a separator made of PE, with a porosity pr of 65%, and a thickness d of 14 μm, the others are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com