Doped cerium oxide-based solid oxide fuel cell and preparation method thereof

A solid oxide and fuel cell technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve problems such as hindering the application, and achieve the effect of increasing the open circuit voltage, simple and effective process, efficient and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

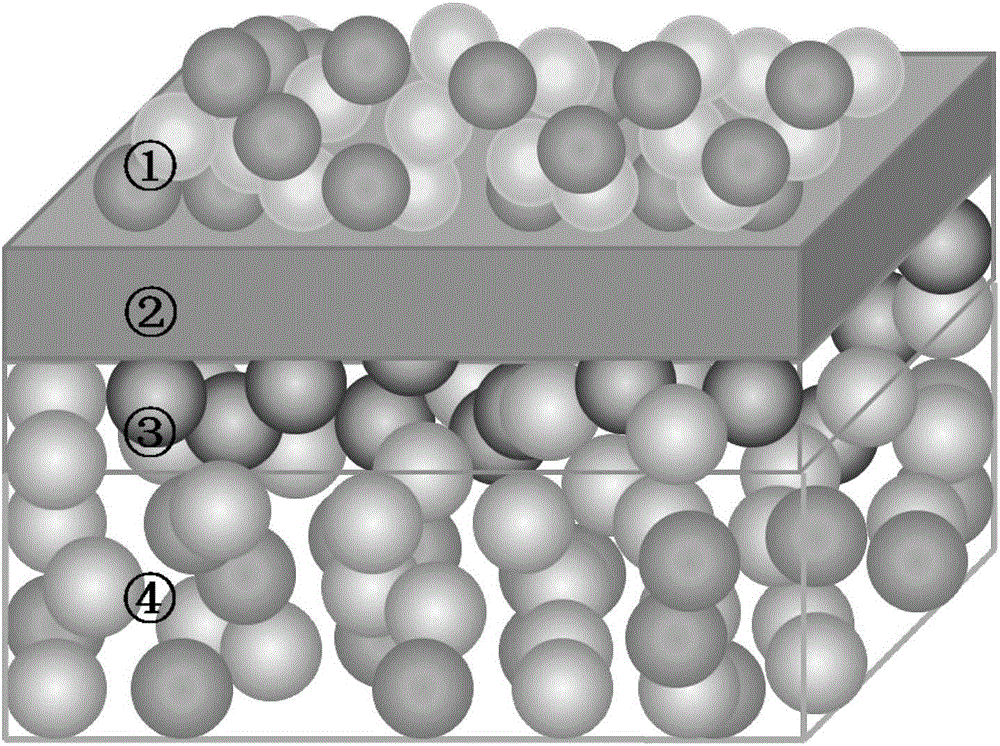

[0058] The present invention also provides a preparation method of the doped ceria-based solid oxide fuel cell, which includes the following steps:

[0059] A) A green body with an anode support, an anode functional layer containing Ba and / or Sr and an electrolyte layer doped with cerium oxide is calcined at a high temperature at 1200-1400°C to obtain a half-cell ceramic chip; the calcining temperature is more Preferably it is 1350 degreeC.

[0060] B) Prepare a cathode layer on the surface of the electrolyte layer of the half-cell ceramic sheet obtained in step A), and obtain the doped ceria-based solid oxide fuel cell after sintering.

[0061] Preferably, the step A) is specifically:

[0062] 1) The anode support ceramic powder is mixed with the pore former, and the anode support ceramic green body is prepared by the dry pressing method;

[0063] 2) Disperse the anode functional layer ceramic powder on the anode support base, and prepare a double-layer ceramic green body with anode s...

Embodiment 1

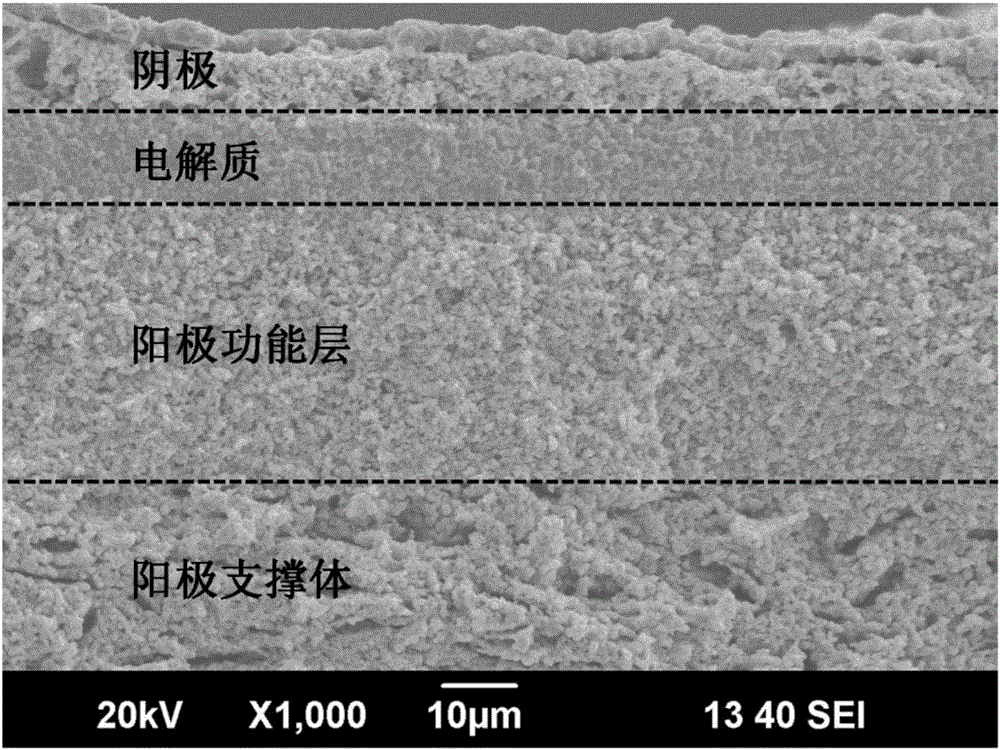

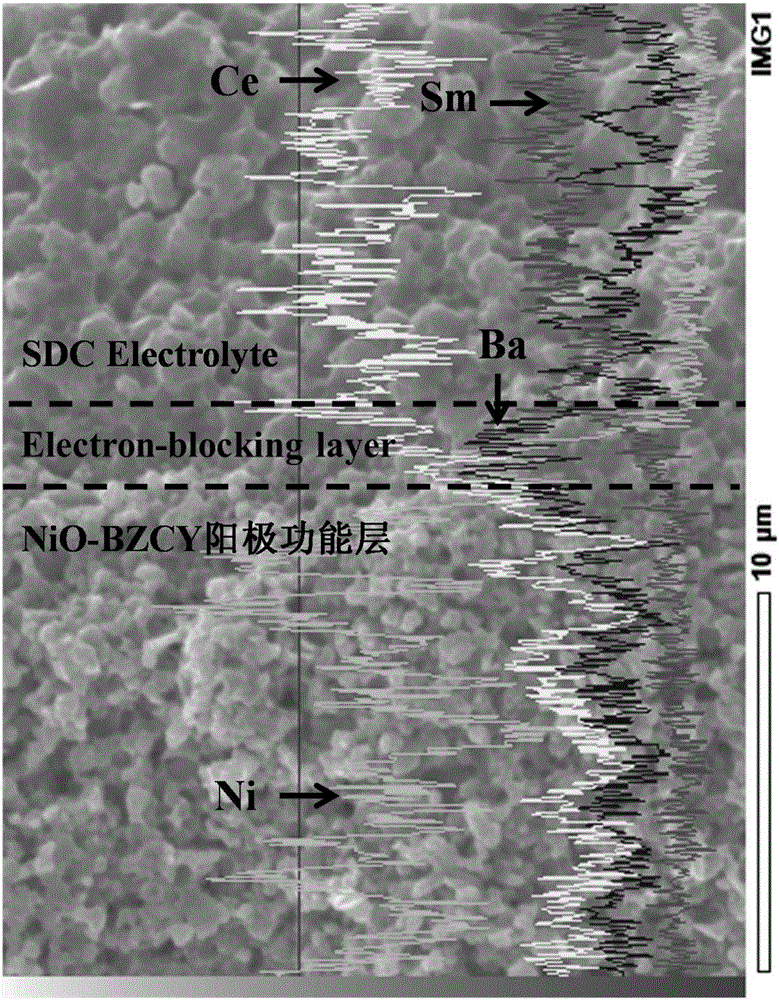

[0083] Preparation of NiO-SDC|NiO-BZCY|SDC|SSC-SDC flat anode support SOFC

[0084] The electronic conductive phase NiO powder in the anode support and the anode functional layer is prepared by decomposition of basic nickel carbonate at 600°C, NiO-BaZr 0.1 Ce 0.7 Y 0.2 O 3-δ The (NiO-BZCY) composite ceramic powder is synthesized in one step by the citrate gel combustion method, and calcined in the air at 1000°C for 3 hours to obtain the NiO-BZCY composite powder. In addition, the electrolyte Ce 0.8 Sm 0.2 O 3-δ (SDC) and the electron conduction phase Sm in the cathode layer 0.5 Sr 0.5 CoO 3-δ (SSC) is also synthesized by the citrate combustion method and calcined in air at 600℃ and 950℃ for 3h.

[0085] After mixing the above-mentioned anode support NiO and SDC powder in a mass ratio of 60:40, adding 20% starch, ball milling in ethanol for 12 hours, and drying in an oven at 80°C for 24 hours to obtain a uniformly mixed anode Support ceramic powder.

[0086] Take an appropriate ...

Embodiment 2

[0102] Example 2: Preparation of NiO-SCYb|NiO-SCYb|SDC|PSCF-SDC flat anode support SOFC

[0103] NiO-SrCe in anode support and anode functional layer 0.95 Yb 0.05 O 3-δ The (NiO-SCYb) composite ceramic powder is synthesized in one step by the citrate gel combustion method, and calcined in the air at 1000°C for 3 hours to obtain the NiO-SCYb composite powder. In addition, the electrolyte Ce 0.8 Sm 0.2 O 3-δ (SDC) and the electron conduction phase Pr in the cathode layer 0.6 Sr 0.4 Cu 0.2 Fe 0.8 O 3-δ (PSCF) is also synthesized by the citrate combustion method, and then calcined in the air at 600°C and 900°C for 3 hours.

[0104] The above-mentioned NiO-SCYb composite ceramic powder was added to starch with a mass fraction of 20%, and the mixture was uniformly mixed by ball milling in ethanol for 12 hours, and dried in an oven at 80° C. for 24 hours to obtain a uniformly mixed anode support ceramic powder.

[0105] Take an appropriate amount of the above-mentioned starch-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com