A novel undoped monocrystalline silicon heterojunction solar cell and a preparation method thereof

A solar cell, non-doped technology, applied in the field of solar cells, can solve problems such as high cost and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

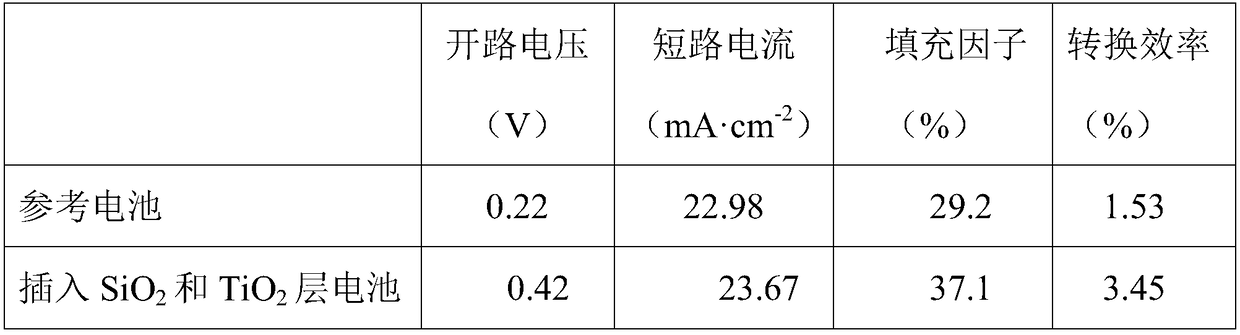

Examples

Embodiment

[0021] 1. Experimental materials

[0022] (1) n-type silicon wafer (CZ non-polished, 190μm, 0.8-5Ω.cm)

[0023] (2) Silica (purity > 99.9%)

[0024] (3) Molybdenum trioxide (purity 99.99%)

[0025] (4) Titanium dioxide (purity > 99.9%)

[0026] 2. Solar cell preparation steps

[0027] A. Silicon wafer cleaning: 4×4cm 2 The monocrystalline silicon wafers are cleaned by the standard RCA method, and each step is ultrasonically cleaned with deionized water for 2 minutes. The specific steps are as follows:

[0028] 1) Ultrasonic cleaning with acetone for 10 minutes;

[0029] 2) Ultrasonic cleaning with absolute ethanol for 10 minutes;

[0030] 3) Prepare a NaOH solution with a concentration of 25%, and heat it in a water bath at 80° C. for 20 minutes;

[0031] 4) with (29%) NH 4 OH:(30%)H 2 o 2 : Deionized water = 1:1:5 to prepare cleaning solution, heated in 80°C water bath for 10min;

[0032] 5) with (37%) HCl: (30%) H 2 o 2 : Deionized water = 1:1:5 to prepare clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com