Method for preparing lithium-iron disulfide battery anode piece

A technology of iron disulfide batteries and positive plates, which is applied to the electrodes of primary batteries, etc., and can solve the problems of insufficient high-power discharge performance and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

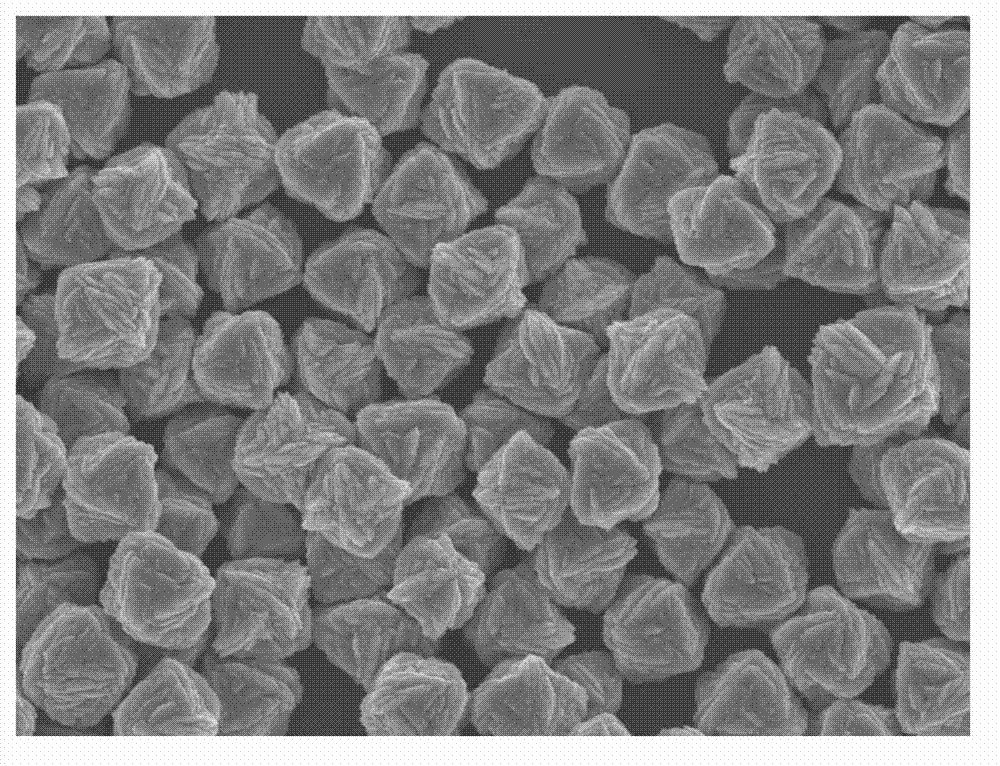

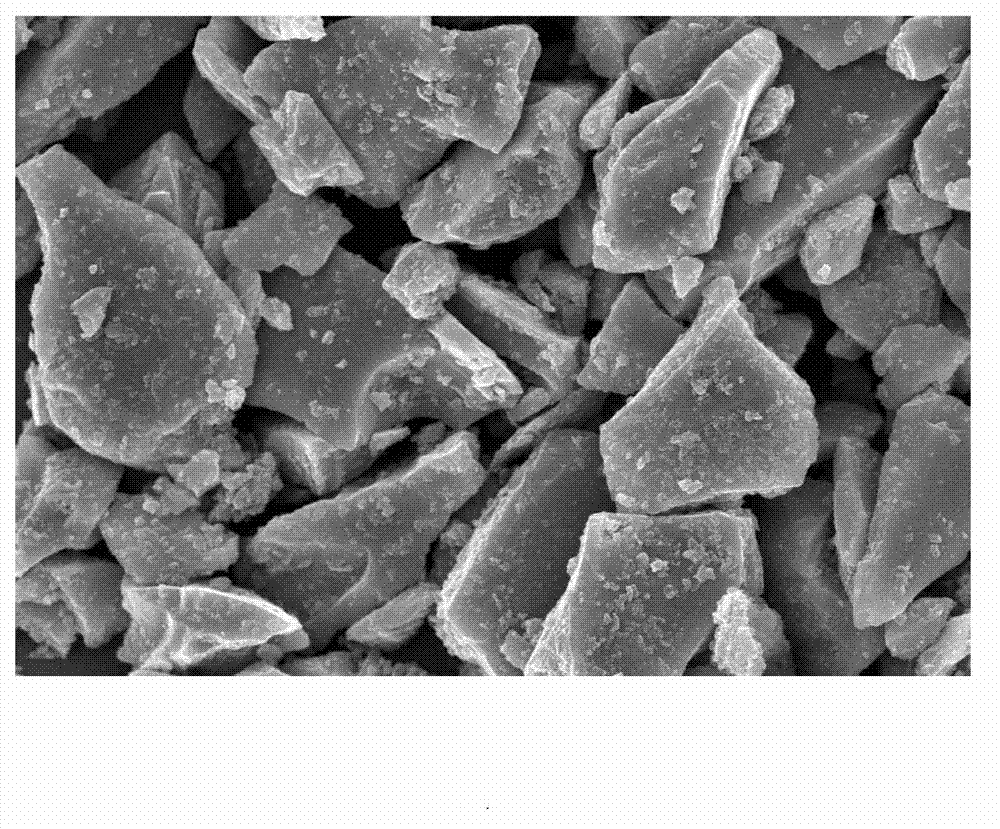

[0027] The invention provides a method for preparing a lithium-iron disulfide battery positive plate, which contains the following steps in sequence: fine-grained FeS 2 powder, coarse particle size FeS 2 The powder is heat-treated in an inert gas atmosphere, the treatment temperature is 200°C-300°C, and the time is 1-5 hours; the fine-grained FeS 2 The particle size distribution range is 0.1~1μm; the coarse particle size FeS 2 The particle size distribution range is 10~60μm. Q2: The heat-treated fine-grained FeS 2 The powder is dispersed in the dispersant, stirred at a speed of 10-50r / min, and ultrasonically dispersed for 1-5 hours at the same time, the ultrasonic power is 300-800W, and the ultrasonic temperature is 20°C-40°C to obtain a mixed suspension; the dispersion The agent is N-methylpyrrolidone, acetone, isobutanol or a mixture of two or three of them; the fine particle size FeS 2 The range of mass ratio to dispersant is 1:5~1:10. Dissolve the binder in the dissol...

Embodiment 1

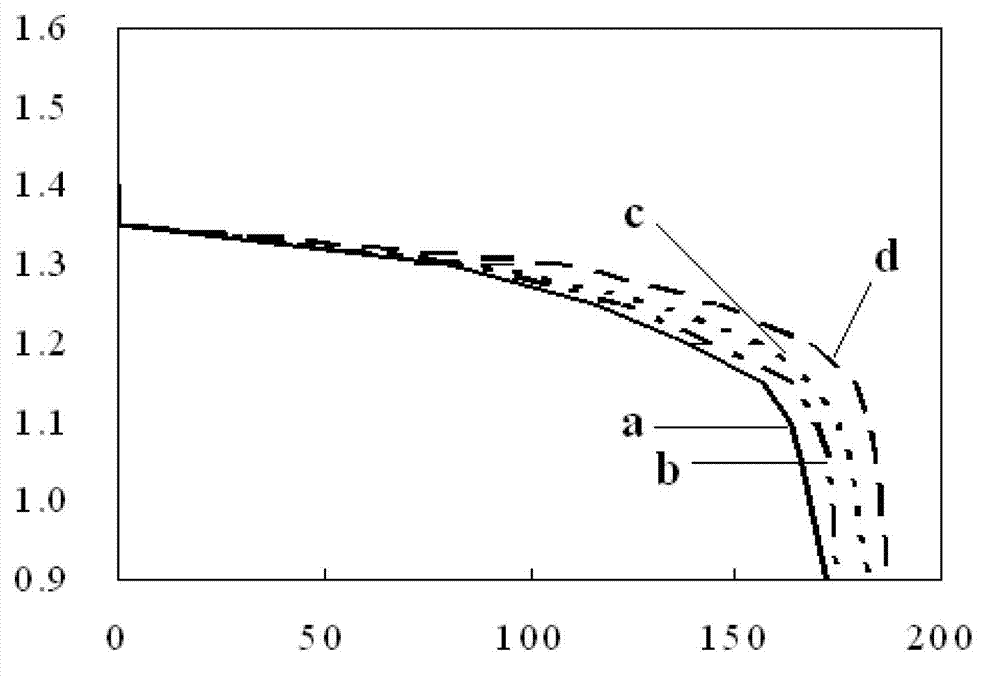

[0033] Weigh fine-grained FeS with a particle size distribution of 0.1-1 μm 2 Coarse particle size FeS with 50g powder and particle size distribution of 10~60μm 2 950 g of powder was heated at 300° C. for 3 hours in a vacuum oven filled with nitrogen. Heat-treated fine-grained FeS 2 The powder is dispersed in a beaker containing 500g of isobutanol, stirred at a speed of 50r / min at a temperature of 40°C, and ultrasonically dispersed at a power of 800W for 3 hours to obtain FeS 2 Suspension. Weigh 55g of styrene-butadiene rubber, disperse it in another beaker containing 550g of isobutanol, stir at a speed of 40r / min for 3 hours, and obtain a uniform solution after completely dissolving. FeS 2 The suspension was transferred to the homogeneous solution 10 times and dispersed with stirring at 30r / min; after the transfer was completed, continue to stir at a speed of 30r / min for 2 hours to obtain FeS 2 viscous suspension. Weigh 31g of acetylene black, and heat-treated coarse pa...

Embodiment 2

[0035] Weigh fine-grained FeS with a particle size distribution of 0.1-1 μm 2 100g powder, coarse particle size FeS with particle size distribution of 10~60μm 2 900 g of powder was heated at 250° C. for 1 hour in a vacuum oven filled with nitrogen. Heat-treated fine-grained FeS 2 The powder is dispersed in a beaker containing 500g of N-methylpyrrolidone, stirred at a speed of 20r / min at a temperature of 20°C, and ultrasonically dispersed at a power of 300W for 1 hour to obtain FeS 2 Suspension. Weigh 33g of polyvinylidene fluoride, disperse it in another beaker containing 400g of N-methylpyrrolidone, stir at a speed of 20r / min for 1 hour, and obtain a uniform solution after completely dissolving. FeS 2 The suspension was transferred to the homogeneous solution 20 times and dispersed with stirring at 20r / min; after the transfer, continue to stir at a speed of 20r / min for 1 hour to obtain FeS 2 viscous suspension. Take by weighing carbon black 55g, and through heat-treated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com