Iron disulfide positive electrode material and preparation method thereof

A technology of iron disulfide and positive electrode materials, applied in the direction of positive electrodes, nanotechnology for materials and surface science, battery electrodes, etc., can solve problems such as poor high-current discharge performance, high battery open circuit voltage, and large particle size. Achieve the effect of improving conductivity, stable voltage platform and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

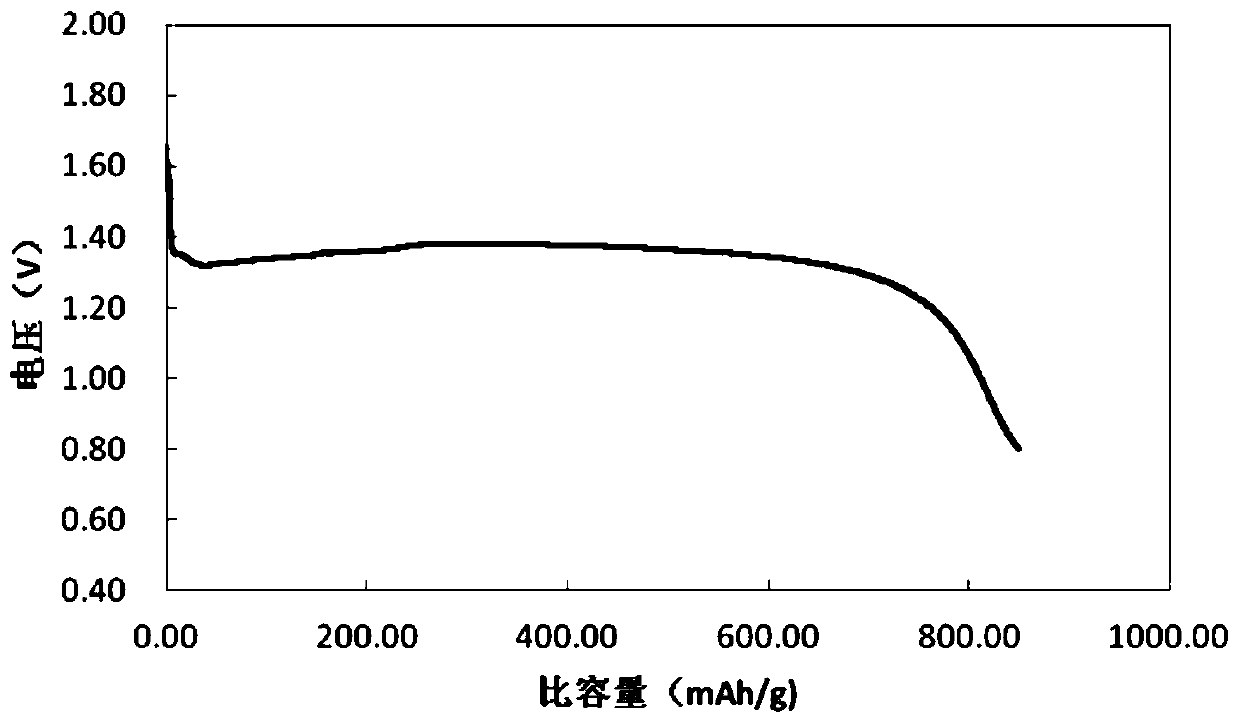

Embodiment 1

[0029] 1), take 100g of natural iron disulfide and place it in a ball mill tank, and at a stirring speed of 200r / min, stirring for 3h, ball mill the natural iron disulfide into fine particles with an average particle size of 10 μm;

[0030] 2) Put the ball-milled iron disulfide granular iron into a mixing tank, add 1L of 0.3mol / L dilute hydrochloric acid, stir for 4 hours at a stirring speed of 300r / min, and filter the stirred mixture with distilled water to wash;

[0031] 3), add 1L of 1.4mol / L dilute sulfuric acid solution to the iron disulfide particles obtained in step 2), mix and stir in a stirring tank, the stirring speed is 300r / min, the stirring time is 4h, and suction filtration is carried out after the stirring is completed;

[0032] 4) The precipitate after suction filtration was washed with distilled water and absolute ethanol in sequence, and after washing, it was baked in a vacuum environment at 100° C. for 3 hours to obtain iron disulfide after removing impuriti...

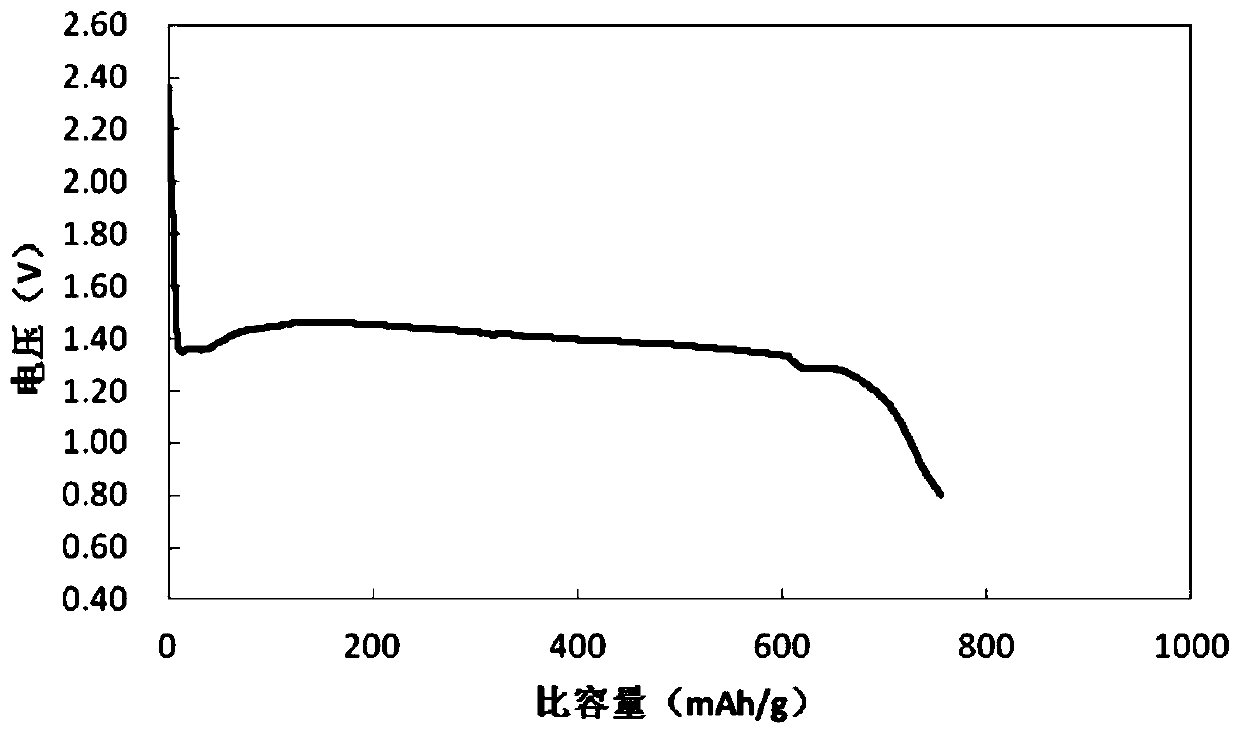

Embodiment 2

[0037] 1), take 100g of natural iron disulfide and place it in a ball mill tank, and at a stirring speed of 200r / min, stirring for 3h, ball mill the natural iron disulfide into fine particles with an average particle size of 10 μm;

[0038] 2) Put the ball-milled iron disulfide particles into a mixing tank, add 1L of 0.3mol / L dilute hydrochloric acid, stir for 4 hours at a stirring speed of 300r / min, and filter the stirred mixture with distilled water to wash;

[0039] 3), add 1L of 1.4mol / L dilute sulfuric acid solution to the iron disulfide particles obtained in step 2), mix and stir in a stirring tank, the stirring speed is 300r / min, the stirring time is 4h, and suction filtration is carried out after the stirring is completed;

[0040] 4) The precipitate after suction filtration was washed with distilled water and absolute ethanol in sequence, and after the washing was completed, it was baked in a vacuum environment at 100° C. for 3 hours to obtain iron disulfide after rem...

Embodiment 3

[0045] 1), take 100g of natural iron disulfide and place it in a ball mill tank, and at a stirring speed of 200r / min, the stirring time is 3h, and ball mill the natural iron disulfide into fine particles with an average particle size of 10 μm;

[0046] Put the ball-milled iron disulfide particles into a stirring tank, add 1L of 0.3mol / L dilute hydrochloric acid, stir for 4 hours at a stirring speed of 300r / min, suction filter the stirred and mixed mixture, and wash with distilled water;

[0047] 3), add 1L of 1.4mol / L dilute sulfuric acid solution to the iron disulfide particles obtained in step 2), mix and stir in a stirring tank, the stirring speed is 300r / min, the stirring time is 4h, and suction filtration is carried out after the stirring is completed;

[0048] 4) The precipitate after suction filtration was washed with distilled water and absolute ethanol in sequence, and after the washing was completed, it was baked in a vacuum at 100° C. for 2.5 hours to obtain iron disul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com