Plasm-aided selenium sulfuration treatment device and process

A plasma and vulcanization treatment technology, applied in metal material coating process, semiconductor devices, gaseous chemical plating, etc., can solve the problems of thin film crystalline quality or structure, poor reactivity, low band gap, etc. High conversion efficiency, increased reactivity, and the effect of reducing heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

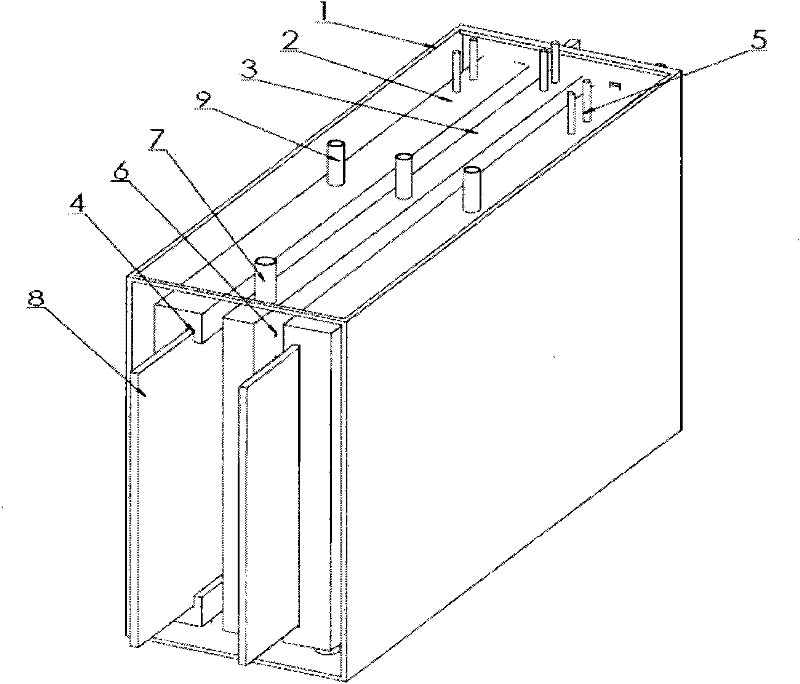

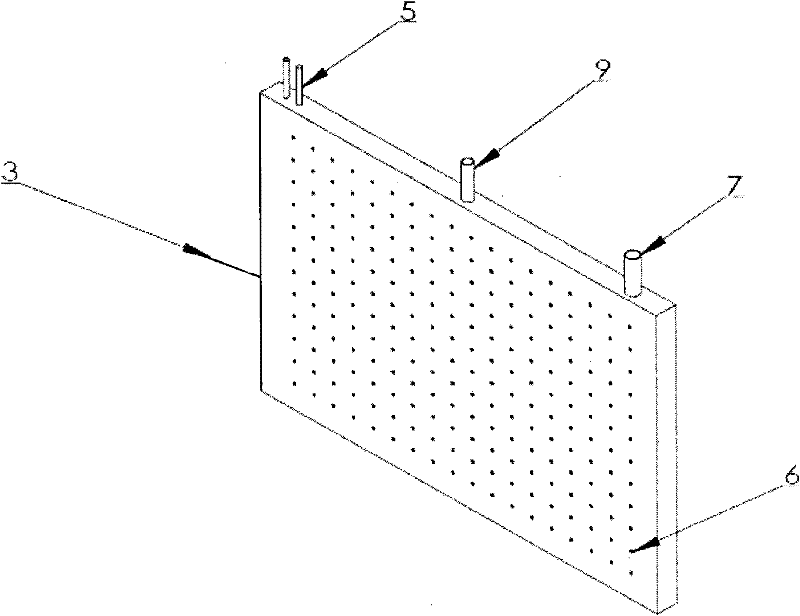

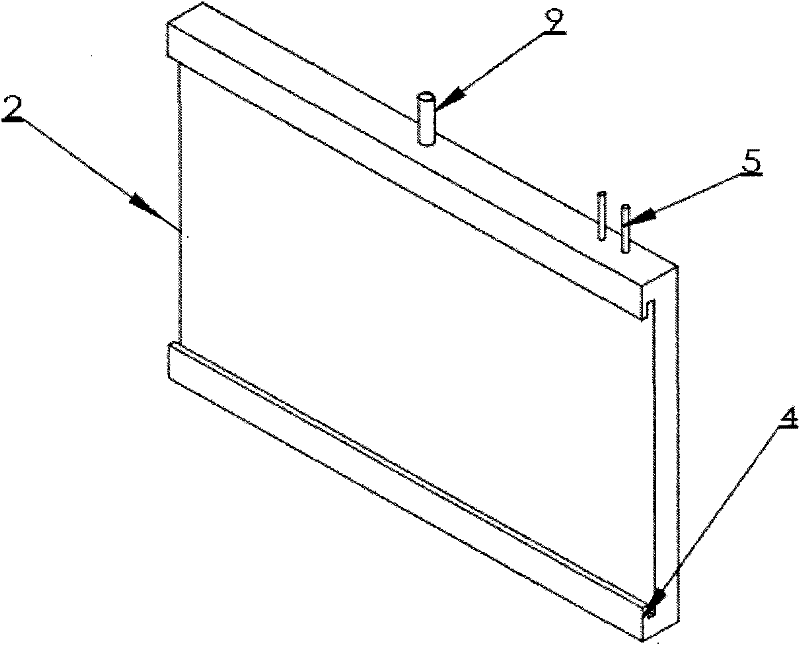

Image

Examples

Embodiment 1

[0033] Selenium vulcanization treatment of embodiment 1 Cu-In metal prefabricated layer

[0034] Sputter and deposit 0.6-1.4 μm thick metal Mo on ordinary soda-lime glass, use laser scribing, and then sputter or evaporate a layer of NaF (thickness 0.1-0.3 μm) (or Na 2 S), then sputtering deposit copper indium or copper indium alloy, the atomic ratio (Cu / In) of copper and indium is 0.85: 1.0~0.95: 1.0, put them into the base on the cathode in the capacitively coupled parallel plate radio frequency plasma device On the sheet rack 4, close the vacuum chamber to evacuate. When the mechanical pump is linked with the molecular pump or the vacuum diffusion pump, the vacuum reaches 10 -2 ~10 -5 Pa, start the heating device inside the cathode plate and the anode plate, wherein the temperature change of the cathode plate is as follows Figure 4 shown. That is, let the battery substrate 8 evenly heat up at a rate of 0.5-2°C / s, and after stabilizing at about 100°C for 10-20 minutes, c...

Embodiment 2

[0037] Example 2 CuIn 0.3 Ga 0.7 Selenization Treatment of Metal Prefabricated Layer

[0038] The pre-preparation process of the electrode on the surface of the battery substrate is the same as that of Example 1. A layer of NaF (thickness 0.1-0.3 μm) (or NaF) (or NaF) is sputtered or evaporated on the surface of the Mo film. 2 S), and then sputtering deposited copper-gallium alloy (CuGa 0.3 , thickness 0.8~1.2μm), sputtering deposited indium (0.5~0.8μm), or copper-gallium-indium layered deposition respectively, the total chemical ratio should satisfy Cu(Ga 0.3 In 0.7 ) Se 2 , and requires Cu / (In+Ga)=1:1.0~1:1.15, this is because indium gallium has a certain transformation loss in the selenization process, and the doping of sodium ions is beneficial to reduce the copper indium gallium metal prefabricated layer selenium The crystallization temperature, grain growth and flatness of the film surface during the chemical transformation process increase the carrier concentration...

Embodiment 3

[0042] Embodiment 3CIGS carries out selenium vulcanization

[0043]The CIGS semiconductor thin film formed after selenization of CuInGa metal pre-set layer, if vulcanized, can form wide bandgap, high resistance, n-type homogeneous pn junction, which can improve the quality of CIS and CIGS thin film. In this embodiment, according to the method of embodiment 2, in the later stage of preparing CIGS thin film material by plasma-assisted selenization, the composition of the gas is changed to input Ar+H 2 S or Ar+S+H 2 Finally, sulfur-containing high-resistance Cu(In 0.7 Ga 0.3 ) (SeS) layer, use EDX (energy dispersive X-ray analyzer) to test the depth of the surface layer of the sulfur-containing film, and determine the sulfur-passing time (3-10min) to control its thickness at 10-20nm; this sulfur-containing surface film It constitutes an n-type semiconductor layer or a high-resistance layer of CIGS that is wider than the forbidden band width of the underlying CIGS film, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com