Patents

Literature

608results about How to "Reduce ambient temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

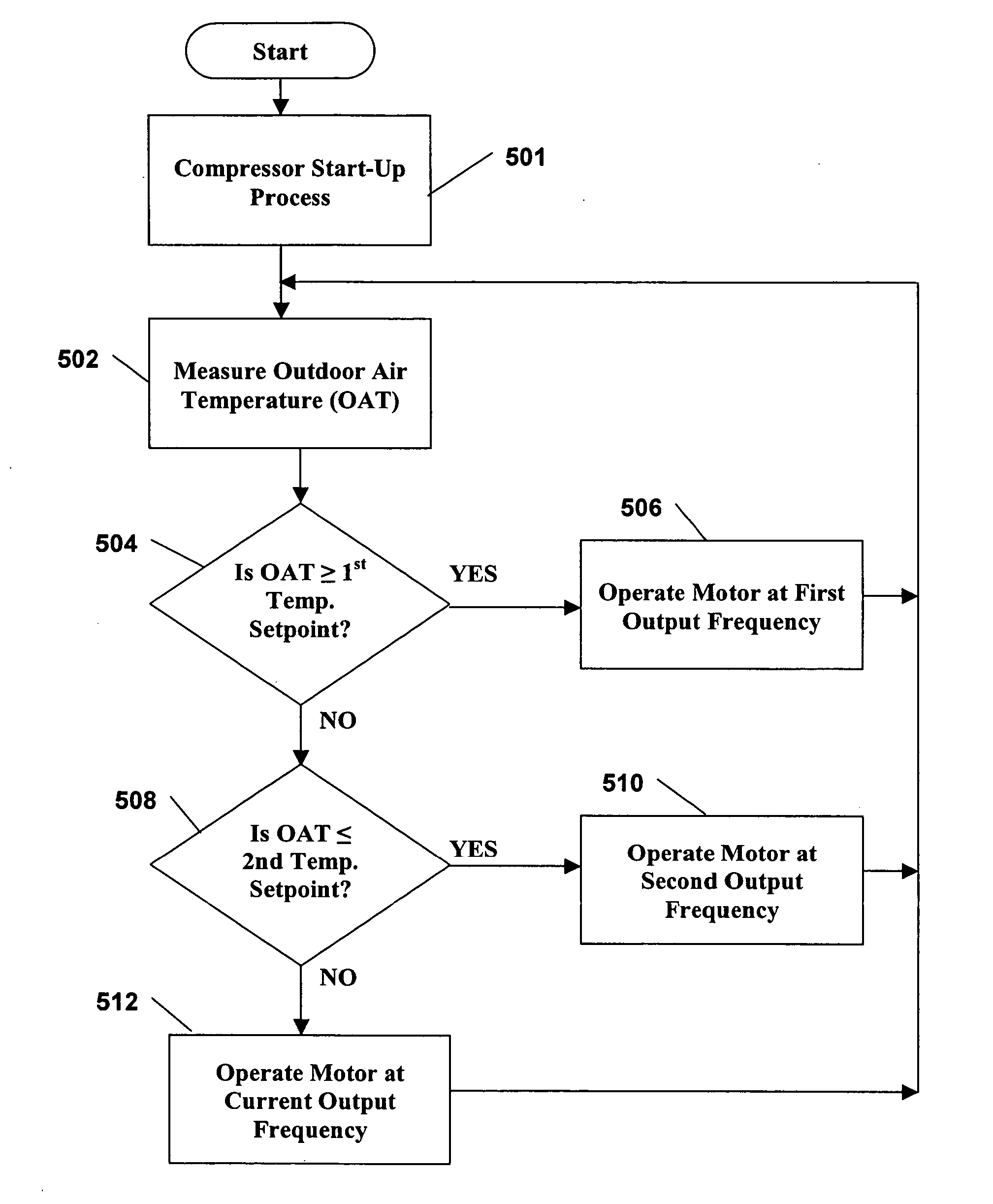

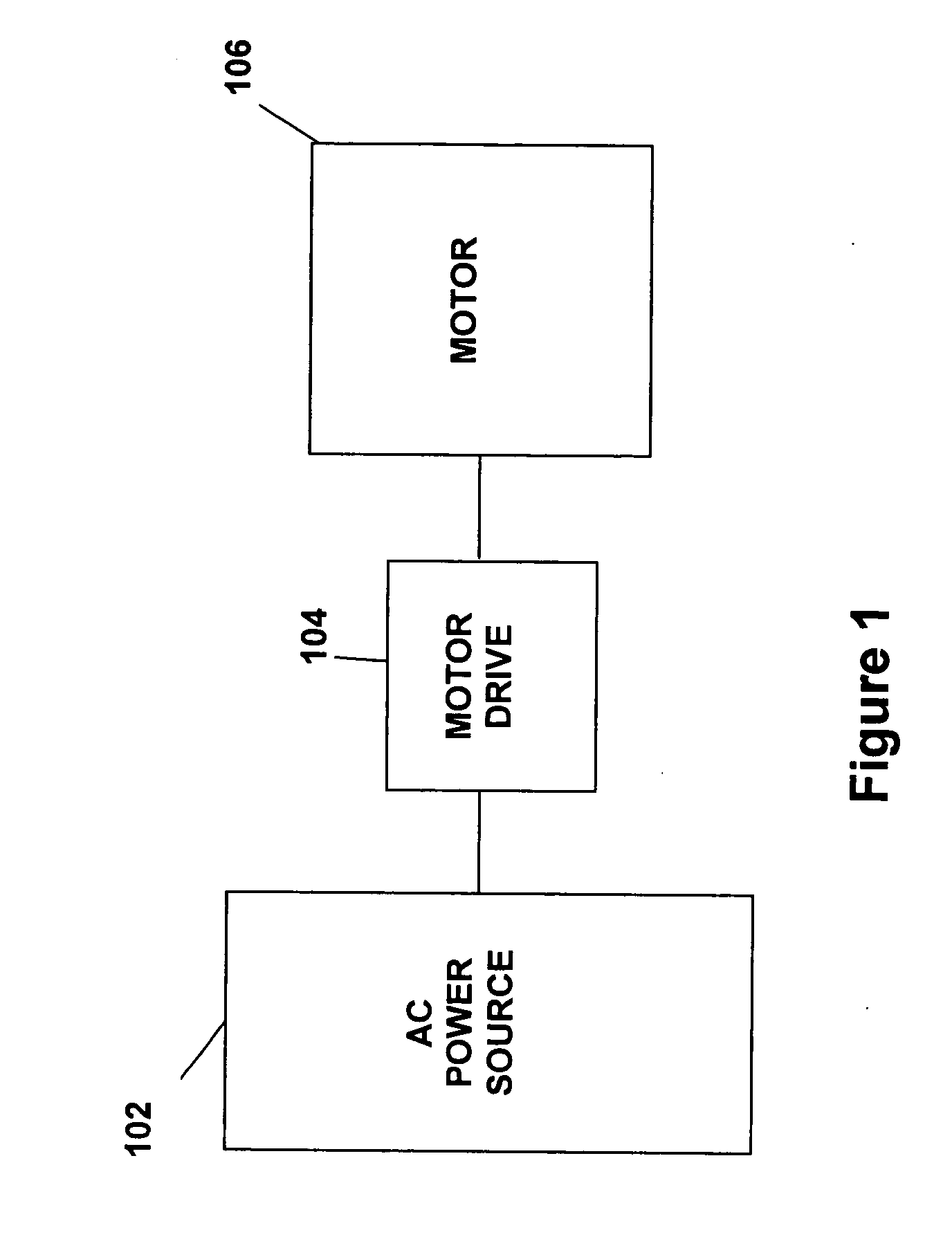

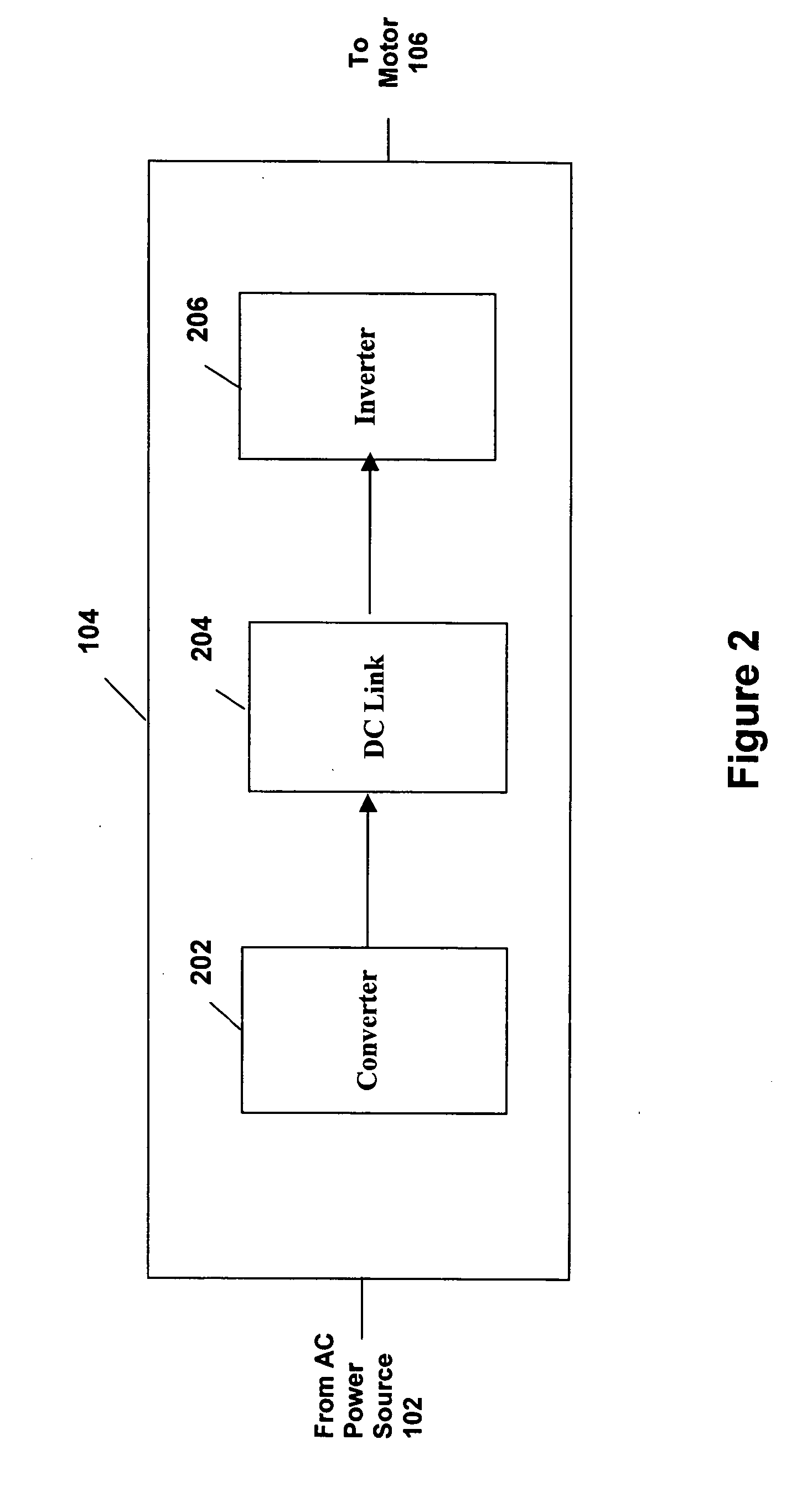

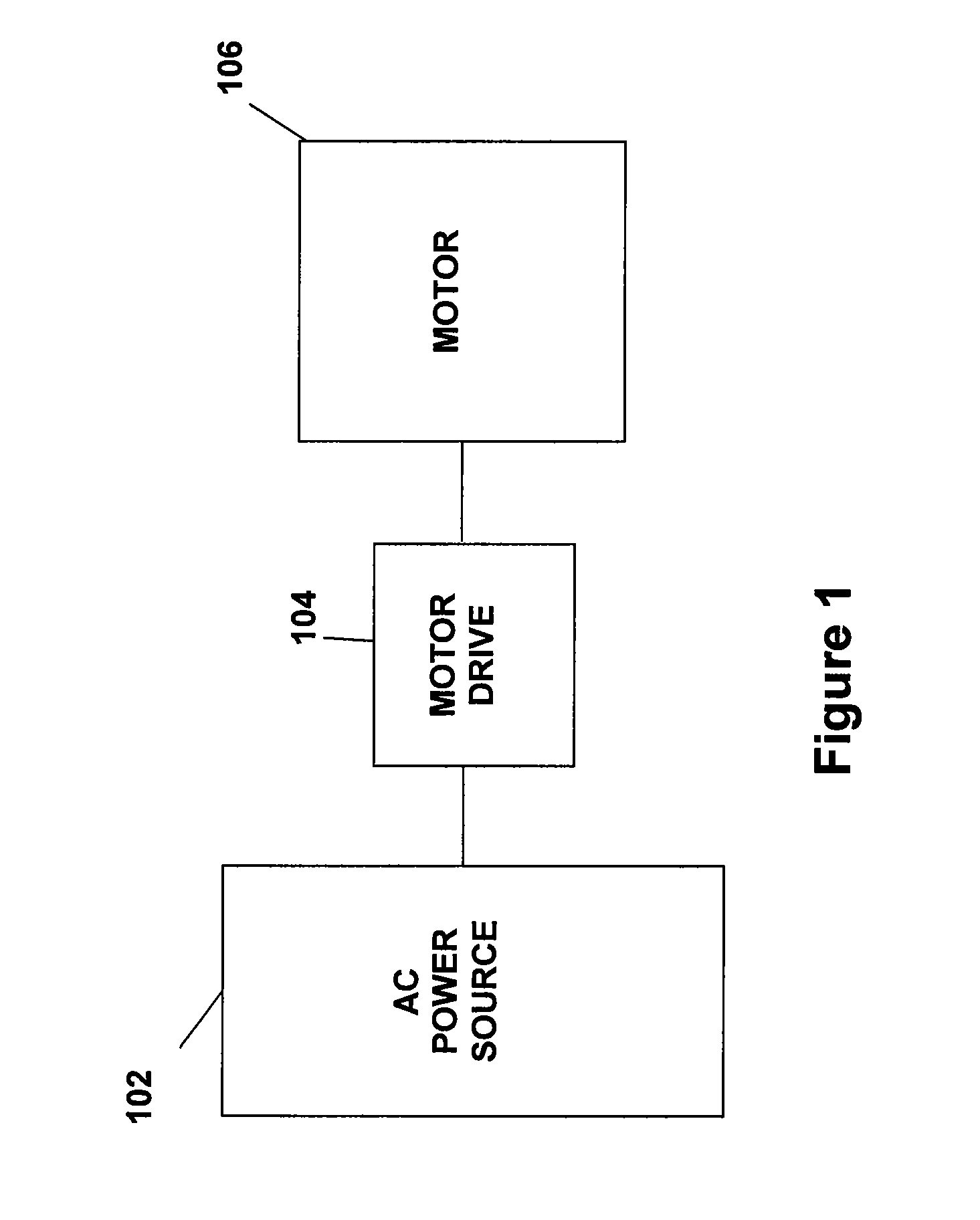

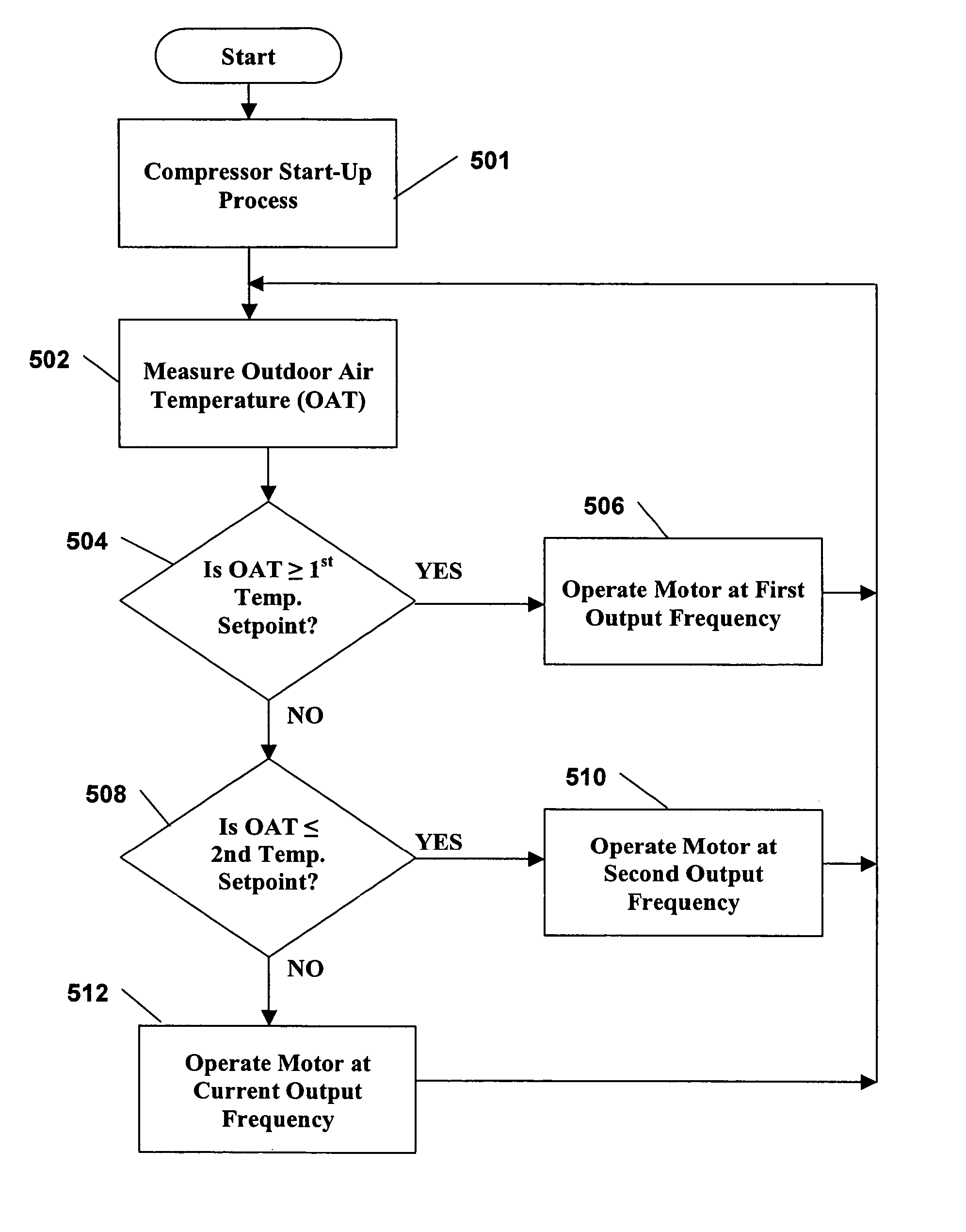

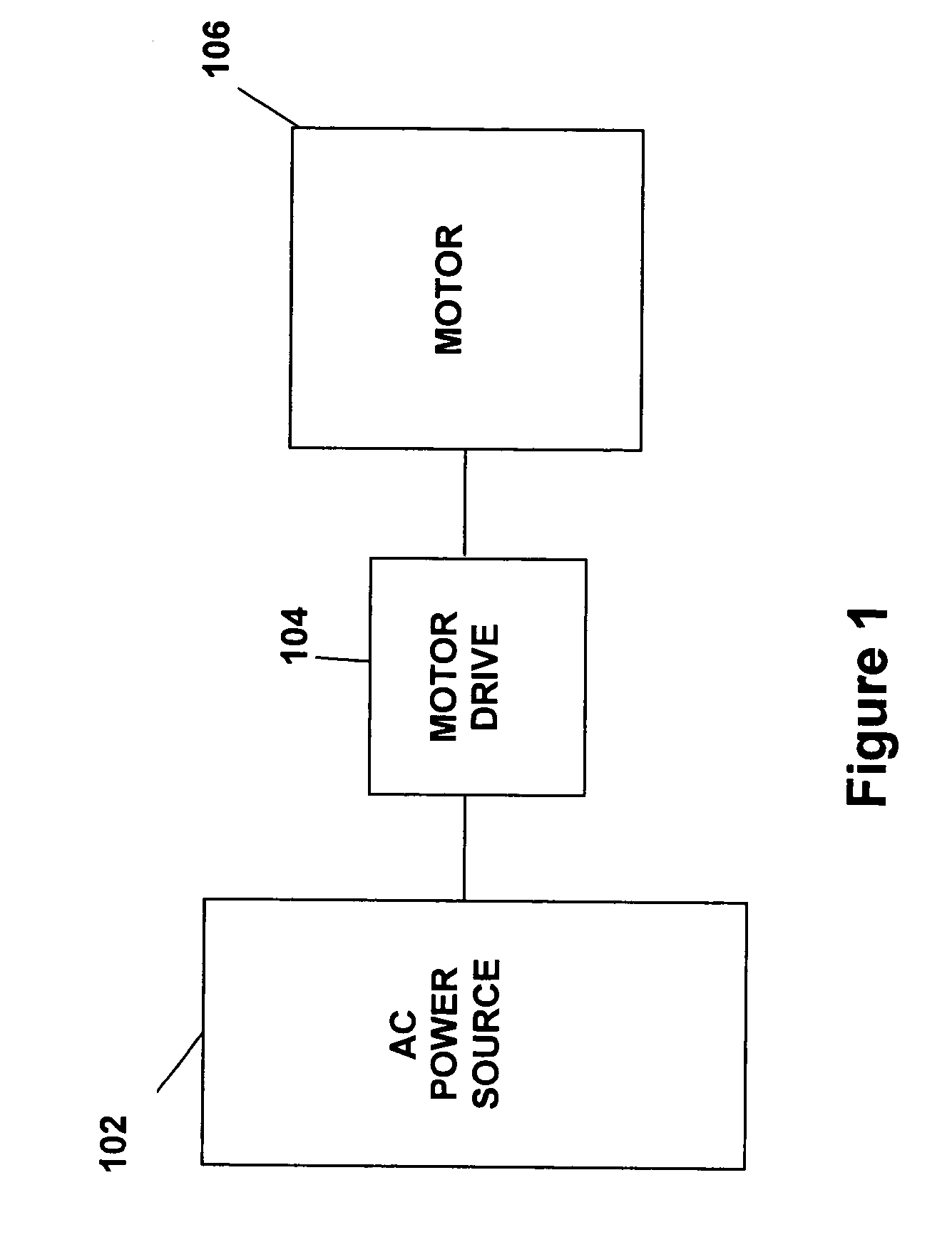

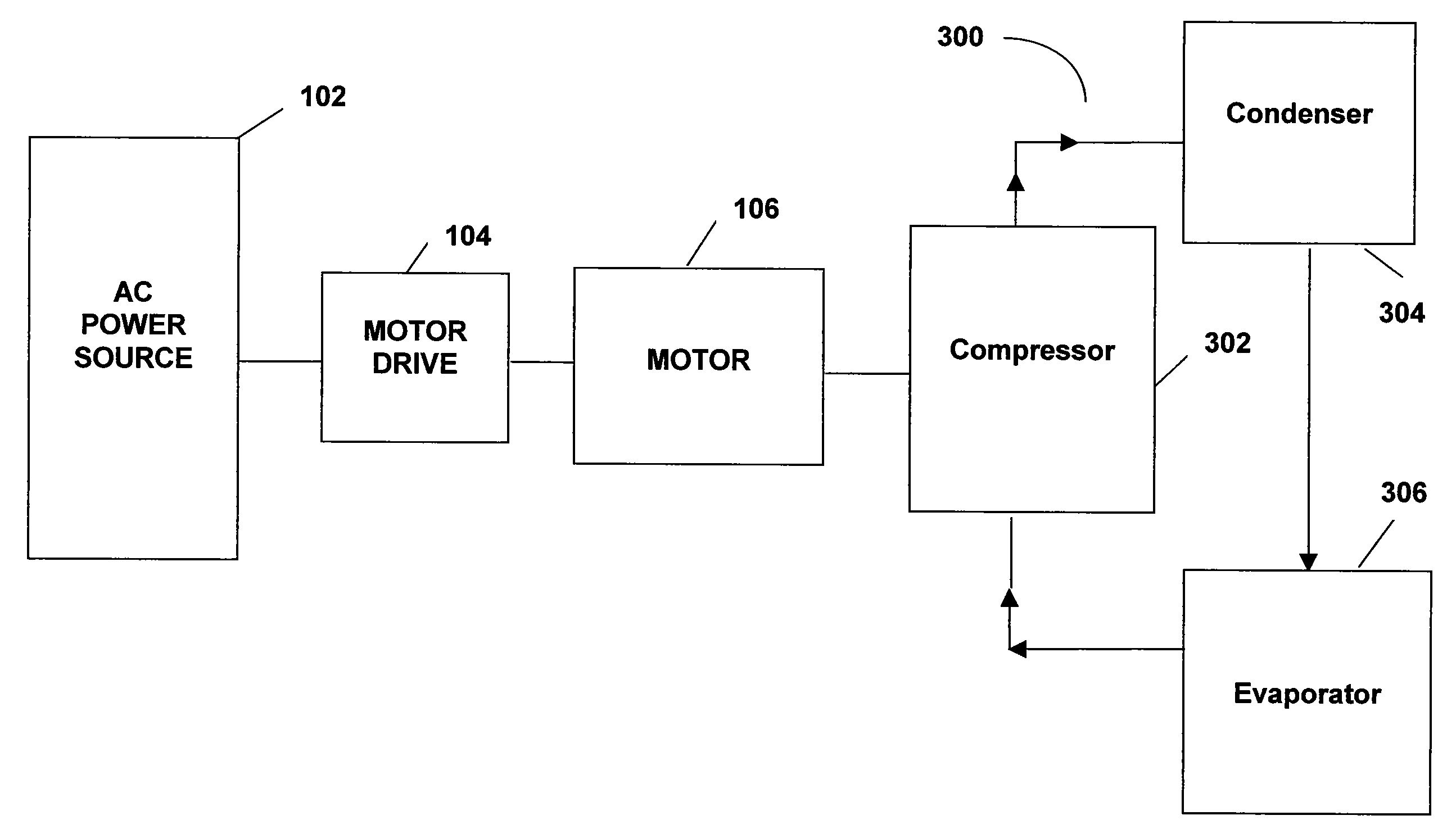

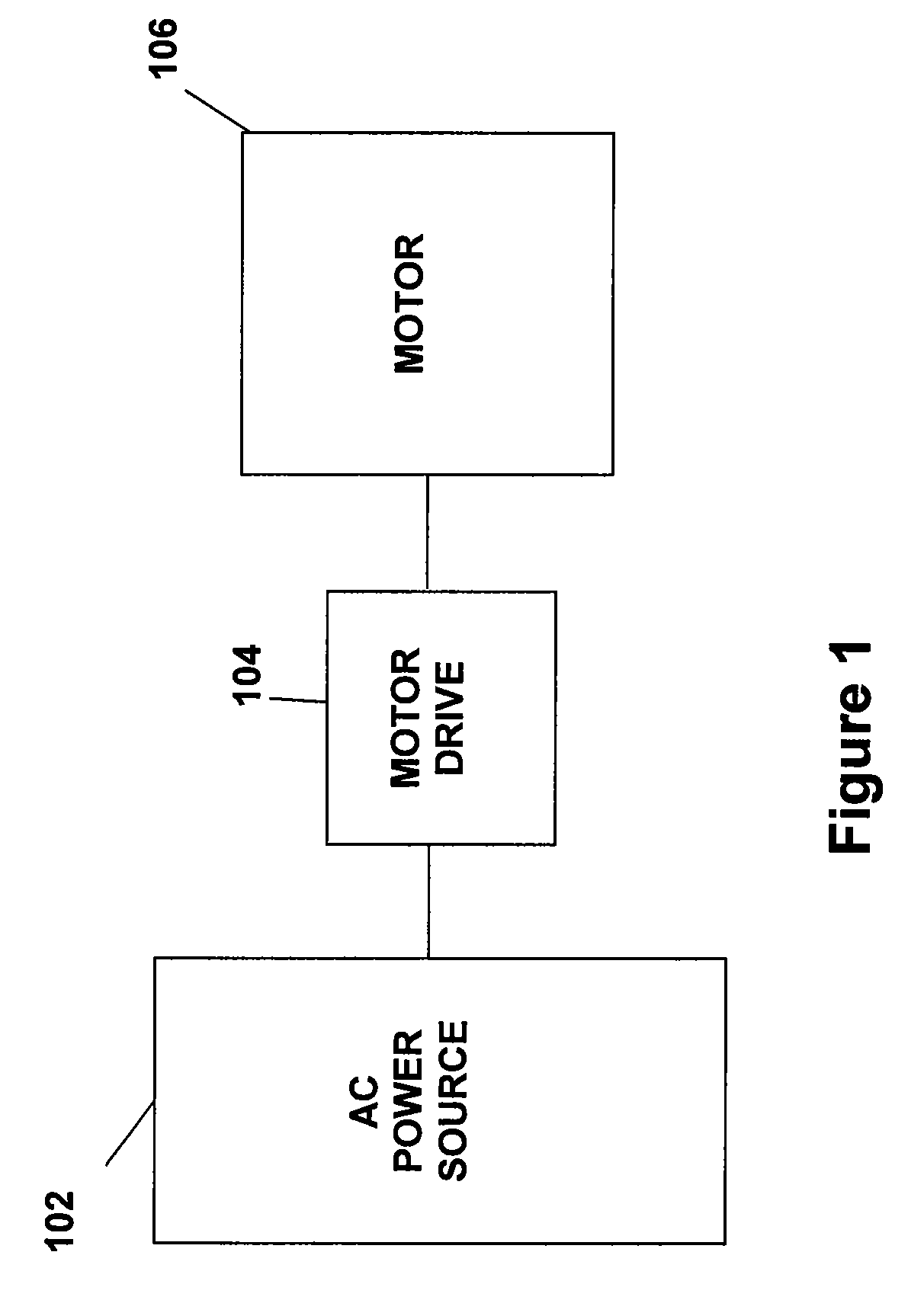

System and method for compressor capacity modulation

InactiveUS20070032909A1Increase capacityImprove efficiencySampled-variable control systemsComputer controlEngineeringOutdoor temperature

A system and method is provided to control and operate a compressor to have two or more discrete output capacities in response to an outdoor temperature measurement. During operation of the compressor in an air conditioning or cooling mode, the compressor has a first output capacity in response to the outdoor temperature being greater than a first temperature setpoint and the compressor has a second output capacity in response to the outdoor temperature being less than a second temperature setpoint.

Owner:BRISTOL COMPRESSORS INT

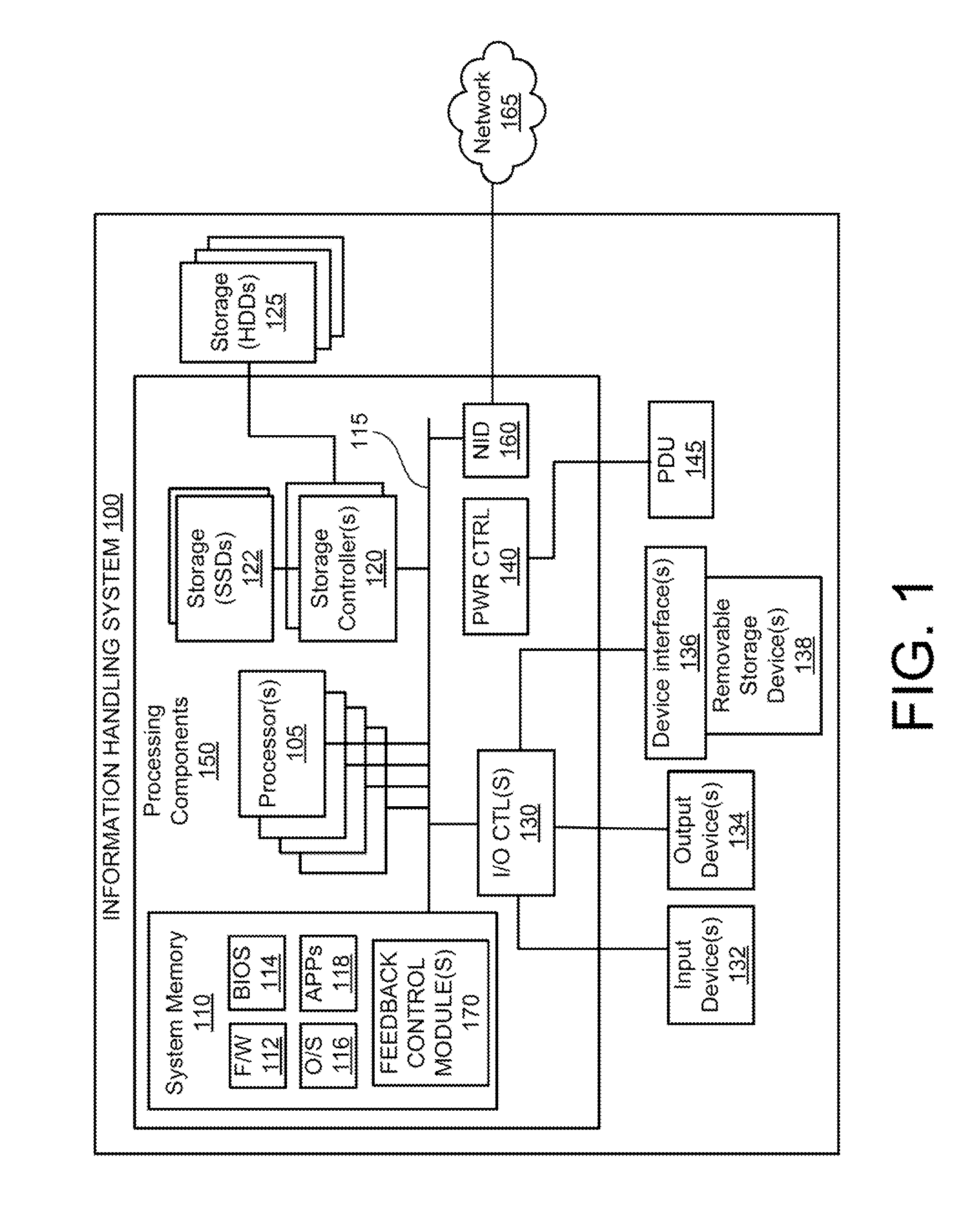

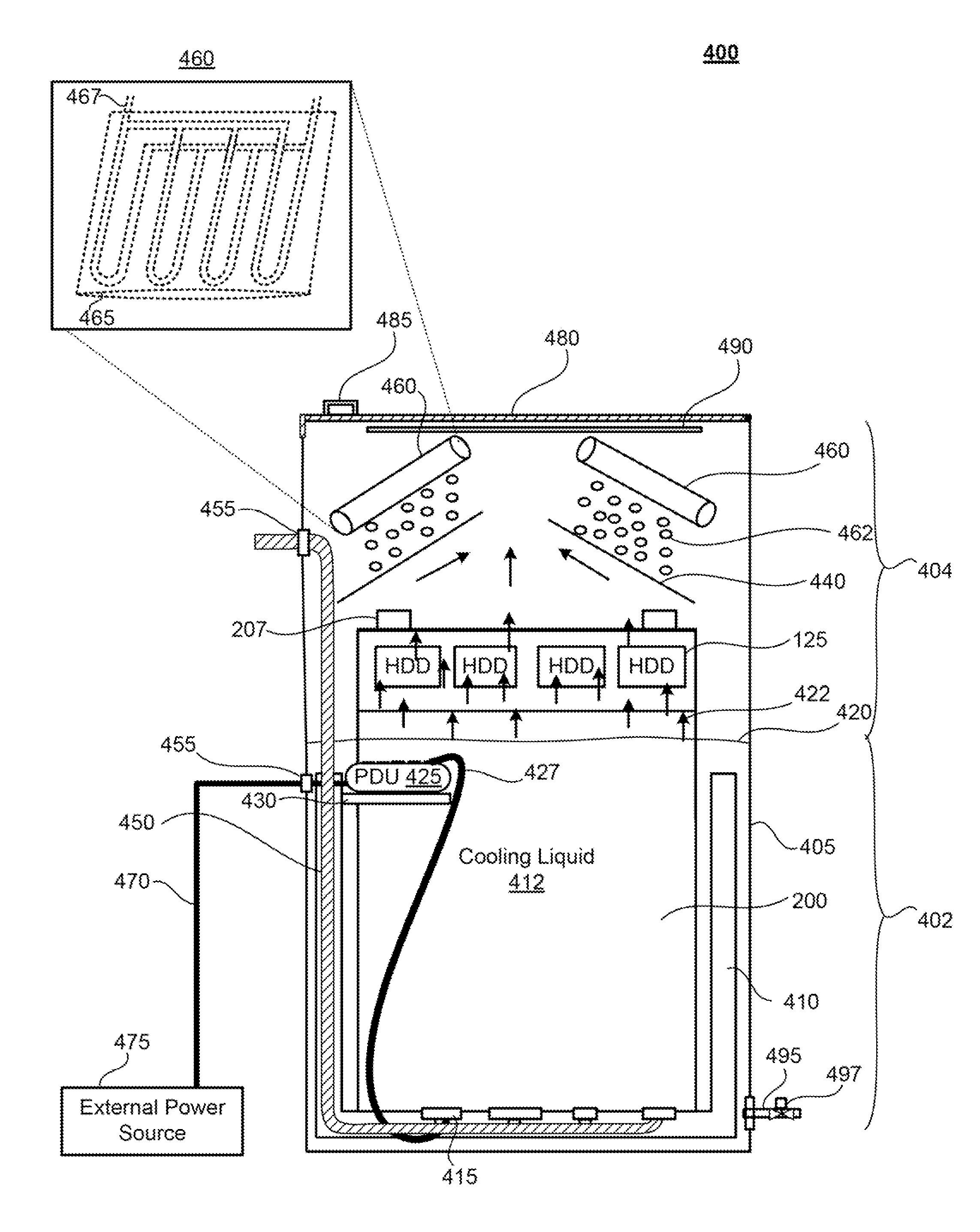

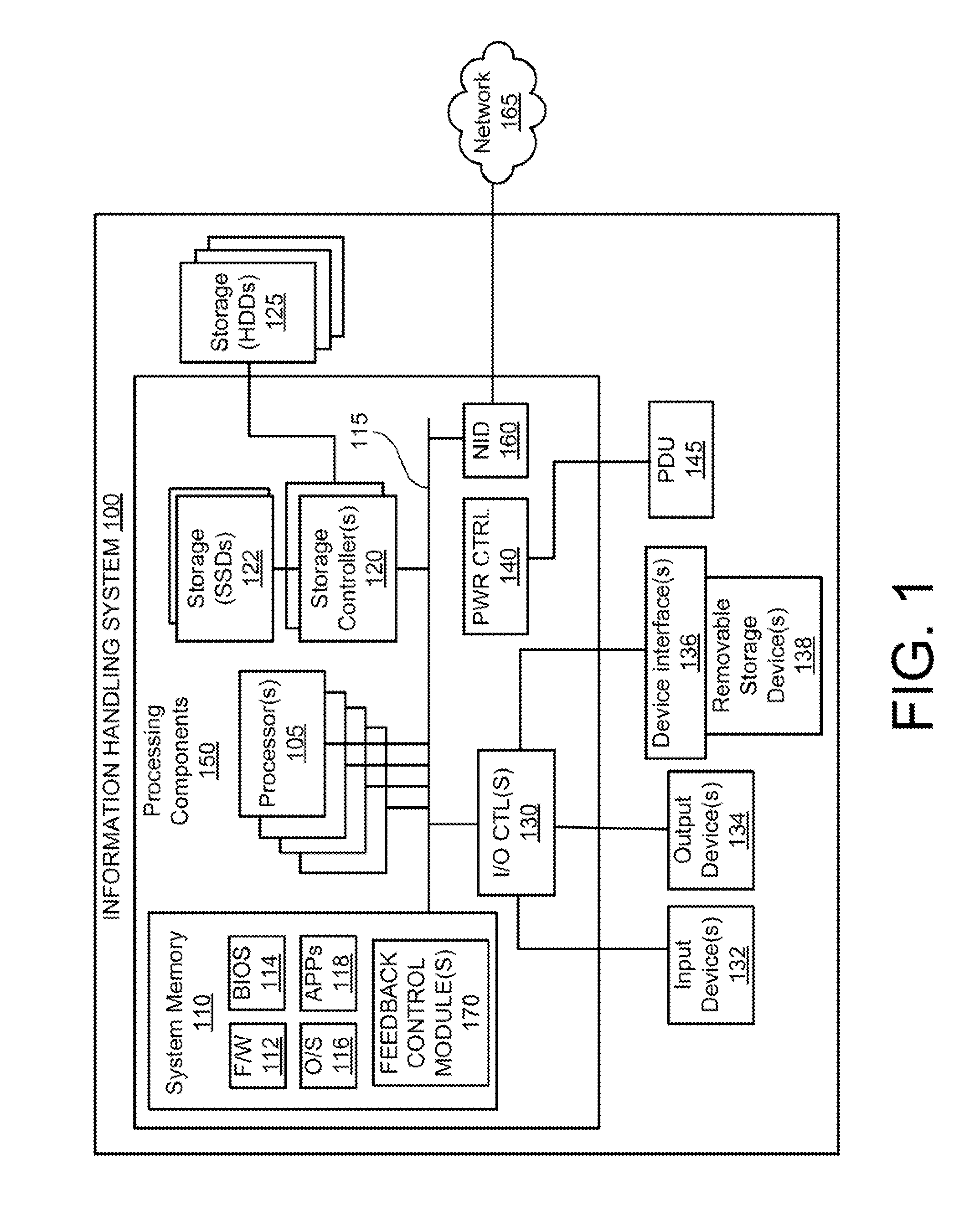

Techniques for Controlling Vapor Pressure in an Immersion Cooling Tank

ActiveUS20150060009A1Eliminate increase in pressureMaximize the effectAir-treating devicesTemperatue controlDifferential pressureTransducer

A method that controls pressure within an immersion cooling tank having condensation fluid flowing through a condenser, includes: a controller receiving a signal that indicates a current level of vapor pressure within the tank; determining from the signal when the current level of vapor pressure exceeds or is below a first preset threshold pressure level; and in response to the current level of vapor pressure exceeding or being below the first preset threshold pressure level, signaling a flow control mechanism that modulates a flow rate of the condensation fluid through the condenser to increase or decrease the rate of flow from a current rate of flow. The controller receives the signal by a pressure sensor within the immersion cooling tank detecting the current vapor pressure, generating the signal and forwarding the signal to the controller. The pressure sensor can be a differential pressure transducer that measures a differential pressure internal to and outside of the immersion tank.

Owner:DELL PROD LP

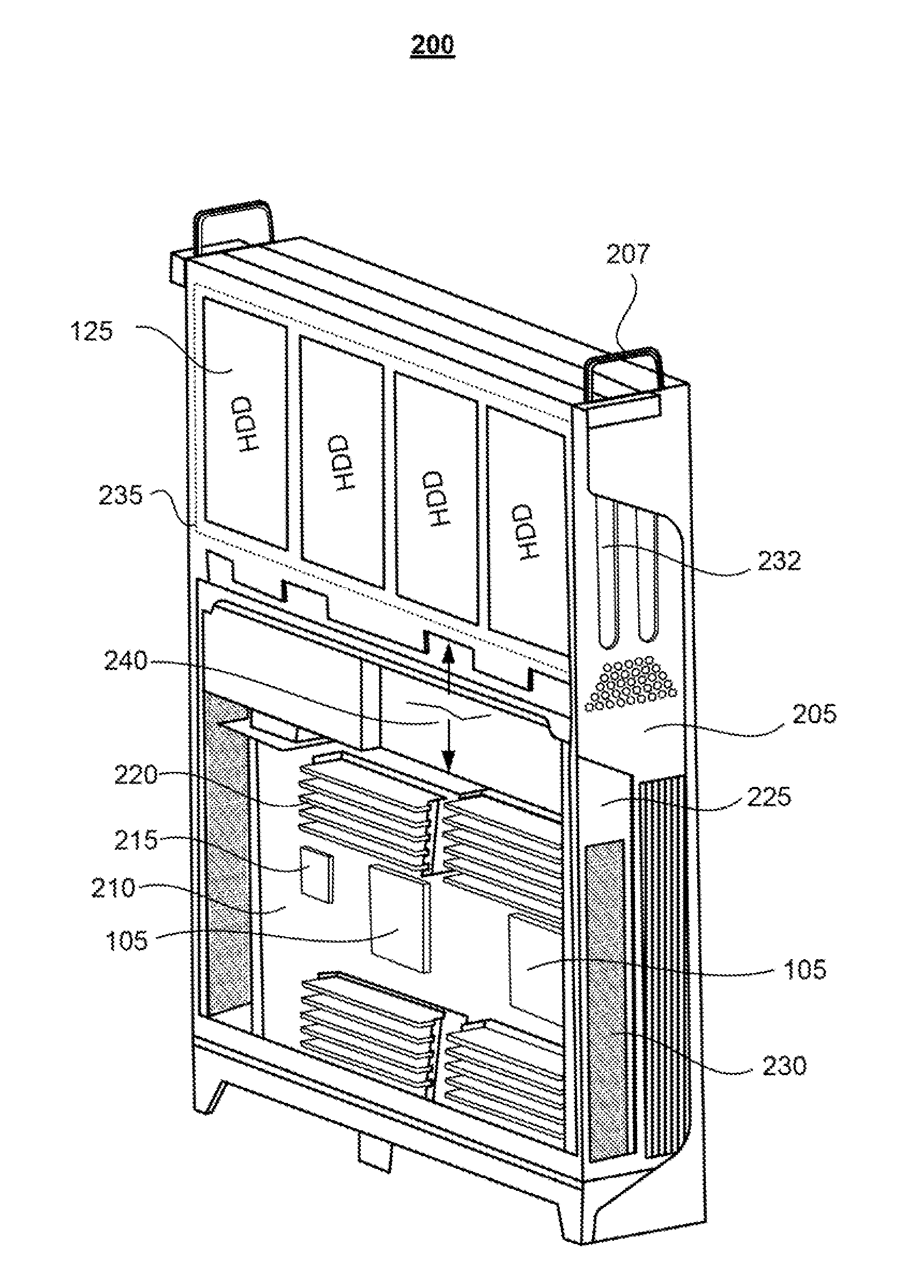

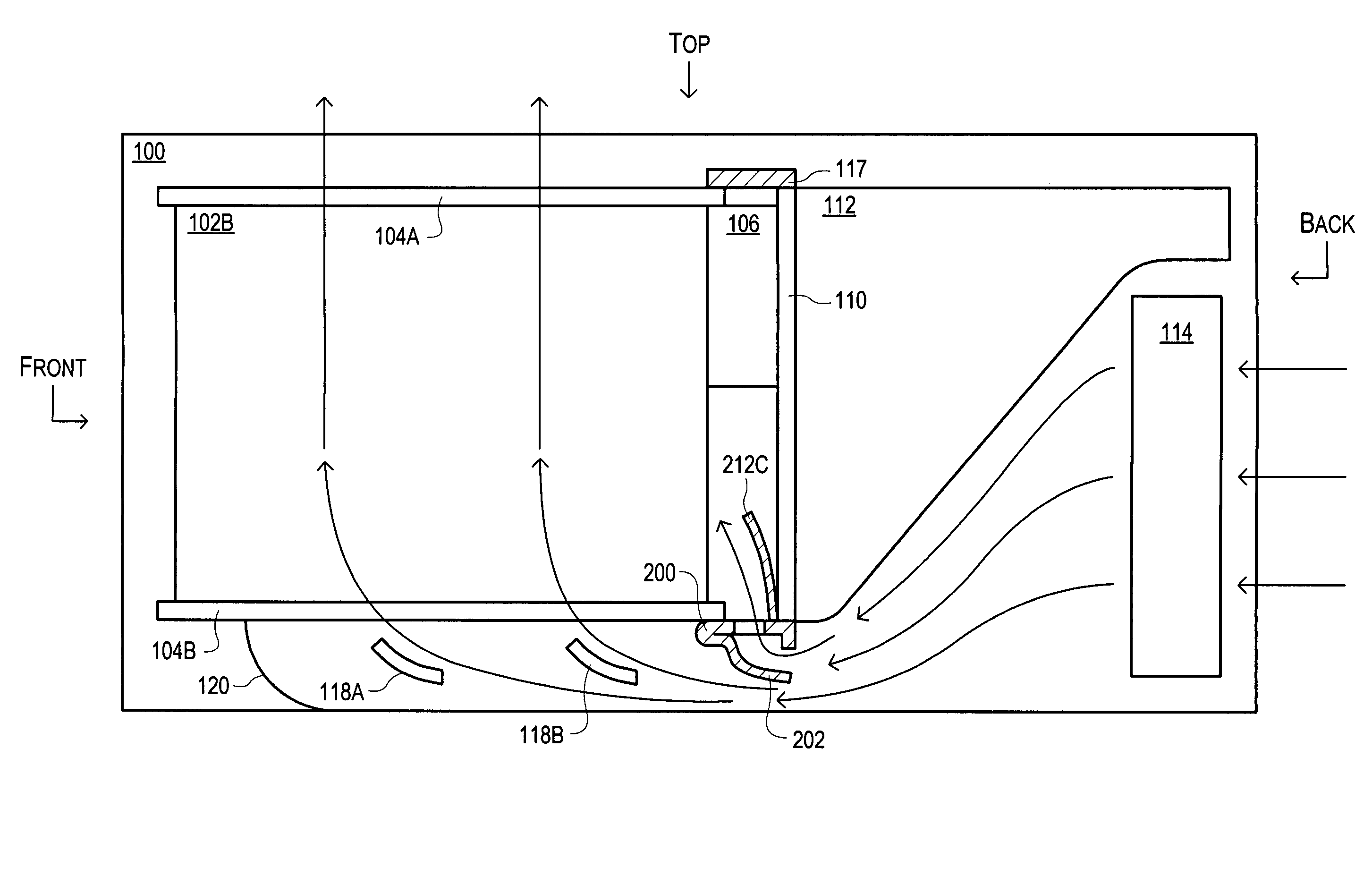

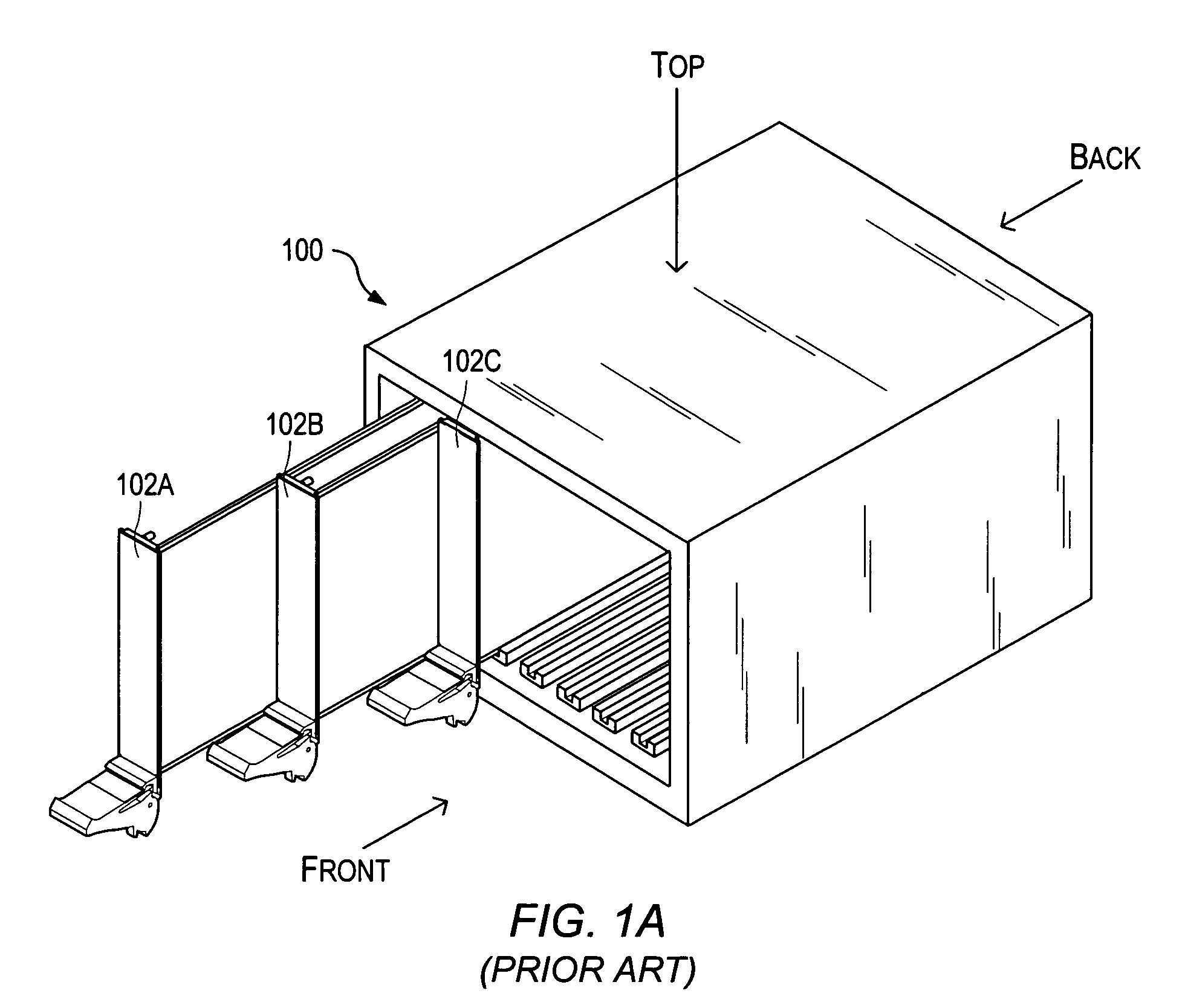

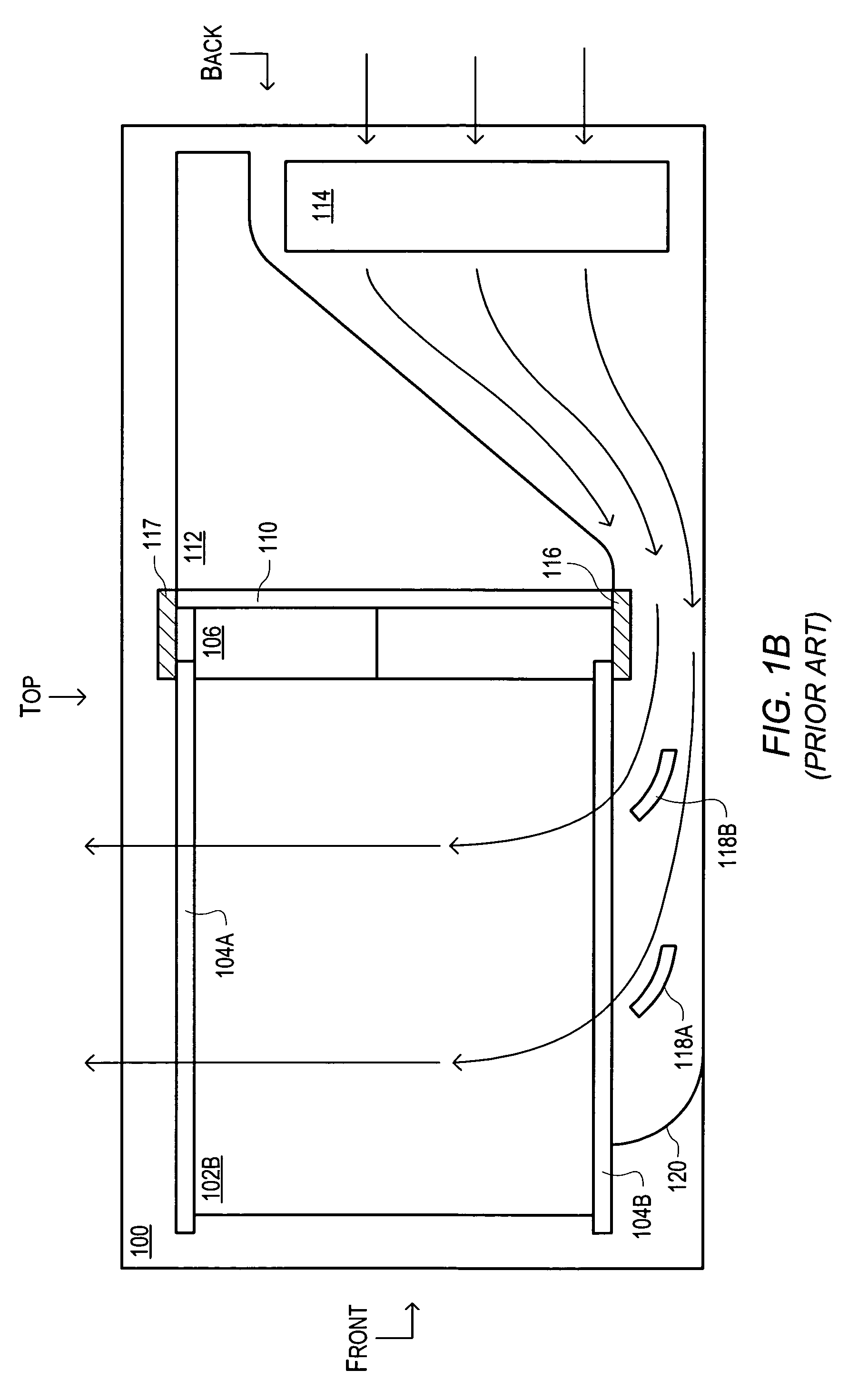

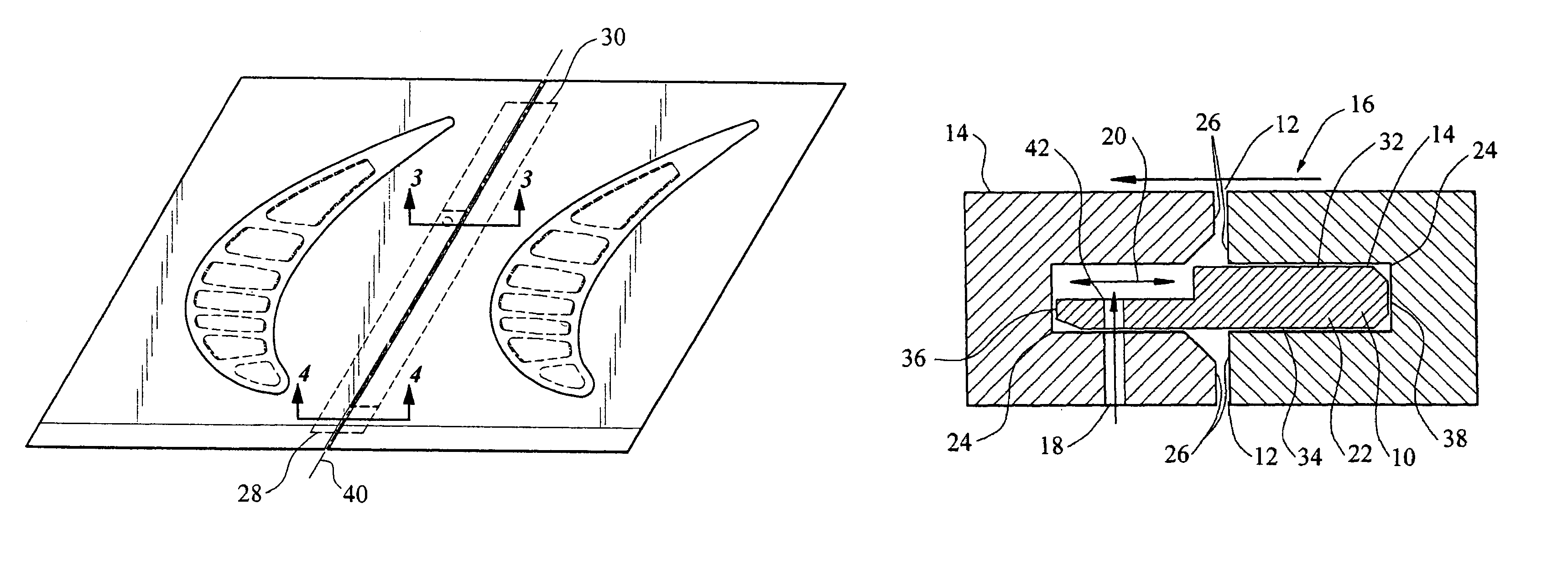

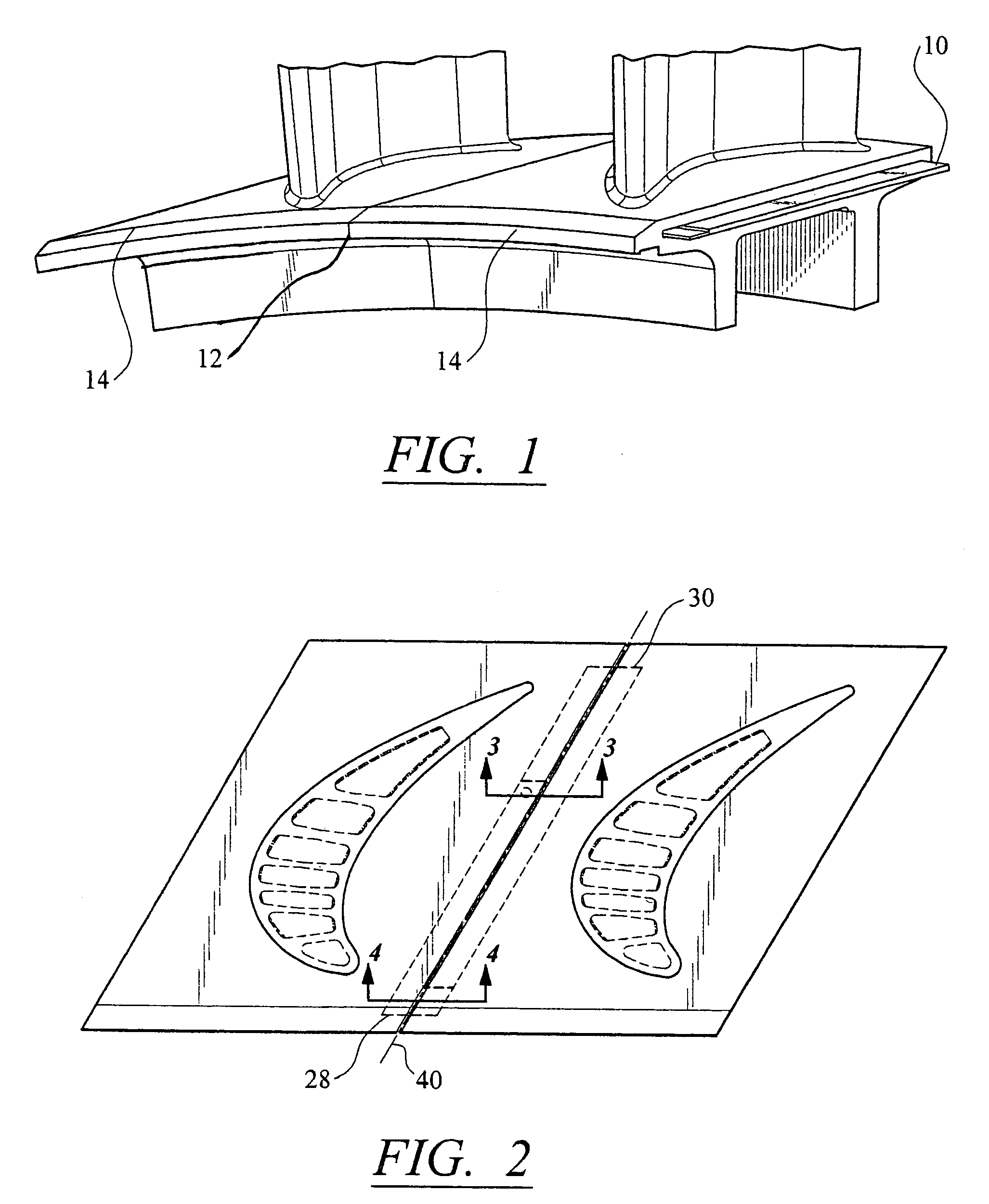

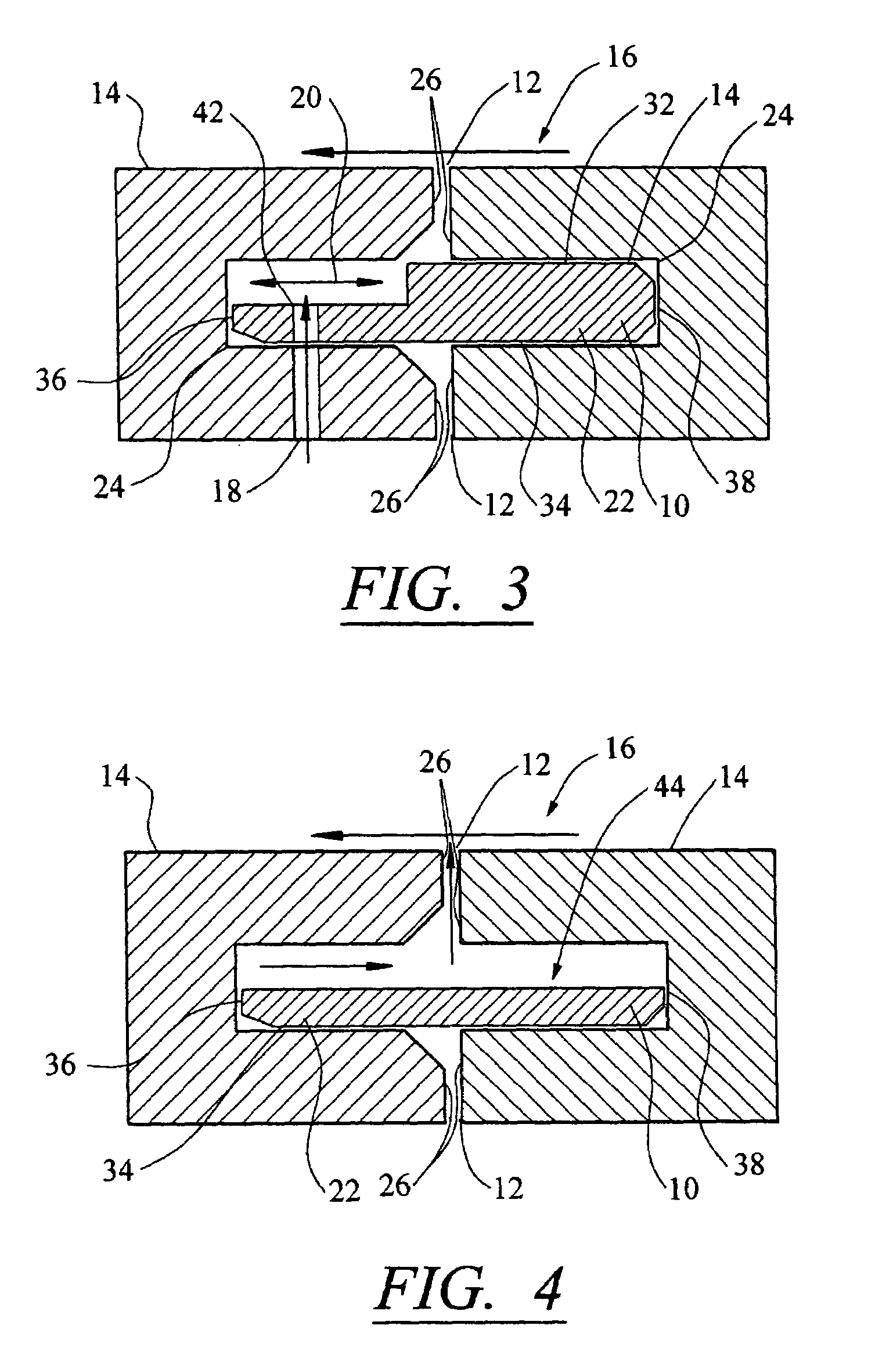

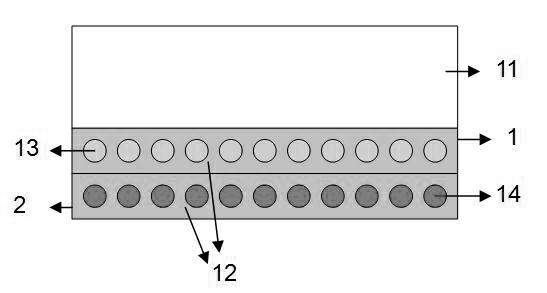

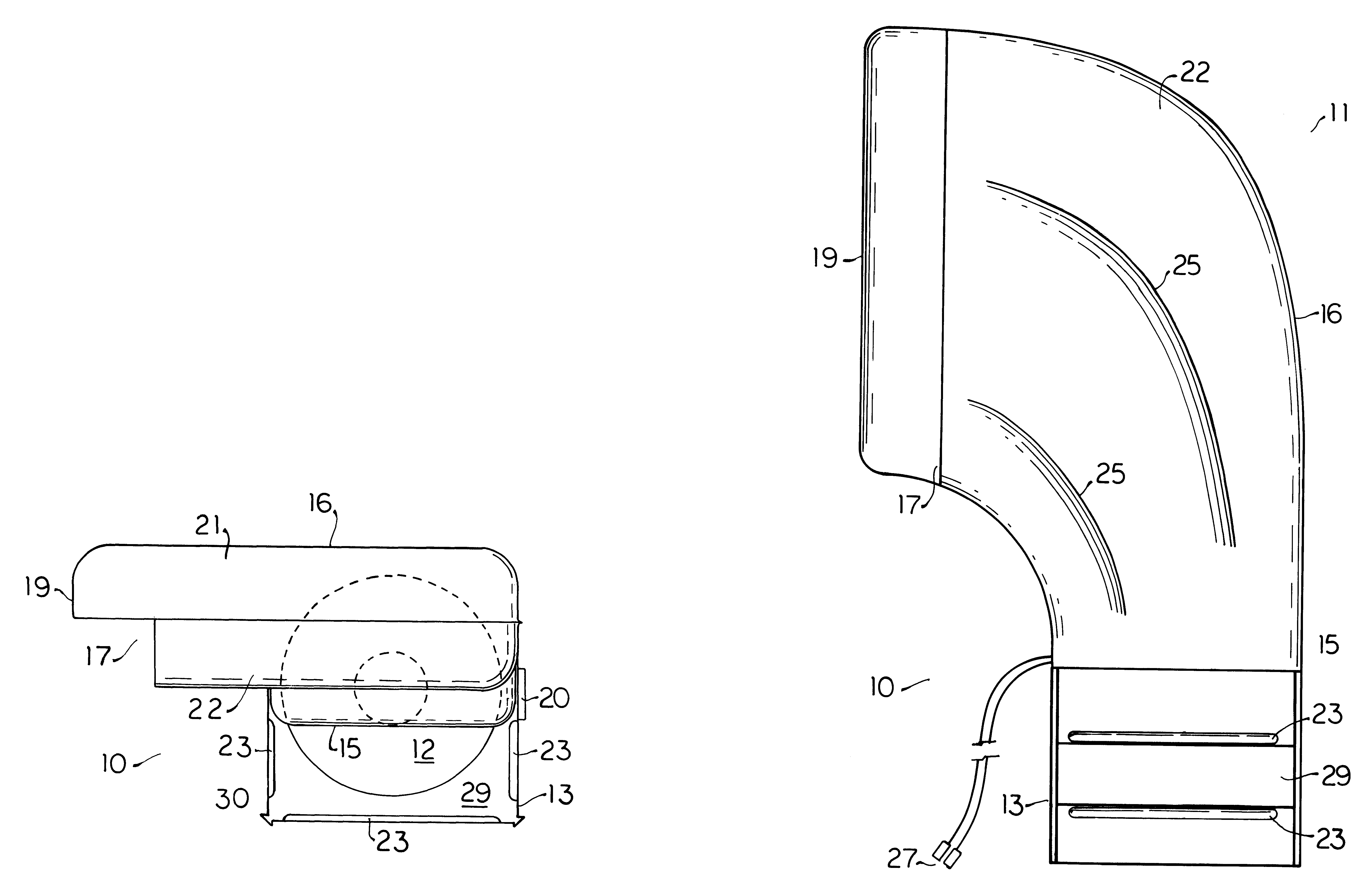

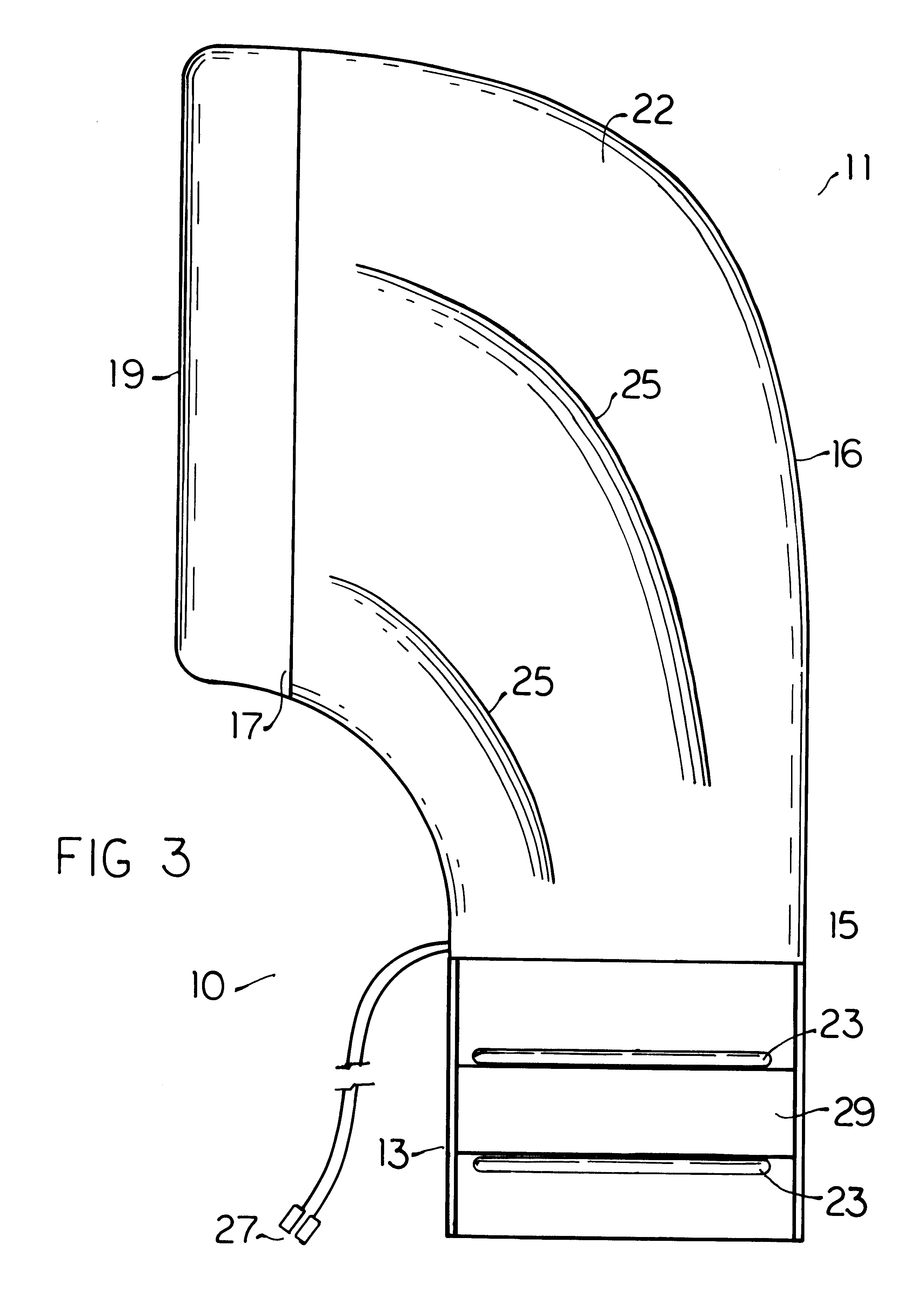

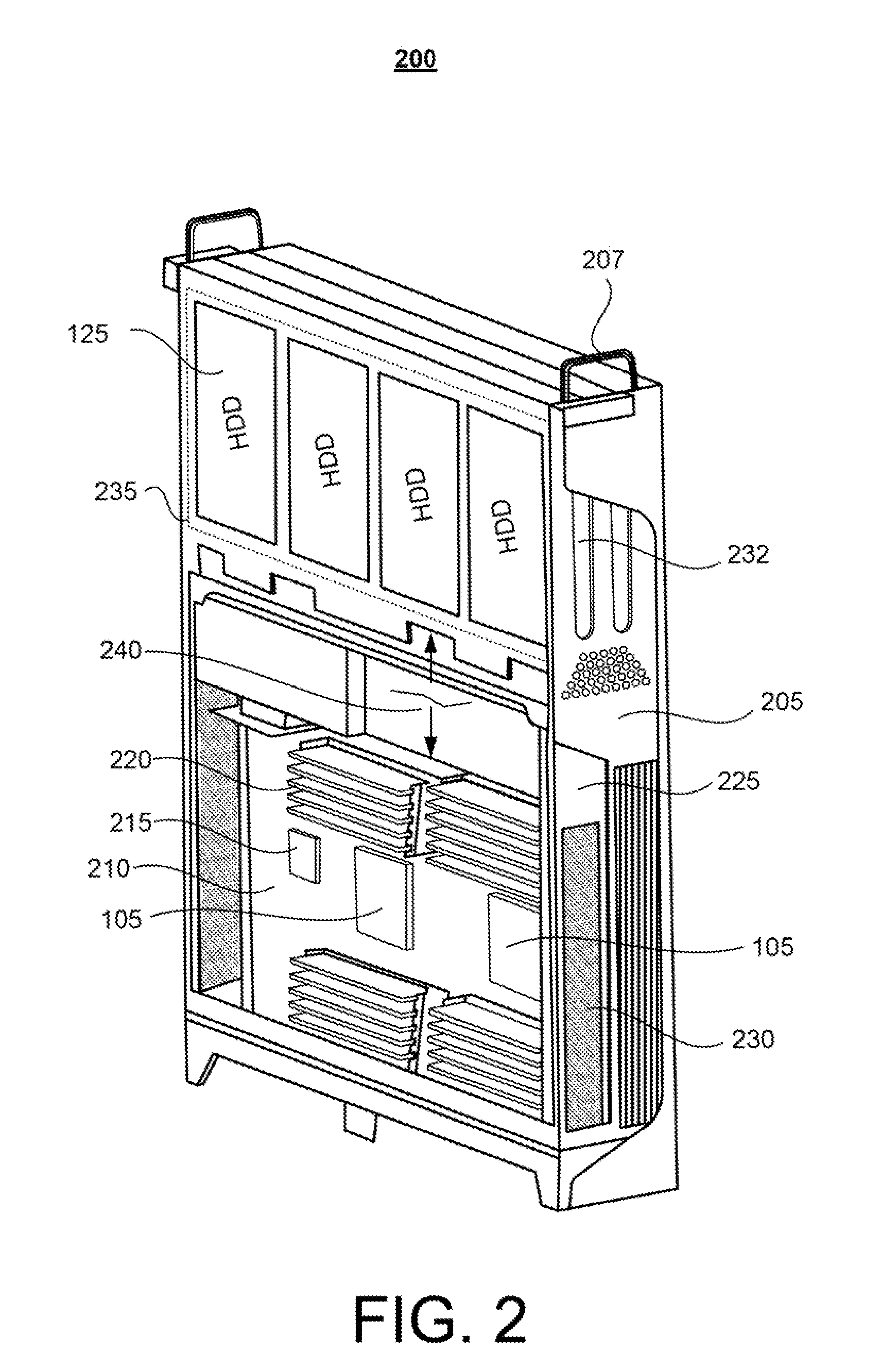

Vented and ducted sub-rack support member

ActiveUS7355850B2Increase airflowReduce ambient temperatureCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersEngineeringBackplane

A chassis for plug-in modules may be provided with a vented and ducted sub-rack support member. The vented and ducted sub-rack support member may deflect a portion of the air flowing within the chassis through vents in the top surface of the vented and ducted sub-rack support member in order to increase the air flow to heat producing components mounted on the backplane above the support member. The increased air flow may increase air flow velocity and decrease the ambient temperature of the air around these components and improve the dissipation of heat from each component into the air. Air flow above the vented and ducted sub-rack support member may also be redirected by upper deflectors mounted on the support member to portions of plug-in cards adjacent to the upper deflectors and may provide additional cooling to components on the plug-in cards near the backplane.

Owner:NATIONAL INSTRUMENTS

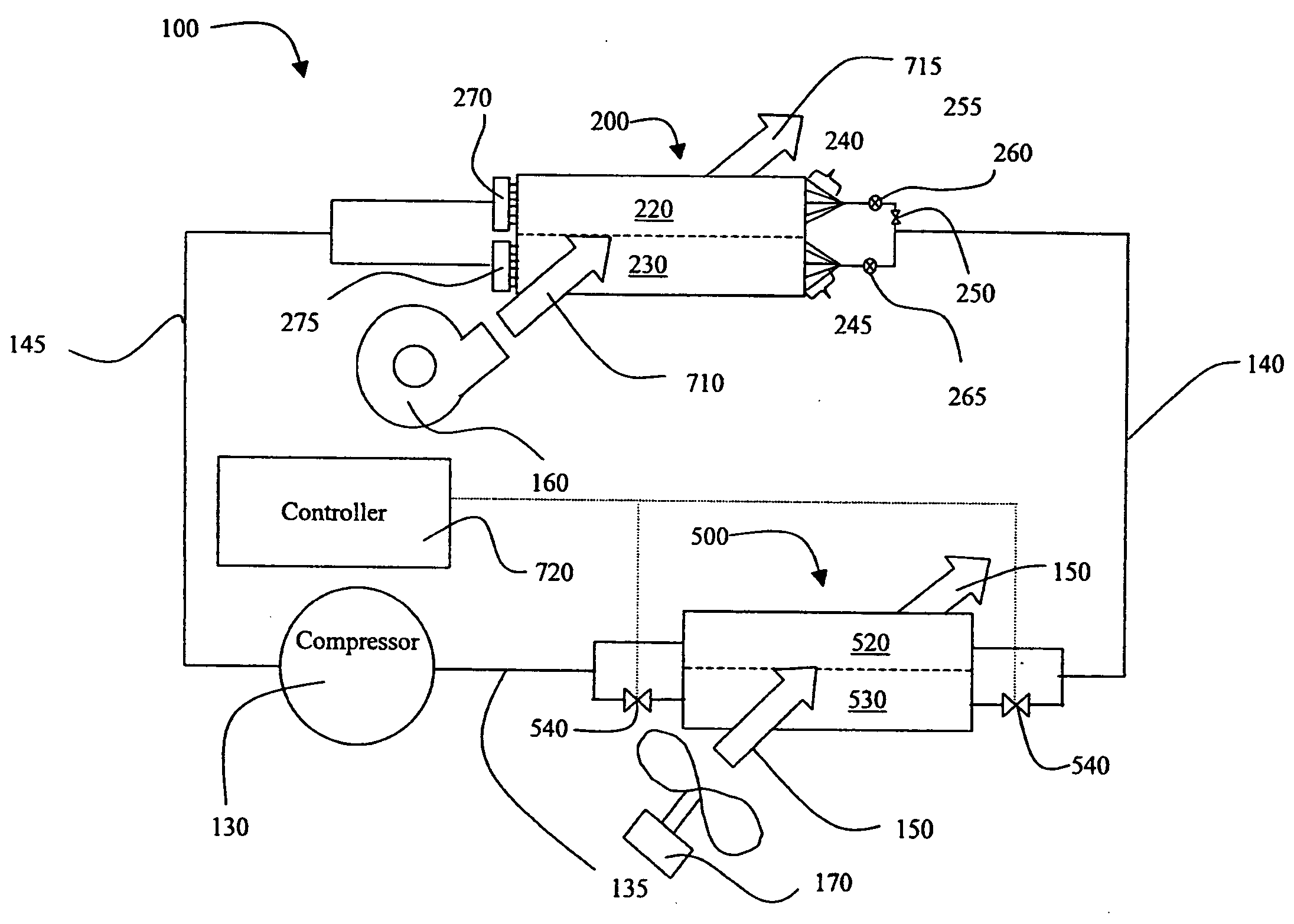

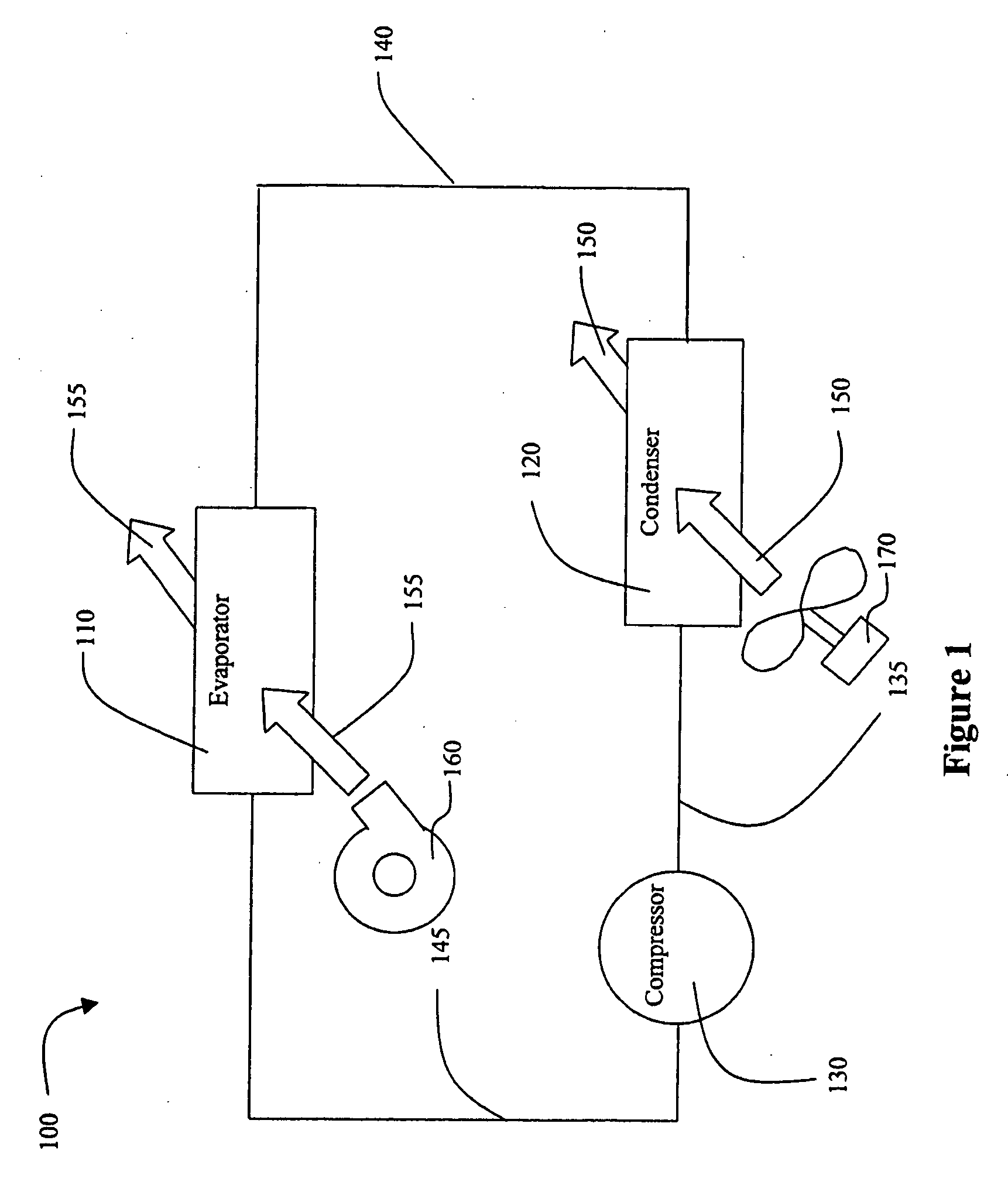

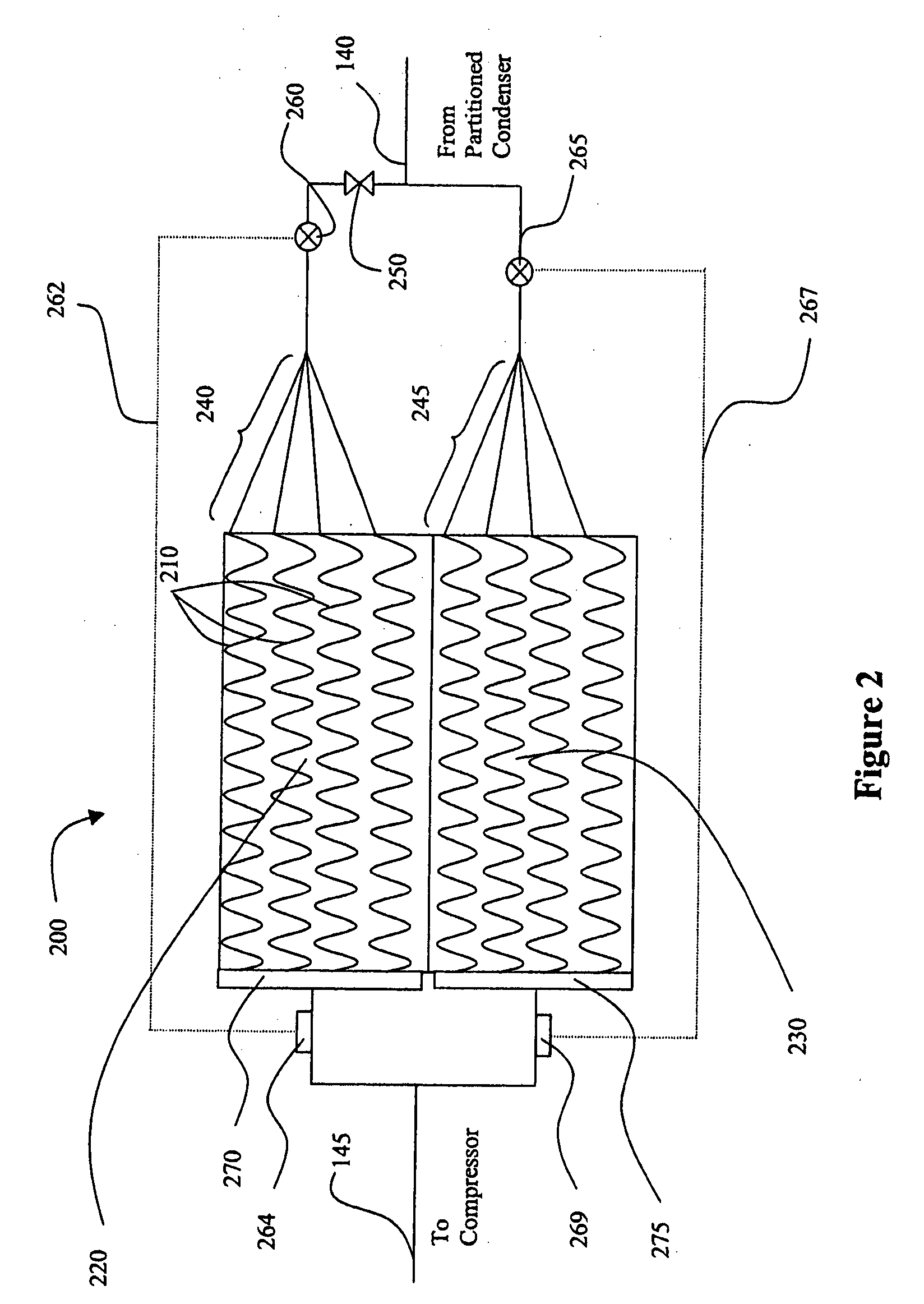

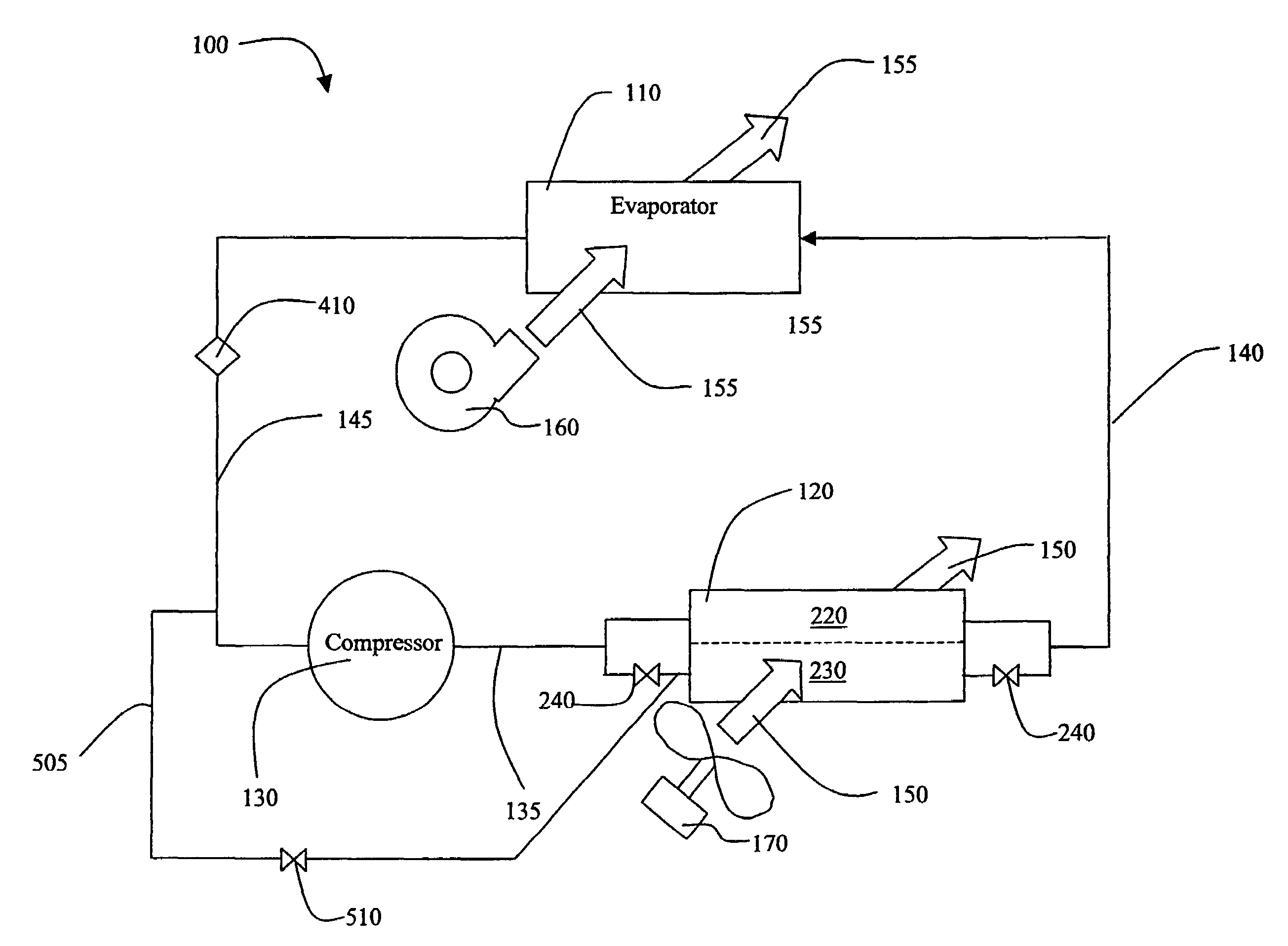

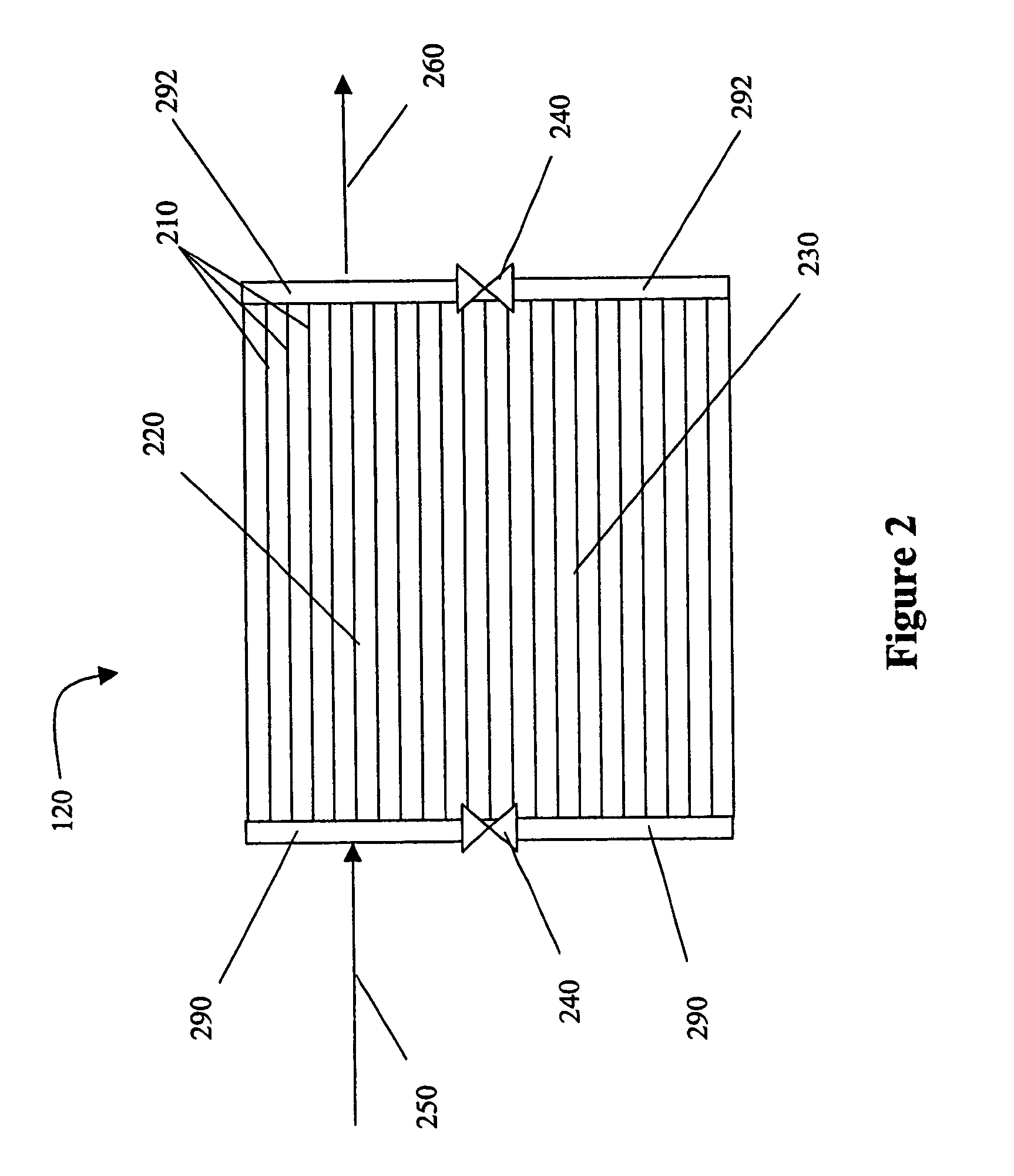

Method and system for dehumidification and refrigerant pressure control

InactiveUS20060288713A1Prevent freezingIncrease system pressureEvaporators/condensersCompression machines with several evaporatorsControl systemSystem pressure

A method for dehumidification and controlling system pressure in a refrigeration system includes providing a refrigeration system having a compressor, a condenser and an evaporator connected in a closed refrigerant loop. Each of the condenser and evaporator have a plurality of refrigerant circuits. A first heat transfer fluid is flowed over the condenser and a second heat transfer fluid is flowed over the evaporator. At least one of the refrigerant circuits of the condenser is isolated to provide a decreased amount of heat transfer area within the condenser and to increase the refrigerant pressure within the refrigeration system when the refrigerant pressure within the refrigeration system is at or below a predetermined pressure. At least one of the refrigerant circuits of the evaporator is isolated to dehumidify and maintain the temperature of the second heat transfer fluid at or above a predetermined temperature when dehumidification is required.

Owner:YORK INT CORP

Cooling system for a seal for turbine vane shrouds

InactiveUS7217081B2Avoid premature failureIncrease temperaturePump componentsSealingTurbine bladeCooling fluid

Owner:SIEMENS ENERGY INC

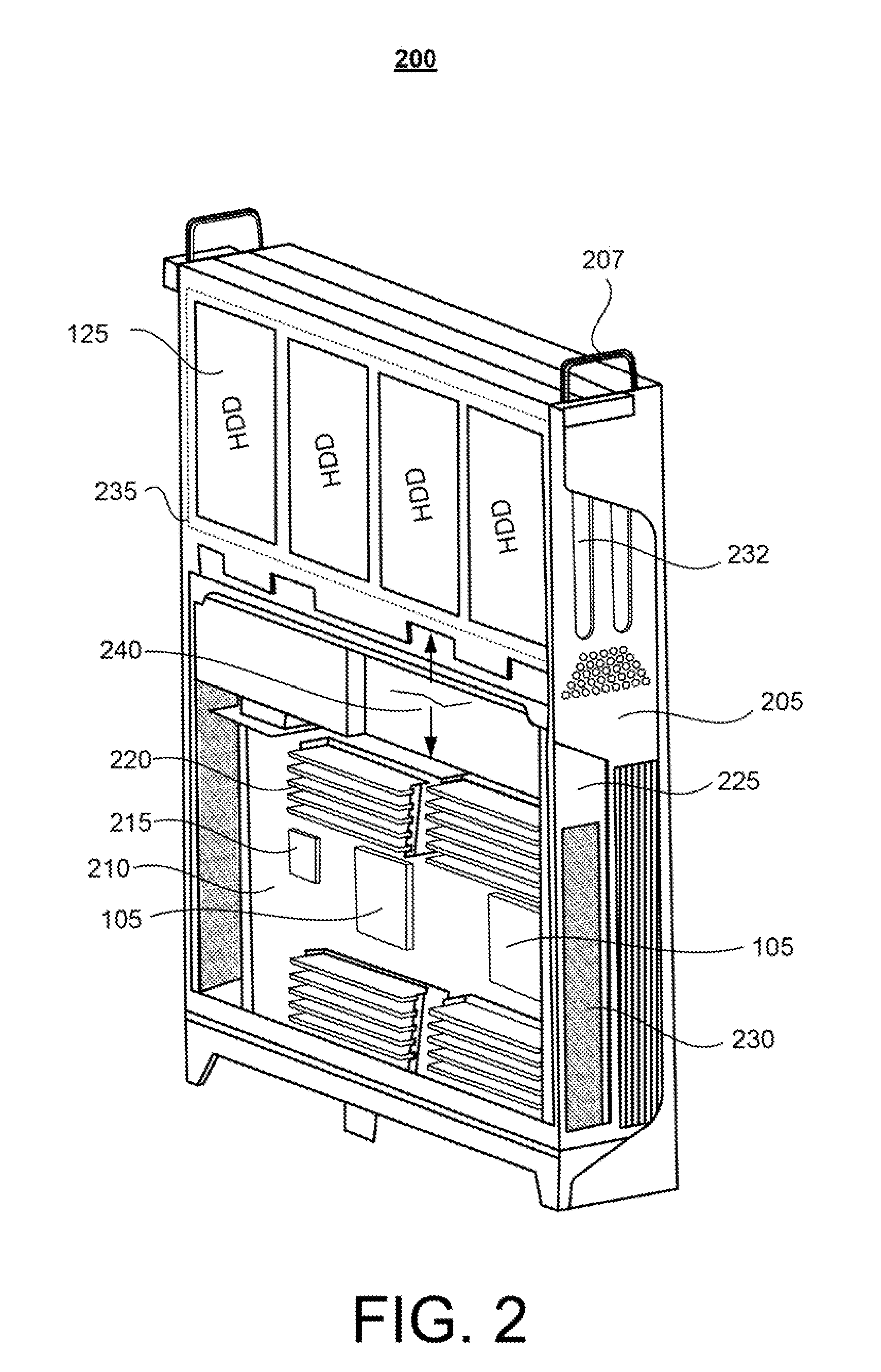

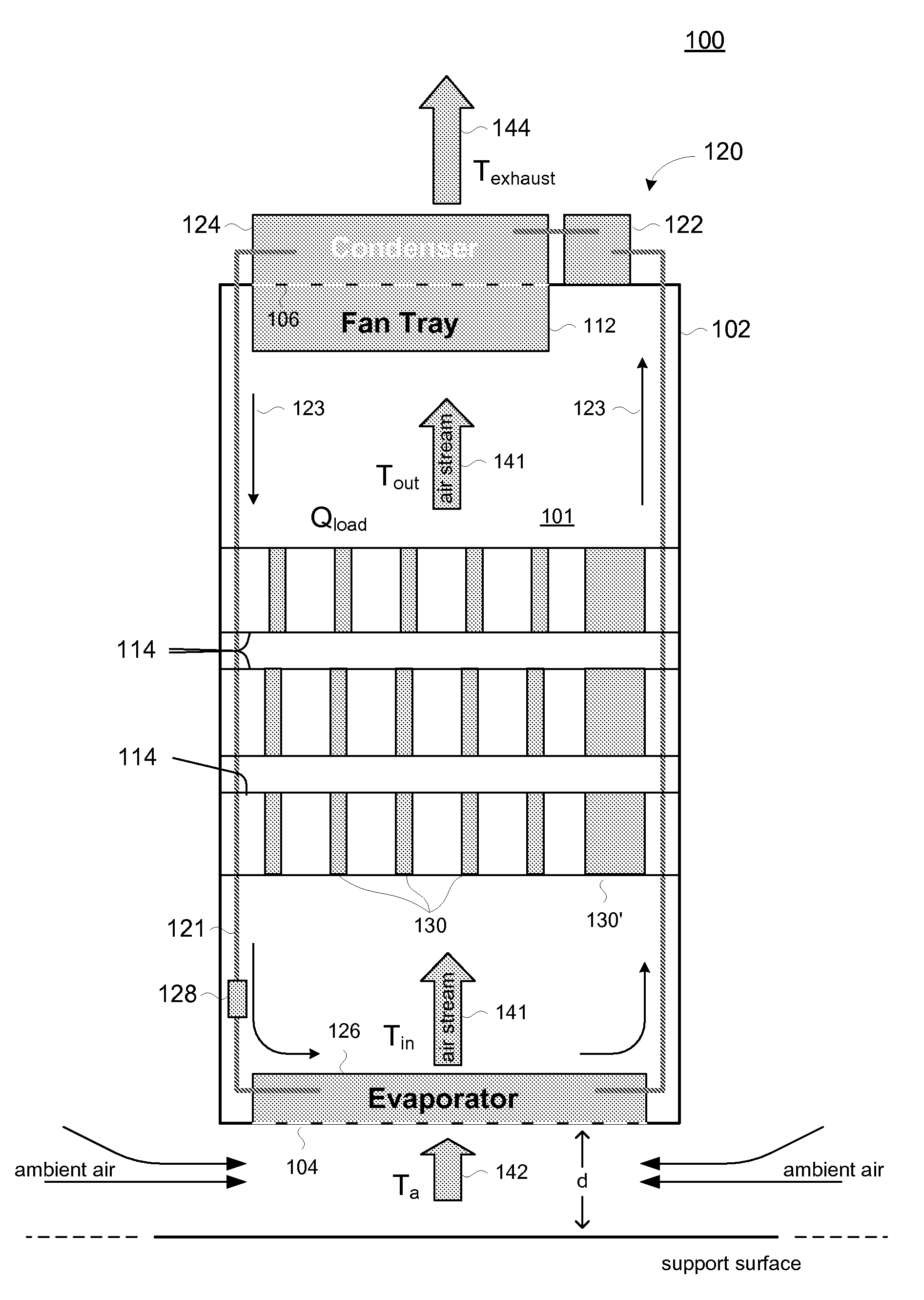

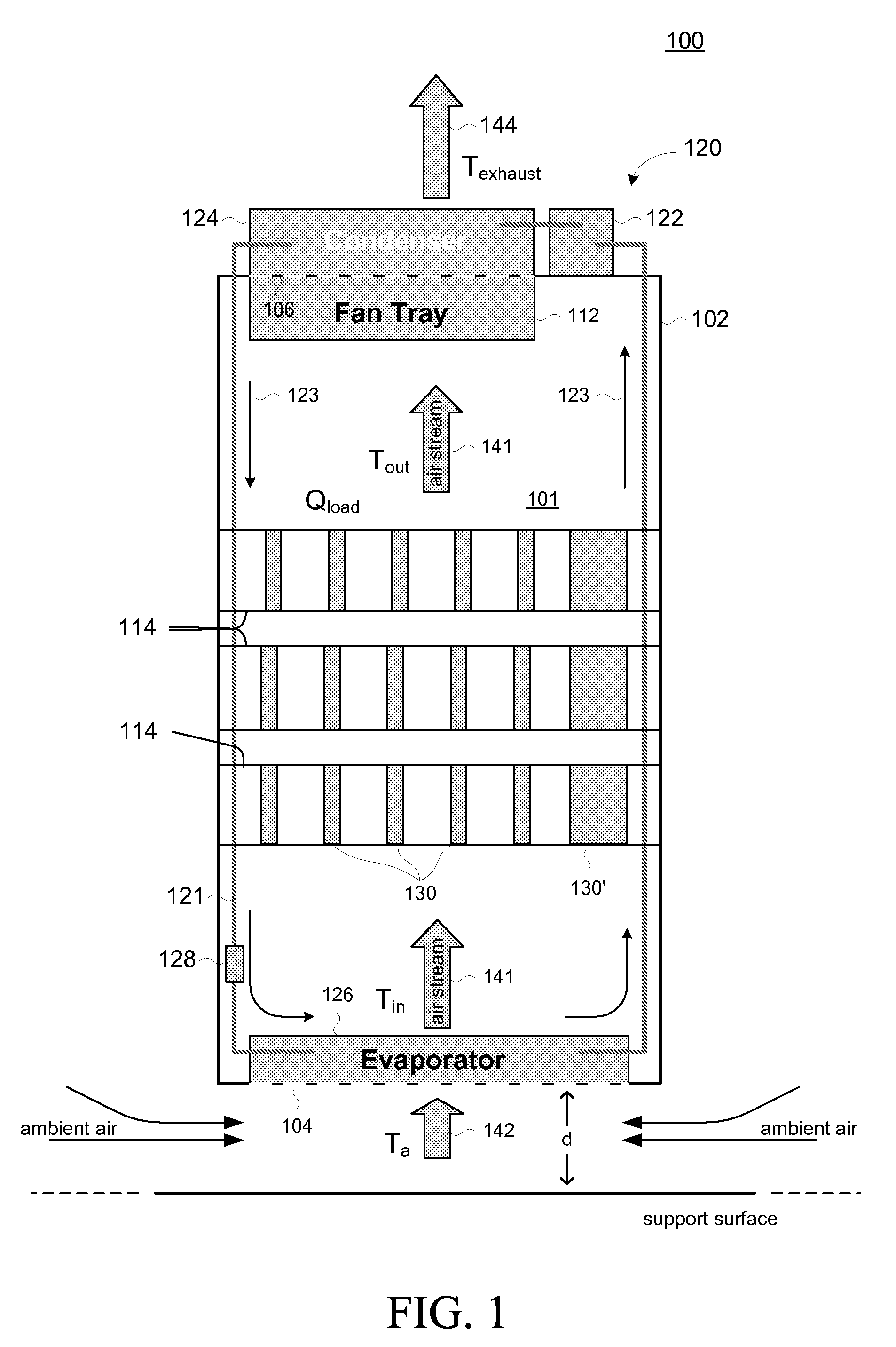

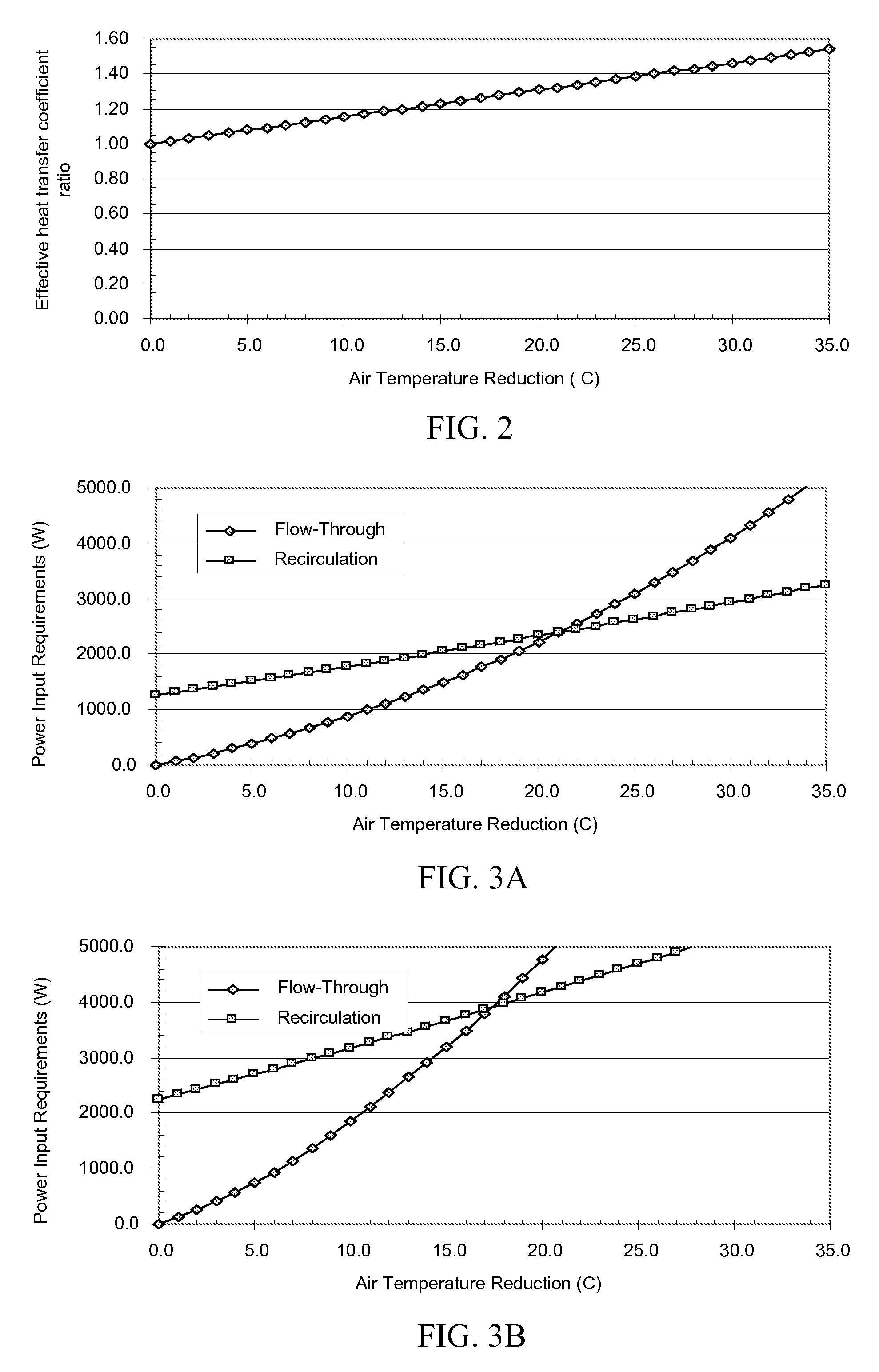

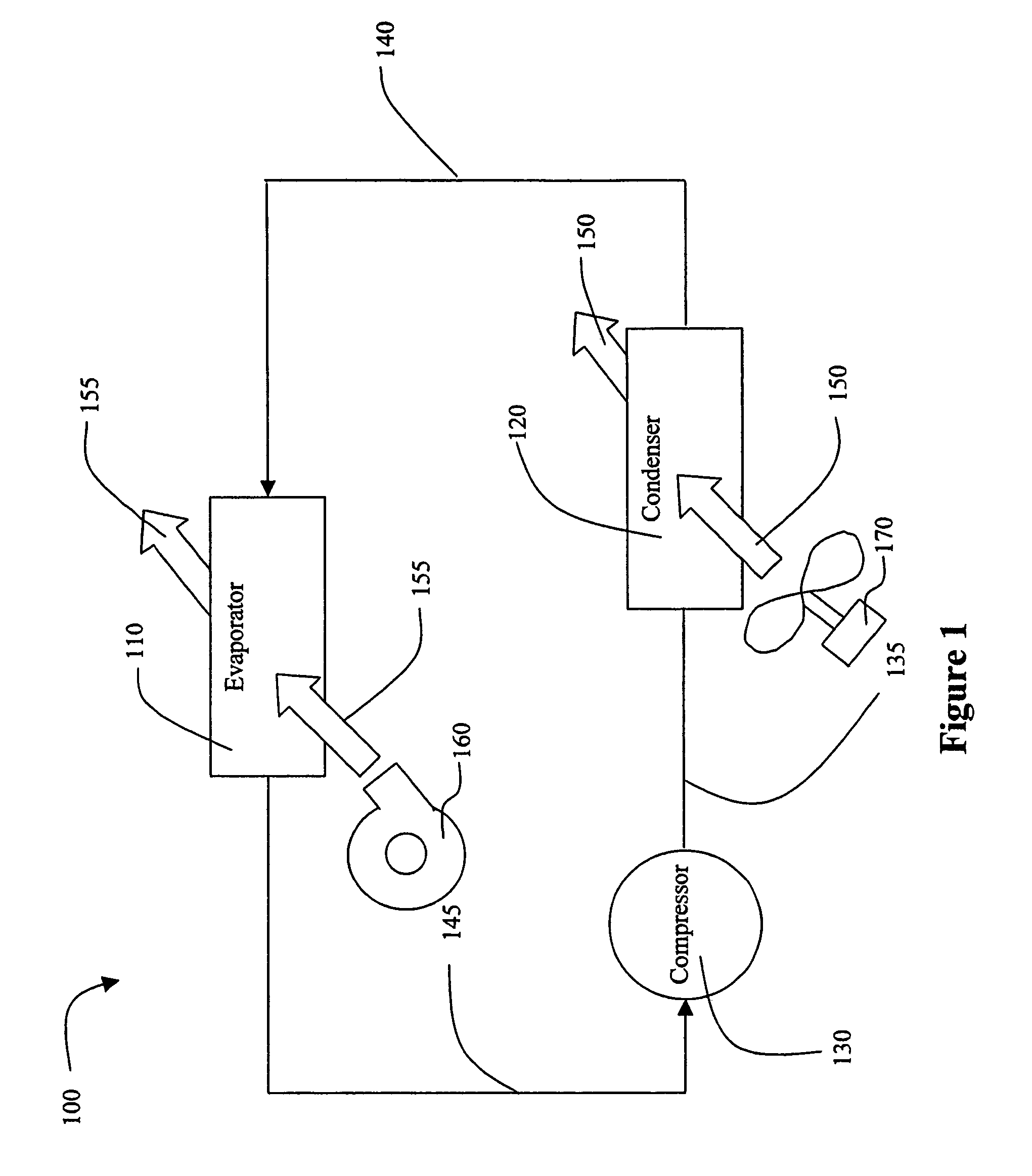

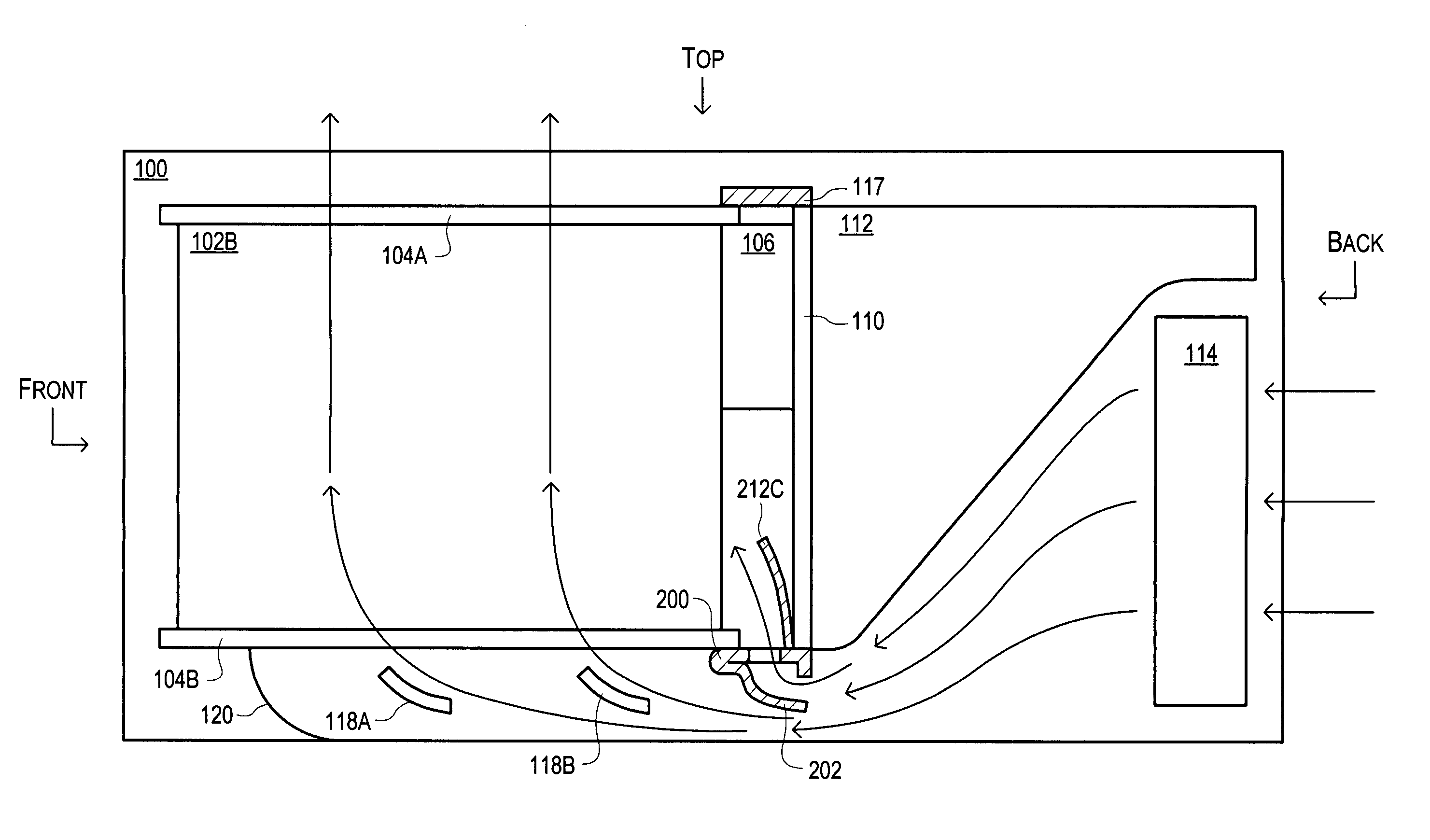

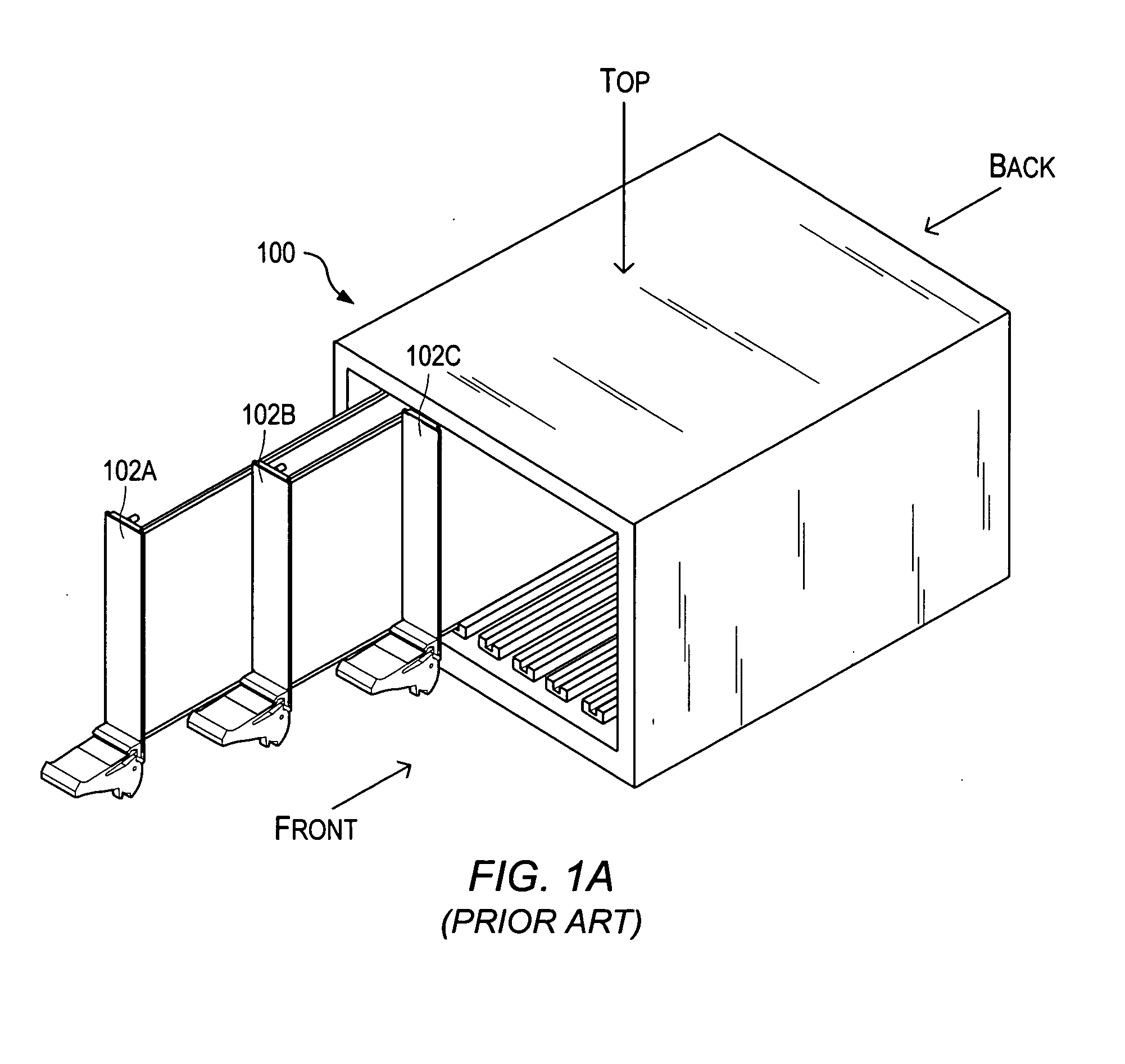

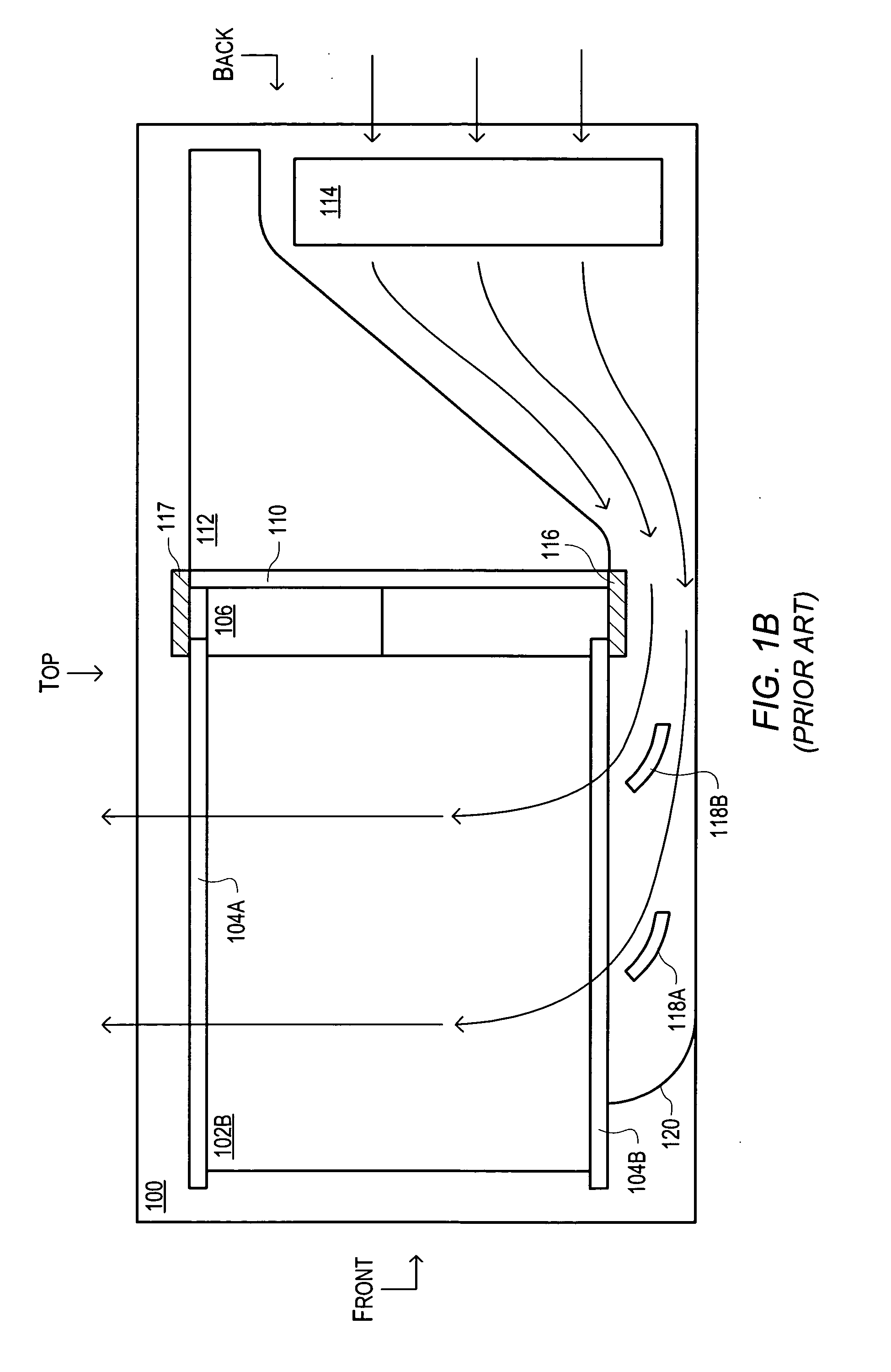

Flow-Through Air Conditioning for Electronics Racks

InactiveUS20090310300A1Reduce power inputComponent with highLighting and heating apparatusCasings/cabinets/drawers detailsEngineeringAir conditioning

A cabinet adapted with a cooling system is described. Embodiments include electronics cabinets which house electronic equipment. A flow of air is set up in the interior of the cabinet by drawing in ambient air. The incoming air is cooled by an evaporator component of a cooling system. The cooled air cools the electronics and in the process becomes heated air. The heated air serves to cool a condenser component of the cooling system, thereby further heating the heated air. The heated air is then exhausted from the cabinet.

Owner:MINEBEA CO LTD

Glass coating containing fluorophor and method for producing glass coating, and light-emitting device and method for manufacturing light-emitting device

ActiveCN102633440ASolve the cooling problemReduce ambient temperatureSolid-state devicesSemiconductor devicesOrganic solventMetallurgy

The invention relates to a glass coating containing a fluorophor and a method for producing the glass coating, and a light-emitting device containing the glass coating and a method for manufacturing the light-emitting device. The method for producing the glass coating containing the fluorophor comprises the following steps of: (1) mixing the powder of glass B and the powder of fluorophor C, an organic solvent and a binder in a mass ratio of 100: (1-100): 150 together into even paste; (2) evenly spreading the paste on a glass substrate A, and drying the glass substrate A coated with the paste so that the organic solvent is completely volatilized; and (3) sintering the dried glass substrate A coated with the paste, thereby obtaining the glass coating containing the fluorophor on the surface of the glass substrate A, wherein the process of sintering is as follows: increasing the temperature to temperature D1, so that the binder is decomposed and volatilized completely, and then increasing the temperature to temperature D2 so that the powder of glass B is softened and united to form a continuous glass body, thus obtaining the glass coating containing the fluorophor C on the surface of the glass substrate A.

Owner:镇江瑞吉光电科技有限公司

Method for refrigerant pressure control in refrigeration systems

ActiveUS7559207B2Increase system pressureReduce ambient temperatureCompression machines with non-reversible cycleFluid circulation arrangementRefrigerant distributionEngineering

A method and system for controlling refrigerant pressure in an HVAC system. The method includes providing a compressor, a condenser and an evaporator connected in a closed refrigerant loop. The condenser has a header arrangement capable of distributing refrigerant to a plurality of refrigerant circuits within the condenser. The header arrangement also is capable of selectively isolating at least one of the circuits from refrigerant flow. Refrigerant pressure is sensed at a predetermined location in the refrigeration system. At least one of the circuits is isolated when the refrigerant pressure is less than or equal to a predetermined pressure.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

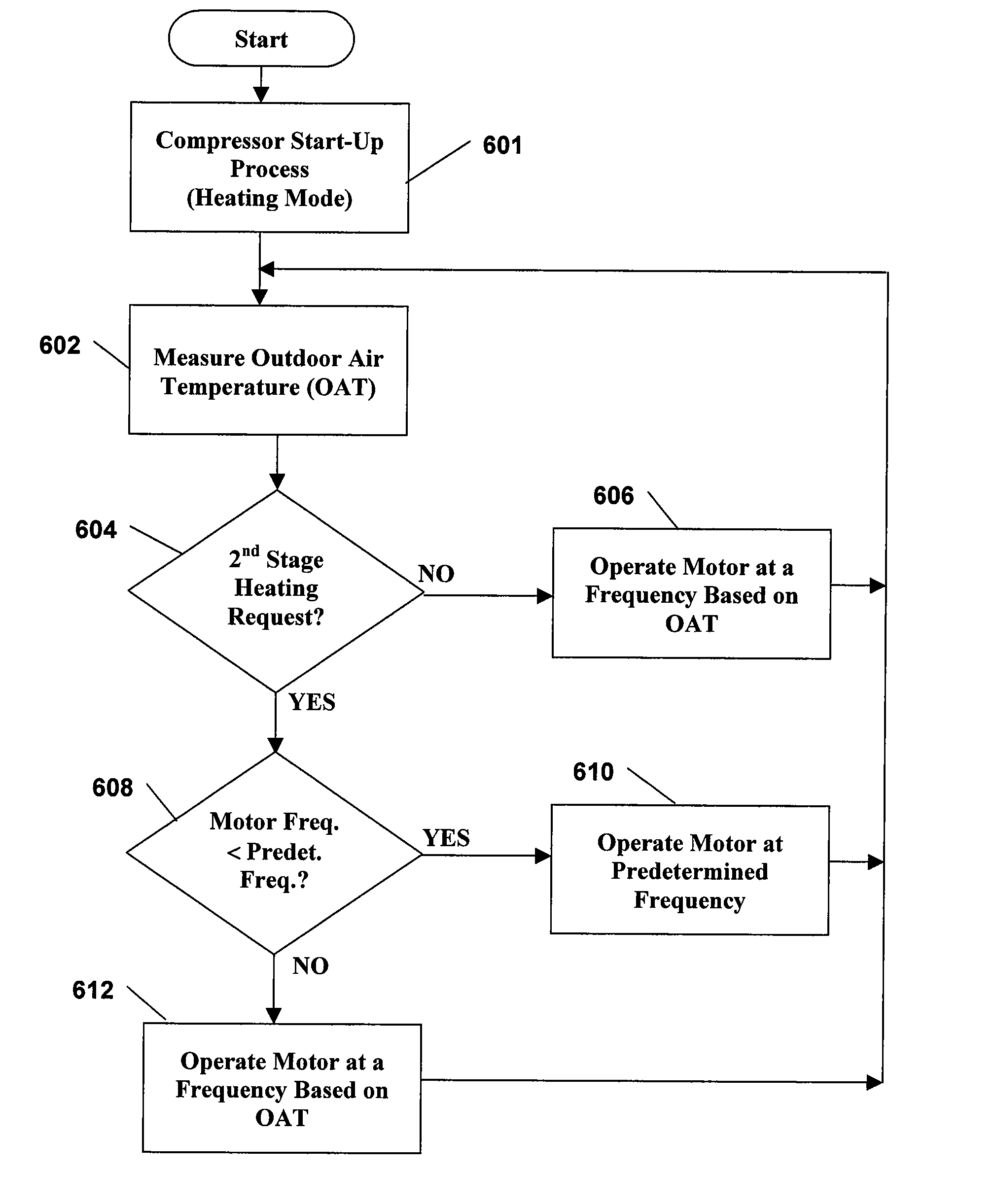

System and method for compressor capacity modulation in a heat pump

InactiveUS20080041081A1Increased system performance and efficiency and capacity controlReduced outdoor ambient temperatureCompression machines with non-reversible cycleEfficient regulation technologiesOutdoor temperatureTemperature measurement

A system and method is provided to control and operate a compressor to have two or more discrete output capacities in response to an outdoor temperature measurement. During operation of the compressor in an air conditioning or cooling mode, the compressor has a first output capacity in response to the outdoor temperature being greater than a first temperature setpoint and the compressor has a second output capacity in response to the outdoor temperature being less than a second temperature setpoint. During operation of the compressor in a heating mode, the compressor has different output capacities based on the outdoor ambient temperature.

Owner:BRISTOL COMPRESSORS INT

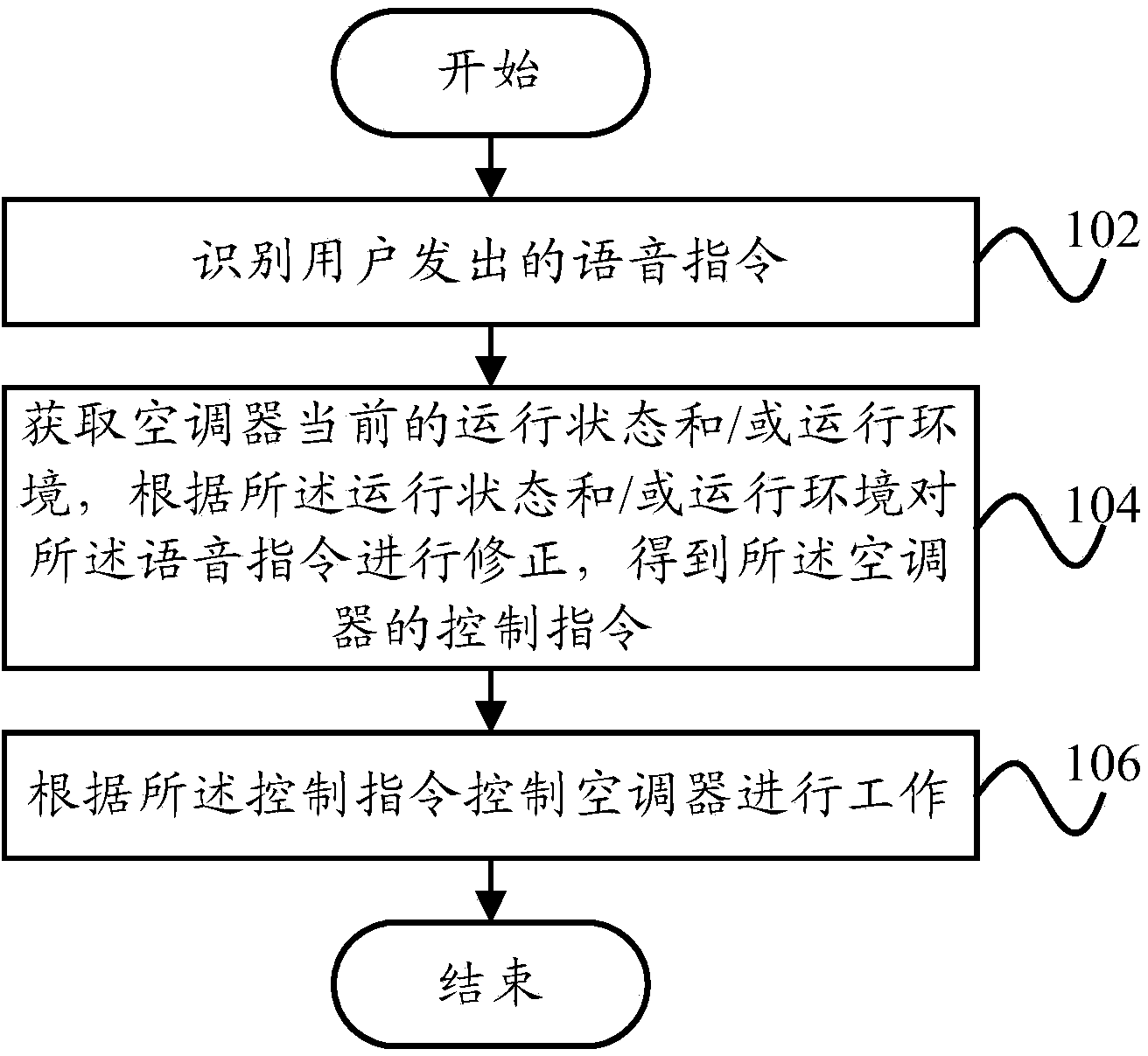

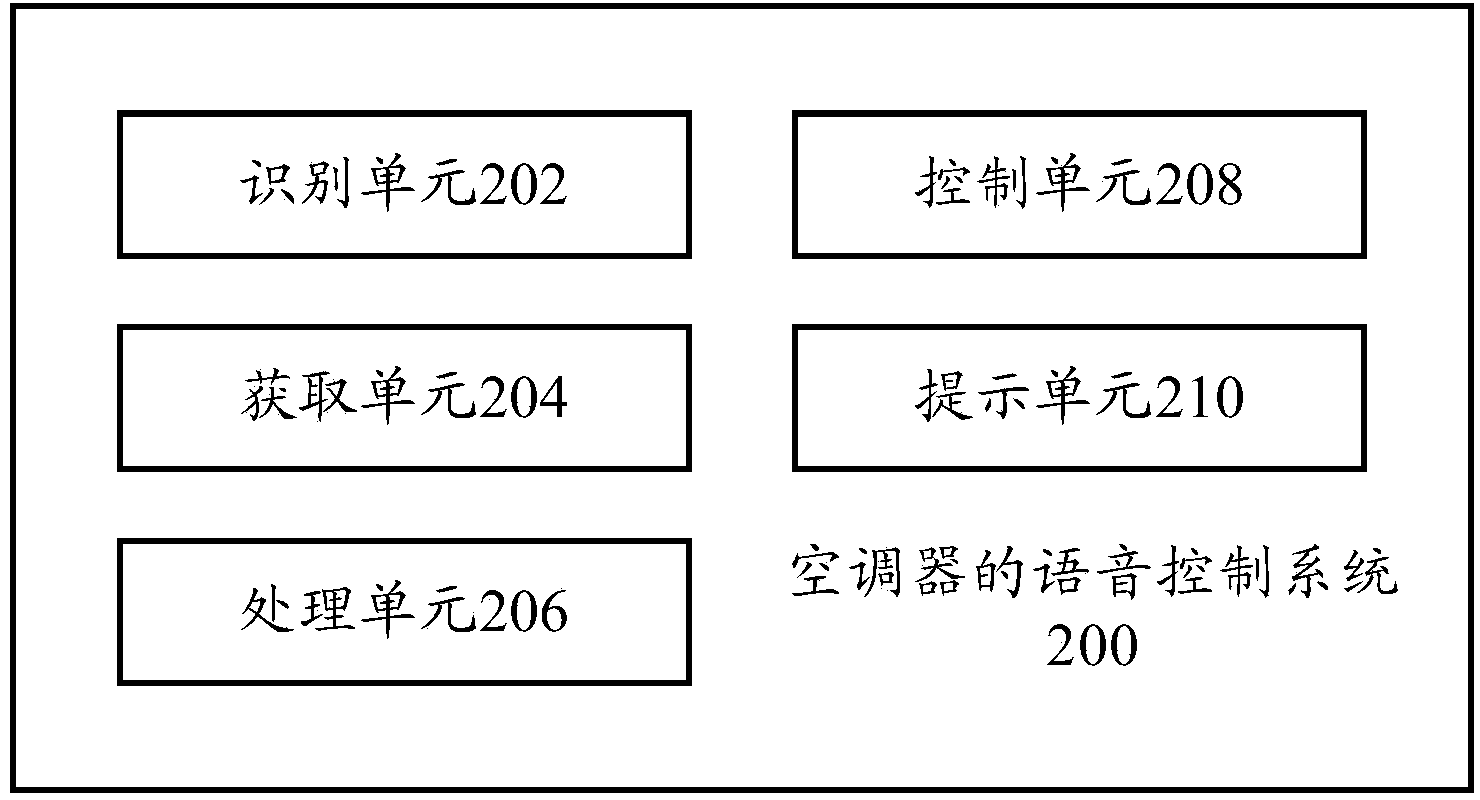

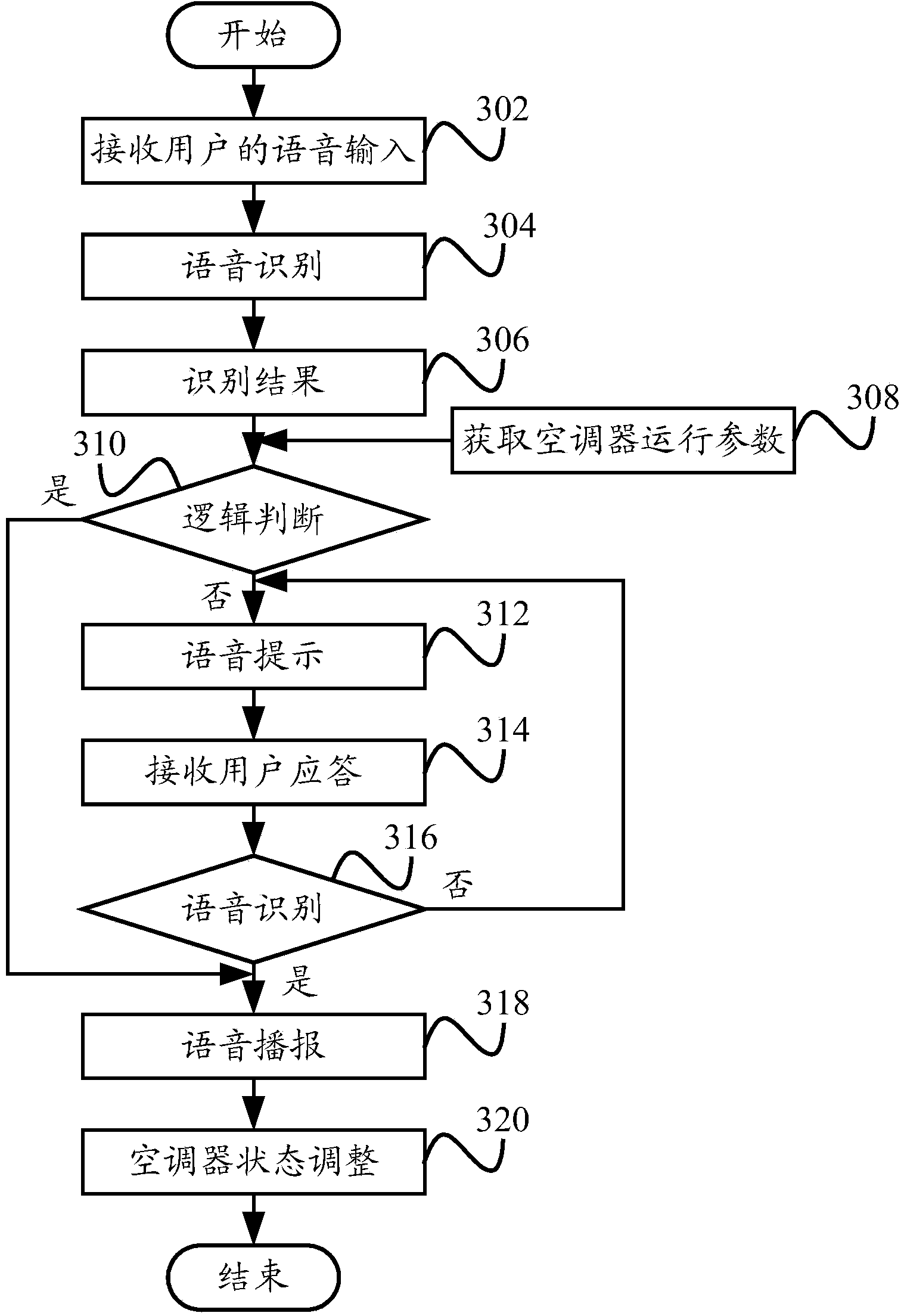

Voice control method and voice control system for air-conditioner

InactiveCN104240702AImprove experienceMeet the actual control needsSpace heating and ventilation safety systemsLighting and heating apparatusControl systemSpeech control

The invention provides a voice control method for an air-conditioner and a voice control system for the air-conditioner. The voice control method for the air-conditioner comprises the steps that a voice instruction sent by a user is identified; the current operating state and / or the current operating environment of the air-conditioner are obtained, and the voice instruction is corrected according to the operating state and / or the operating environment to obtain a control instruction of the air-conditioner; the air-conditioner is controlled to work according to the control instruction. According to the technical scheme, the accuracy of voice control over the air-conditioner can be improved, and the experience of carrying out voice control on the air-conditioner of the user is promoted.

Owner:GUANGDONG MIDEA GRP WUHU REFRIGERATING EQUIP CO LTD

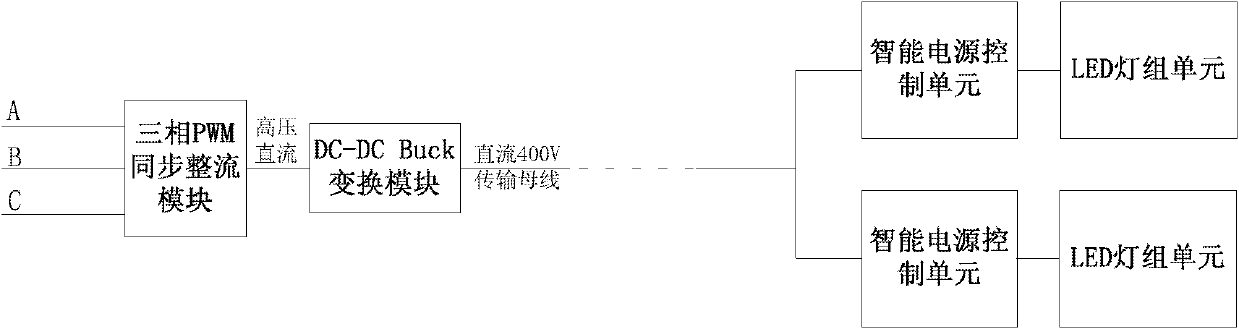

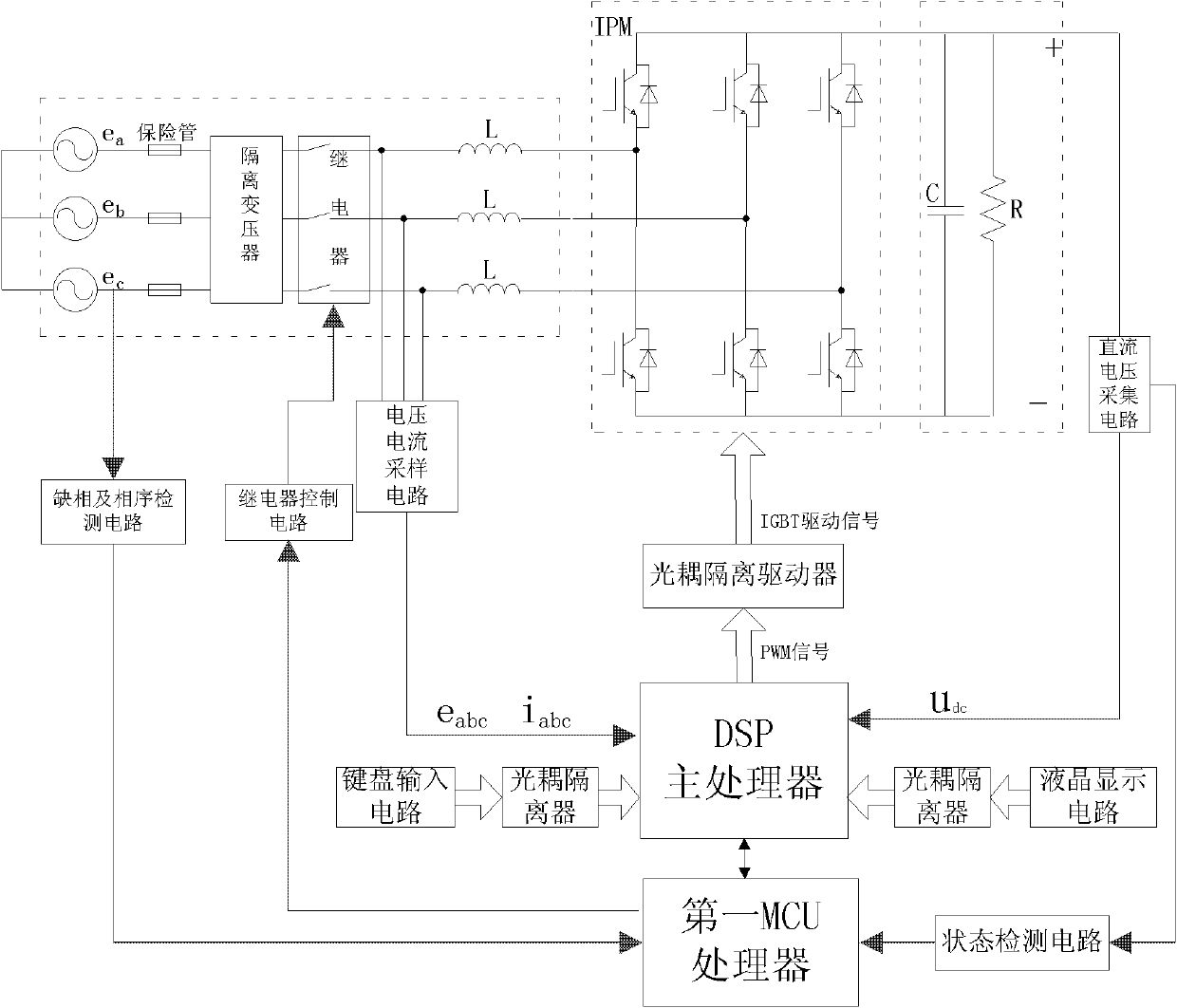

LED (Light Emitting Diode) illumination intelligent control system

InactiveCN102438378AImprove working environment temperatureReduce heat radiationAc-dc conversionElectric light circuit arrangementPower factorHigh-voltage direct current

The invention relates to an LED (Light Emitting Diode) illumination intelligent control system which comprises a synchronous rectification unit used for providing direct-current power for at least two intelligent power control units, wherein the output end of each intelligent power control unit is connected with a corresponding LED light group unit via an electric wire; and the synchronous rectification unit is connected with each intelligent power control unit by a high-voltage direct-current bus. In the intelligent control system, stable constant-voltage direct current is provided for an LED illumination system by the synchronous rectification unit, so that the whole illumination system can operate under high power factor with less harmonic wave. the corresponding LED light group units are dynamically and precisely dimmed by the intelligent power control units, and the LED operation situation is detected in real time and communication with an external control center is carried out. The intelligent control system has the characteristic of reasonable structure, and is convenient to control, the working environment temperature of an LED light group can be improved, and the reliability and the service life of an LED illumination light can be improved.

Owner:MACMIC SCIENCE & TECHNOLOGY CO LTD

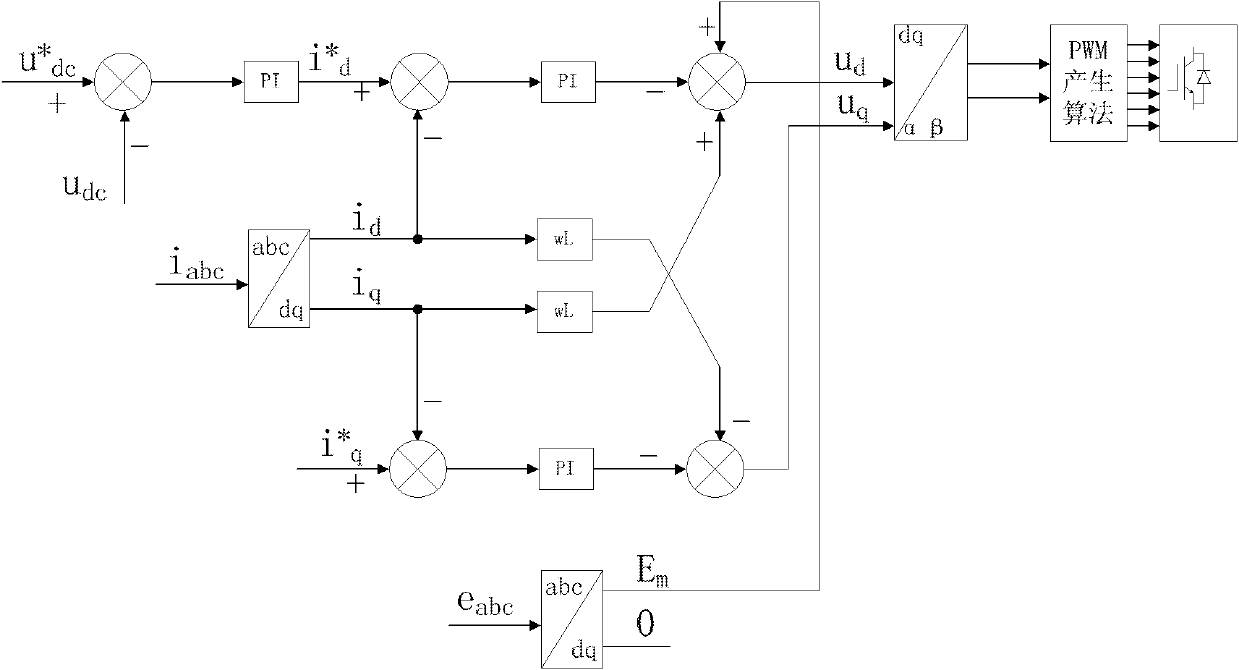

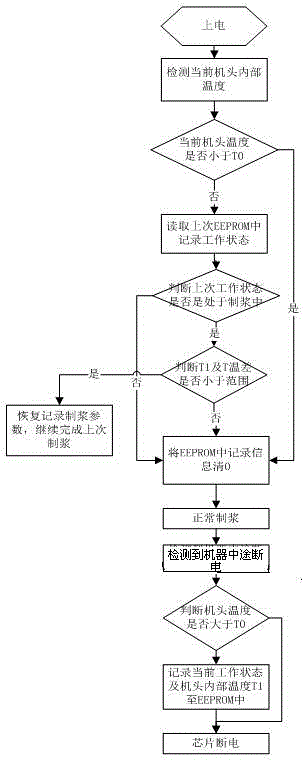

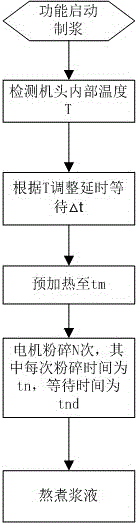

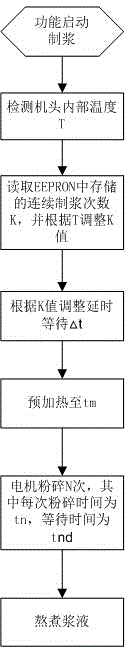

Soybean milk machine control method

ActiveCN104958011APlay a protective effectReduce ambient temperatureProgramme controlComputer controlElectricityMachine control

The invention relates to a soybean milk machine control method. A soybean milk machine comprises a machine head and a cup body, and the machine head is buckled to the upper portion of the cup body; the pulping process of the soybean milk machine includes the heating stage, the smashing stage and the boiling stage; a motor used for driving a smashing device is arranged in the machine head; and the soybean milk machine is characterized in that a temperature measurement device used for detecting the environment temperature T of the machine head is arranged in the machine head, and is electrically connected with a control chip, a temperature threshold value T0 is preset in the control chip, and the pulping process of the soybean milk machine is adjusted through the control chip according to the environment temperature T of the machine head and the temperature threshold value T0. The temperature measurement device used for detecting the environment of the machine head is arranged in the machine head, so that the control chip obtains the working condition of the soybean milk machine at current, the pulping process can be automatically modified, or the environment temperature is decreased by delaying starting of the pulping process, or the sufficient radiating time is provided for the motor by prolonging the working interval time of the motor, and it is guaranteed that the soybean milk machine is reliable and safe accordingly.

Owner:HONGYANG HOME APPLIANCES

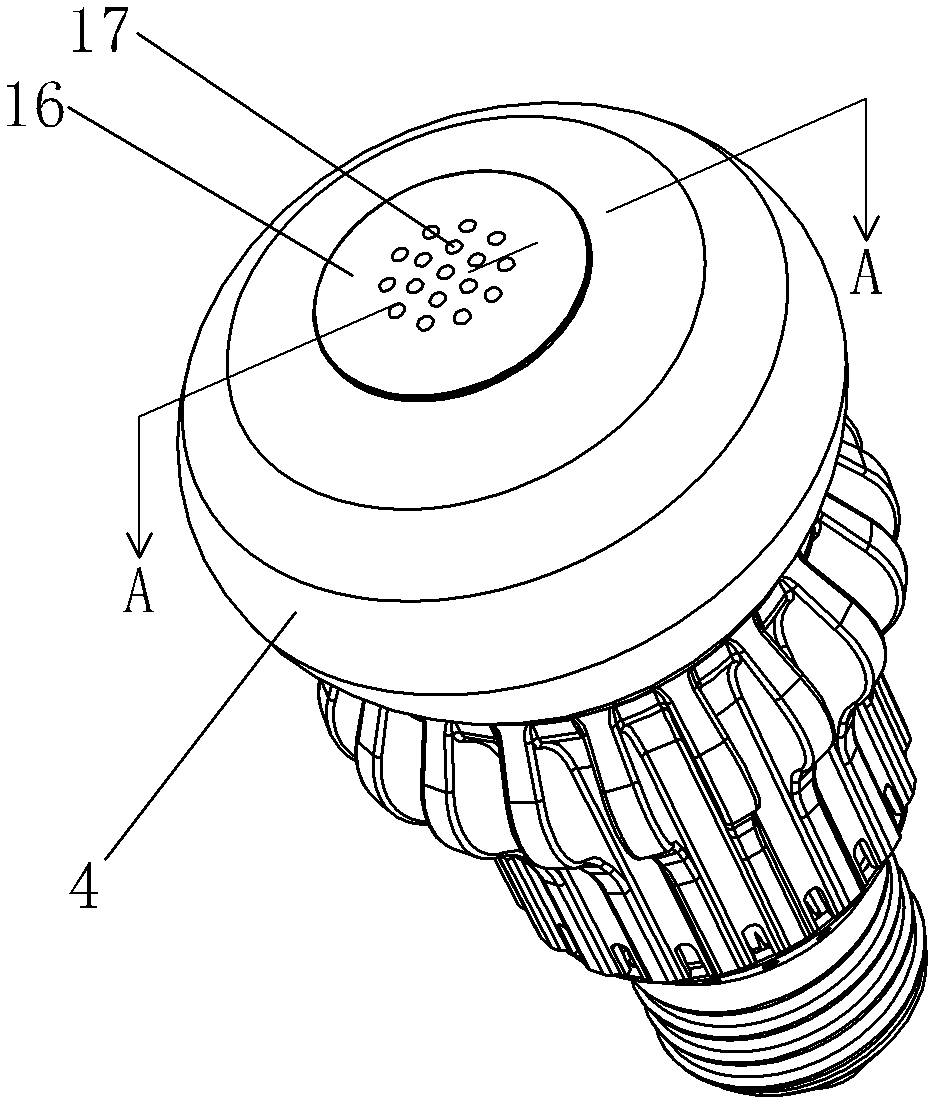

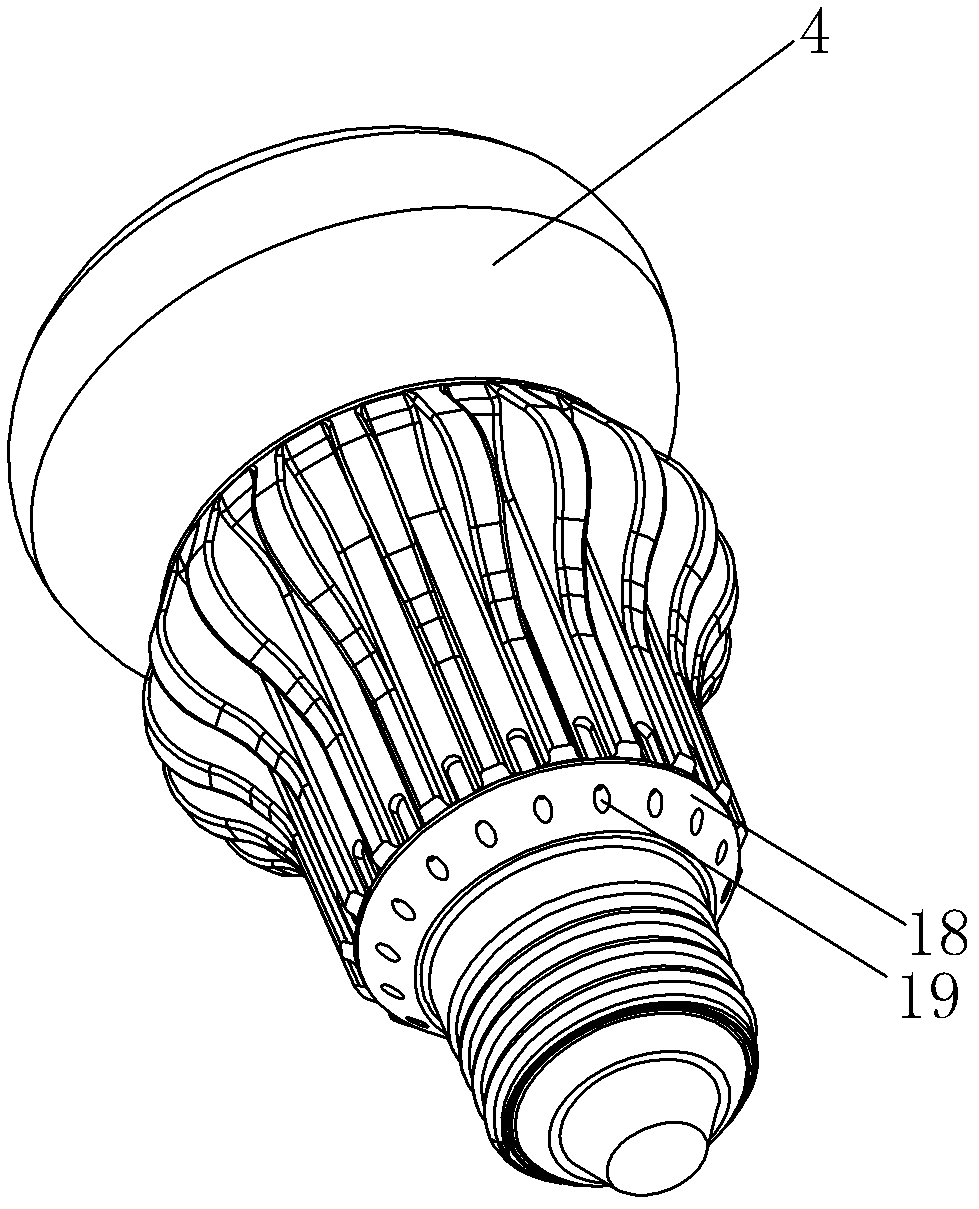

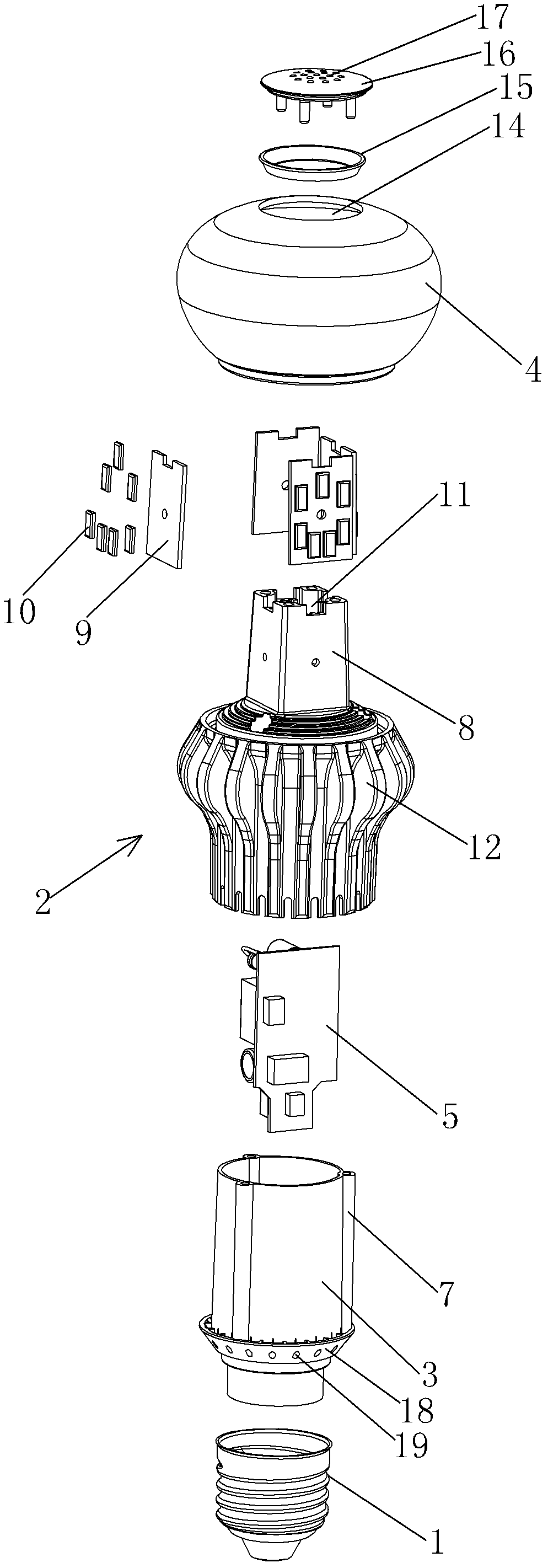

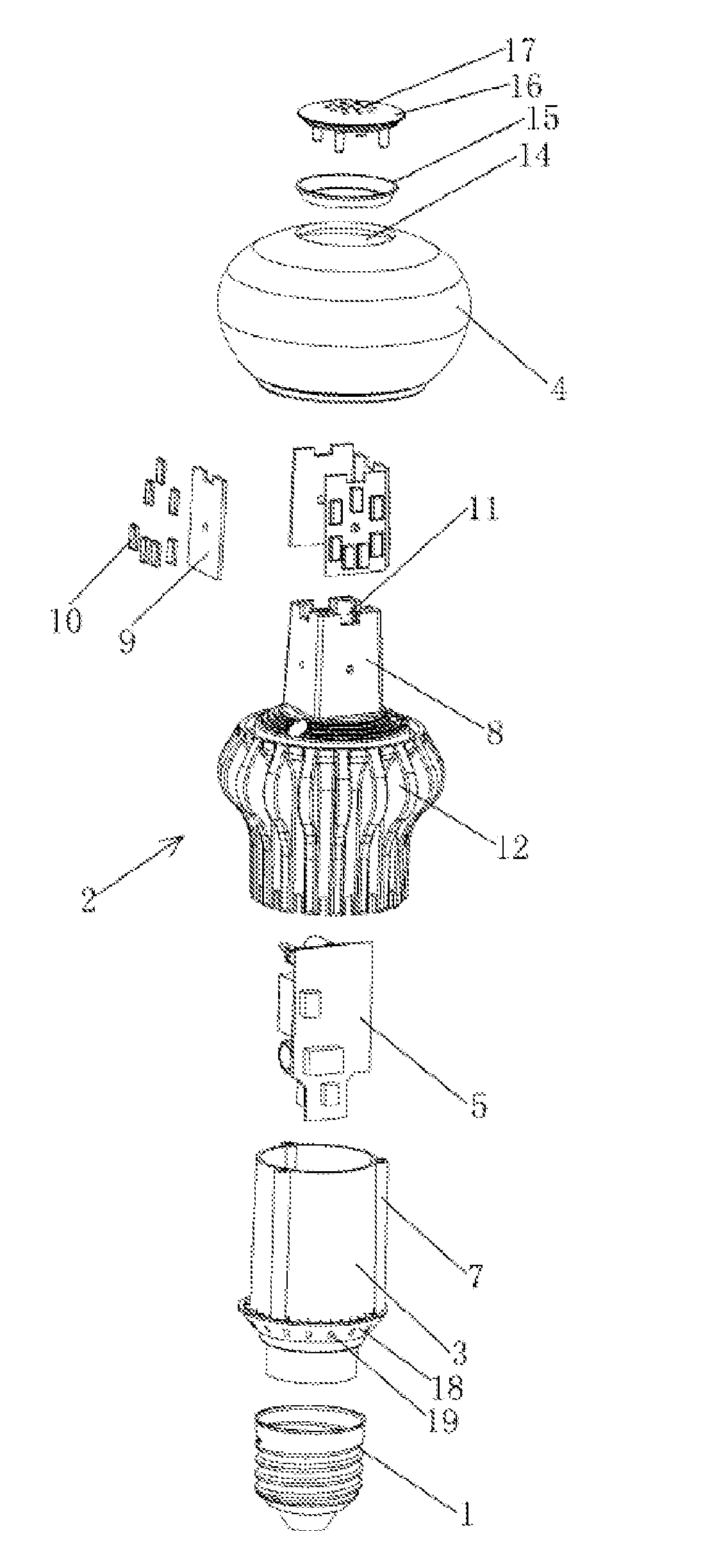

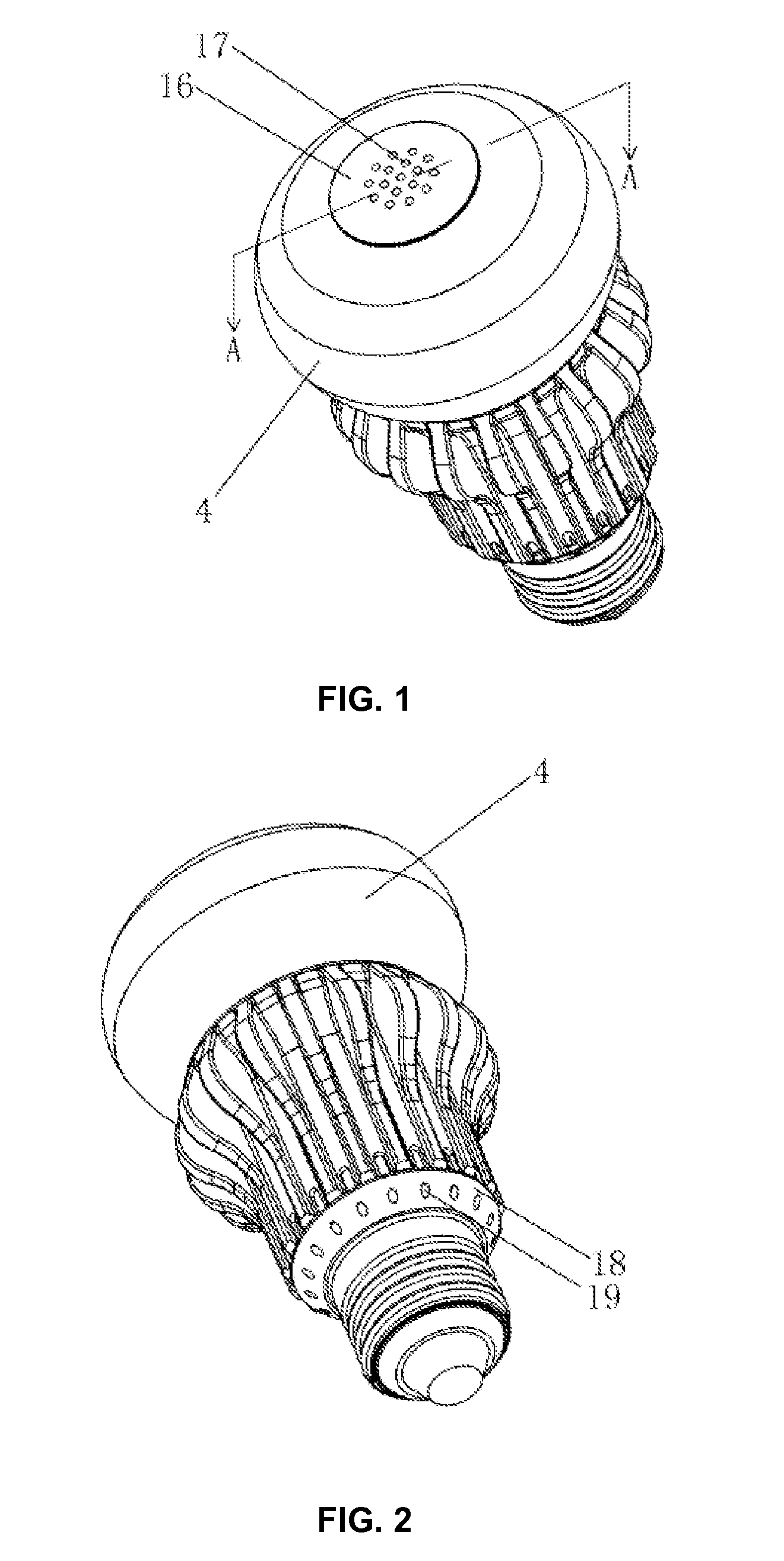

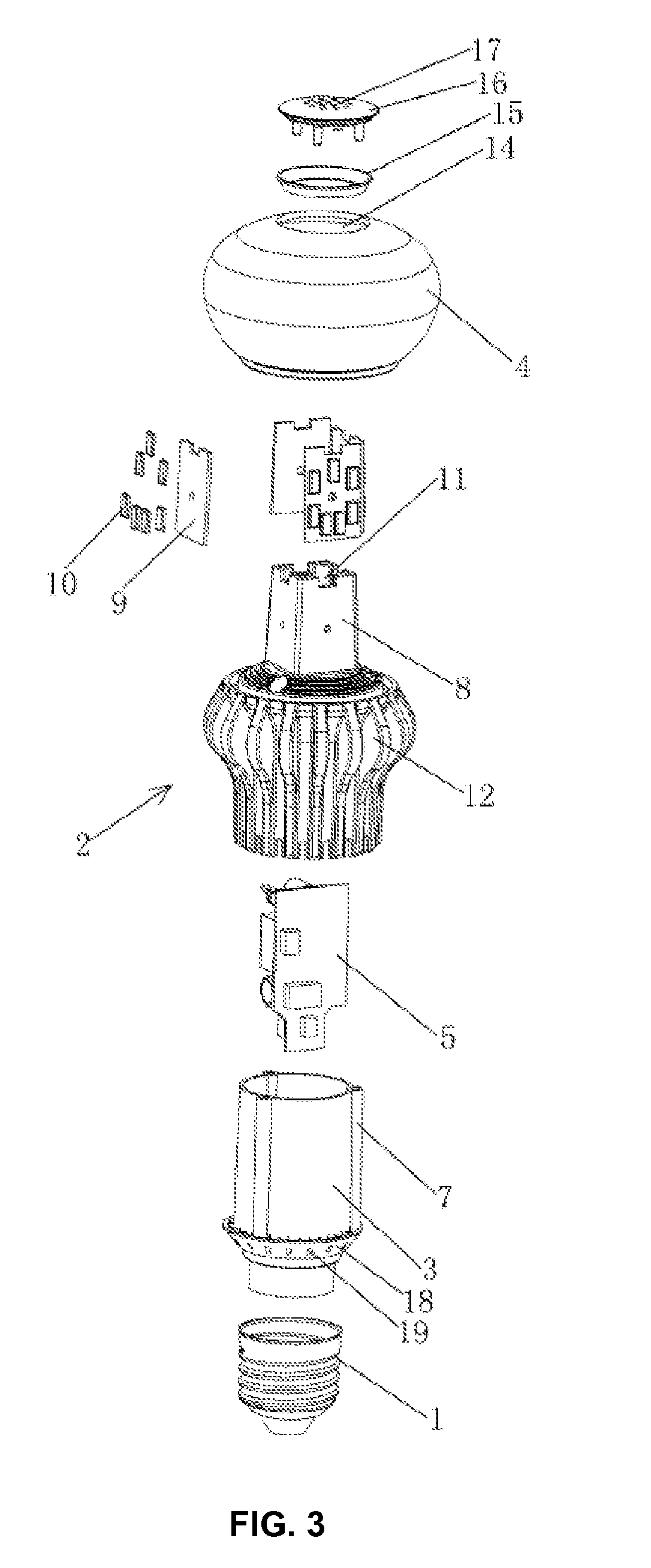

LED (light-emitting diode) lamp convenient to dissipate heat

InactiveCN102384452AReduce ambient temperatureReduce the temperaturePoint-like light sourceElectric circuit arrangementsEngineeringLight head

The invention discloses an LED (light-emitting diode) lamp convenient to dissipate heat, which comprises a lamp cap, a heat dissipating lamp cup, a driving power source housing and a bulb housing, wherein the interior of the heat dissipating lamp cup adopts a hollow structure; the heat dissipating lamp cup is connected with the driving power source housing in a sleeved manner; a gap for ventilation is reserved between the driving power source housing and the inner wall of the heat dissipating lamp cup; a lamp holder higher than the upper surface of the lamp cup is arranged at the upper part of the heat dissipating lamp cup; a substrate is arranged on one side wall of the lamp holder; an LED light source is fixed on the substrate; a ventilation channel passing through the whole lamp holder is arranged in the lamp holder; a ventilation hole is formed at the top of the bulb housing; the gap is communicated with the ventilation channel of the lamp holder through air; the lower part of the gap is communicated with external air; and the upper part of the ventilation channel is communicated with the external air through the ventilation hole of the bulb housing. According to the LED lamp, the air flow channel is arranged at the inner part of a lamp body, so that heat produced by a driving power source and the LED light source can be brought away by the air, the working ambient environment of the power source is reduced, the service life of the power source is guaranteed, the temperature of a housing of the lamp cup can be effectively reduced, and double hands of people can be further protected from scald.

Owner:SENGLED OPTOELECTRONICS

System and method for compressor capacity modulation

InactiveUS7628028B2Increase capacityImprove efficiencySampled-variable control systemsComputer controlEngineeringOutdoor temperature

A system and method is provided to control and operate a compressor to have two or more discrete output capacities in response to an outdoor temperature measurement. During operation of the compressor in an air conditioning or cooling mode, the compressor has a first output capacity in response to the outdoor temperature being greater than a first temperature setpoint and the compressor has a second output capacity in response to the outdoor temperature being less than a second temperature setpoint.

Owner:BRISTOL COMPRESSORS INT

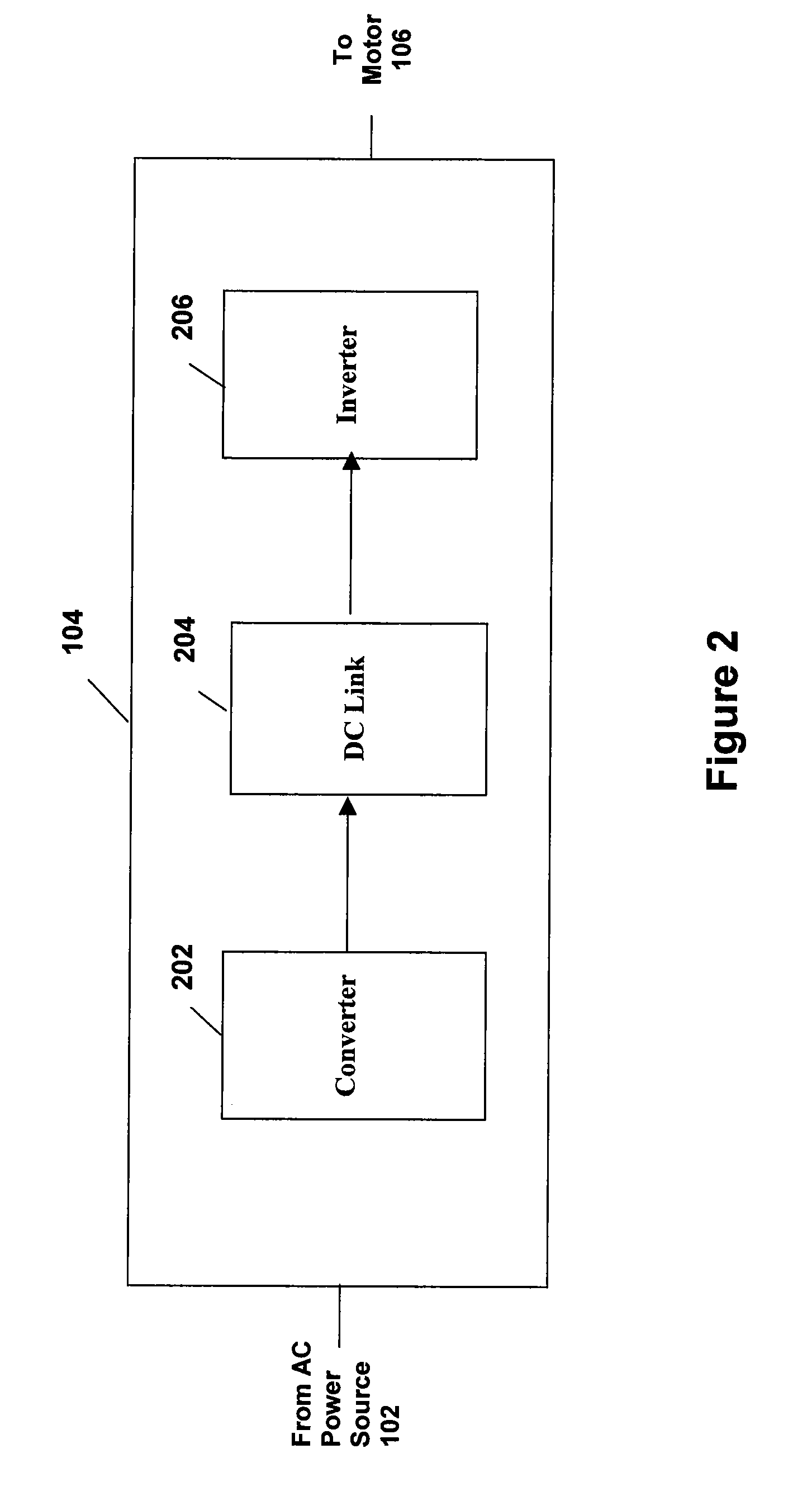

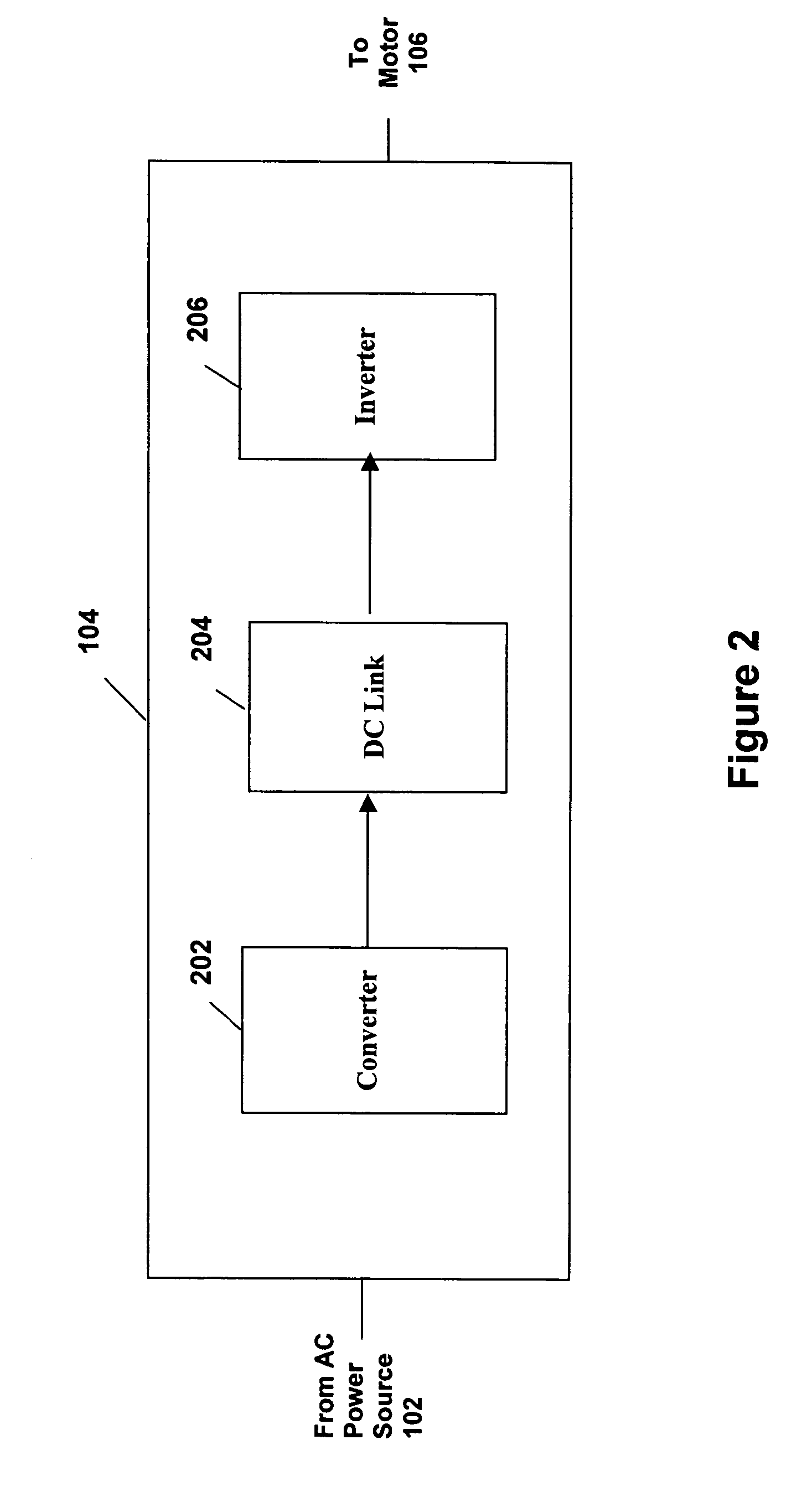

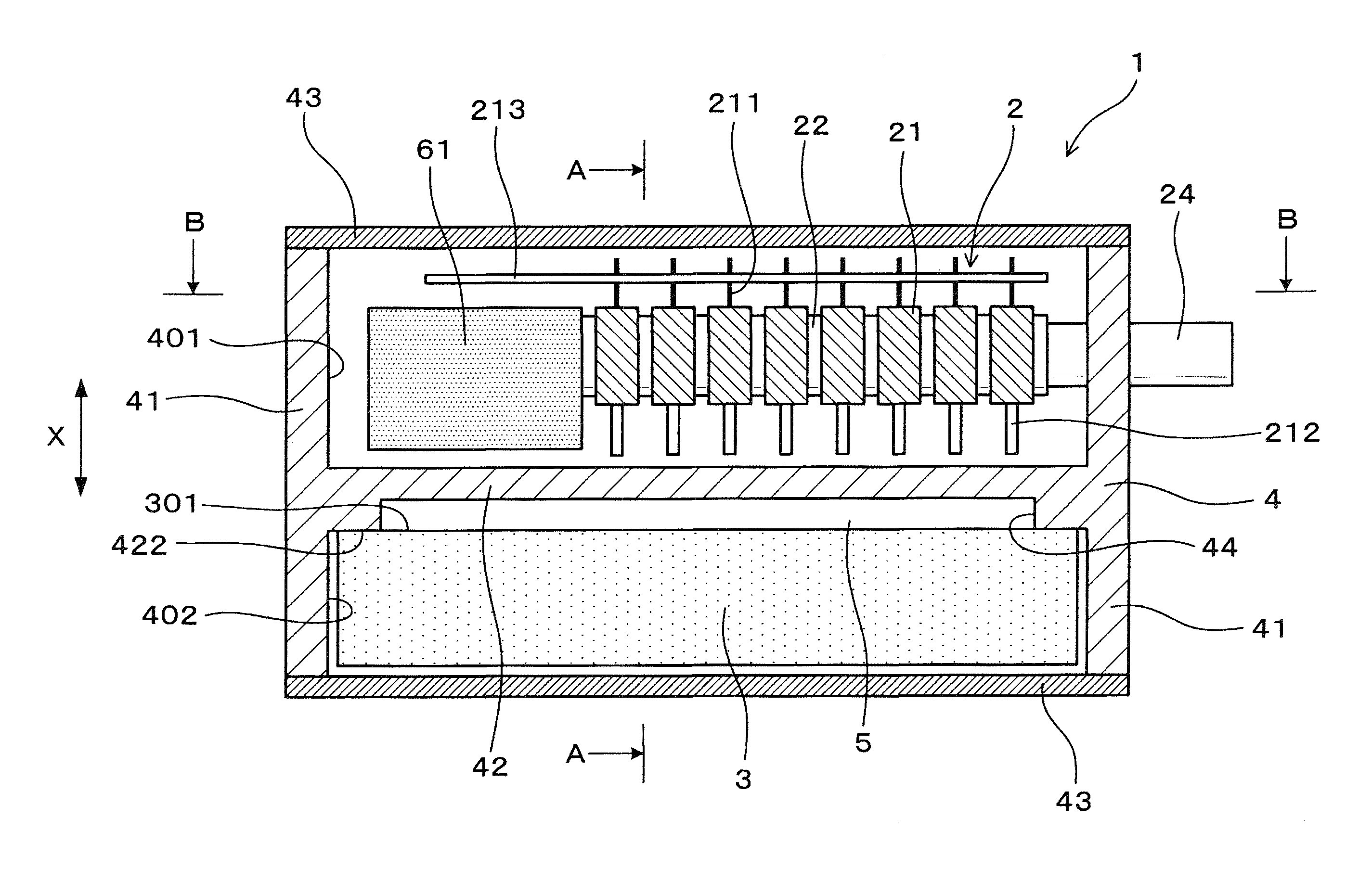

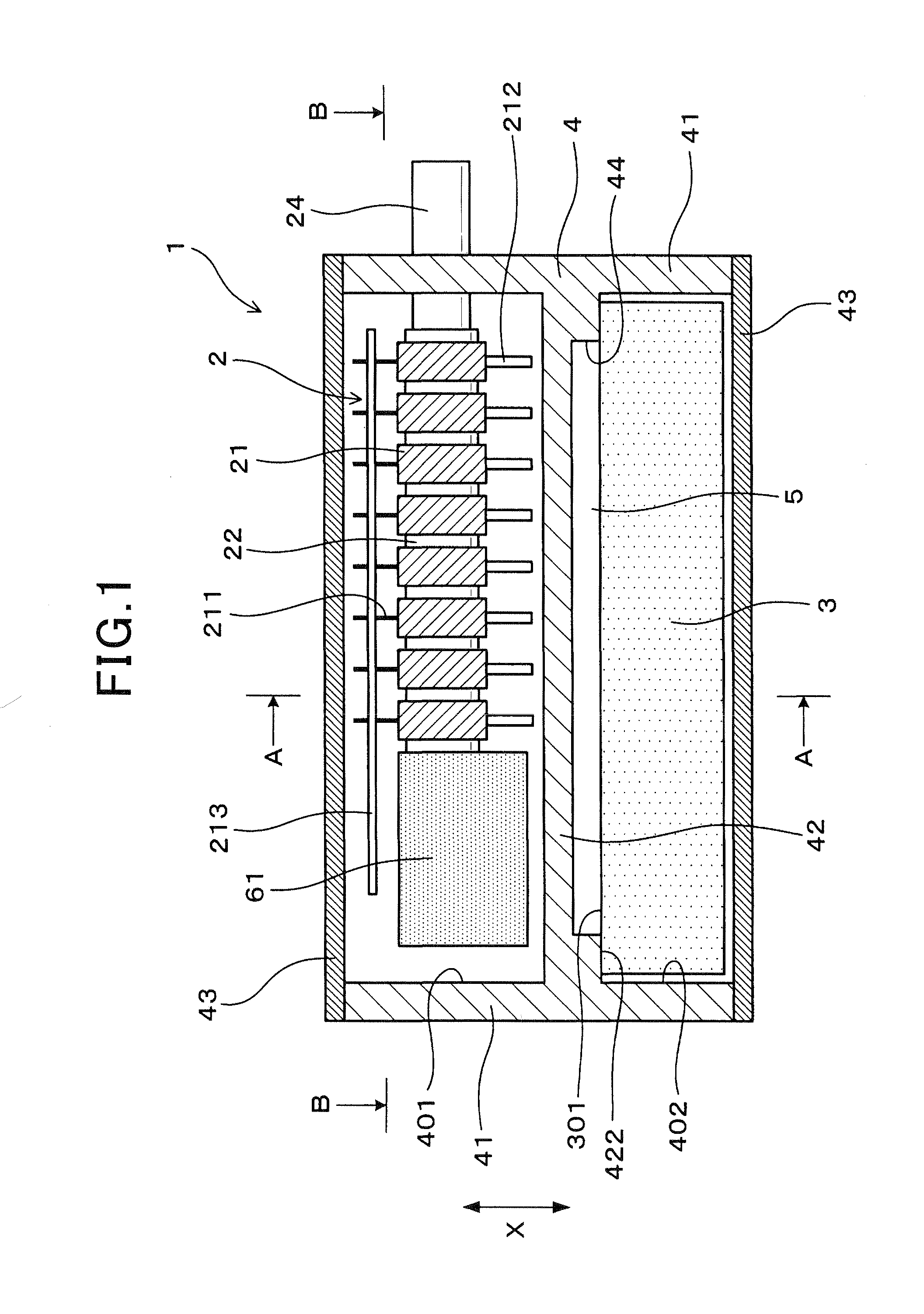

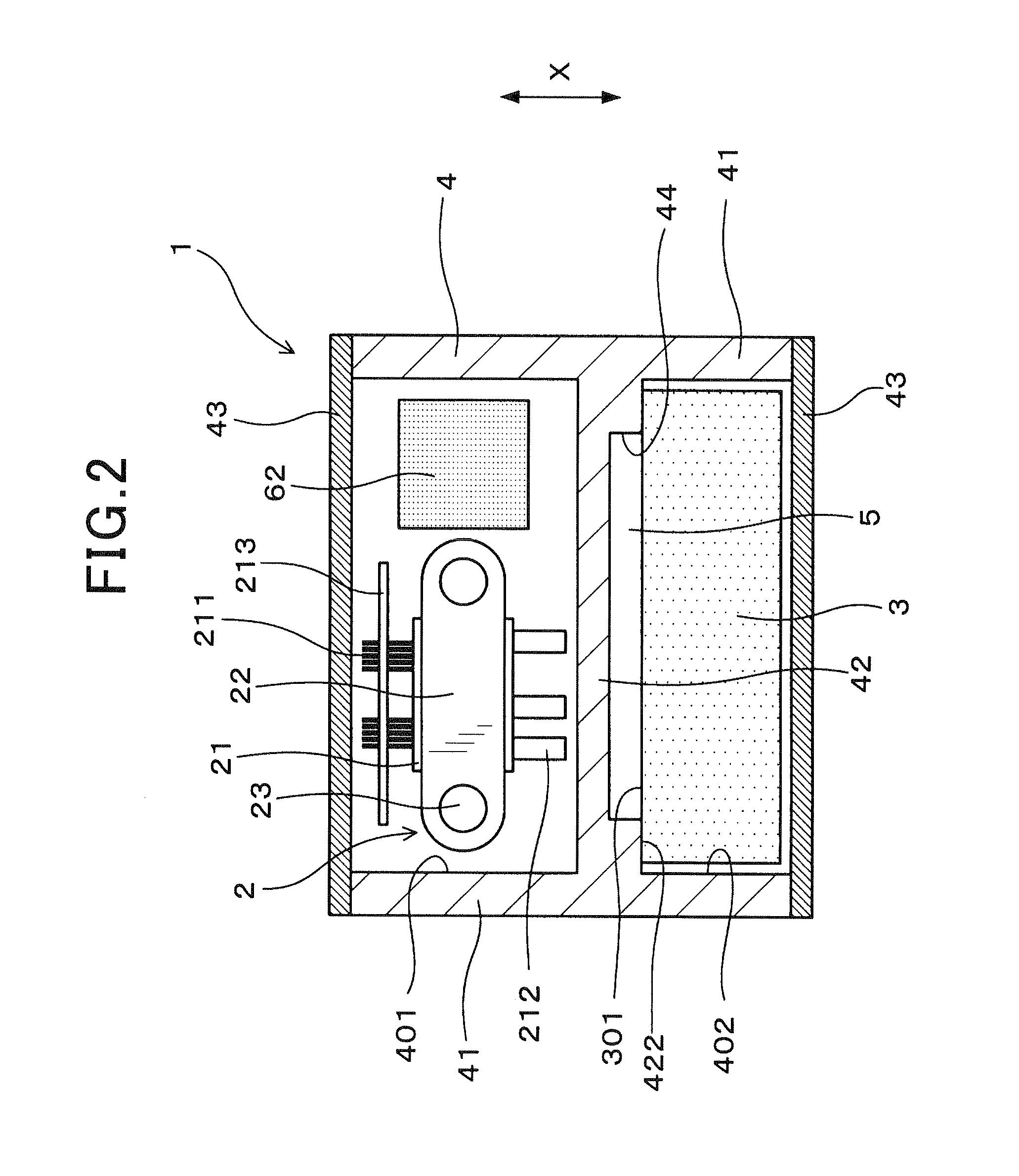

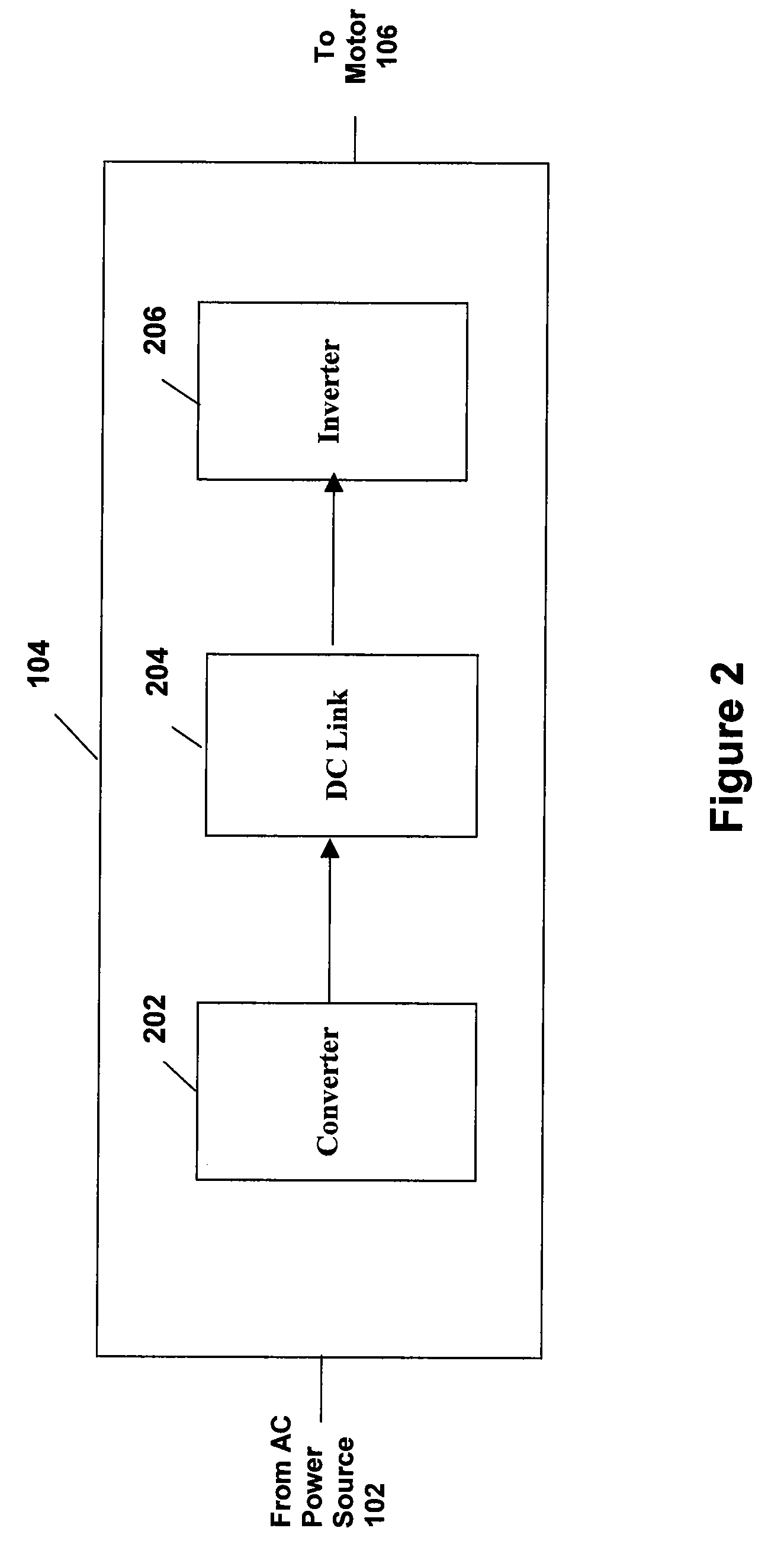

Electric power conversion apparatus

ActiveUS20120250252A1Suppress increase in ambient temperatureHeat resistance is ensuredSolid-state devicesCooling/ventilation/heating modificationsElectrical and Electronics engineeringCoolant

An electric power conversion apparatus includes first and second electric power conversion devices and a housing. The first and second electric power conversion devices are arranged to overlap each other in an overlap direction. The housing receives both the first and second electric power conversion devices therein. The housing has a partition wall that extends between the first and second electric power conversion devices to partition the housing into first and second parts in which the first and second electric power conversion devices are respectively received. The partition wall has a coolant passage formed therein, thereby allowing a coolant to flow through the coolant passage.

Owner:DENSO CORP

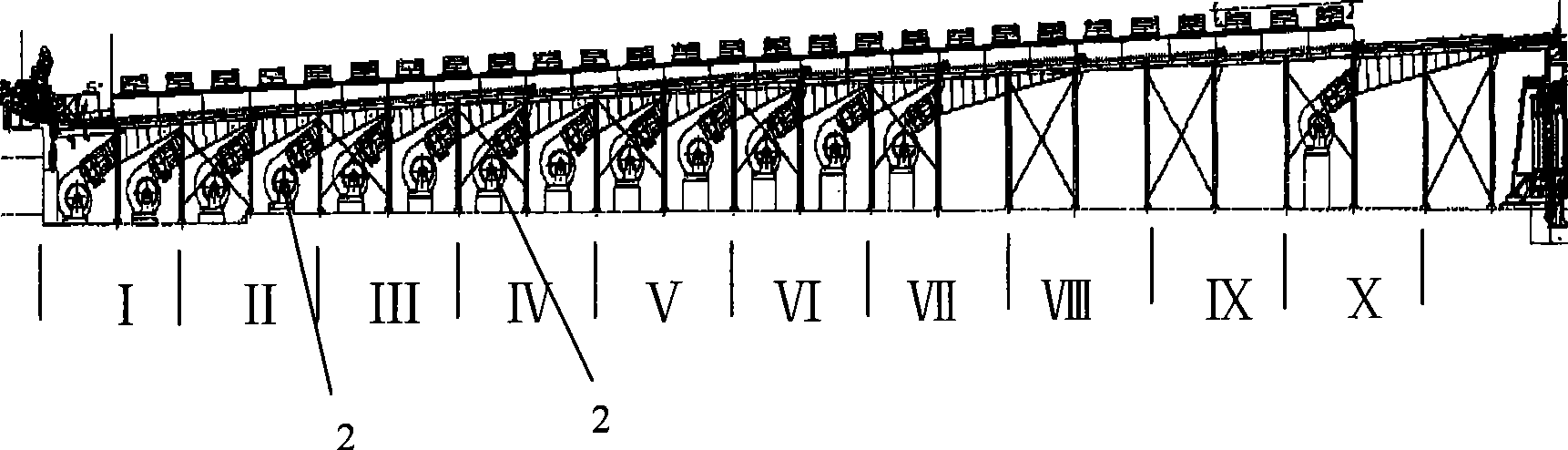

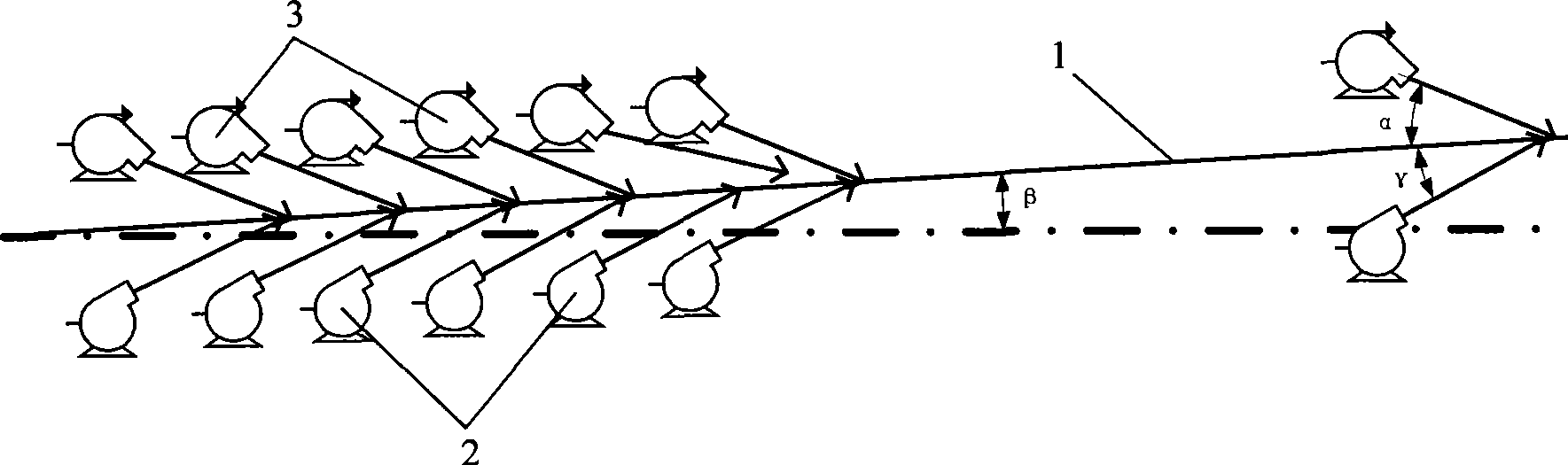

Stelmor line cooling method and cooling apparatus of high-speed rod-rolling mill

ActiveCN101480669ACool evenlyRealize top and bottom air coolingWork treatment devicesMetal rolling arrangementsWire rodEngineering

The invention relates to a cooling method and a cooling device for a stelmor wire of a high-speed wire mill. The cooling device for a stelmor wire of a high-speed wire mill adopts the structure that the lower side of a transport roller way of a stelmor wire is sequentially provided with a plurality of upper draught fans along the direction of the transport roller way, the upper side of the transport roller way of the stelmor wire is also sequentially provided with a plurality of lower draught fans along the direction of the transport roller way, the upper draught fans are arranged on a steel structural frame which can be conveyed in a hanging way, an air outlet of each upper draught fan is symmetrical to an air outlet of each lower draught fan relative to the transport roller way, and an included angle between the air direction of each upper draught fan and the transport roller way is equal to an included angle between the air direction of each lower draught fan and the transport roller way. The cooling method is applicable to the cooling device. Furthermore, additionally provided with the the draught fans on the transport roller way, the cooling device realizes the upper air cooling and the lower air cooling of the wires, increases the cooling speed, and causes the wires to be cooled more evenly, thereby the invention solves the problems of nonuniform wire contact-point structure and nonuniform mechanical property.

Owner:BAOSHAN IRON & STEEL CO LTD

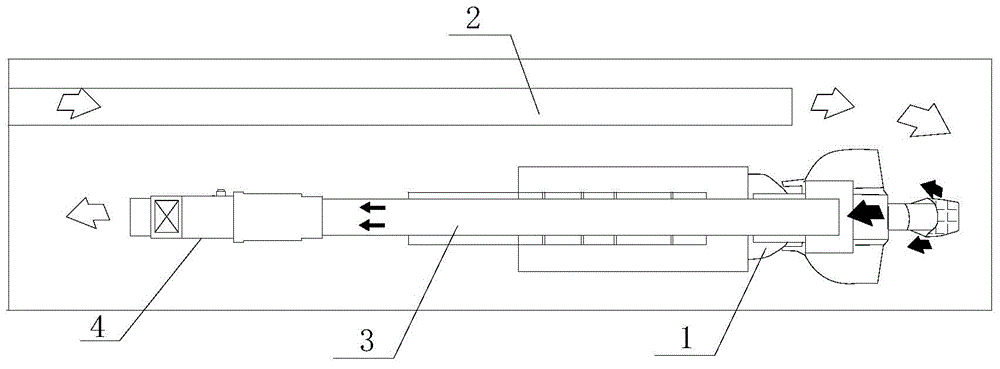

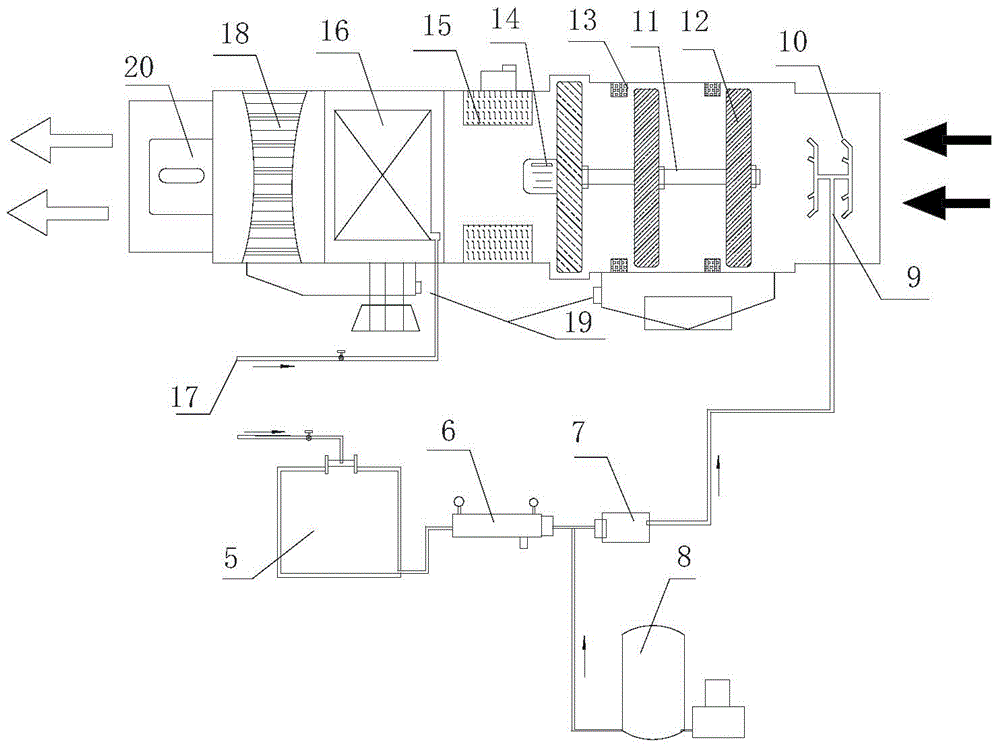

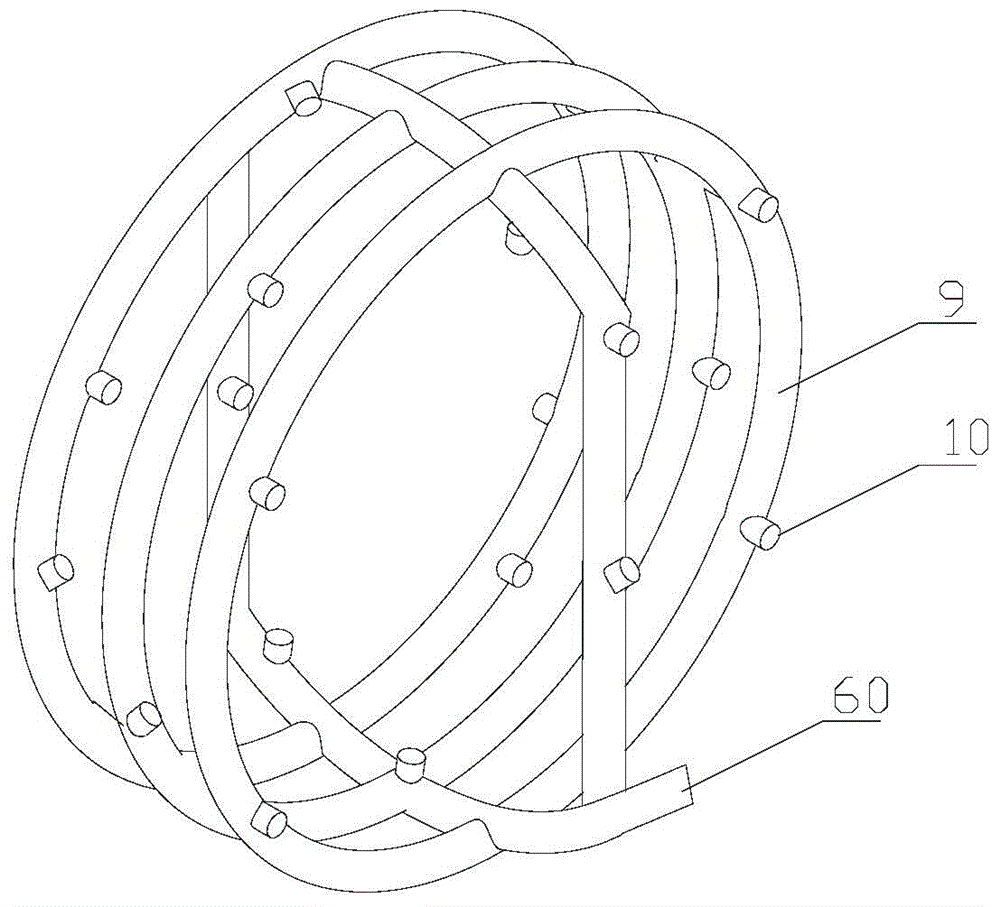

Wet-type dust-capturing wind current cooling device

ActiveCN104474819ACompact structureReduce volumeCombination devicesTemperature controlWorking environment

The invention provides a wet-type dust-capturing wind current cooling device mounted at a head-on rear position of a mining working face mining machine, connected with an outlet end of a polluted wind pumping canister and comprising a cover shell, and a spray dedusting device, a cyclone centrifugal dedusting device, a dust screen filtering device, an air cooling type heat exchanger and a baffle plate demister which are connected in order inside the cover shell; positions of the cover shell walls below the cyclone centrifugal dedusting device and the baffle plate demister are respectively provided with drainage pipe ports. Fully-mechanized excavating working face dust capturing and wind current cooling works are combined together, with a treatment mode of firstly dust capturing and then wind current cooling, polluted wind is firstly subjected to multi-stage dust capturing treatment and then is demisted and cooled, the working face wind current temperature is controlled in a suitable temperature, a safe and comfortable working environment of the down-hole working face is ensured, and the problems of high temperature and high dust of the mine mining working face are better solved.

Owner:SHANDONG UNIV OF SCI & TECH

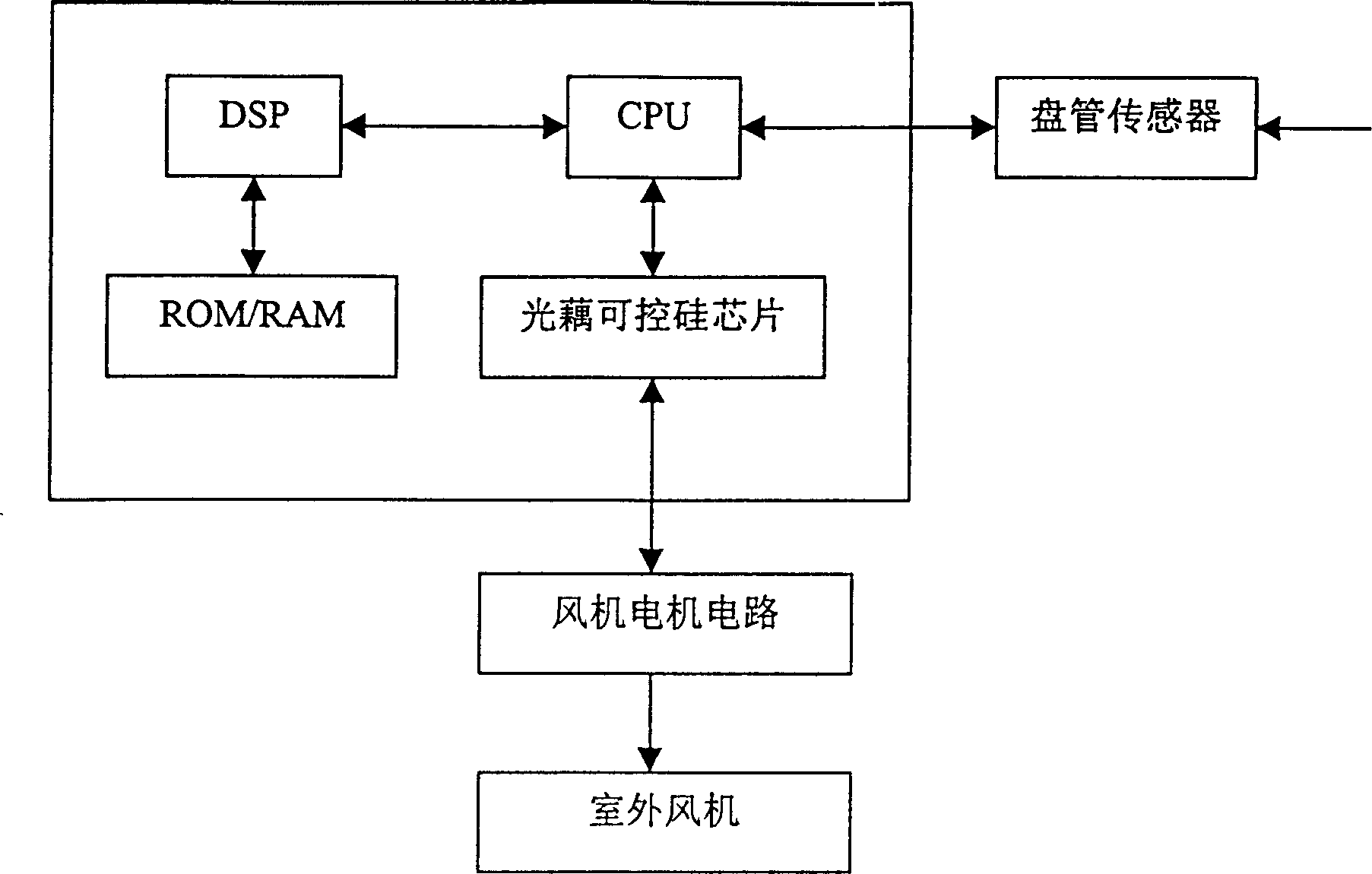

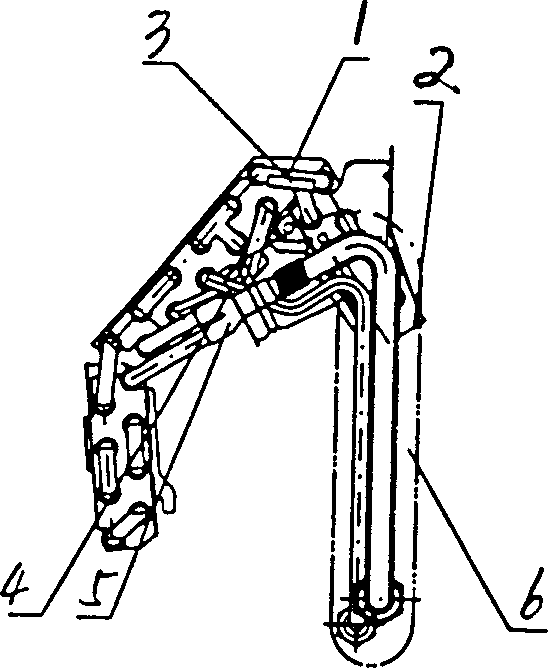

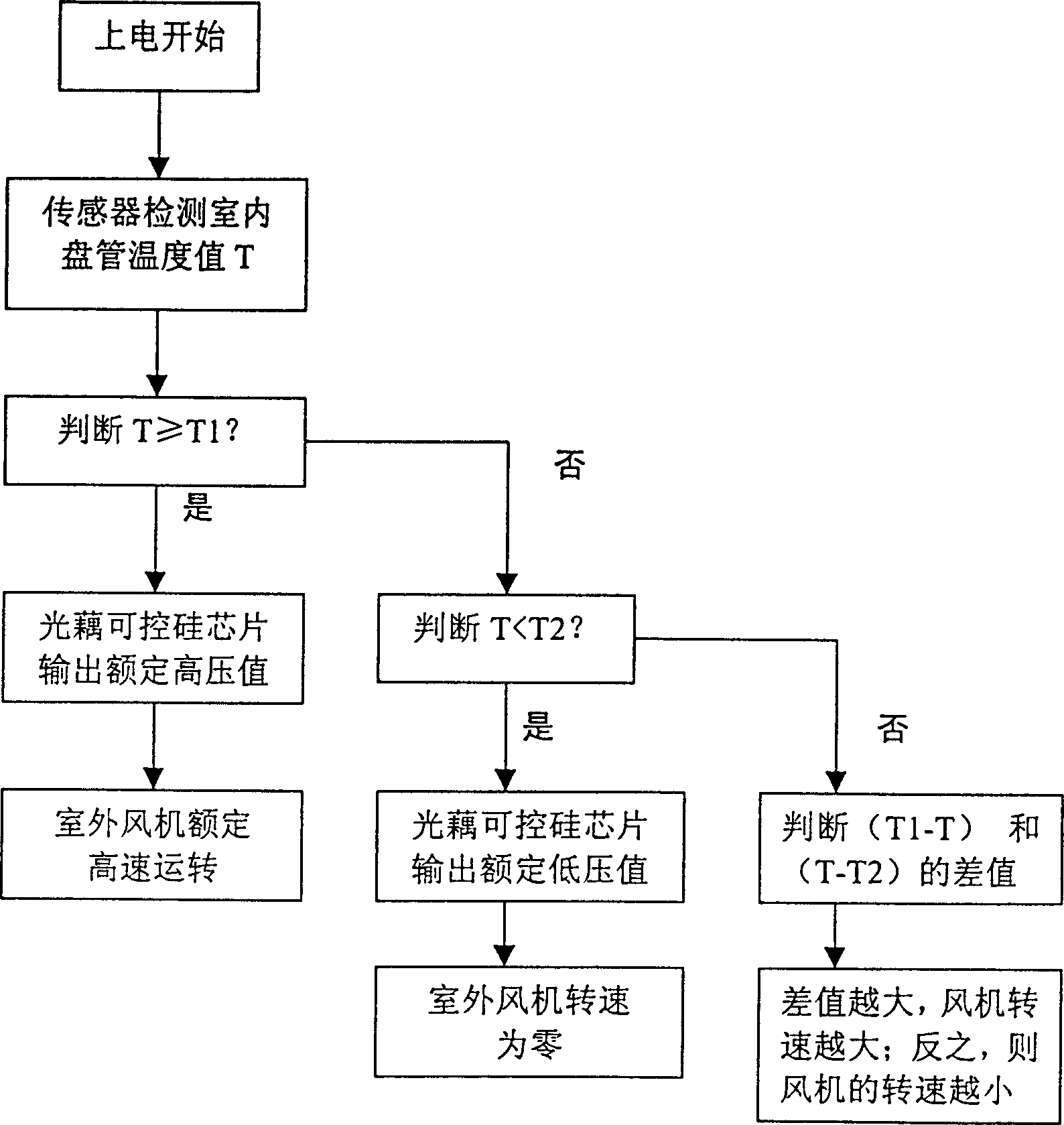

Method for preventing indoor coiled-tube from over-low temp., and air-conditioner thereof

InactiveCN1580660AReduce frostingRealize indoor cooling operationMechanical apparatusSpace heating and ventilation safety systemsMicrocontrollerEngineering

This is a method to prevent the indoor coil-pipe's temperature over lower, and its air conditioner. In the CPU of monotype set, install a temperature test block of the coil-pipe. Use the light-coupled silicon controlled method, according to the temperature of test value to control the alternating voltage of outdoor set, then to realize control the rotating speed of blower in the outdoor set. This invention provide a new electric-control method for fixed-frequency air conditioner, it can dynamic control the rotating speed of outdoor set's blower, to adjust the exchange efficient of this system in certain time interval.

Owner:HAIER GRP CORP +1

System and method for compressor capacity modulation in a heat pump

InactiveUS20090266091A1Increase capacityImprove efficiencyHeat pumpsCompression machines with non-reversible cycleEngineeringOutdoor temperature

A system and method is provided to control and operate a compressor to have two or more discrete output capacities in response to an outdoor temperature measurement. During operation of the compressor in an air conditioning or cooling mode, the compressor has a first output capacity in response to the outdoor temperature being greater than a first temperature setpoint and the compressor has a second output capacity in response to the outdoor temperature being less than a second temperature setpoint. During operation of the compressor in a heating mode, the compressor has different output capacities based on the outdoor ambient temperature.

Owner:BRISTOL COMPRESSORS INT

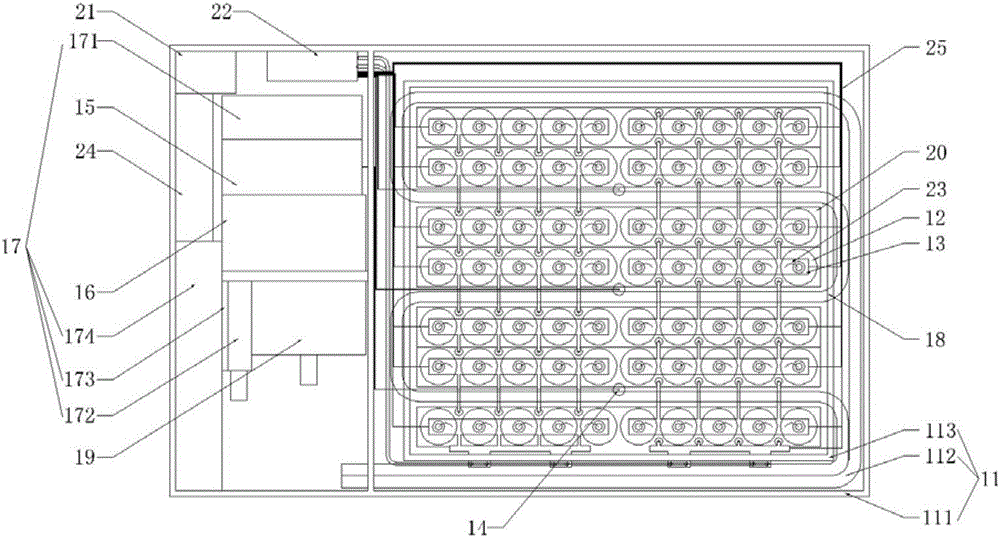

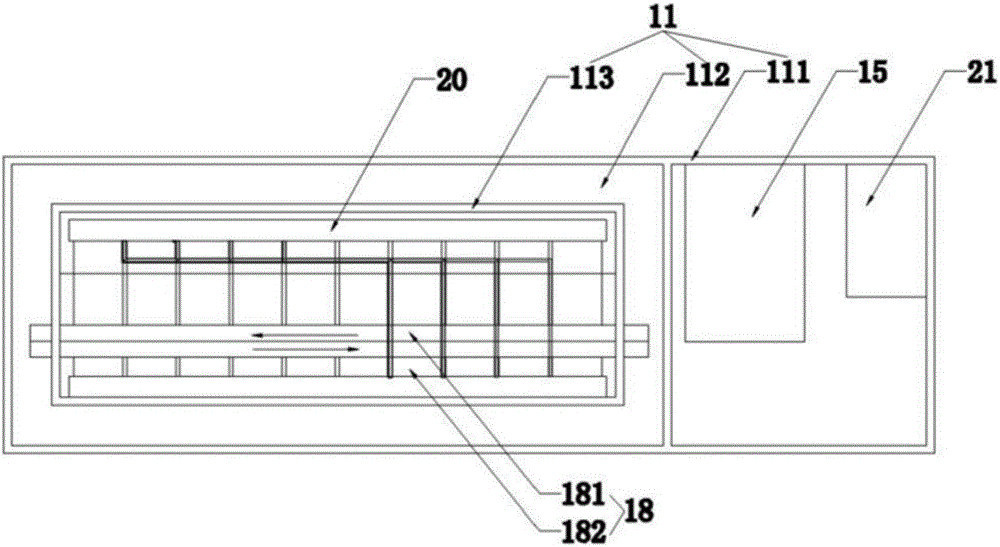

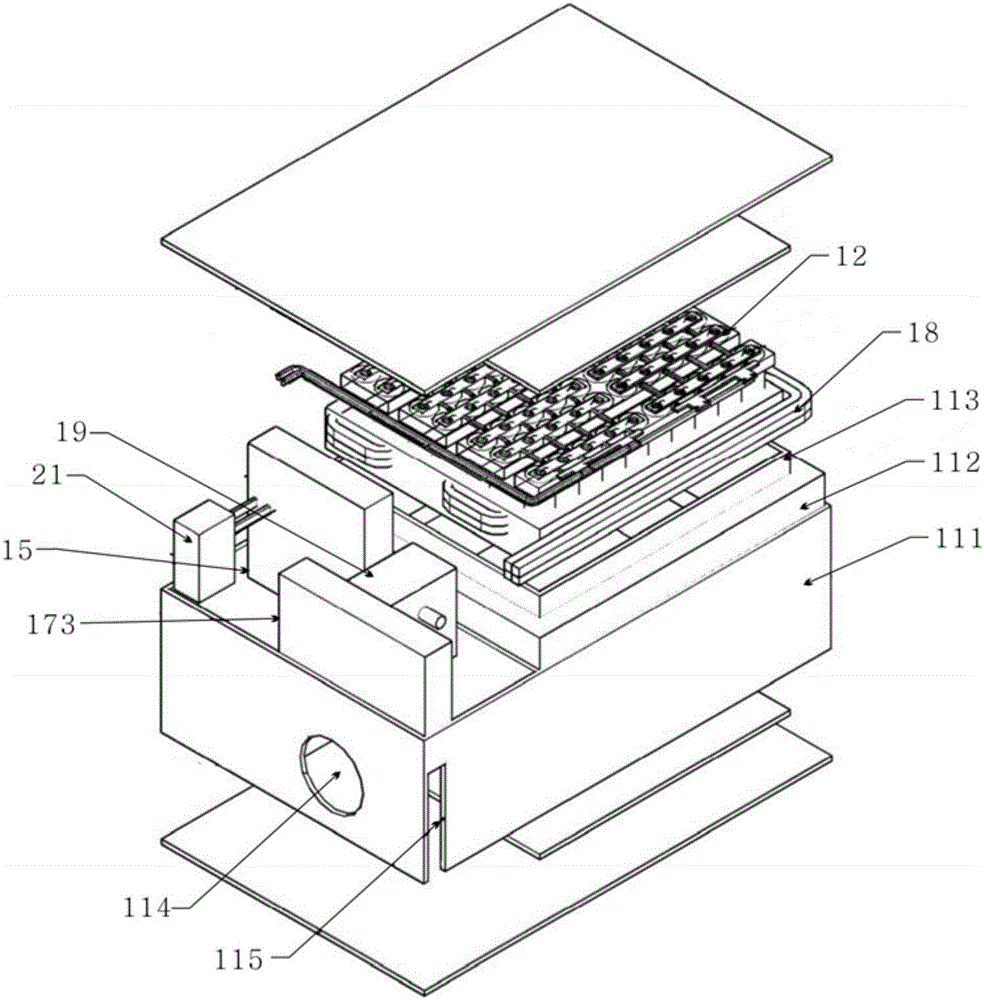

Battery system

InactiveCN106384852AReduce ambient temperatureIncrease the ambient temperatureCells structural combinationVehicular energy storageTemperature controlInner loop

The invention provides a battery system, and belongs to the technical field of batteries. The battery system comprises a case, a plurality of sections of battery cells, a temperature collecting probe, a BMS (battery management system), a heating and refrigeration assembly, a liquid flowing pipeline, a heat conduction medium and a water pump, wherein the liquid flowing pipeline passes through a gap formed among the plurality of sections of battery cells; the water pump drives the heat conduction medium to realize circulation flowing inside the pipeline; the temperature collecting probe and the heating and refrigeration assembly are electrically connected with the BMS; the BMS controls the heating and refrigeration assembly to work according to the temperature information feedback by the temperature collecting probe; the heating and refrigeration assembly and the liquid flowing pipeline perform heat exchange through a water cooling head so as to realize the heating and the refrigeration on the heat conduction media inside the liquid flowing pipeline; the whole temperature control system is directly controlled by the BMS. The battery system is provided with the temperature collecting probe, the heating and refrigeration assembly and the BMS; the environment temperature of the battery cells is regulated through controlling the temperature of the heat conduction media inside the liquid flowing pipeline, so that the battery cells always work in a set temperature range.

Owner:王波

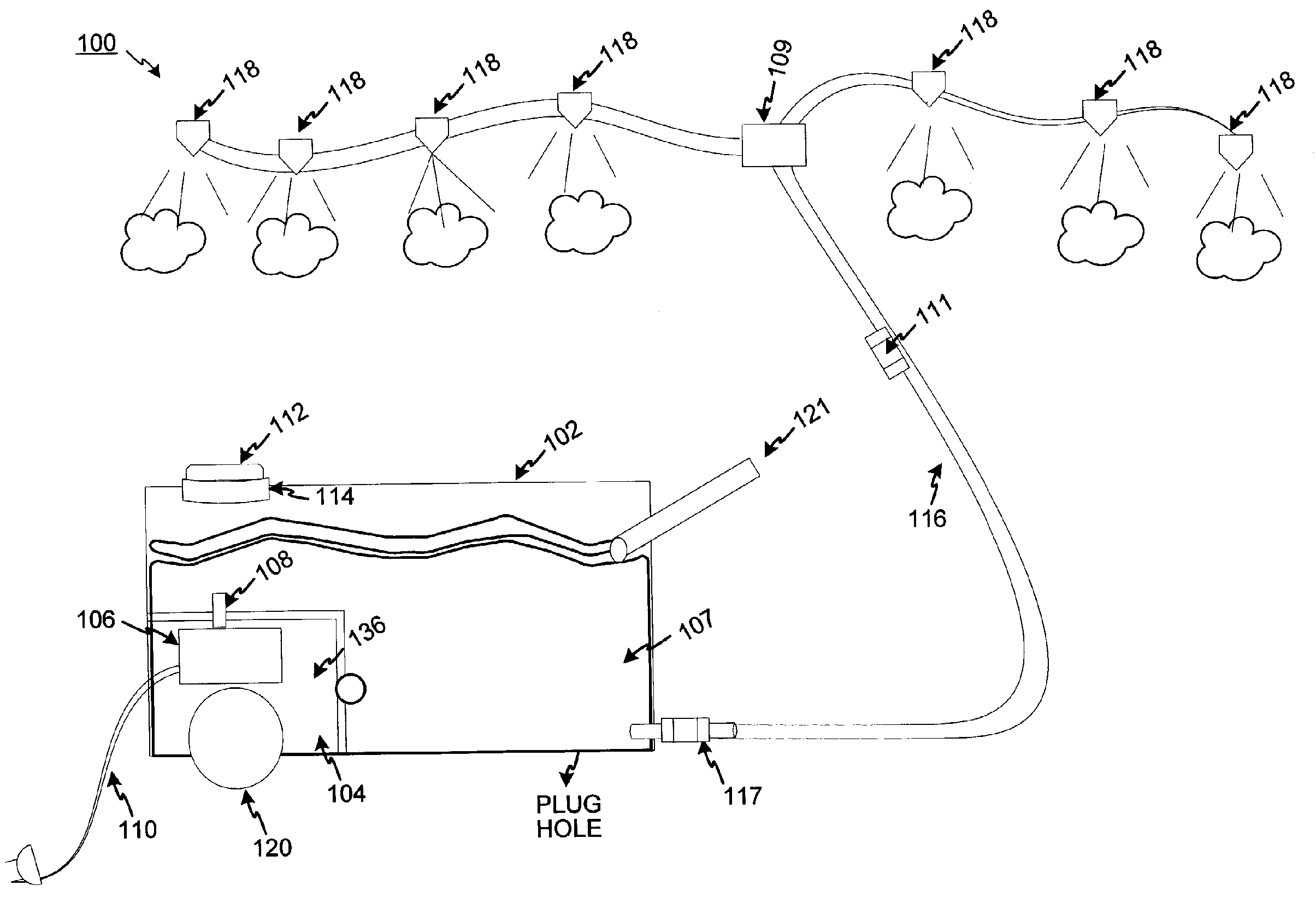

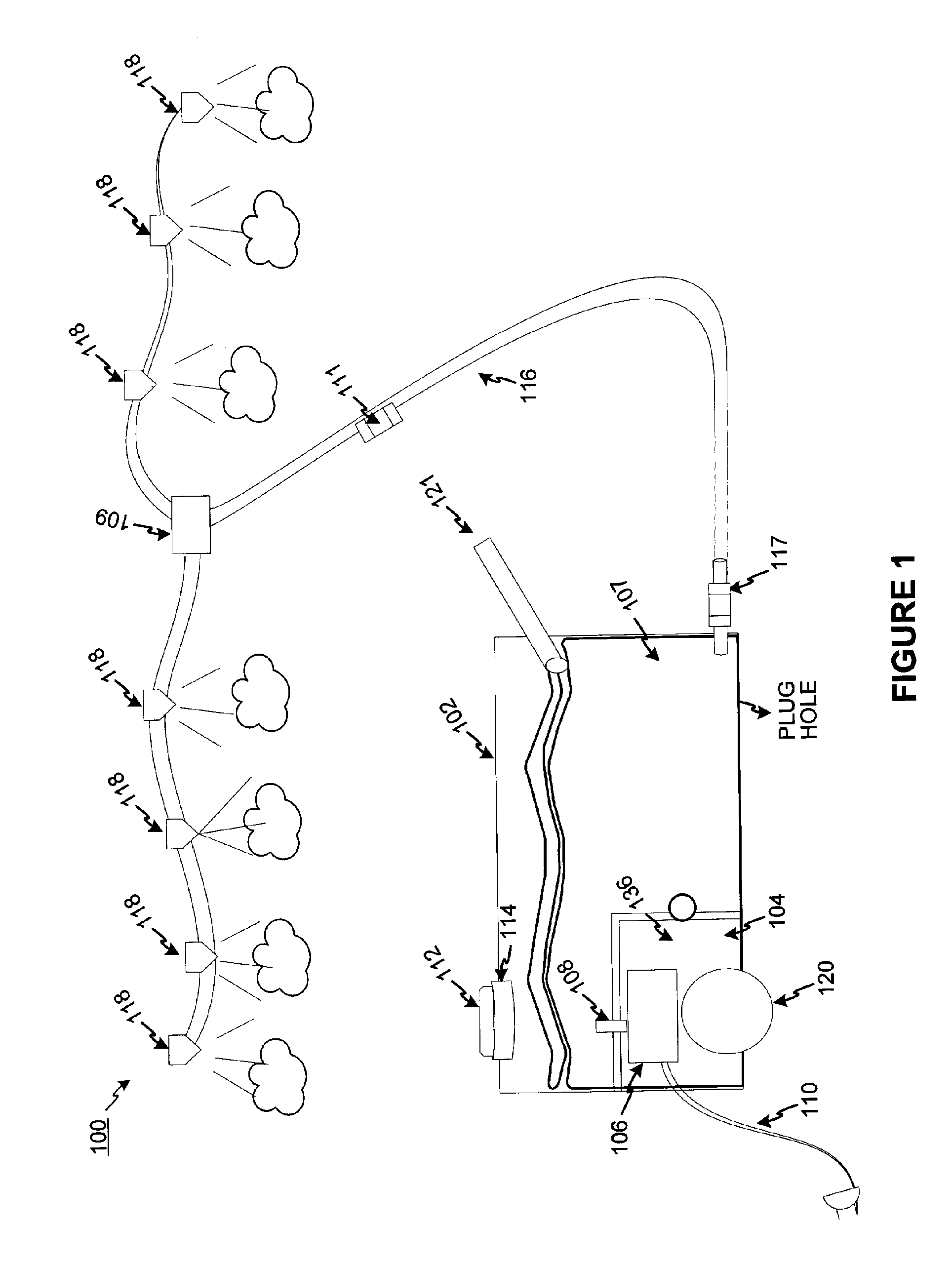

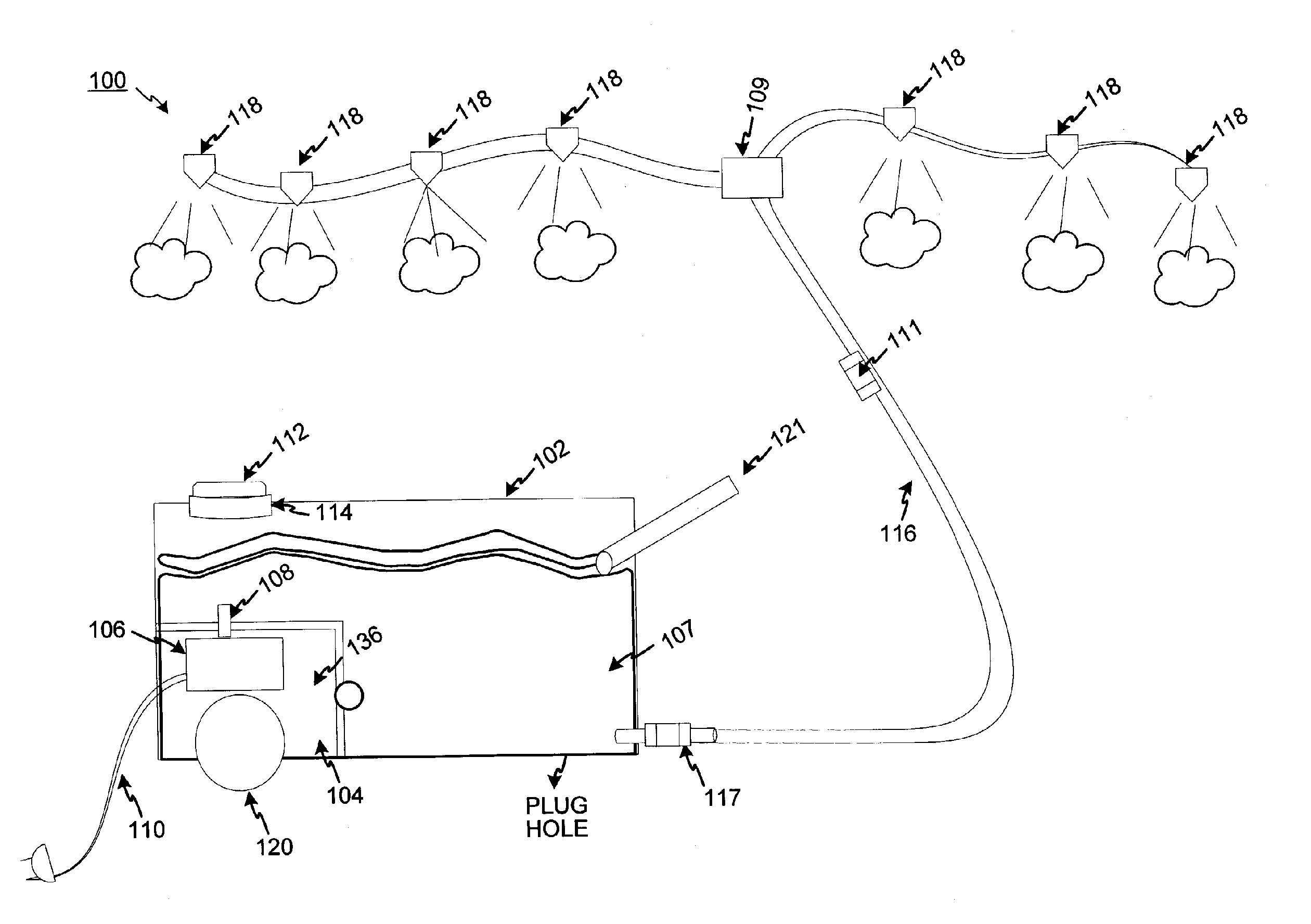

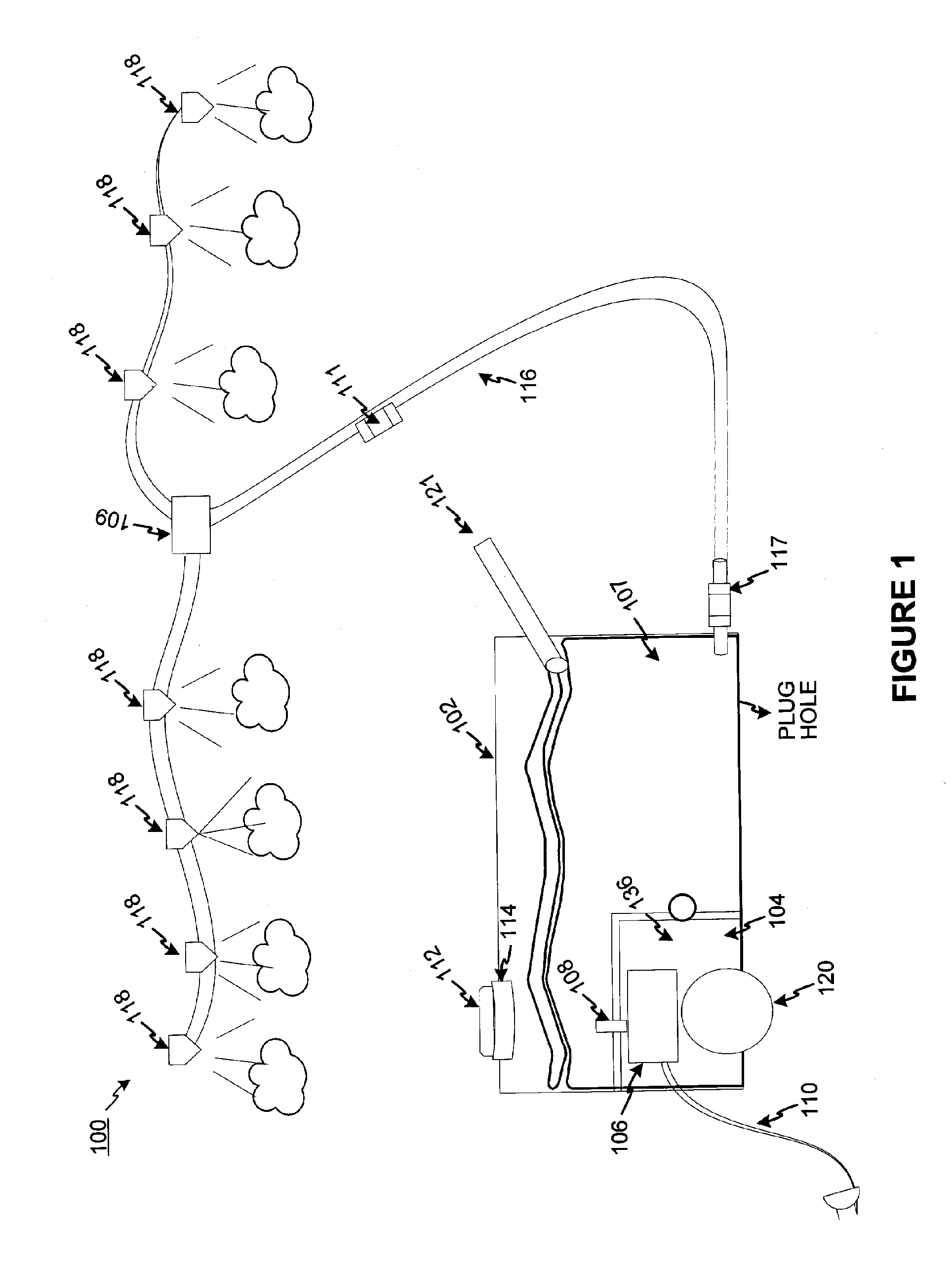

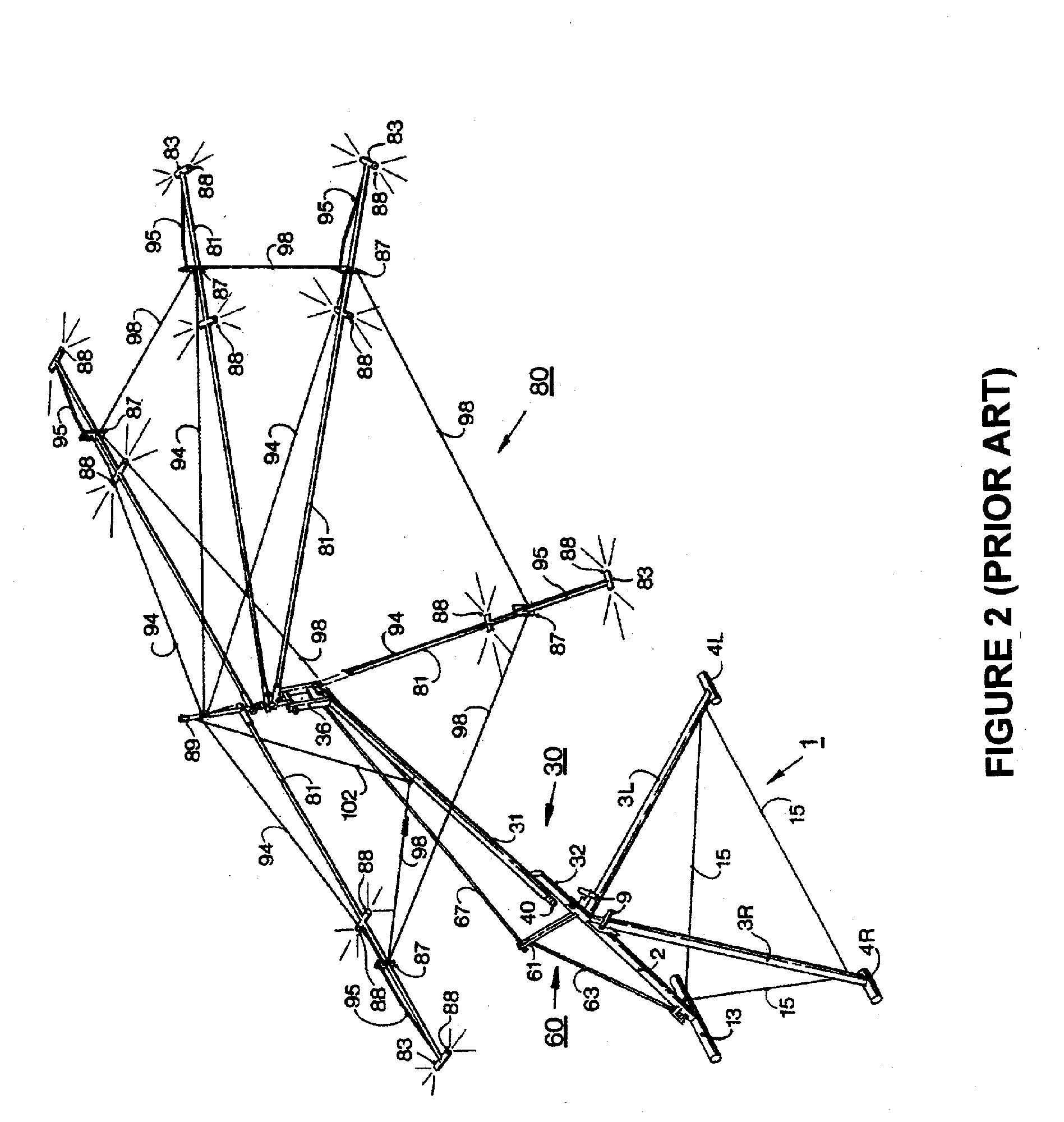

Portable mister for adjusting ambient temperature

InactiveUS7418832B2Reduce ambient temperatureIncrease in sizeAir-treating devicesDomestic cooling apparatusUser needsEngineering

Owner:FERRONO WILLIAM R +1

Portable mister for adjusting ambient temperature

InactiveUS20050082390A1Reduce ambient temperatureIncrease in sizeAir-treating devicesDomestic cooling apparatusUser needsAmbient air

A portable mister for cooling ambient air is disclosed comprising a housing for entirely containing a cooling agent, an irrigation system connected to the housing for receiving the cooling agent from the housing and dispersing the cooling agent in ambient air, and a pump for facilitating the transfer of the cooling agent to the irrigation system. The mister is portable in that the cooling agent is entirely enclosed in a portable housing. That is, the mister user need not connect the mister to a continuous cooling agent source for operation. Additionally, the irrigation system is configured for placement to cool the ambient air of a broad area. The housing may include a system for including a fragrance in the cooling agent. The fragrance including system facilitates added a pleasant aroma to the dispersed cooling agent.

Owner:FERRONO WILLIAM R +1

LED lighting device including heat dissipation structure and method for making the same

InactiveUS20140247606A1Reduce ambient temperatureExtend your lifePrinted circuit assemblingNon-electric lightingLight sourceEngineering

Owner:SENGLED OPTOELECTRONICS

High-efficiency thermochromic nano composite powder with core-shell structure and preparation method thereof

ActiveCN108659812AHigh visible light transmittanceWill not affect daylightingMaterial nanotechnologyNanoopticsVanadium dioxideThermochromism

The invention discloses a high-efficiency thermochromic nano composite powder with a core-shell structure. The composite powder takes a VO2 layer as a core layer and a tungsten bronze compound layer as a shell layer; the VO2 layer is vanadium dioxide nano-powder, the smallest dimension in three-dimensional dimensions of the VO2 layer is not more than 100nm, and the tungsten bronze compound layer is MxWO3, wherein M is selected from any one of NH4+, Cs+, K+, Na+ or Li+; the value of x ranges from 0.01 to 0.8; and the thickness of the tungsten bronze compound layer is less than 60nm, an infraredabsorption characteristic of a tungsten bronze material is utilized to enable the shell layer to absorb heat, and the heat is quickly transferred to VO2 particles in the core layer through the closely connected core-shell structure, which results in the temperature rise and phase change of VO2, so as to reduce the ambient temperature required by the phase change of VO2, improve the thermal response speed of VO2, shorten the phase change reaction time and achieve an effect of efficient thermochromism.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

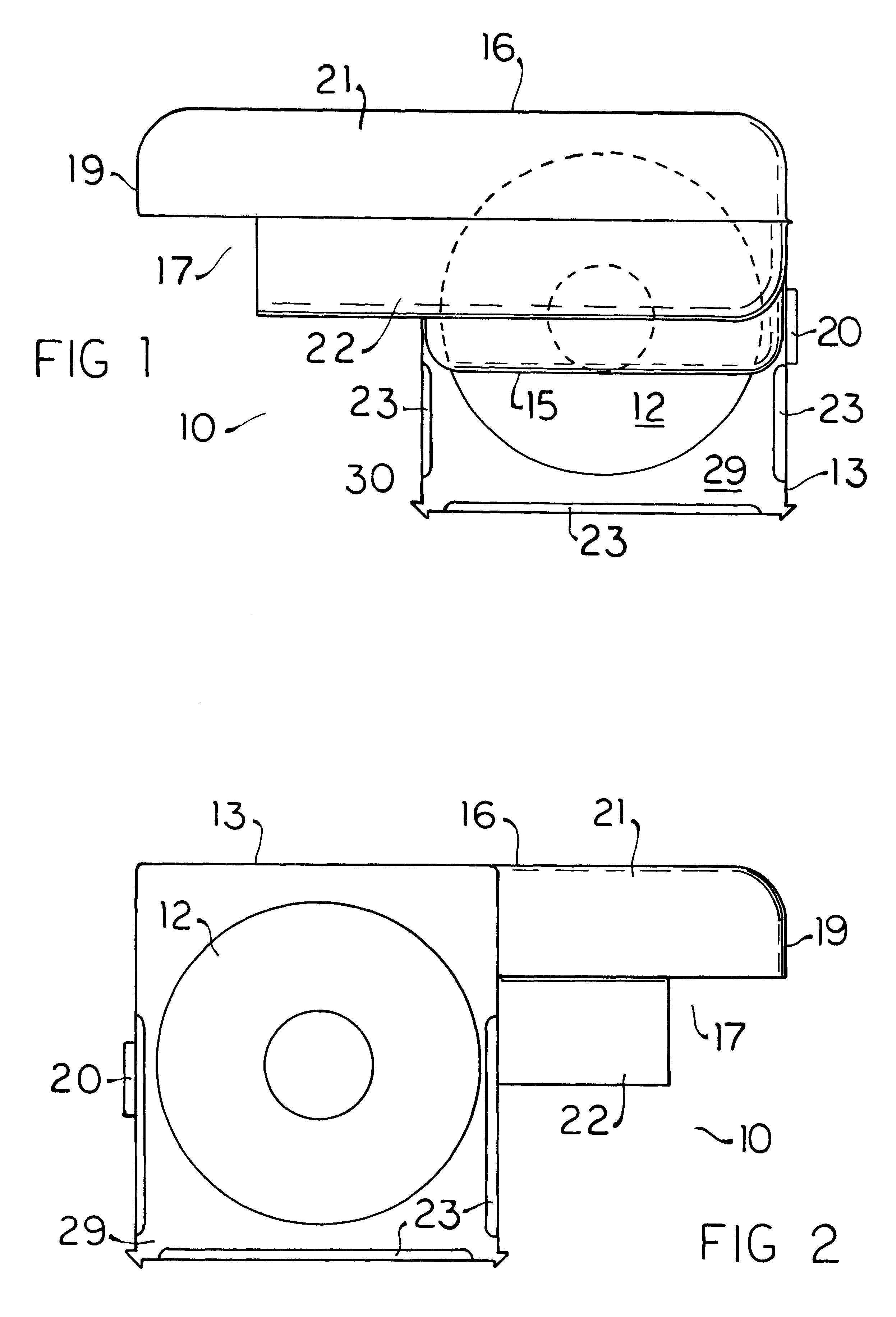

Retrofit Computer Cooler

InactiveUS6256197B1Reduce stepsReduce ambient temperatureDomestic stoves or rangesDigital data processing detailsChillerAirflow

An arcuate duct has an inlet continuous with a housing about a blower and an outlet perpendicular to the blower which further has a lip directing the air flow perpendicularly. The arcuate duct transforms an air flow intake along an X axis smoothly to air flow parallel a Y axis and the outlet lip directs the air flow parallel a Z axis given a horizontal disposition of the arcuate duct main body which utilized in a desktop PC. A vertical disposition is utilized in a tower type PC. In either case the blower is disposed adjacent an opening in the rear of the PC enclosure created by removing a removable panel and the arcuate main duct body is positioned between the IC cards and HDD on one side and the PC enclosure on the other side, being slightly compressed between the two to maintain positioning. Air flow through the arcuate duct is directed against the CPU and RAM. The lower portion of the blower is left open to blow air directly ahead past the IC cards against the HDD and auxiliary disk drives in front. The arcuate duct outlet is larger than the inlet minimizing back pressure and promoting laminar flow therethrough while an abrupt change of direction caused by the lip of the outlet induces turbulent flow and increased convection. Installation requires no rearrangement of components in the PC and no fixed attachment to the PC.

Owner:GALIS OSCAR

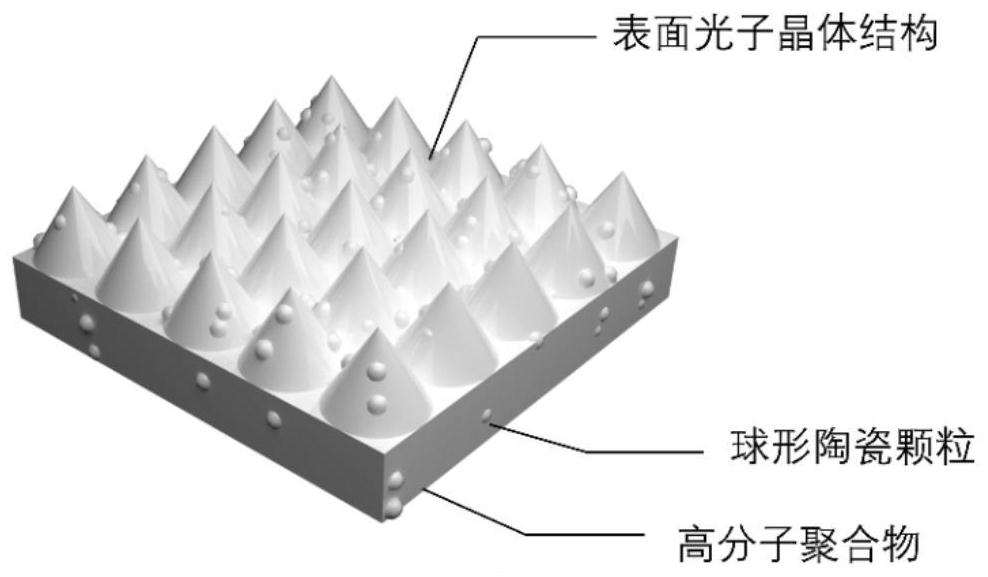

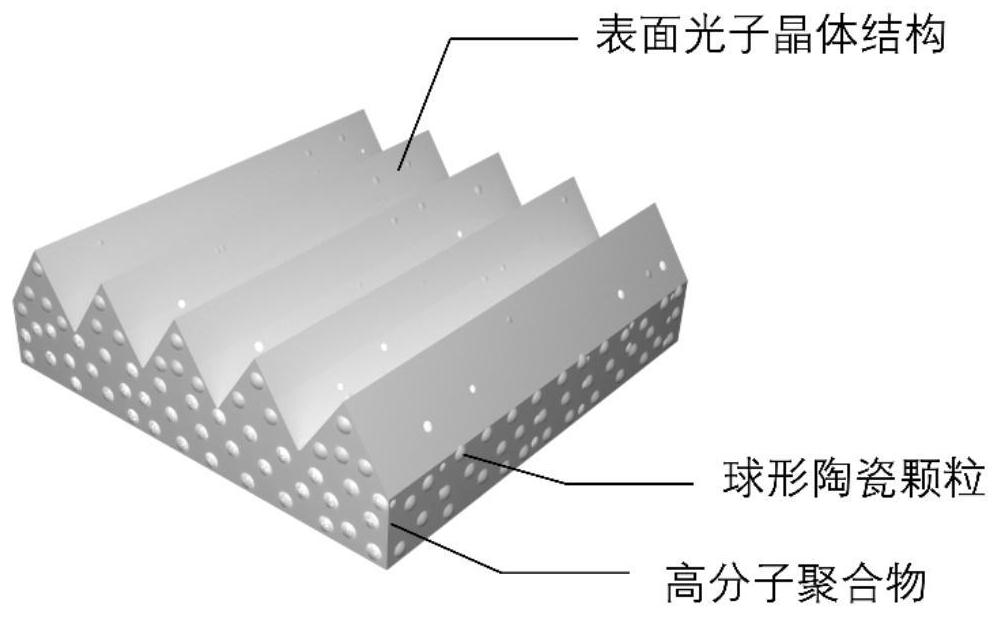

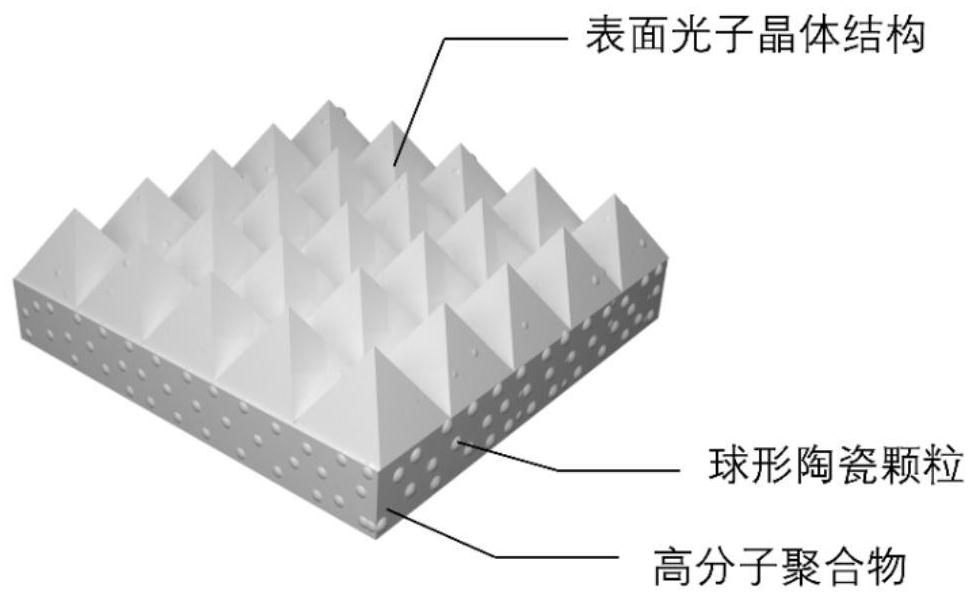

Radiation cooling film and preparation method and application thereof

The invention discloses a radiation cooling film which is formed by mixing ceramic particles, an organic solution and a curing agent, mixing the ceramic particles with an organic curing precursor solution, and curing, a micro-nano photon structure array is formed on the surface of the film, and the micro-nano photon structure array comprises a plurality of arrayed micro-nano photon structure elements. The invention further discloses a preparation method and application of the radiation cooling film. The film has the reflectivity of 95% in the sunlight band and the radiance of 96% in the atmospheric window band, can be lower than the ambient environment by 10 DEG C at most under the illumination condition, and also has good flexibility and strength and excellent hydrophobicity. The radiation cooling film is prepared in a low-cost and large-area manner by adopting a multi-etching double-spin-coating vacuum thermocuring process. The radiation cooling film is applied to the aspects of human body wearable cooling, cooling umbrellas and device heat dissipation, and a cooling method is achieved by removing heat from the surface and the interior of a main body in a heat radiation mode.

Owner:SHANGHAI JIAO TONG UNIV

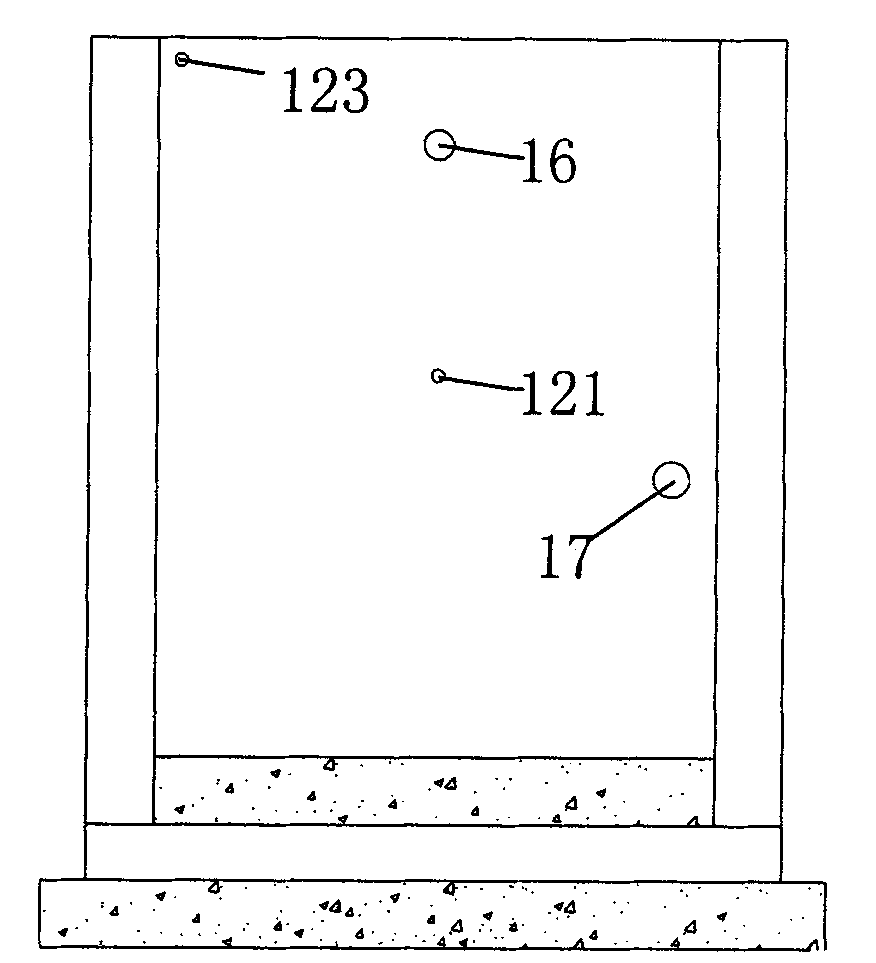

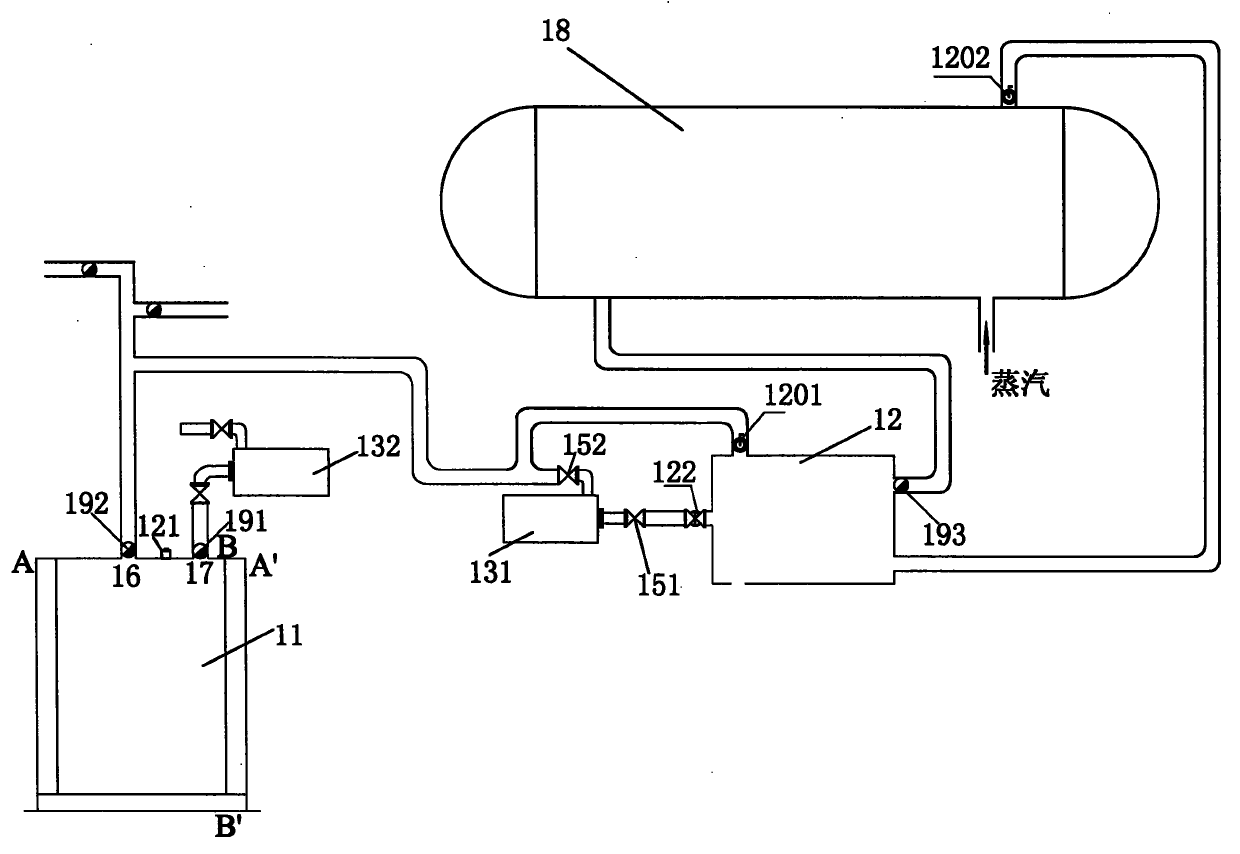

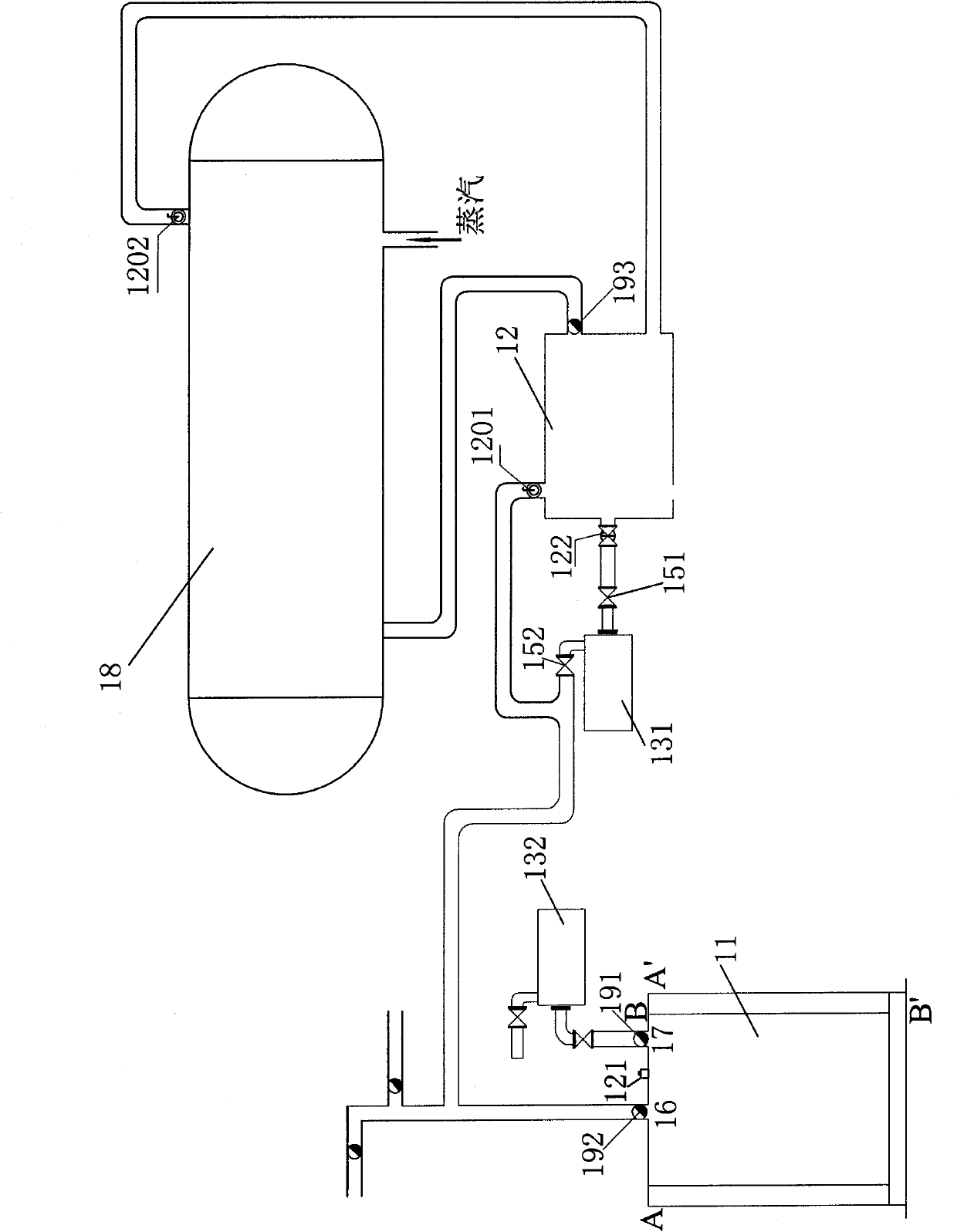

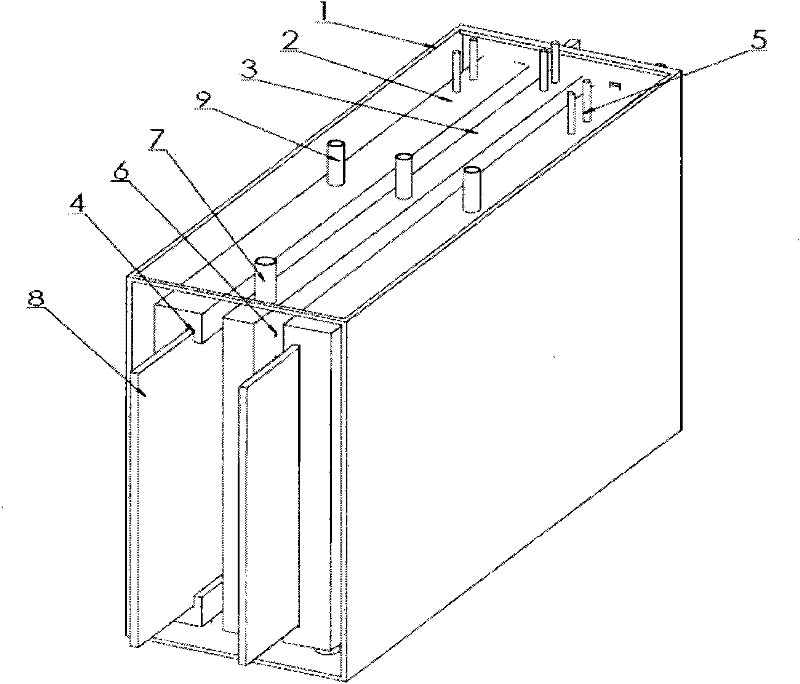

Water curing method and device for centrifuged pretensioned prestressed concrete pipe pile

ActiveCN101905486ATo overcome the lack of maintenance technologyRealize environmentally friendly productionCeramic shaping apparatusWater storage tankEngineering

The invention relates to a pipe pile water curing method. In the method, a water storage tank is arranged, and condensate water and residual steam in a still kettle are guided into the water storage tank; a pipe pile is placed in a steaming and curing pool, the condensate water in the water storage tank is guided into the steaming and curing pool, and the residual steam in water storage tank is guided into the steaming and curing pool; and steaming and curing the pipe pile in the steaming pool for 4-5 hours at 80-90 DEG C. The curing device comprises the steaming and curing pool, the water storage tank and the still kettle, wherein the steaming and curing pool is provided with a water-steam port; the water storage tank is provided with a residual steam outlet, a residual steam inlet, a condensate water outlet and a condensate water inlet; and the still kettle is provided with a steam inlet and a steam outlet. A condensate channel is arranged between the water-steam port of the steaming pool and the condensate water outlet of the water storage tank, and a steam channel is arranged between the water-steam port of the steaming pool and the residual steam outlet of the water storage tank. The condensate water inlet of the water storage tank is communicated with the condensate water outlet of the still kettle through a third electric control valve and a pipeline, and the steam inlet of the water storage tank is communicated with the steam outlet of the still kettle through a second steam valve and a pipeline.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

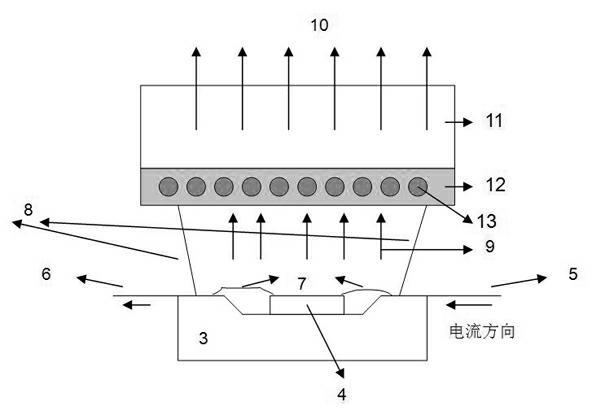

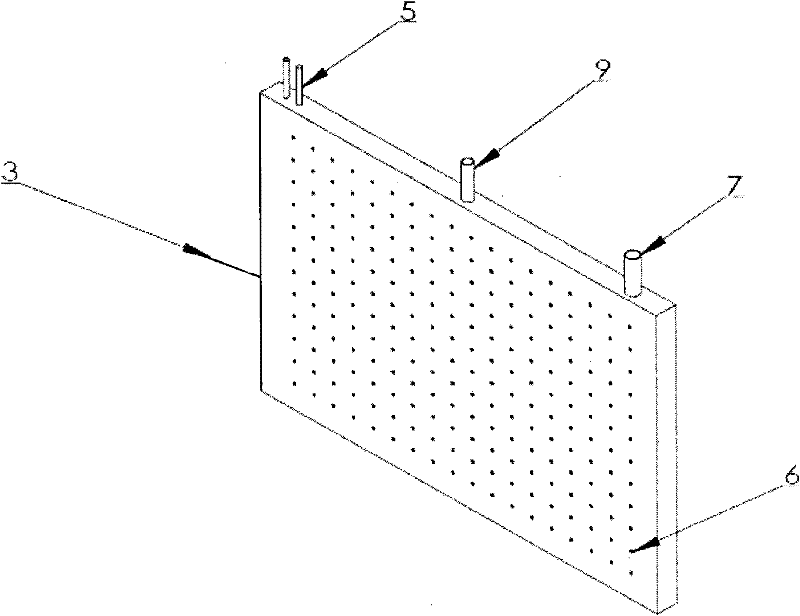

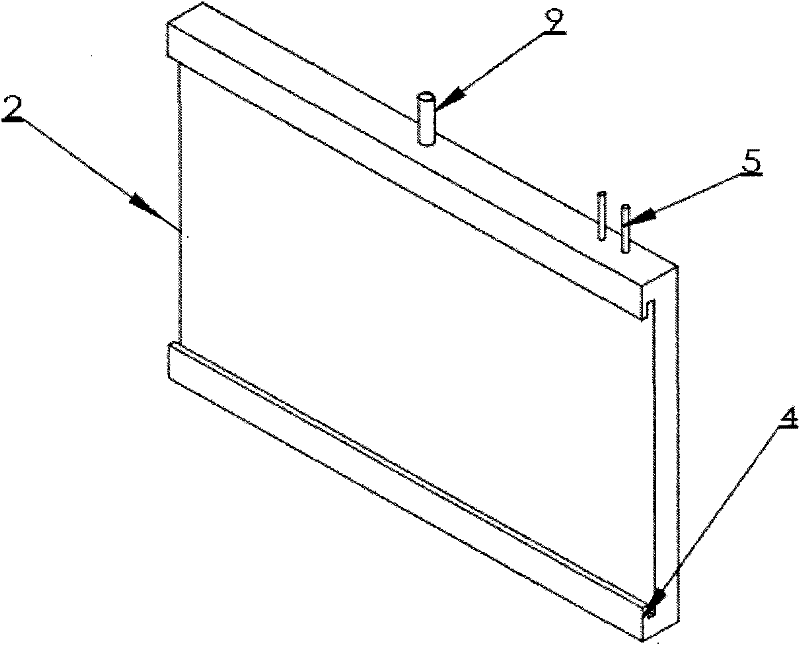

Plasm-aided selenium sulfuration treatment device and process

InactiveCN102051603ALow heating temperatureImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingFilm materialVacuum chamber

The invention relates to a plasm-aided selenium sulfuration treatment device arranged in a vacuum chamber. The plasm-aided selenium sulfuration treatment device comprises a shell, a cathode plate and an anode plate, wherein the cathode plate and the anode plate are alternately stacked to form a plasm generator, the cathode plate is provided with a groove for fixing a semiconductor film substrate, and small holes are uniformly distributed on the surface of the anode plate which is provided with a gas pipe, an independent internal heating electrode and an anode temperature-measuring point. The process based on the treatment device comprises the following steps of: (1) precasting a metal layer on the semiconductor film material according to the proportions of a chemical formula and then putting in the groove of the cathode plate; and (2) putting in the vacuum chamber to vacuumize, switching on a power supply to heat the cathode plate and the anode plate, switching on a power supply of the plasm generator and adding the mixed gases of selenium or sulfur, hydrogen and argon. The invention has the advantages that selenium ions have high reaction activity, the selenizing reaction of the metal precast layer is complete, the photoelectric conversion efficiency is high, and the substrate has lower heating temperature and is hardly deformed. An electronic mode is adopted to monitor the change of capacitive reactance between the two electrodes, know the conversion development and reduce the defective index of the industrial production.

Owner:NANKAI UNIV

Techniques for controlling vapor pressure in an immersion cooling tank

ActiveUS9464854B2Decrease the amount of vapor in the tankGood for condensationVolume/mass flow measurementElectrical apparatus contructional detailsSteam pressureDifferential pressure

A method that controls pressure within an immersion cooling tank having condensation fluid flowing through a condenser, includes: a controller receiving a signal that indicates a current level of vapor pressure within the tank; determining from the signal when the current level of vapor pressure exceeds or is below a first preset threshold pressure level; and in response to the current level of vapor pressure exceeding or being below the first preset threshold pressure level, signaling a flow control mechanism that modulates a flow rate of the condensation fluid through the condenser to increase or decrease the rate of flow from a current rate of flow. The controller receives the signal by a pressure sensor within the immersion cooling tank detecting the current vapor pressure, generating the signal and forwarding the signal to the controller. The pressure sensor can be a differential pressure transducer that measures a differential pressure internal to and outside of the immersion tank.

Owner:DELL PROD LP

Vented and ducted sub-rack support member

ActiveUS20070230119A1Decrease air temperatureDissipate any improvementCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersBackplaneAirflow

A chassis for plug-in modules may be provided with a vented and ducted sub-rack support member. The vented and ducted sub-rack support member may deflect a portion of the air flowing within the chassis through vents in the top surface of the vented and ducted sub-rack support member in order to increase the air flow to heat producing components mounted on the backplane above the support member. The increased air flow may increase air flow velocity and decrease the ambient temperature of the air around these components and improve the dissipation of heat from each component into the air. Air flow above the vented and ducted sub-rack support member may also be redirected by upper deflectors mounted on the support member to portions of plug-in cards adjacent to the upper deflectors and may provide additional cooling to components on the plug-in cards near the backplane.

Owner:NATIONAL INSTRUMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com