LED (Light Emitting Diode) illumination intelligent control system

An intelligent control system and LED lighting technology, applied in energy-saving control technology, lighting devices, light sources, etc., can solve the problems of increased light decay of LED chips, reduced forward current, and increased maintenance and use costs, so as to improve the working environment temperature, The effect of improving reliability and life and reducing the chance of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

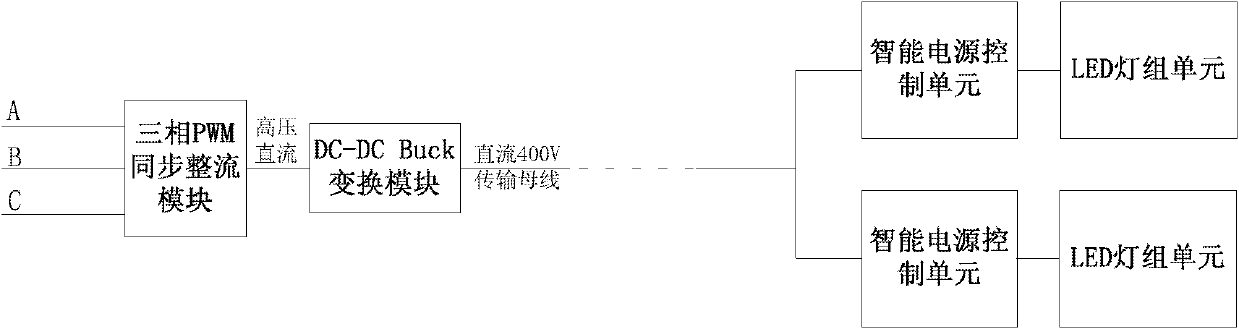

[0035] See figure 1 As shown, the LED lighting intelligent control system of the present invention includes a synchronous rectification unit for providing DC power to at least two intelligent power supply control units, and the output ends of each intelligent power supply control unit are connected to the corresponding LED lamp group units through wires, synchronously The rectifier unit is connected to the intelligent power supply control unit through each high-voltage DC bus, and provides constant voltage DC to multiple intelligent power supply control units through the synchronous rectification unit, and each intelligent power supply control unit completes the drive control and detection of its corresponding LED lamp group unit, and supplies LED The light unit provides power and PWM control signals.

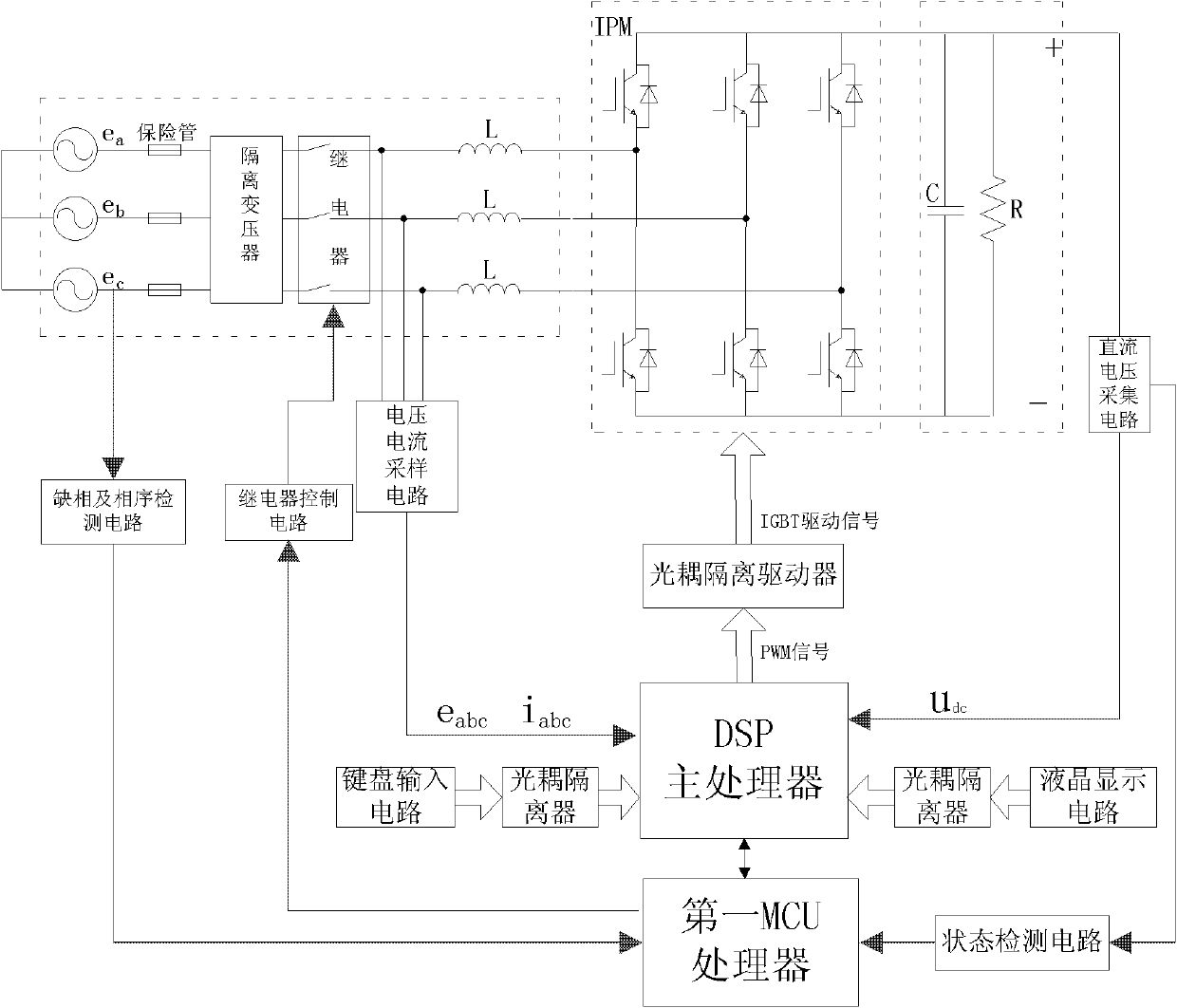

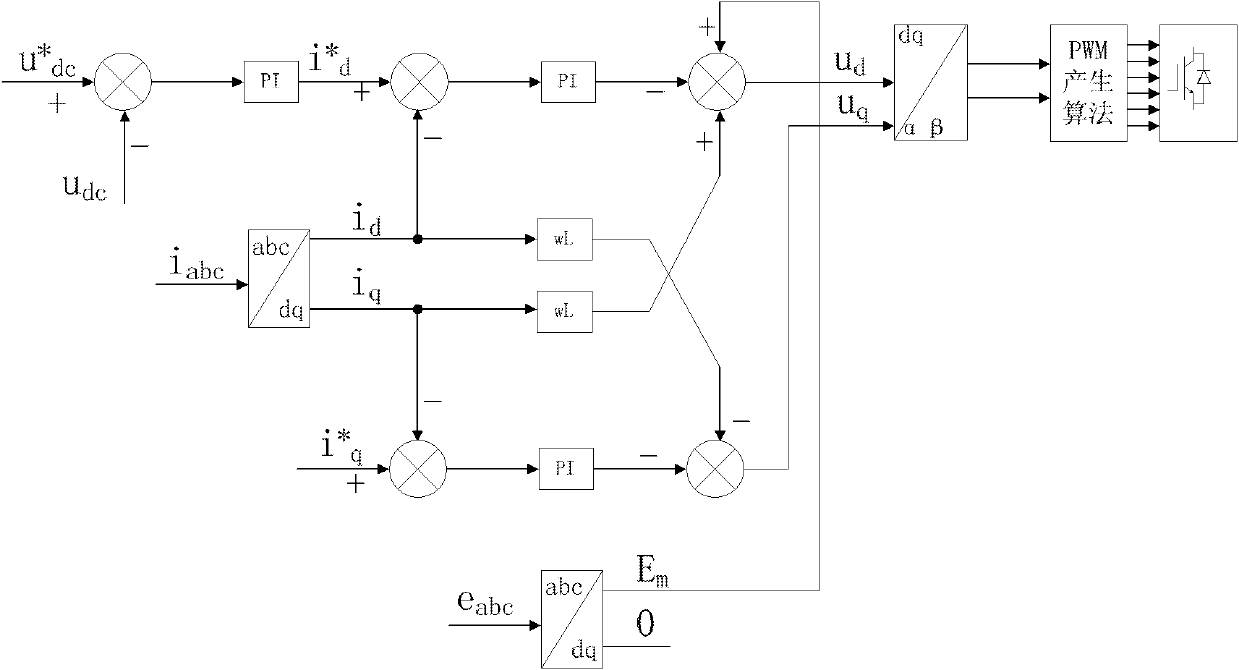

[0036] See figure 1 , 2 As shown, the synchronous rectification unit of the present invention includes a three-phase PWM synchronous rectification module and a DC-DC Buck con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com