Heat pump type curing barn environment humidity control system

A technology of environmental humidity and control system, applied in control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc., can solve problems such as heat pump can not continue to work, heat conduction steel pipe frosting, unsafe and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

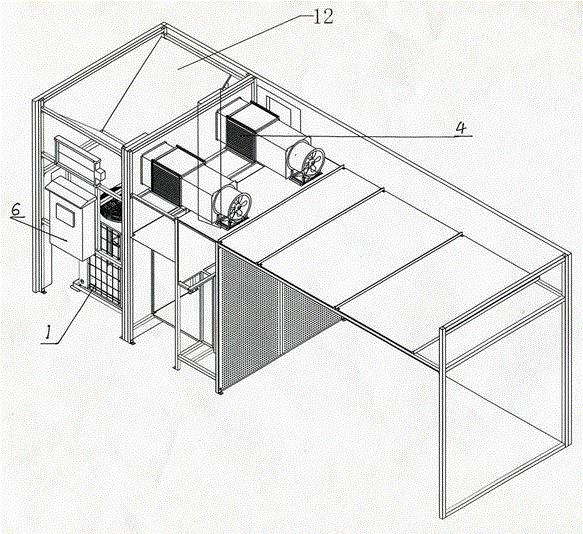

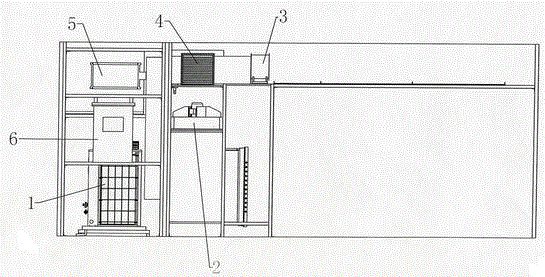

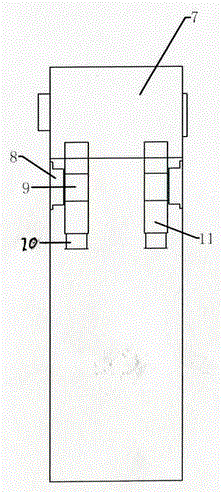

[0012] This technical solution is based on the exhaust gas recycling structure. See figure 1 , 2 , 3, and the electrical automatic control system (such as Figure 4 Shown).

[0013] The technical solution is composed of a roasting barn and a heat pump unit room. The heat pump unit room 7 is provided with a heat pump unit 1, a circulating fan 2, a dehumidification fan 3, an electrical control cabinet 6 and a heat exchanger 9 with air intake and dehumidification. The heat pump unit room is a fully enclosed room, and an exhaust air duct 12 is laid above the heat pump unit room, and an exhaust air door 5 is installed on the port of the exhaust air duct. The moisture exhaust duct 11 is introduced into the exhaust air duct between the heat pump units. The moisture exhaust air duct is equipped with a moisture exhaust damper 10, and the moisture exhaust duct is located in the circulating return air duct on the upper part of the roasting barn to prevent the heat pump unit The external air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com