Method for squeezing oil by wetting, steaming and frying cottonseed kernels

A technology of steaming and frying cottonseed kernels, which is applied in the direction of fat oil/fat production, fat material recycling, fat generation, etc. It can solve problems such as uneven wetting, limited equipment capacity, and inability to effectively increase production capacity, so as to improve the working environment and ambient temperature, capacity and production efficiency increase, and the effect of reducing water vapor volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

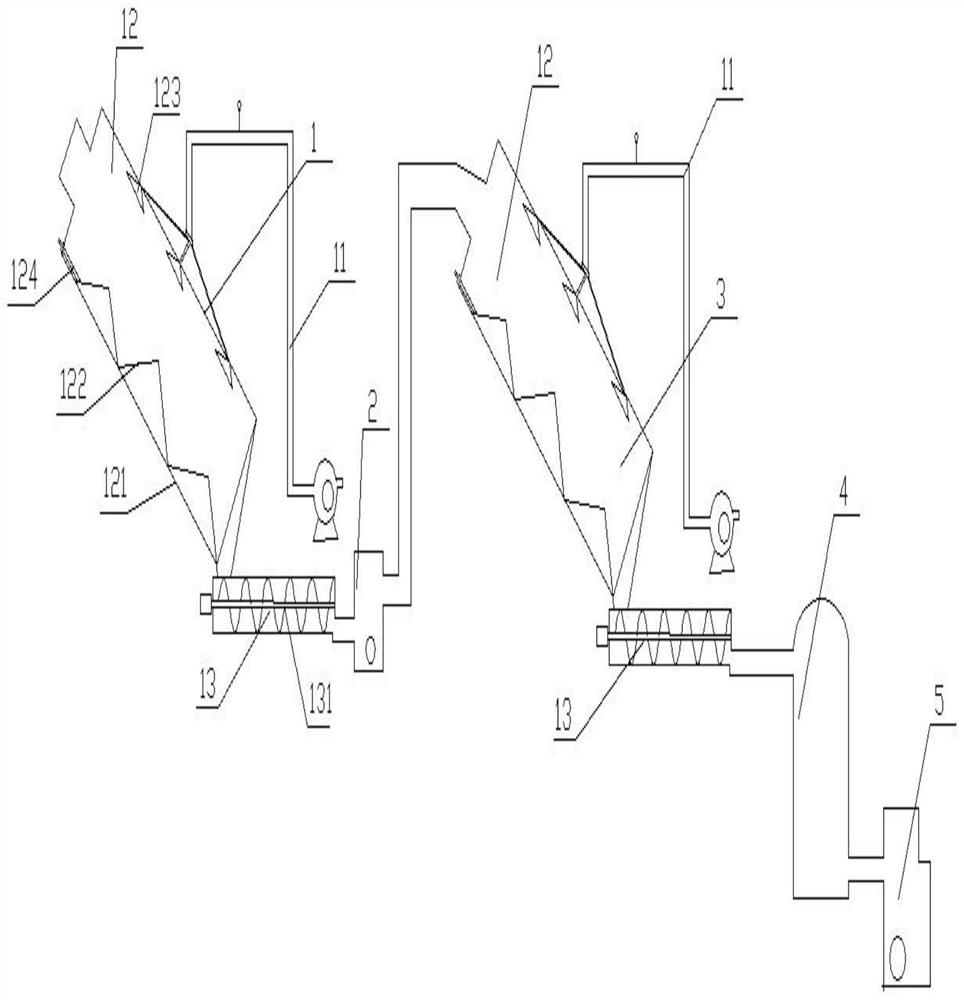

[0019] Embodiment 1, the present invention also includes a kind of method of cottonseed kernel wetting, steaming, frying and oil pressing, comprising the following steps:

[0020] Step 1, primary wetting: send the cottonseed kernels into the water-material contact humidifier 12 of the primary wetting system 1, open the atomizing nozzle 123, and the sprayed droplets fall to the cottonseed kernels below. At the same time, since the long cylindrical box 121 is inclined downward from one end of the feeding port to one end of the discharging port, the cottonseed kernels fall from one end of the feeding port to the other end of the discharging port under the action of gravity. In addition, the bottom of the long cylindrical box is provided with a plurality of baffle plates 122 that are hingedly connected to each other in a zigzag shape. The cottonseed kernels are blocked and buffered by the baffle plates 122, the falling speed is slowed down, the wetting time is prolonged, and the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com