Patents

Literature

366results about How to "Increase the ambient temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

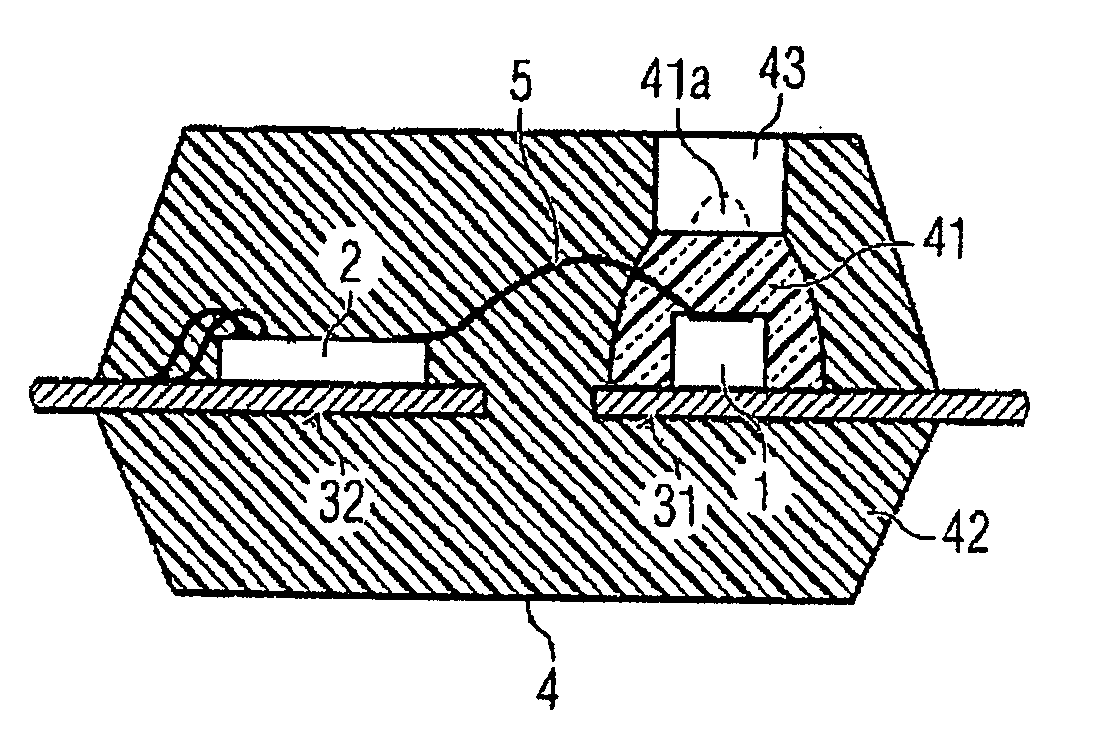

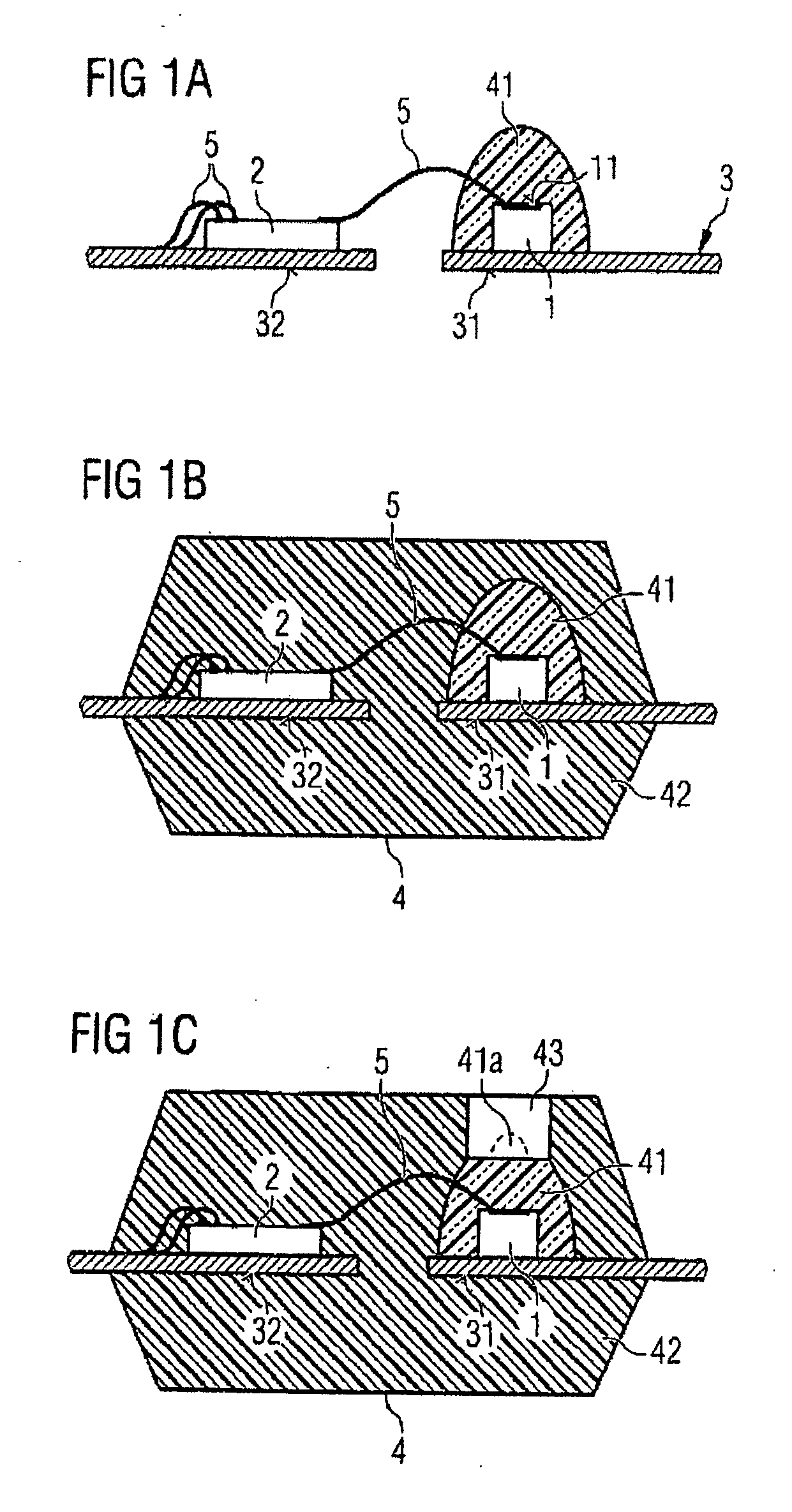

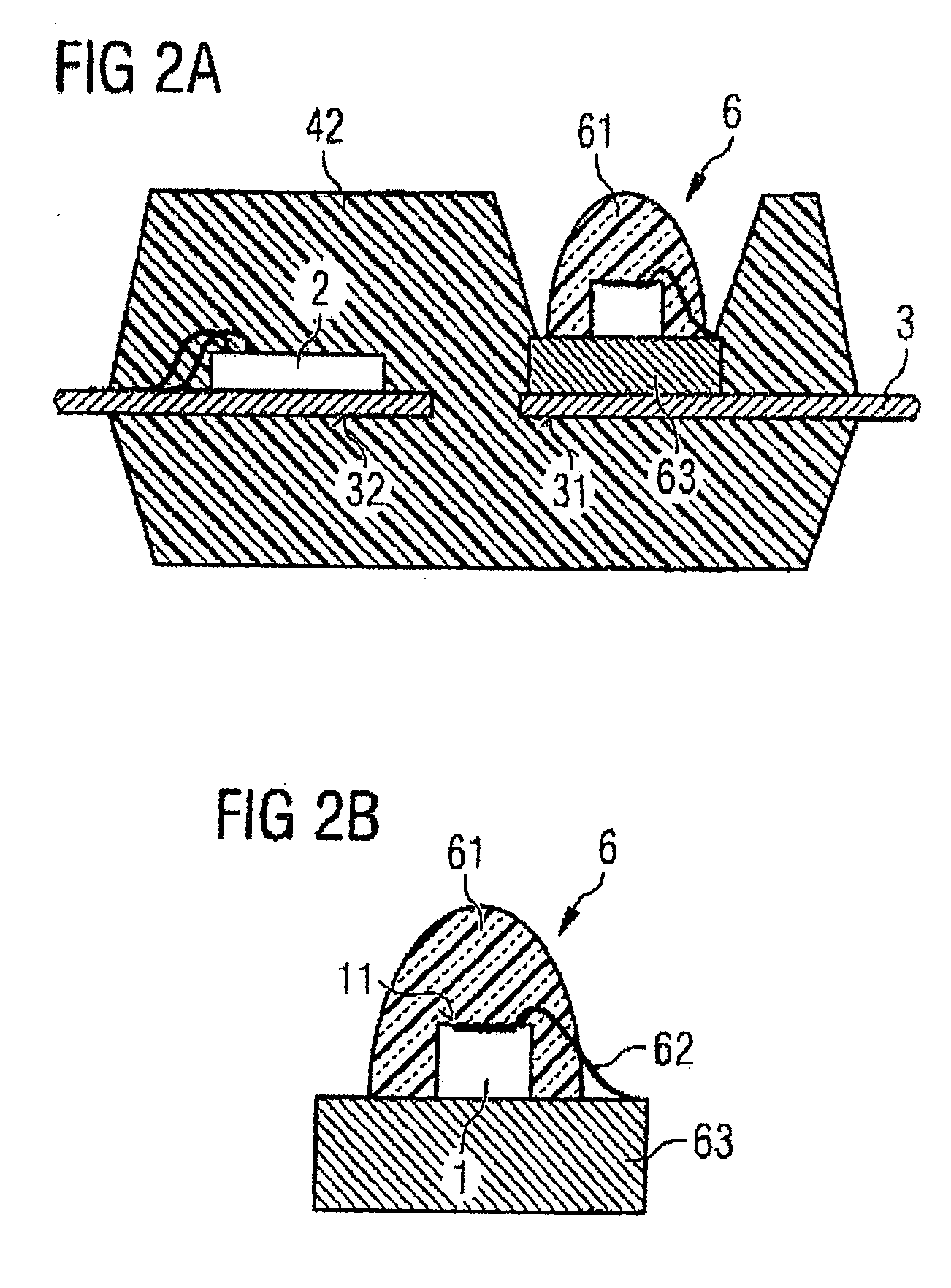

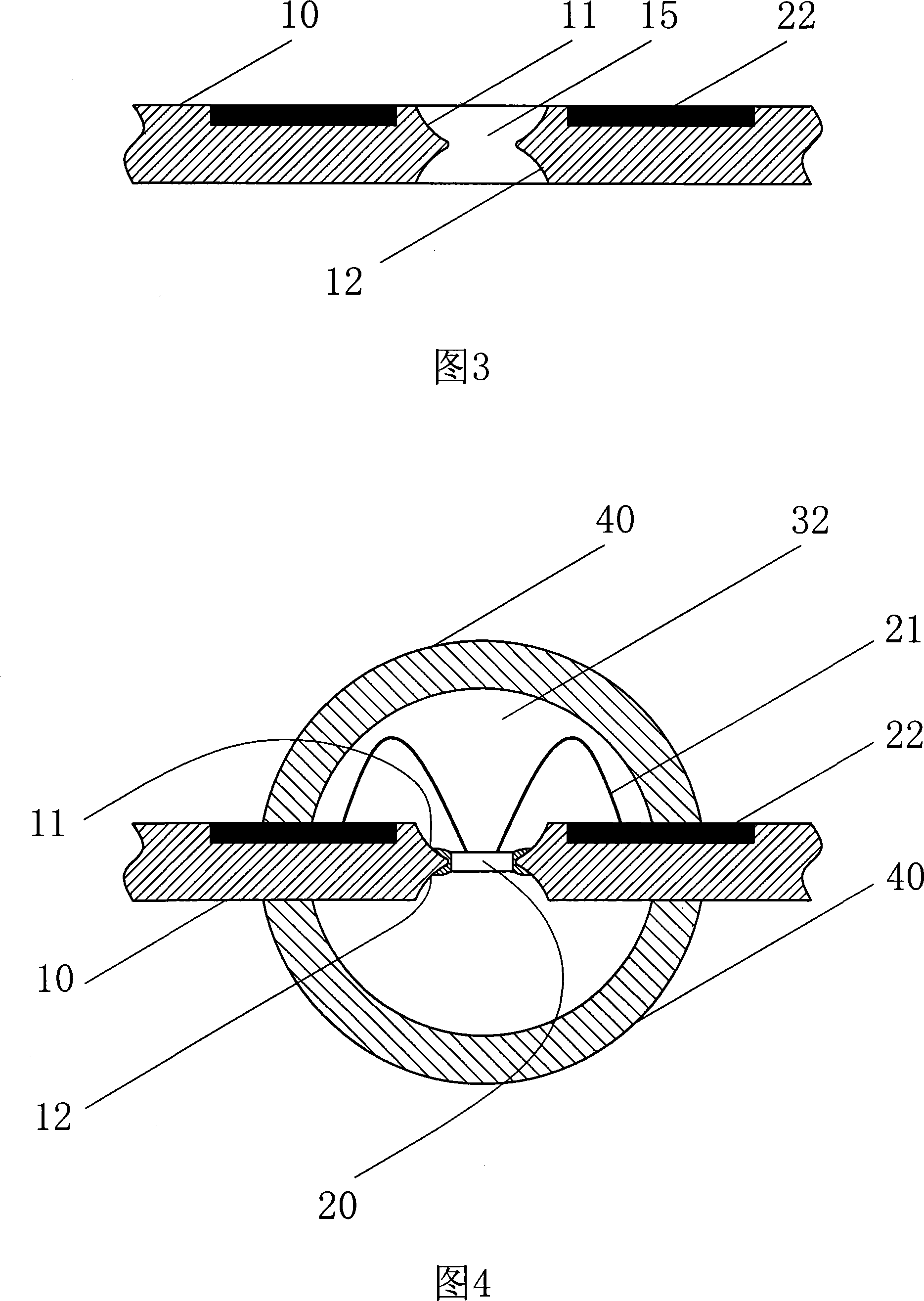

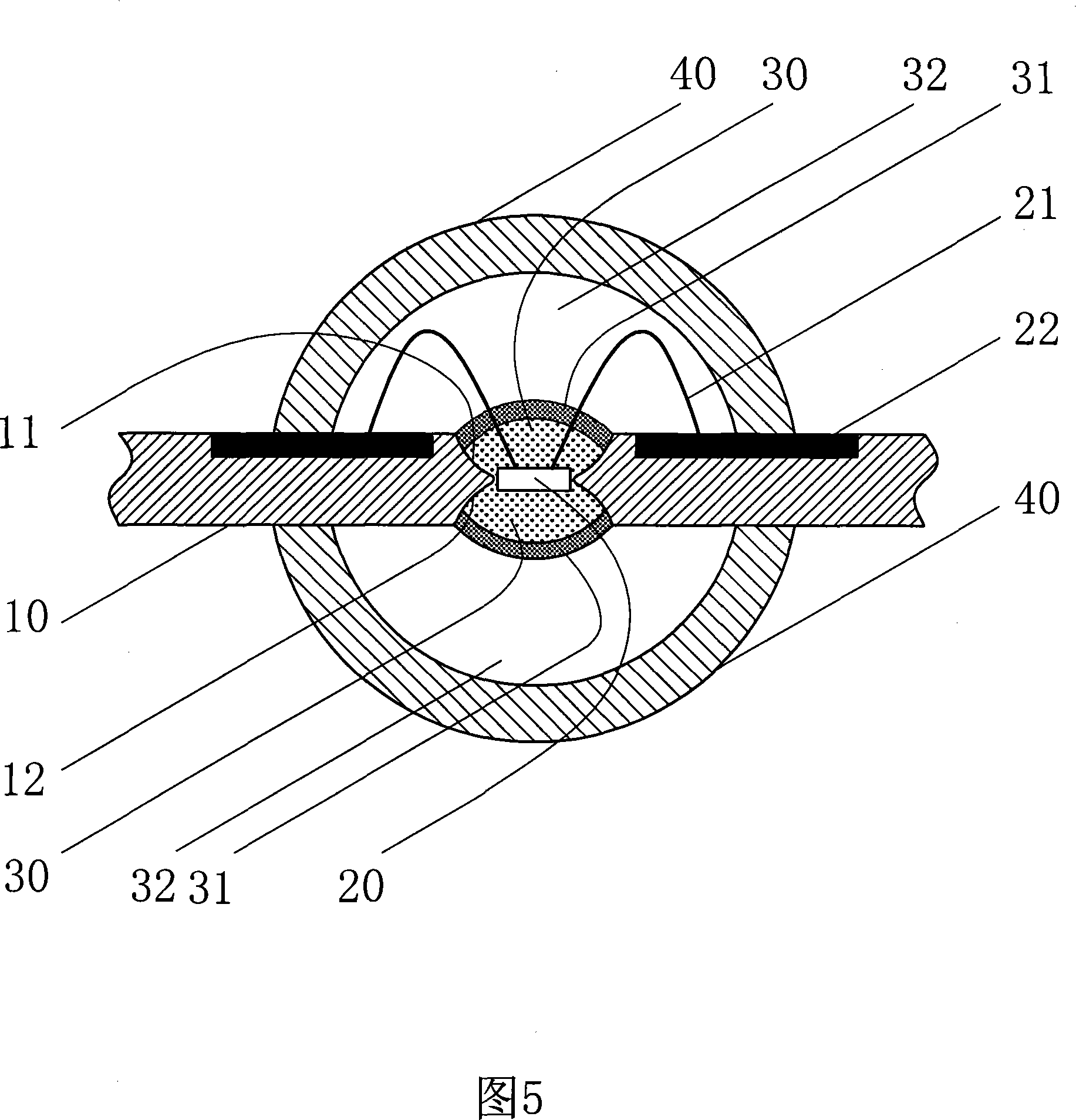

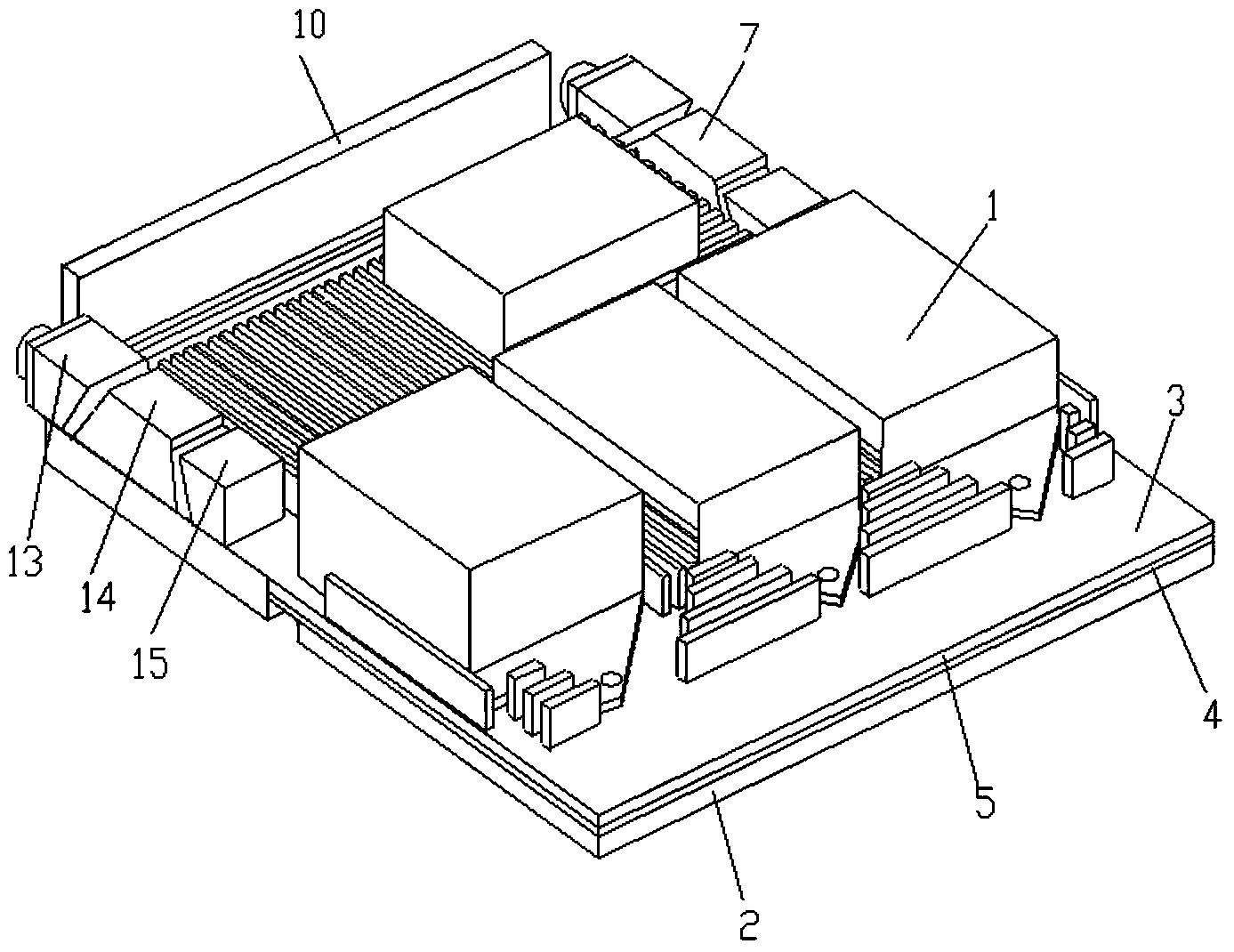

Optical or electronic module and method for its production

InactiveUS20060027479A1Broaden applicationImprove thermal performanceLaser detailsFlexible coversEngineeringElectronic component

One or more aspects of the invention relate to an optical or electronic module with at least one optical or electronic component and a plastic package within which the component is embedded. The component has an operative region that facilitates operative connection with surroundings. The plastic package has a first region, which comprises a transparent polymer compound, and a second region, which comprises a non-transparent polymer compound. The first region extends such that it borders the operative region of the component.

Owner:AVAGO TECHNOLOGIED FIBER IP SINGAPORE PTE LTD

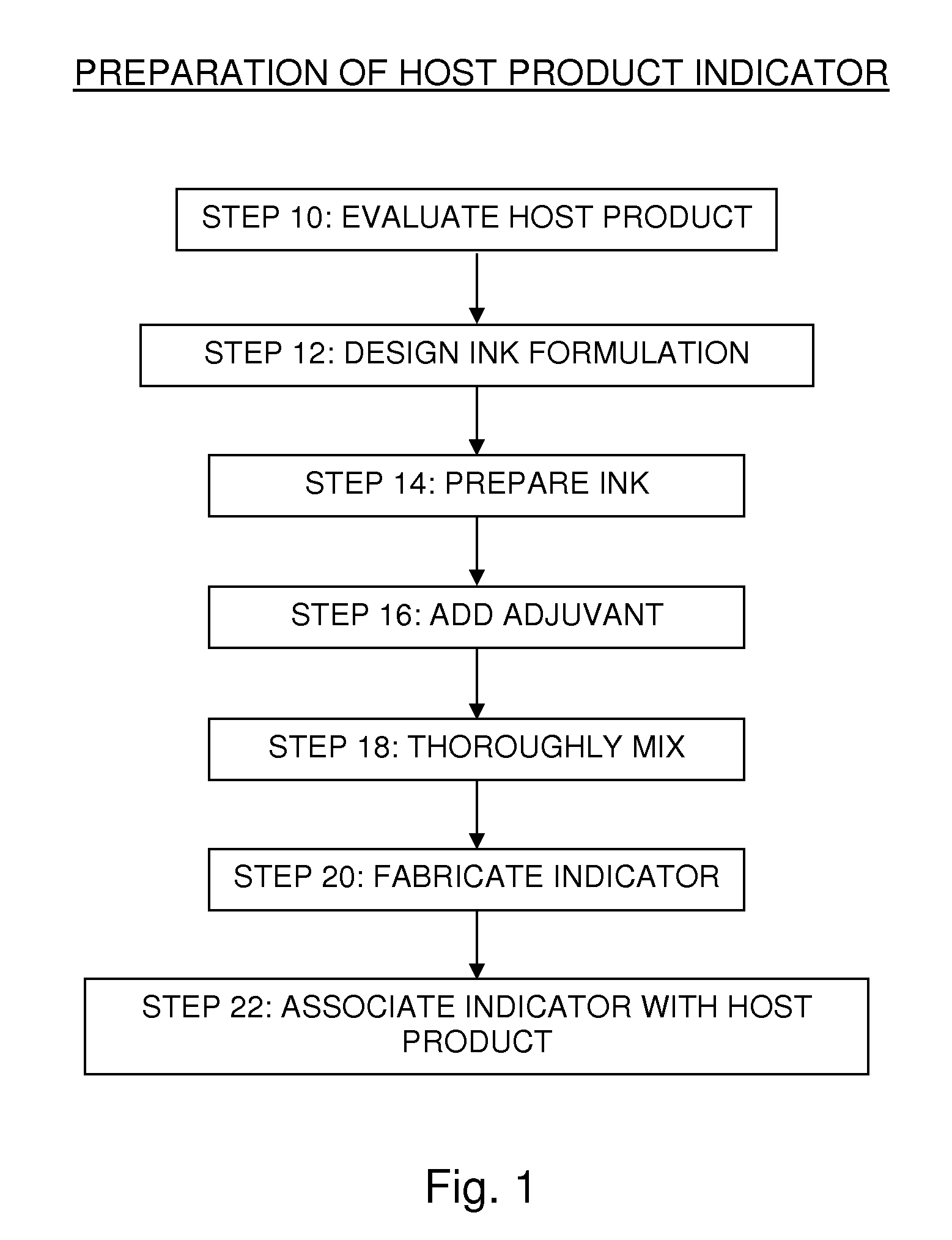

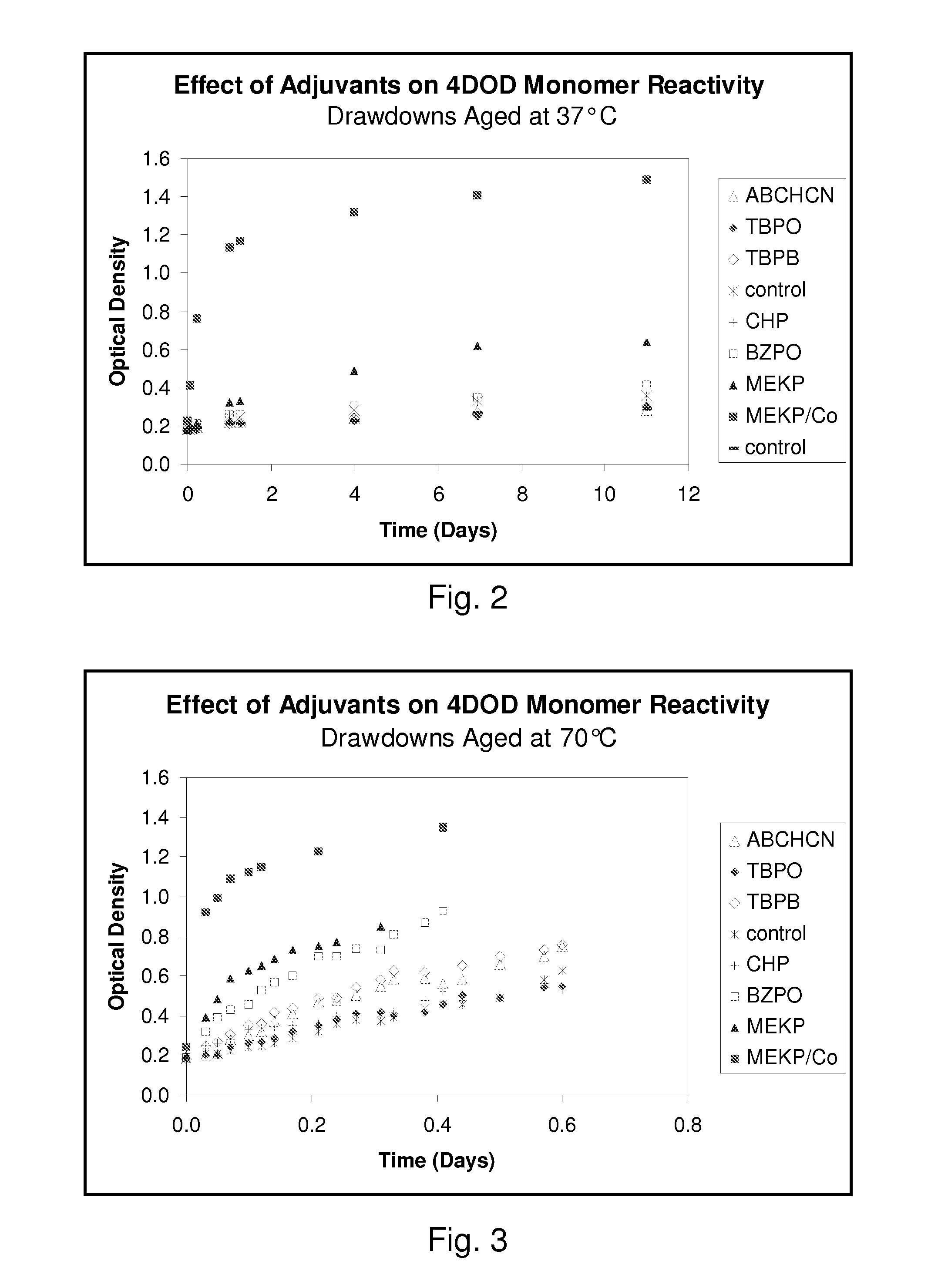

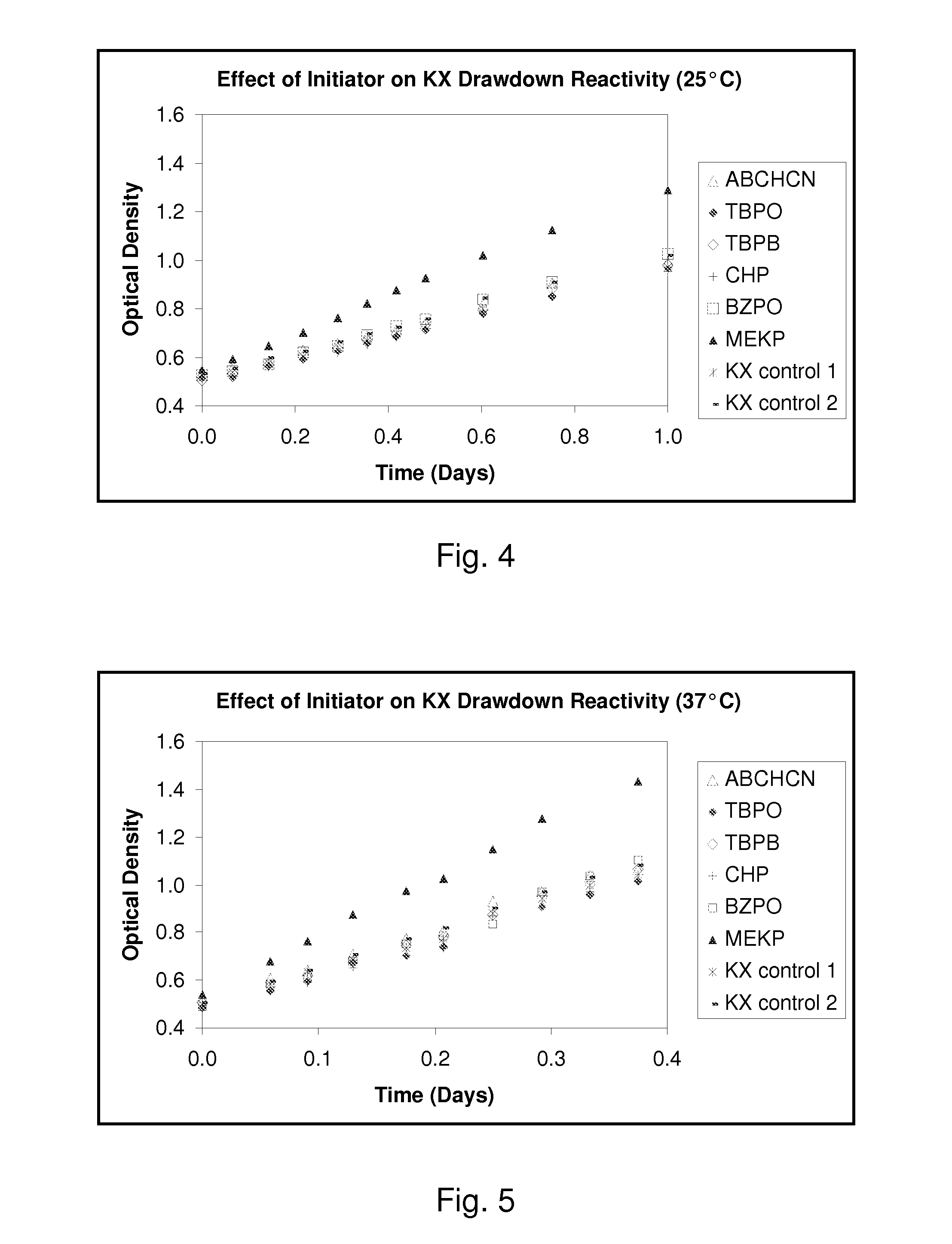

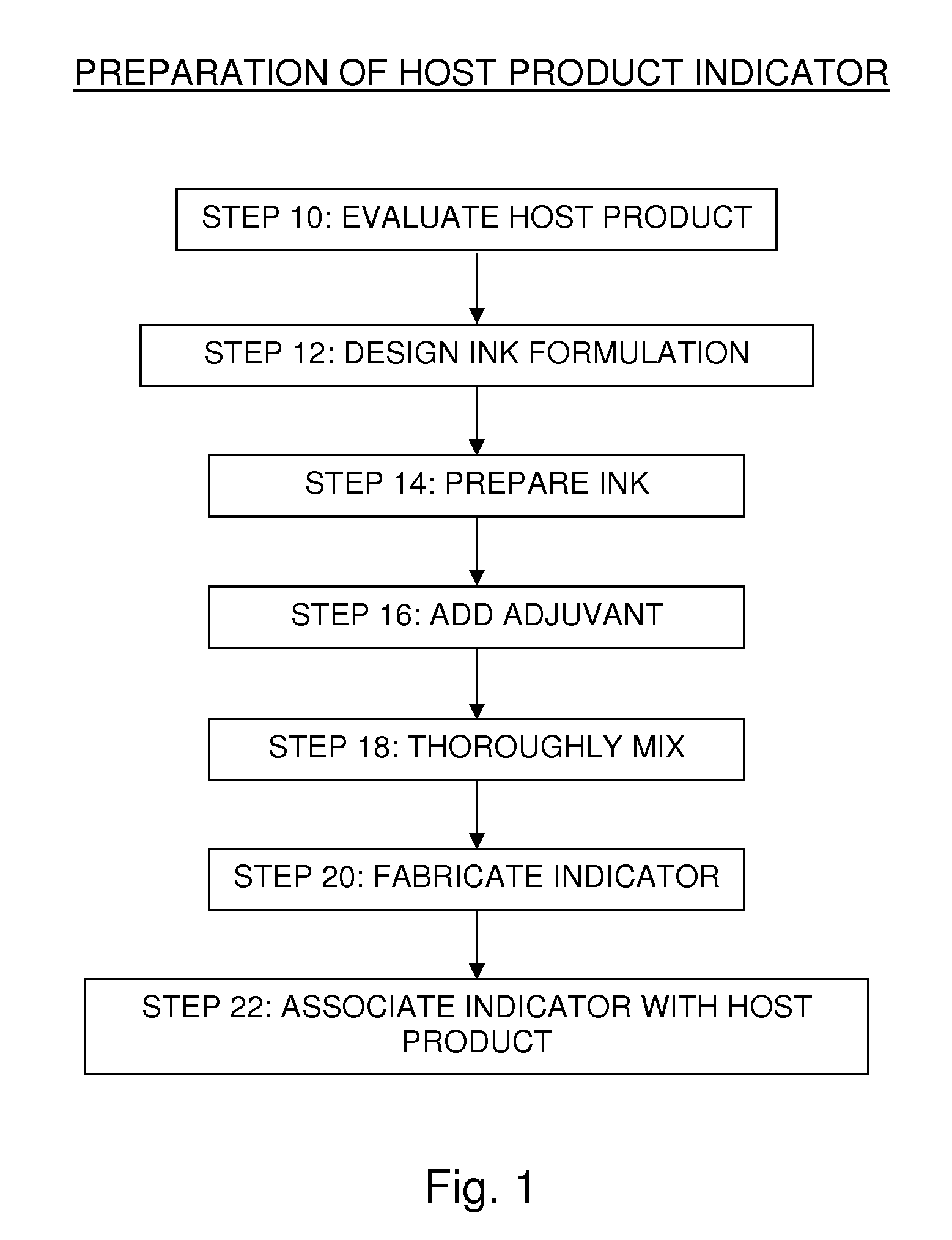

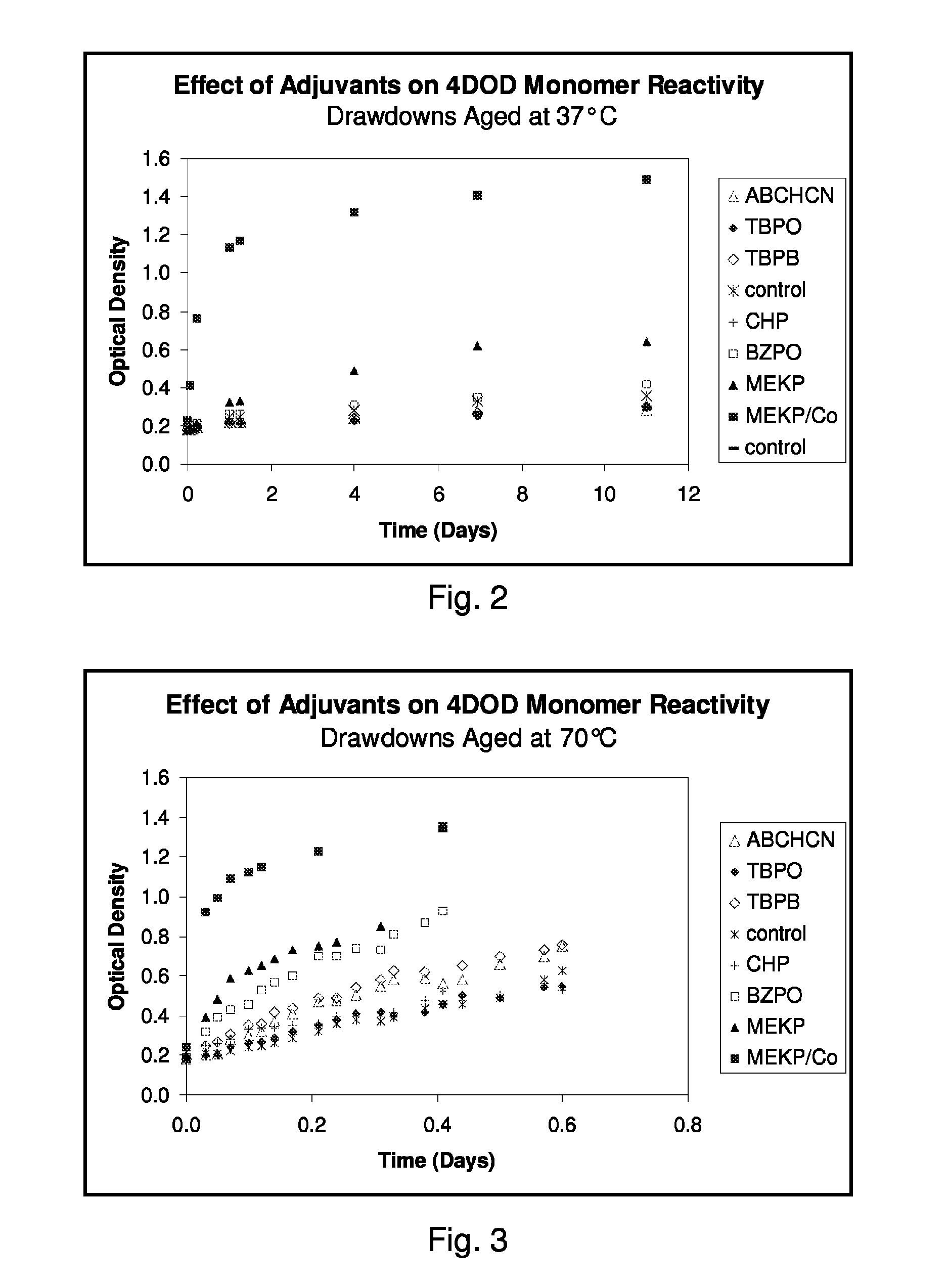

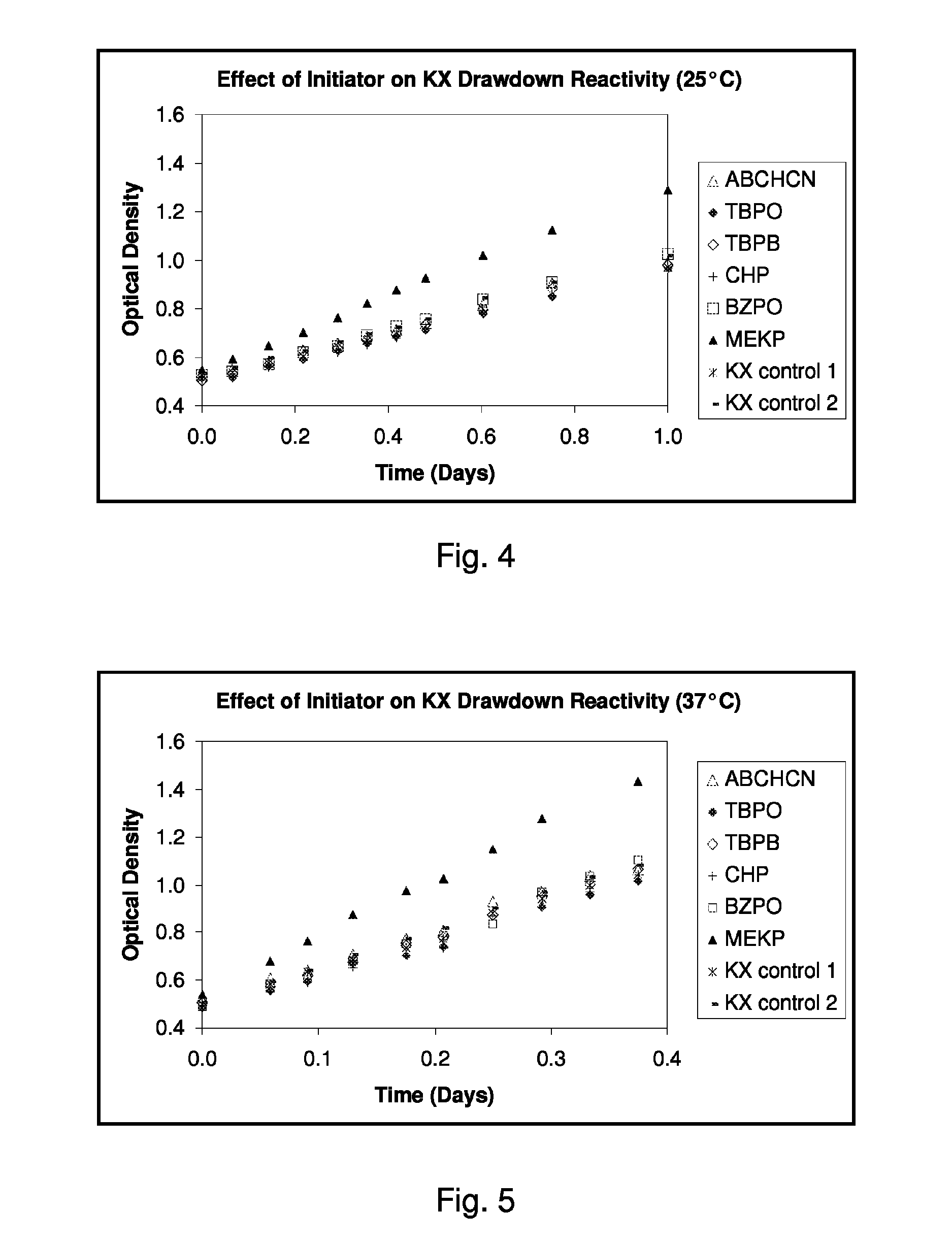

Adjuvant-mediated reactivity enhancement of polymerizable polyacetylenic materials

ActiveUS20080004372A1Enhance ambient temperature thermal reactivityIncrease the ambient temperatureDecorative surface effectsFibre treatmentChemistryMethyl ethyl ketone peroxide

Indicator inks, indicators formed by printing or otherwise utilizing the inks and host products utilizing the indicators are disclosed. Reactivity-enhancing adjuvants stimulate enhanced thermal reactivity of diacetylenic or other indicator agents capable of responding to ambient thermal conditions with a visual change signaling an end point. The diacetylenic or other agents may be sensitive or relatively insensitive to ambient temperatures. Use of a reactivity-enhancing adjuvant provides a useful means for adapting the reactivities of indicator agents to the response characteristics of prospective host products, for example perishables such as vaccines or fresh fish and maturables such as fruit, cheese and wine. Some exemplary adjuvants include low-temperature polymerization initiators, for example methyl ethyl ketone peroxide and polymerization accelerators, for example cobalt compounds. Such initiators and accelerators can also be used in combination.

Owner:TEMPTIME CORP

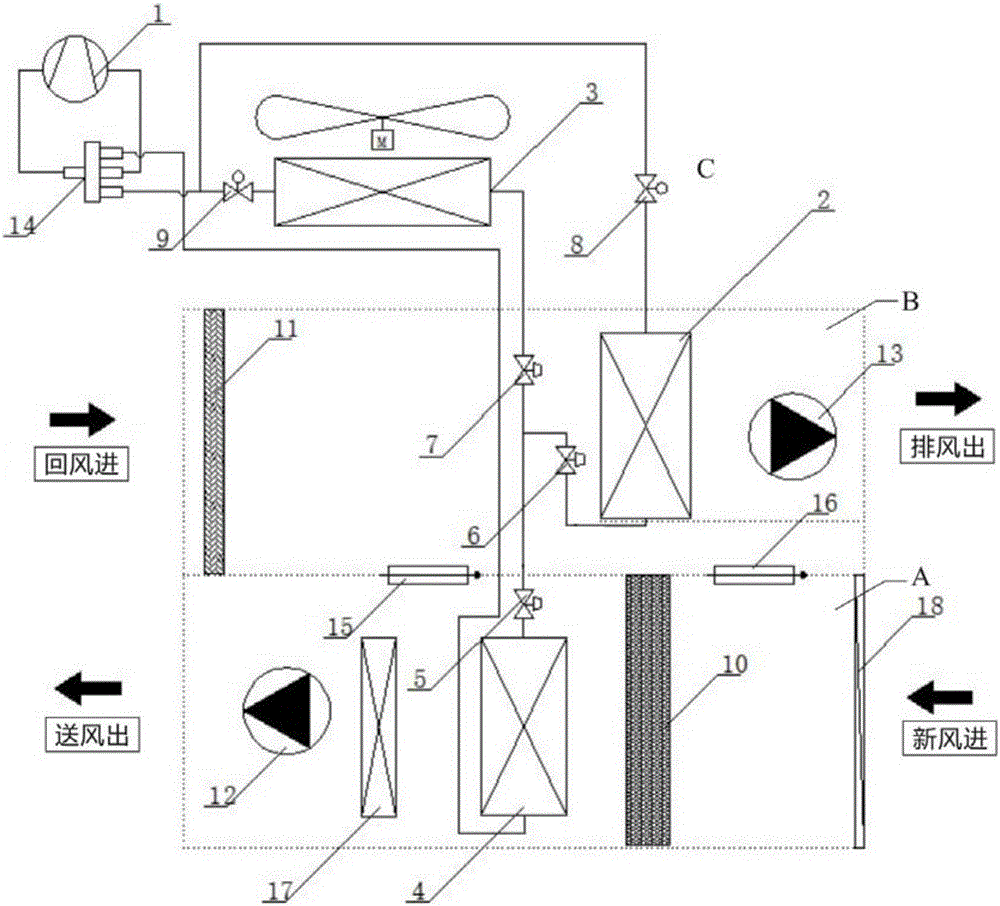

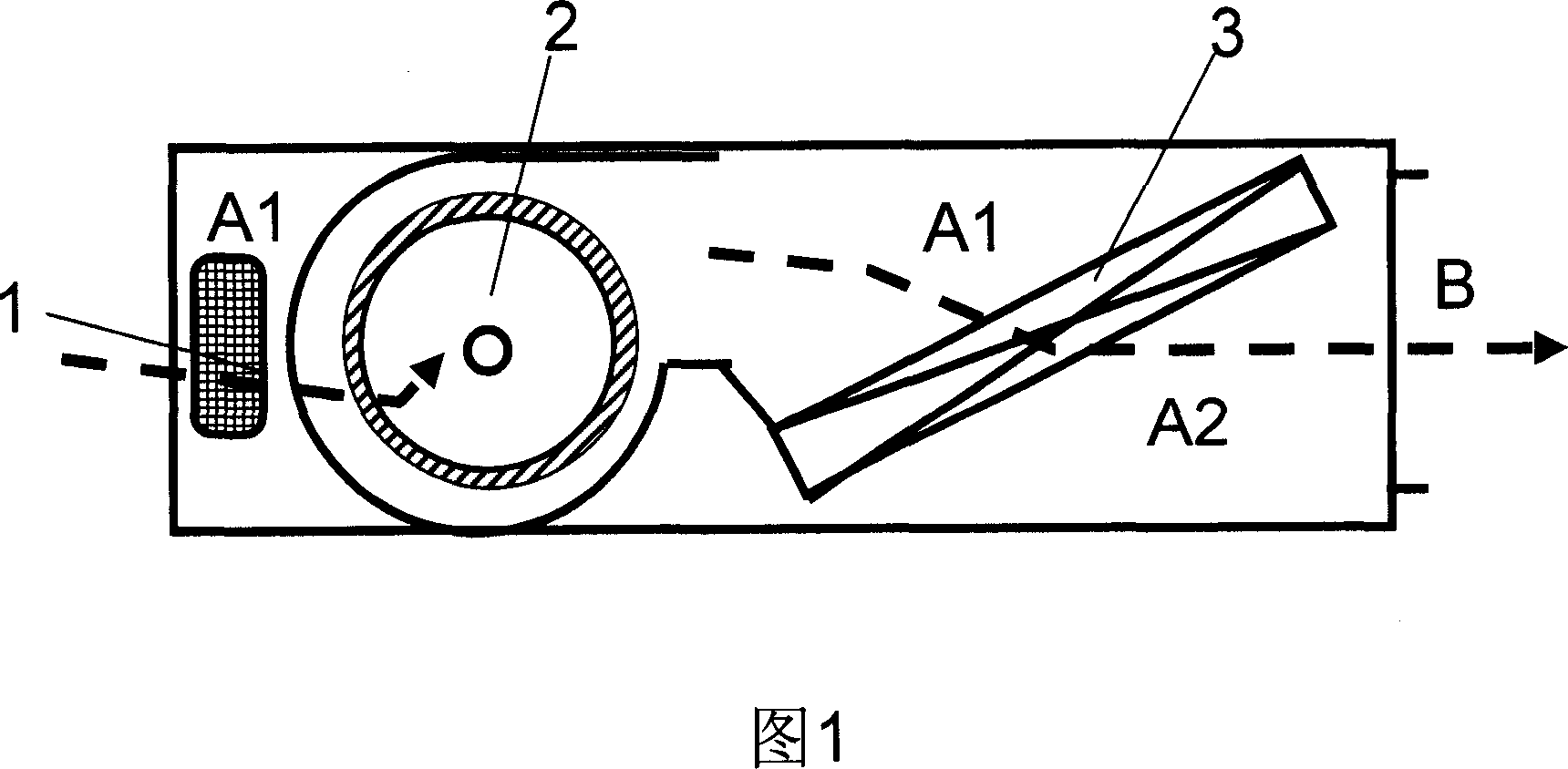

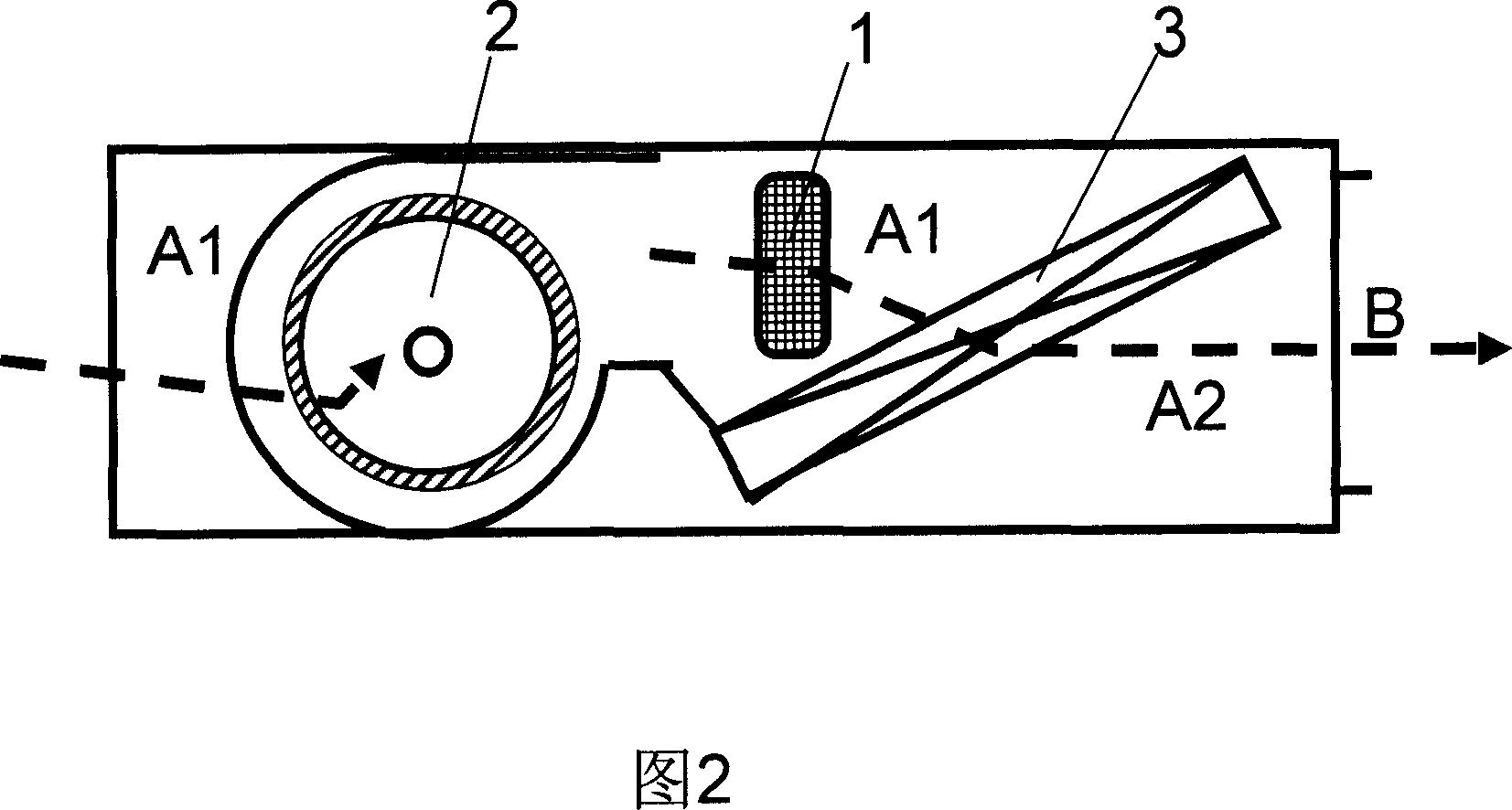

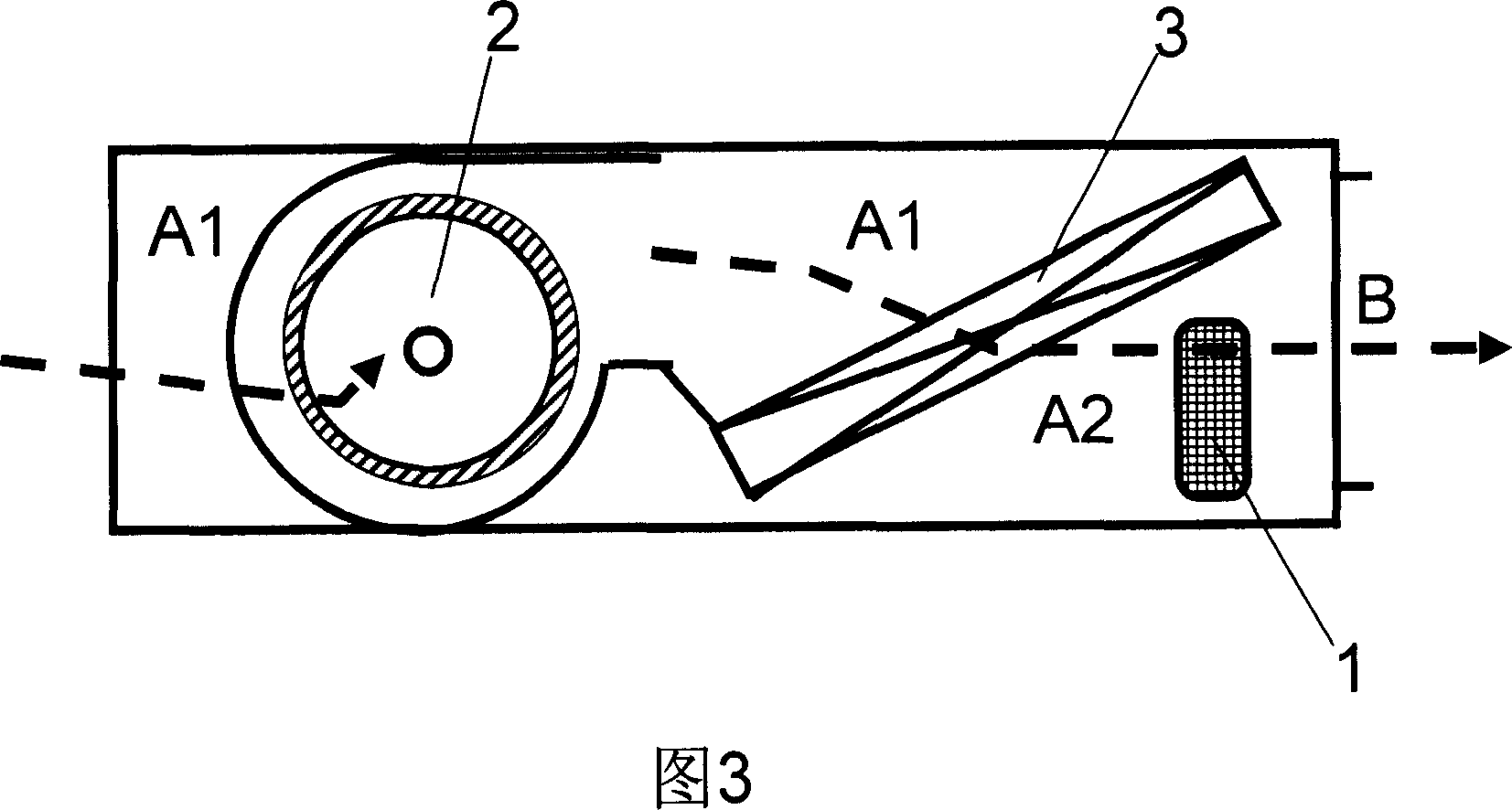

Multi-condenser and double-return-air bypass dehumidification fresh air unit and air conditioning method

ActiveCN105890070ALower condensation temperatureAvoid lossMechanical apparatusSpace heating and ventilation safety systemsEvaporationCondensation temperature

The invention relates to a multi-condenser and double-return-air bypass dehumidification fresh air unit and an air conditioning method. The multi-condenser and double-return-air bypass dehumidification fresh air unit comprises an air feed channel and an exhaust channel. A first heat exchanger and an air feeder are sequentially arranged at the position of the air feed channel. A second heat exchanger and an exhaust fan are sequentially arranged at the position of the exhaust channel. The second heat exchanger is connected with an auxiliary heat exchanger. A first return air bypass valve and a second return air bypass valve are arranged between the air feed channel and the exhaust channel. According to the multi-condenser and double-return-air bypass dehumidification fresh air unit, during refrigerating, the second heat exchanger serves as a condenser, a refrigerant is condensed through the indoor low-temperature exhaust air, the condensation temperature of the unit is reduced, and reheating is conducted through mixing of bypass return air and low-temperature fed air on the air feed side so that cooling capacity losses caused by cold and heat offset can be avoided; in a heating inner circulation mode, an outdoor unit can be started to rapidly increase the indoor environment temperature; and in an outer circulation mode, the second heat exchanger serves as an evaporator, the refrigerant is made to be evaporated through the heat of indoor exhaust air, the evaporation pressure and the heating capacity of the unit are increased, the power consumption of the unit is reduced, and the frosting risk of the unit is avoided.

Owner:JIANGSU HUIJU ARCHITECTURE TECH CO LTD

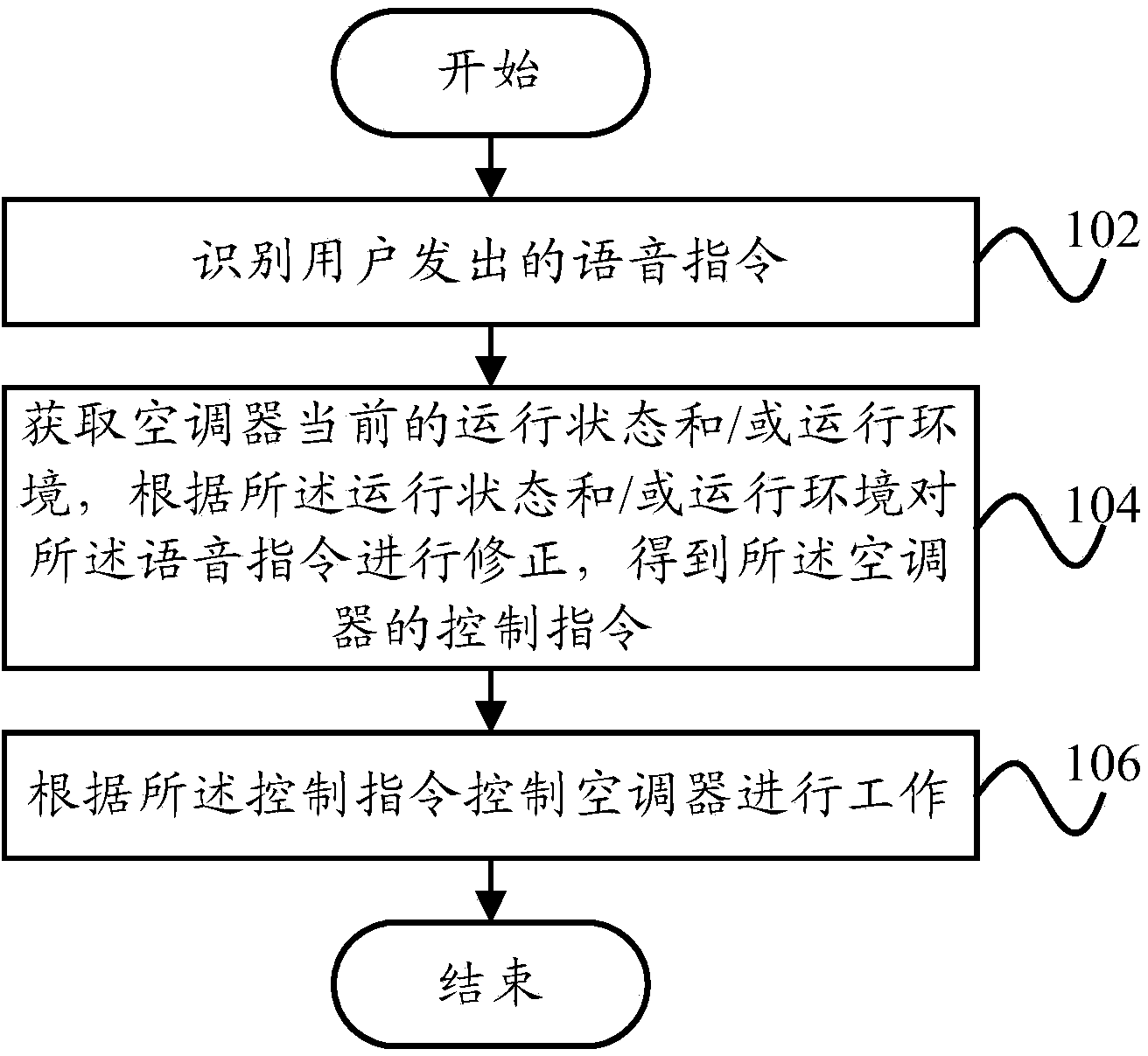

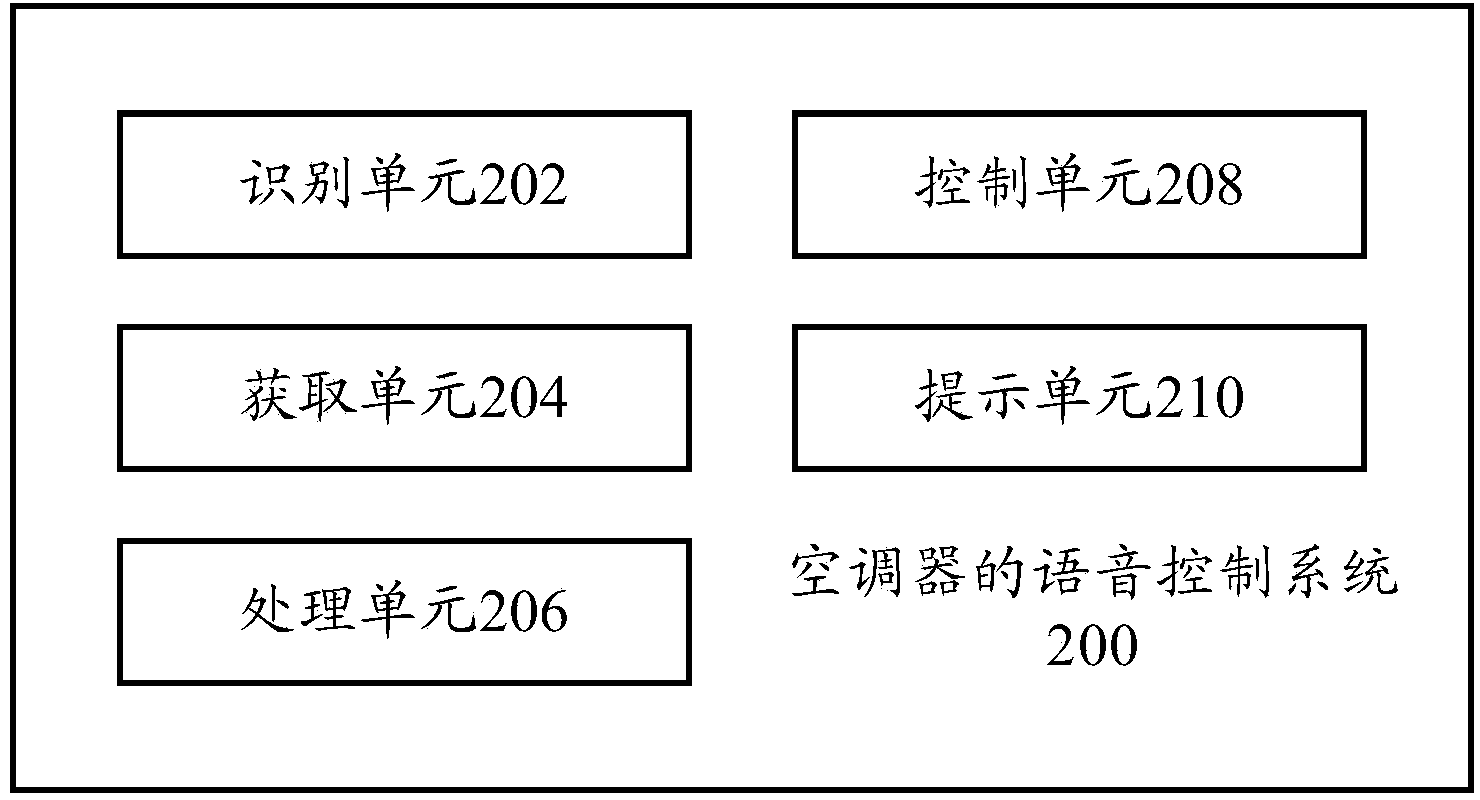

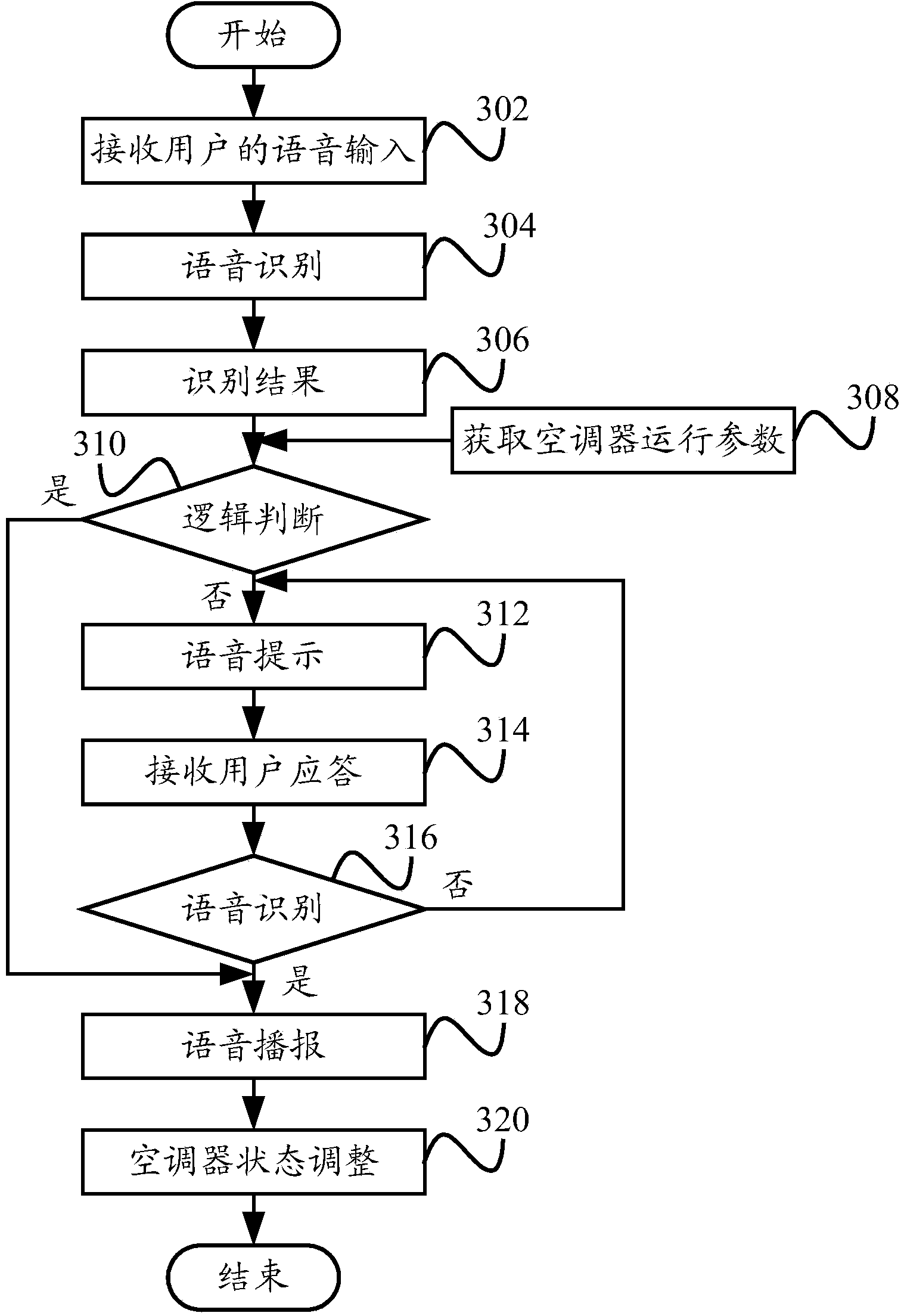

Voice control method and voice control system for air-conditioner

InactiveCN104240702AImprove experienceMeet the actual control needsSpace heating and ventilation safety systemsLighting and heating apparatusControl systemSpeech control

The invention provides a voice control method for an air-conditioner and a voice control system for the air-conditioner. The voice control method for the air-conditioner comprises the steps that a voice instruction sent by a user is identified; the current operating state and / or the current operating environment of the air-conditioner are obtained, and the voice instruction is corrected according to the operating state and / or the operating environment to obtain a control instruction of the air-conditioner; the air-conditioner is controlled to work according to the control instruction. According to the technical scheme, the accuracy of voice control over the air-conditioner can be improved, and the experience of carrying out voice control on the air-conditioner of the user is promoted.

Owner:GUANGDONG MIDEA GRP WUHU REFRIGERATING EQUIP CO LTD

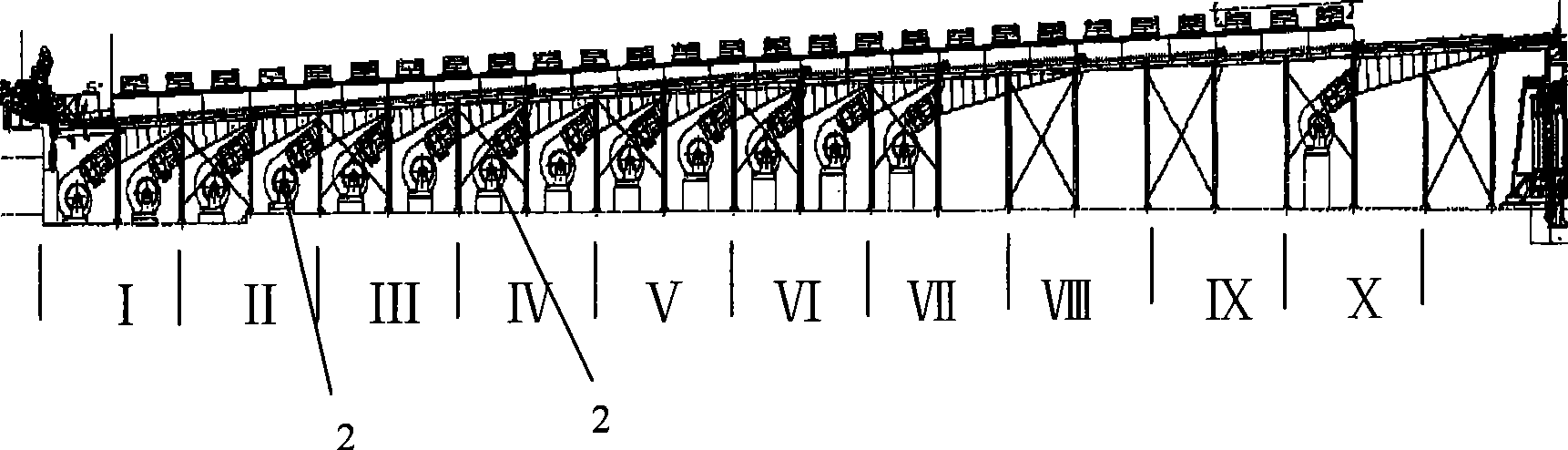

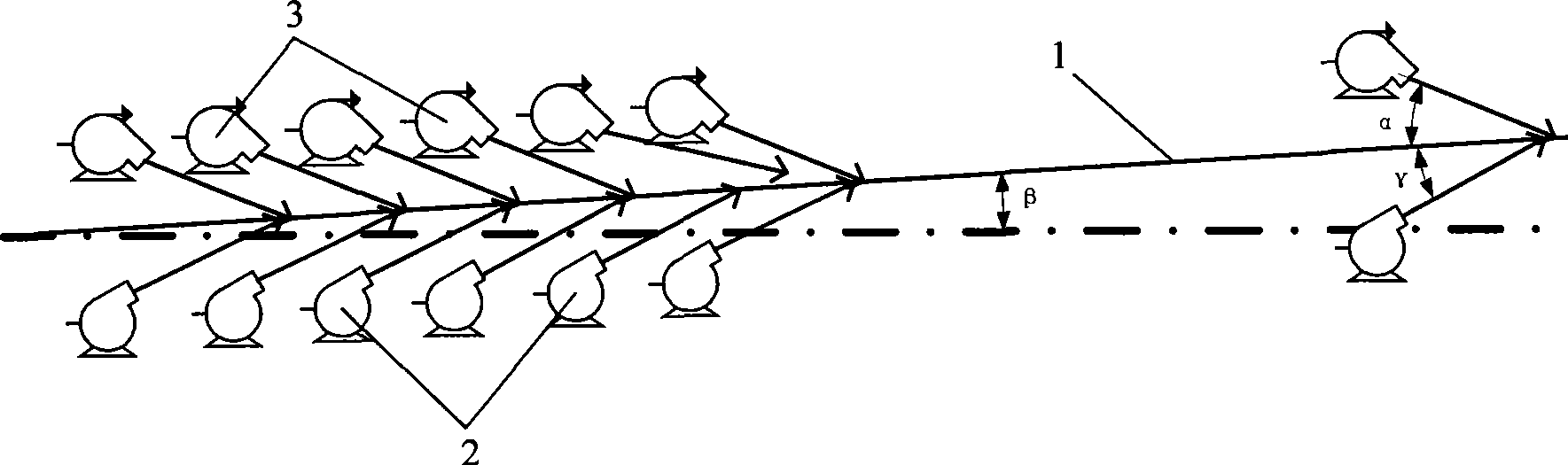

Stelmor line cooling method and cooling apparatus of high-speed rod-rolling mill

ActiveCN101480669ACool evenlyRealize top and bottom air coolingWork treatment devicesMetal rolling arrangementsWire rodEngineering

The invention relates to a cooling method and a cooling device for a stelmor wire of a high-speed wire mill. The cooling device for a stelmor wire of a high-speed wire mill adopts the structure that the lower side of a transport roller way of a stelmor wire is sequentially provided with a plurality of upper draught fans along the direction of the transport roller way, the upper side of the transport roller way of the stelmor wire is also sequentially provided with a plurality of lower draught fans along the direction of the transport roller way, the upper draught fans are arranged on a steel structural frame which can be conveyed in a hanging way, an air outlet of each upper draught fan is symmetrical to an air outlet of each lower draught fan relative to the transport roller way, and an included angle between the air direction of each upper draught fan and the transport roller way is equal to an included angle between the air direction of each lower draught fan and the transport roller way. The cooling method is applicable to the cooling device. Furthermore, additionally provided with the the draught fans on the transport roller way, the cooling device realizes the upper air cooling and the lower air cooling of the wires, increases the cooling speed, and causes the wires to be cooled more evenly, thereby the invention solves the problems of nonuniform wire contact-point structure and nonuniform mechanical property.

Owner:BAOSHAN IRON & STEEL CO LTD

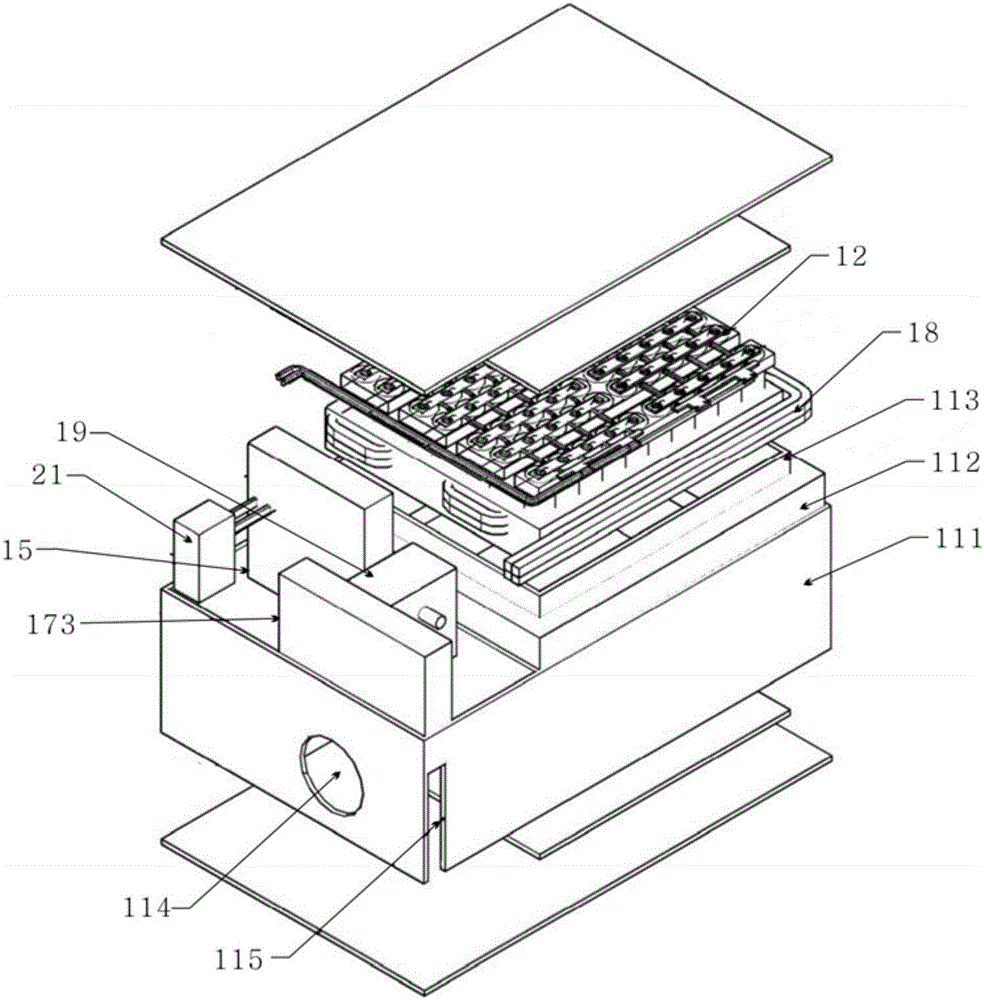

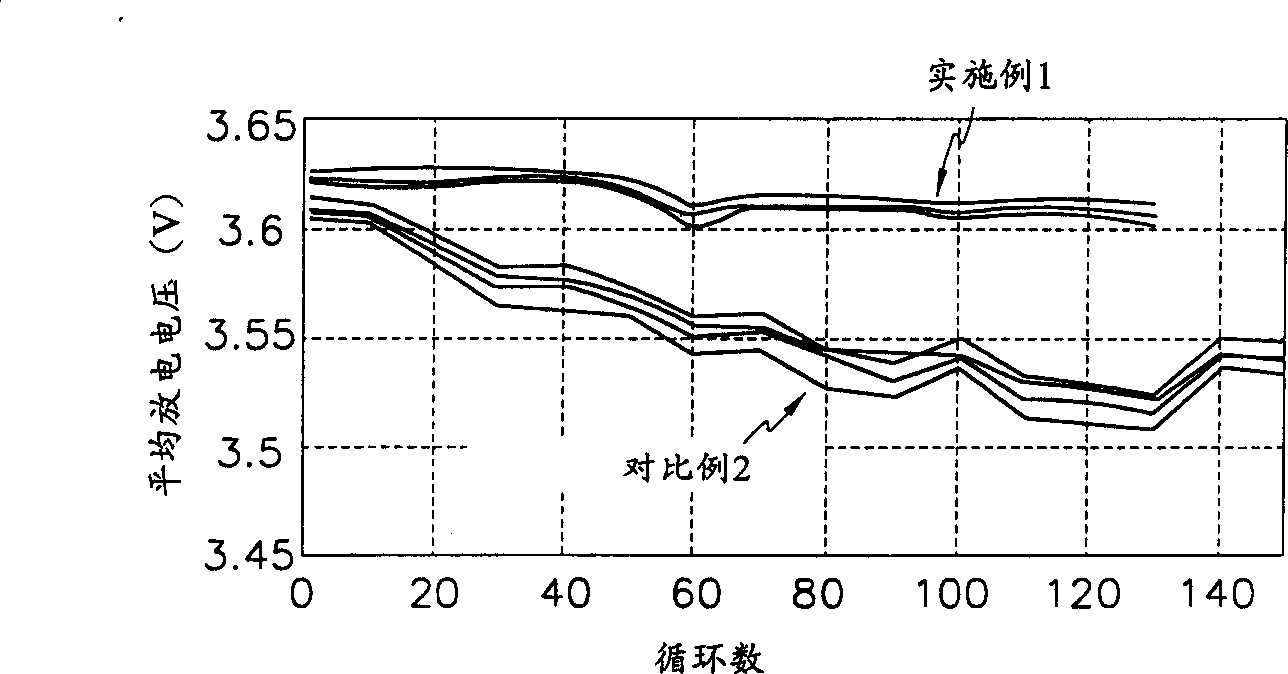

Power battery low-temperature charging heating system

InactiveCN105870542AImprove performanceImprove cycle lifeSecondary cells testingPower batteryElectrical battery

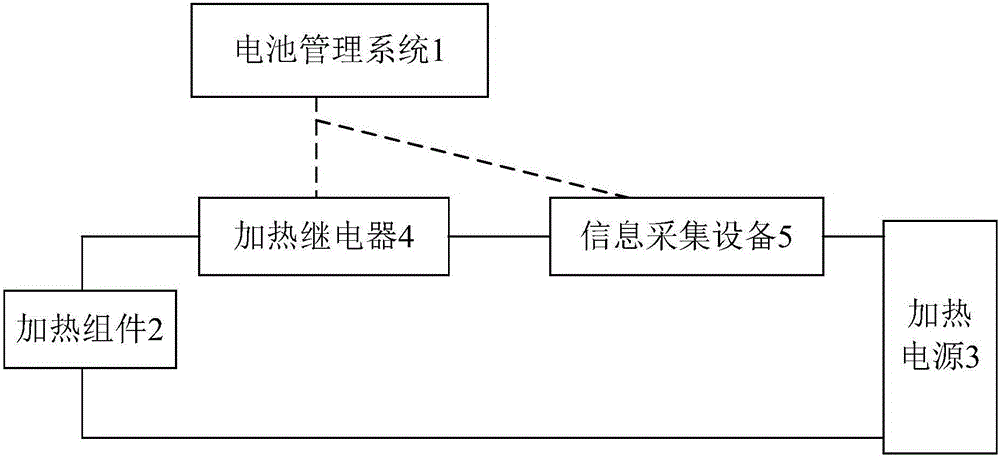

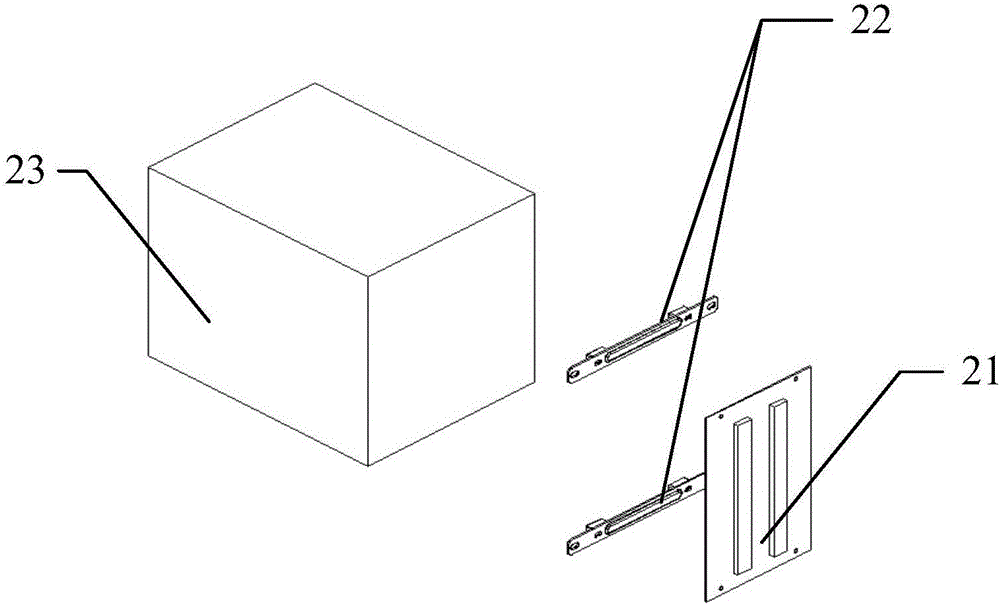

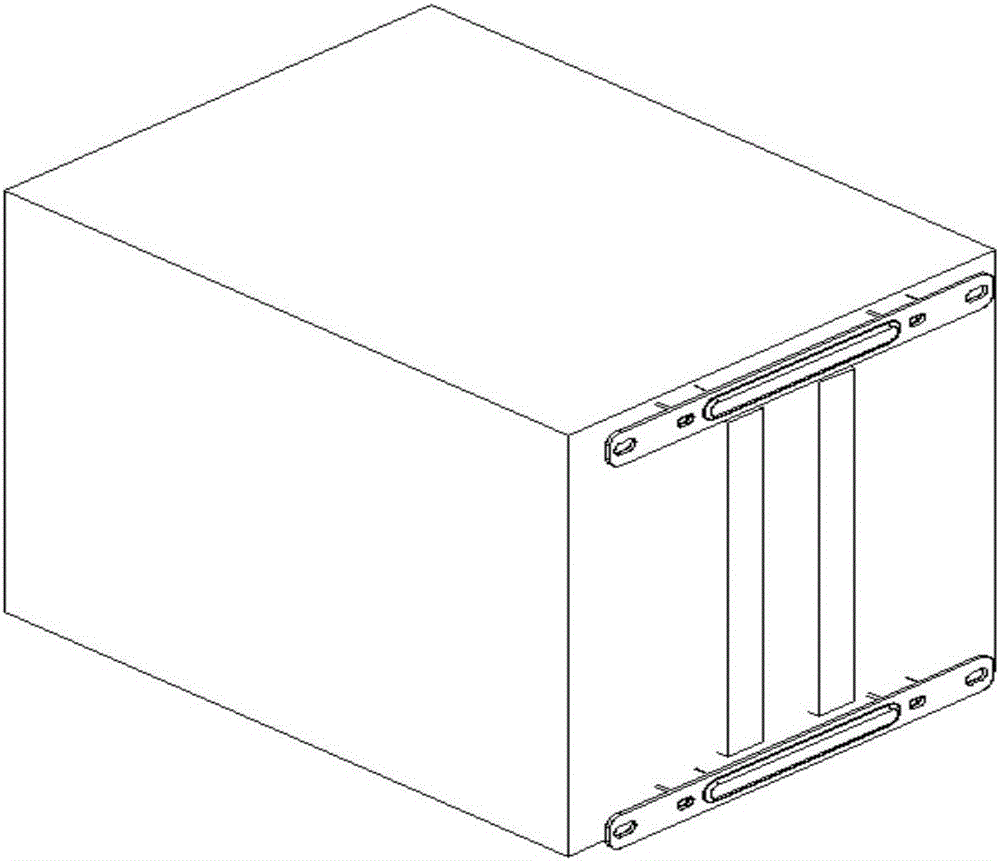

The invention provides a power battery low-temperature charging heating system which comprises a battery managing system, a power battery module, a heating power source, a heating assembly, a heating relay and an information collection device. The battery managing system, the heating relay and an information managing system form a control loop of the heating system. The heating assembly, the heating relay, the information collection device and the heating power source are in hard connection through a wire harness or a copper bar to form a heating loop of the heating system. The heating assembly can provide heat for the power battery module for heating when the power battery module is in a low-temperature environment. The battery managing system accurately adjusts the heating power of the heating assembly according to current, voltage, temperature and other information collected by the information collection device, the internal environment temperature of a power battery is rapidly improved, it is ensured that the power battery module is evenly heated, and the effect of lowering the temperature difference of the power battery module and parts is achieved, so that the performance of the power battery is improved, and the cycle life of the power battery is prolonged.

Owner:深蓝汽车科技有限公司

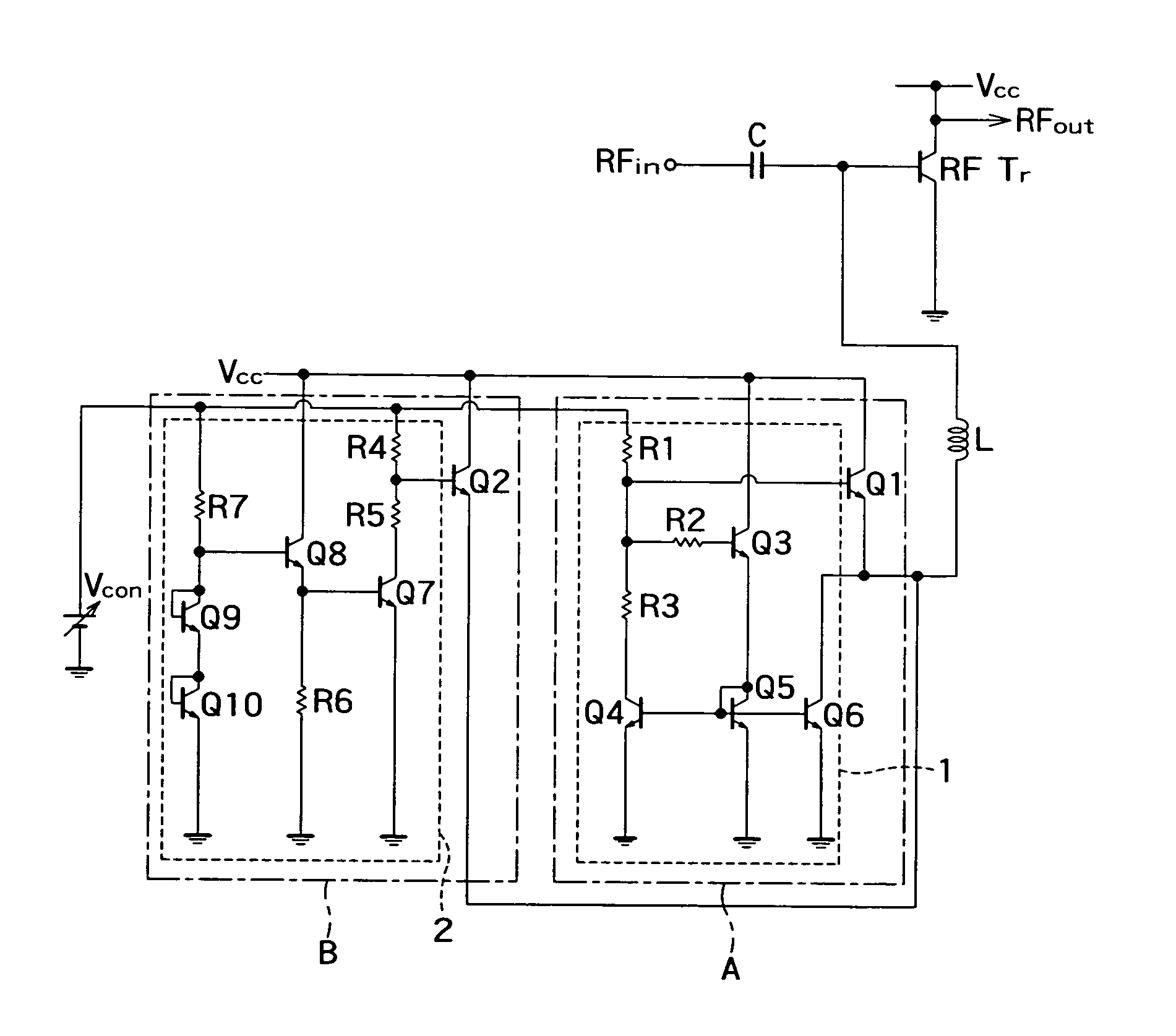

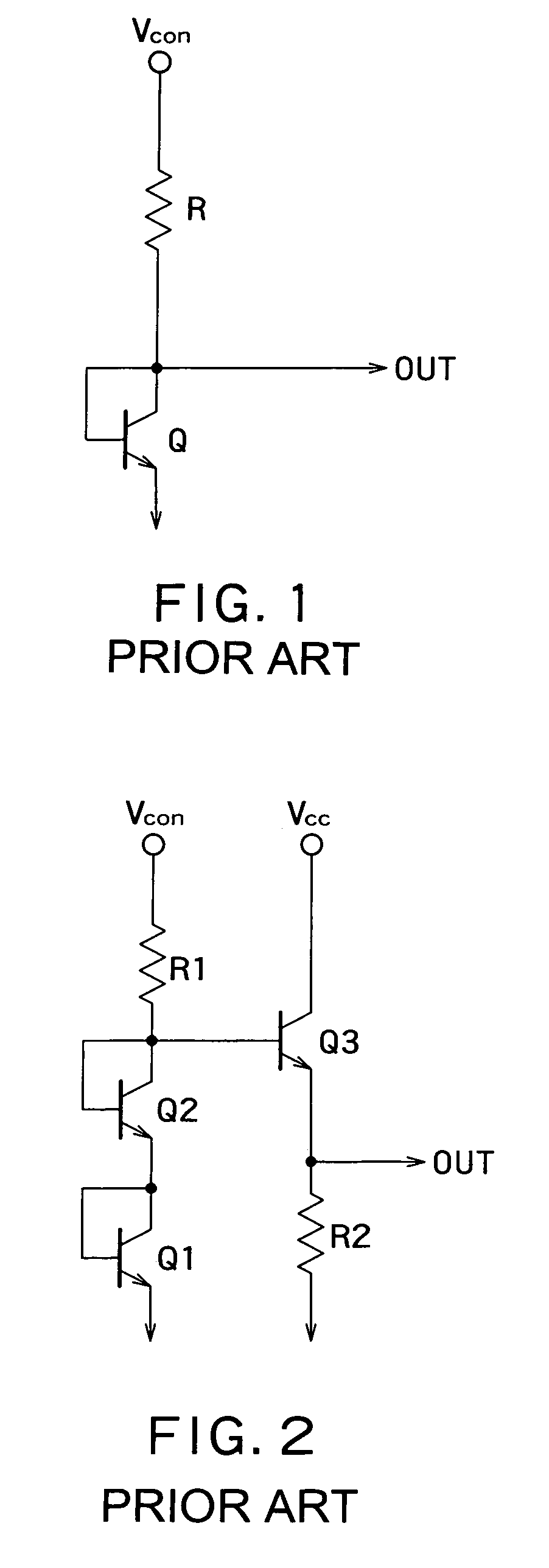

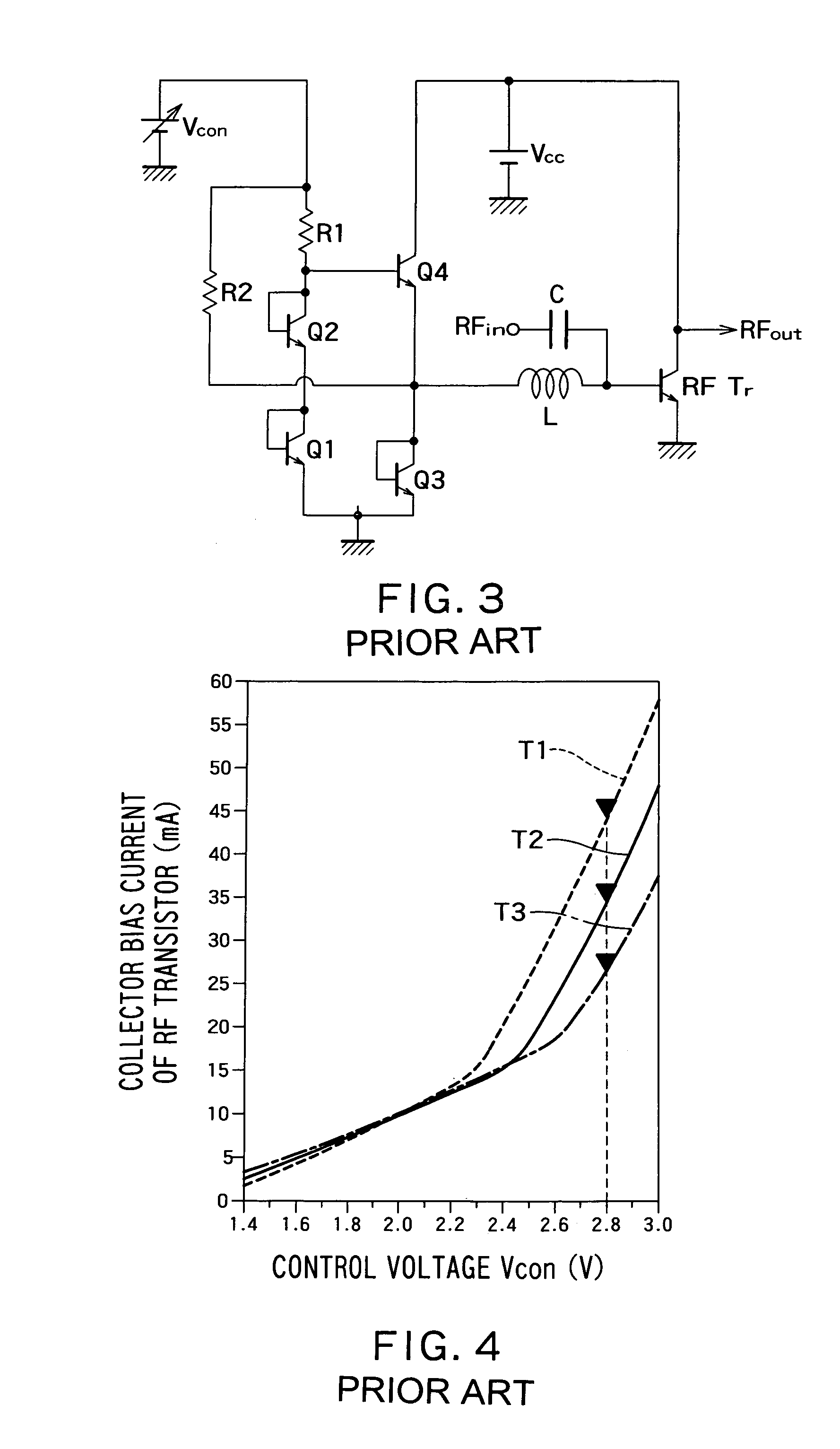

Bias current supply circuit and amplification circuit

InactiveUS7009453B2Increase the amount addedIncrease temperatureHigh frequency amplifiersAmplifier modifications to reduce temperature/voltage variationEngineeringIncrease temperature

A bias current supply circuit according to an embodiment of the invention includes a first transistor and a second transistor which form two emitter followers cooperating to supply a base bias current of a bipolar transistor for signal amplification, a normal temperature characteristic circuit which has normal temperature characteristics increasing an amount of current supply with increasing temperature and supplies a base current to the first bipolar transistor, and a reverse temperature characteristic circuit which has reverse temperature characteristics decreasing the amount of current supply with increasing temperature and supplies a base current to the second bipolar transistor.

Owner:KK TOSHIBA

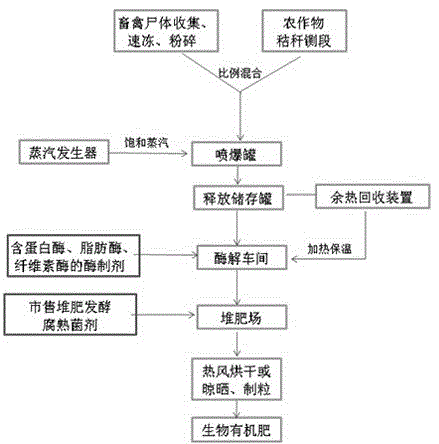

Livestock carcase harmless disposal technology and biological organic fertilizer processing method

InactiveCN105016797AIncrease contact areaSpeed up the fermentation processBio-organic fraction processingOrganic fertiliser preparationChemistryDual effect

The invention relates to a method for conducting harmless disposal on various livestock carcases through a method of comprehensively utilizing and combining the physical technology, the chemical technology and the biological technology, and processing the livestock carcases into biological organic fertilizer. The livestock carcases can be processed into biological organic fertilizer rick in nitrogen, phosphorus, potassium and various microelements by further conducting enzymolysis through protease, lipase and the like and conducting compost thermophilic fermentation and drying after conducting sterilization, deordorization and gelatinization through a high-temperature and high-pressure steam explosion technology with the livestock carcases as main raw materials and with crop straw as adsorption carriers and filler. The biological organic fertilizer has the beneficial effects of being capable of holding water and fertilizer and being released slowly, durable, and the like. The biological organic fertilizer can be safely and trustingly used for organic vegetables, fruit and other products due to the fact that the detection shows that the biological organic fertilizer is free of pathogenic bacteria and antibiotic drug residues. No emission of sewage or germs or drug residues or poisonous gas is caused in the whole process, and the dual effects of protecting the environment and utilizing resources to the maximum extent are achieved.

Owner:霍英军

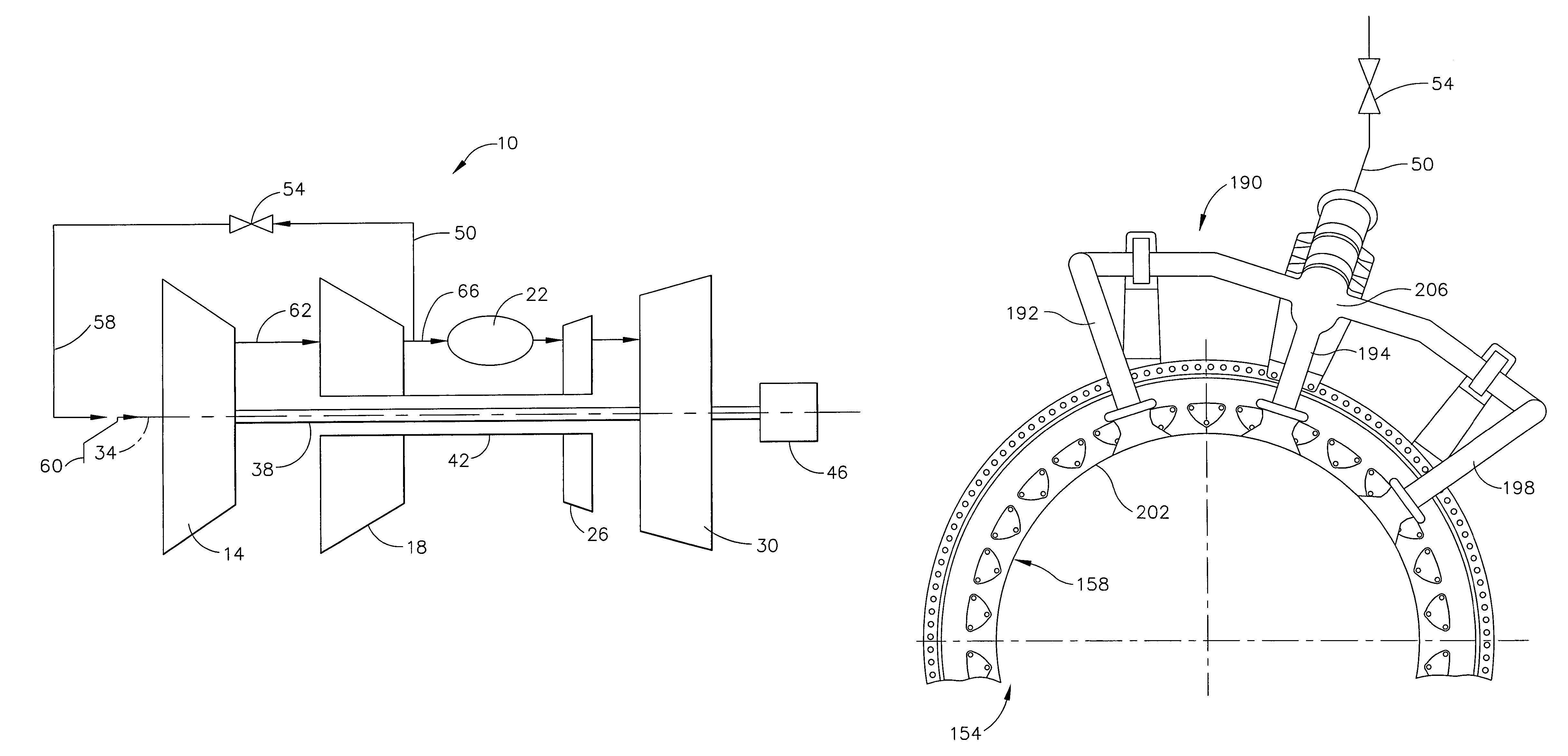

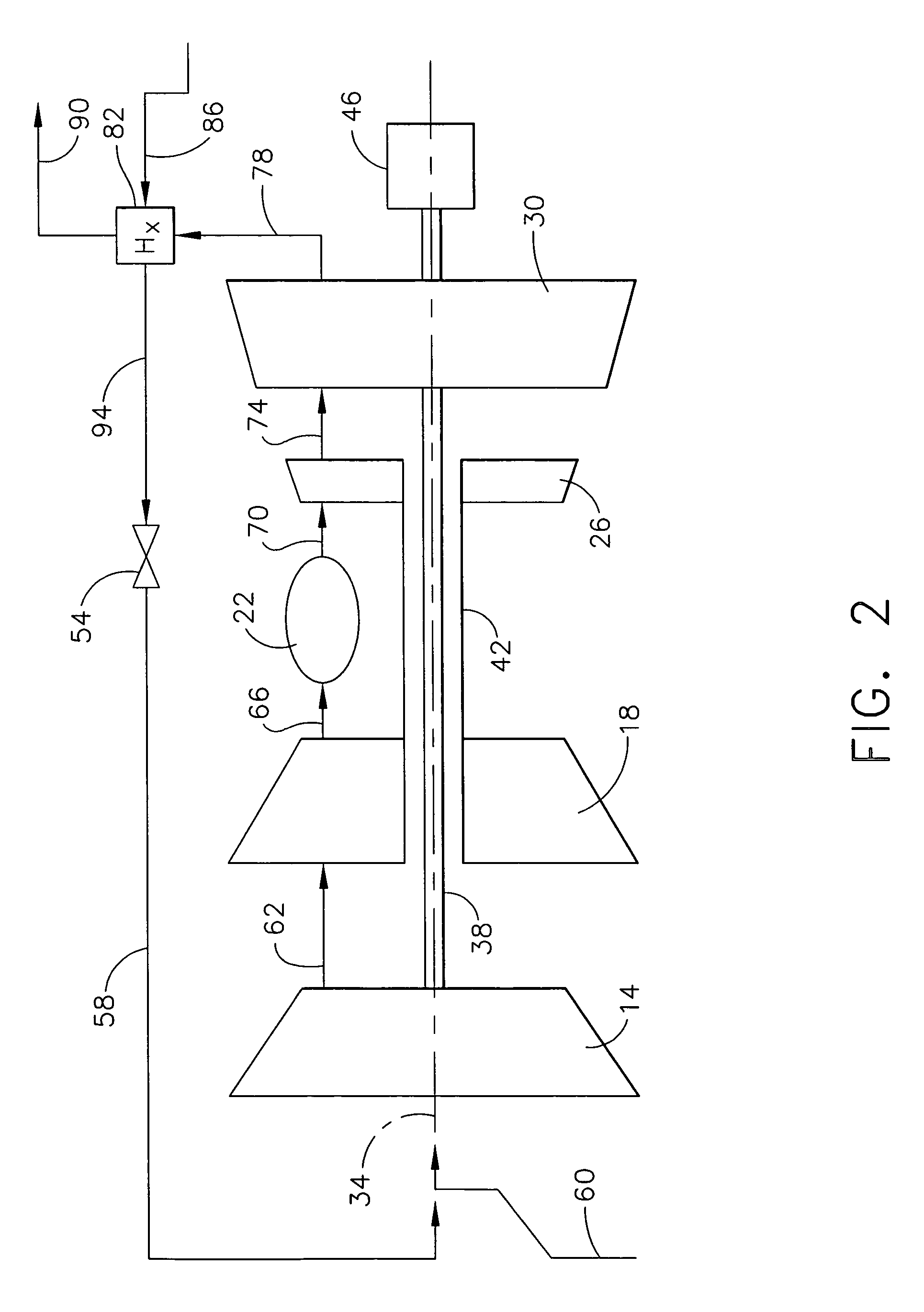

HVAC system with powered subcooler

ActiveUS7908881B2Large capacityImprove efficiencyEvaporators/condensersCompression machines with several condensersCooling capacityRefrigerant

An HVAC system having a main circuit and a subcooler circuit. The main circuit includes a main circuit evaporator, a main circuit expansion device, a main circuit condenser and a main circuit compressor connected in a closed refrigerant loop. The subcooler circuit includes a subcooler evaporator, a subcooler expansion device, a subcooler condenser and a subcooler compressor connected in a closed refrigerant loop. The subcooler evaporator is arranged and disposed to exchange heat between liquid refrigerant in the main circuit and the refrigerant in the subcooler circuit to cool the liquid refrigerant in the main circuit prior to entering the main circuit evaporator. The operation of the subcooler circuit provides an increased cooling capacity per unit of a mass flow of cooling fluid through the main circuit condenser and subcooler condenser for the HVAC system with a predetermined design efficiency.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

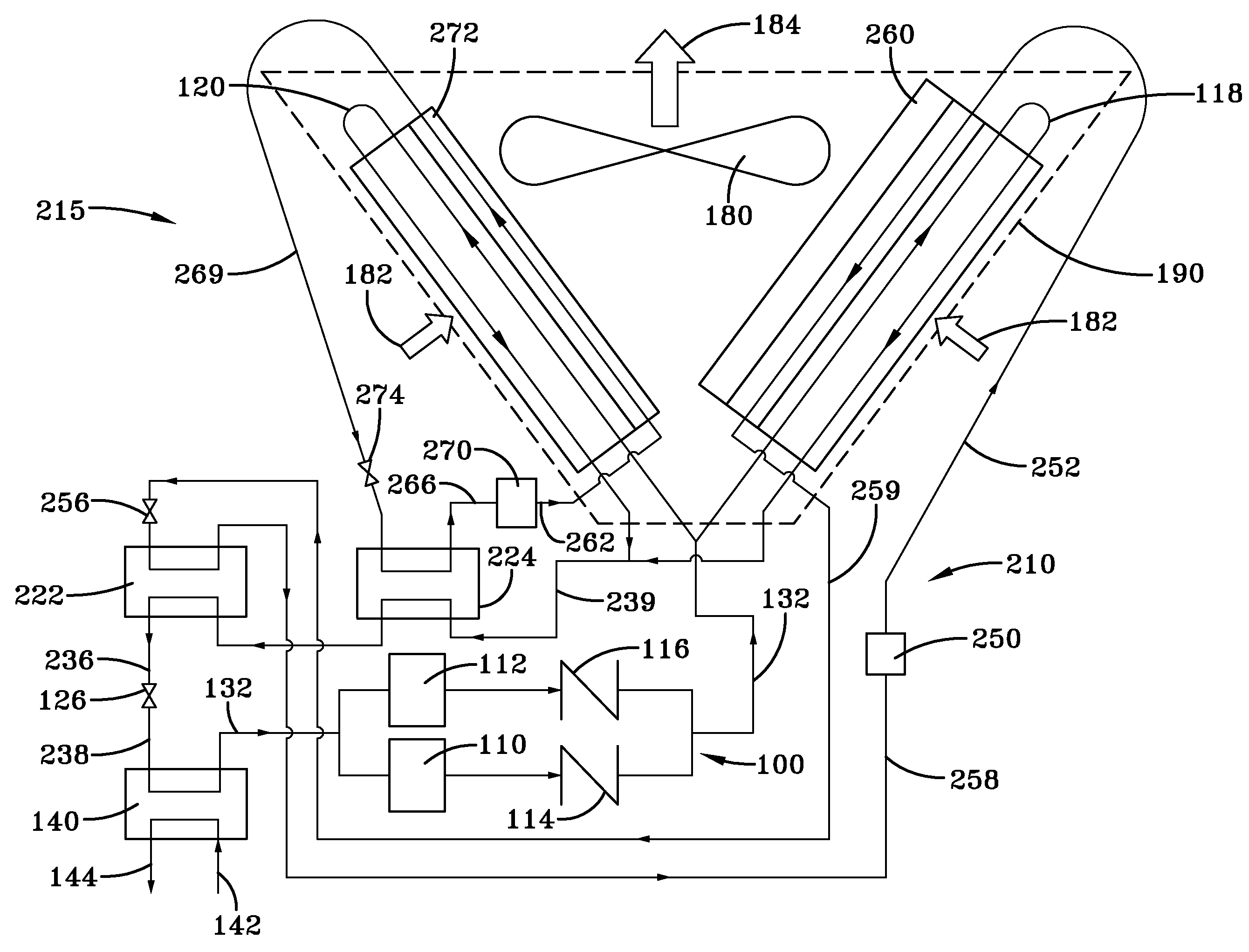

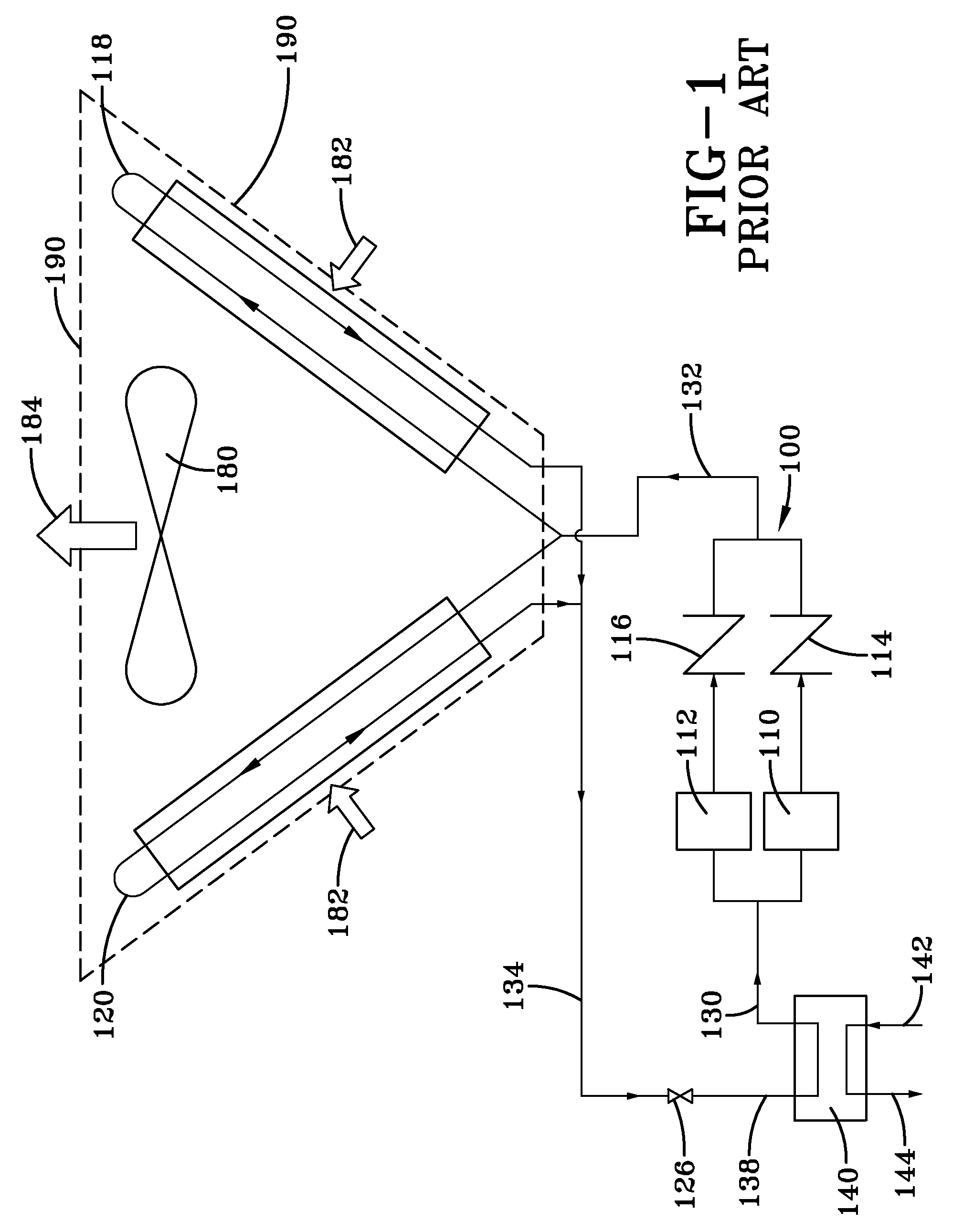

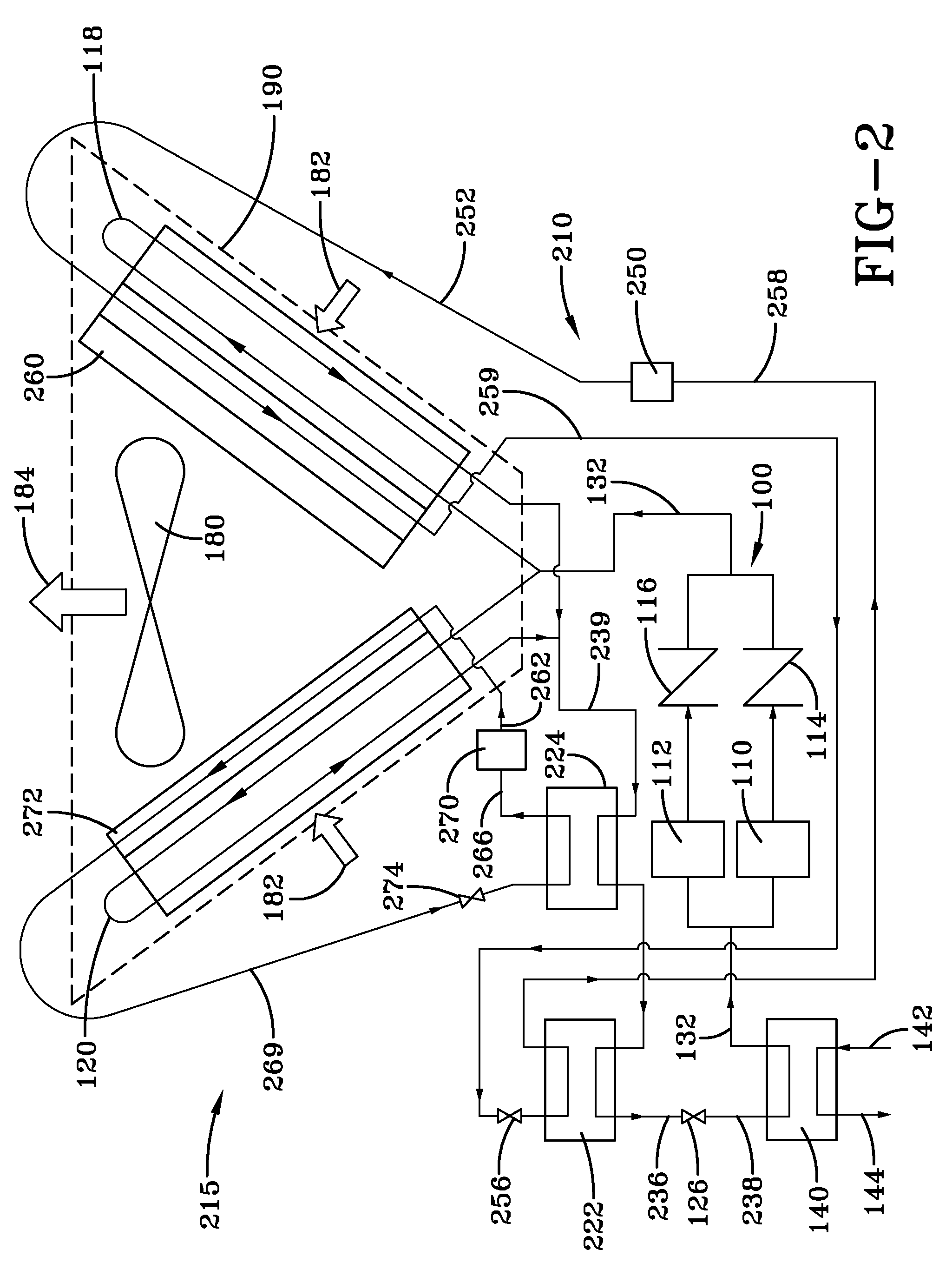

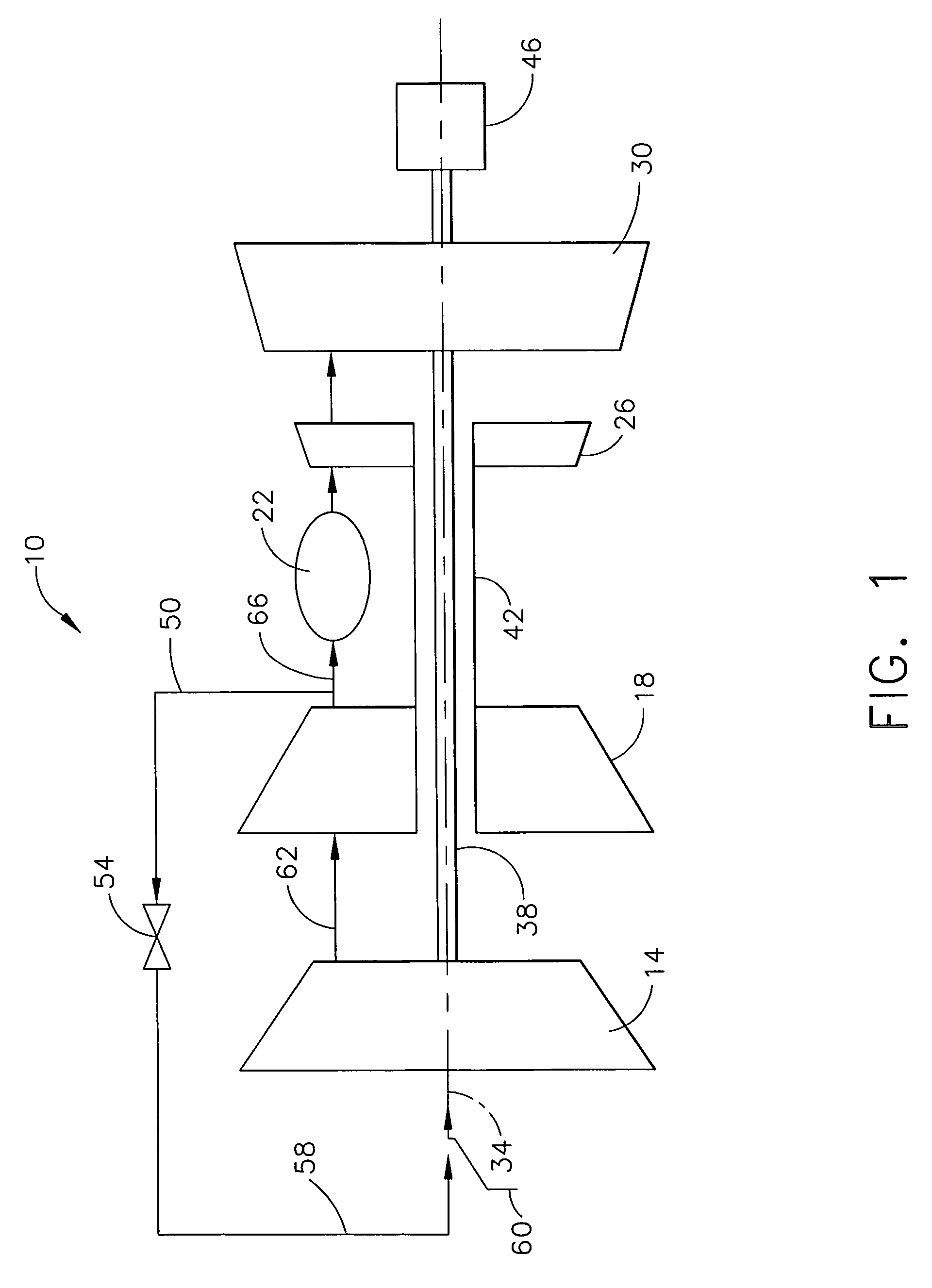

System and method for improving thermal efficiency of dry low emissions combustor assemblies

ActiveUS7185495B2Improve thermal efficiencyIncrease the ambient temperatureContinuous combustion chamberEngine manufactureCombustorBleed air

A gas turbine engine system having improved thermal efficiency, which comprises: (1) an inlet air stream; and (2) a dry low emissions combustor assembly having an air inlet for receiving the inlet air stream, at least one bleed air port and an air outlet for discharging at least a portion of the received air from the inlet air stream. This system includes a source of warmer air capable of raising the ambient temperature of the inlet air stream received by the air inlet of the dry low emissions combustor assembly while operating at a partial load until the system reaches a new equilibrium state having improved thermal efficiency. Also disclosed is a method for improving the thermal efficiency of the dry low emissions combustor assembly, which comprises the step of including a source of warmer air with the inlet air stream received by the air inlet of the dry low emissions combustor assembly while operating at a partial load until the system reaches a new equilibrium state having improved thermal efficiency.

Owner:GENERAL ELECTRIC CO

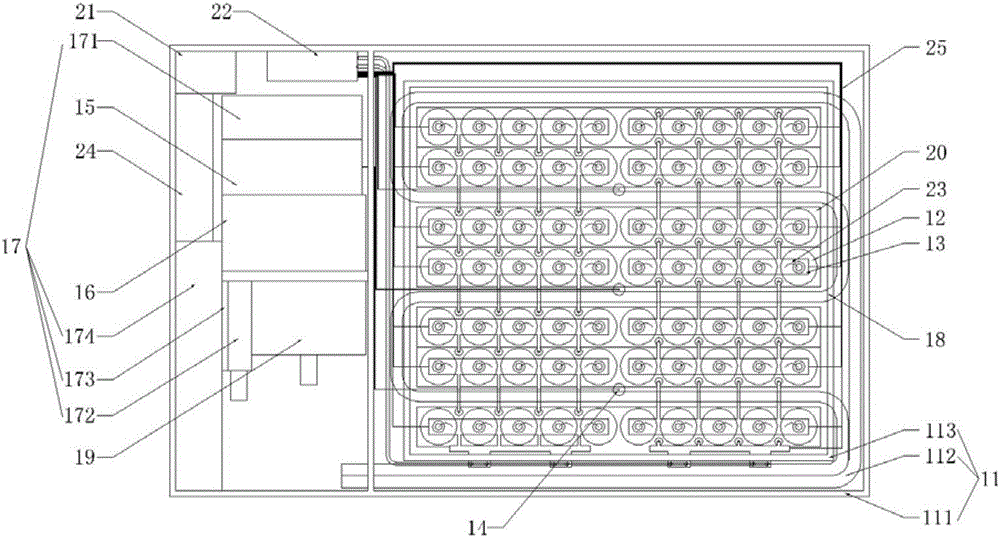

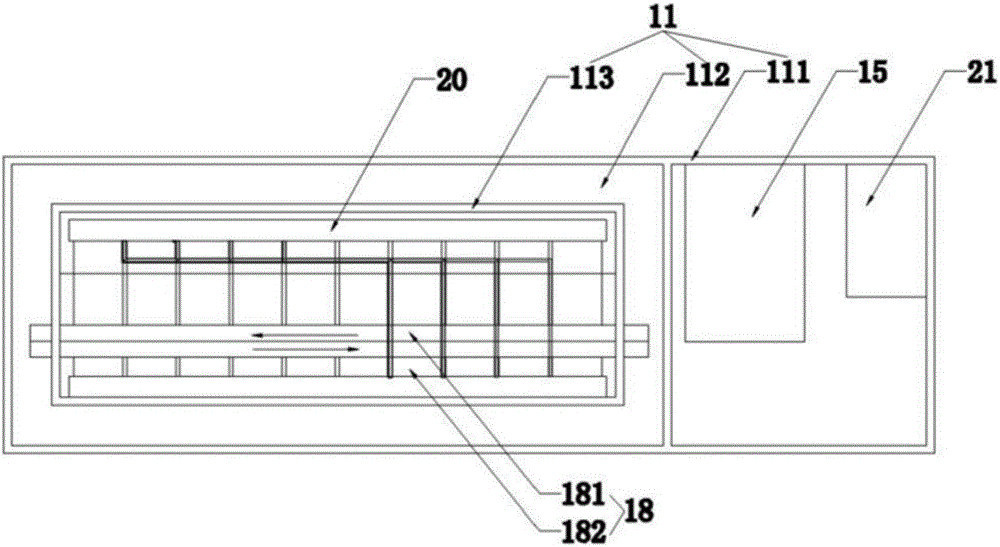

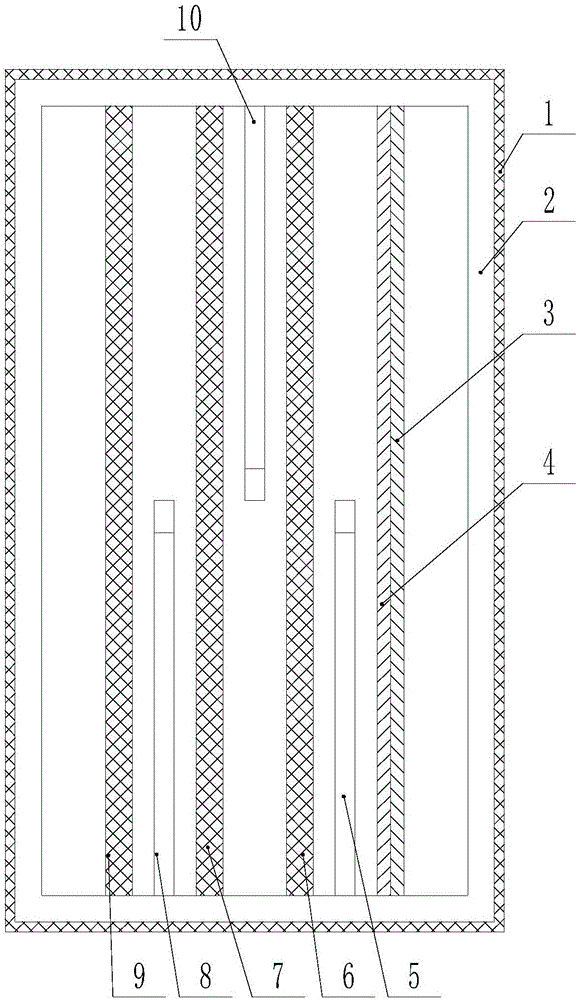

Battery system

InactiveCN106384852AReduce ambient temperatureIncrease the ambient temperatureCells structural combinationVehicular energy storageTemperature controlInner loop

The invention provides a battery system, and belongs to the technical field of batteries. The battery system comprises a case, a plurality of sections of battery cells, a temperature collecting probe, a BMS (battery management system), a heating and refrigeration assembly, a liquid flowing pipeline, a heat conduction medium and a water pump, wherein the liquid flowing pipeline passes through a gap formed among the plurality of sections of battery cells; the water pump drives the heat conduction medium to realize circulation flowing inside the pipeline; the temperature collecting probe and the heating and refrigeration assembly are electrically connected with the BMS; the BMS controls the heating and refrigeration assembly to work according to the temperature information feedback by the temperature collecting probe; the heating and refrigeration assembly and the liquid flowing pipeline perform heat exchange through a water cooling head so as to realize the heating and the refrigeration on the heat conduction media inside the liquid flowing pipeline; the whole temperature control system is directly controlled by the BMS. The battery system is provided with the temperature collecting probe, the heating and refrigeration assembly and the BMS; the environment temperature of the battery cells is regulated through controlling the temperature of the heat conduction media inside the liquid flowing pipeline, so that the battery cells always work in a set temperature range.

Owner:王波

Air conditioner and controlling method therefor

InactiveCN1991255AIncrease wind temperatureHigh work pressureSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringHeat exchanger

The invention relates to an air conditioner, comprising indoor unit and outdoor unit. Indoor heat exchanger and air supply apparatus are set in the indoor unit. Thereinto, there is at least a heating device in the indoor device and the heating device runs during defrosting of said air conditioner. The heating device is set at the upstream or downstream of indoor heat exchanger. The invention provides a control method of air conditioner. The method comprises defrosting of air conditioner when achieving the condition of defrosting and running of heating device at least when said air conditioner defrosts. The air conditioner and the control method of invention can shorten the defrosting time and make the indoor temperature not decrease. Furthermore, it can make the temperature in door improve quickly under the low temperature.

Owner:PANASONIC CORP

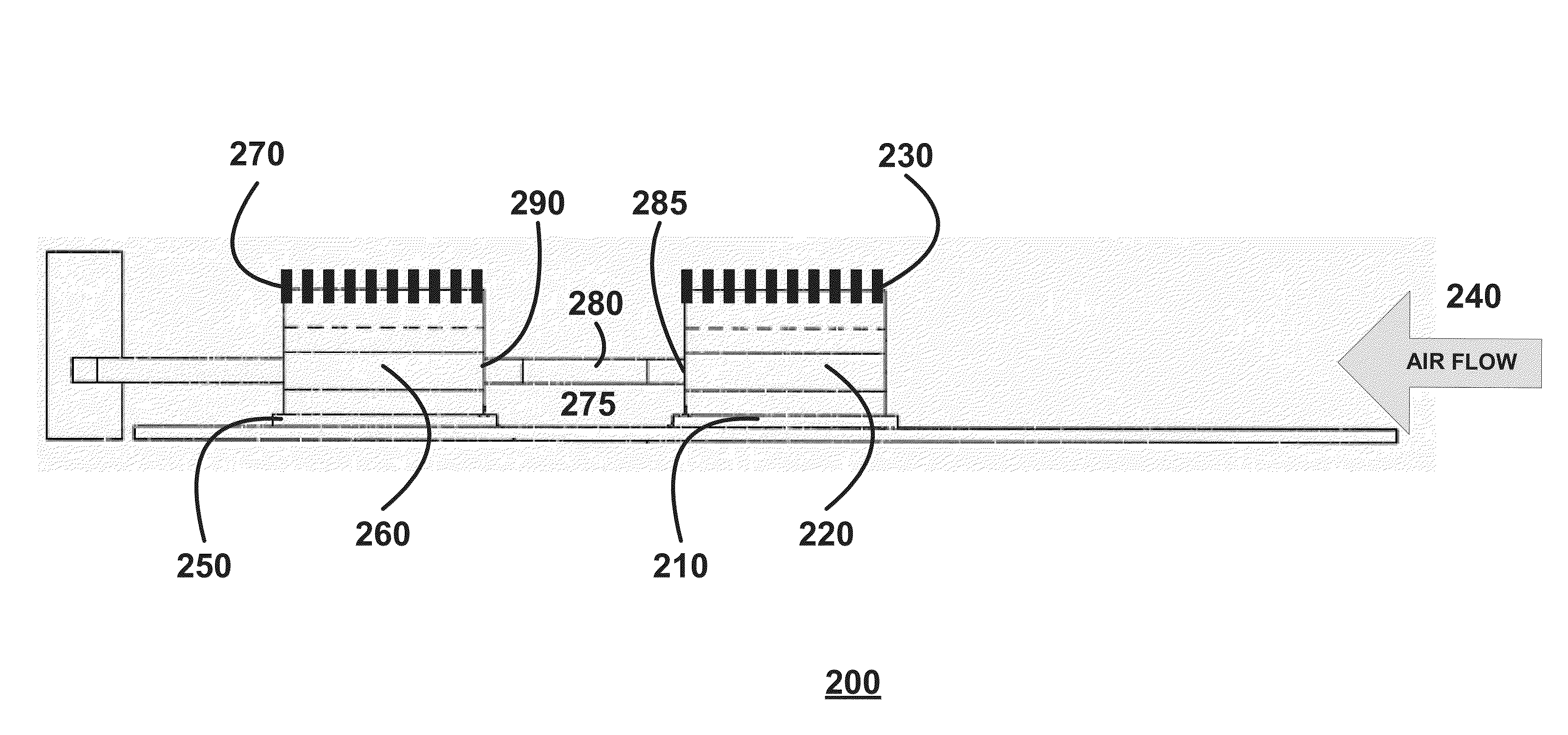

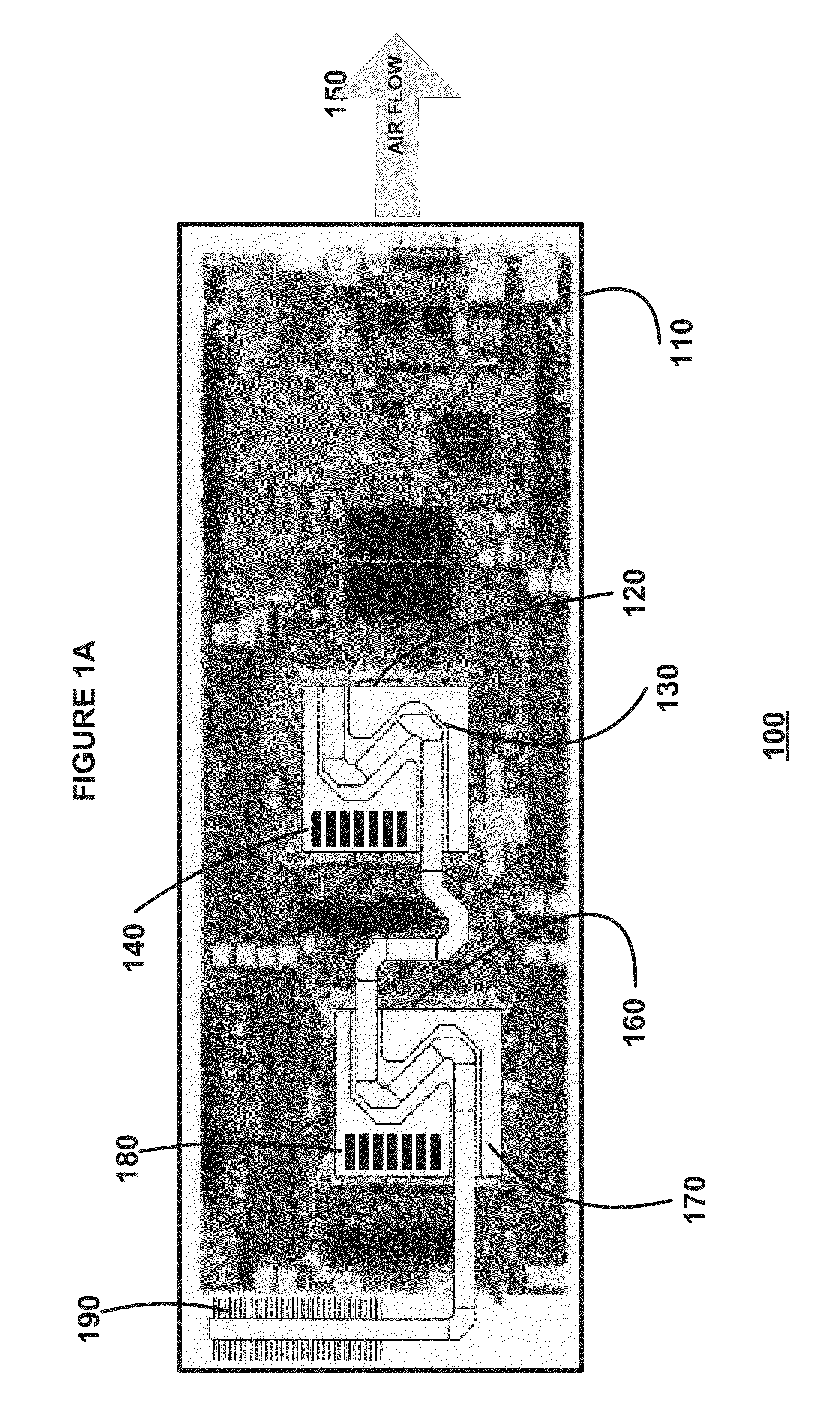

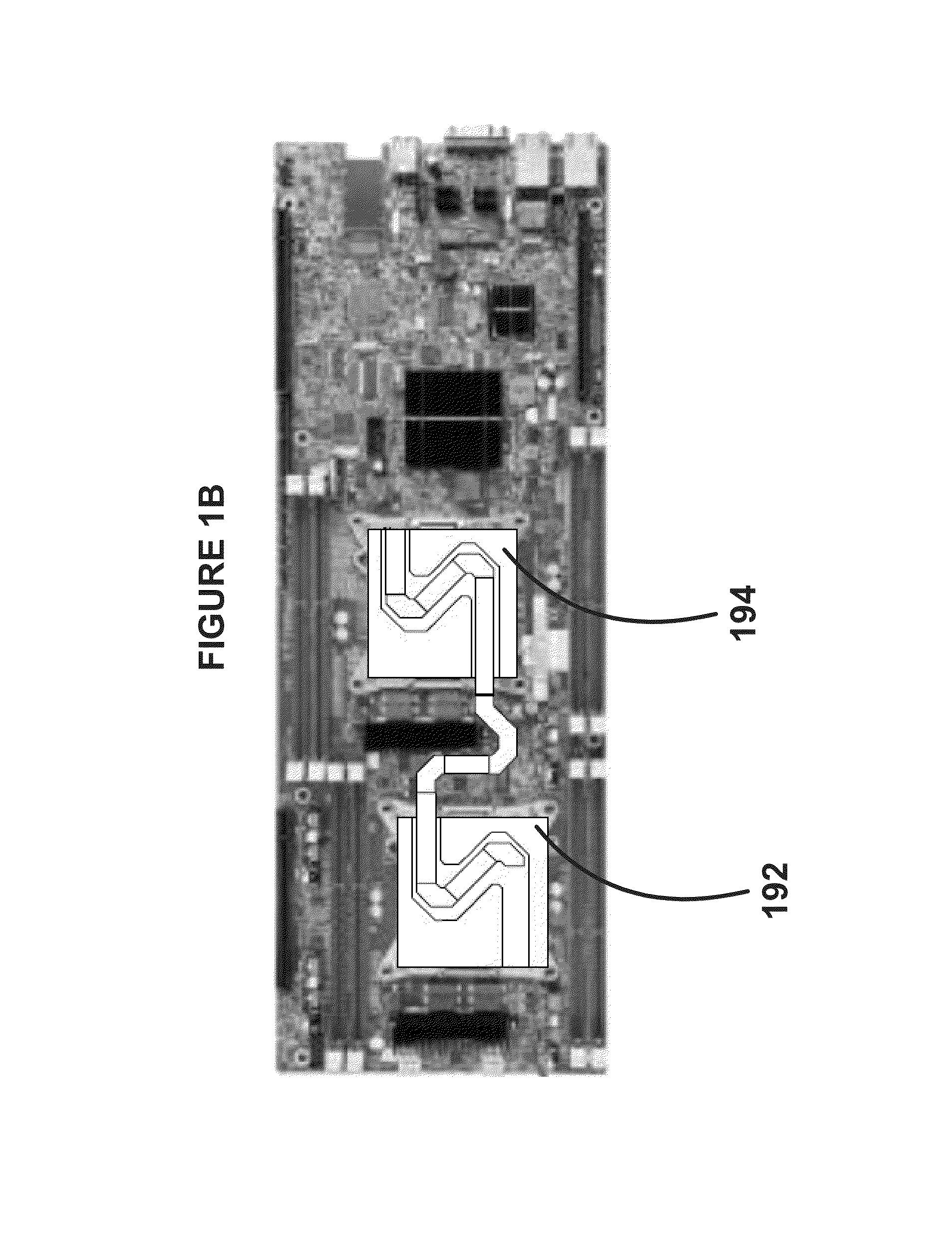

System for cooling multiple in-line central processing units in a confined enclosure

InactiveUS20140268553A1Improve system performanceImprove reliabilityDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat pipe

A system for cooling multiple in-line CPUs in a confined enclosure is provided. In an embodiment, the system may include a front CPU and a front heat sink that may be coupled to the front CPU. The front heat sink may have a plurality of fins and a corresponding fin pitch. The system may further include a rear CPU disposed in line with the front CPU and a rear heat sink coupled to the rear CPU. The rear heat sink may have a plurality of fins and a corresponding fin pitch. The fin pitch of the rear heat sink may be higher than the fin pitch of the front heat sink. In another embodiment, the front and rear heat sinks may be coupled together by one or more heat pipes.

Owner:RPX CORP

Adjuvant-mediated reactivity enhancement of polymerizable diacetylenic materials

ActiveUS8067483B2Increase the ambient temperatureDecorative surface effectsDuplicating/marking methodsAdjuvantMethyl ethyl ketone peroxide

Indicator inks, indicators formed by printing or otherwise utilizing the inks and host products utilizing the indicators are disclosed. Reactivity-enhancing adjuvants stimulate enhanced thermal reactivity of diacetylenic or other indicator agents capable of responding to ambient thermal conditions with a visual change signaling an end point. The diacetylenic or other agents may be sensitive or relatively insensitive to ambient temperatures. Use of a reactivity-enhancing adjuvant provides a useful means for adapting the reactivities of indicator agents to the response characteristics of prospective host products, for example perishables such as vaccines or fresh fish and maturables such as fruit, cheese and wine. Some exemplary adjuvants include low-temperature polymerization initiators, for example methyl ethyl ketone peroxide and polymerization accelerators, for example cobalt compounds. Such initiators and accelerators can also be used in combination.

Owner:TEMPTIME CORP

MDI base polyurethane prepolymer with low MDI monomer content

InactiveCN1380346AImprove wet strengthIncrease the ambient temperaturePolyureas/polyurethane adhesivesConjugated diene hydrocarbon adhesivesMonomer compositionPolymer science

A prepolymer composition comprises a reaction product of 4,4'-diphenylmethane diisocyanate (MDI) with a polyol composition comprising a propylene oxide based polyether polyol. The prepolymer composition consists of at least 80 weight (wt.%) perfect prepolymers and less than 2 wt.% free MDI monomer. Independent claims are included for the following: (1) An improved polyurethane adhesive composition which comprises a polyurethane prepolymer composition and optionally an isocyanate-reactive curative; and (2) A method for adhesively joining or sealing two substrates using a polyurethane adhesive composition, which involves applying polyurethane adhesive composition on a substrate and contacting the adhesive to another substrate, such that a bond is formed.

Owner:코임유에스에이인크

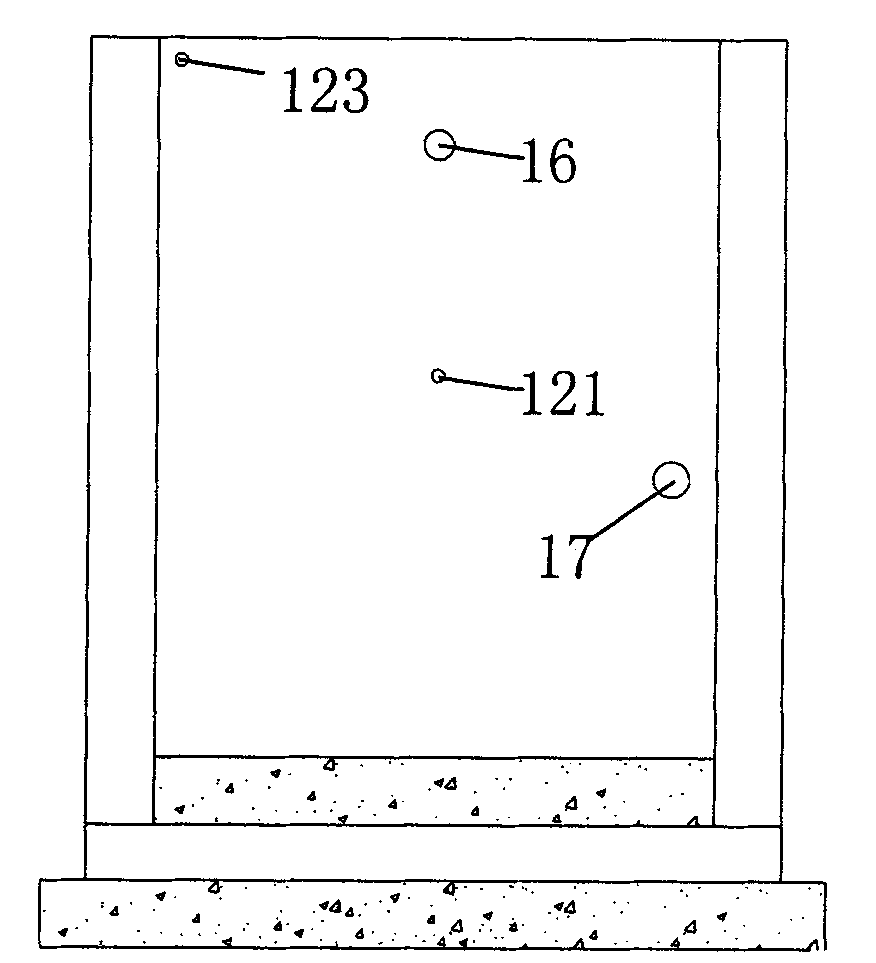

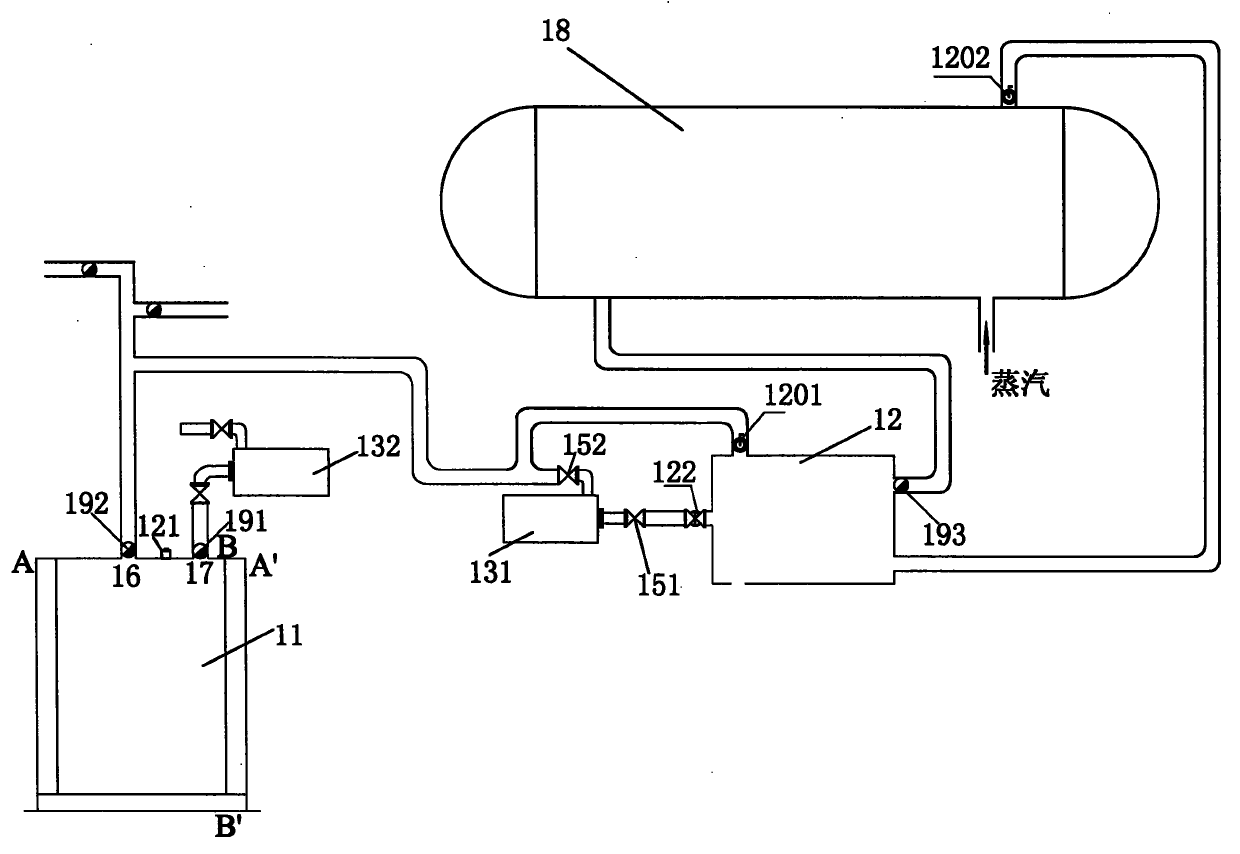

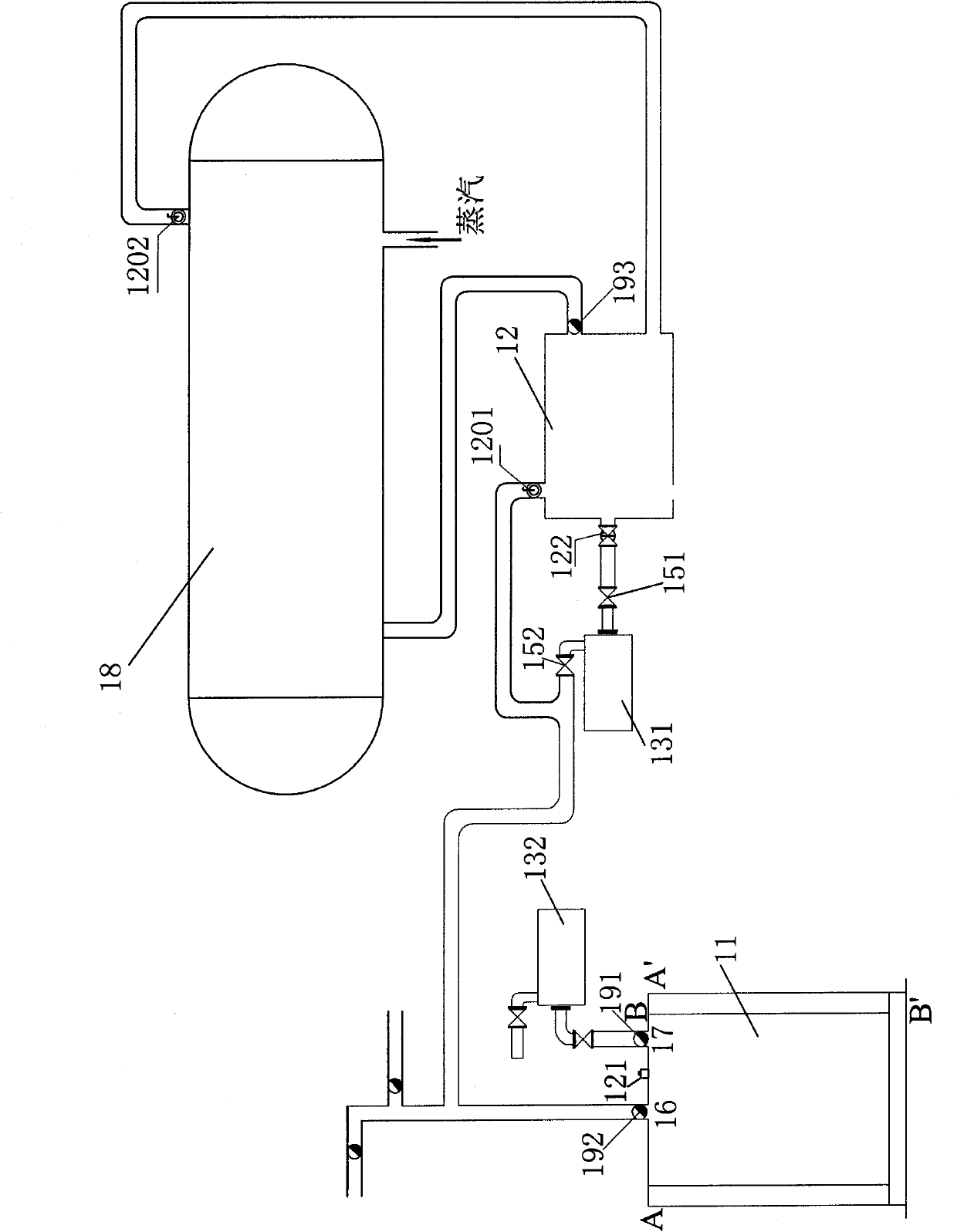

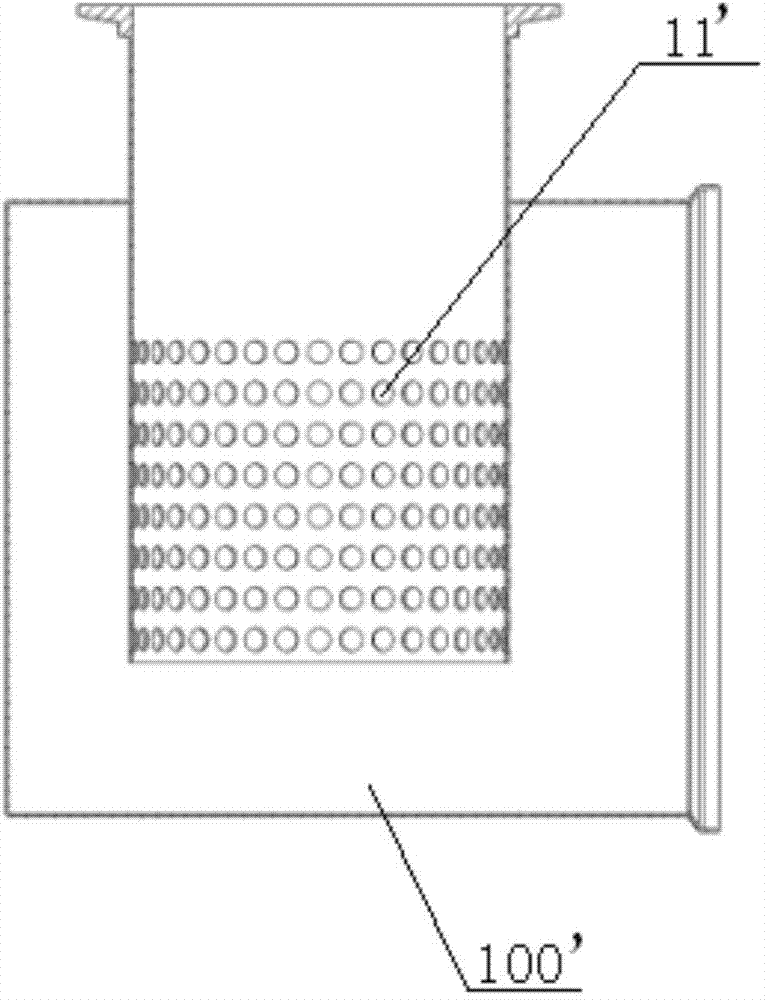

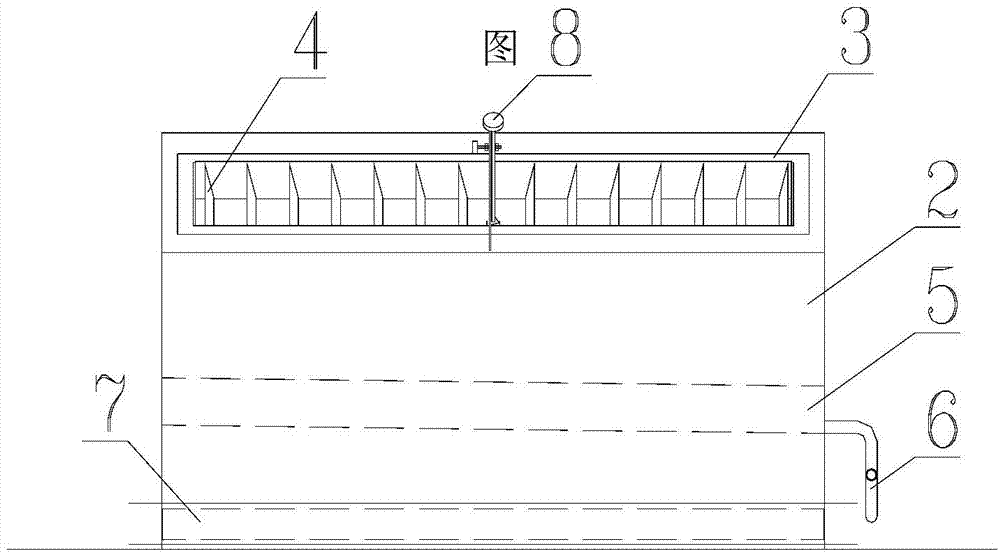

Water curing method and device for centrifuged pretensioned prestressed concrete pipe pile

ActiveCN101905486ATo overcome the lack of maintenance technologyRealize environmentally friendly productionCeramic shaping apparatusWater storage tankEngineering

The invention relates to a pipe pile water curing method. In the method, a water storage tank is arranged, and condensate water and residual steam in a still kettle are guided into the water storage tank; a pipe pile is placed in a steaming and curing pool, the condensate water in the water storage tank is guided into the steaming and curing pool, and the residual steam in water storage tank is guided into the steaming and curing pool; and steaming and curing the pipe pile in the steaming pool for 4-5 hours at 80-90 DEG C. The curing device comprises the steaming and curing pool, the water storage tank and the still kettle, wherein the steaming and curing pool is provided with a water-steam port; the water storage tank is provided with a residual steam outlet, a residual steam inlet, a condensate water outlet and a condensate water inlet; and the still kettle is provided with a steam inlet and a steam outlet. A condensate channel is arranged between the water-steam port of the steaming pool and the condensate water outlet of the water storage tank, and a steam channel is arranged between the water-steam port of the steaming pool and the residual steam outlet of the water storage tank. The condensate water inlet of the water storage tank is communicated with the condensate water outlet of the still kettle through a third electric control valve and a pipeline, and the steam inlet of the water storage tank is communicated with the steam outlet of the still kettle through a second steam valve and a pipeline.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

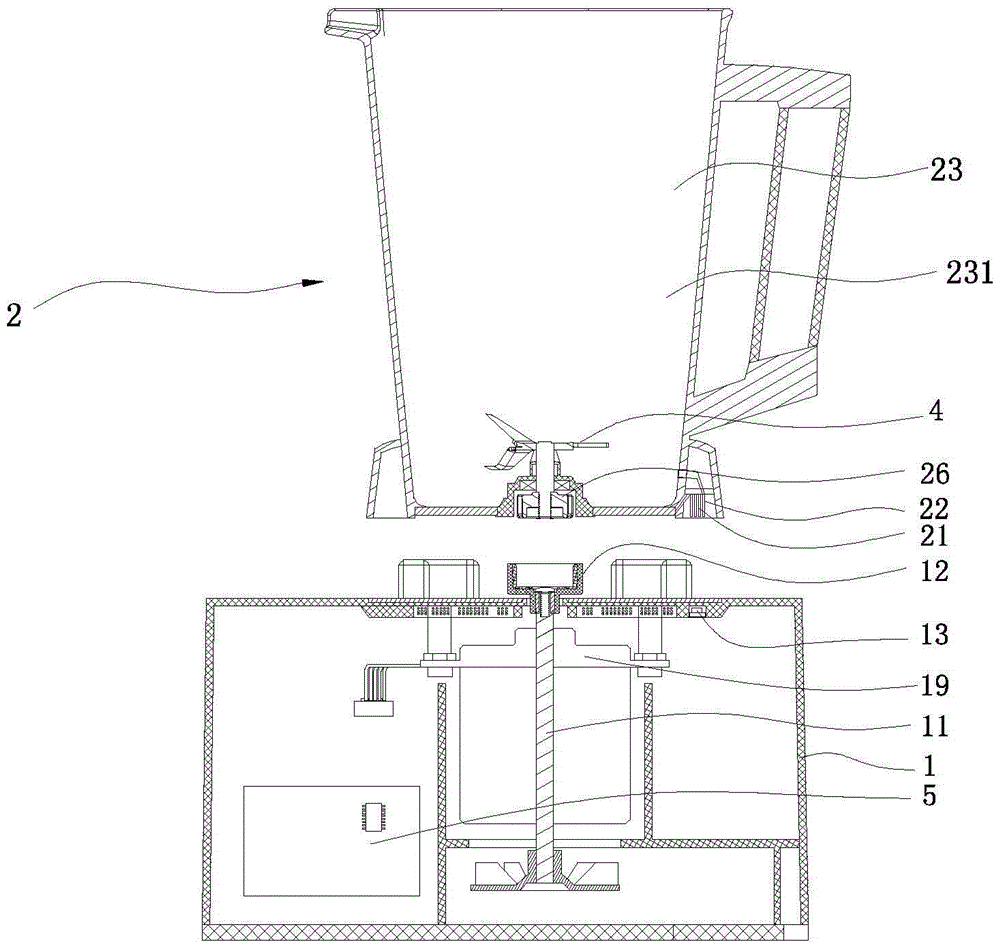

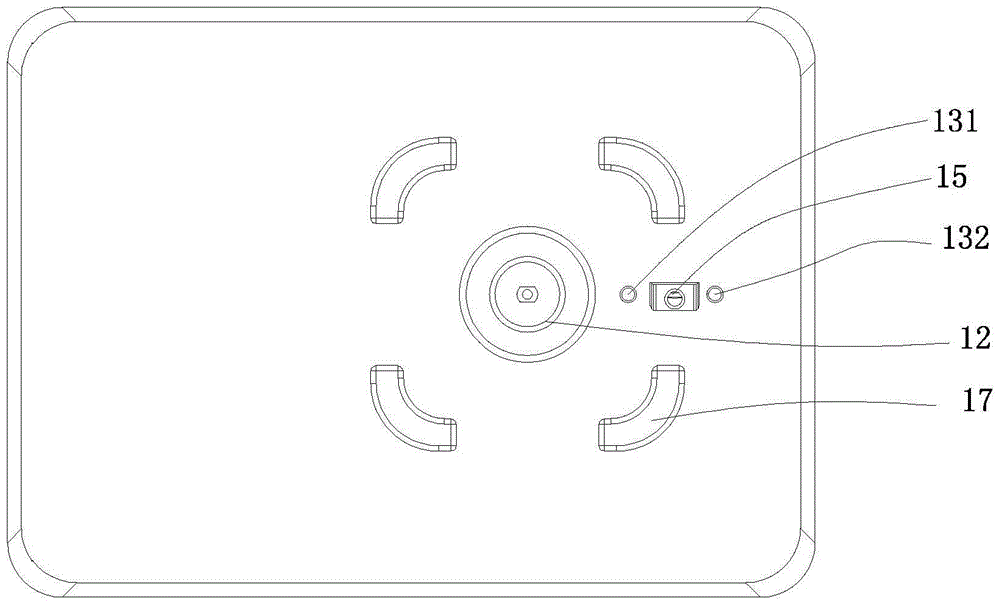

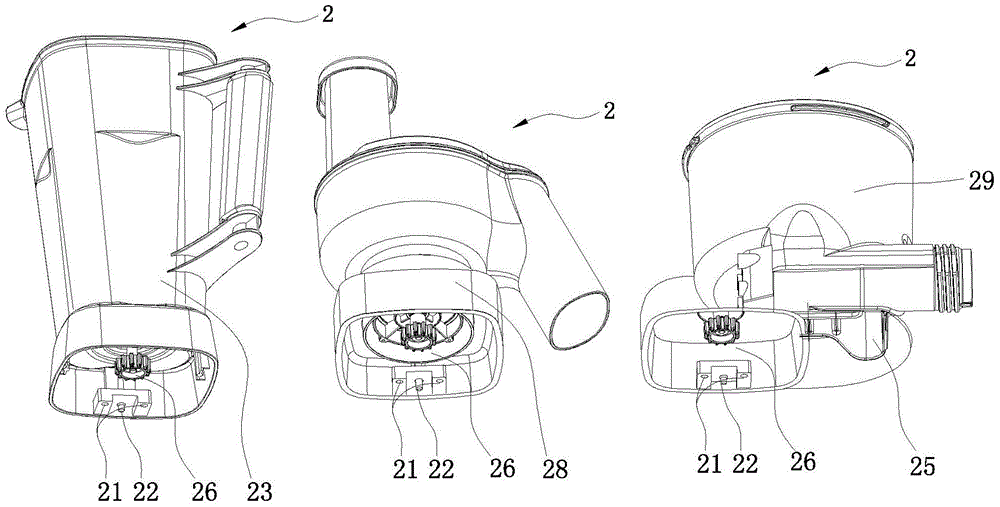

Multifunctional food processing platform

The invention relates to the technical field of domestic kitchen appliances, in particular to a multifunctional food processing platform. The multifunctional food processing platform comprises a machine base. A driving motor is arranged in the machine base. A speed feedback device is arranged on the driving motor. Matched food processing assemblies are arranged on the platform body. A plurality of sensors used for detecting whether the food processing assemblies are mounted in place or not are arranged on the machine base. A trigger mechanism is arranged at the bottoms of the food processing assemblies and corresponds to the sensors. The sensors are triggered by the trigger mechanism to identify the types of the processing assemblies. According to the types of the food processing assemblies, a control system controls the driving motor to act through the sensors, so that the food processing assemblies are driven to work correspondingly. Multiple functions of the platform are achieved, and the platform is more intelligent, automatic and humanized to use and can achieve the effect that foods manufactured through all functions are good in effect.

Owner:JOYOUNG CO LTD

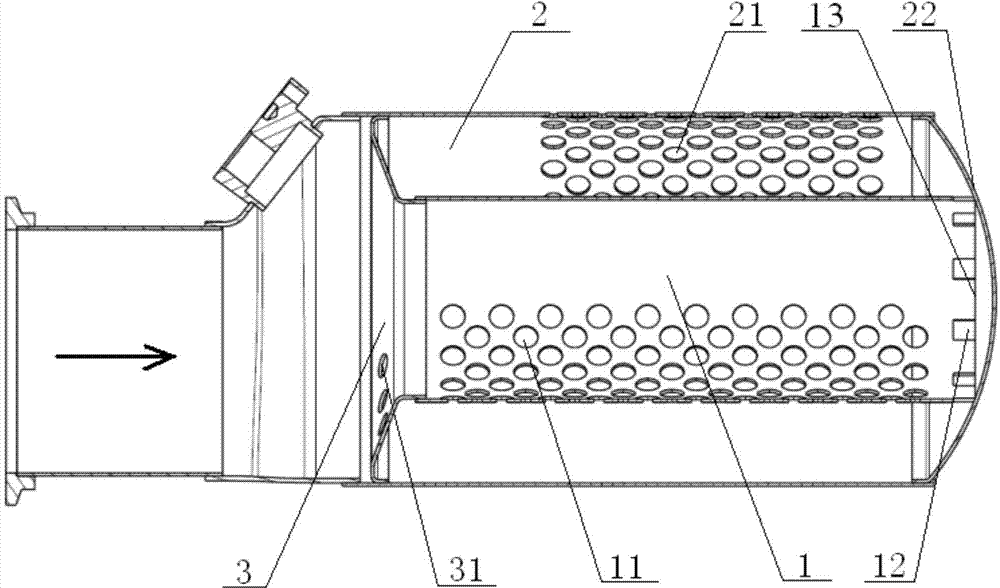

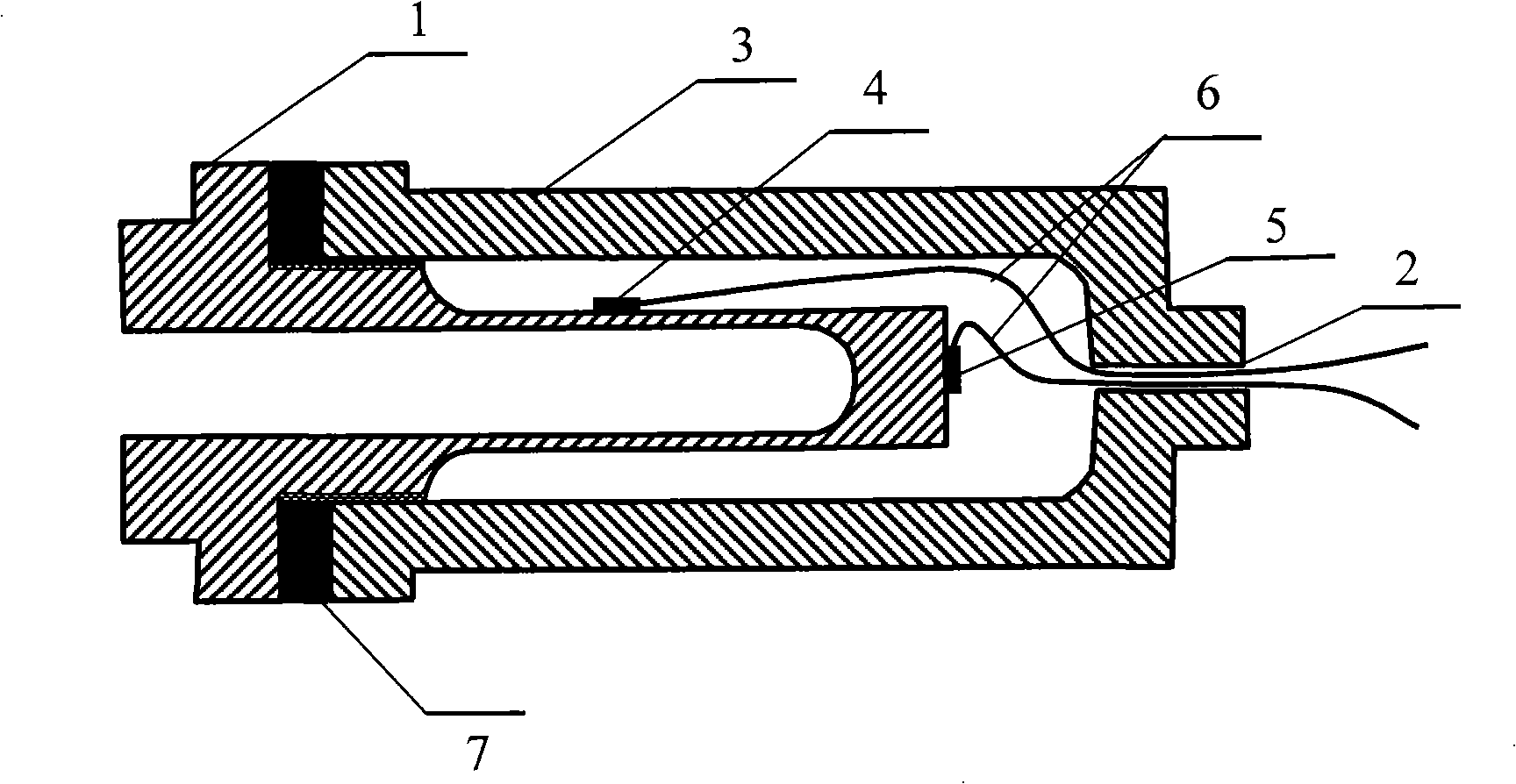

Air inlet pipe of SCR tail gas processing system and SCR tail gas processing system

ActiveCN104121081APrevent crystallizationIncrease profitExhaust apparatusSilencing apparatusEngineeringExhaust pipe

The invention discloses an air inlet pipe of an SCR tail gas processing system. The air inlet pipe comprises a first guiding pipe and a second guiding pipe arranged outside the first guiding pipe in a sleeved mode. The side wall of the first guiding pipe is provided with a plurality of first guiding holes, and the side wall of the second guiding pipe is provided with a plurality of second guiding holes. The air inlet end of the first guiding pipe is connected with a urea nozzle of the system and an engine exhaust pipe. The second guiding holes are connected with a catalyst reactor of the system. According to the double-layer air inlet pipe, the air disturbance is increased through the double layers of guiding holes of the double-layer air inlet pipe, the probability that liquid urea drops touch the inner wall of the air inlet pipe is reduced, the urea is prevented from being crystallized, the liquid urea drops and the tail gas can be evenly mixed in the flowing process, and the utilization rate of the liquid urea drops is improved. In addition, the air inlet pipe has a good insulating function. The invention further provides the SCR tail gas processing system with the air inlet pipe.

Owner:WEICHAI POWER CO LTD

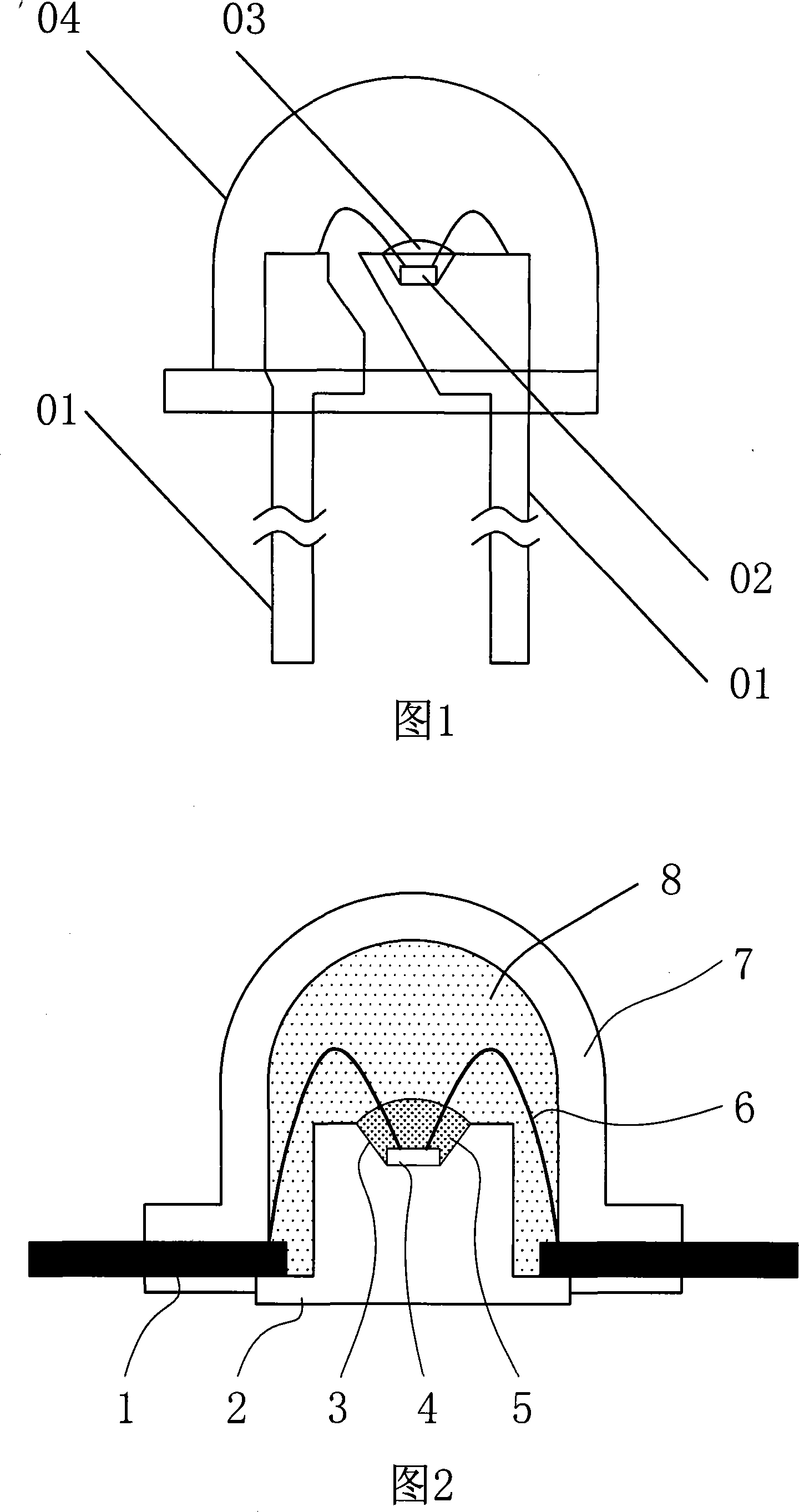

Bidirectional luminescent heat radiation LED

InactiveCN101123289AHigh light efficiencyHigh luminous intensitySemiconductor/solid-state device detailsElectric circuit arrangementsLuminous intensityEngineering

The invention relates to a light-emitting diode (LED) technology, namely, a LED of bidirectional luminescence and heat radiation. The lead wire are led from the positive and negative electrodes on the LED chips respectively and connected to the guide pin extends to the outside of the lens cap. The chip can be covered by the lens cap, at least one chip is fixed in the through hole on the substrate, but also the transparent and adiabatic medium is positioned on the external surface of the chip, and then the external surface of the medium or the lens cap is equipped with a phosphor layer. The invention has the advantages that lighting effect of LED can increase 16 to 36 percent due to the bidirectional luminescence of the chip of the invention, due to separation of the phosphor and the chip in white LED, the phosphor is not easily heated, aged and carbonized and blacken, the color temperature and the illumination intensity is stable. The luminous flux of the product is still more than 90 percent of the initial luminous flux and the product can be made into various light-emitting LED light after aging test of 5000 hours.

Owner:CHANG HSIN HIGH INTENSITY LED DONG GUAN

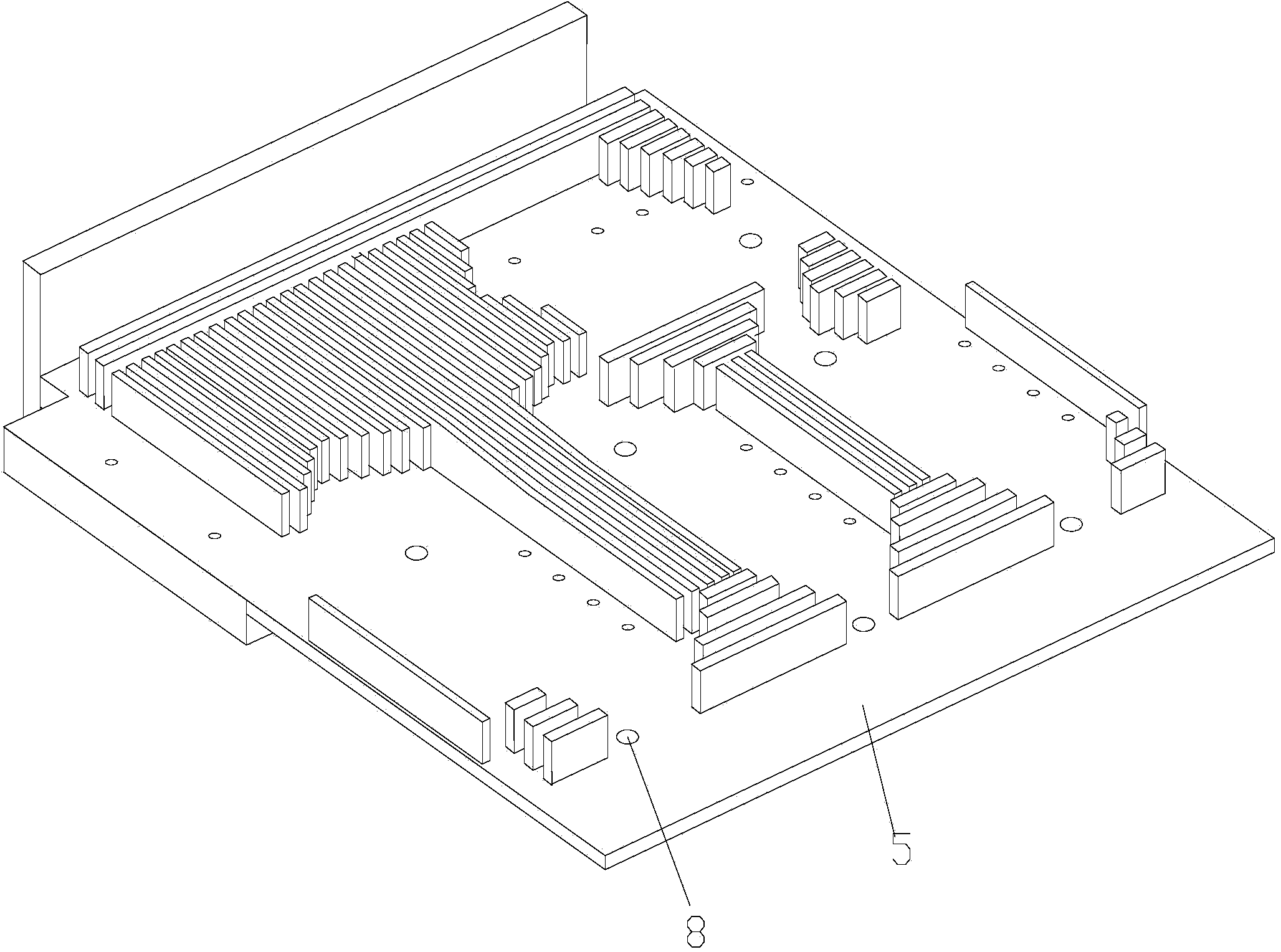

Circuit board heat conduction optimization design structure for onboard aviation product

ActiveCN103687450AIncrease cooling areaReduce thermal contact resistanceCooling/ventilation/heating modificationsAviationSilica gel

The invention provides a circuit board heat conduction optimization design structure for an onboard aviation product. A heat-conductive board is arranged between a high-power highly-heat-radiating device and a PCB. The heat-conductive board is directly and additionally arranged on the PCB, so that the heat dissipation area is greatly increased; meanwhile, a soft silica gel heat-conductive fin is additionally arranged between the high-power highly-heat-radiating device and a heat-conductive aluminum plate so that an air gap can be eliminated, thermal contact resistance between the device and the heat-conductive aluminum plate can be reduced, and heat generated by the device can be rapidly conducted to the heat-conductive aluminum plate. A T-shaped structure of a heat-conductive and radiation heat exchange face is additionally arranged at the top of the heat-conductive aluminum plate. After the soft silica gel heat-conductive fin is additionally arranged on the upper end face of the T-shaped structure, the T-shaped structure is connected with a box body sealing cover into a whole, so that heat is effectively conducted to the surface of a box body, and the heat dissipation area is increased. A wedge-shaped pressing mechanism is adopted, so that the contact area between the heat-conductive aluminum plate and the box body is increased, heat conduction is effectively achieved, the temperature of the surface of an electronic device is rapidly lowered, and the service life of the product is prolonged.

Owner:SHAANXI BAOCHENG AVIATION INSTR

Power distribution box with novel shell structure

InactiveCN105119162AGuaranteed to workIncrease the ambient temperatureBoards/switchyards circuit arrangementsGlass fiberPlastic materials

The invention discloses a power distribution box with a novel shell structure and belongs to the electric power technical field. The power distribution box with the novel shell structure comprises a frame; the frame is made of an integrated high-strength glass fiber reinforced plastic material; and an electromagnetic shielding layer, a heat insulating layer, an insulating layer and a fireproof layer are arranged in the frame. With the power distribution box with the novel shell structure provided by the above technical scheme adopted, the problems of high possibility of being etched, in capability of shielding interferences of external environment and electromagnetic environment on an intelligent control device exiting on the shell of a traditional power distribution box can be solved, and a power source can be cut off timely when a short-circuit fire occurs, and personnel security can be ensured.

Owner:国网山东沂南县供电公司 +1

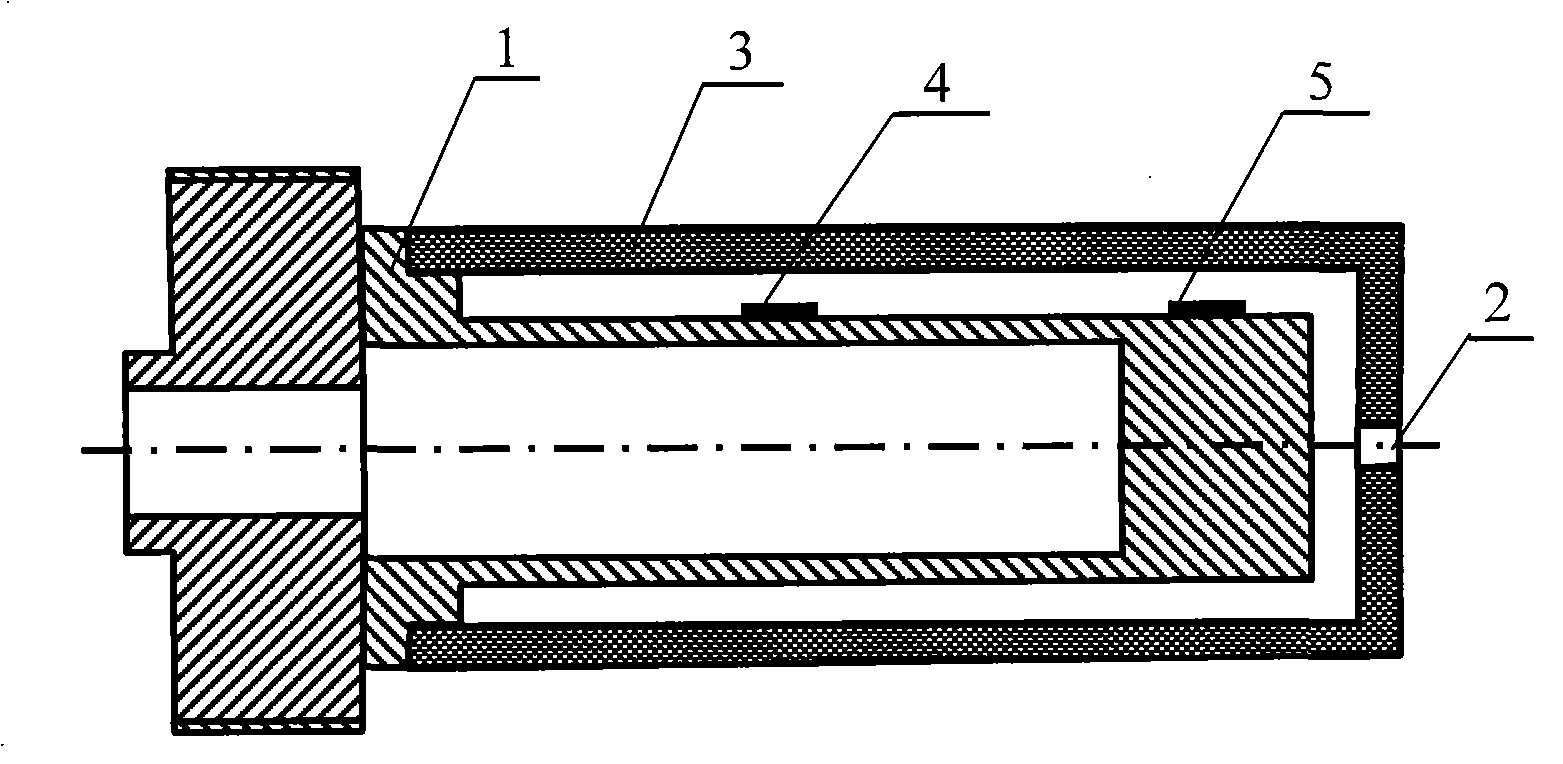

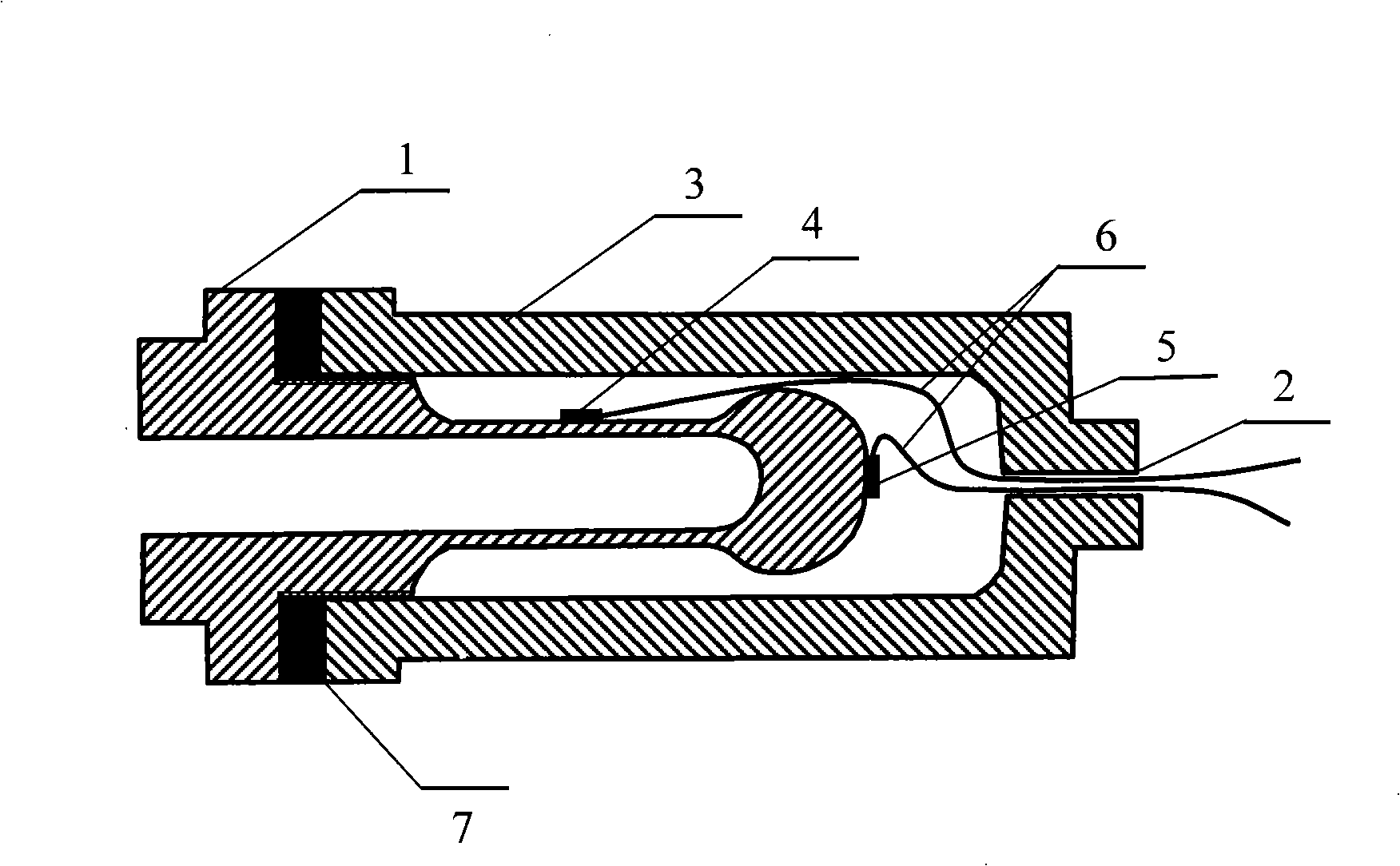

Inner arced ceiling thin wall straining cartridge throw-in type optical fibre Bragg grating pressure sensor

InactiveCN101266179AExpand the measurement rangeGuaranteed tightnessFluid pressure measurement by optical meansGratingOperating temperature range

An inner arc top thin wall strain cylinder drop-type optical fiber Bragg grating pressure sensor, belonging to the field of sensor technology, relates to a drop-type optical fiber Bragg grating pressure sensor for pressure measurement, characterized in that the inner side top of a metal thin wall inner cylinder is arc structured; both of the pressure-measuring optical fiber Bragg grating and the temperature compensating optical fiber Bragg grating are packaged in metallization; the pressure-measuring optical fiber Bragg grating is welded to the outer wall side of the metal thin wall inner cylinder axially with metal; the temperature compensating optical fiber Bragg grating is welded to the top outer side of the metal thin wall inner cylinder with metal; the pressure-measuring optical fiber Bragg grating is vertical to temperature compensating optical fiber Bragg grating to each other; two signal extraction single mode fibers are also packaged in metallization locally when passing through an optical fiber exit hole, and welded to the optical fiber exit hole with metal so as to close the optical fiber exit hole. The invention improves pressure-measuring range for a pressure sensor so as to solve the crossing sensitive problem of two Bragg gratings, which enhances operating temperature range for the sensor.

Owner:DALIAN UNIV OF TECH

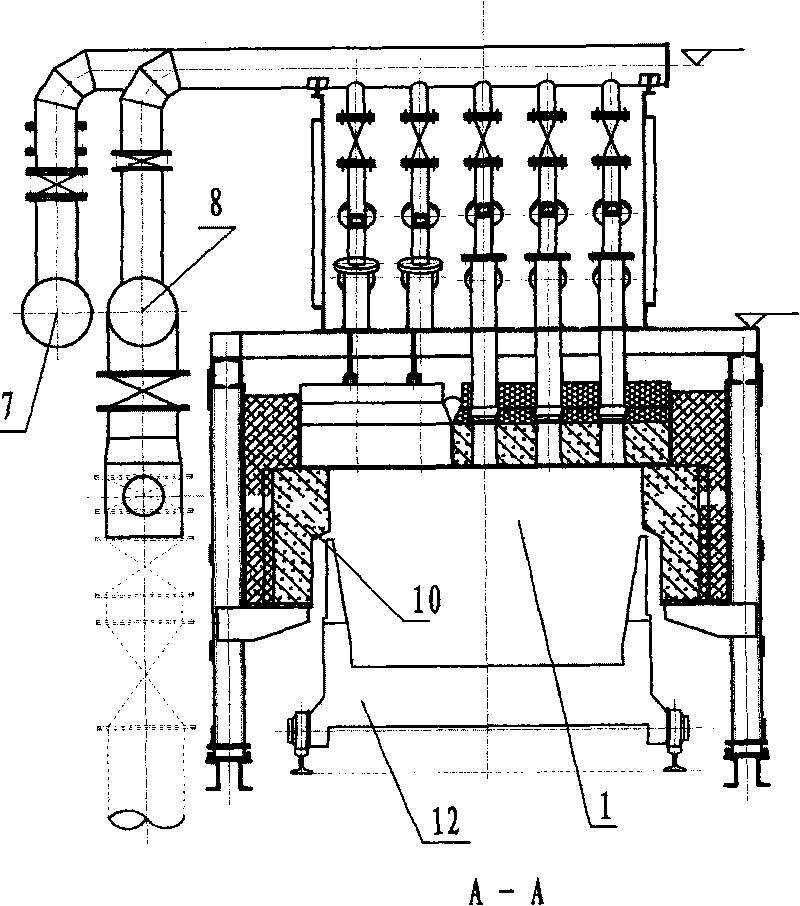

Single preheating, sintering, igniting and heat insulating furnace

The invention relates to a single preheating, sintering, igniting and heat insulating furnace with the advantages of simple structure, little pollution, obvious energy saving effect and high safety. The furnace comprises an igniting section and a heat insulating section, wherein the igniting section and the heat insulating section are connected into a whole and are arranged on a sintering machine table. The heat insulating section comprises an air preheating furnace, and an air heat exchanger is arranged in the air preheating furnace. The igniting section comprises a plurality of burning nozzles, and each burning nozzle is connected with a blast furnace gas pipe and a hot air pipe. A cold air inlet and a cold air input tube of the air heat exchanger are connected, and a fan is arranged on the cold air input tube. A hot air outlet of the air heat exchanger is connected with an inlet of the hot air tube. The air heat exchanger is arranged on a trolley. When the single preheating, sintering, igniting and heat insulating furnace is in working, the sintering compound of the waste gas trolley outputted by the air preheating furnace is insulated, and sucked into a large fume passage by the sintering compound surface of the trolley. The large fume passage is connected with the hot waste gas heat energy recovery system and the waste gas treating system to recover and utilize heat energy and remove harmful elements of sulphur and the like in the waste gas.

Owner:常州市黑山烧结点火炉制造有限公司

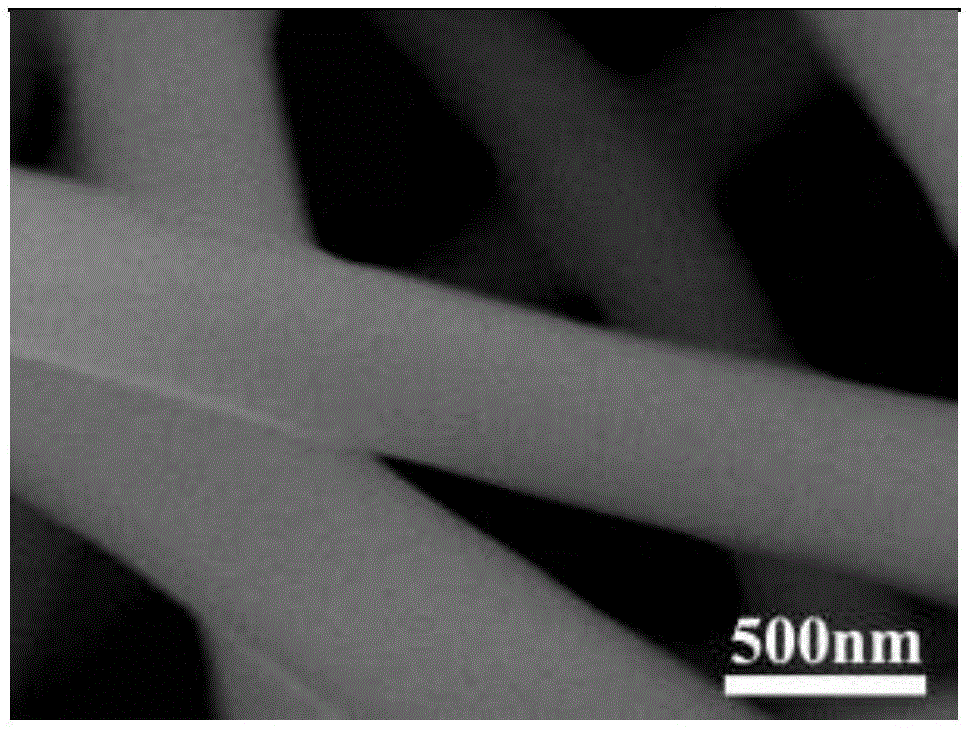

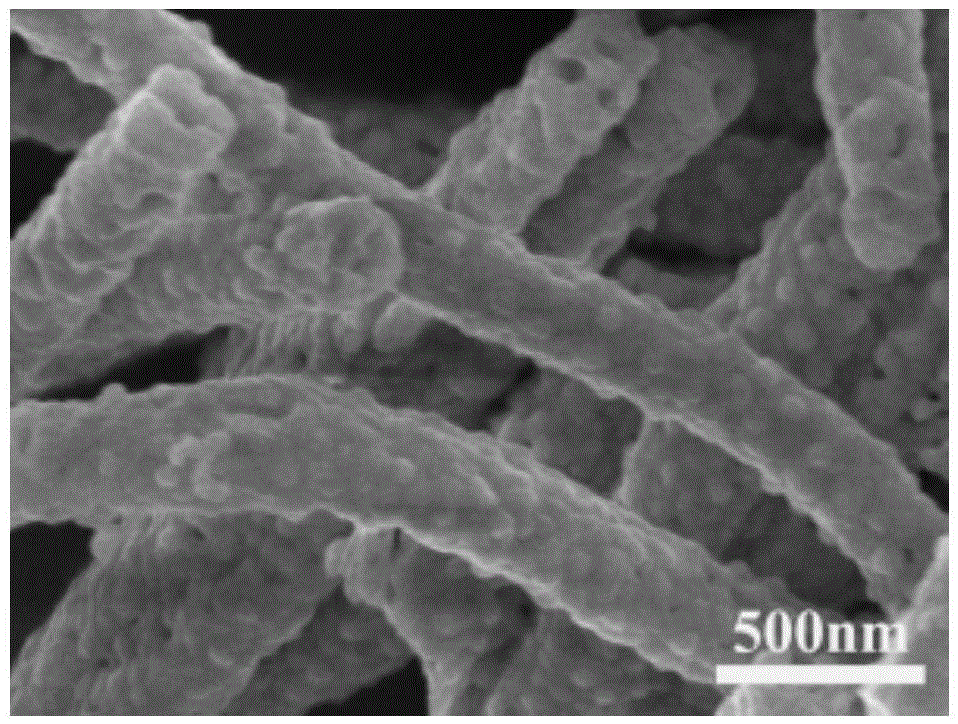

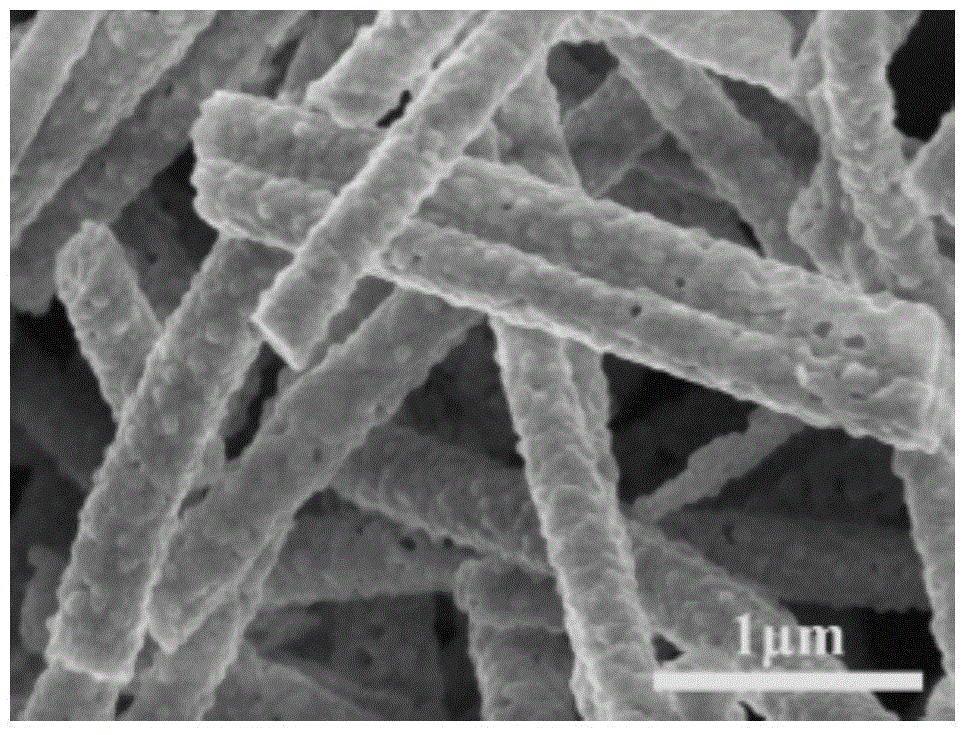

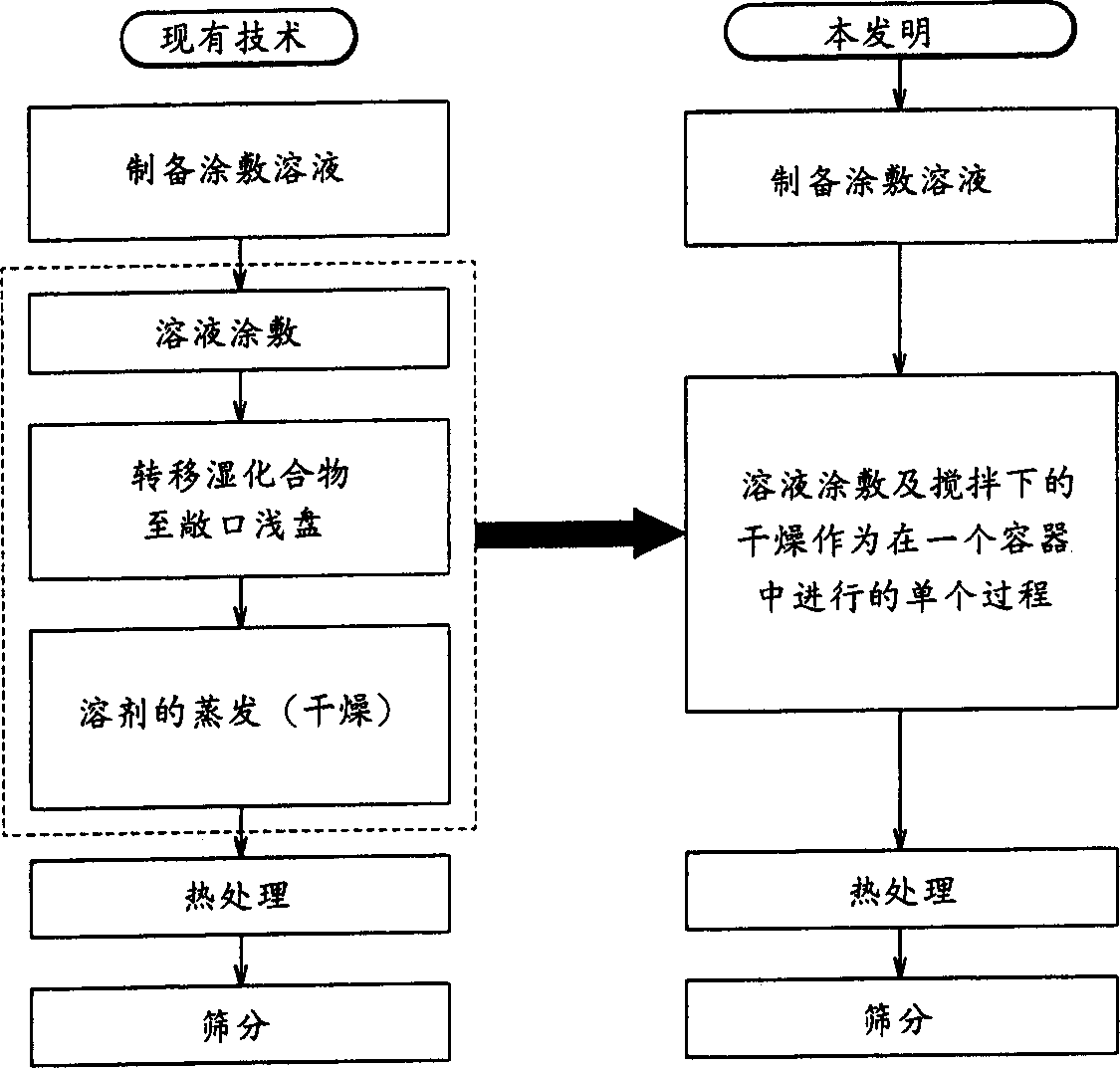

BiVO4 full mesoporous fiber material and preparation method thereof

InactiveCN105420854AImprove conductivityRealize regulationInorganic material artificial filamentsElectro-spinningControllabilityFiber

The invention discloses a BiVO4 full mesoporous fiber material and a preparation method thereof. The fiber material comprises three elements including Bi, V and O; the surface of the fiber material adopts a porous structure; the fiber material comprises monoclinic BiVO4 crystals. According to a scheme, the BiVO4 fiber material with higher structured crystallinity is provided and further has excellent micropore distribution and good fine controllability of a microporous structure.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

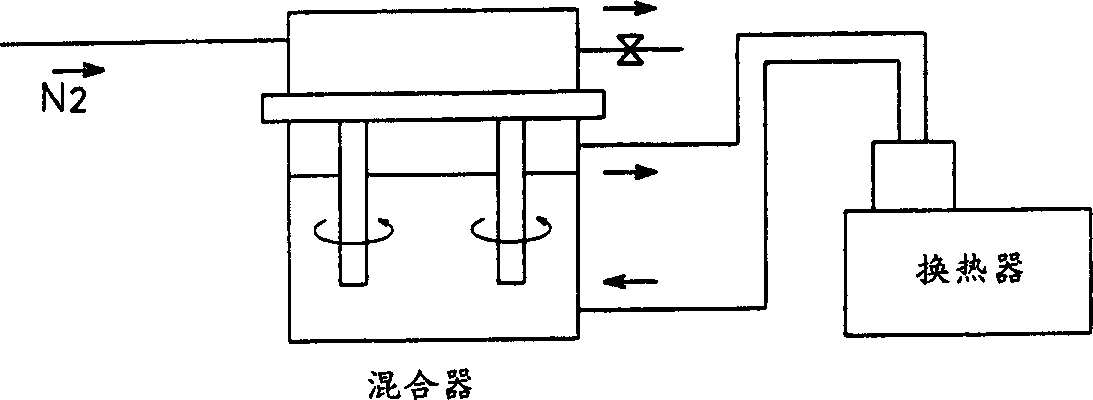

Method for preparing positive electrode active material of rechargeable lithium cell

InactiveCN1346158AIncrease the ambient temperatureElectrode thermal treatmentNon-aqueous electrolyte accumulatorsSolventAqueous solution

Owner:SAMSUNG SDI CO LTD

Brushless direct-current magnetic water pump

ActiveCN105065290AReduce temperature riseExtend your lifePump componentsPump installationsImpellerEngineering

Owner:河北深海电器有限公司

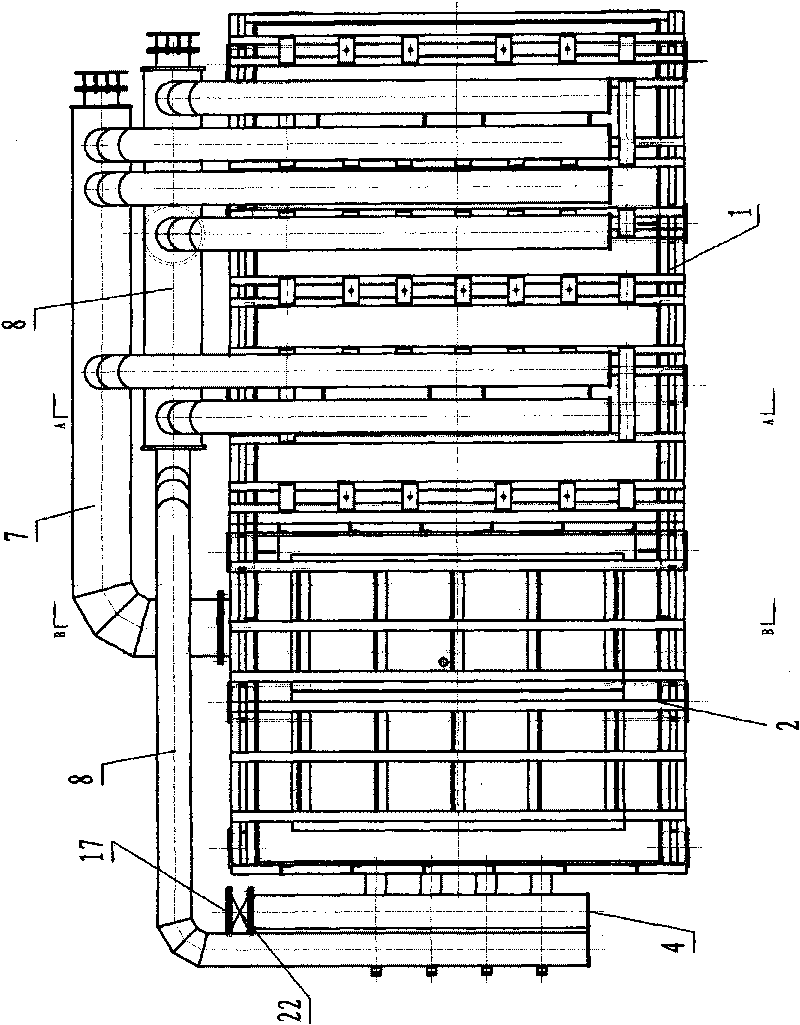

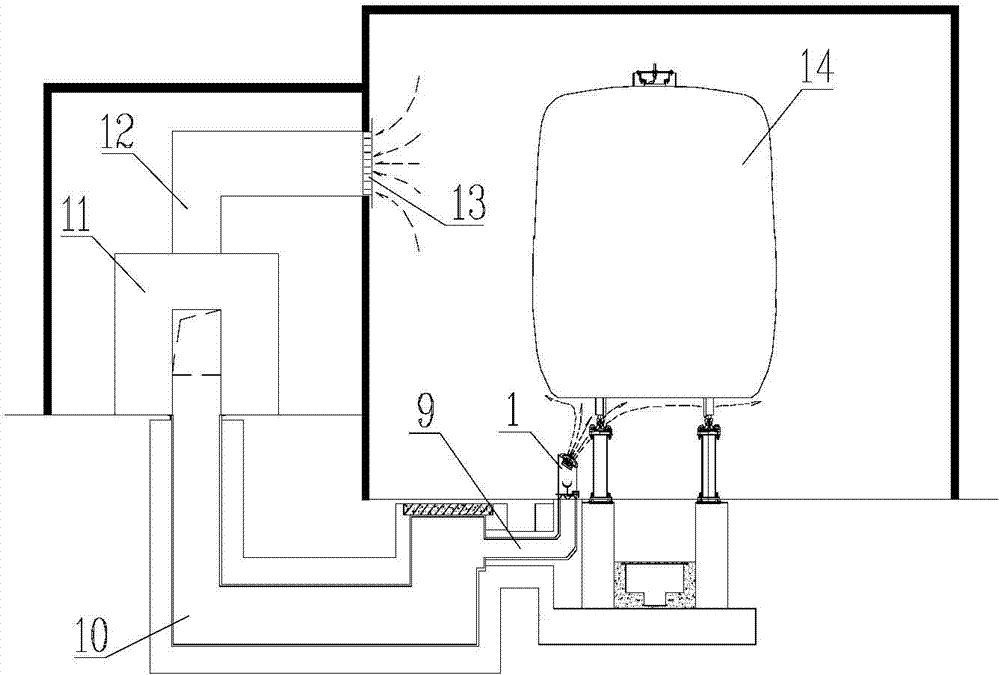

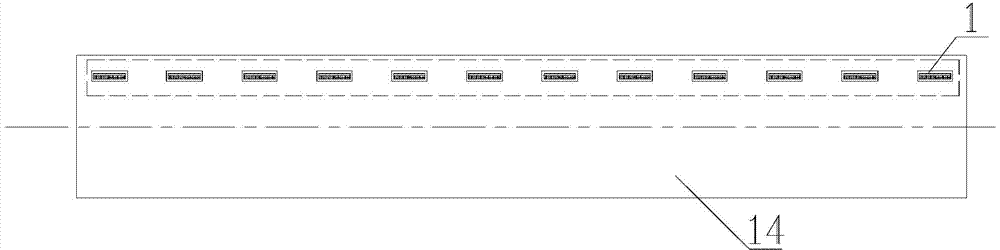

Hot air supply device for quick deicing and snow removing system at bottom of high-speed rail train

InactiveCN103879384AImprove reliabilityImprove effectivenessCleaning apparatus for vehicle exteriorsRailway auxillary equipmentAir volumeOperating time

The invention discloses a hot air supply device for a quick deicing and snow removing system at the bottom of a high-speed rail train. The hot air supply device comprises air supply columns arranged on one side of a deicing and snow removing station of the train, the air supply columns are lined up on the ground and evenly arranged, and 11-13 air supply columns are arranged corresponding to each section of train body. The air supply columns are fixed to the ground, communicated with an underground civil engineering delivery conduit and connected with a hot air unit in a hot air machine room through the underground civil engineering delivery conduit. Each air supply column of the hot air supply device comprises a column body, an air supply port, an air supply angle four-way regulating and locking device and an air quantity regulating valve, the air supply port is arranged on the top of the air supply column, and the air supply angle four-way regulating and locking device is arranged in the air supply port. According to the hot air supply device, hot air at a certain speed is blown out towards the bottom of the train through the air supply columns, heat exchange between ice and snow and the train body can be enhanced and the overall environment temperature of a garage can be improved through the air supply temperature and flowing of the hot air, and the functions of quick deicing and snow removing can be achieved. According to the hot air supply device, it can be guaranteed that the longest deicing operating time at the bottom of the compartment of the train is less than one hour, and technological requirements can be met.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

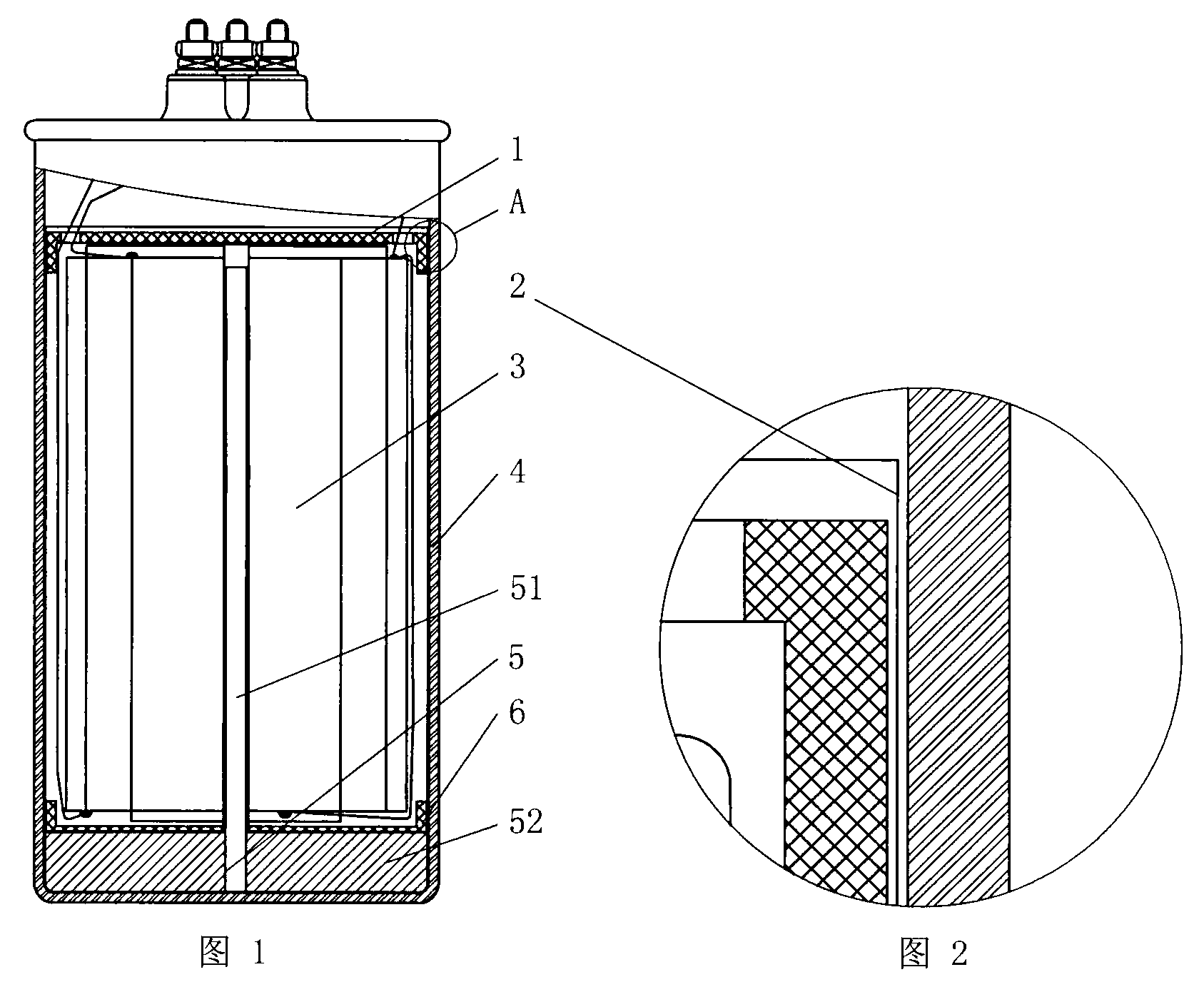

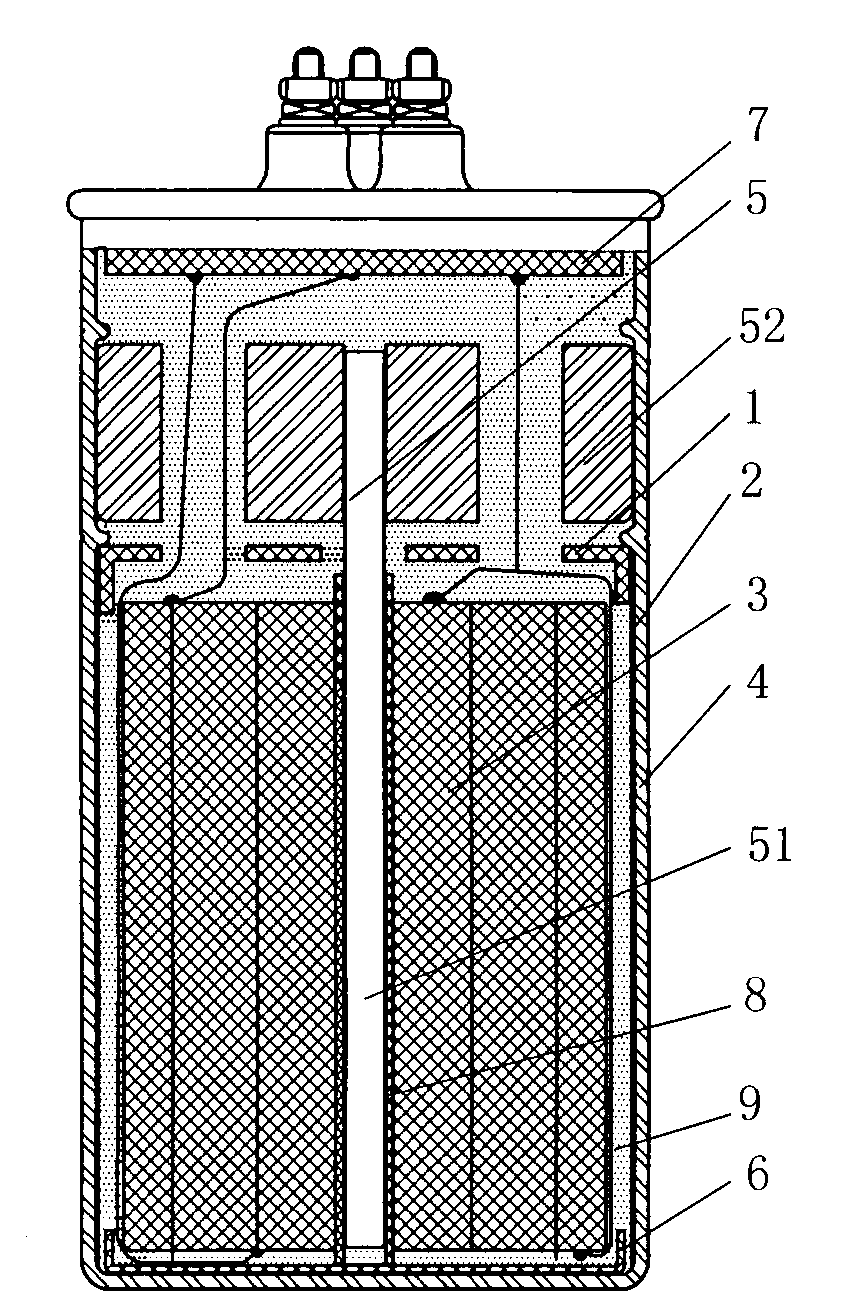

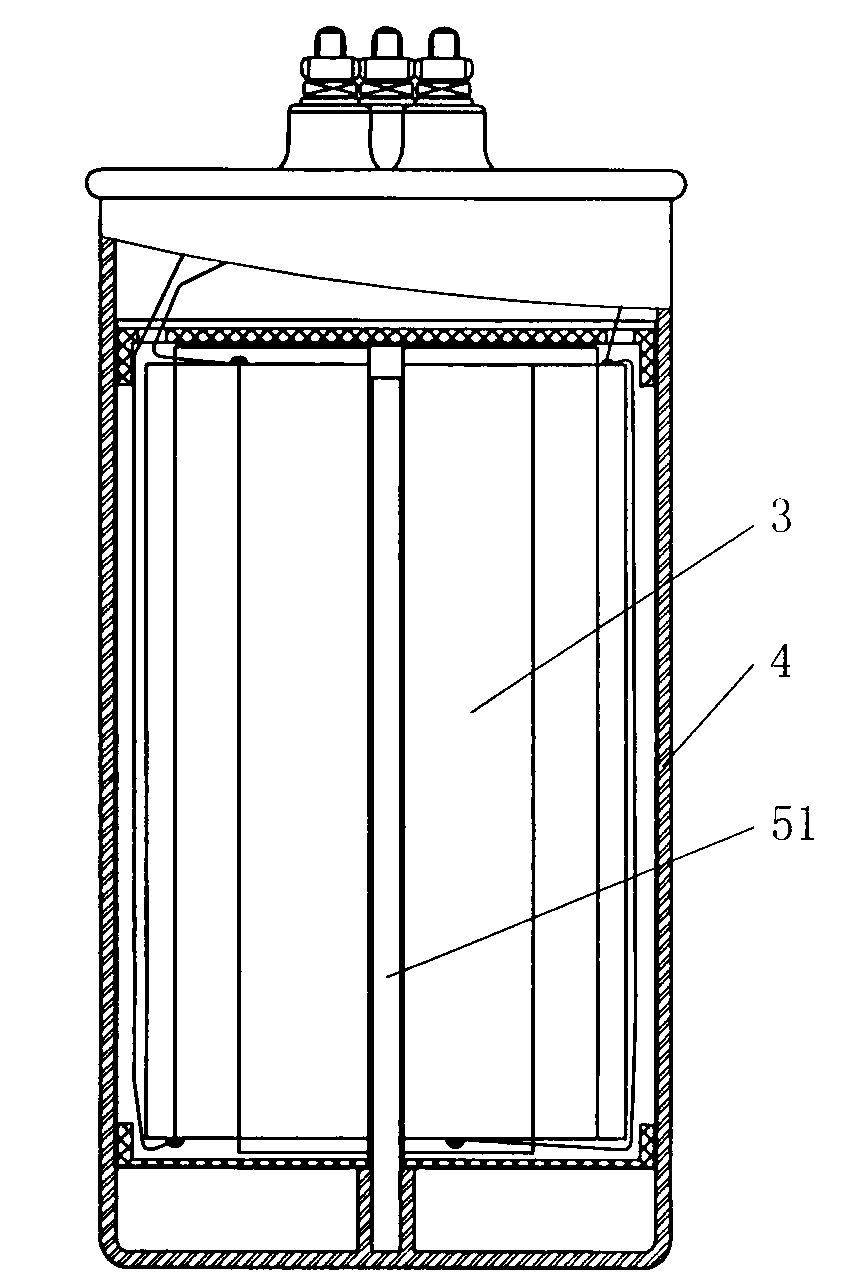

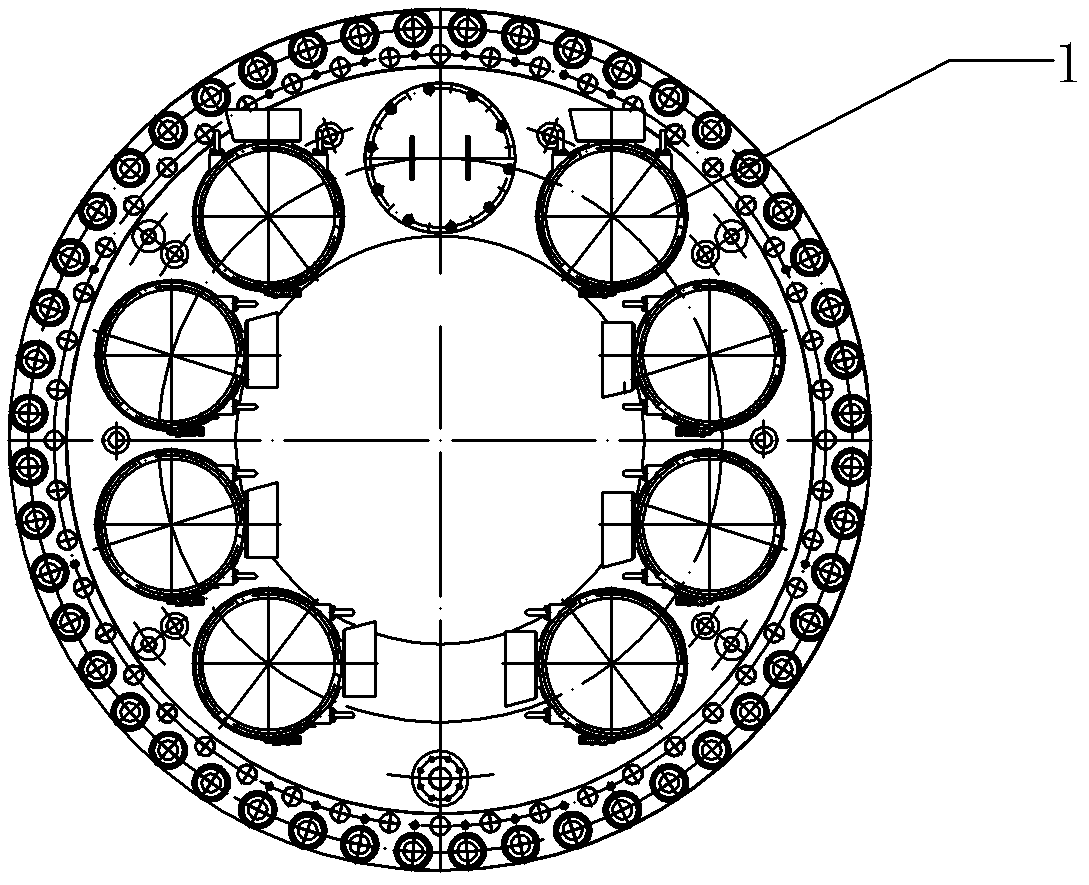

Capacitor

ActiveCN102930979AIncrease the ambient temperatureSmall temperature differenceCapacitorsEngineeringTemperature difference

The invention relates to a capacitor. Internal heat is conducted out via a heat pipe, the temperature difference between the interior and the surface of the capacitor is reduced, so that the reliability of the capacitor is increased, and the service life is prolonged. The capacitor comprises a core formed by rolling, a heat pipe device, a shell, a locating sleeve and insulating paper, wherein the heat pipe of the heat pipe device is arranged in the center of the core. The heat in the center of the capacitor is conducted to the surface of the capacitor in time by using the heat transfer principle of the heat pipe, so that the temperature difference between the interior and the surface of the capacitor is reduced, and the environment temperature borne by the capacitor is increased.

Owner:GUANGDONG SHUNRONG ELECTRIC

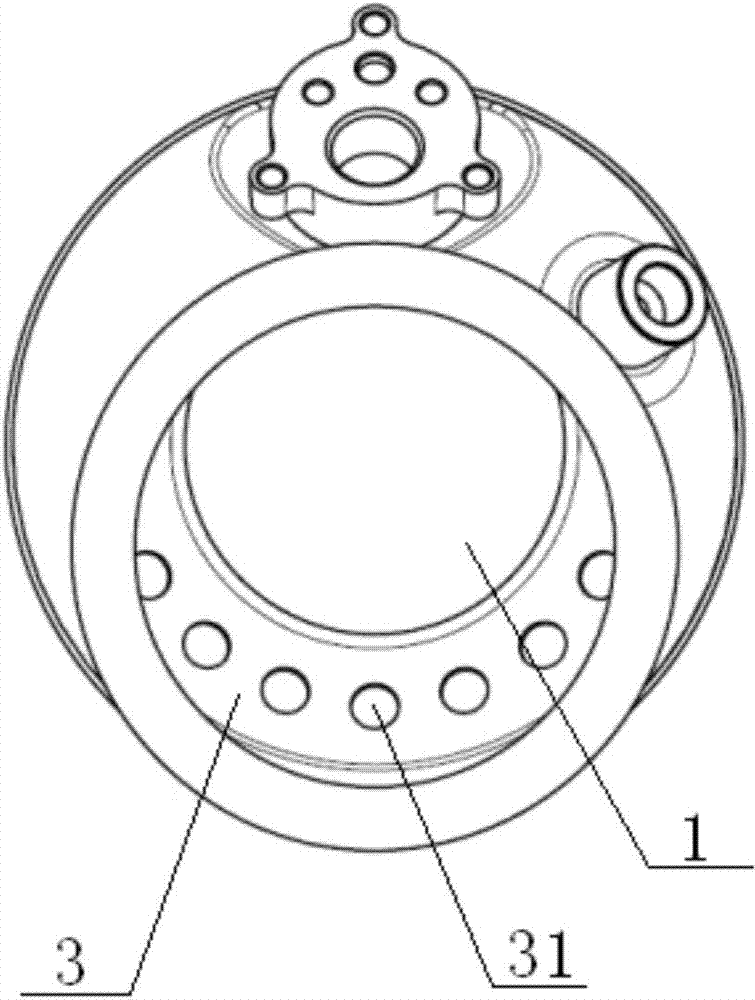

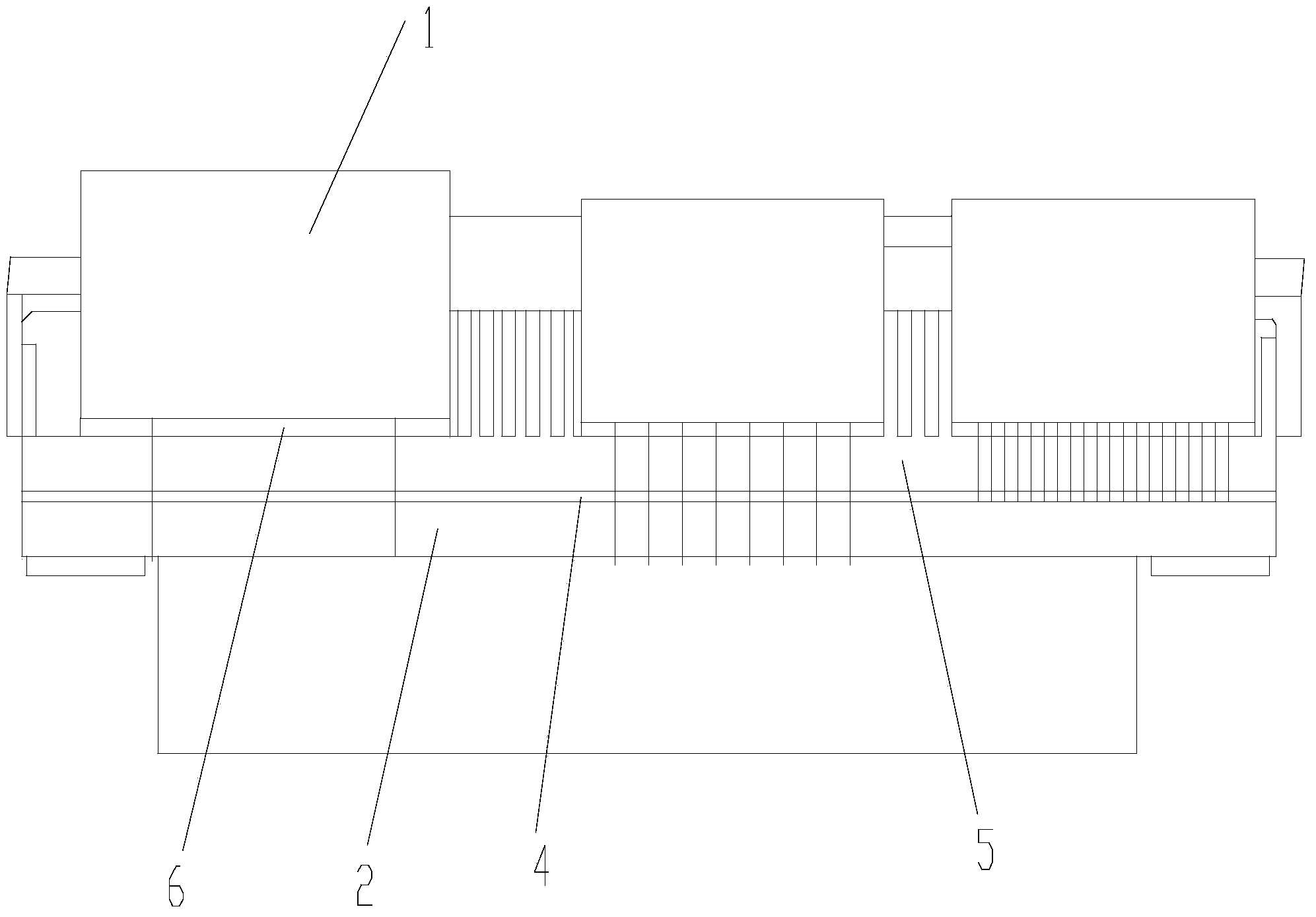

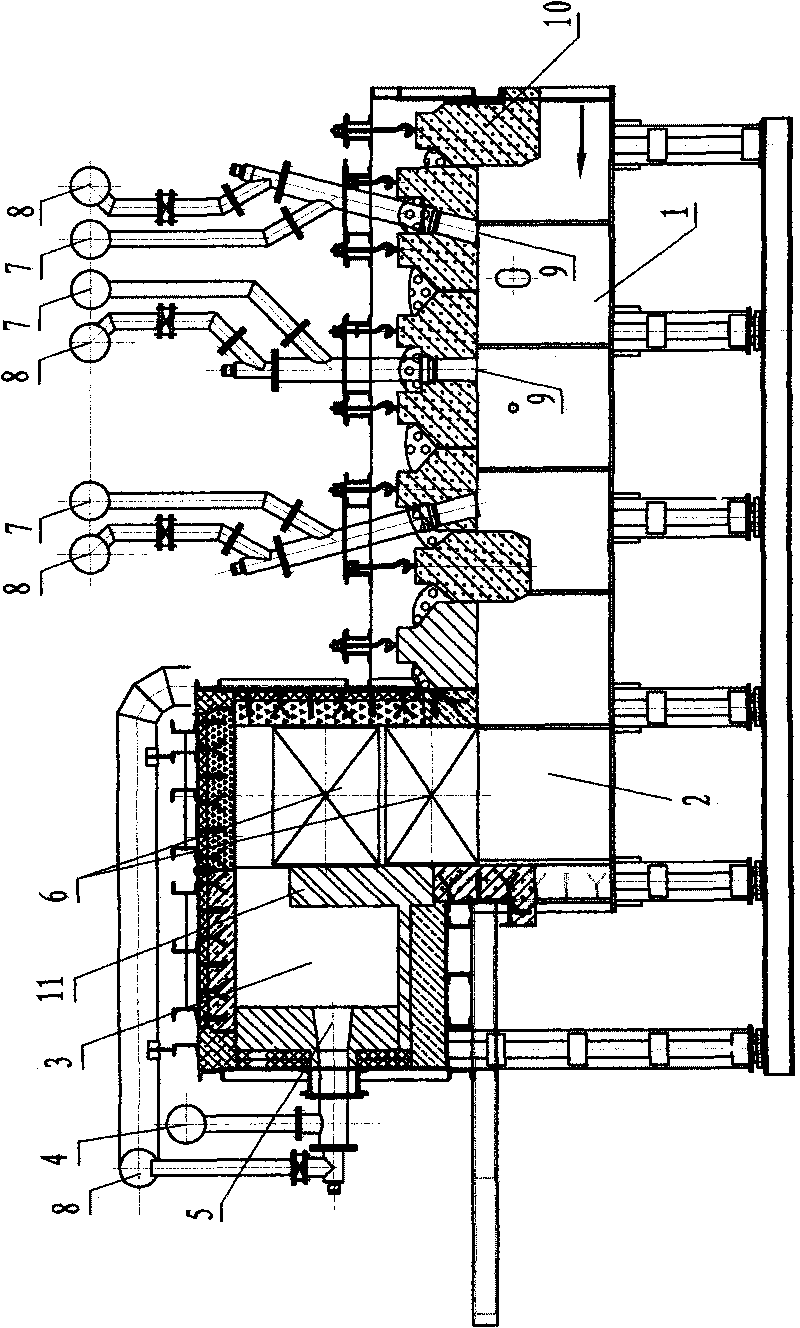

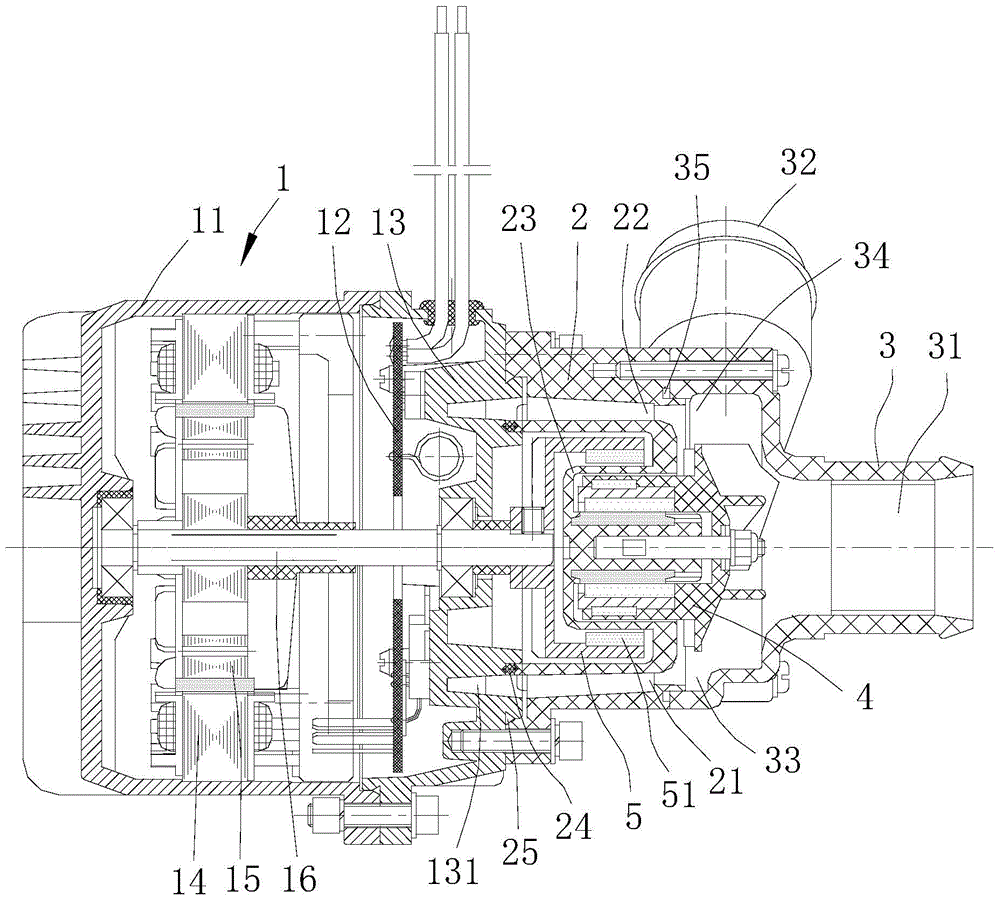

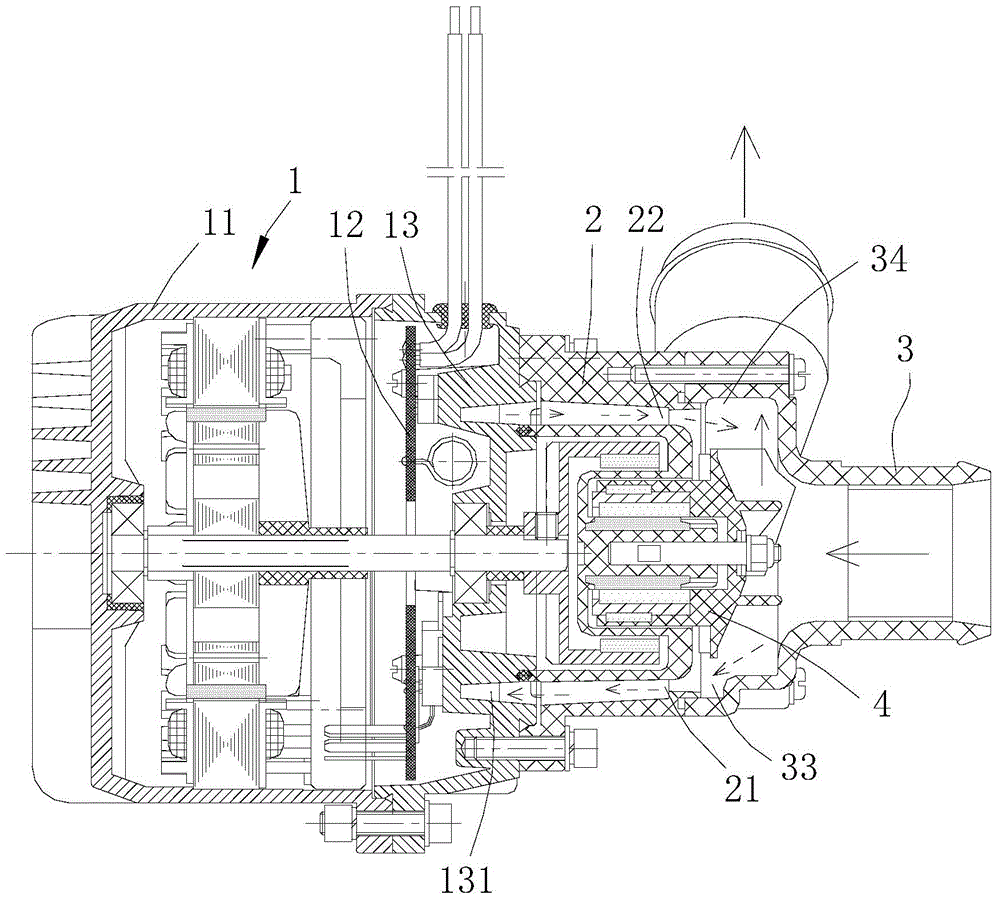

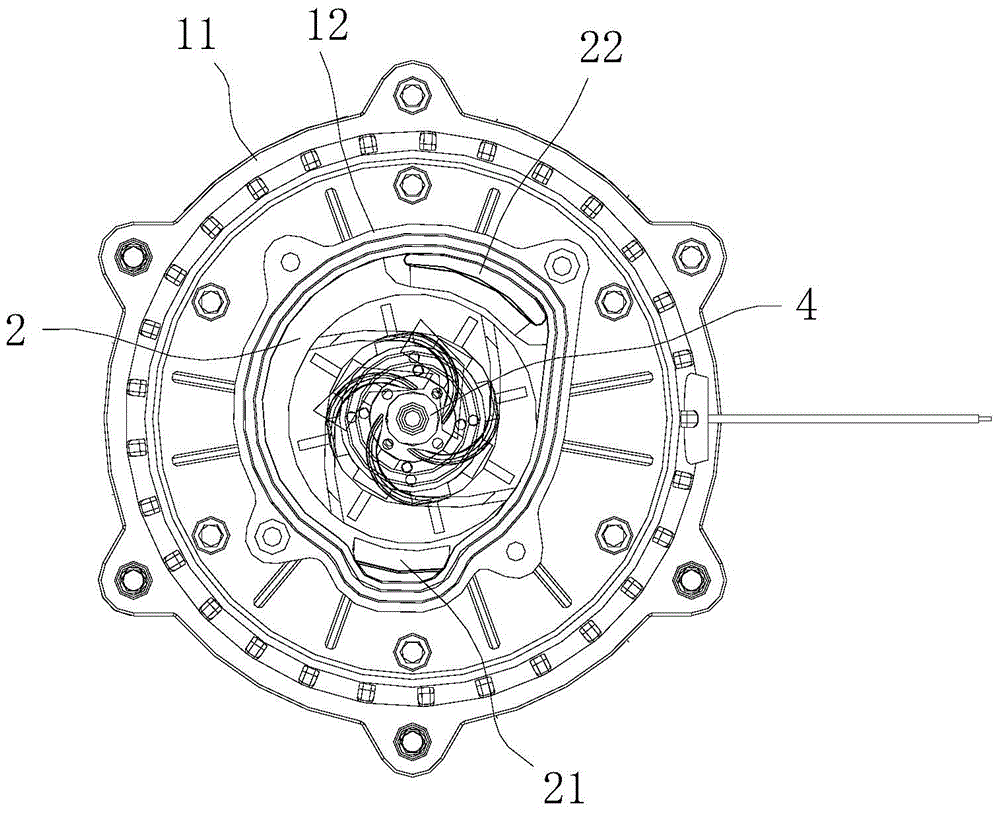

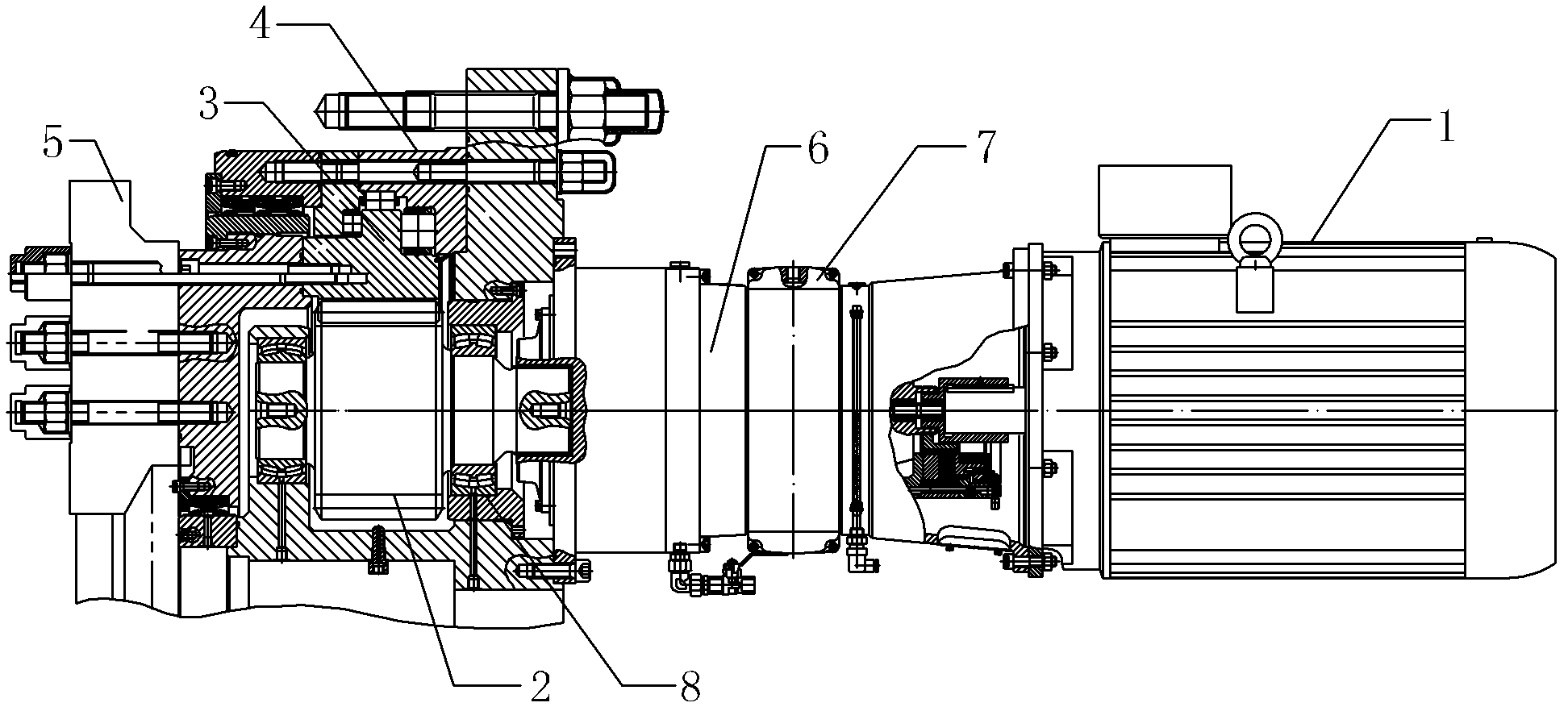

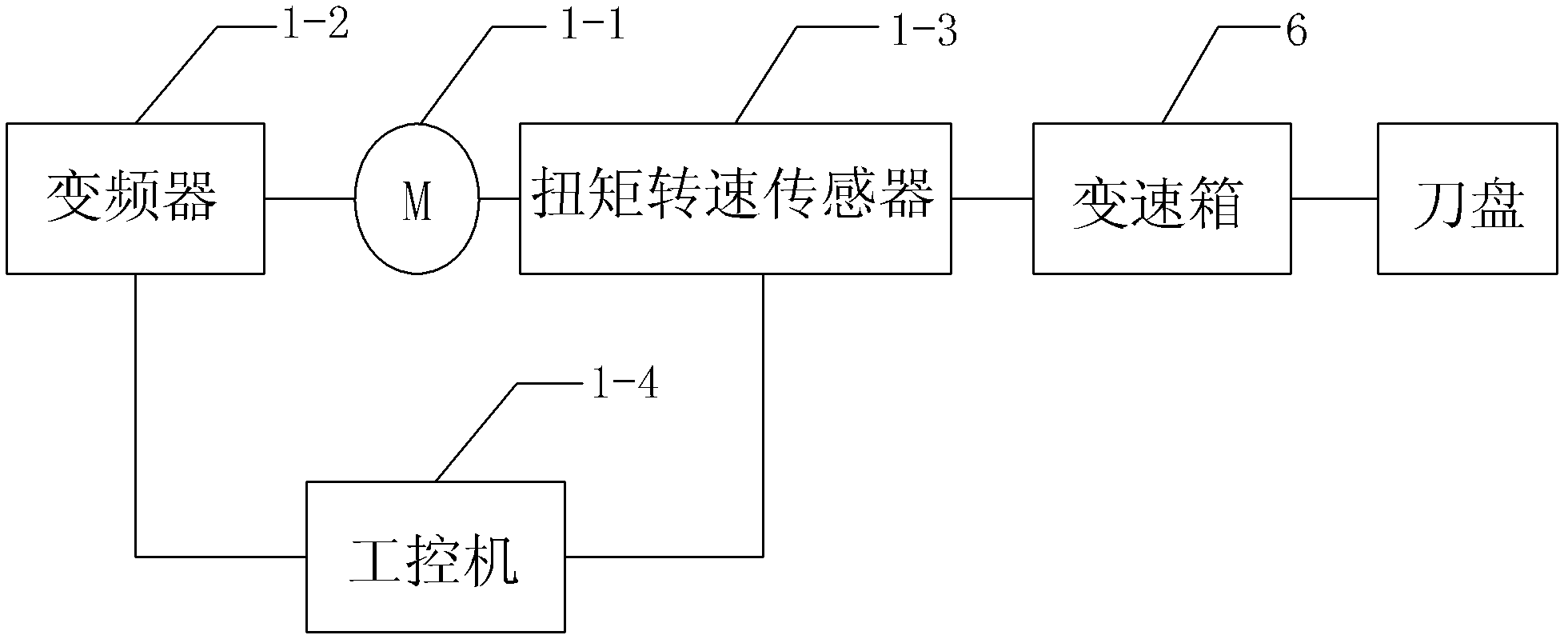

Main driving mechanism of six-arm cutterhead used for shield machine

ActiveCN102359380AConstant powerIncrease reflectionMechanical energy handlingTunnelsControl theoryDriving mode

The invention discloses a main driving mechanism of a six-arm cutterhead used for a shield machine. The main driving mechanism comprises a shield machine cutterhead and a main driving mechanism. The main driving mechanism is characterized by mainly comprising a synchronous variable frequency motor (1), a gear device (2) and a main bearing (3), wherein the output end of the variable frequency motor (1) is tightly connected with the input end of the gear device (2); the output end of the gear device (2) is connected with the main bearing (3) and drives the main bearing (3) to rotate; the main bearing (3) is connected with a shield machine cutterhead by connected flanges (4); the upper part of the main bearing is provided with a sealing assembly (5); the synchronous variable frequency motor (1) is provided with brake; and the variable frequency motor (1), the gearing device (2) and the main bearing (3) are connected to form a dismountable integral structure. In the invention, the synchronous variable frequency motor serves as a driving mode, full-amount torque can be reached when speed is regulated within a range from 0 to 50Hz, and the main driving mechanism has the beneficial effect of small starting current, high efficiency and small noise harm and is simple to maintain.

Owner:海瑞克(广州)隧道设备有限公司

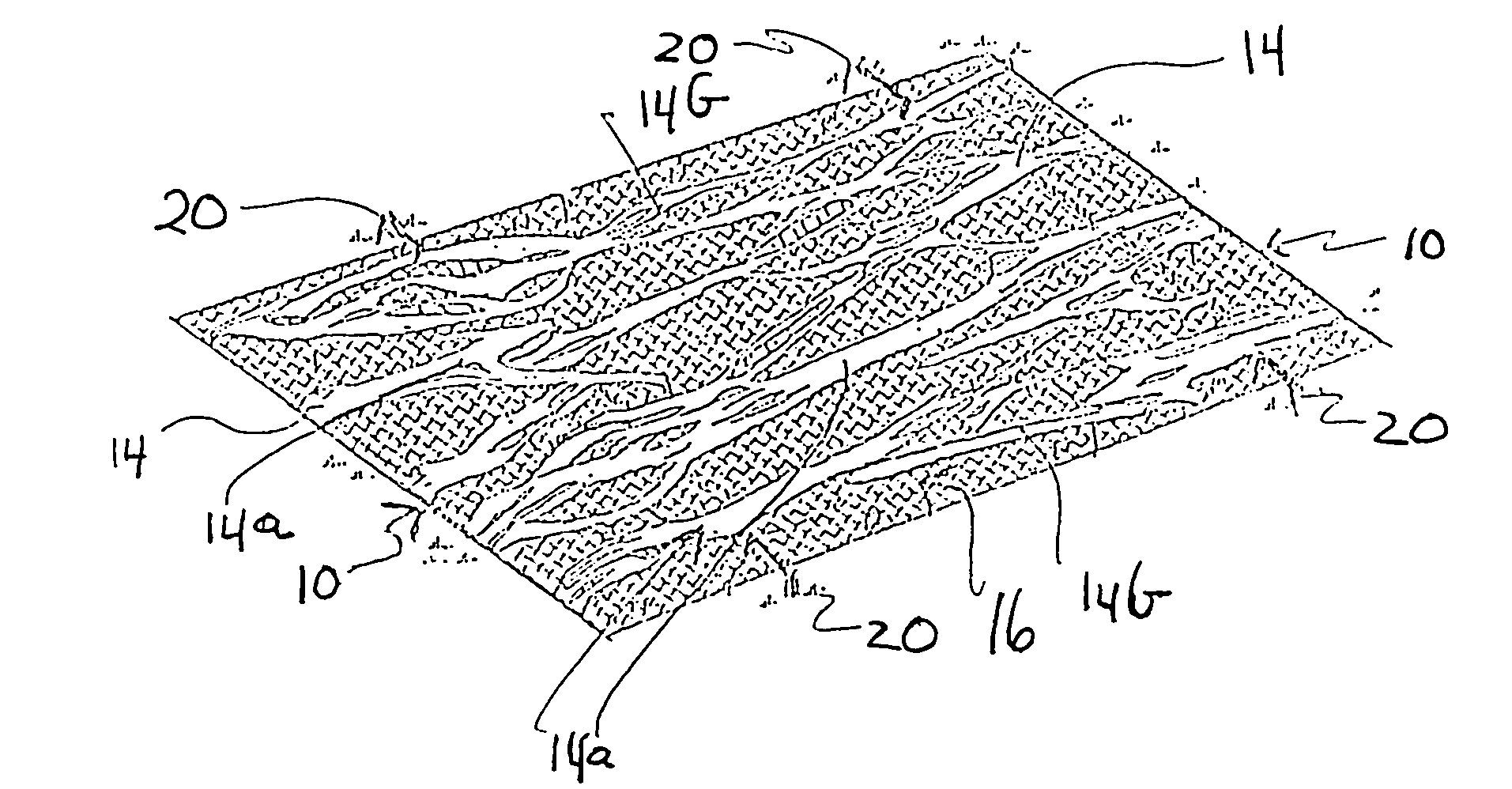

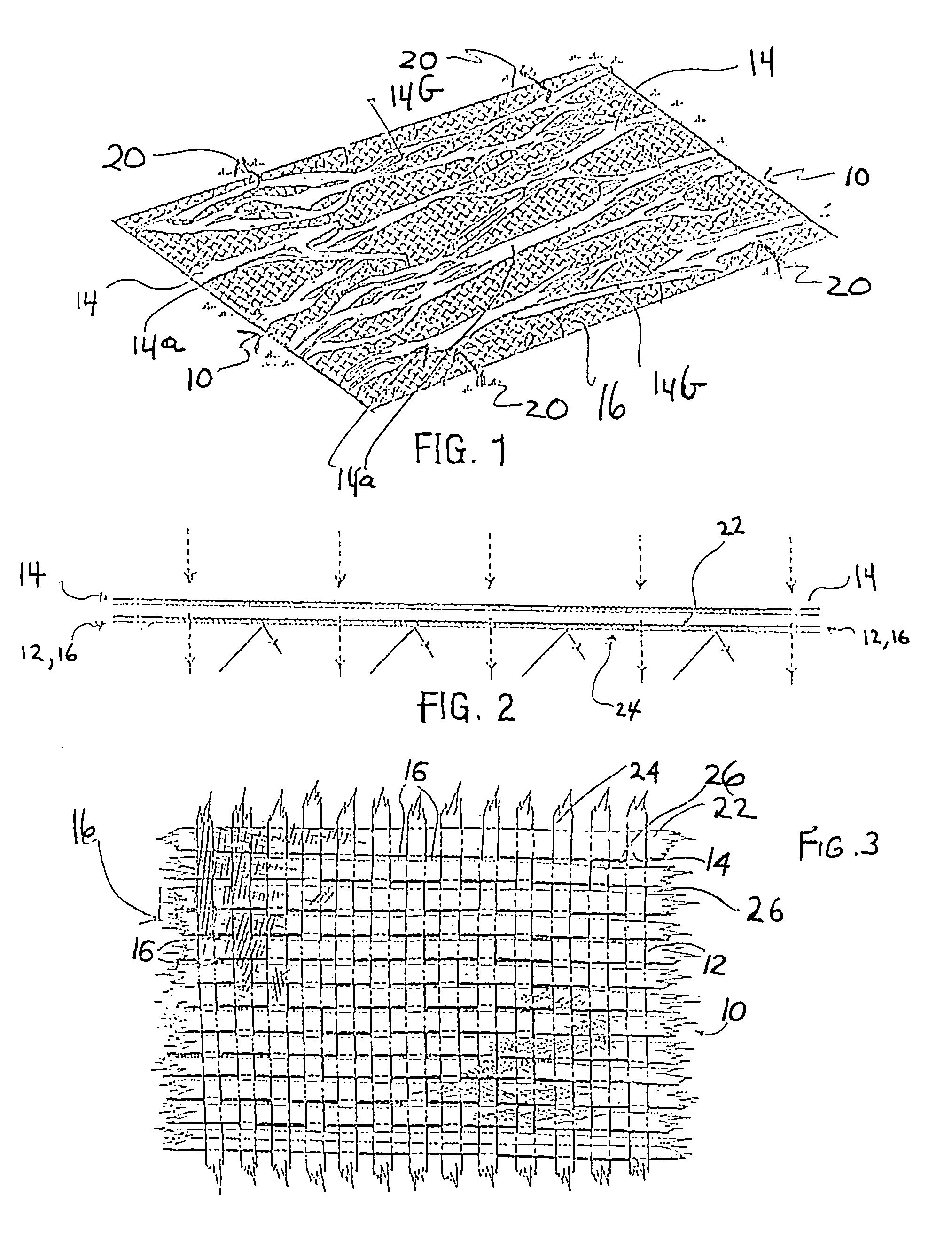

Method and protective, E.G., for grass protection, restoration, seed germination

InactiveUS7207136B2Increase the ambient temperatureHigh heating temperatureFlower holdersPlant protective coveringsThin layerEngineering

A protective heat absorbing and heat reflective covering material comprising an open mesh weave of scrim material, the mesh having warp and weft strips forming a substantially thin layer having opposed major surfaces, where at least one of the warp or weft strip materials is a heat absorbing or heat reflecting material, and at least one of the major surfaces of the scrim material has a discontinuous coating having heat reflecting or heat absorbing properties opposite to that of the warp and or weft strip, the discontinuous coating thereon at least partially covering the surface.

Owner:HINSPERGER PETER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com