Method for preparing positive electrode active material of rechargeable lithium cell

A technology for positive active materials and rechargeable lithium batteries, which can be used in battery electrodes, non-aqueous electrolyte batteries, positive electrodes, etc., and can solve the problems of low capacity, difficulty in manufacturing, and instability of manganese-based materials

- Summary

- Abstract

- Description

- Claims

- Application Information

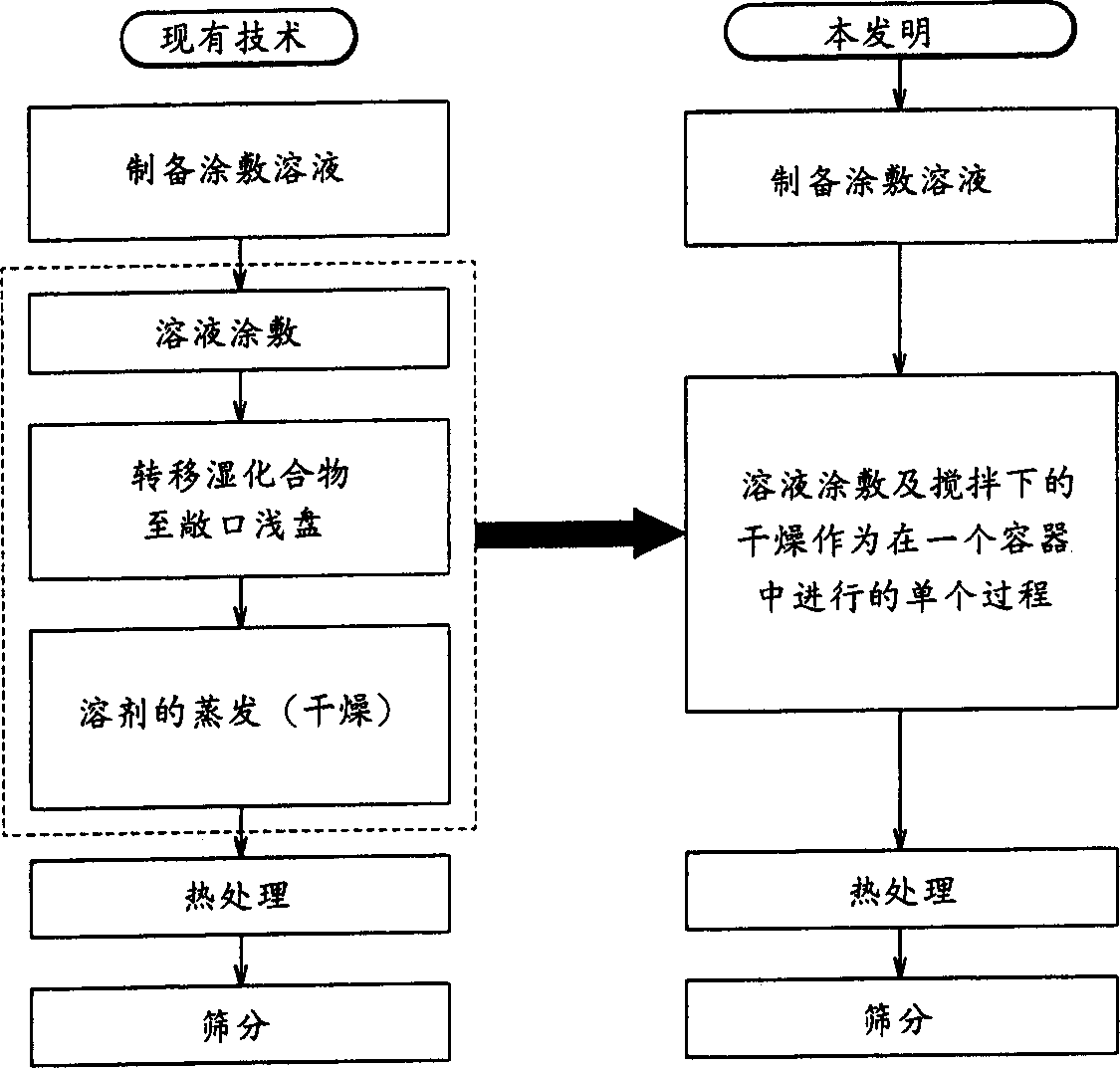

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

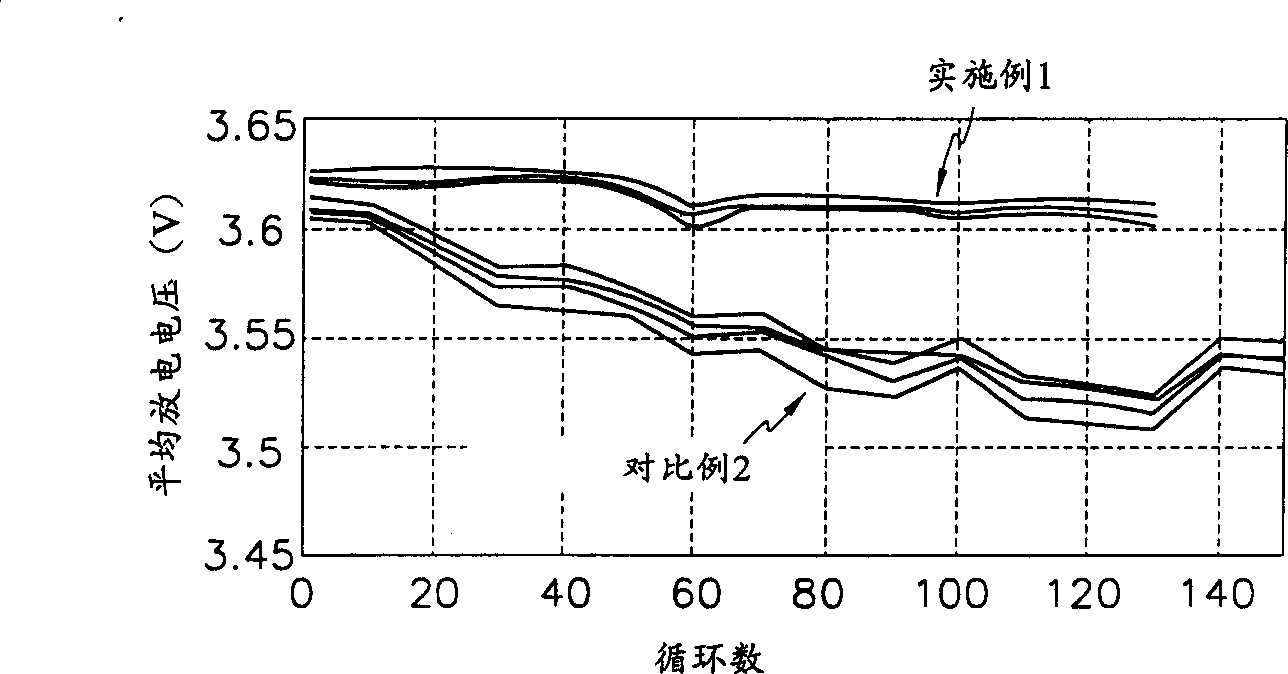

Embodiment 1

[0056] 5 g of aluminum isopropoxide powder was dissolved in 95 g of ethanol to prepare a 5% aluminum isopropoxide solution (solution preparation step).

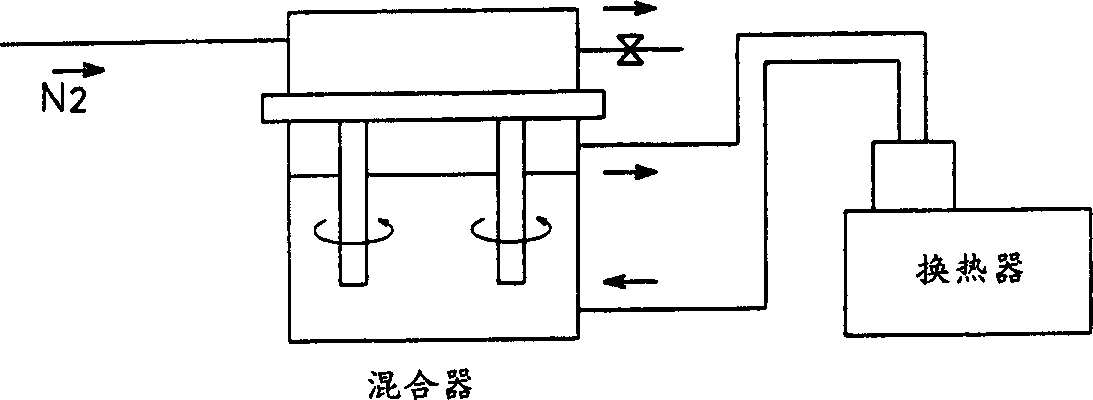

[0057] The aluminum isopropoxide solution and 50 g LiCoO 2 The powder was placed in a mixer with a jacketed heat exchanger and mixed well for about 10 minutes. Next, nitrogen gas was injected into the mixer while maintaining the temperature of the mixer chamber at 60° C. by circulating hot water through the heat exchanger. Stirring of the mixture was continued for an additional 30 minutes while a continuous stream of dry nitrogen was injected to evaporate the ethanol. The resulting dry powder was uniformly coated with the aluminum intermediate compound (one-step process).

[0058] The fine powder was heat-treated at 600°C under flowing air (heat treatment process). The heat-treated powders were sieved to collect powders of appropriate size as positive electrode active materials.

Embodiment 2

[0060] The same method as in Example 1 was used to prepare the positive electrode active material, except that 3 g of aluminum isopropoxide powder was dissolved in 97 g of ethanol to prepare a 3% aluminum isopropoxide solution.

Embodiment 3

[0062] The same method as in Example 1 was used to prepare a positive electrode active material, except that 1 gram of aluminum isopropoxide powder was dissolved in 99 grams of ethanol to prepare a 1% aluminum isopropoxide solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com