Hot air supply device for quick deicing and snow removing system at bottom of high-speed rail train

A technology for air supply device and train, which is applied in the direction of vehicle exterior cleaning device, railway auxiliary equipment, etc., to reduce the workload of manual snow removal, improve reliability and effectiveness, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

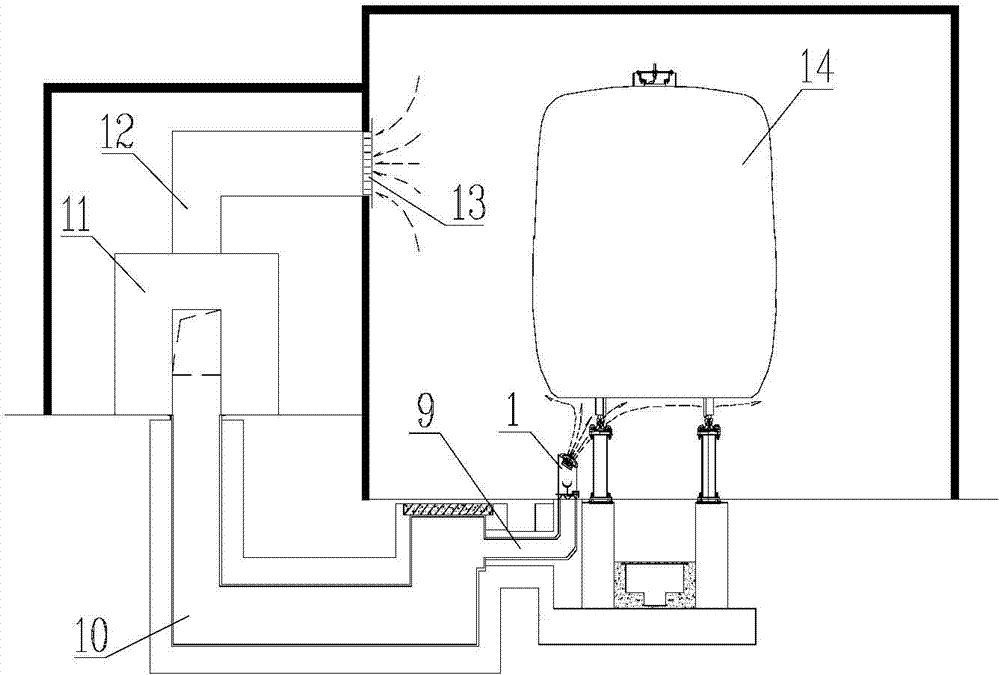

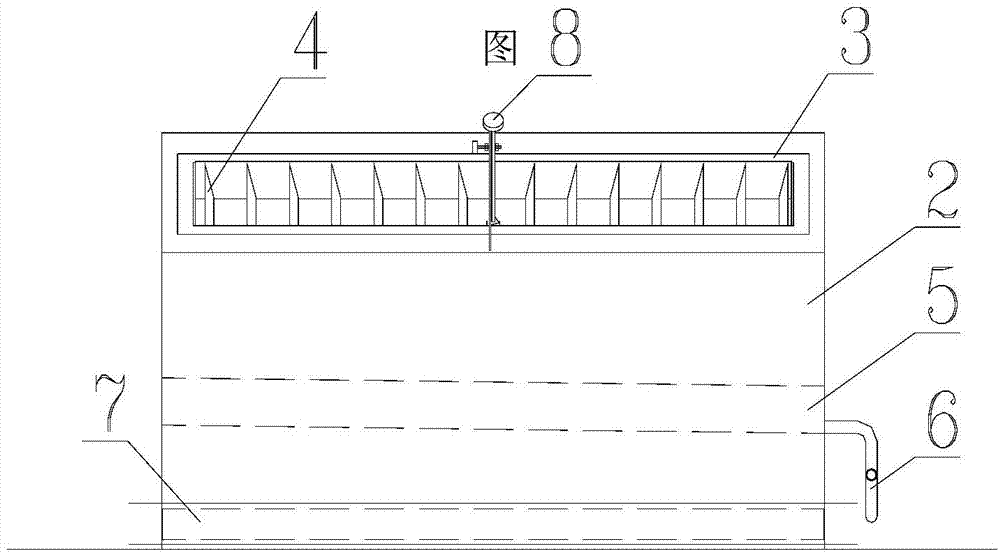

[0023] The technical solution of the present invention is further described in conjunction with the accompanying drawings.

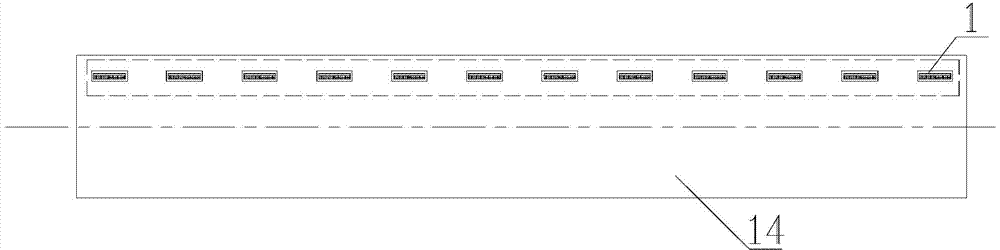

[0024] figure 2 The installation status of the blowing column of the hot air blowing device according to the present invention is shown. Such as figure 2 as shown,

[0025] The air supply column 1 of the hot air supply device for the rapid ice melting and snow removal system at the bottom of the high-speed rail train involved in the present invention is arranged on the ground on one side of the high-speed rail train body 14 parked at the ice melting and snow removal station, corresponding to a train body Arrange 11 to 13 air supply columns 1 evenly in a row, and the distance between the air supply columns 1 and the center of the track is controlled between 1200mm and 1400mm. The opening of the air branch pipe 9 on the ground is fixed by a flange connection. These air-supply pillars corresponding to a train body just constitute a set of hot-blast ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com