Patents

Literature

66results about How to "Fulfill process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

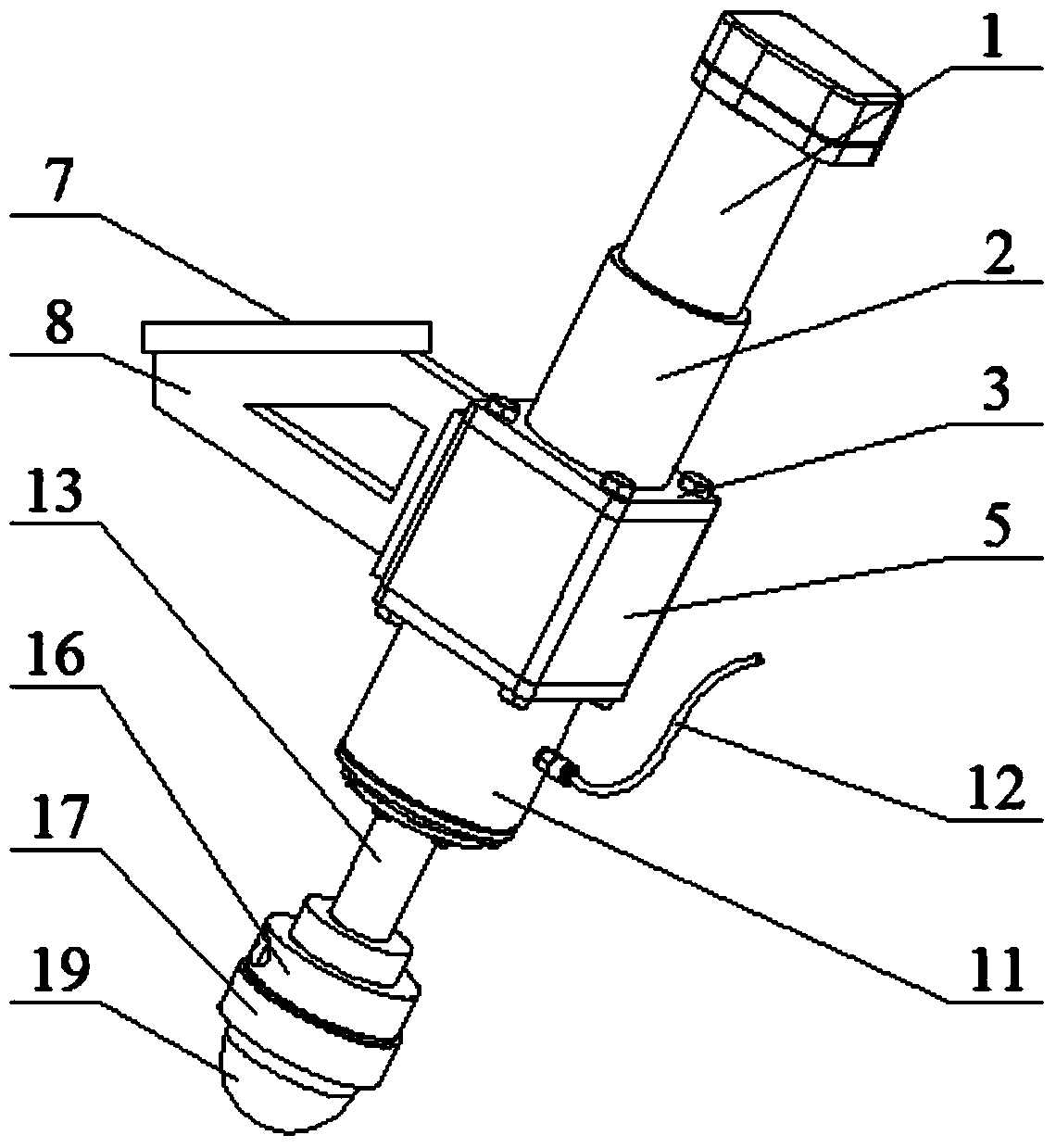

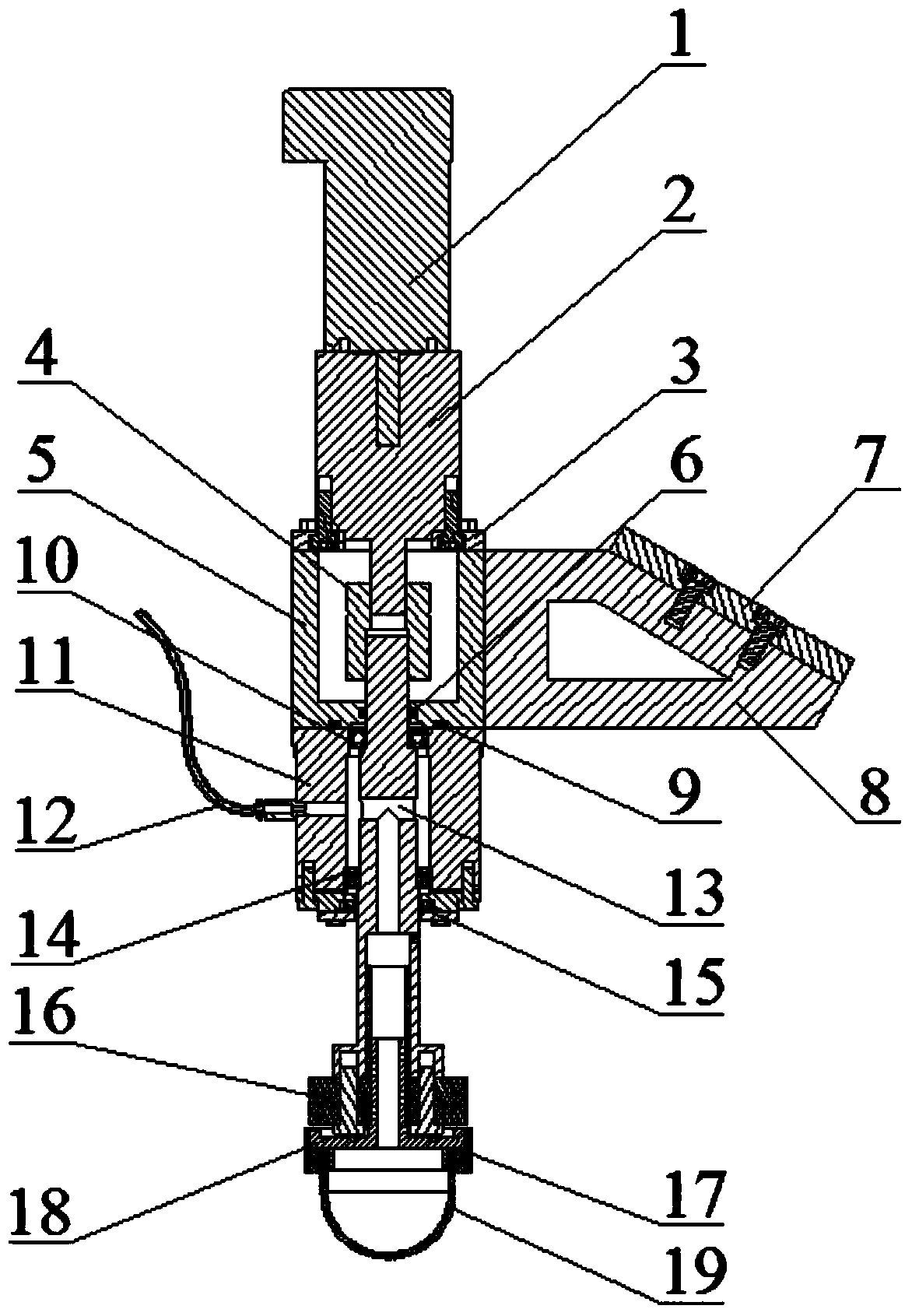

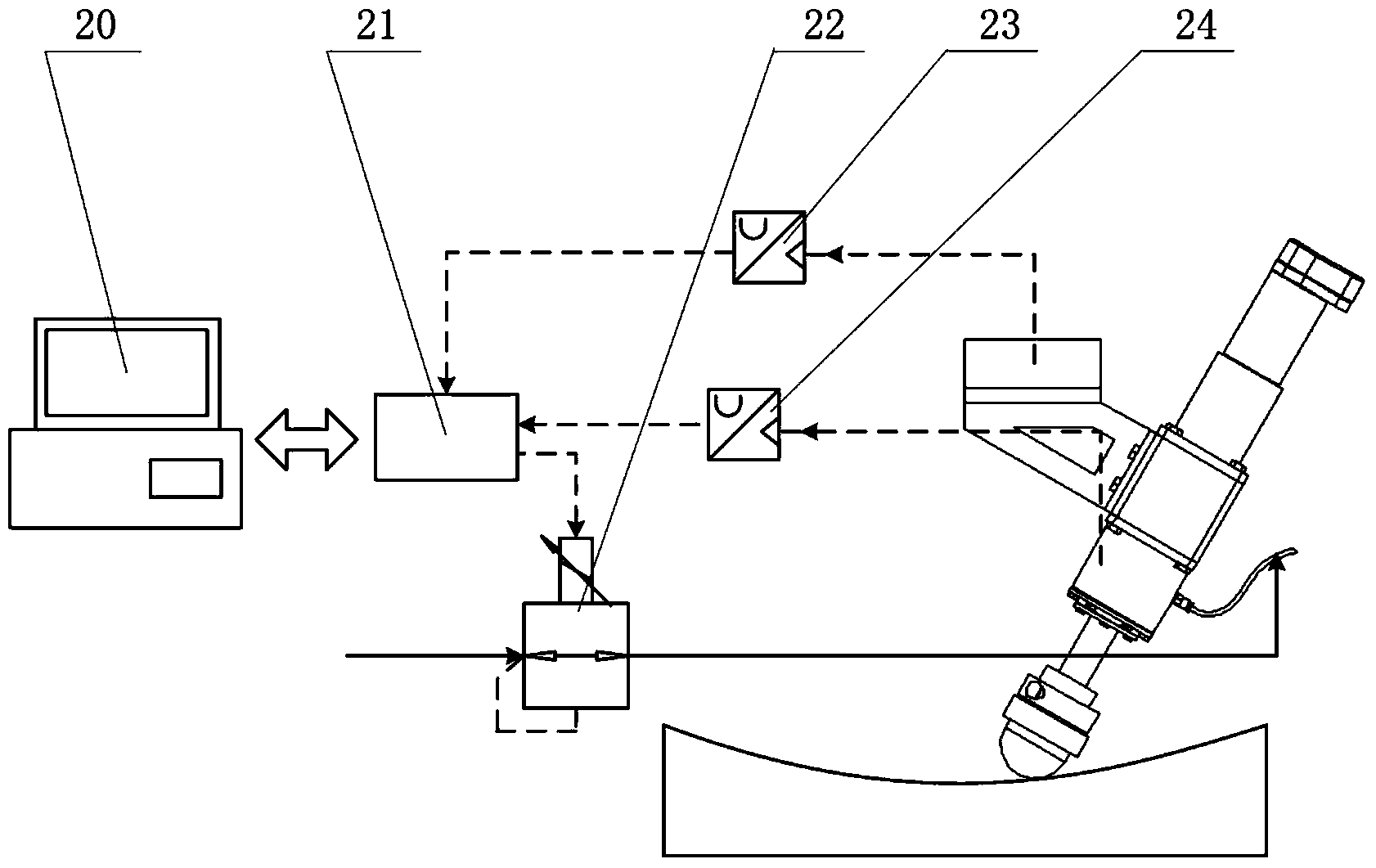

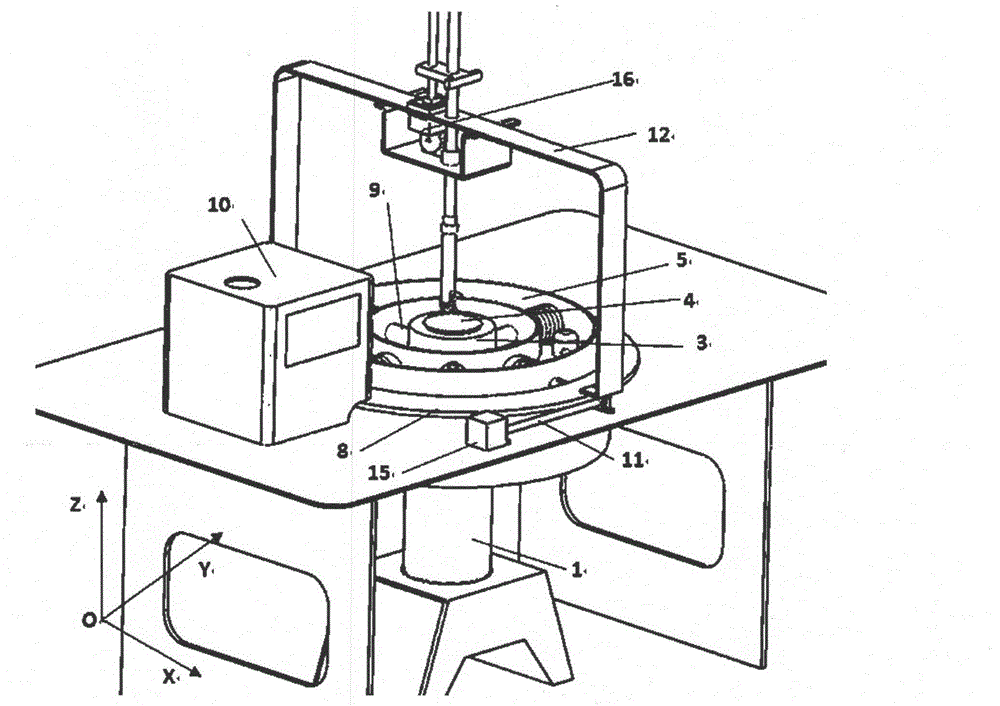

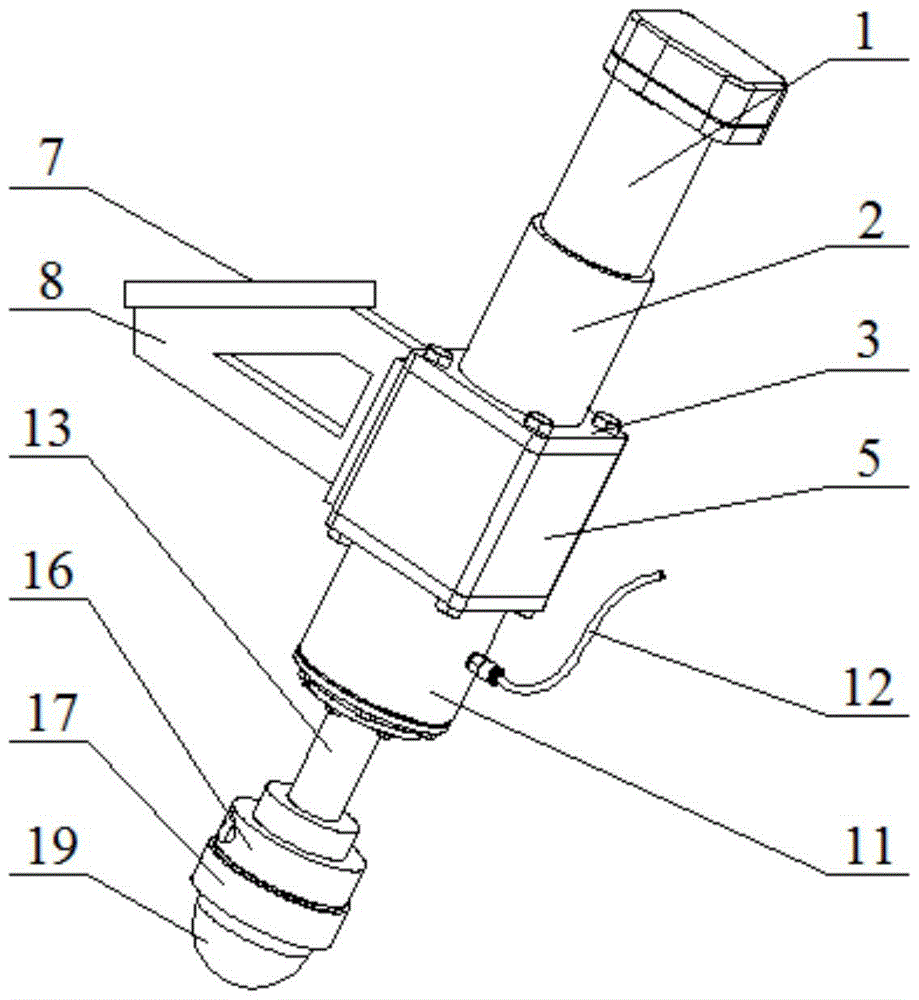

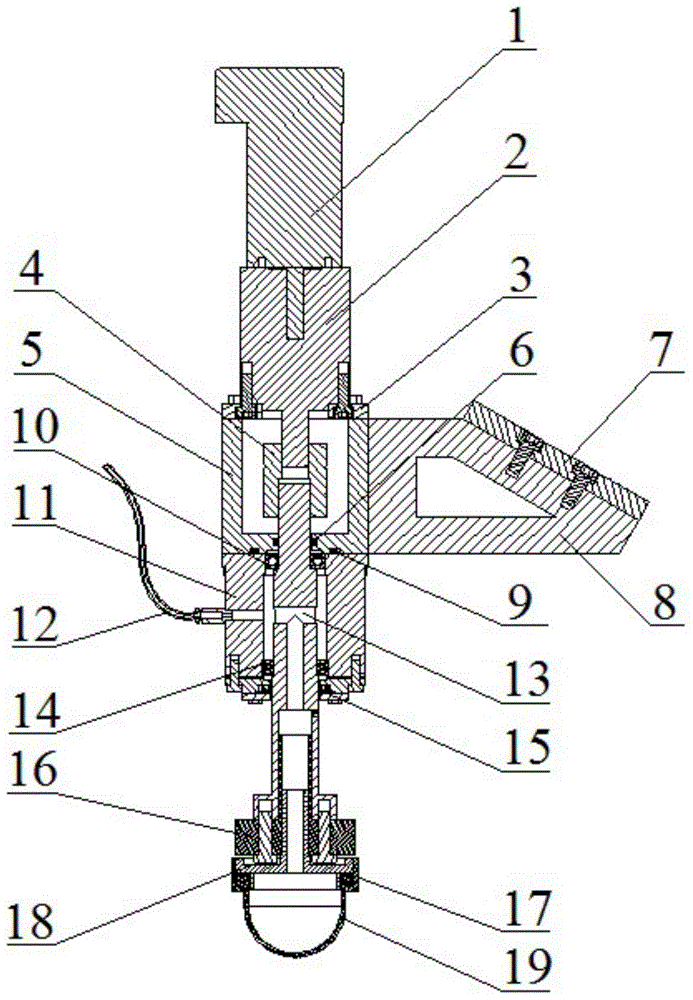

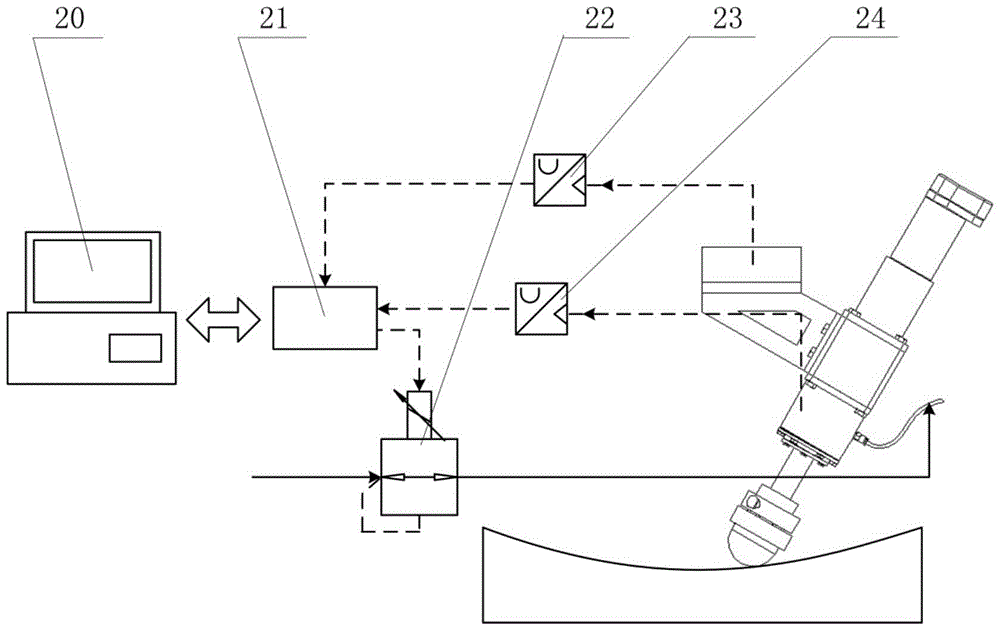

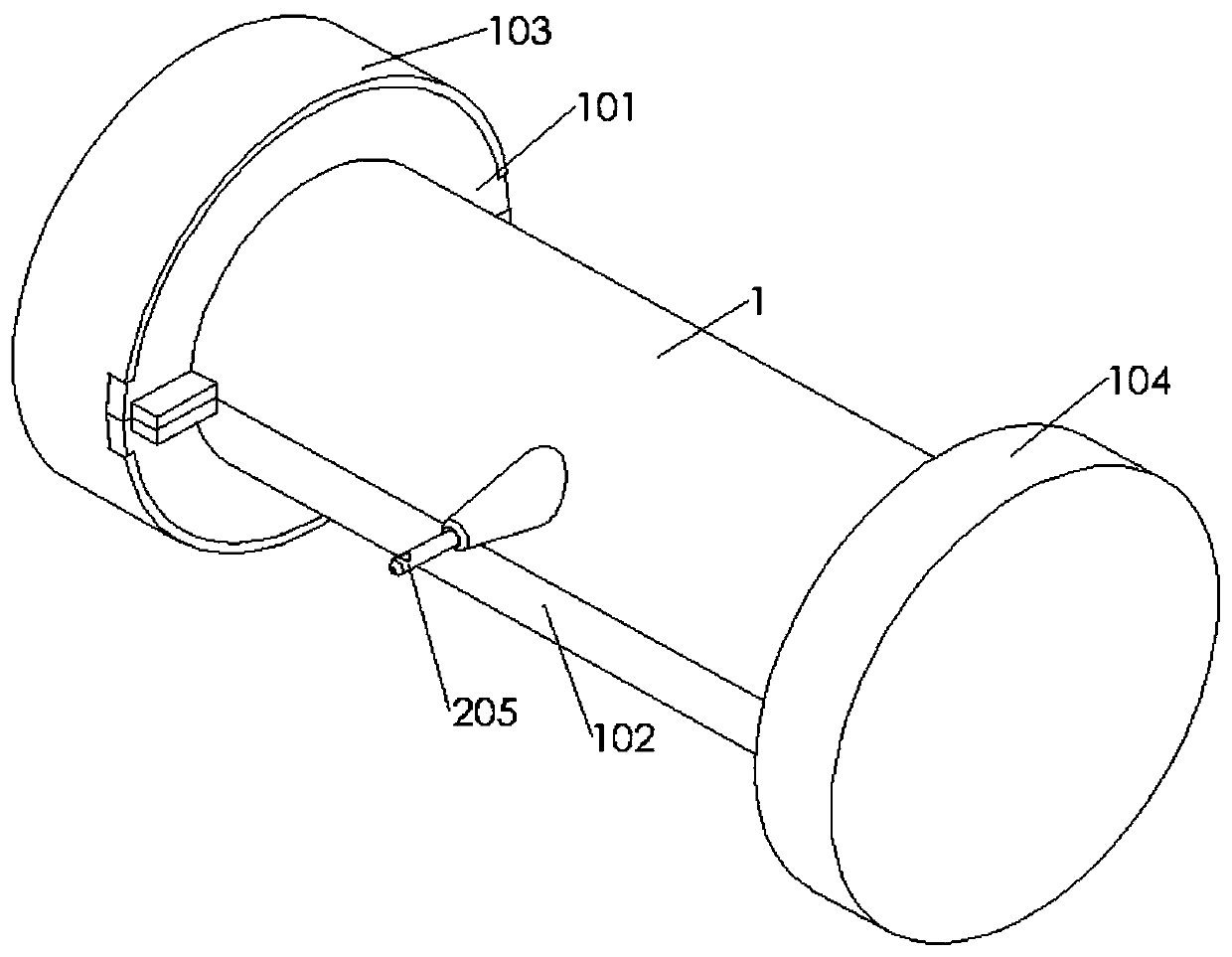

Air bag polishing tool and system and method

ActiveCN104369064AFulfill process requirementsStable polishingPolishing machinesOptical surface grinding machinesContact pressurePositive pressure

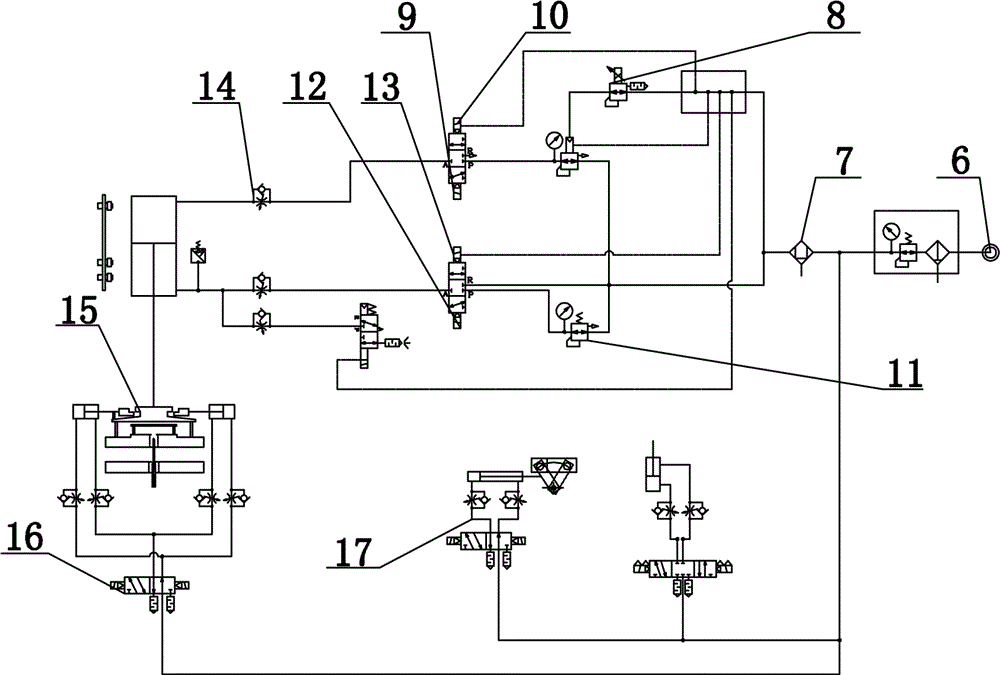

The invention discloses an air bag polishing tool and system and method. The air bag polishing tool comprises a motor, a speed reducer, a hollow rotating shaft and an air bag, wherein the motor, the speed reducer, the hollow rotating shaft and the air bag are sequentially connected. The hollow rotating shaft is provided with a hollow cavity, the two ends of the hollow cavity are communicated to the air bag and a ventilation guide pipe respectively, and an electrical proportional valve is arranged on the ventilation guide pipe. The air bag polishing tool further comprises a pressure intensity sensor for detecting the pressure intensity of air in the air bag and a pressure sensor for detecting the positive pressure of the tool. By means of the air bag polishing tool, based on the electrical proportional valve, the contact pressure and the contact pressure intensity of a polished surface can be controlled in real time, the air bag polishing tool can meet the requirements of different machined surfaces for different machining pressures, the machining accuracy can be improved, the polishing process can be simplified, the machining cost can be reduced, and the air bag polishing tool is simple in structure and easy to control.

Owner:江苏拓域智能装备有限公司

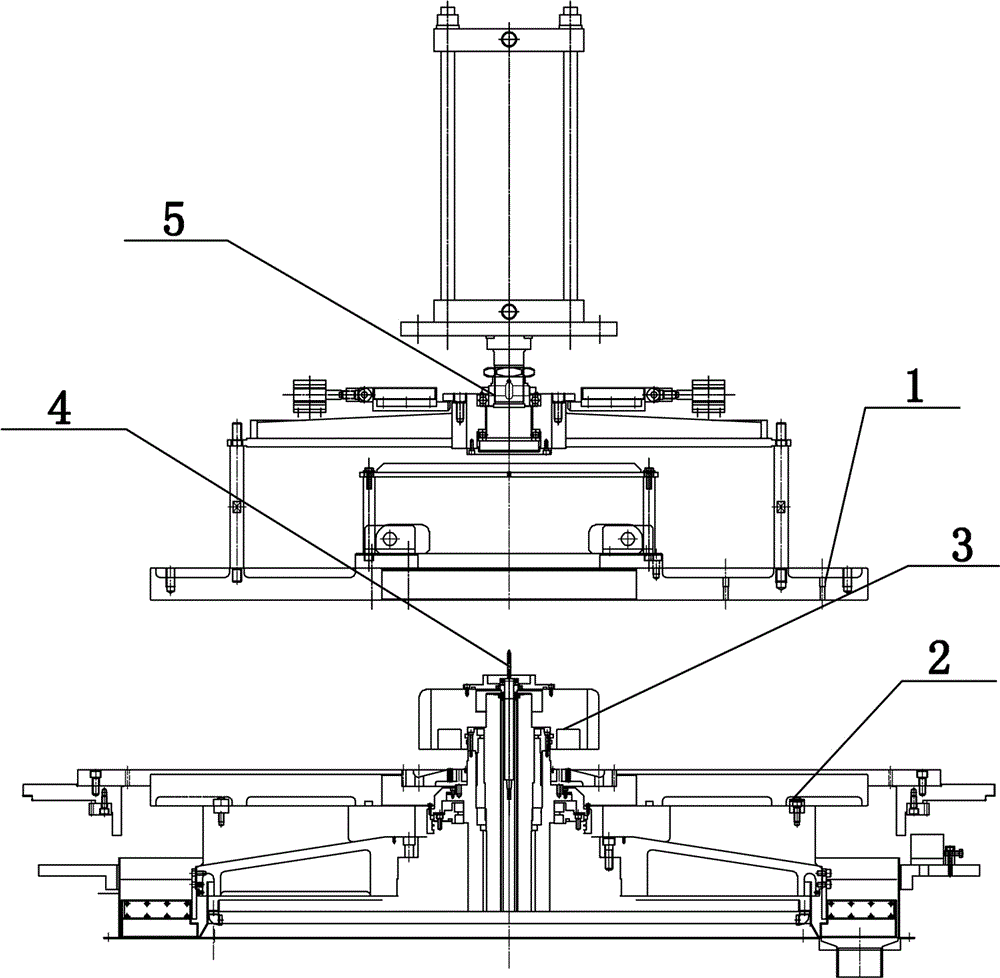

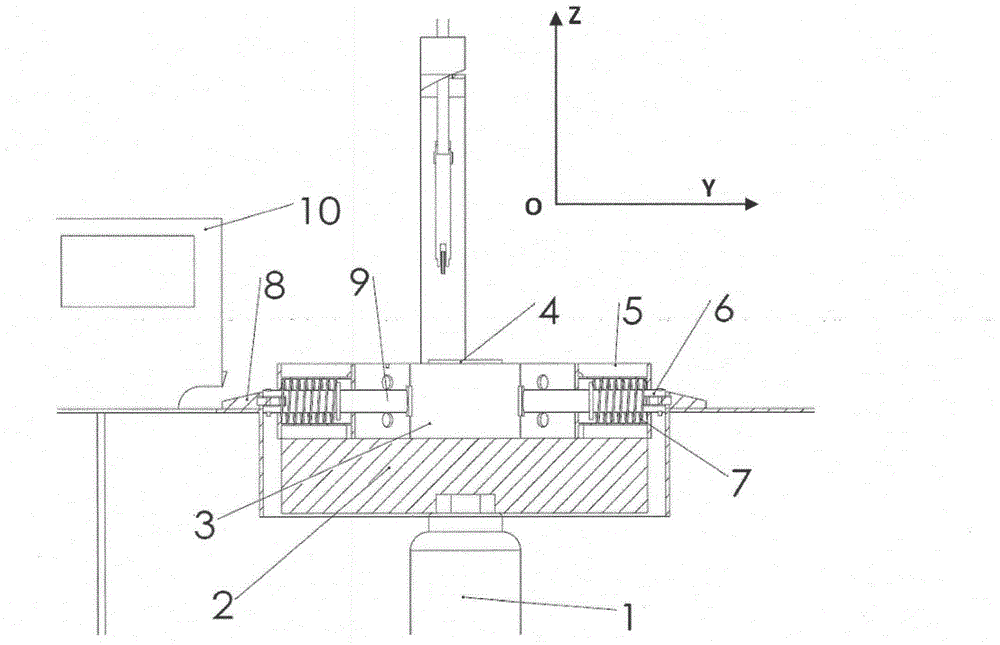

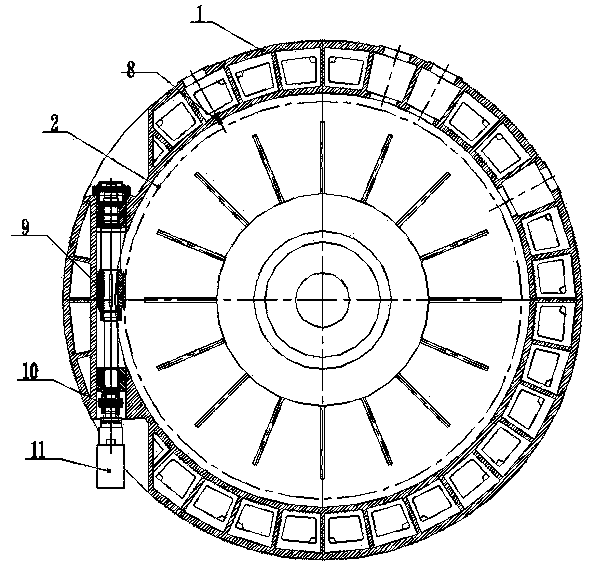

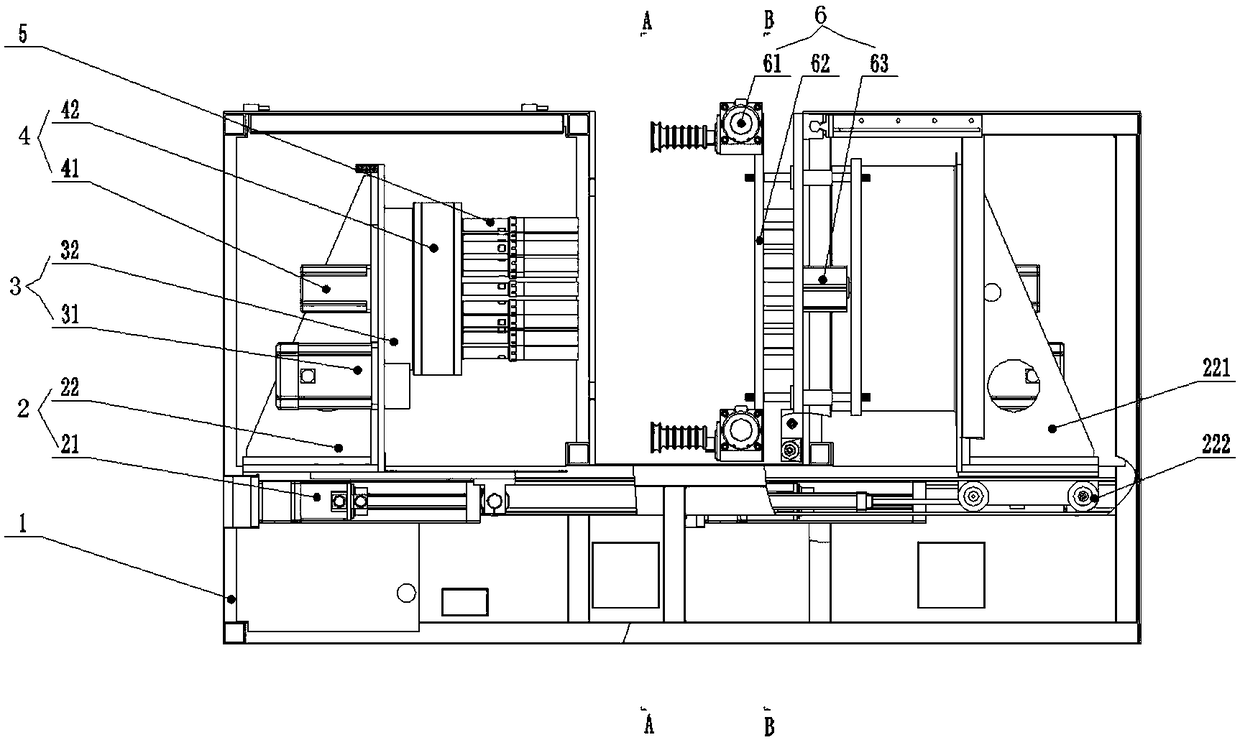

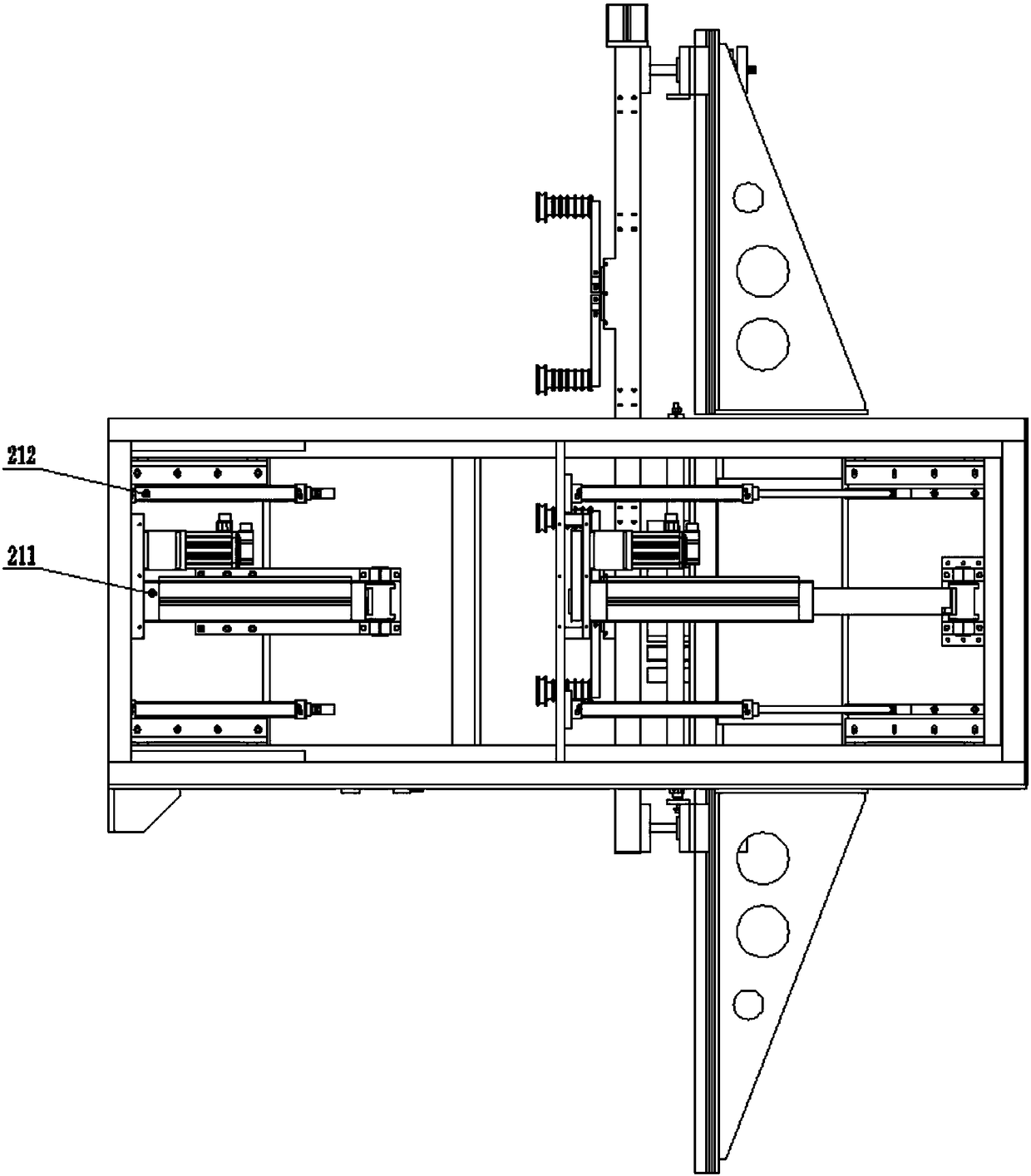

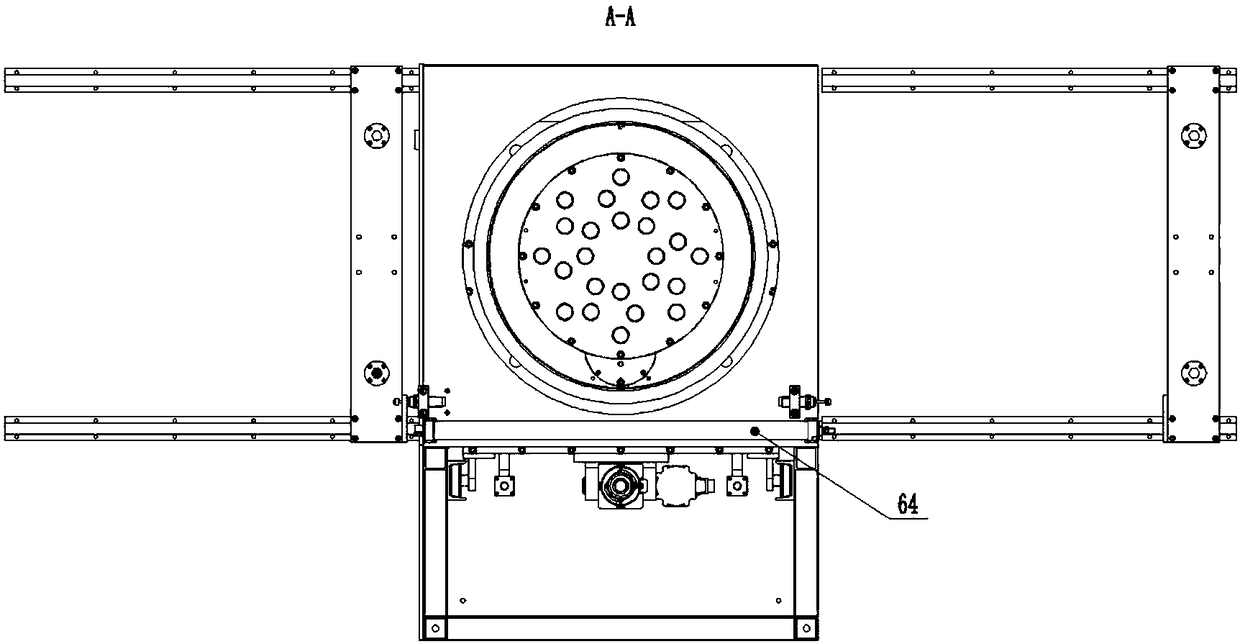

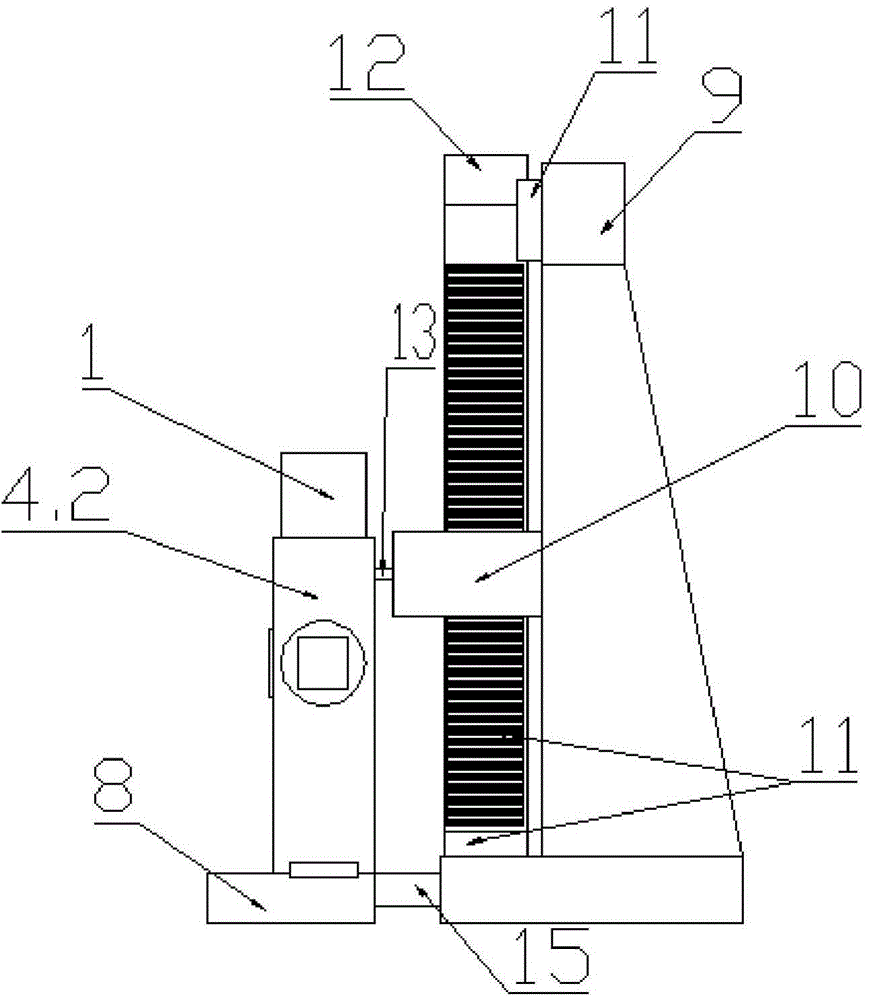

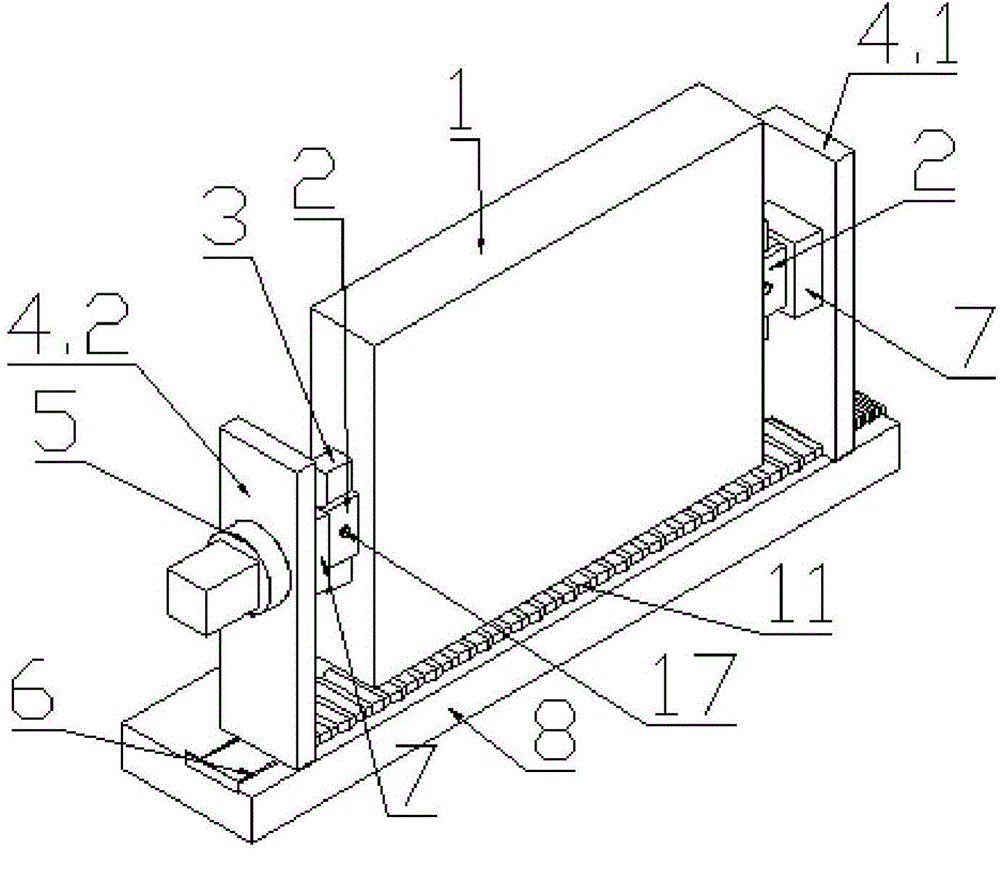

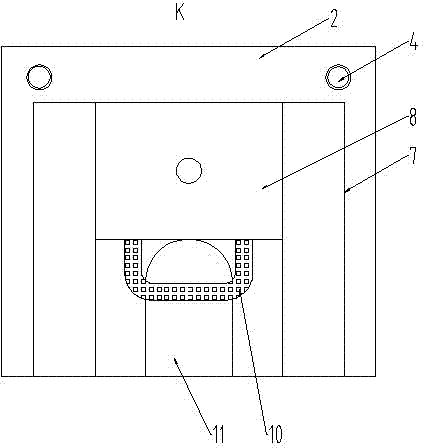

Workpiece fixed-size compensation type double-sided grinding device and method

InactiveCN105458908AFulfill process requirementsMeasure dimensions accuratelyLapping machinesGrinding/polishing apparatusCombined useEngineering

The invention relates to a workpiece fixed-size compensation type double-sided grinding device and method. An upper fixed disk and a lower fixed disk are arranged in cooperation; the upper fixed disk is connected to a control mechanism; a sun gear is arranged in the middle of the lower fixed disk; a height meter is arranged in the axis of the sun gear; the top end of the height meter is right opposite to the center of the upper fixed disk; the height meter is connected to the control mechanism; and the control mechanism is connected with the upper fixed disk sequentially through a pneumatic mechanism and a cylinder; a planetary gear is meshed with the outer side of the sun gear and is provided with a through hole; and a lower fixed disk inner gear ring is meshed with the planetary gear. Through the combination with control over time and height, influences of the rotating speed, pressure and other external factors are eliminated during primary grinding, it is guaranteed that the measurement size is accurate, the workpiece measurement size value is relatively stable while the external factors are the same, the fixed-size grinding is performed at the moment, the size grinding technological requirement of a workpiece can be met at a time, the size of the ground workpiece is controlled through combination of grinding time control and height sensor control, control can be performed easily, the large-batch and automatic production requirement of the workpiece is met, and grinding precision is improved.

Owner:TDG MACHINERY TECH

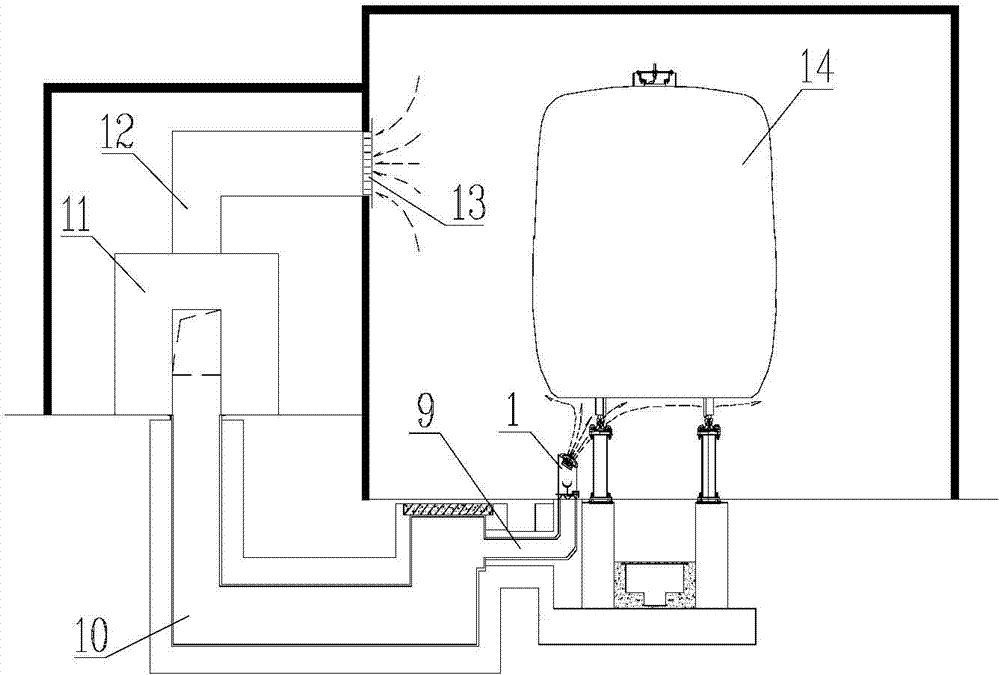

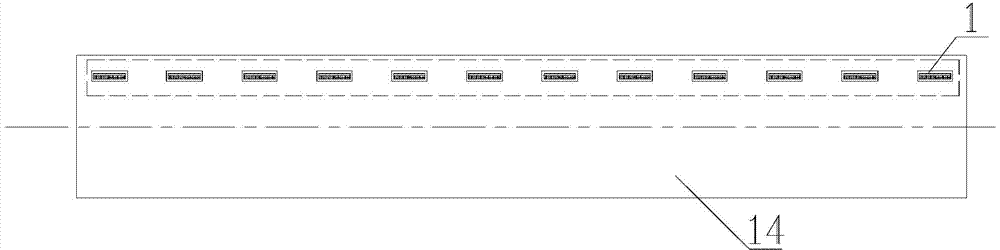

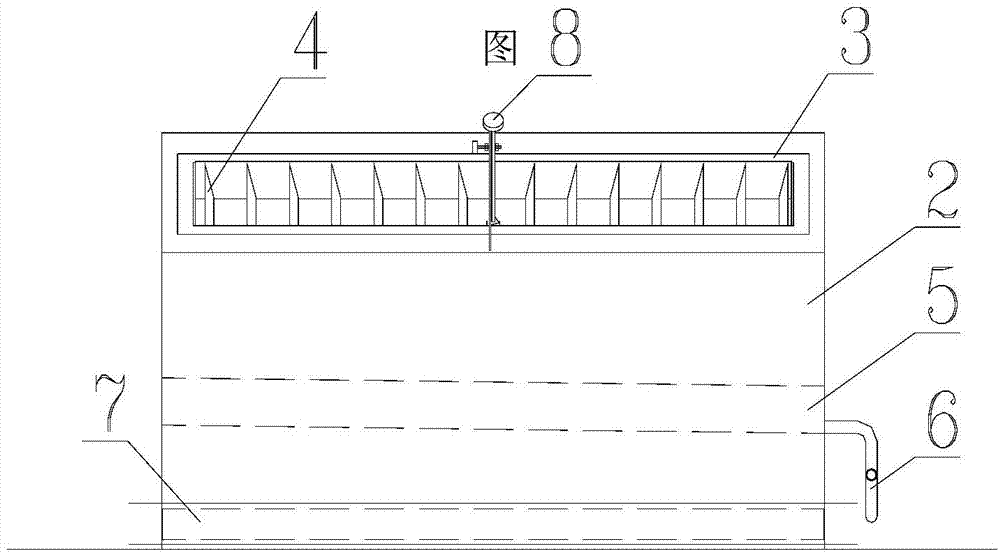

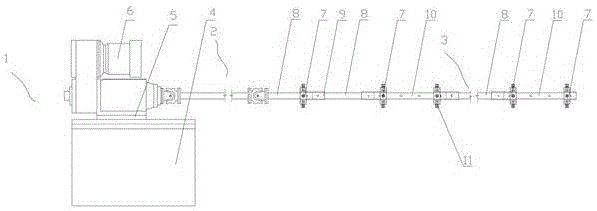

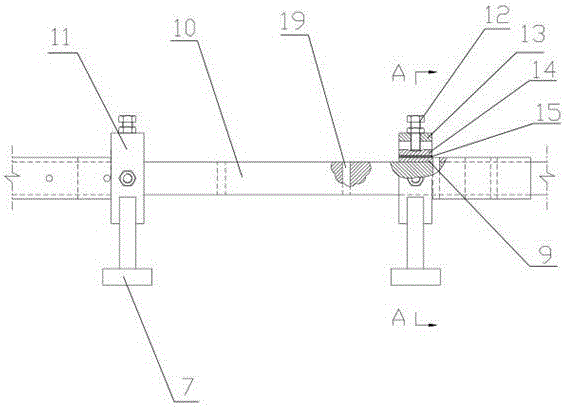

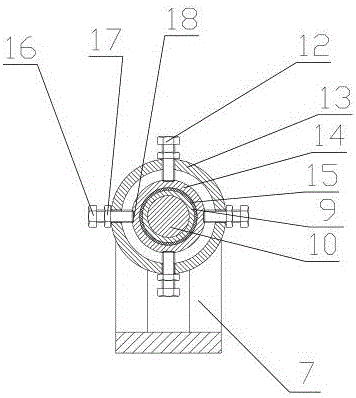

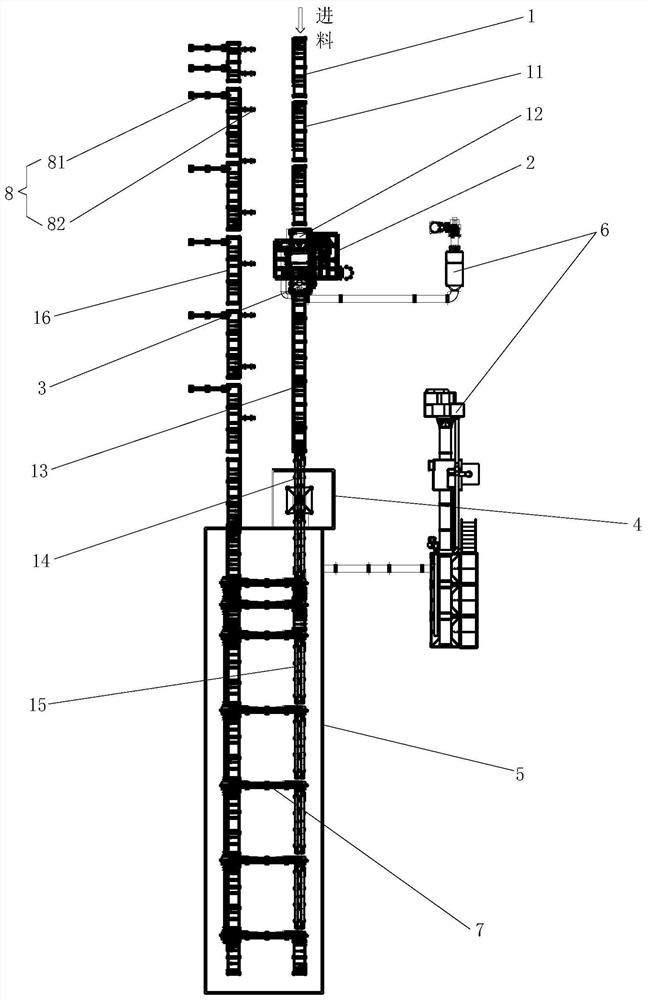

Hot air supply device for quick deicing and snow removing system at bottom of high-speed rail train

InactiveCN103879384AImprove reliabilityImprove effectivenessCleaning apparatus for vehicle exteriorsRailway auxillary equipmentAir volumeOperating time

The invention discloses a hot air supply device for a quick deicing and snow removing system at the bottom of a high-speed rail train. The hot air supply device comprises air supply columns arranged on one side of a deicing and snow removing station of the train, the air supply columns are lined up on the ground and evenly arranged, and 11-13 air supply columns are arranged corresponding to each section of train body. The air supply columns are fixed to the ground, communicated with an underground civil engineering delivery conduit and connected with a hot air unit in a hot air machine room through the underground civil engineering delivery conduit. Each air supply column of the hot air supply device comprises a column body, an air supply port, an air supply angle four-way regulating and locking device and an air quantity regulating valve, the air supply port is arranged on the top of the air supply column, and the air supply angle four-way regulating and locking device is arranged in the air supply port. According to the hot air supply device, hot air at a certain speed is blown out towards the bottom of the train through the air supply columns, heat exchange between ice and snow and the train body can be enhanced and the overall environment temperature of a garage can be improved through the air supply temperature and flowing of the hot air, and the functions of quick deicing and snow removing can be achieved. According to the hot air supply device, it can be guaranteed that the longest deicing operating time at the bottom of the compartment of the train is less than one hour, and technological requirements can be met.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

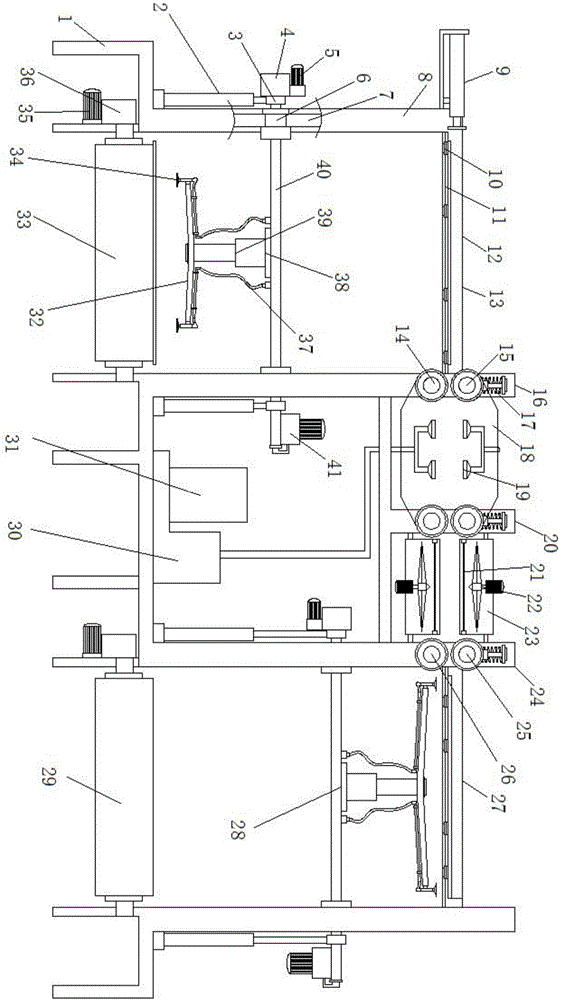

Pipelined automatic surface treatment equipment of liquid crystal display glass board

ActiveCN106391369AFulfill process requirementsRealize the requirements of automated productionLiquid surface applicatorsCoatingsLiquid-crystal displayEngineering

The invention discloses pipelined automatic surface treatment equipment of a liquid crystal display glass board. The equipment comprises a rack, wherein a first stand and a second stand are arranged at the upper end of the rack and internally provided with slide rails; a charge mechanism is mounted between the slide rails; a discharging board is arranged between the upper ends of the first stand and the second stand; an electric push rod is arranged on the left side of the upper end of the first stand; a third stand is arranged on the right side of the second stand; an atomization spraying case is arranged between the third stand and the second stand; a fourth stand is arranged at the right end of the third stand; two drying devices arranged in a butt manner are arranged between the third stand and the fourth stand; a fifth stand is arranged on the right side of the fourth stand; and a second discharging board and a discharging mechanism are arranged between the fifth stand and the fourth stand. The equipment is novel in structure, operates stably, can meet processing requirements of a novel spraying technology of the liquid crystal display glass board and pipelined automatic production requirements, greatly improves processing efficiency and meets operating requirements.

Owner:浙江三禾智能装备股份有限公司

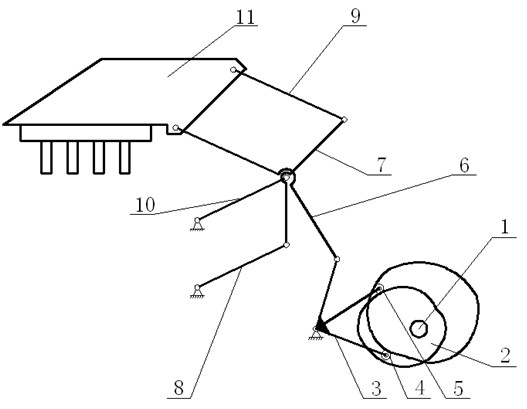

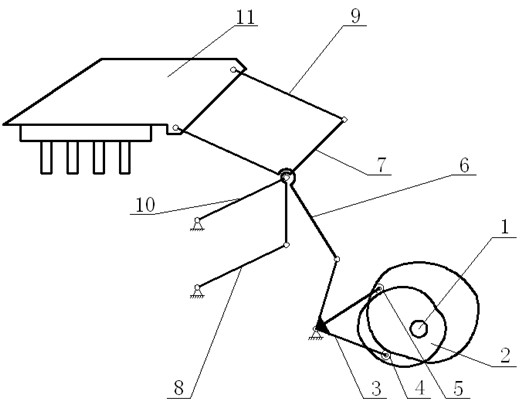

Conjugate cam connecting rod combination packing mechanism

InactiveCN102678872AFlexibility to meet job requirementsCompact structureGearingPackaging bottlesUniform rotationEngineering

The invention discloses a conjugate cam connecting rod combination packing mechanism. The motive power is transmitted to a conjugate cam which is consolidated with a cam shaft through the cam shaft which is in a hinged connection with a rack, the conjugate cam is connected with a swing rod cam pair, the conjugate cam pushes a swing rod to swing, and the movement of the swing rod is transmitted to a packing platform through a rod piece component. The uniform rotation of the cam shaft is changed to the movement of the packing platform by the conjugate cam connecting rod combination packing mechanism, by means of a contour design of the conjugate cam, the movement rule of the packing platform is controlled, so that the starting and finishing processes of a packing operation can be stable. Simultaneously, by means of the contour design of the cam, the stopping and pausing of the packing platform can be conveniently achieved during the moving process, the packing operation requirement can be flexibly met, the mechanism is compact in structure, the packing process requirement can be flexibly met, and the stopping and pausing functions can be achieved by a mechanical mode.

Owner:ZHEJIANG SCI-TECH UNIV

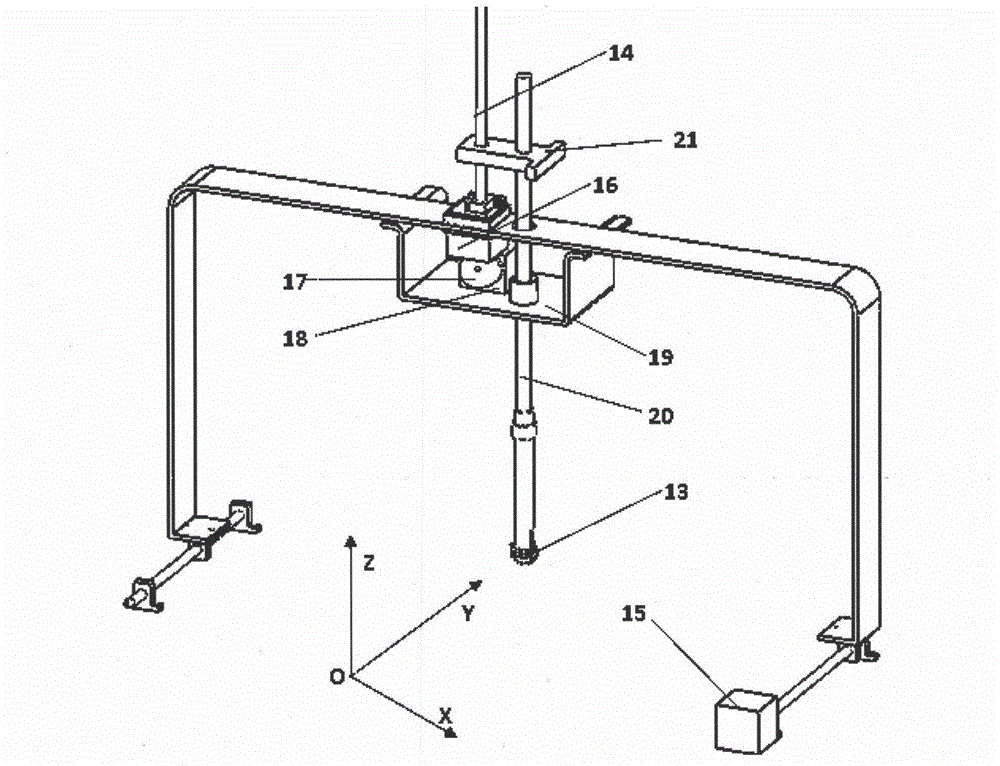

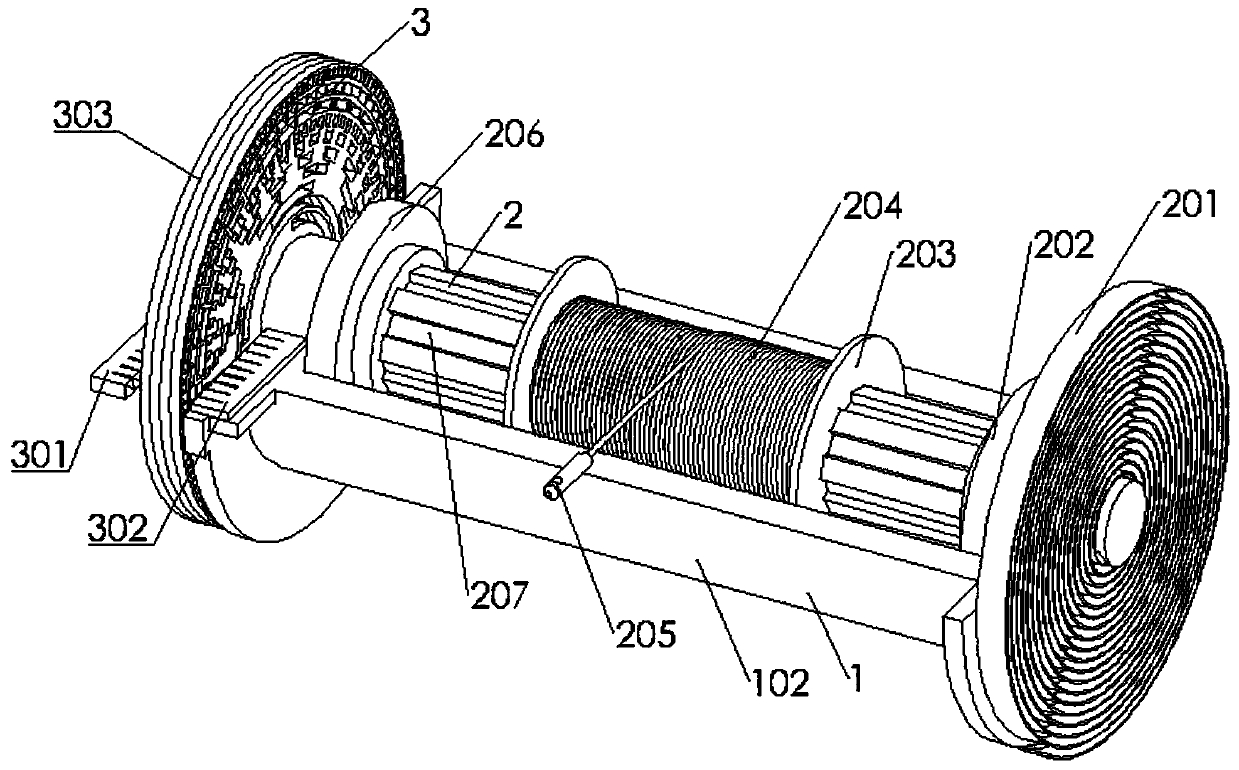

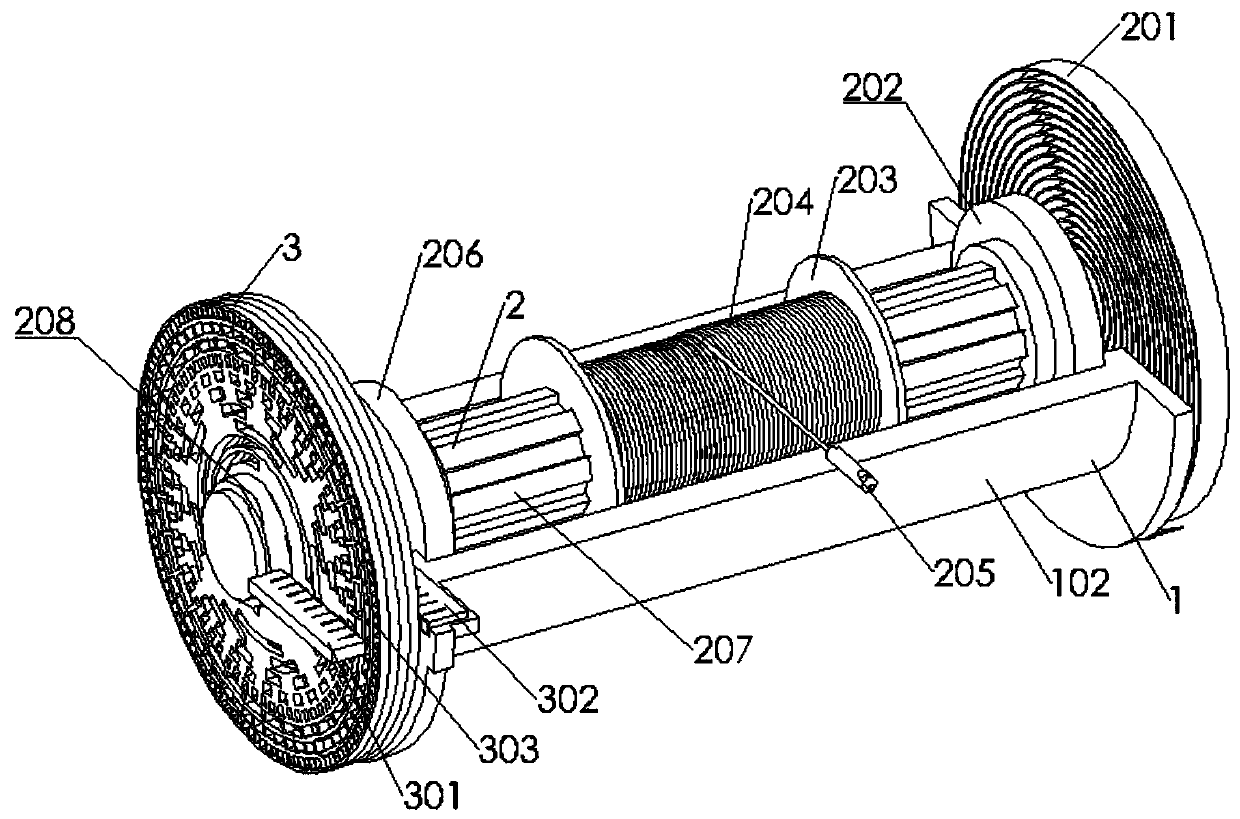

Dynamic balancer for revolved body

InactiveCN102980724AFulfill process requirementsStatic/dynamic balance measurementCircular discClosed loop feedback

The invention relates to a dynamic balancer for a revolved body, which is characterized in that the dynamic balancer comprises a speed regulation alternating current motor, a transmission disk driven by the speed regulation alternating current motor, a support component fixedly connected with the transmission disk, a revolved body, a displacement signal generator, a control box and a grinding mechanism, wherein the revolved body is positioned and clamped by the support component; the transmission disk is arranged on a workbench; the transmission disk and the support component are driven by the alternating current motor to provide a torque for the revolved body to drive the revolved body to rotate; the displacement signal generator reflects an eccentric displacement signal of the revolved body revolving at a high speed on an X-Y plane to a position that can be detected by a sensor; the eccentric displacement signal of the revolved body is detected and output to a controller by the sensor; and a control system controls the rotating speed of the revolved body, grinding position depth and feedback signal treating. The measuring and processing principle of the dynamic balancer is that a centrifugal force has an effect on the revolved body with eccentric mass in a rotating motion; with the adoption of a uniform measuring reference, a uniform processing reference and a man-machine interaction type closed-loop feedback control mode; and requirements on the measuring and processing of different accuracies can be met.

Owner:DONGHUA UNIV

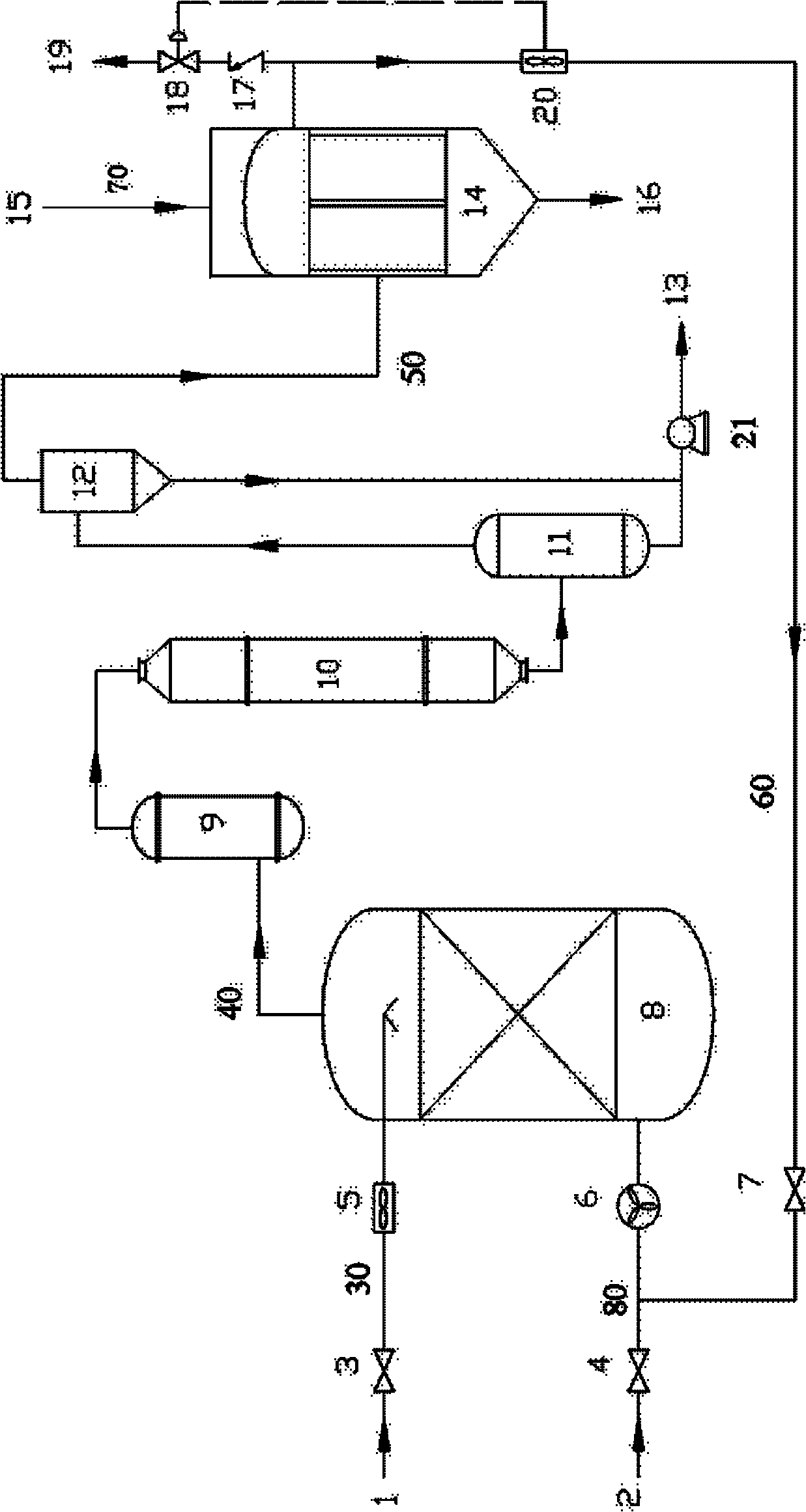

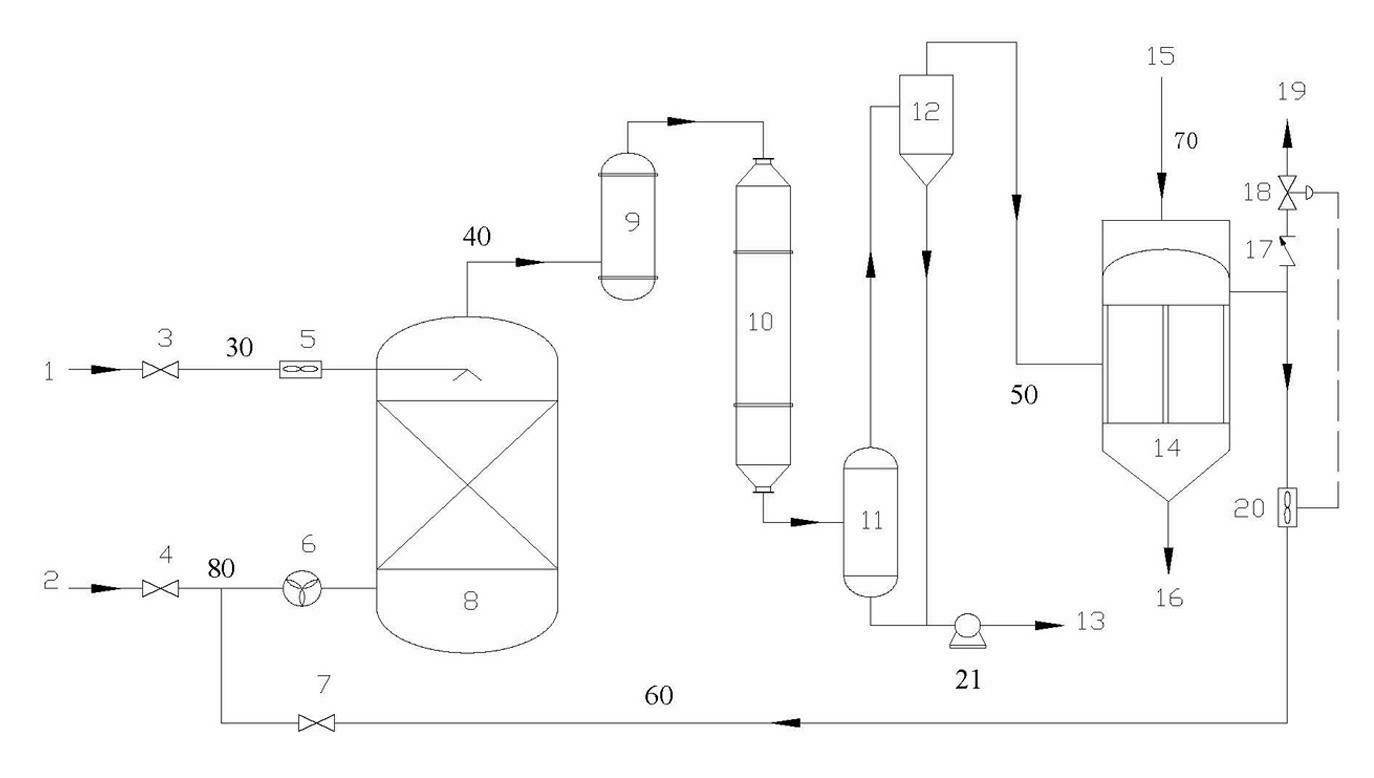

Sulfonated tail gas recycling method and sulfonated tail gas recycling system

ActiveCN102513039AEmission reductionLow investment costCombination devicesLiquid-gas reaction processesProcess engineeringSulfur trioxide

The present invention relates to a sulfonated tail gas recycling method and a sulfonated tail gas recycling system. The purpose of the present invention is to provide the method and the system, wherein the method and the system have characteristics of less waste gas discharge and less wastewater discharge, and the system has characteristics of reasonable structure, easy manufacture, and low cost. The technical scheme is that: the sulfonated tail gas recycling method comprises the following steps that: dry air enters the lower part of a sulfur trioxide evaporator, and is subjected to counter current contact with liquid sulfur trioxide entering the upper part of an vaporizing mixer so as to evaporate into the sulfur trioxide gas; the sulfur trioxide gas is cooled, enters a sulfonator, is subjected to a contact reaction with an organic material in the sulfonator, and then is output; the sulfonated tail gas is separated from the liquid, wherein the separated liquid material is output and enters a neutralization system, the separated sulfonation tail gas enters an electrostatic demister to carry out a demisting treatment, the partial discharged sulfonated tail gas enters an alkali washing processing system, and the remaining sulfonated tail gas is conveyed to the lower part of the sulfur trioxide mixing evaporator to recycle. The pipeline system of the sulfonated tail gas recycling system is arranged according to the method.

Owner:JIAXING ZANYU TECH DEV CO LTD

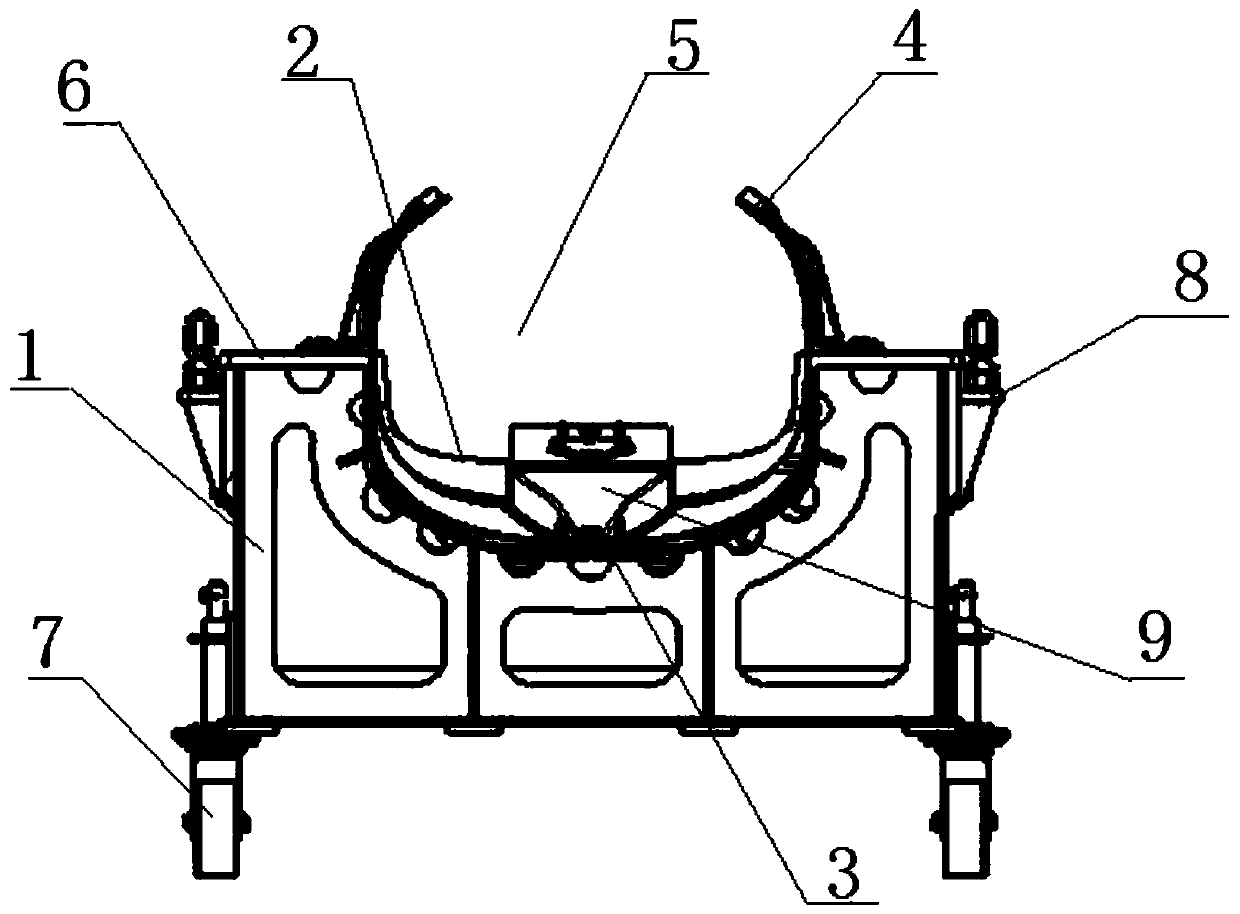

Composite material machine body skin integral forming tool and technology

PendingCN109774194ALow costFulfill process requirementsDomestic articlesEngineeringMechanical engineering

The invention discloses a composite material machine body skin integral forming tool and technology, and relates to the technical field of unmanned aerial vehicle composite material manufacturing. A framework and a tool template are included. Installing grooves are formed in the two opposite faces of the framework, the two installing grooves are oppositely arranged, and the two ends of the tool template are fixedly clamped in the two installing grooves. Two detachable movable blocks are further arranged on the upper surface of the framework and located on the two sides of the tool template correspondingly, a continuous face is formed by the inner side faces of the two detachable movable blocks and the work face of the tool template, and a curing cavity is formed by the two detachable movable blocks and the tool template. The special technology is combined with the special tool, so that integral forming of large-curvature composite material unmanned aerial vehicle machine body skins isachieved.

Owner:SICHUAN XIN WAN XING CARBON FIBER COMPOSITES

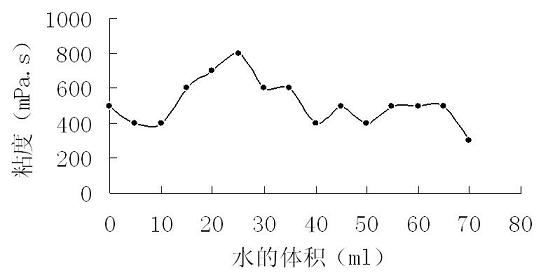

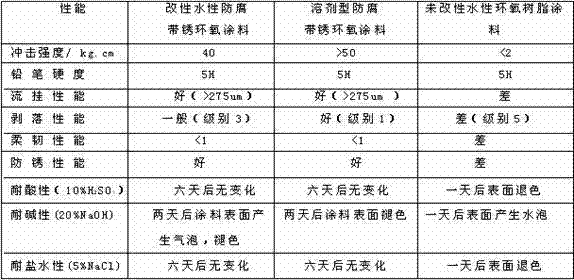

Synthesis of modified aqueous epoxy resin and method for preparing antiseptic rusty paint

ActiveCN101775108AGood water dispersibilityGood storage stabilityAnti-corrosive paintsEpoxySynthesis methods

The invention discloses synthesis of modified aqueous epoxy resin and a method for preparing antiseptic rusty paint, relating to synthesis of epoxy resin and a method for preparing paint. The invention solves the problems of the traditional aqueous epoxy resin antiseptic paint that storing stability of base material resin and water resistance and corrosion resistance of an aqueous epoxy resin antiseptic paint coating film can not be met simultaneously. the synthesis method of modified aqueous epoxy resin comprises the steps of: mixing Span 60 with Tween 20, adding E-51; heating and stirring, and dropwise adding distilled water till the system viscosity is suddenly reduced; and finally dropwise adding an initiating agent and a monomer to carry out heating reaction. The method for preparing antiseptic rusty paint comprises the steps of: mixing the modified aqueous epoxy resin, a corrosion inhibitor and a rust preventing agent, stirring and grinding; adding a defoaming agent, a curing agent and deionized water; and stirring the mixture to obtain the modified aqueous epoxy resin antiseptic rusty paint. The invention simultaneously meets the storing stability of the base material resin of the aqueous epoxy resin antiseptic paint and the water resistance and the corrosion resistance of the aqueous epoxy resin antiseptic paint coating film.

Owner:HARBIN INST OF TECH

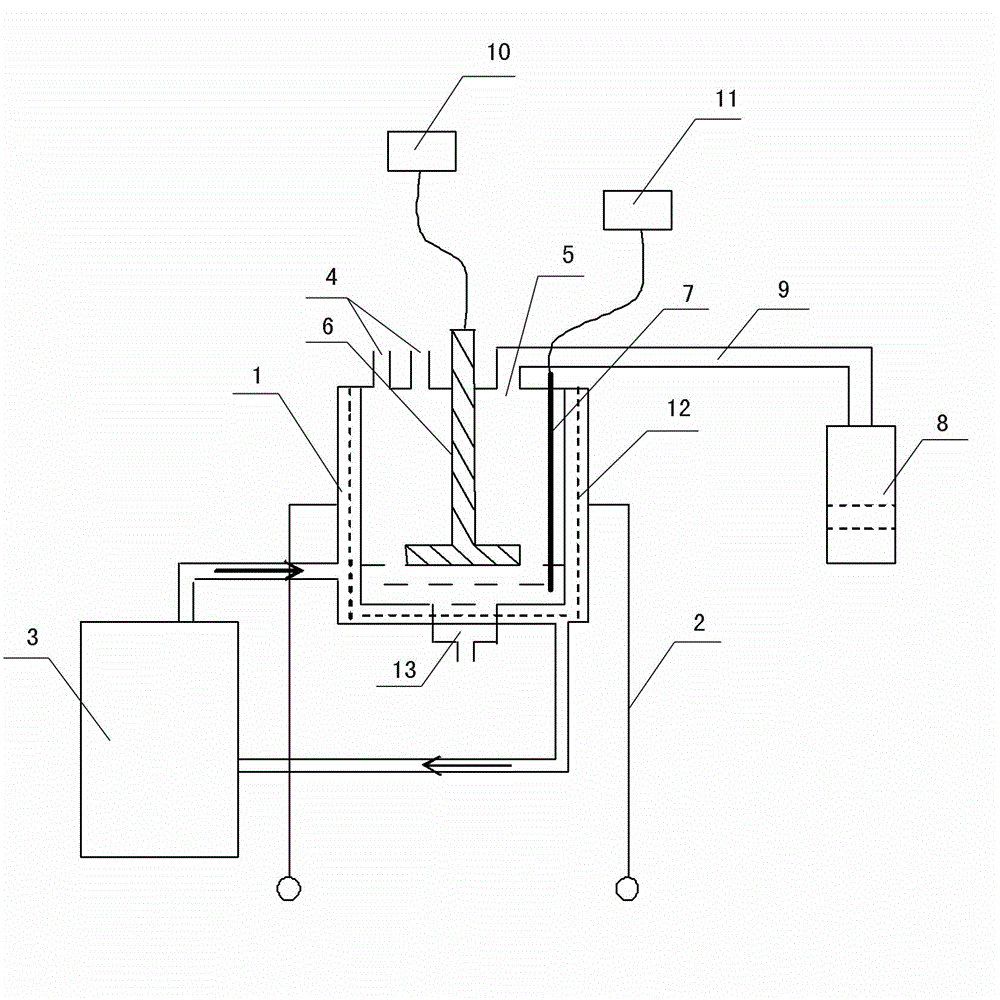

Industrial large-scale reaction vessel for preparing graphene

InactiveCN102744028AAvoid pollutionFulfill process requirementsGrapheneChemical/physical/physico-chemical stationary reactorsAutomatic controlChemical reaction

The invention relates to an industrial large-scale reaction vessel for preparing grapheme. The reaction vessel comprises a shaft sealing apparatus, a transmission apparatus, a protection supporting framework (2), a gas collecting bottle (8), a frequency-conversion speed-regulation stirrer (6) and a temperature measurement tube (7). The protection supporting framework (2) is provided with a reaction bottle (1), wherein the reaction bottle (1) is connected with a thermostatic bath (3) on outside thereof, and is provided with charging ports (4) and an exhaust emission port (5) at the upper part thereof and a discharging port (13) at the lower part thereof. The reaction bottle can automatically control reaction temperature, stirring speed and constant-temperature state during a whole process of preparation of oxide grapheme. Pollution of different raw materials can be prevented by using a plurality of charging ports. The reaction vessel has advantages of wide range of constant temperature, large volume and compact structure, and is suitable for physical and chemical reactions in large doses.

Owner:泰州巨纳新能源有限公司

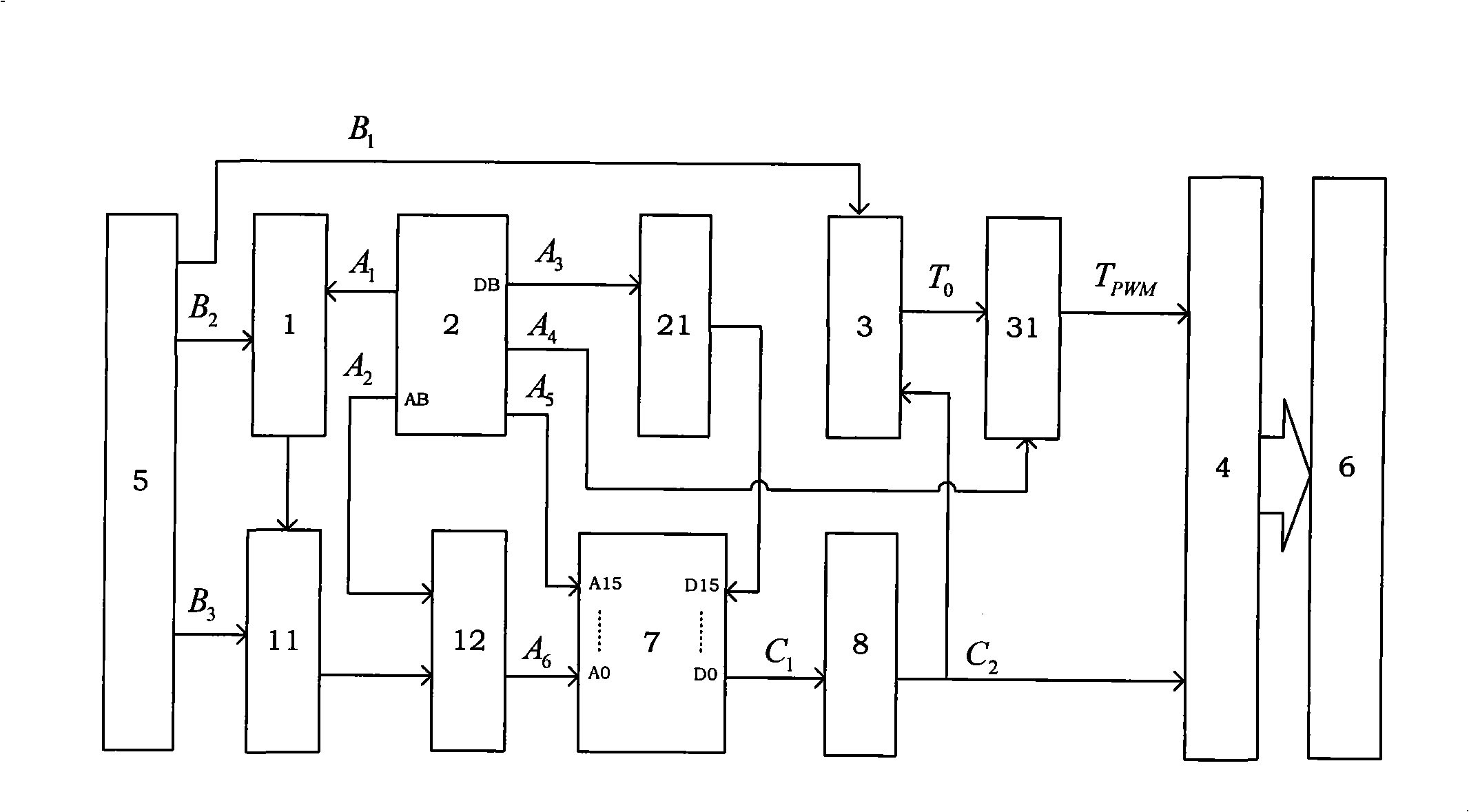

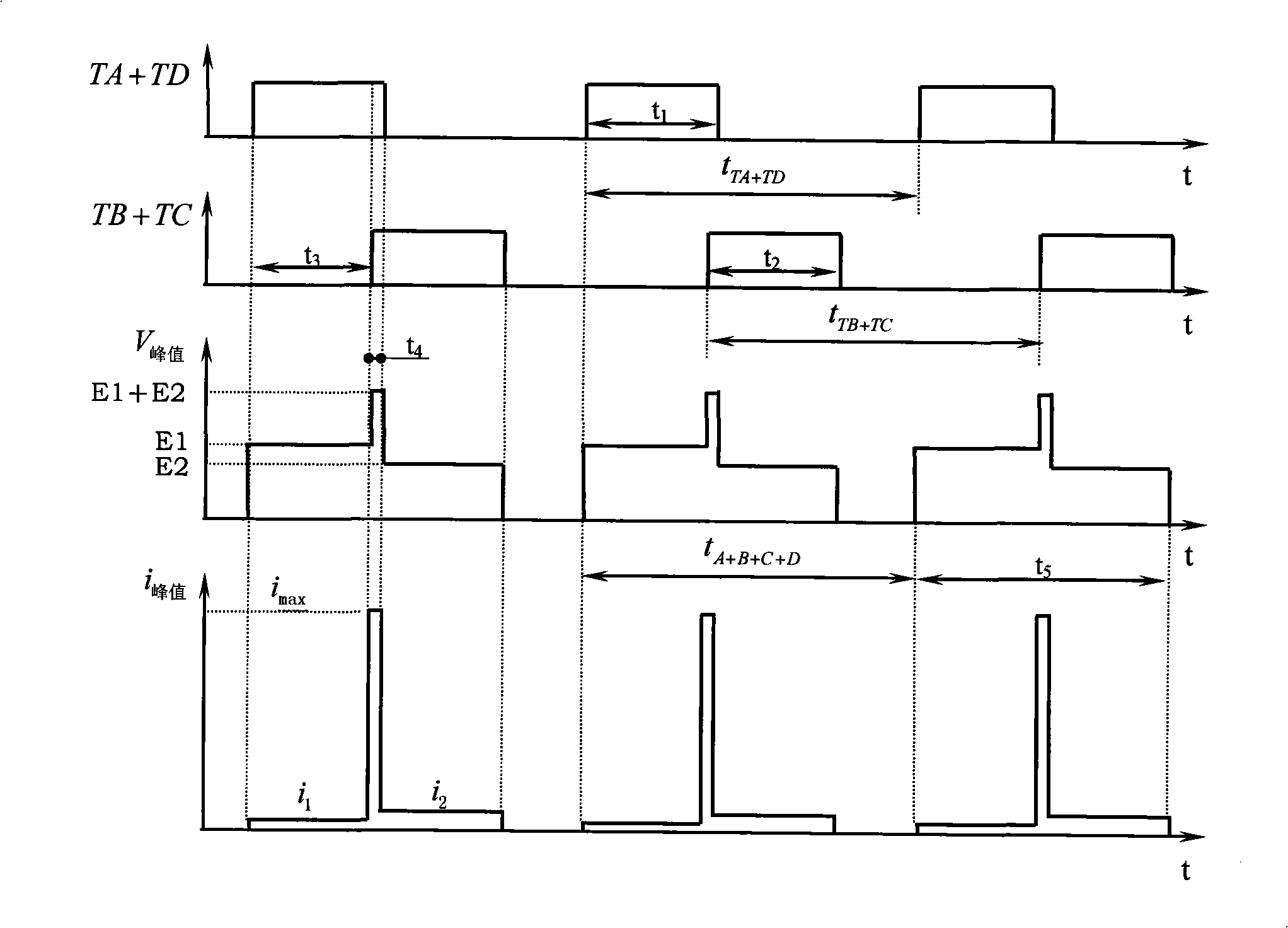

Numerical control wire-electrode cutting impulsing power source with controllable current waveform

InactiveCN101254560AMeet cutting requirementsFulfill process requirementsElectric circuitsShift registerNumerical control

The invention discloses a wire-cutting pulse power source with controllable current waveform, which comprises a clock and a sequential control circuit (5), a cycle controller (1), an address generator (11), an address selector (12), a central processor (2), a data driver (21), a shift register (3), a multiplexer (31), a drive, isolate and output control circuit (4), a power amplifier (6), a read-only memory (7) and a data latch (8), wherein wave data is stored in the read-only memory (7). The wave data is electrical parameter signals with different pulse widths, different cycles and current peaks suitable for different processing requirements. The wire-cutting pulse power source with controllable current waveform can output two drive signals with same waveform but different phases for processing a workpiece, thus effectively improving the surface quality of the workpiece.

Owner:HARBIN INST OF TECH +1

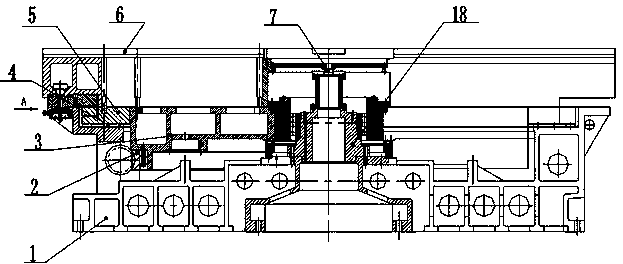

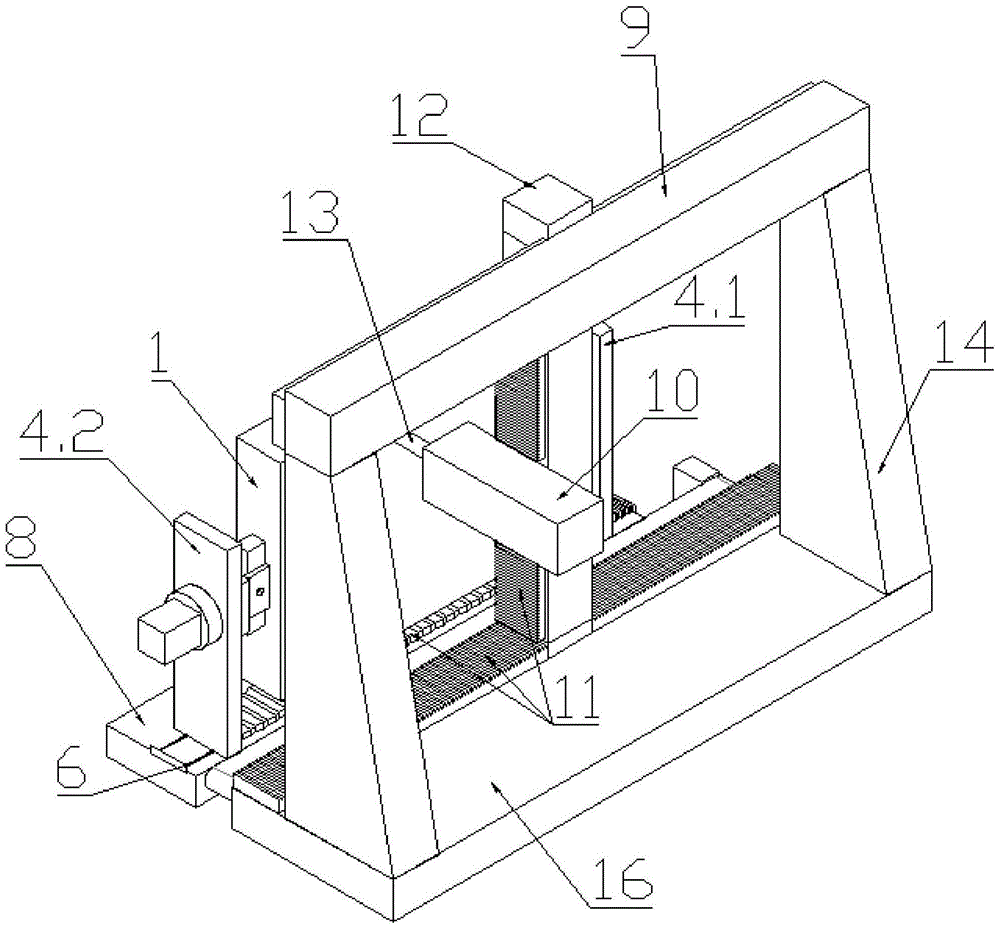

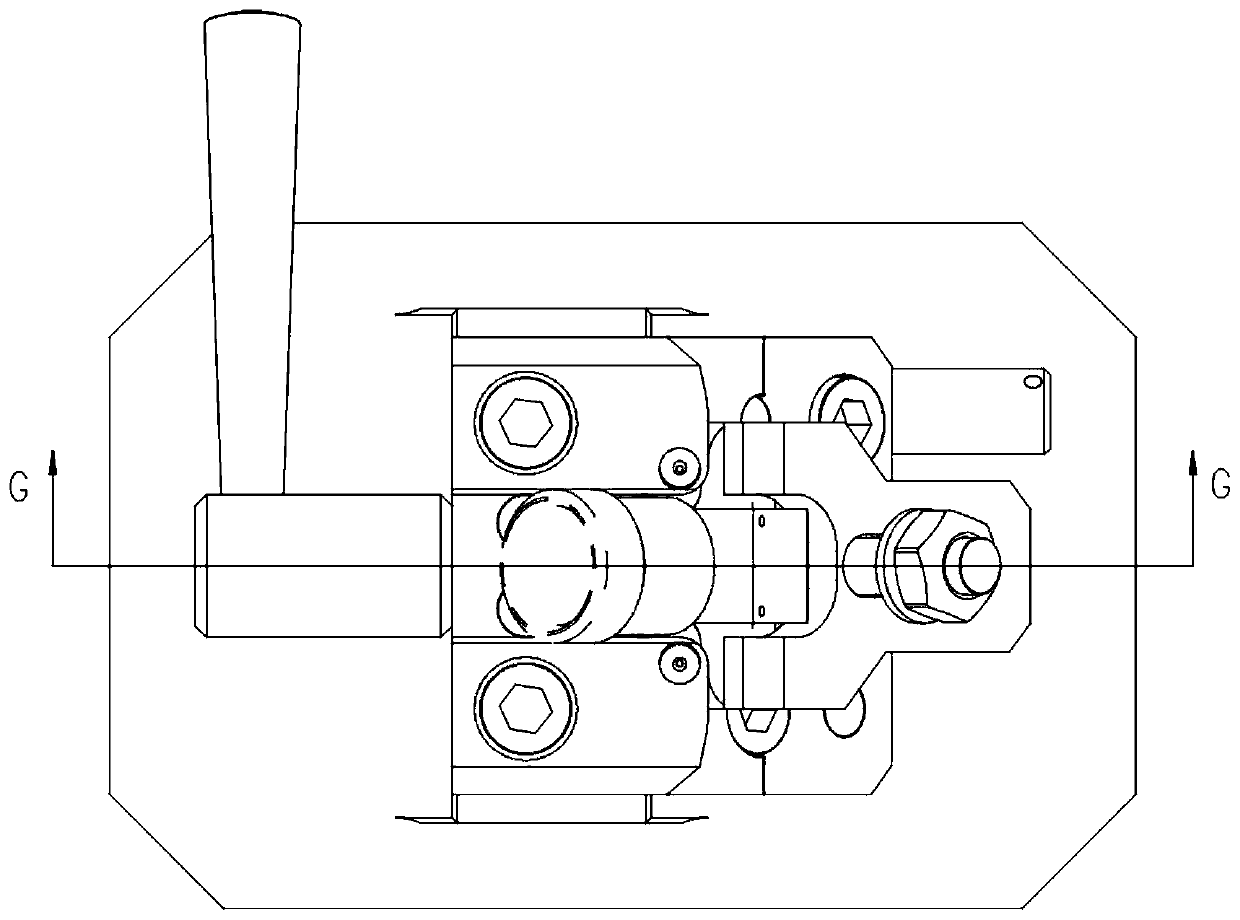

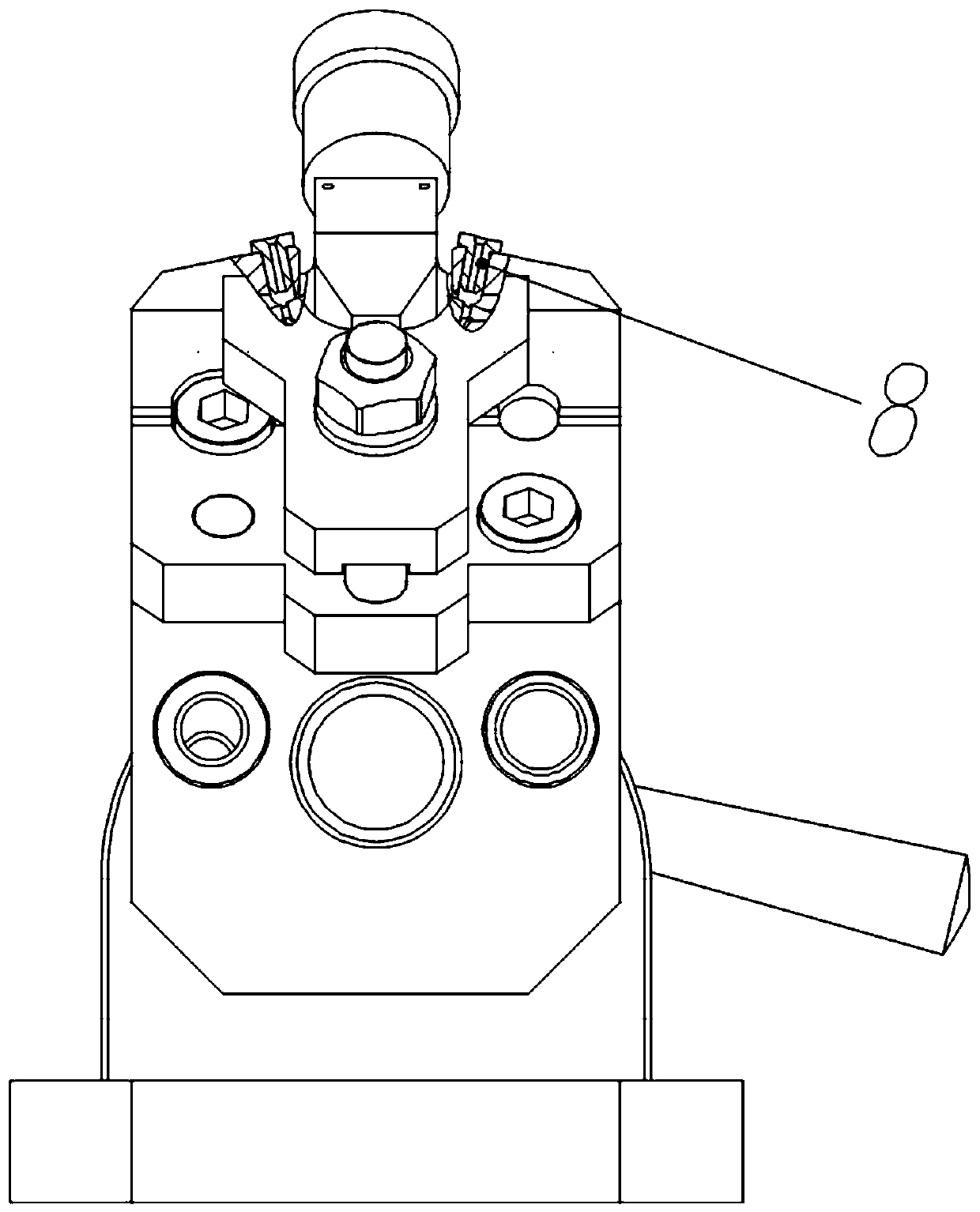

Large linkage digital control rotation equipment for bolt drawing machine

InactiveCN103624558AFulfill process requirementsRealize precise machining requirementsPrecision positioning equipmentLarge fixed membersHydraulic cylinderCoupling

The invention provides large linkage digital control rotation equipment for a bolt drawing machine. The large linkage digital control rotation equipment comprises a body, wherein a main shaft and a sensor are arranged on the body, a worm wheel is arranged on the main shaft and meshed with a worm rod, a working platform is arranged at the uppermost end of the body, the worm rod is connected with a servo motor through a coupler, and is a dual-screw pitch gradually-thickening worm rod, a worm wheel hub is fixedly arranged on the worm wheel and fixedly connected with the working platform, a coder is arranged on the working platform, a guide rail is arranged at the lower end of the working platform, a wear plate is arranged between the guide rail and the body, a plurality of pairs of brake blocks are uniformly arranged below the working platform and are fixedly connected with the working platform, a piston rod is arranged at the upper ends of the brake blocks and penetrates through the brake blocks to be connected with a piston in a hydraulic cylinder, a disc spring is arranged between the piston rod and the brake blocks, and a brake column is arranged between the brake blocks and the piston. The rotation equipment provided by the invention is capable of meeting processing requirements on bolt drawing machines for a nuclear power plant and other various large-size and super-heavy workpieces.

Owner:YANTAI TONGYONG MECHANICAL EQUIP

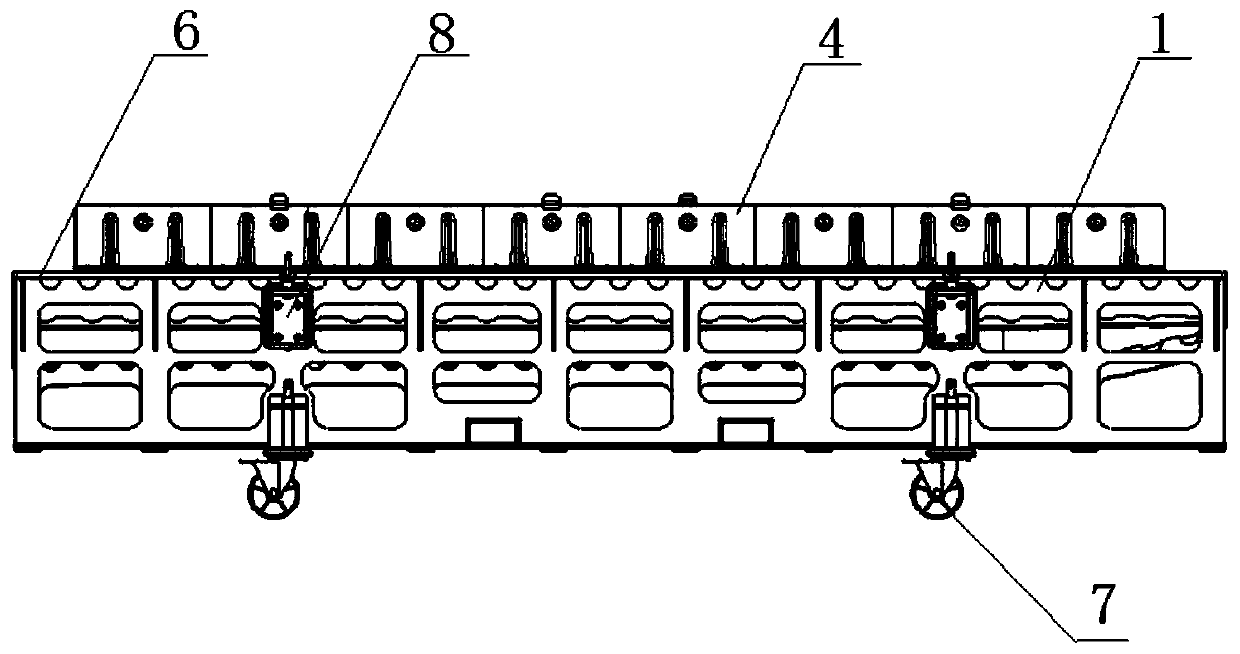

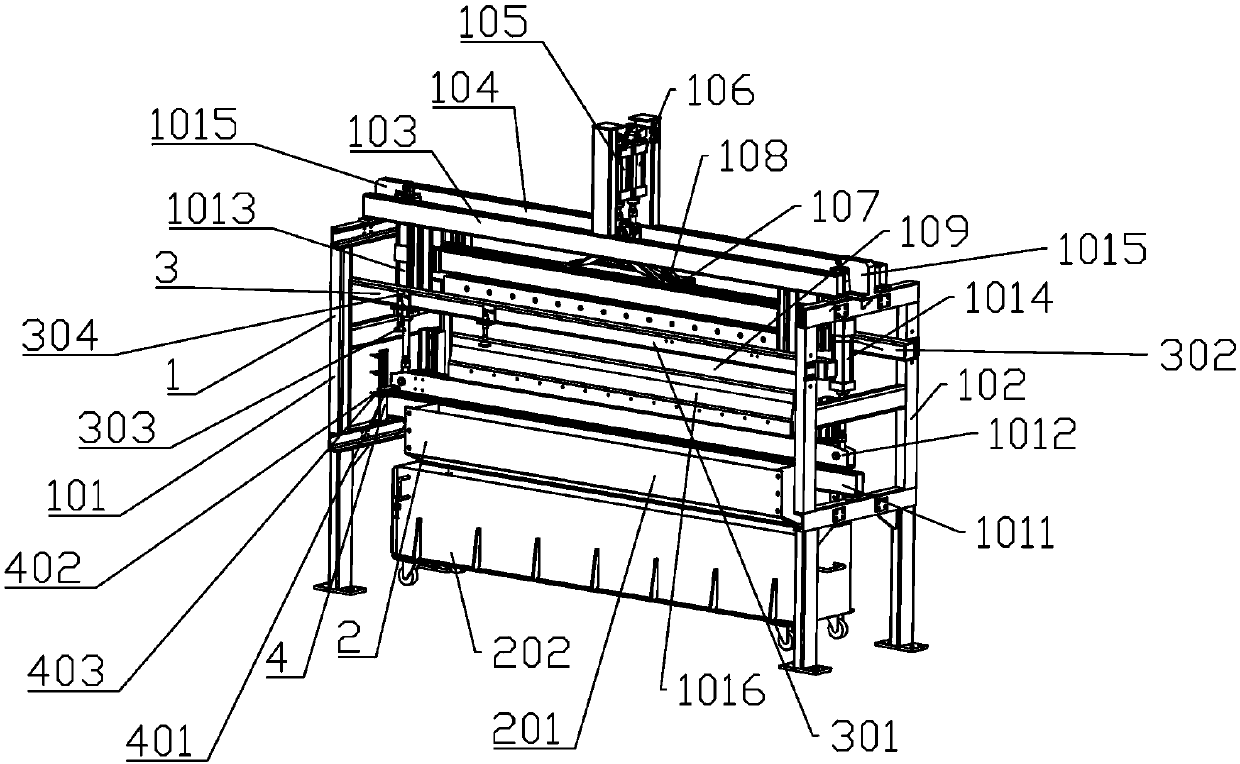

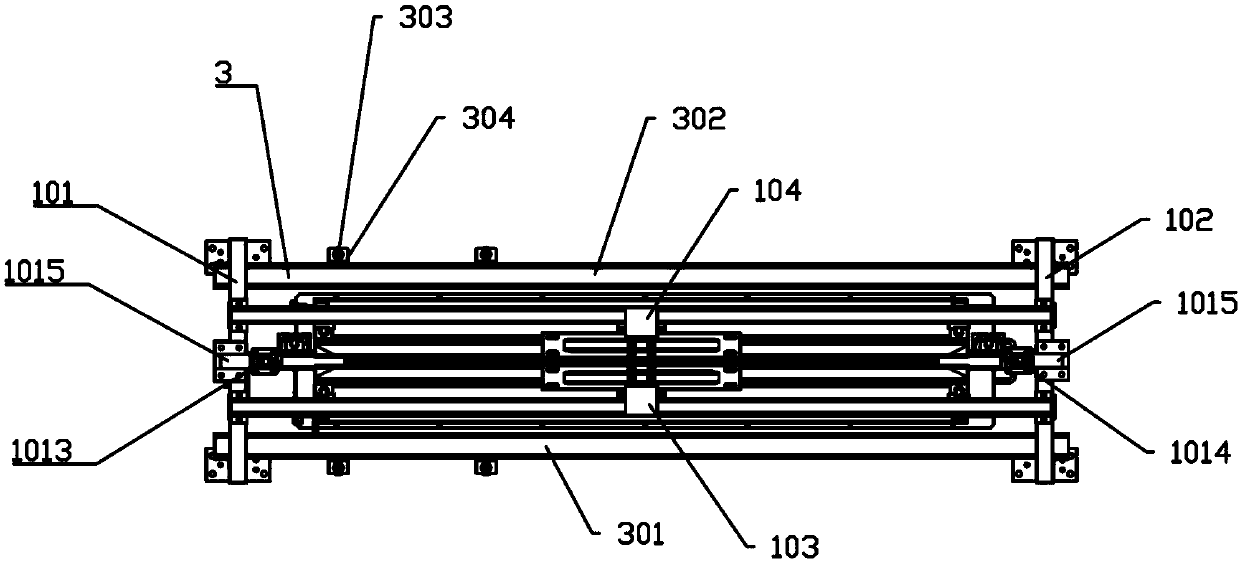

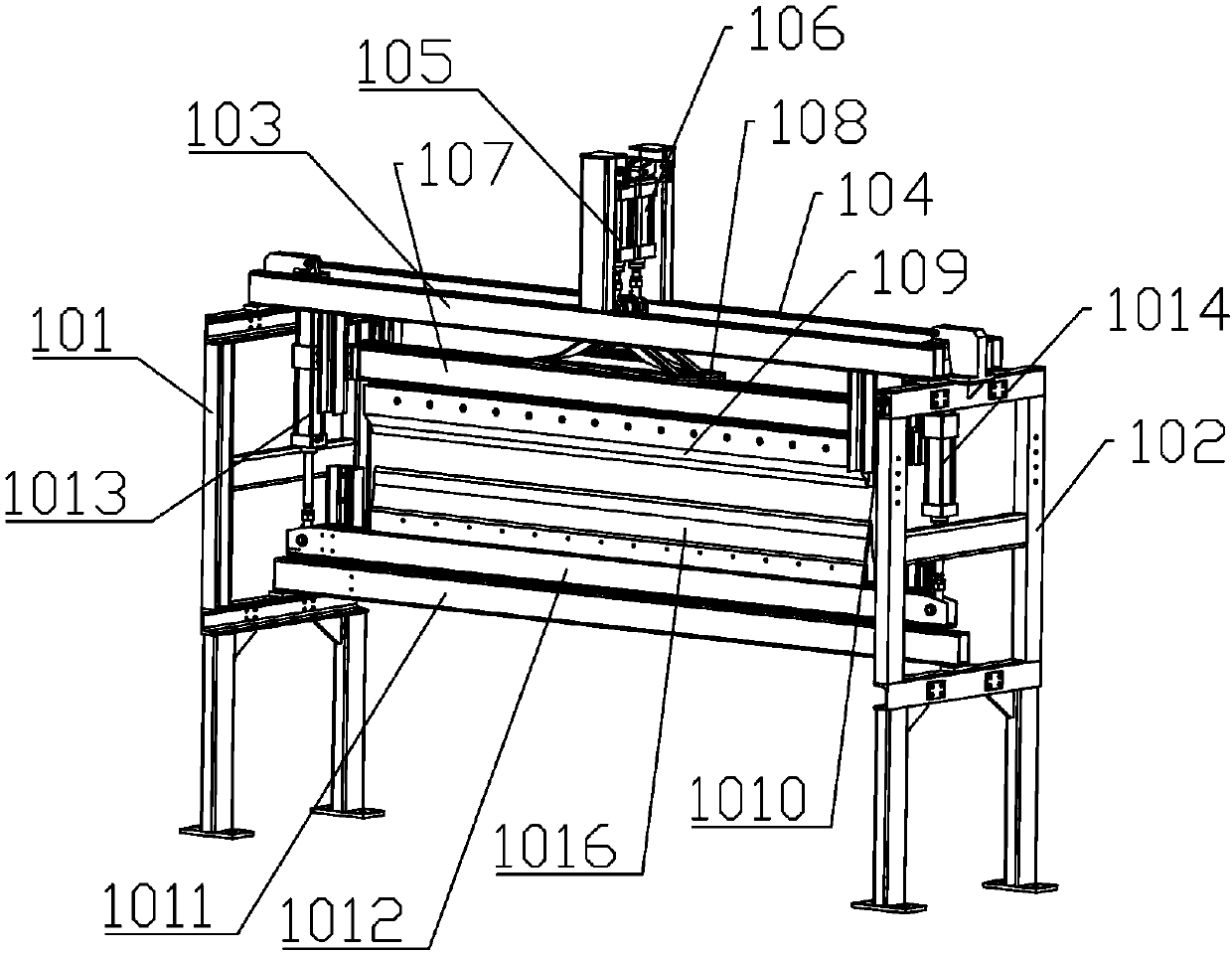

Deburring machine device for aluminum alloy hub

PendingCN108555720ASolve the problem that the burr cannot be removedRealize continuous productionEdge grinding machinesGrinding feedersEngineeringAlloy

The invention discloses a deburring machine device for an aluminum alloy hub. The deburring machine device comprises an equipment stander, wherein translation mechanisms are arranged at two ends of the equipment stander, a main shaft tank revolution mechanism and a main shaft tank mechanism are respectively at the top end of the translation mechanism at one end of the equipment stander, the main shaft tank revolution mechanism comprises a revolution driving element and a revolution transmission, and an output end of the revolution driving element is connected with the revolution transmission;the main shaft tank mechanism comprises a main shaft tank rotation driving unit and a main shaft tank transmission, an output end of the main shaft tank rotation driving unit is connected with the main shaft tank transmission, and the main shaft tank transmission is connected with the driving element through a gear; and a hairbrush is arranged on one side of the main shaft tank transmission, and aclamping and conveying mechanism is arranged at the top end of the translation mechanism at the other end of the equipment stander. According to the deburring machine device, different specificationsof hub burrs can be completely cleaned through the revolution and rotation of the hairbrush, so that the deburring machine device is relatively efficient, convenient and fast.

Owner:秦皇岛艾科晟智能装备集团有限公司

No-mold casting method and equipment capable of automatically draining sand

ActiveCN104815967ASolve the waste sand accumulation clamping knifeSimple equipmentMoulding machinesMaterial resourcesCasting

The invention discloses a no-mold casting method and equipment capable of automatically draining sand. A processed surface of a sand mold is downwards inclined or vertically arranged; the sand mold is cut through numerical control cutting equipment; and in the processing process, cut waste sand is naturally drained into a sand draining groove under the effect of self gravity. The equipment comprises a numerical control cutting device, a sand box station control device and a waste conveying belt, wherein the numerical control cutting device and the sand box station control device are fixed on the ground in parallel; a sand box mounted on the sand box station control device is positioned in a processing position of the numerical control cutting device; and the waste conveying belt is mounted between the numerical control cutting device and the sand box station control device, and is positioned below a sand mold processing station. The problems of cutter clamping by waste sand accumulation and cutter grinding can be solved without adding an injection device in the equipment or adopting the manual cleanness, so that the equipment is simplified, the manpower and the material resources are saved, and the no-mold casting production cost is reduced.

Owner:鞍山千钢机械制造有限公司

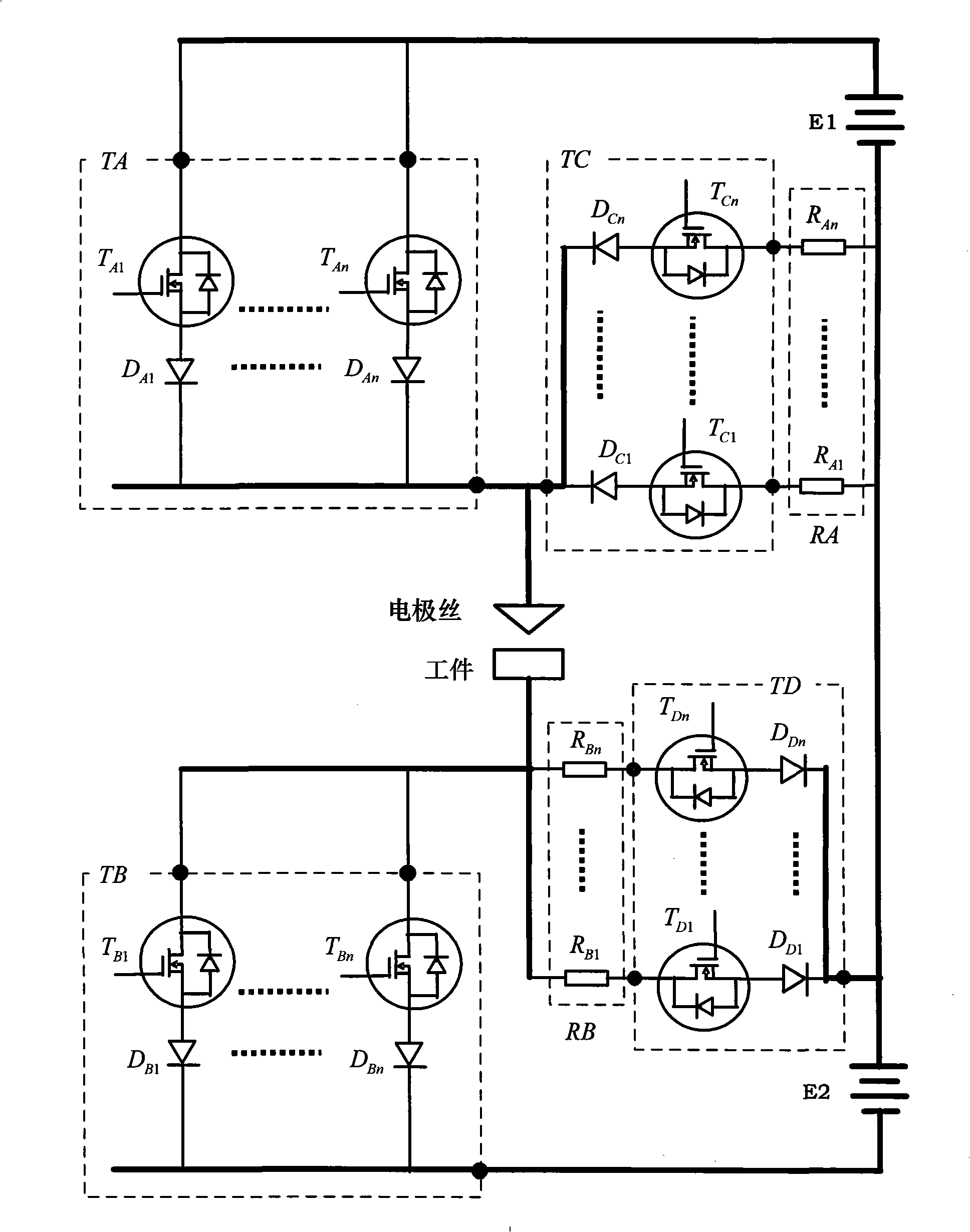

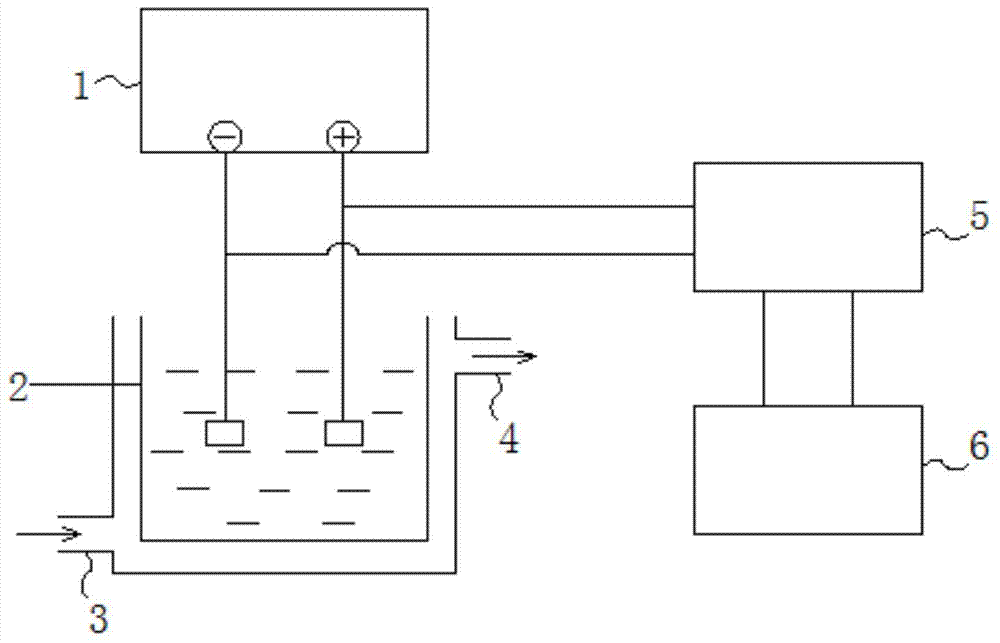

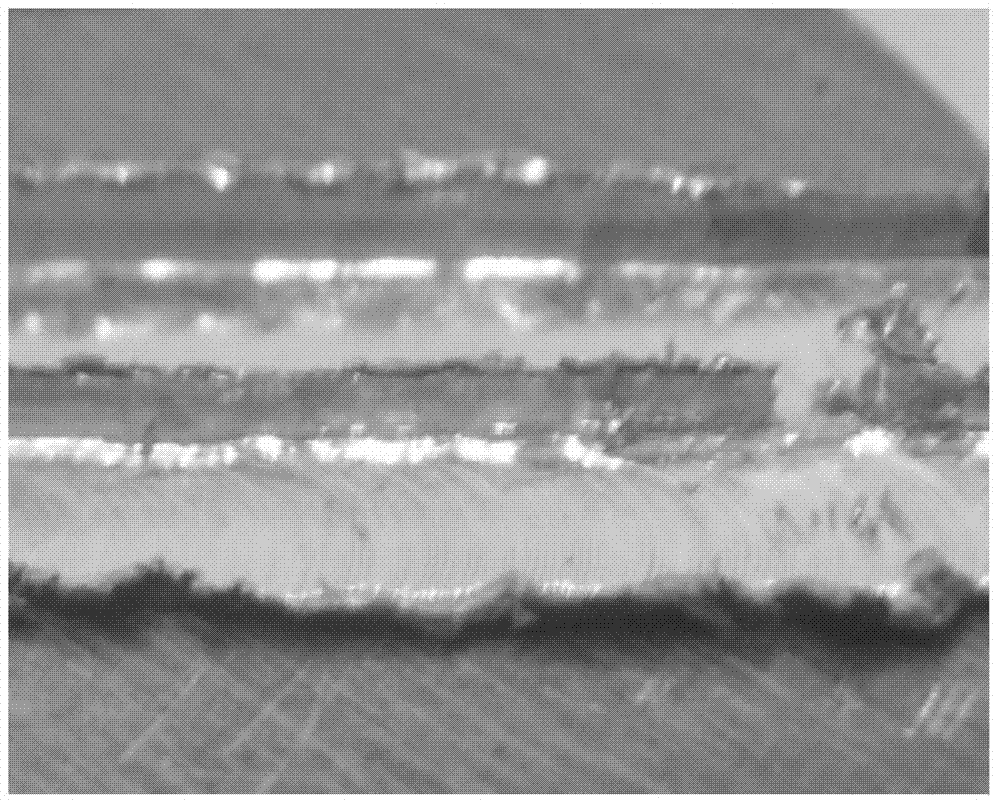

Non-contact micro arc polishing process and device thereof

InactiveCN104120475AFulfill process requirementsAvoid process disadvantagesAnodisationMetalControl system

The invention relates to the field of material processing and in particular relates to a metal product surface non-contact micro arc polishing process and device thereof. The process comprises the following steps: preparing electrolyte, designing parameters of the cathode and anode, controlling a flow field environment, setting parameters of a power supply and performing micro arc polishing. The device comprises a micro arc polishing power supply and an electrolytic cell, wherein the electrolyte is arranged in the electrolytic cell; two poles of the micro arc polishing power supply are inserted into the electrolyte; a cooling water system is arranged at the periphery of the electrolytic cell; and the two poles of the micro arc polishing power supply are electrically connected with a control system through a signal acquisition unit. With adoption of the process and device, the micro arc polishing process has the advantage that atomic-scale layer-by-layer stripping can be performed, the process defect of inconsistent interference of the electrode potential is overcome, the process is not limited by anode metal components and phase composition, complex curved surface shape members can be met, and the process aims of sub-micron to nano-scale precision polishing and machining requirements can be achieved.

Owner:NANJING UNIV OF TECH

Free-cutting stainless steel and application thereof

ActiveCN111621710AFulfill security requirementsMeet environmental protection requirementsMetallurgySS - Stainless steel

The invention discloses free-cutting stainless steel. The free-cutting stainless steel is characterized by comprising the following components: 0.01-0.03 wt% of C, 0.6-0.9 wt% of Si, 2.5-3 wt% of Mn,23-25 wt% of Cr, 0.06-0.09 wt% of P, 0.01-0.3 wt% of S, 1.8-2.6 wt% of Mo, 0.40-0.60 wt% of V, 0.001-0.03 wt% of B, 0.1-0.3 wt% of Se, 0.1-0.3 wt% of Ce, 0.05-0.15 wt% of Bi, 0.01-0.03 wt% of T, and the balance Fe and inevitable impurities. The free-cutting stainless steel has lead-free elements, the technical problem of not reducing the performance but removing Pb elements is solved, and finallythe stainless steel meets the use attributes of environment friendliness, safety and health.

Owner:启东市荣盛铜业有限公司

Airbag polishing tool, system and method

ActiveCN104369064BFulfill process requirementsStable polishingPolishing machinesOptical surface grinding machinesContact pressurePositive pressure

The invention discloses an air bag polishing tool and system and method. The air bag polishing tool comprises a motor, a speed reducer, a hollow rotating shaft and an air bag, wherein the motor, the speed reducer, the hollow rotating shaft and the air bag are sequentially connected. The hollow rotating shaft is provided with a hollow cavity, the two ends of the hollow cavity are communicated to the air bag and a ventilation guide pipe respectively, and an electrical proportional valve is arranged on the ventilation guide pipe. The air bag polishing tool further comprises a pressure intensity sensor for detecting the pressure intensity of air in the air bag and a pressure sensor for detecting the positive pressure of the tool. By means of the air bag polishing tool, based on the electrical proportional valve, the contact pressure and the contact pressure intensity of a polished surface can be controlled in real time, the air bag polishing tool can meet the requirements of different machined surfaces for different machining pressures, the machining accuracy can be improved, the polishing process can be simplified, the machining cost can be reduced, and the air bag polishing tool is simple in structure and easy to control.

Owner:江苏拓域智能装备有限公司

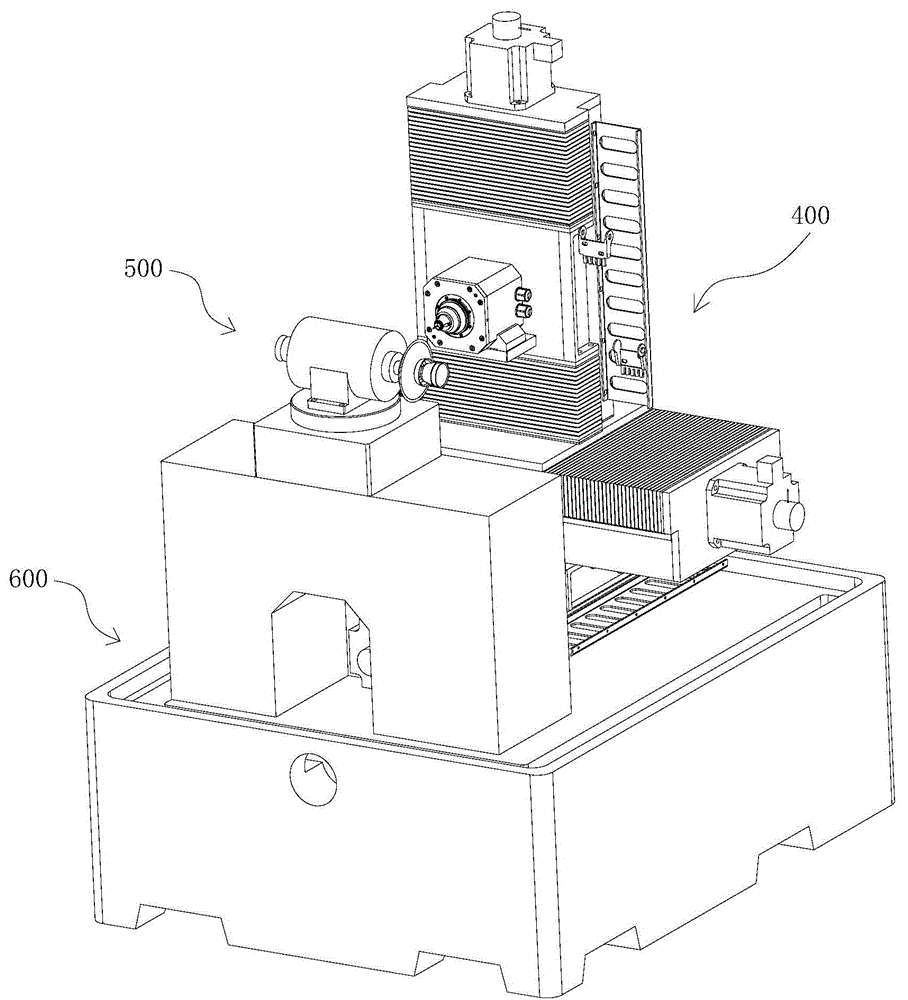

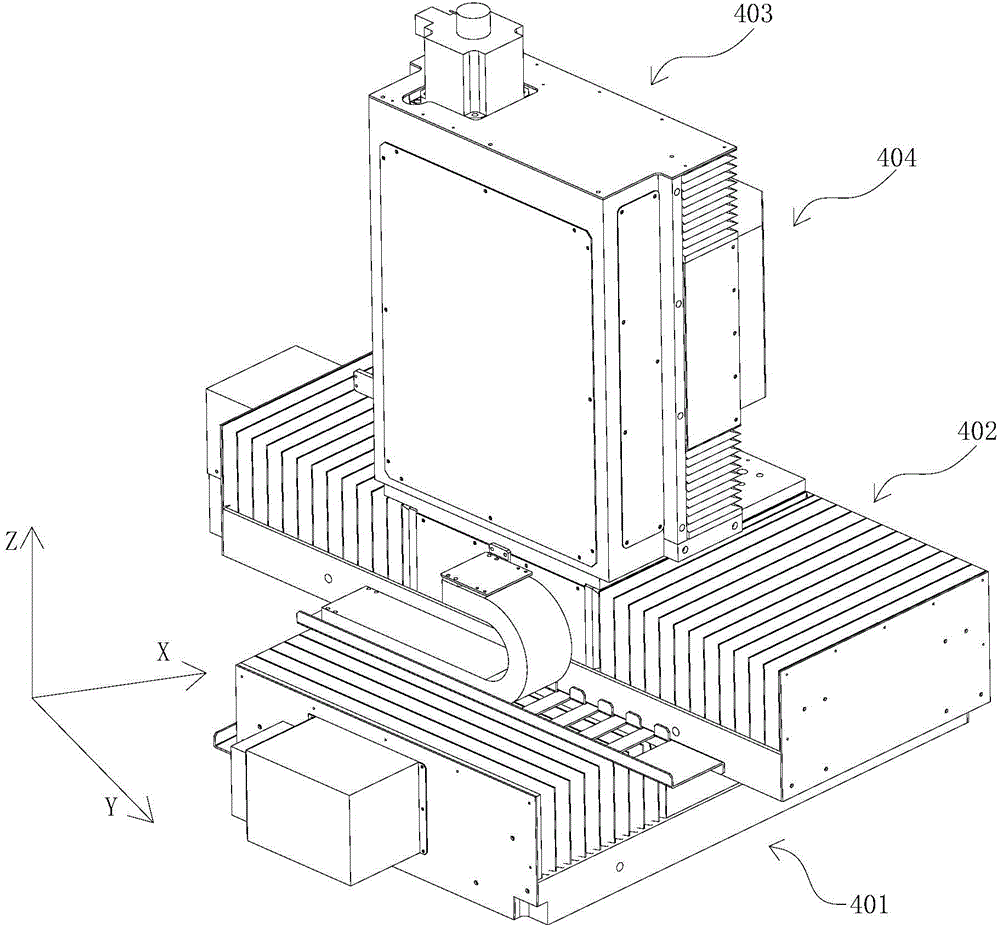

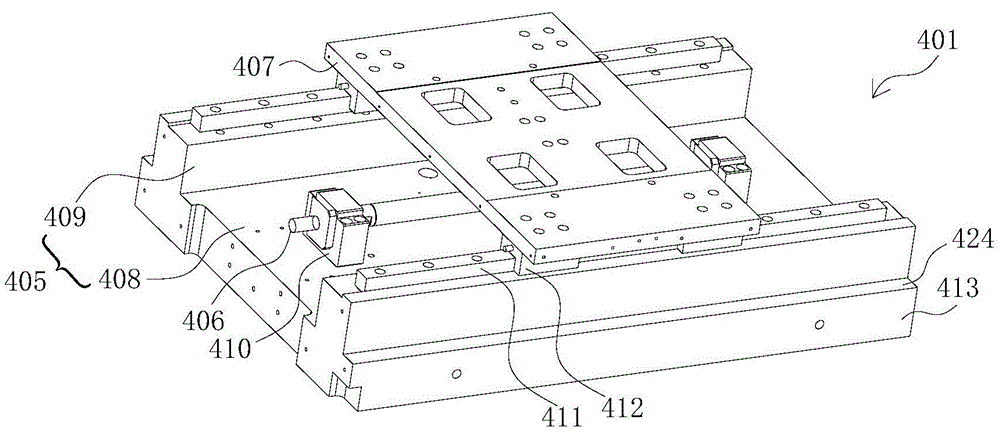

Six-axis five-linkage tool grinding machine

InactiveCN104942686ARealize multi-degree-of-freedom adjustmentFulfill process requirementsGrinding machinesEngineeringMachining

The invention discloses a six-axis five-linkage tool grinding machine which comprises a machine base, a mounting assembly for material mounting and a machining assembly for material machining. The mounting assembly and the machining assembly are arranged on the machine base. The mounting assembly and the machining assembly are oppositely arranged. The machine base comprises a machine base body, the machine base body is provided with a surface, a plurality of mounting holes for fixing the mounting assembly are formed in the surface, and a supporting table for fixing the machining assembly is arranged on the surface in a protruding mode. Convenience is provided for production through the mounting assembly and the machining assembly oppositely arranged on the machine base. An X linear axis component, a Y linear axis component and a Z linear axis component of the mounting assembly are stacked and arranged in a transmission mode, a first rotary shaft component for material clamping is fixed to one linear axis component, and multi-freedom-degree adjustment on the material mounting position can be achieved through linkage of the three linear axis components and the first rotary shaft component. A spindle component for machining is in transmission connection with a second rotary shaft component, the spindle component is controlled through a frequency converter, and multiple workpiece machining needs can be met.

Owner:昆山艾思迪机械科技有限公司

Stay wire type displacement sensor based on absolute coding

ActiveCN110631614ARealize absolute measurementHigh measurement accuracyMeasurement apparatus housingsConverting sensor outputEngineeringAbsolute measurement

The invention provides a stay wire type displacement sensor based on absolute coding. The displacement sensor comprises a shell, a winding unit and a coding unit; the shell is used for installing thewinding unit and the coding unit and plays a role in sealing; the winding unit is arranged in the shell and is used for winding a stay wire; the coding unit is arranged on the shell and the winding unit and is used for acquiring displacement signals. The absolute measurement of the stay wire displacement can be realized, and the application range is wider in comparison with the incremental measurement; the position of the winder can be automatically adjusted along a spline, the relation between the stay wire displacement and the corner of the winder does not need to be corrected in the later period, the measurement precision is high, the coded disc is convenient to process, and high-resolution coding can be realized.

Owner:中远海运港口有限公司 +1

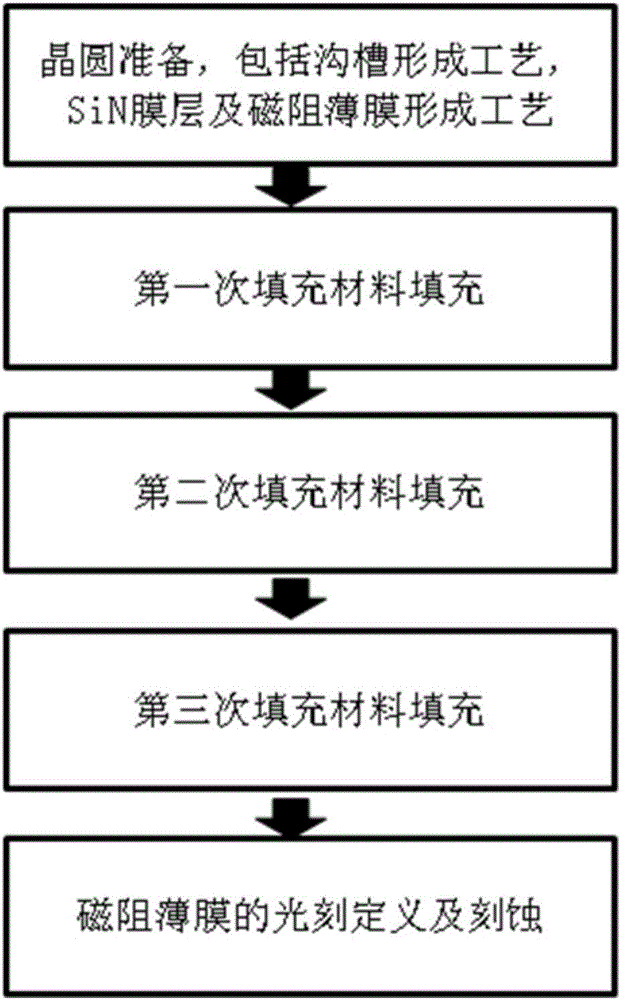

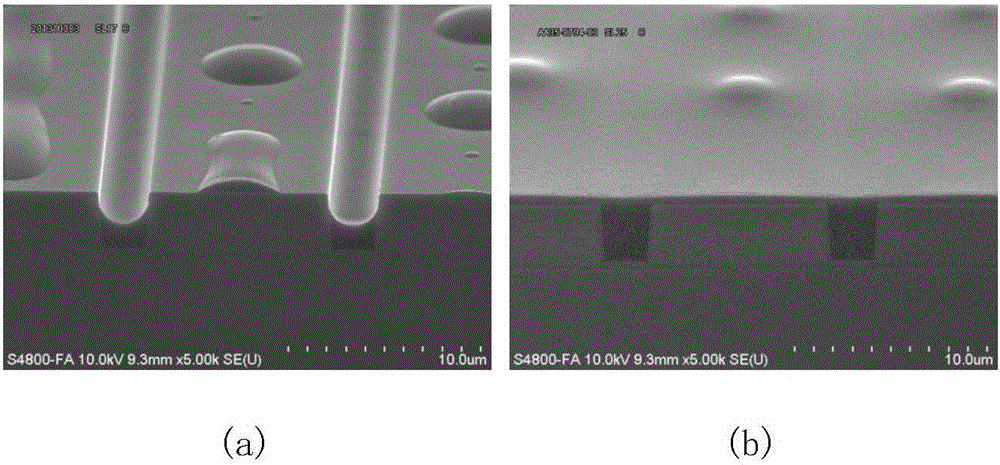

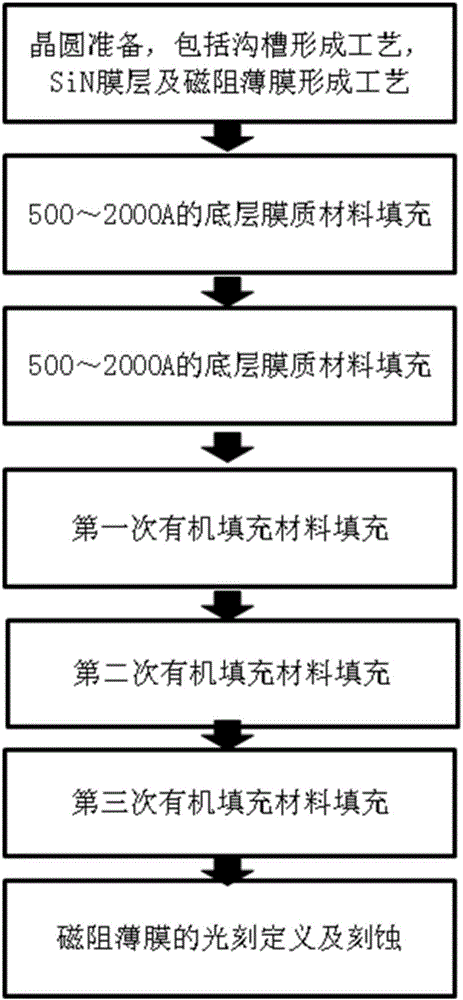

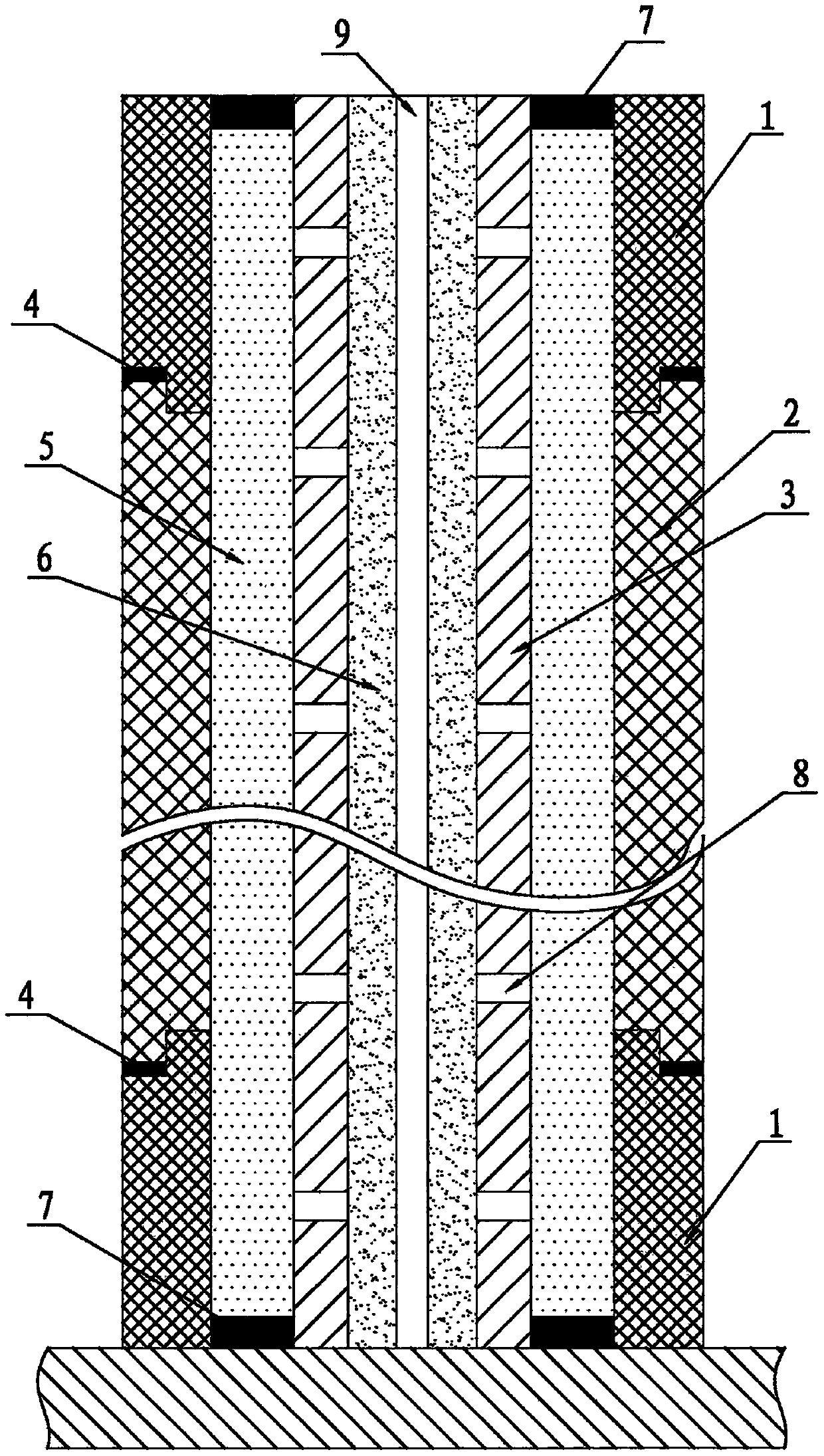

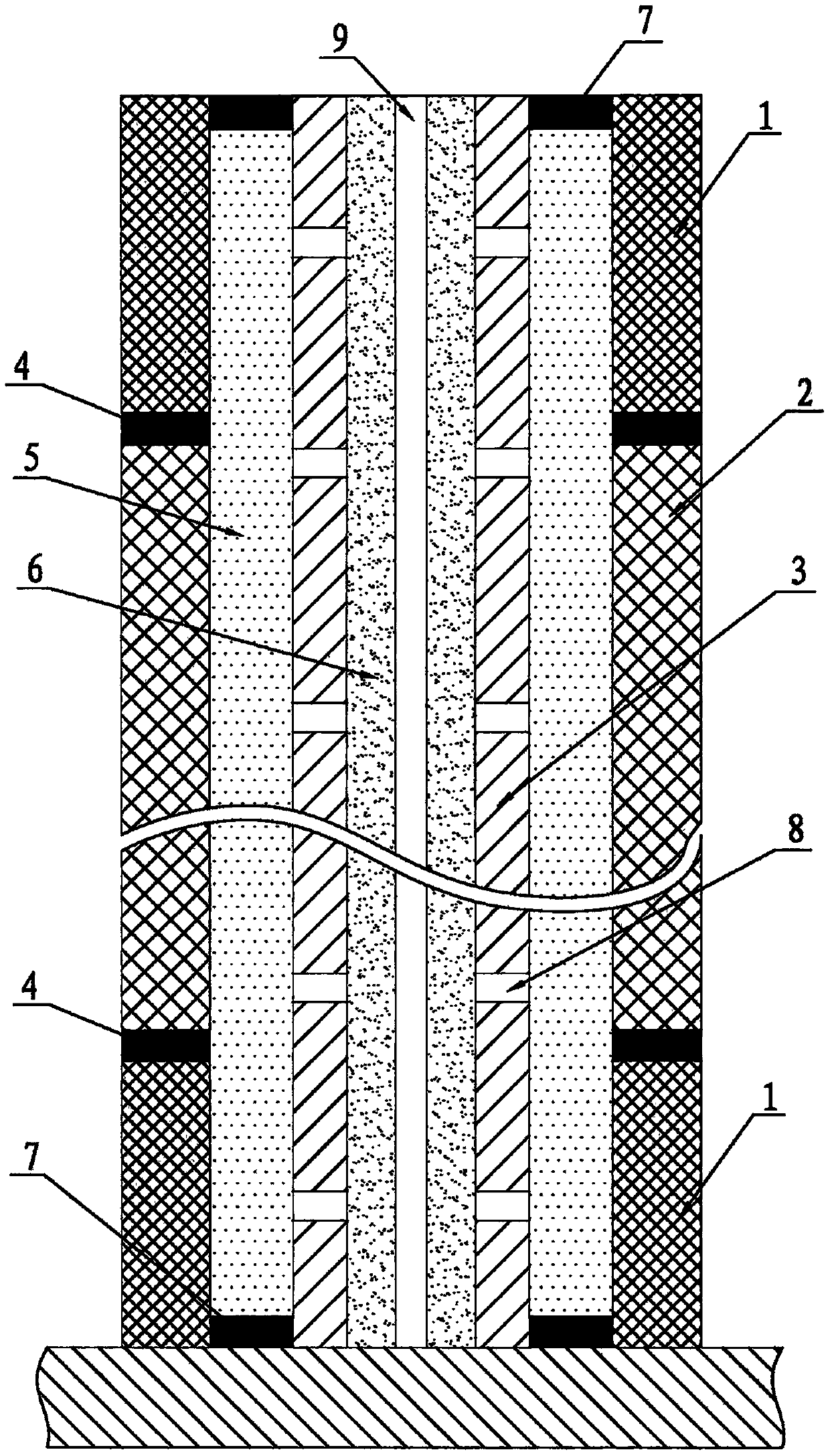

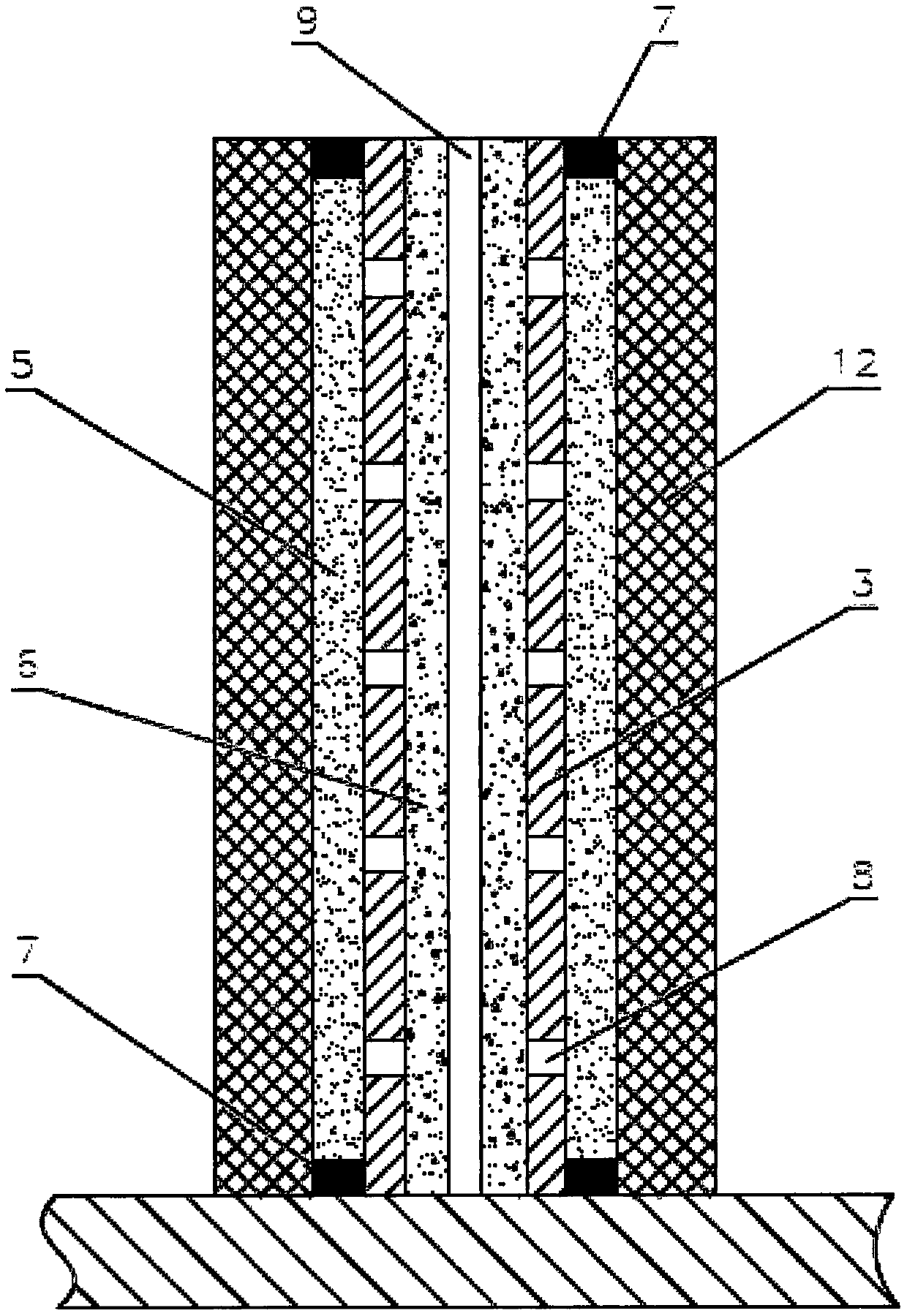

3D AMR groove filling technique

InactiveCN105720190AImprove flatnessProcess requirements to achieve fillingGalvano-magnetic device manufacture/treatmentFilling materialsMagnetoresistance

The invention discloses a 3D AMR groove filling technique, which comprises the following steps: (1) forming a groove and a magnetoresistance film on the surface of a wafer; (2) filling the bottom part of the groove with 500-2,000angstrom underlying membranous material; (3) filling the 500-2,000angstrom underlying membranous material again on the basis of the underlying membranous material filled in the step (2); and (4) filling the underlying membranous material filled in the step (3) with an organic filler material in three steps. By the characteristics of the adhesivity between different materials, the fill capability of the material and the like, the flatness of the wafer surface before pattern definition of the magnetoresistance film in a Z direction is improved by a filling method employing twice underlying membranous material filling and triple material filling, so that normal subsequent magnetoresistance film etching is ensured.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Casting long and thin hole forming sand core structure

InactiveCN109954838AGuarantee the shape qualityReduced dimensional accuracyFoundry mouldsFoundry coresButt jointSteel tube

The invention discloses a casting long and thin hole forming sand core structure. End portion fireproof casing pipes, a transition fireproof casing pipe, a process steel pipe, a casing pipe bonding resin layer, an outer sand core layer, an inner sand core layer and end face sealing layers are included. The transition fireproof casing pipe is arranged between the end portion fireproof casing pipes,the transition fireproof casing pipe and the end portion fireproof casing pipes are in butt joint through the casing pipe bonding resin layer to form a hollow fireproof casing pipe. The process steelpipe is coaxially arranged in an inner hole of the fireproof casing pipe. A ventilation hole is formed in a pipe body of the process steel pipe. The outer sand core layer is arranged between an innerhole of the process steel pipe and the inner hole of the fireproof casing pipe. The inner sand core layer is arranged in the inner hole of the process steel pipe. The end face sealing layers are arranged at the two ends of the outer sand core layer. An air outlet channel is arranged at the center of the inner sand core layer. According to a long and thin casting hole sand core of the structure, the defects that an ordinary sand core is low in surface fireproof degree and is prone to burning losses, burning through, washing damage or washing fracture through high-temperature molten iron can beeliminated, sand discharging and process steel pipe recycling and repeated usage are facilitated, the sand usage amount is small, and the casting cost is low.

Owner:KEHUA HLDG

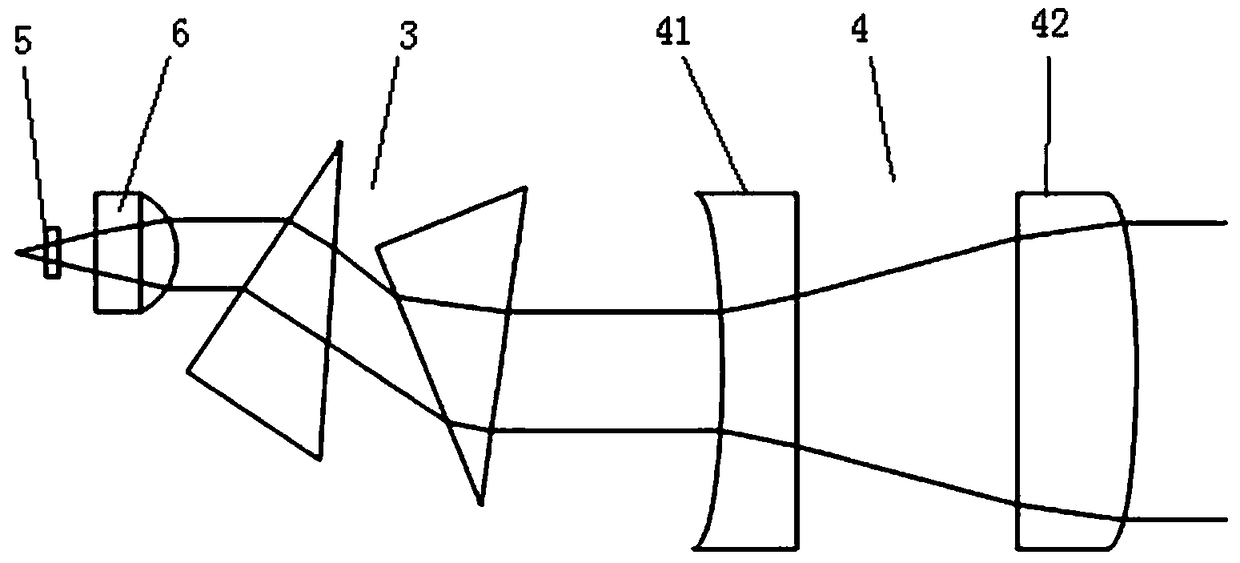

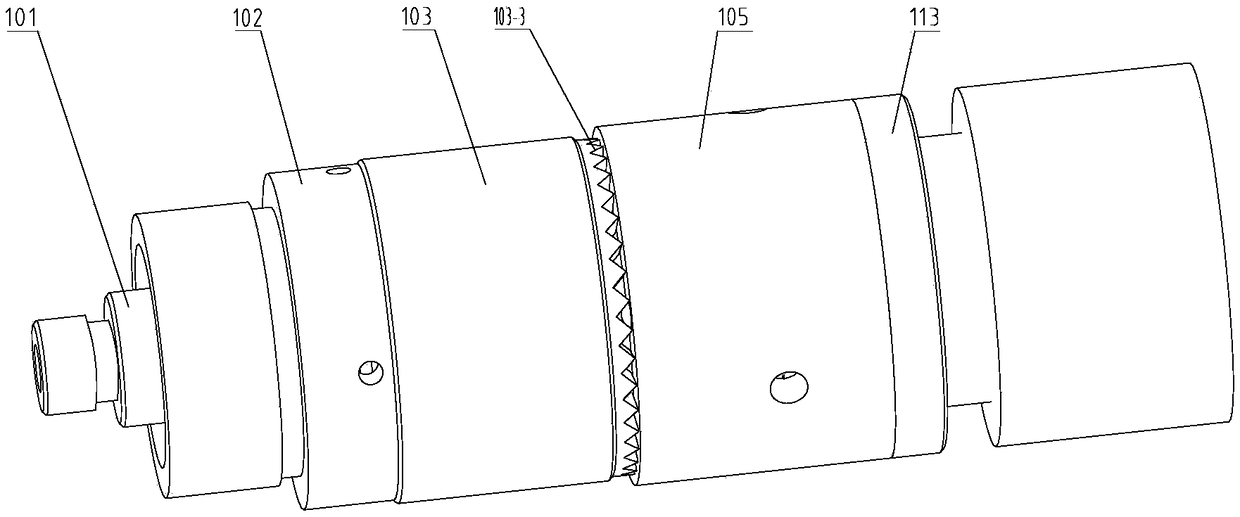

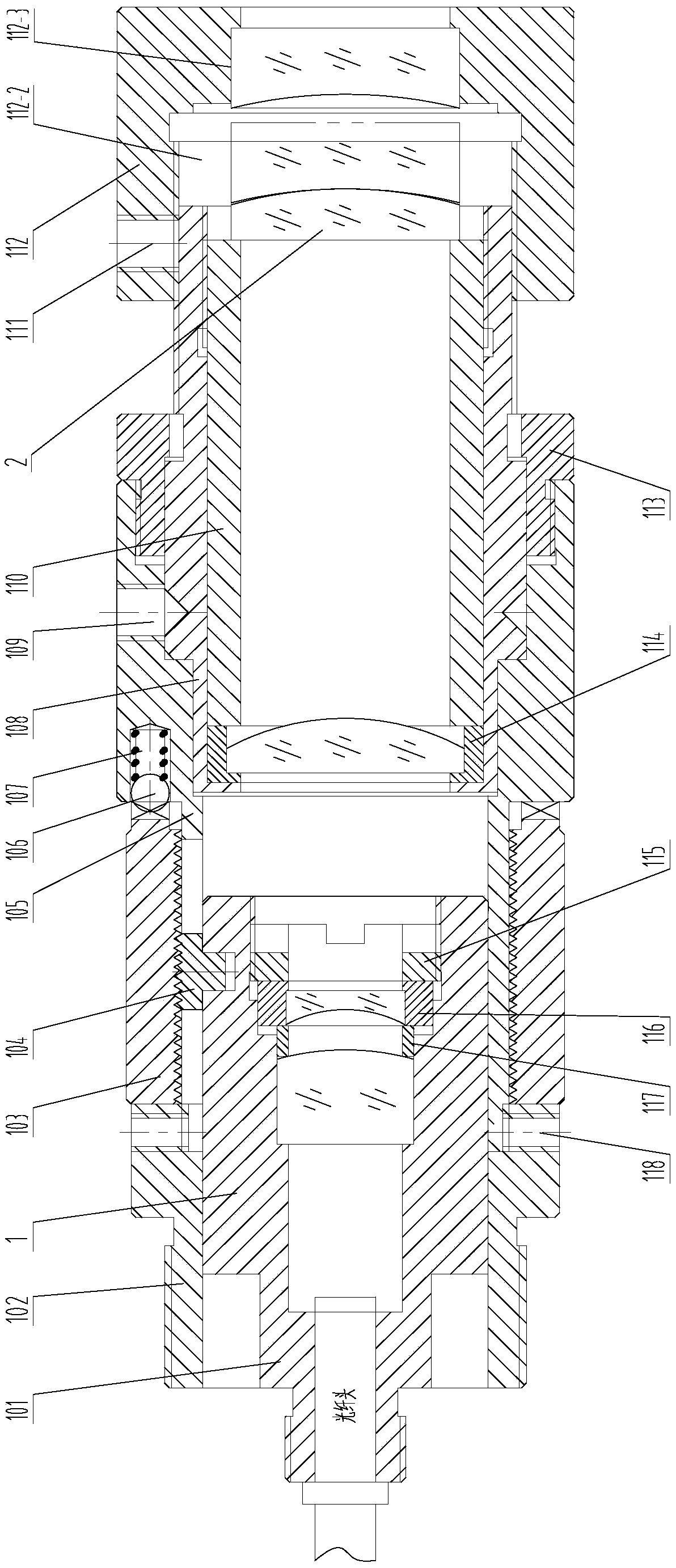

Adjusting device converting circular beam into elliptical beam

ActiveCN109471266ADoes not affect cleanlinessFulfill process requirementsOptical elementsQuality levelEngineering

The invention discloses an adjusting device converting a circular beam into an elliptical beam. The adjusting device comprises an optical part and a mechanical part, one end of an optical fiber is used for connecting optical fiber heads, a first plano-convex lens and a plano-concave cylindrical mirror are installed in an cavity of the optical fiber joint at intervals, the end cover and the fixingsleeve tube sleeve the head of the optical fiber joint, a threaded sleeve tube sleeves the fixing sleeve tube, and the threaded sleeve tube and the optical fiber joint are connected through a T-shapedthread which penetrates through the fixing sleeve tube; a plano-convex cylindrical mirror and a second plano-convex lens are installed in a cavity of an adjusting sleeve tube at intervals, a plano-concave lens is installed in a cavity of a plano-concave lens seat, and the other end of the adjusting sleeve tube is in threaded connection with the plano-concave lens seat. The device has the advantages that the circular beam output by a laser device can be rapidly converted into the elliptical beam, the overall adjustment is simple, the implementation is easy, the production cost can be effectively reduced, the production efficiency can be effectively improved, processing demands on objects of different shapes can be achieved, and the processing quality level is greatly improved.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

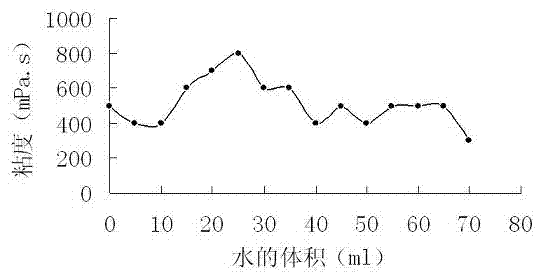

Synthesis of modified aqueous epoxy resin and method for preparing antiseptic rusty paint

ActiveCN101775108BGood water dispersibilityGood storage stabilityAnti-corrosive paintsEpoxyDistilled water

The invention discloses synthesis of modified aqueous epoxy resin and a method for preparing antiseptic rusty paint, relating to synthesis of epoxy resin and a method for preparing paint. The invention solves the problems of the traditional aqueous epoxy resin antiseptic paint that storing stability of base material resin and water resistance and corrosion resistance of an aqueous epoxy resin antiseptic paint coating film can not be met simultaneously. the synthesis method of modified aqueous epoxy resin comprises the steps of: mixing Span 60 with Tween 20, adding E-51; heating and stirring, and dropwise adding distilled water till the system viscosity is suddenly reduced; and finally dropwise adding an initiating agent and a monomer to carry out heating reaction. The method for preparingantiseptic rusty paint comprises the steps of: mixing the modified aqueous epoxy resin, a corrosion inhibitor and a rust preventing agent, stirring and grinding; adding a defoaming agent, a curing agent and deionized water; and stirring the mixture to obtain the modified aqueous epoxy resin antiseptic rusty paint. The invention simultaneously meets the storing stability of the base material resin of the aqueous epoxy resin antiseptic paint and the water resistance and the corrosion resistance of the aqueous epoxy resin antiseptic paint coating film.

Owner:HARBIN INST OF TECH

Fully-automatic glass breaking-off device

ActiveCN107739150ARealize the process requirements of productionFulfill process requirementsGlass severing apparatusOperabilityEngineering

The invention relates to a fully-automatic glass breaking-off device. The fully-automatic glass breaking-off device comprises a breaking-off mechanism, a scrap guiding mechanism, a glass supporting mechanism and a limiting induction mechanism. According to the fully-automatic glass breaking-off device, a whole sheet of glass can be subjected to edge and sheet breaking-off operation, and thus, theprocess requirements on production of glass of small sheets of certain specifications are met; when one edge of the whole sheet of glass is subjected to vertical downward edge breaking-off action, a single edge breaking-off cylinder is used for providing a downward acting force, output power is stable, a cylinder output speed can be rapidly and conveniently regulated, and the edge breaking-off action is reliable; a proximity switch is adopted as a control element for the edge and sheet breaking-off operation, thus, positions, relative to the whole sheet of glass, of cutter blades can be accurately controlled, the glass is subjected to the edge and sheet breaking-off operation after the cutter blades move to proper positions, and thus, the operability is good while the locating accuracy ishigh; glass scraps generated during the edge and sheet breaking-off operation of the glass are subjected to timely collecting treatment through the scrap guiding mechanism, meanwhile, a glass trolleyis ingenious in structural design, and thus, the operability of pouring of the glass scraps by working personnel is improved.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

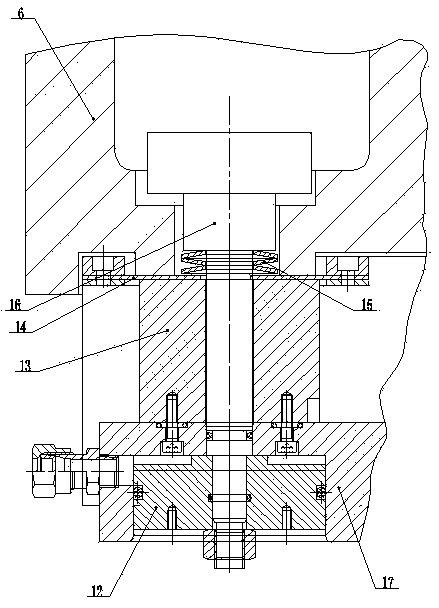

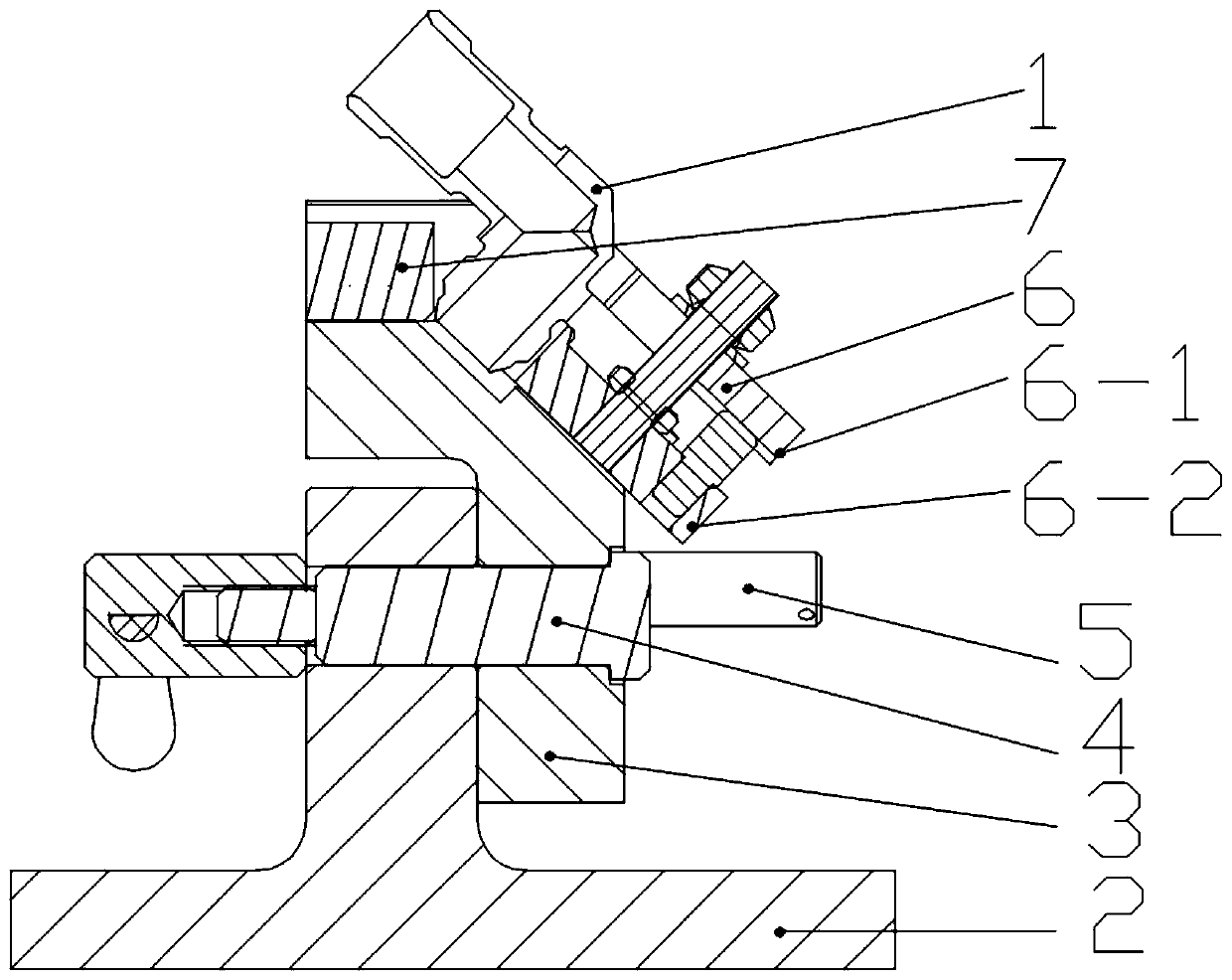

A method for boring a rotary hinge water seal seat using a rotary hinge water seal seat boring device

ActiveCN104325168BFulfill process requirementsGuaranteed machining accuracy requirementsBoring/drilling machinesTransfer systemMechanical engineering

The invention discloses a rotating hinge water seal seat boring device. The rotating hinge water seal seat boring device comprises a power system, a force transfer system and a boring system; the power system comprises a sliding table seat, a sliding table and a boring head, wherein the boring head is connected with the sliding table and slides along the sliding table seat, the boring head is connected with the force transfer system, and the force transfer system is connected with the boring system; the boring system comprises a plurality of support seats, connecting rods, a connecting sleeve and a boring rod, wherein a radial adjusting mechanism is arranged on each support seat, the boring rod corresponds to an axial hole to be bored, and the two ends of the boring rod are respectively, coaxially and rotatably connected with the radial adjusting mechanism on each support seat; every two adjacent support seats are respectively and rotatably connected through the connecting rod. The invention also discloses a method for boring a rotating hinge water seal seat by using the boring device. The boring device and the boring method are simple in structure and convenient to use, the coaxiality of each hinge axle hole of the rotating hinge water seal seat is ensured by means of the coaxiality of the support seats, and the machining precision requirement can be met.

Owner:SINOHYDRO BUREAU 12 CO LTD

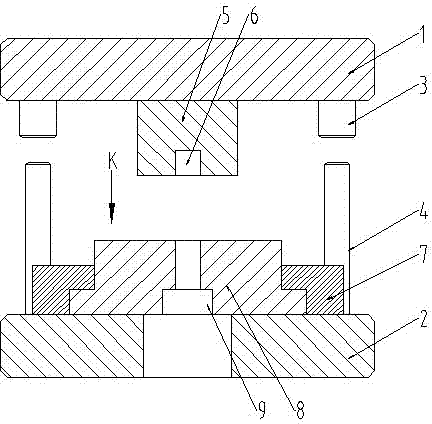

Hot-upset mold

InactiveCN104759570ATo achieve the purpose of upsetting and pressing out different shapesFulfill process requirementsForging/hammering/pressing machinesPush pullMaterials science

The invention discloses a hot-upset mold. The hot-upset mold comprises an upper template and a lower template, wherein the upper template and the lower template are guided through a guide sleeve and a guide column component; an upper mold is fixed on the upper template; a blind hole for positioning a rod material is formed in the end part of the upper mold; a slide way is fixed on the lower template; a lower mold is in guide connection with the slide way; a molding cavity is formed in the lower mold; a push-pull handle is arranged on the lower mold; a material return opening is formed in the lower template; when the lower mold is located in a pull-out state, a hot-upset workpiece can drop down from the material return opening; the lower mold and the lower template are formed to the closed molding cavity to guarantee the filling of metal totally according to the appearance of the molding cavity, so that the purpose of upsetting different shapes at the end part of the rod material is achieved; the hot-upset mold is simple in structure and convenient to operate, saves the time, can realize the requirements of machining different shapes at the end part of the rod material, and reduces the manufacturing cost.

Owner:HUBEI XINGYUAN SCI & TECH

Automatic rust removal spraying system and method for turnout steel rail

PendingCN114472042AReasonable structure layoutMeet the requirements of paintingPretreated surfacesAbrasive machine appurtenancesMetallurgySurface cleaning

The invention relates to an automatic rust removal and spraying system and method for a turnout steel rail. The system comprises a conveying line, a saw steel rail surface rust removal shot blasting machine, a surface cleaning device, a paint spraying room, a drying room, a waste gas treatment device, a steel rail transplanting mechanism and a discharging mechanism. The method comprises the steps that (1) a steel rail workpiece is placed on a feeding conveying line; (2) the steel rail is conveyed into a saw steel rail surface rust removal shot blasting machine to be subjected to shot blasting and rust removal treatment; (3) conveying into a surface cleaning device for deep cleaning through a surface derusting and cleaning conveying line; (4) carrying into a paint spraying room for paint spraying; (5) the steel rail workpieces are conveyed into a drying room to be dried, and then the dried steel rail workpieces are conveyed to a discharging conveying line through a steel rail transplanting mechanism; and (6) discharging by a discharging mechanism. Rapid rust removal and full-section coating of the surface of the steel rail can be achieved, the derusted steel rail can reach a certain degree of finish, the good rust removal effect is achieved, the coating requirement of the steel rail is met, and the coated steel rail can reach a certain anti-corrosion effect and meet the technological requirement.

Owner:CHINA RAILWAY BAOQIAO (NANJING) CO LTD +2

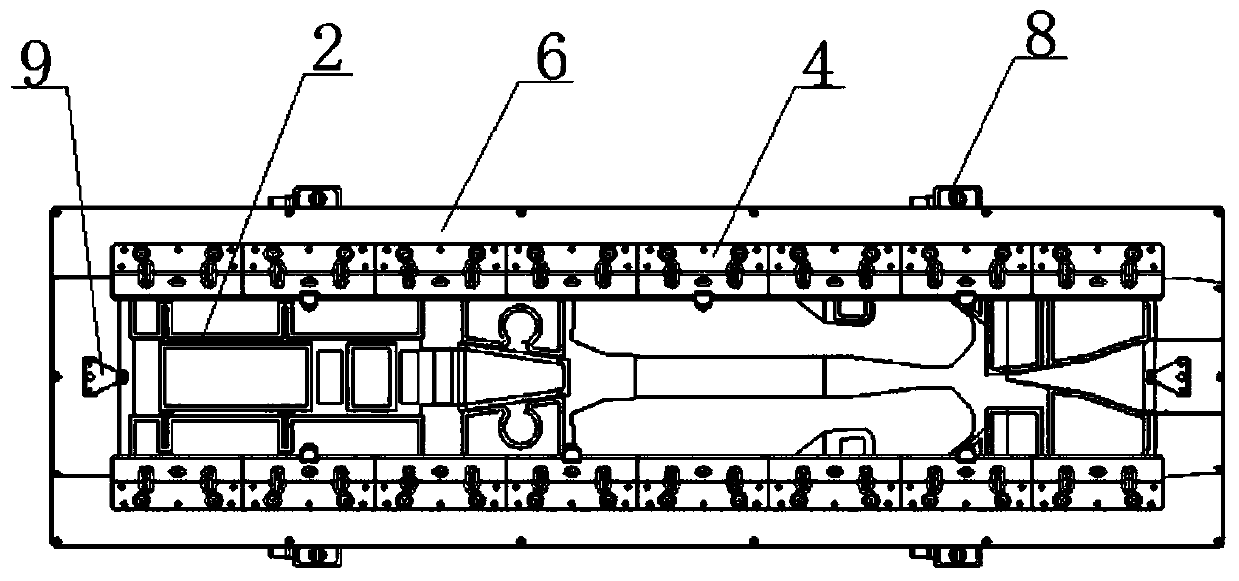

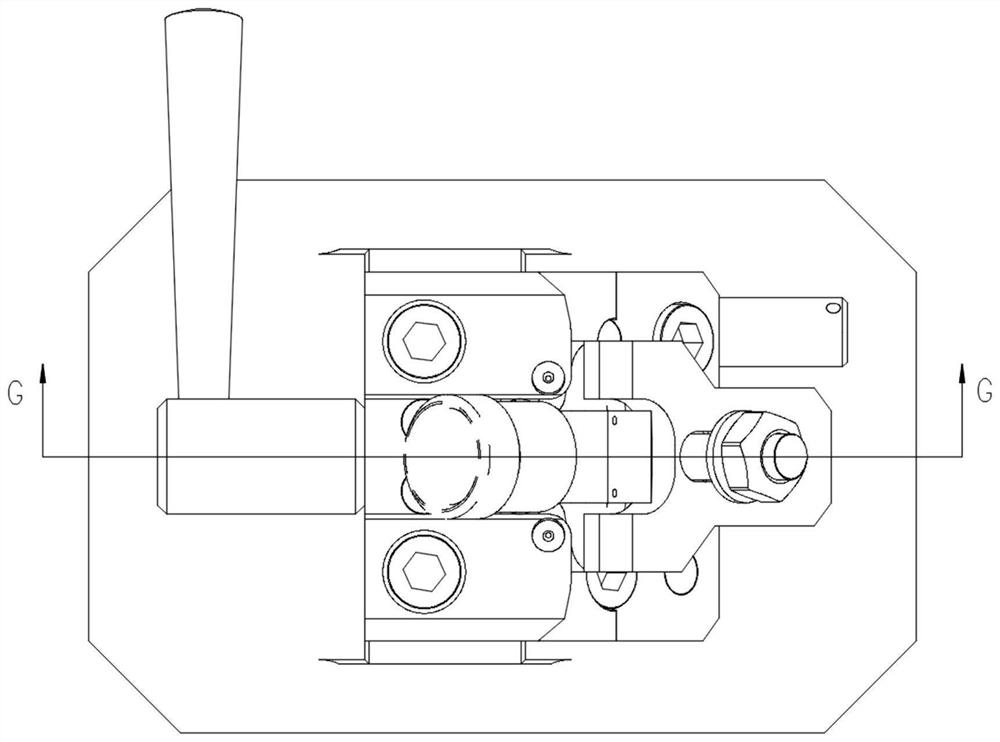

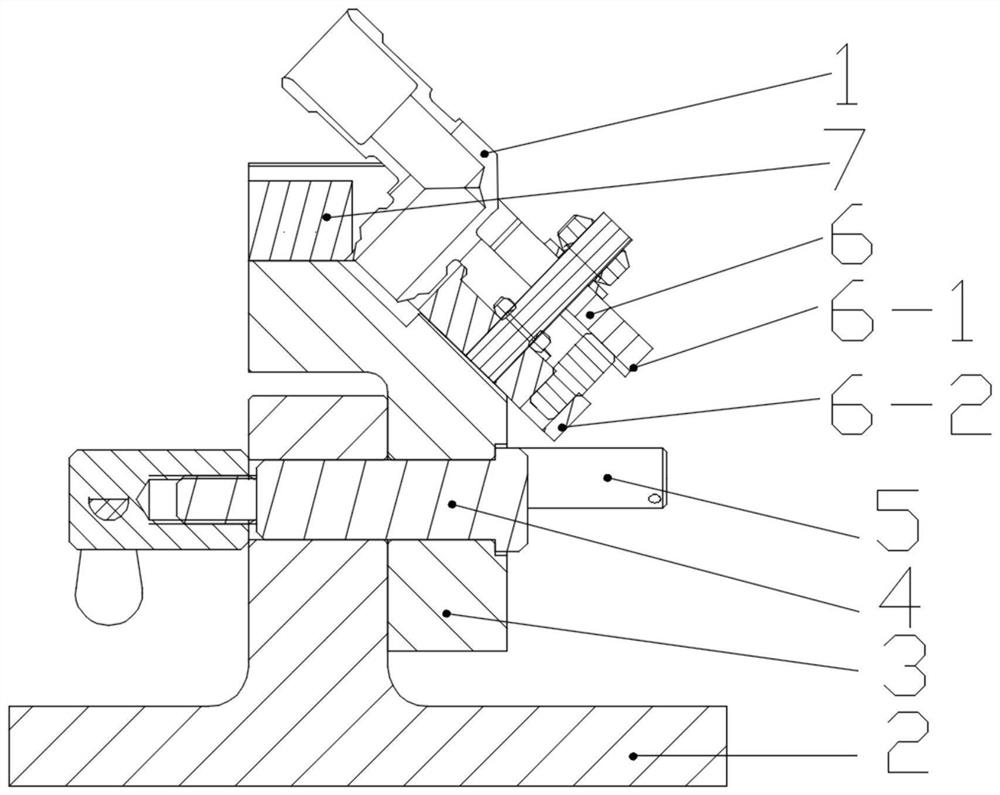

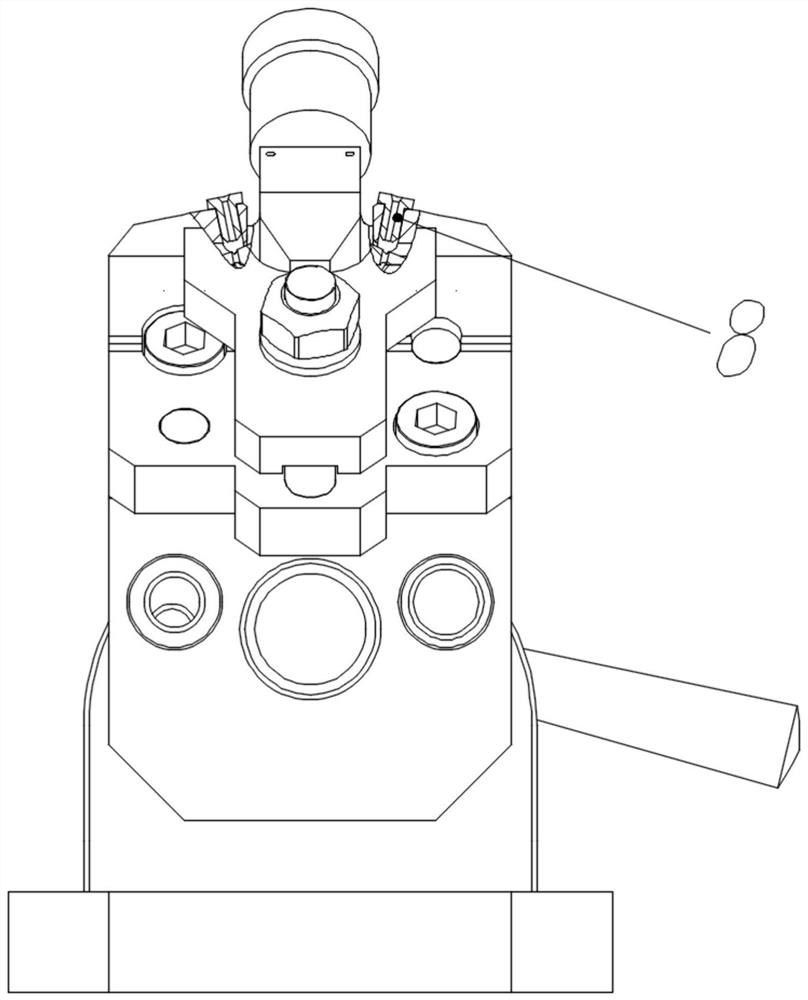

Clamp for multi-angle drilling

The invention relates to a clamp for multi-angle drilling. The clamp comprises a base, a rotating support and a pressing mechanism, wherein the rotating support comprises a rotating base, a plug pin,a drill plate and a rotating shaft, the rotating shaft sequentially penetrates through the rotating base and the base and can rotate around the rotating base, the other end of the rotating shaft is connected with a handle, the drill plate is installed on the rotating base, a through hole corresponding to a hole to be machined is formed on the drill plate, a pressing mechanism comprises a pressingblock I, a pressing block II and a supporting block, a screw sequentially penetrates through the pressing block I and the pressing block II to fix the pressing block I and the pressing block II on anupper inclined surface of the rotating base, a positioning groove is formed on the pressing block II, the supporting block is placed in the positioning groove to support the pressing block I, an anglehole with the same angle as a to-be-machined hole of a machined workpiece is formed in the rotating base, a through hole corresponding to the angle hole is formed in the base, and a plug pin is inserted into the corresponding angle hole and the through hole to achieve rapid positioning of the angle. The clamp can reduce dependence of a pipe on numerical control equipment, improve machining efficiency and simplify operation steps.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

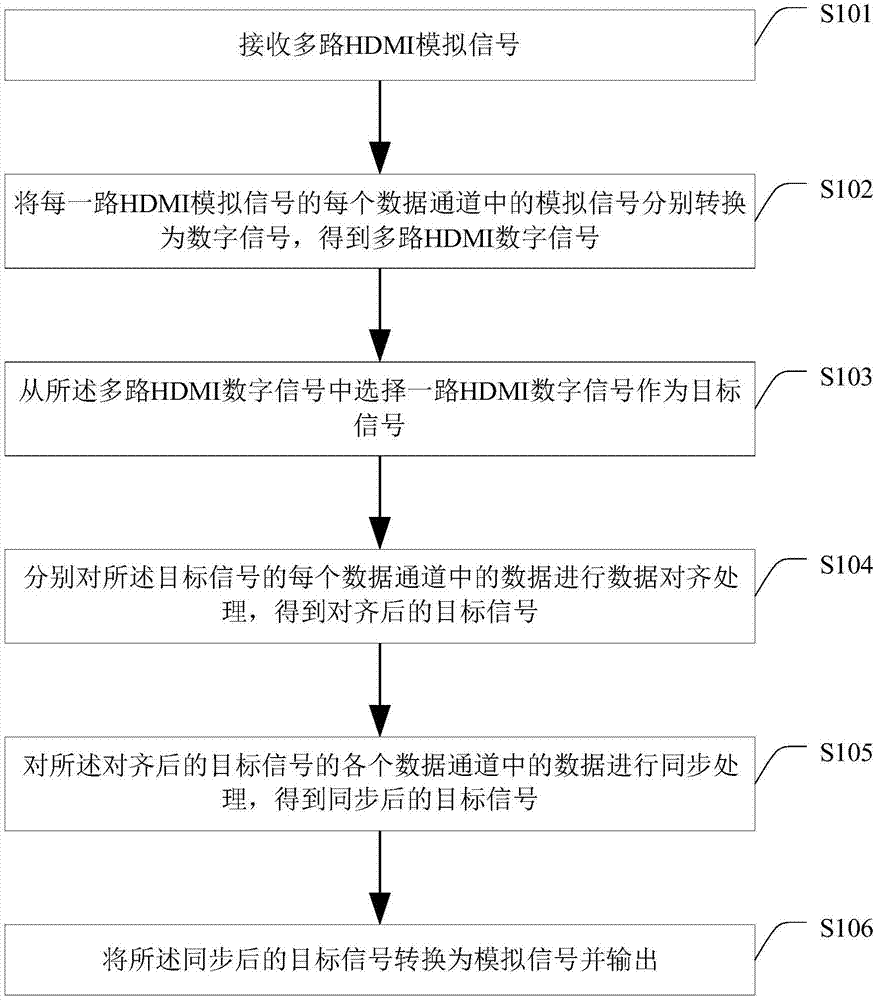

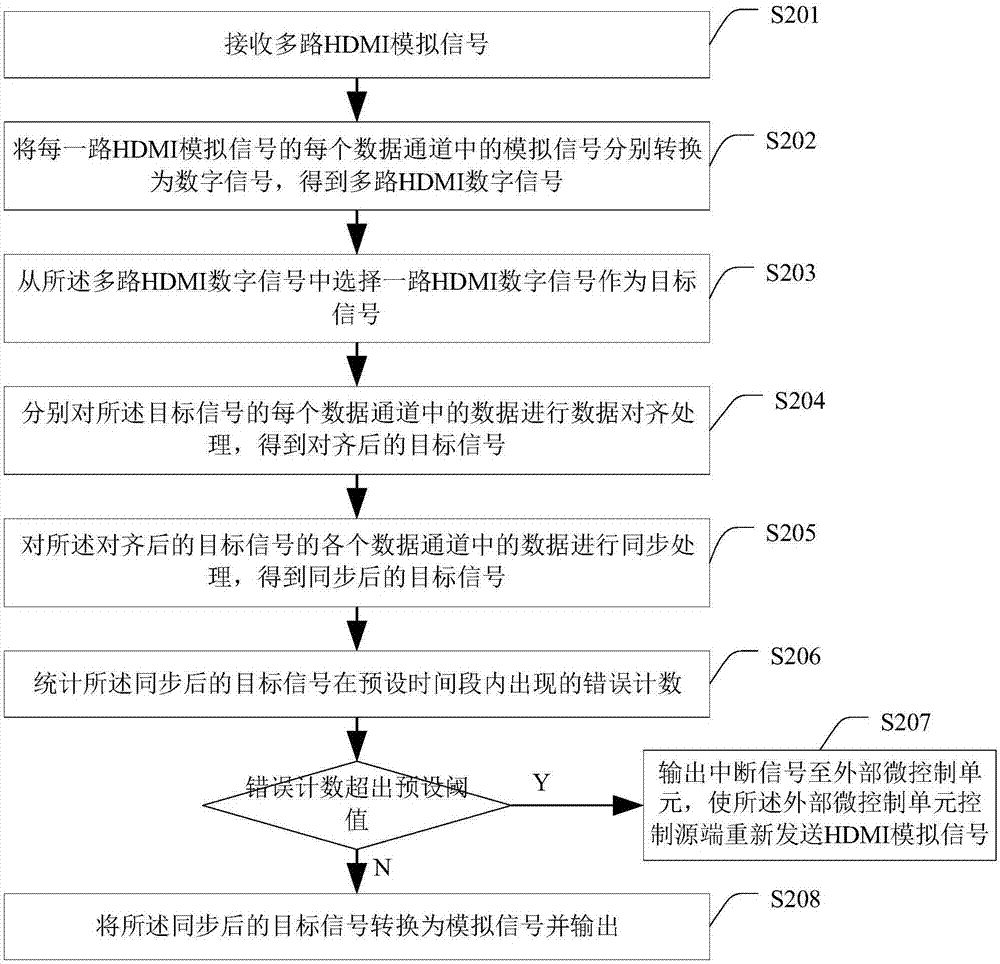

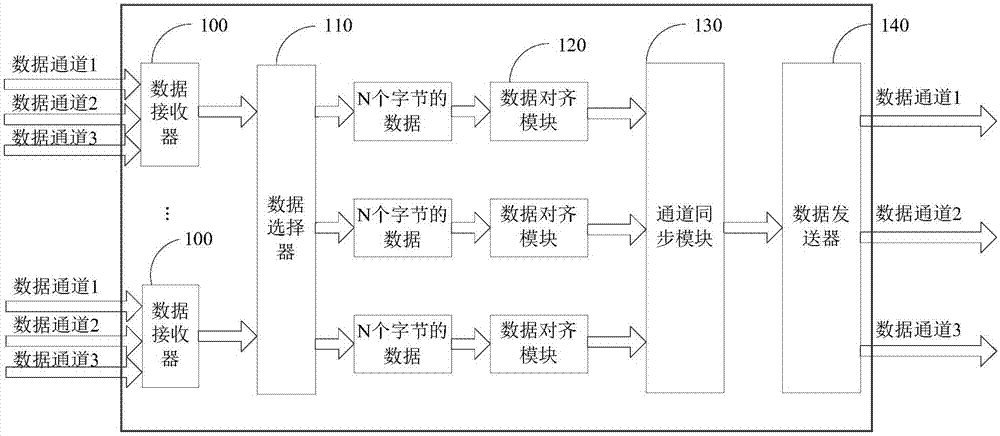

Signal switching method and system

InactiveCN107483862AReduce the digital clock frequencyReduce processing requirementsTelevision system detailsColor television detailsHDMITarget signal

The invention provides a signal switching method. The method comprises the following steps: receiving multiple HDMI analog signals; respectively converting an analog signal in each data channel of each HDMI analog signal into a digital signal so as to obtain multiple HDMI digital signals; selecting one HDMI digital signal from multiple HDMI digital signals as a target signal; performing data alignment processing on the data in each data channel of the target signal to obtain an aligned target signal; performing synchronization processing on the data in each data channel of the aligned target signal to obtain a synchronized target signal; converting the synchronized target signal into an analog signal to output. By using the signal switching method provided by the invention, the convenient high-definition signal switching processing can be realized under low technological level.

Owner:LONTIUM SEMICON CORP

A jig for multi-angle drilling

ActiveCN110961696BGuaranteed positioning accuracyFulfill process requirementsDrill jigsNumerical controlRotational axis

The invention relates to a fixture for multi-angle drilling, which includes a base, a rotating support, and a pressing mechanism. The rotating support includes a rotating base, a bolt, a drilling template, and a rotating shaft. The rotating shaft passes through the rotating base and the base in sequence. , the rotating seat can rotate around the rotating shaft, the other end of the rotating shaft is connected with a handle, the drilling template is installed on the rotating seat, and a through hole corresponding to the hole to be processed is opened on it; the pressing mechanism includes a pressing block 1, pressing Block 2 and the support block, the screws pass through the compression block 1 and the compression block 2 in turn to fix them on the inclined surface of the swivel seat, the compression block 2 is provided with a positioning groove, and the support block is placed in the positioning groove to support the compression block 1. An angle hole with the same angle as the hole to be processed is opened on the rotating base, and a corresponding through hole is opened on the base, and the fast positioning of the angle is realized by inserting the corresponding angle hole and through hole through the plug. The invention can reduce the pipe's dependence on numerical control equipment, improve processing efficiency and simplify operation steps.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com