Conjugate cam connecting rod combination packing mechanism

A combination technology of conjugate cams and connecting rods, which is applied in packaging, packaging bottles, mechanical equipment, etc., can solve the problems of easy bottle shortage, low working reliability, and affecting production efficiency, so as to achieve compact structure and meet the requirements of packaging. The effect of box work requirements and flexible box work requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

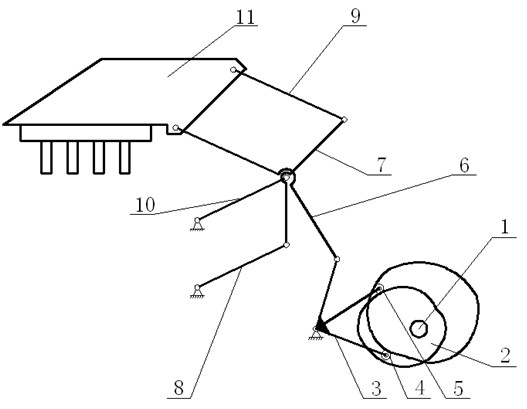

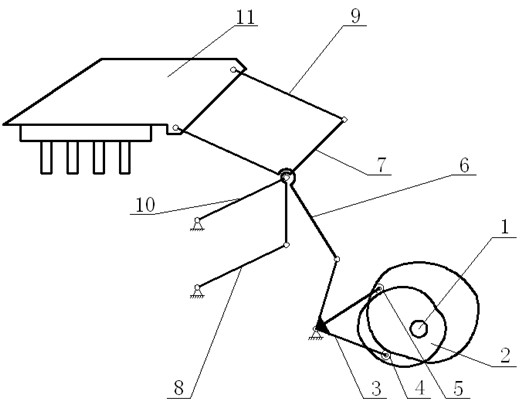

[0014] Such as figure 1 As shown, the power is transmitted to the camshaft 1 installed on the frame, and the conjugate cam 2 is fixedly connected to the camshaft 1; the bottom end of the fork-shaped swing rod 3 is hinged to the frame, and the first roller 4 and the second roller 5 are respectively hinged with the split end of the fork-shaped swing rod 3, the split end of the fork-shaped swing rod 3 is connected with a cam in the conjugate cam 2 through the first roller 4 as a cam pair, and the split end of the fork-shaped swing rod 3 The fork end is connected with another cam in the conjugated cam 2 by the second roller 5; The middle part of the first connecting rod 6 is hinged, the two ends of the second connecting rod 7 are respectively hinged with one end of the third connecting rod 8 and one end of the fourth connecting rod 9, and the other end of the third connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com