Composite material machine body skin integral forming tool and technology

A technology of integral molding and skinning of the fuselage, which is applied to other household appliances, household components, household appliances, etc., can solve problems such as weak bonding, honeycomb instability, and upper panel depression, so as to ensure the molding quality and reduce the difficulty of manufacturing , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

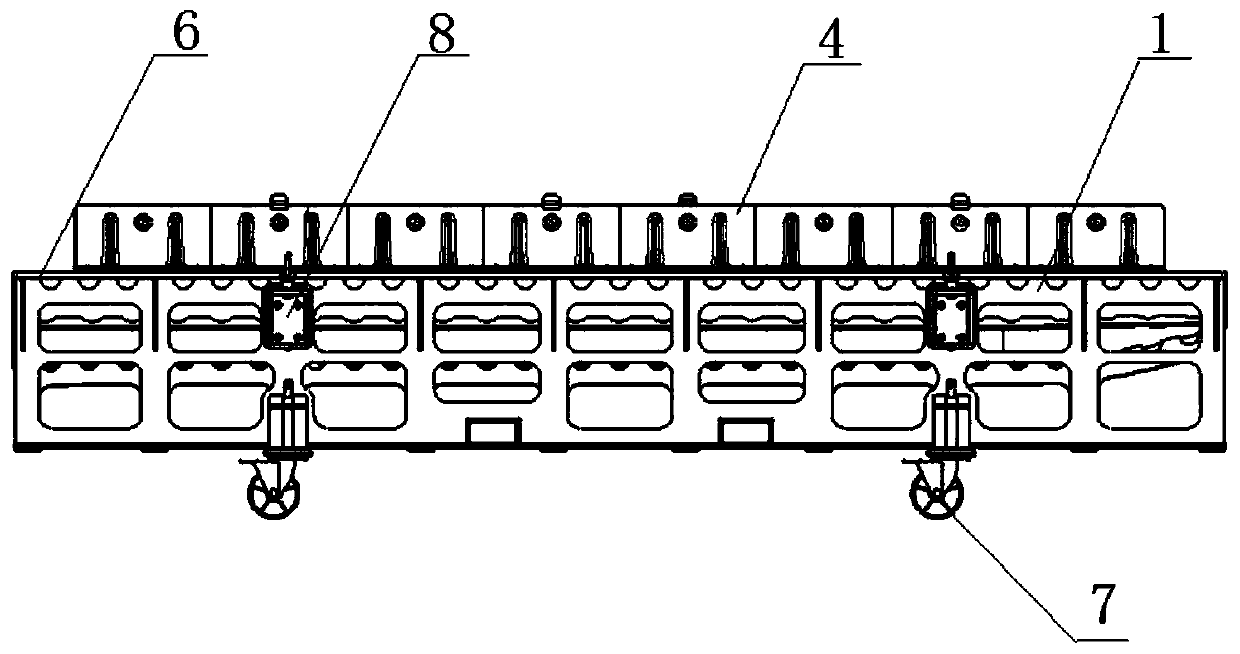

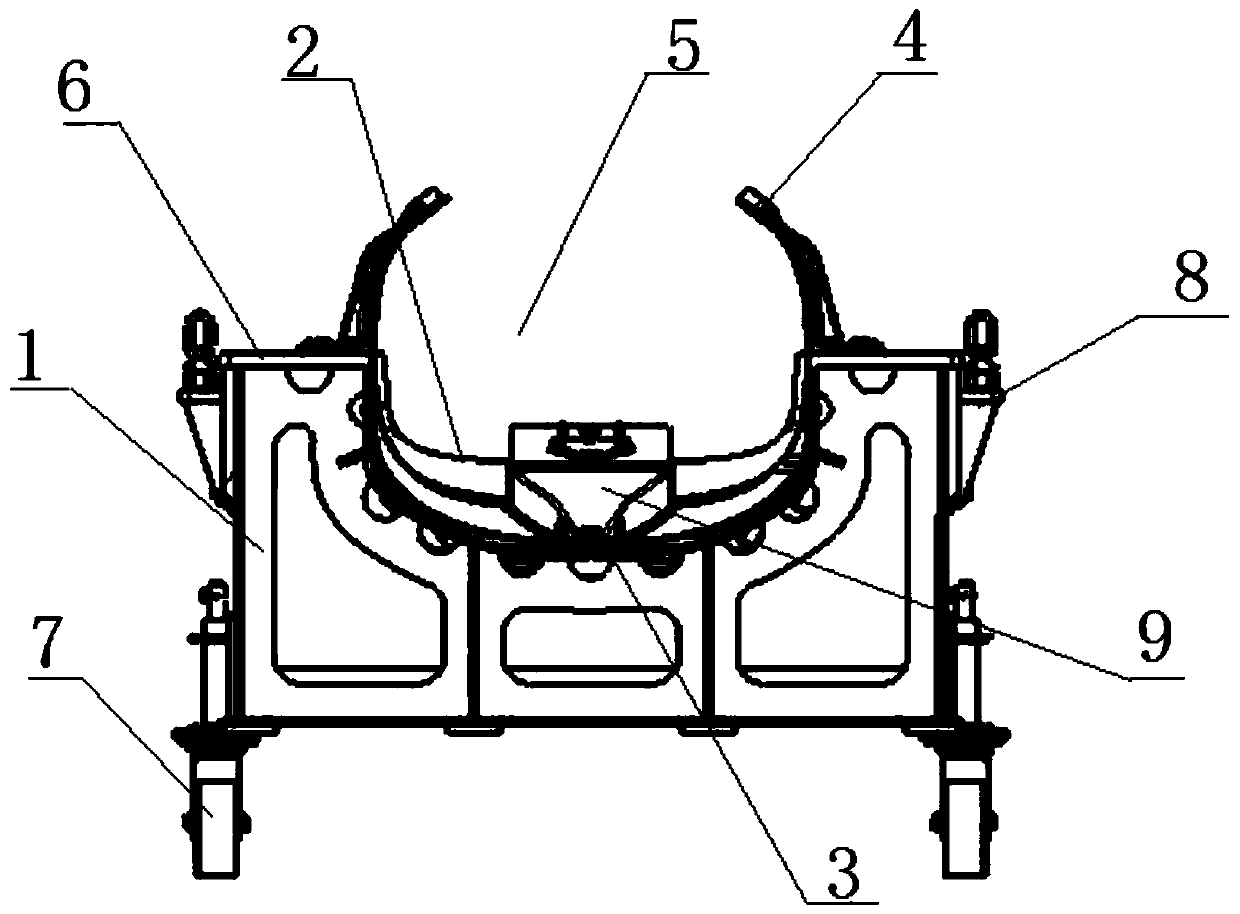

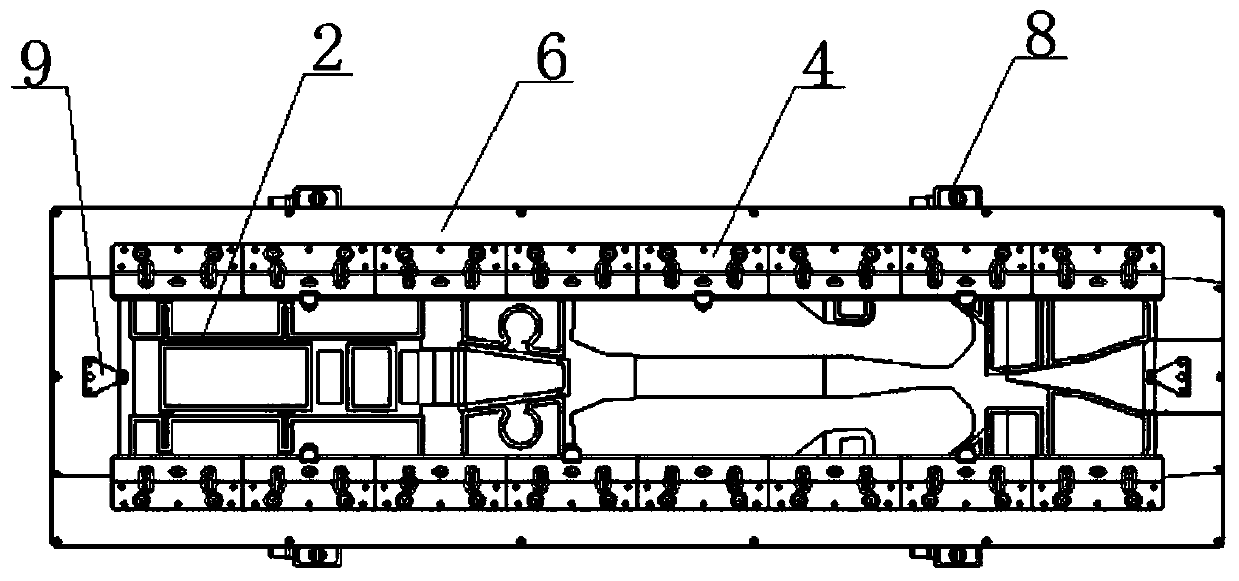

[0036] Figure 1 to Figure 4 Shown is a composite fuselage skin overall molding tooling provided by the present invention, including a frame 1 and a tooling plate 2; two opposite surfaces of the frame 1 are provided with installation grooves 3, and the two installation grooves 3 are relatively arranged, and the two ends of the tooling plate 2 are fixedly fixed on the two installation grooves 3; the upper surface of the frame 1 is also equipped with two groups of detachable blocks 4, and the two groups of detachable blocks 4 are respectively Located on both sides of the tooling pattern 2, the inner surfaces of the two groups of detachable blocks 4 and the working surface of the tooling pattern 2 form a continuous surface, and the two groups of detachable blocks 4 and the tooling pattern 2 form a curing chamber 5.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com