3D AMR groove filling technique

A process method and trench filling technology, applied in the field of 3DAMR trench filling process, can solve the problems affecting etching, uplift, etc., and achieve the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

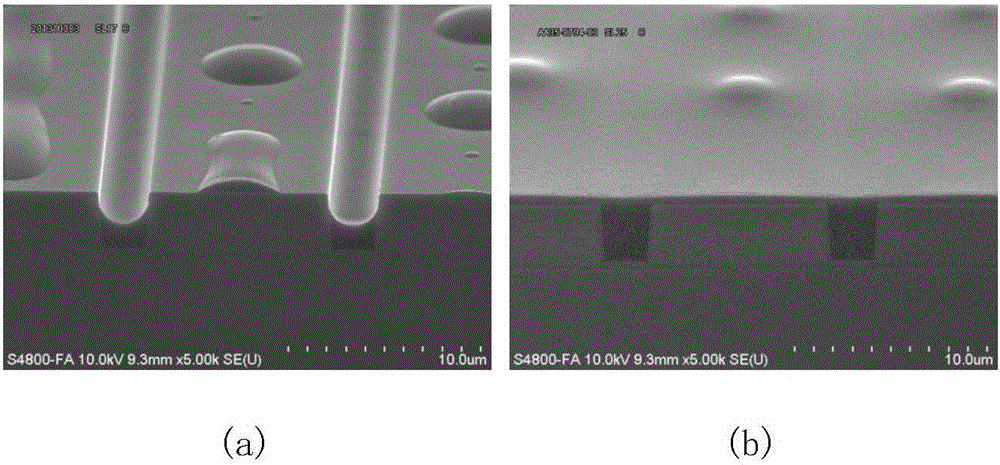

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a more specific understanding of the technical content, characteristics and effects of the present invention, now in conjunction with the accompanying drawings, the present invention is described in detail as follows:

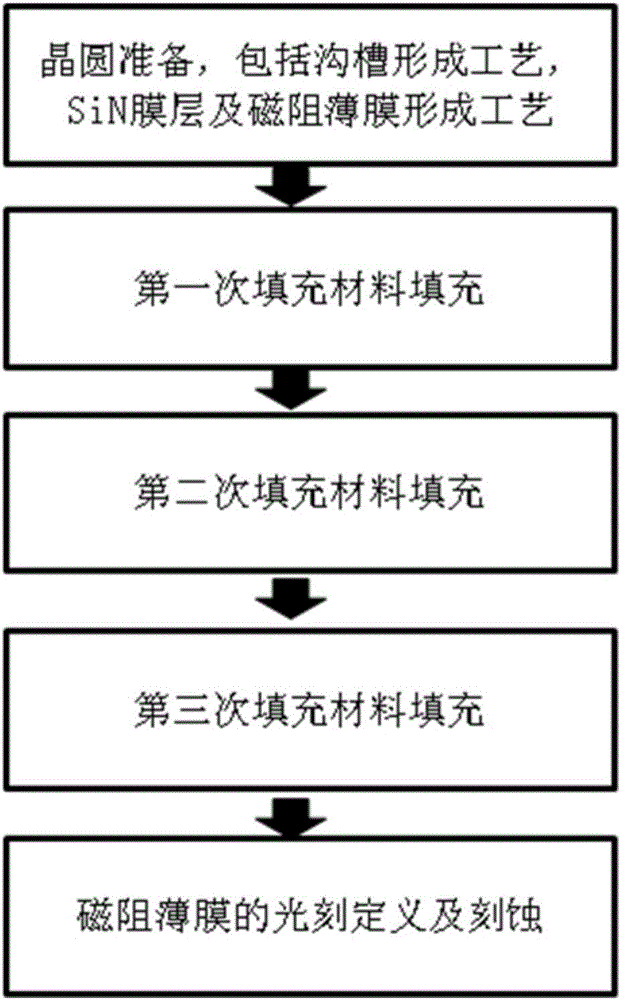

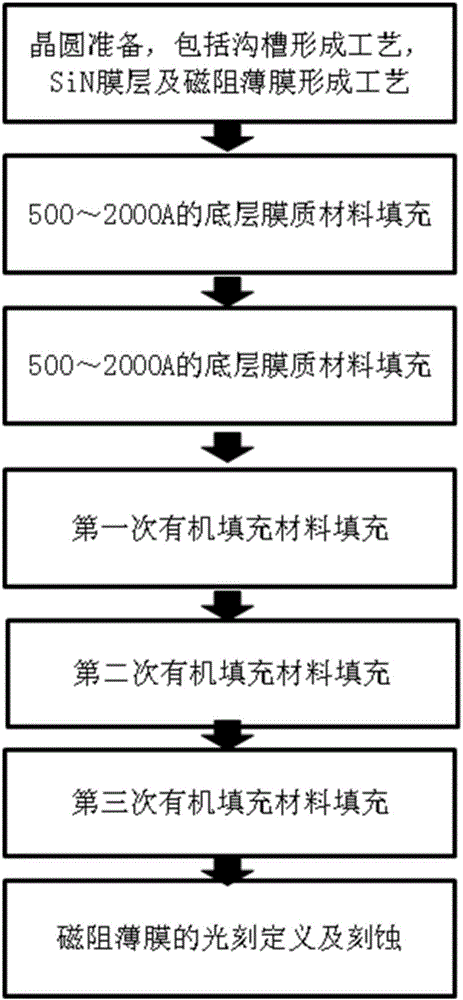

[0023] 3DAMR trench filling process method of the present invention, such as image 3 As shown, it specifically includes the following steps:

[0024] Step 1, wafer preparation: etching to form grooves, and forming SiN film layer and NiFe / TaN magnetoresistive film through SiN deposition process and magnetoresistive film forming process.

[0025] Step 2, fill in the bottom of the trench The underlying membranous material. The underlying film material can be a commonly used BARC (bottom anti-reflection layer) organic material (a type of photoresist).

[0026] The underlying film material is required to have strong adhesion to the wafer surface, and its thickness is usually

[0027] Step 3, on the basis of the underlying membrane mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com