Large linkage digital control rotation equipment for bolt drawing machine

A stretching machine and large-scale technology, applied in the field of machinery, can solve the problem that the rotary table cannot process large workpieces, and achieve the effect of achieving precise processing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

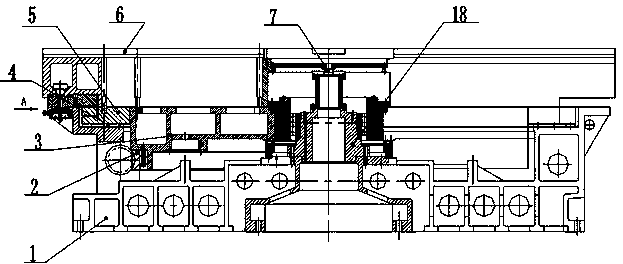

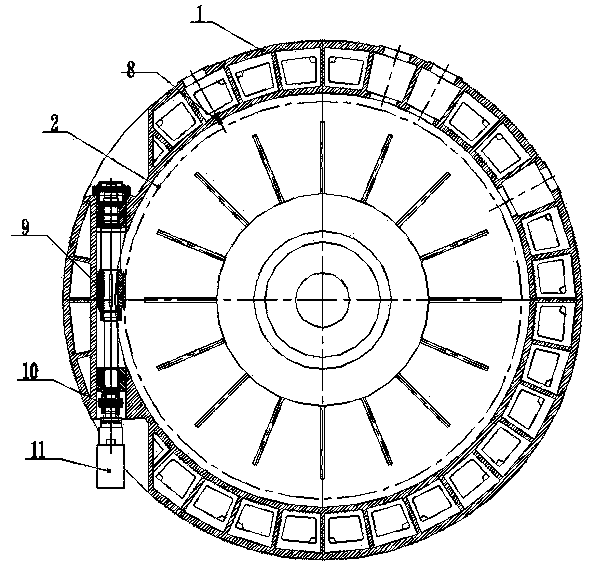

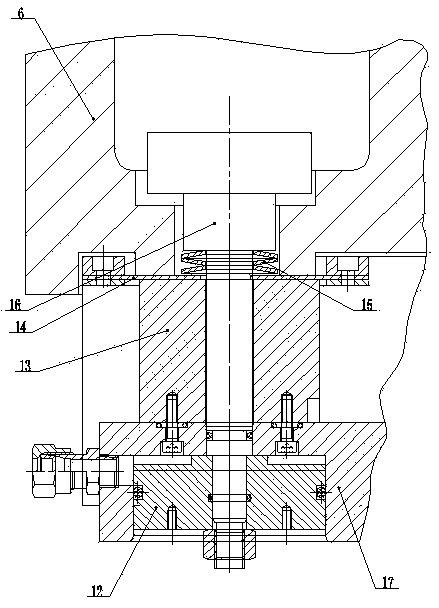

[0011] For better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: The large-scale linkage numerical control rotary equipment for bolt tensioning machines includes a body 1, a main shaft 18 and a sensor 8 are arranged on the main body 1, and a worm gear is installed on the main shaft 18. 2. The worm wheel 2 meshes with the worm 9. The uppermost end of the body 1 is equipped with a workbench 6. The worm 9 is connected to the servo motor 11 through a coupling 10. The worm 9 is a double-pitch gradually thicker worm. The worm wheel 2 is fixed with a worm hub 3 , the worm wheel hub 3 is fixedly connected with the workbench 6, the encoder 7 is installed on the workbench 6, the guide rail 5 is installed at the lower end of the workbench 6, the wear-resistant plate 4 is installed between the guide rail 5 and the body 1, and the workbench 6 is evenly distributed There are 12 pairs of brake pads 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com