A jig for multi-angle drilling

A multi-angle, fixture technology, applied in the direction of drilling dies for workpieces, etc., can solve the problems of manufacturing error benchmark conversion, difficulty in adjusting the angle of the fixture, and a small number of numerical control equipment, so as to control costs, reduce operation difficulty, and meet processing needs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

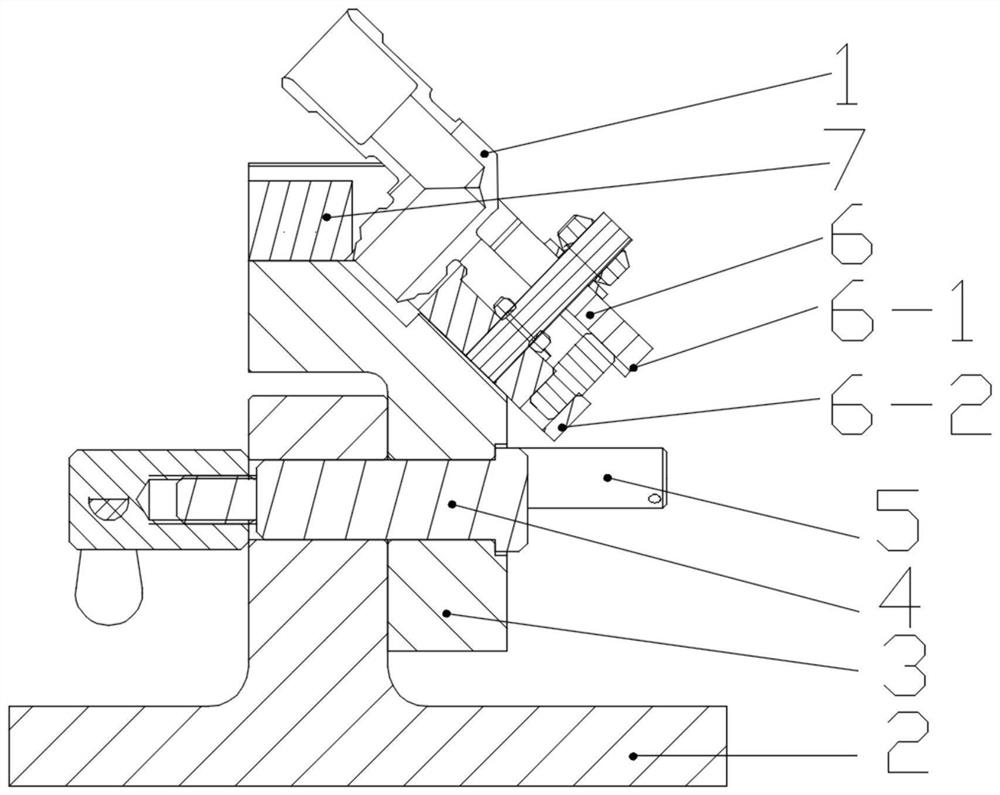

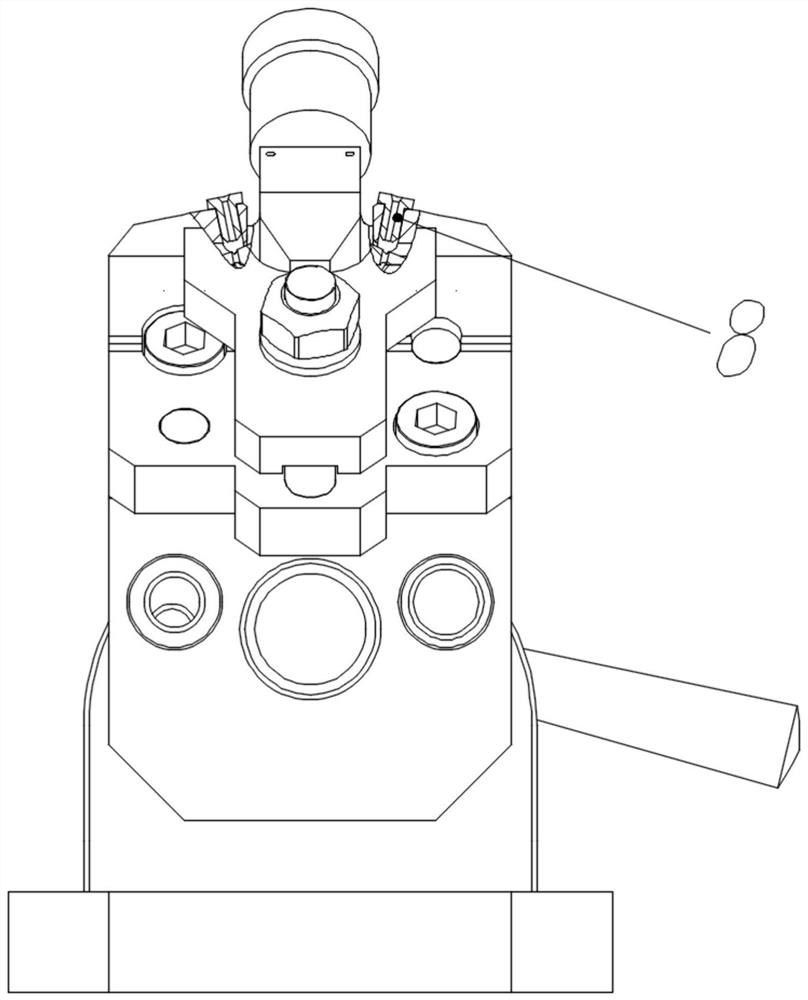

[0014] In order to better explain the present invention and facilitate understanding, the technical solutions and effects of the present invention will be described in detail below through specific implementation manners in conjunction with the accompanying drawings.

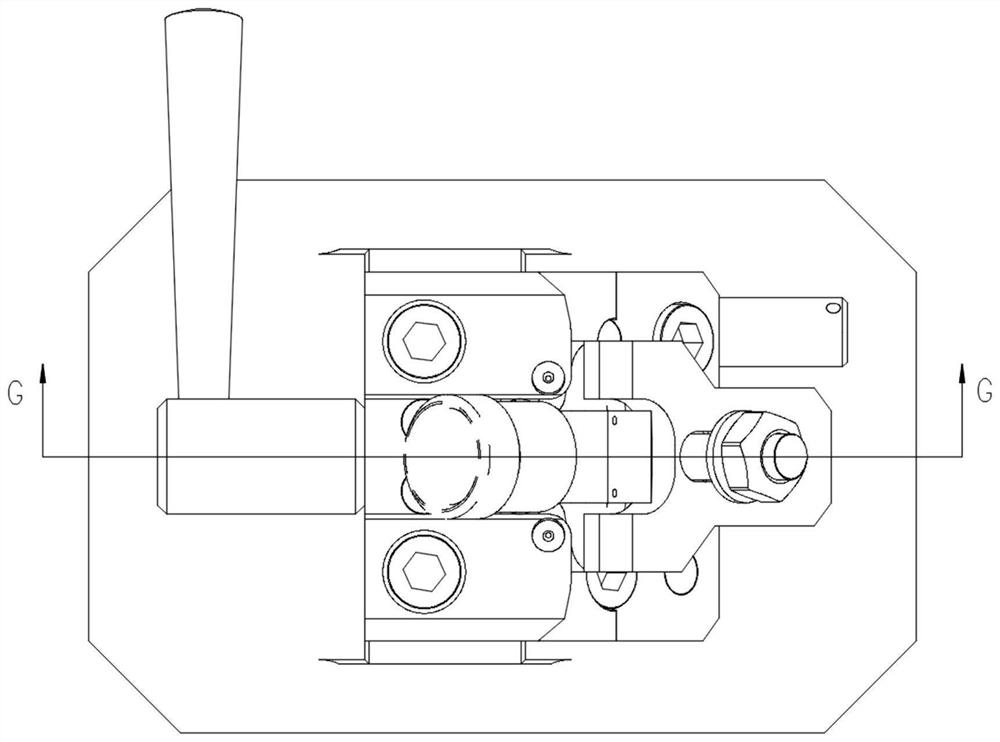

[0015] Such as Figure 1-3 As shown, a jig for multi-angle drilling includes a base 2, a rotating support, and a pressing mechanism 6. The rotating support includes a rotating base 3, a latch 5, a drilling template 7, a rotating shaft 4, and the rotating shaft 4 in turn Through the rotating base 3 and the base 2, the rotating base 3 can rotate around the rotating shaft 4, the other end of the rotating shaft 4 is connected with a handle 9, the handle 9 is threaded to one end of the rotating shaft 4, and the drilling template 7 is installed on the rotating base 3, There is a through hole corresponding to the hole to be processed on it, the through hole is designed according to the position of the hole to be proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com