Hot-upset mold

A mold and hot upsetting technology, which is applied in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve problems such as increased production costs, inability to guarantee process size requirements, and poor end precision. , to achieve the effect of saving time, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

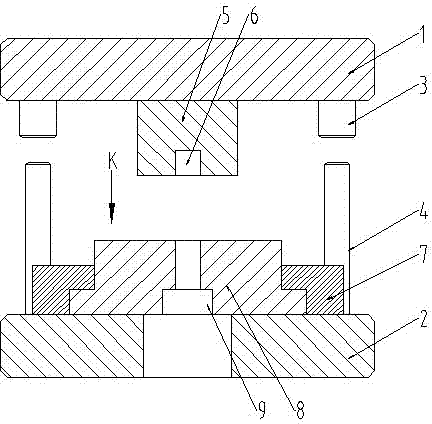

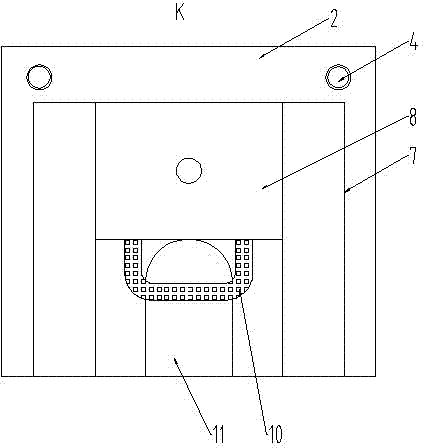

[0009] Such as figure 1 with figure 2 As shown, a hot upsetting mold includes an upper template 1 and a lower template 2. The upper template 1 and the lower template 2 are guided by a guide sleeve 3 and a guide column 4. The upper mold 5 is fixed on the upper template 1 by bolts. , the end of the upper die 5 is provided with a blind hole 6 for positioning the bar, which can contain the upper end of the bar to prevent deformation of the upper end of the bar during upsetting. A slideway 7 is fixed on the lower template 2, and the lower die 8 and The slideway 7 is guided and connected, and the lower mold 8 is provided with a cavity 9; the lower mold 8 is provided with a push-pull handle 10, and the lower template 2 is provided with a material return gap 11. The final workpiece can fall from the material return gap 11; the lower mold 8 and the lower template 2 form a closed cavity during work to ensure that the metal is completely filled according to the shape of the cavity, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com