A method for boring a rotary hinge water seal seat using a rotary hinge water seal seat boring device

A water seal seat and boring technology, which is applied in the field of boring, can solve the problems of excessive coaxiality of the reaming shaft hole, inability to guarantee the accuracy, and the rigidity of the boring bar cannot meet the requirements for use, so as to ensure the processing accuracy and quality requirements. , Simple structure, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

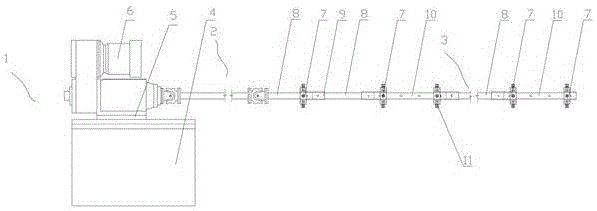

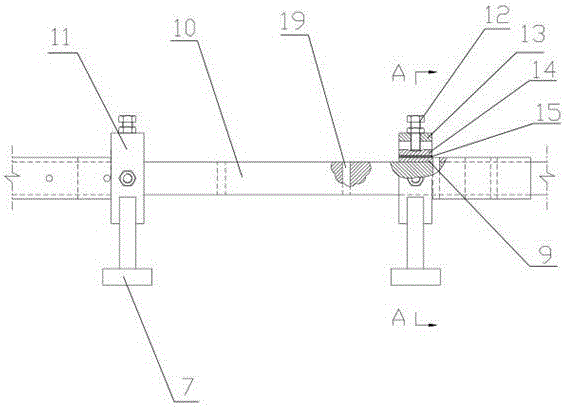

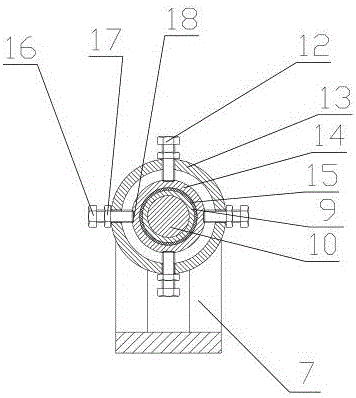

[0045] exist figure 1 In the described embodiment, a boring device for a rotary hinge water seal seat includes a power system 1, a force transmission system 2 and a boring system 3, and the force transmission system 2 is a set of transmission universal couplings. The power system 1 includes a sliding table seat 4, a sliding table 5 and a boring head 6. The boring head 6 is connected with the sliding table 5 and slides along the sliding table seat 4. The boring head 6 is connected with the force transmission system 2, and the force transmission system 2 is connected with the The boring system 3 is connected. The boring system 3 includes a plurality of support seats 7, connecting rods 8, connecting sleeves 9 and boring bars 10. The boring bars 10 are arranged in sections, and each group of hinge shaft holes is correspondingly provided with a section of boring bars 10. , the boring tool hole 19 is set on the boring bar 10 (see figure 2 ). The support seat 7 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com