Automatic rust removal spraying system and method for turnout steel rail

A technology for rails and turnouts, which is applied in the field of rust removal and spraying of turnout rails. It can solve the problems of failure to meet environmental protection requirements, poor anti-corrosion performance of rails, and high labor intensity of workers, and achieve rapid rust removal, full-section coating, and coating quality. Improve and improve the effect of rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

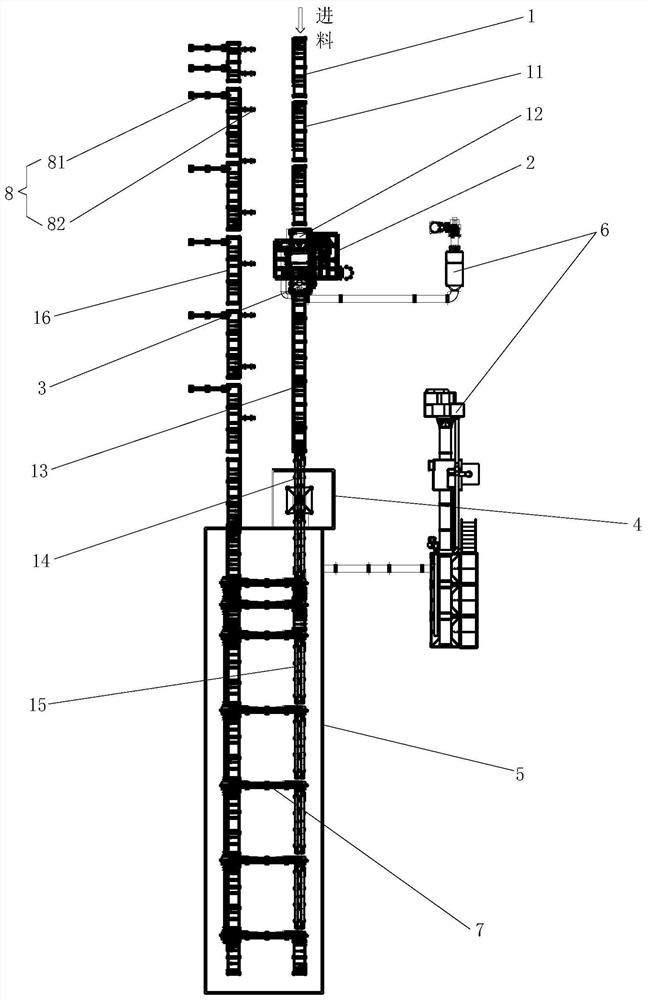

[0021] Such as figure 1 As shown, the automatic derusting and spraying system for turnout rails of the present invention includes a conveying line 1, a sawing rail surface derusting shot blasting machine 2, a surface cleaning device 3, a painting room 4, a drying room 5, a waste gas treatment device 6, and rail transplanting Mechanism 7 and blanking mechanism 8.

[0022] The conveying line 1 is placed on the ground and consists of a supporting frame and a conveying roller table matched and installed on the upper part of the supporting frame; wherein, the conveying line 1 includes a feeding conveying line 11, a surface derusting and cleaning Conveying line 12, painting conveying line 13, transfer conveying line 14, drying conveying line 15 and discharging conveying line 16.

[0023] The saw rail surface derusting shot blasting machine 2 is matched between the feeding conveying line 11 and the surface derusting cleaning conveying line 12 of the conveying line 1. The output end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com