Patents

Literature

96results about How to "Quick rust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

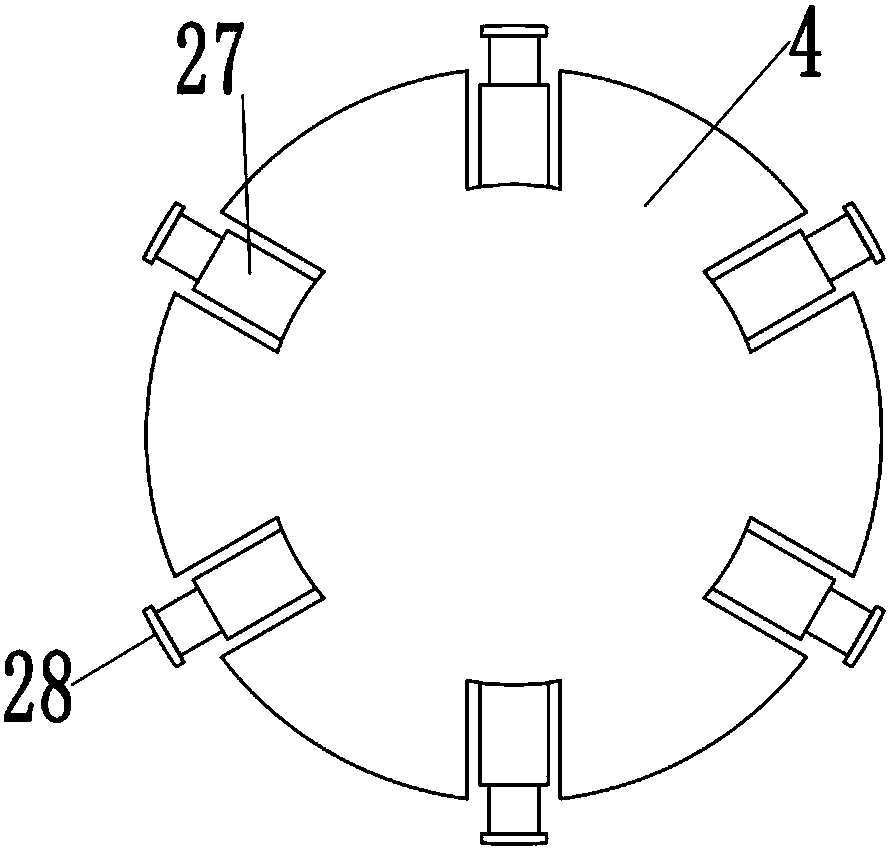

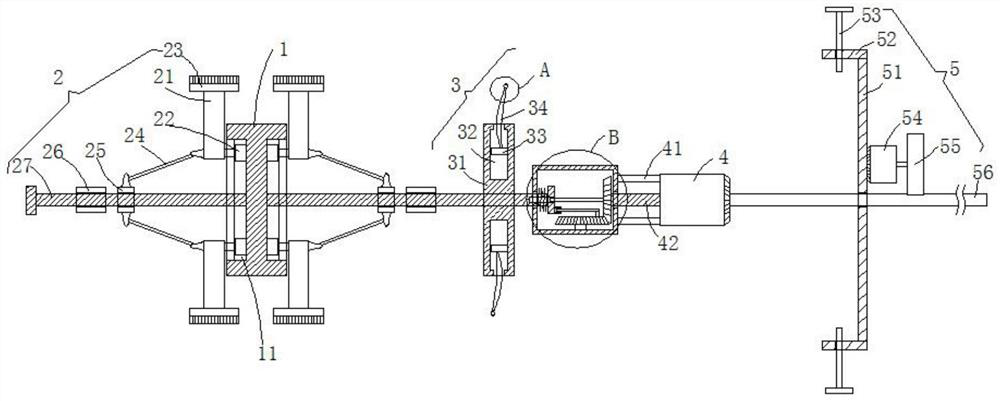

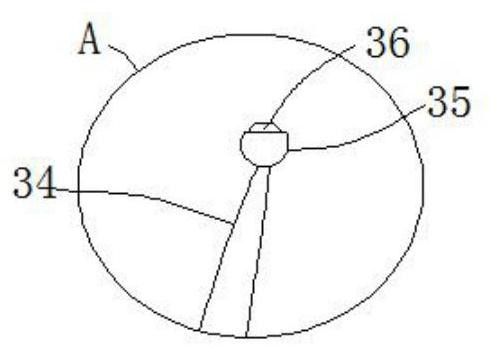

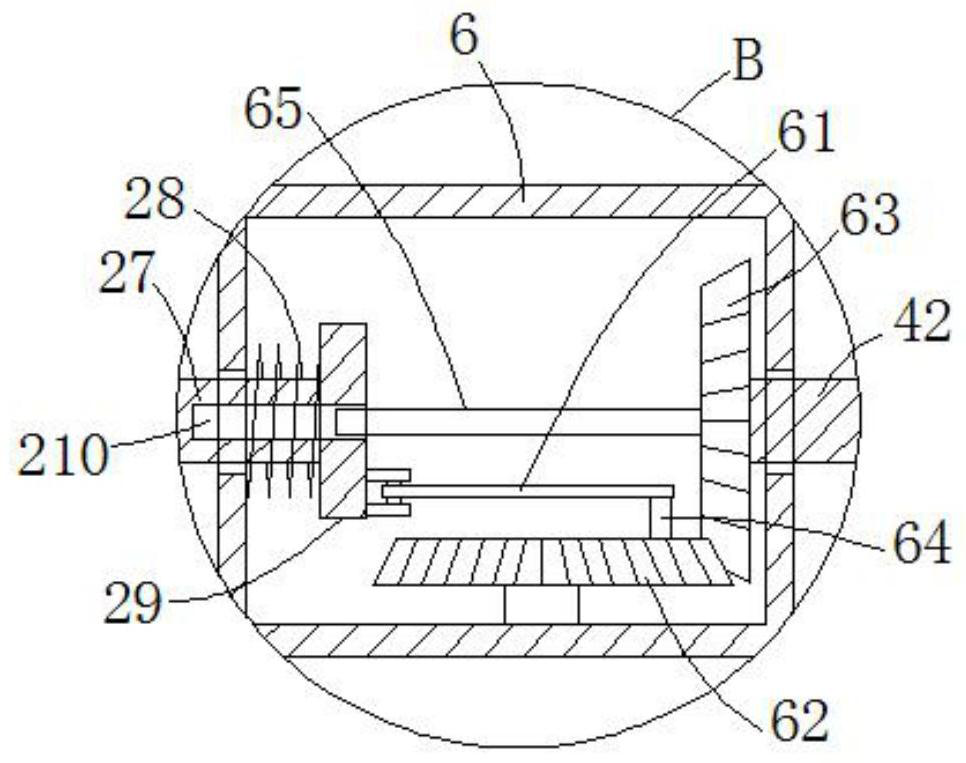

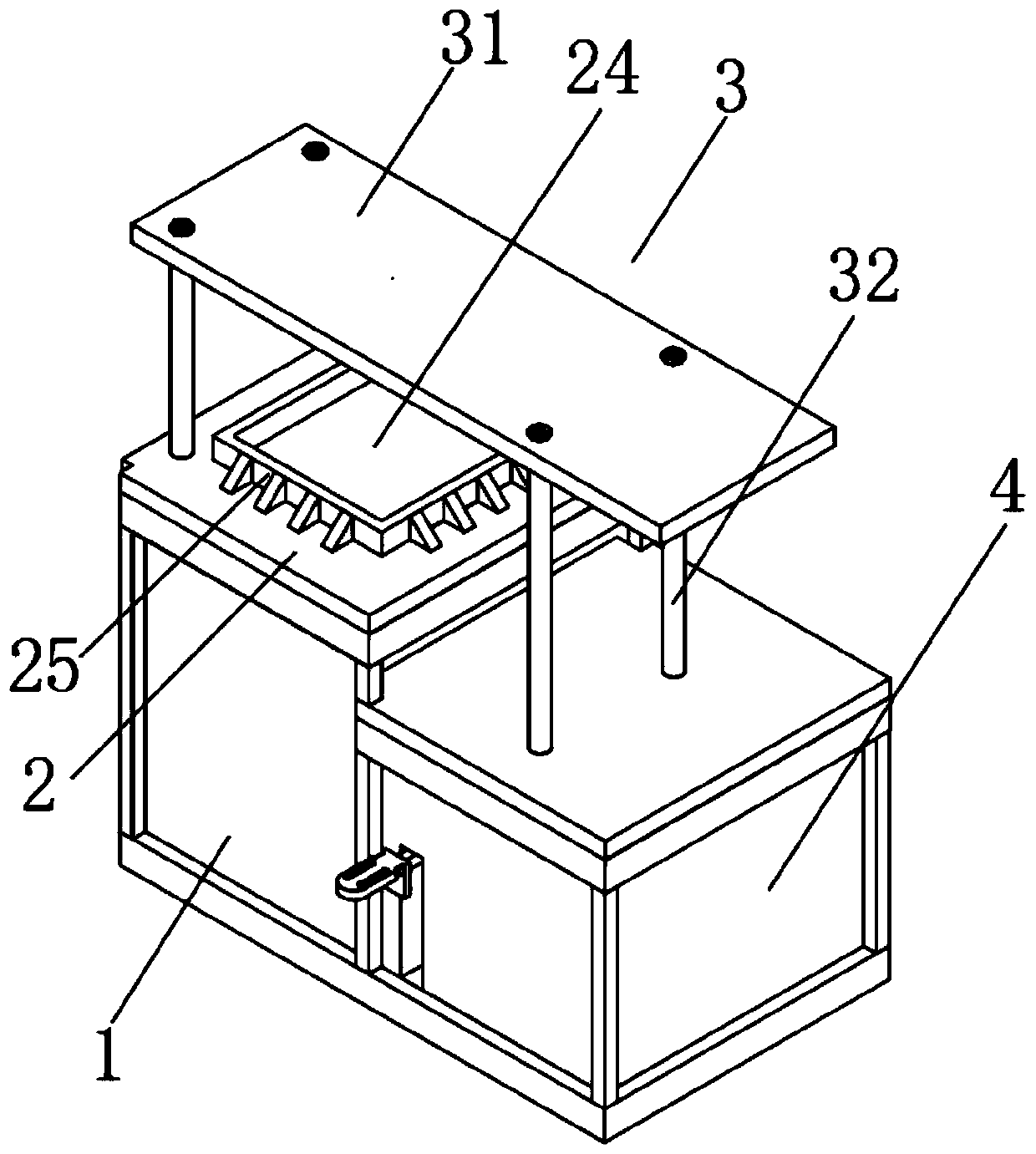

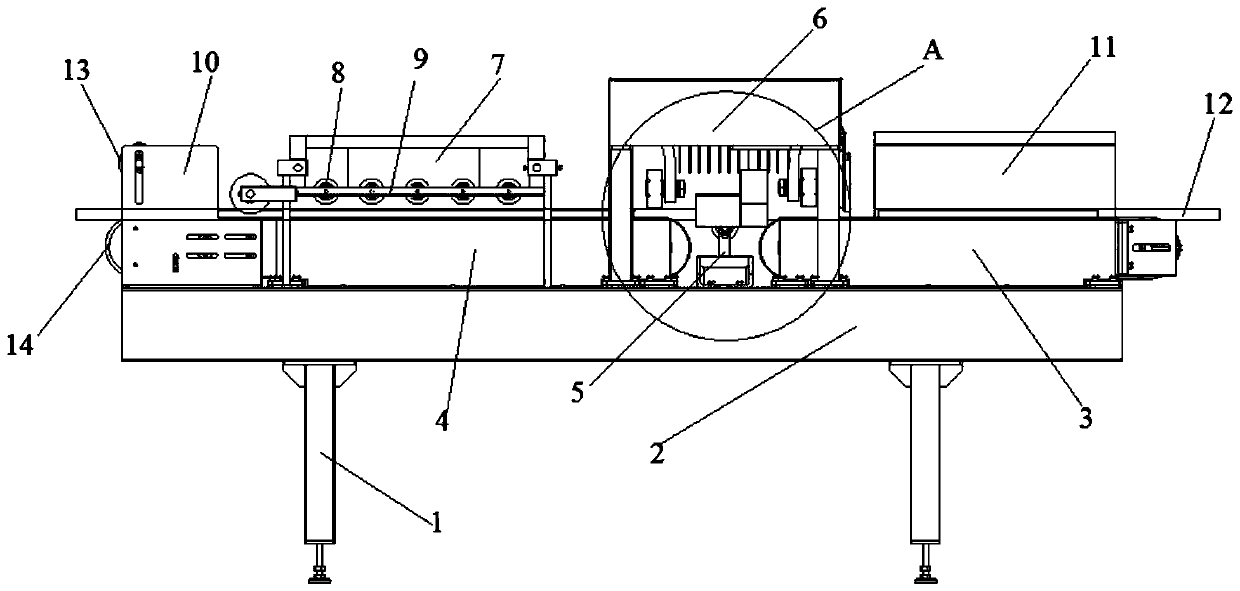

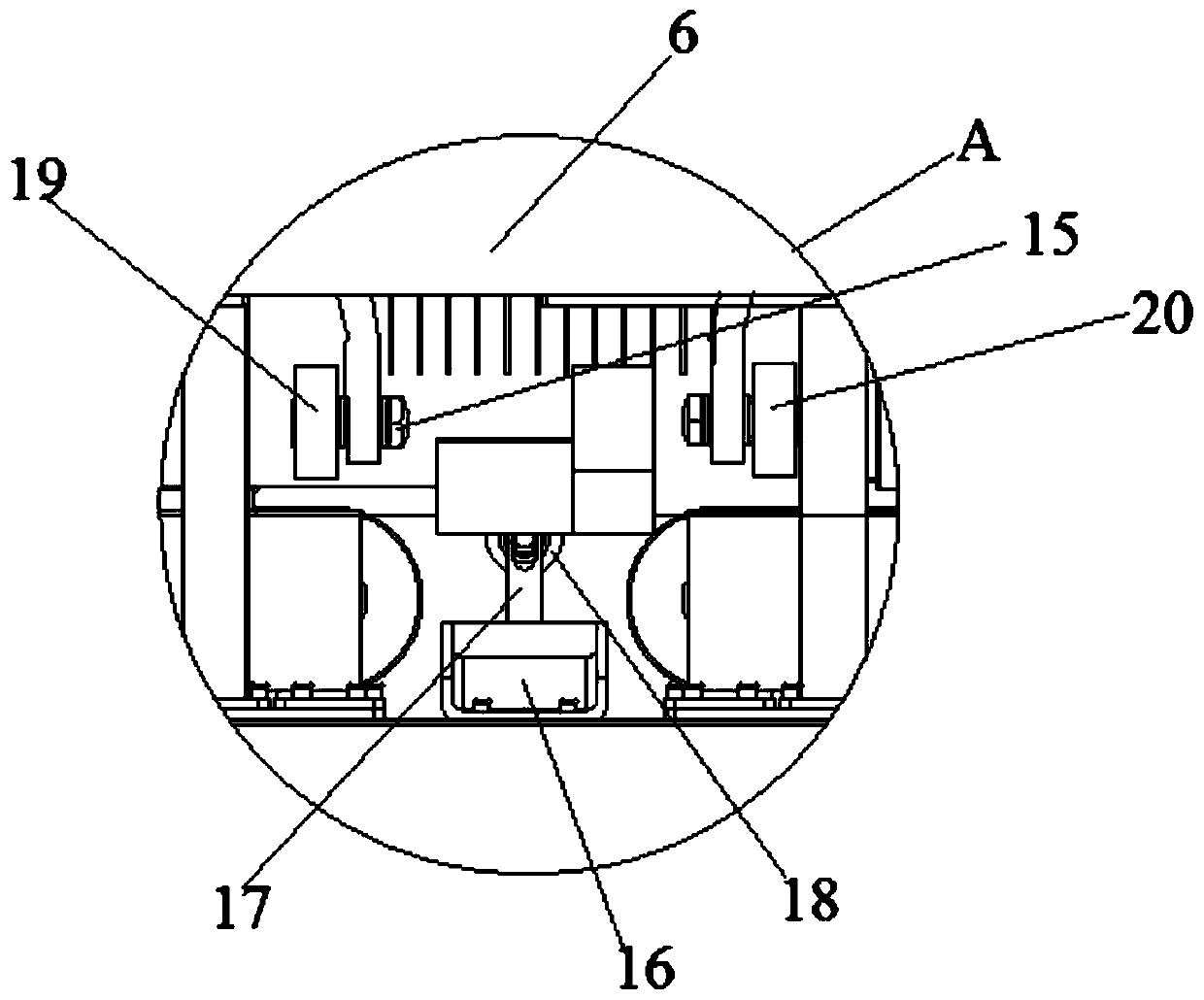

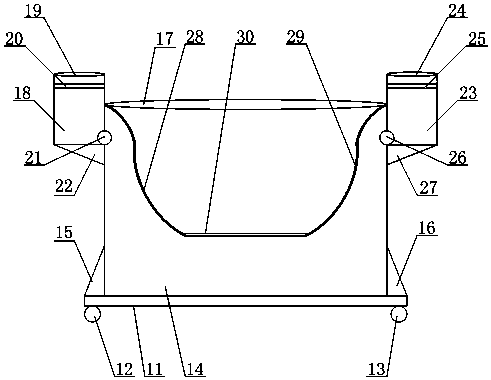

Rust removing and paint spraying device for metal pipes

InactiveCN111167655AEasy to holdNot easy to looseGrinding drivesGrinding machinesMetallurgyElectric machinery

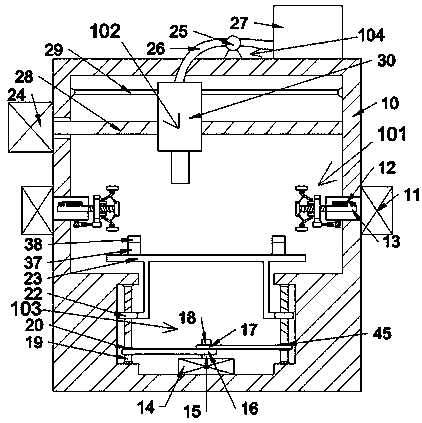

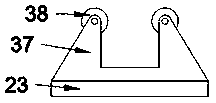

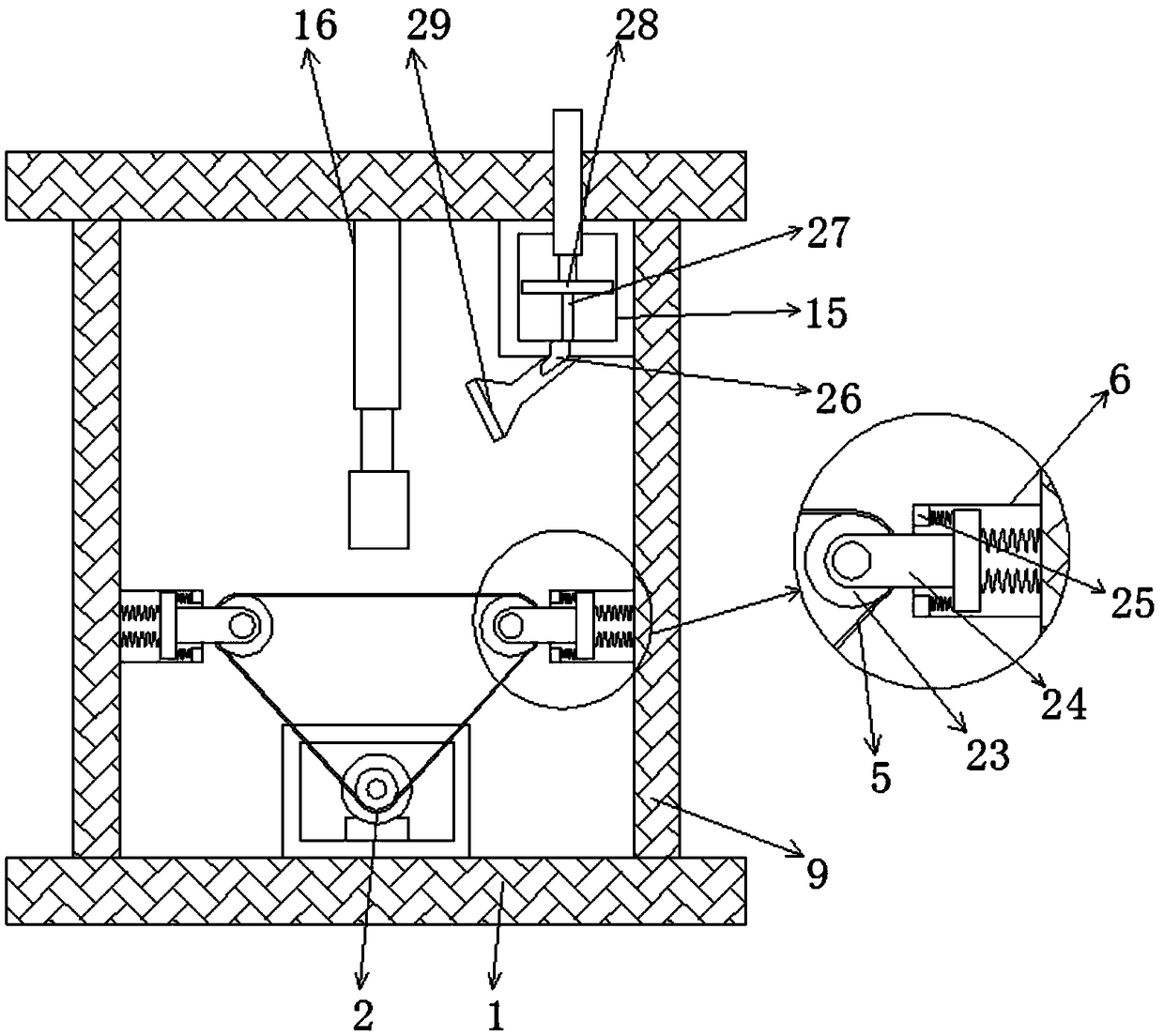

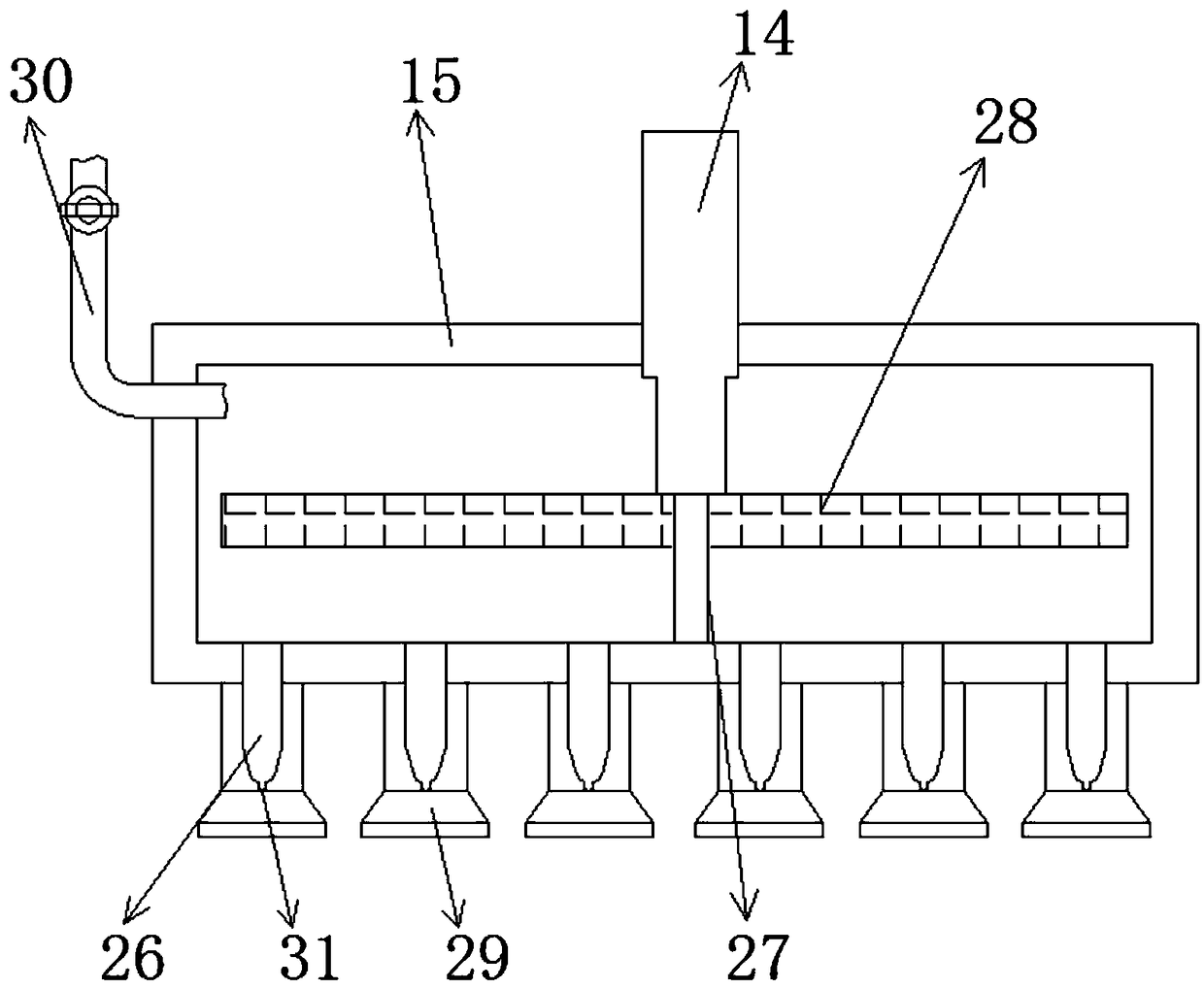

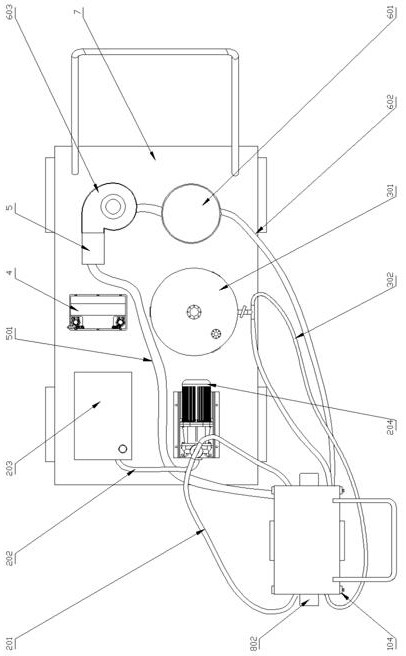

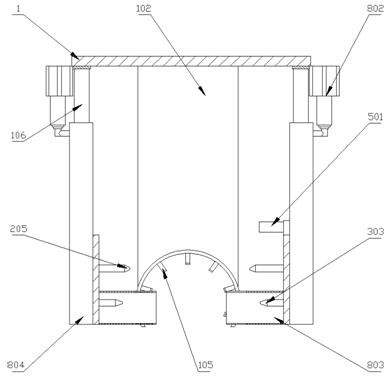

The invention discloses a rust removing and paint spraying device for metal pipes. The rust removing and paint spraying device for the metal pipes comprises a rust removing and paint spraying machinebody arranged on the ground; the rust removing and paint spraying machine body is provided with a fixing rod and a first threaded rod which can be used for installing the rust removing and paint spraying device; a clamping device and a lifting platform are arranged in the rust removing and paint spraying machine body; the clamping device comprises second motors which are symmetrically arranged outside the left side wall and the right side wall; and the lifting platform comprises a third motor which is arranged on the lower portion of the inside of the rust removing and paint spraying machine body. The lifting platform is controlled by the third motor, the metal pipes with different diameters on rollers are collinear with the clamping device, and the clamping effect on the metal pipes is good; and a rust removing device can make a rust removing sheet be in full contact with the metal pipes, and therefore the rust removing effect on the metal pipes is improved; and the metal pipes can besubjected to paint spraying treatment after rust removing is completed, and the production efficiency of the metal pipes is improved.

Owner:PAN AN AIKEN MECHANICAL EQUIP CO LTD

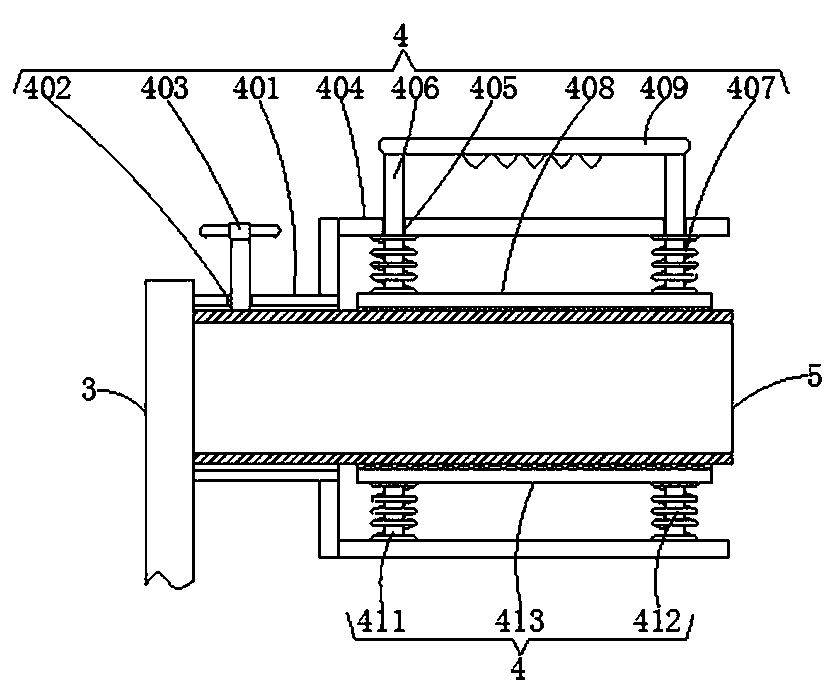

Steel pipe surface rust removal and dirt removal device based on building site construction

InactiveCN109454537AAvoid unevennessExtended service lifeGrinding carriagesGrinding machinesFixed frameArchitectural engineering

The invention belongs to the technical field of buildings, particularly discloses a steel pipe surface rust removal and dirt removal device based on building site construction, and puts forward the following scheme to solve the problems that steel pipes are not clamped sufficiently stably, the rust removal effect is poor, rust stains during rust removal are not cleared timely and caked rust stainscan damage abrasion pieces. The steel pipe surface rust removal and dirt removal device comprises a mounting base; a fixing frame is arranged on the outer wall of the top of the mounting base; a first motor casing is arranged on the outer wall of one side of the top of the mounting base; a first motor is arranged on the inner wall of one side of the first motor casing; a first rotating rod is arranged on an output shaft of the first motor; and first belt wheels are distributed on the outer wall of the first rotating rod at equal intervals. By the aid of the device, rust blocks already bulgingfrom the surfaces of the steel pipes are removed, an abrasion belt is prevented from being scratched by blocky rust stains, the surfaces of the steel pipes are polished sufficiently by the aid of abrasion teeth, the steel pipes are fixed sufficiently, acid pickling is performed on the surfaces of the steel pipes, and the functions of cleaning while rust removal can be realized.

Owner:王亮

Pipeline outer wall rust removal device for civil engineering

Owner:山西华欣久泰科技有限公司

Brightening rust removing agent

The present invention relates to a substance which removes rustiness on the surface of steel and iron, in particular to brightening rust remover, which solves the problem that the steel and the iron have gloomy surfaces after the rust removing in the prior art. The brightening rust remover is composed of materials in the following weight ratio: chlorhydric acid is 30-50 percent, hexamethylene tetramine is 1-5 percent, sodium lauryl sulphate is 2-8 percent, peregal OS-15 is 5-10 percent, and the residual is water. The present invention has the characteristics that rustiness can be removed quickly, the steel and the iron are brighter than the original state after the rustiness is removed, no over corrosion and hydrogen brittleness phenomenon exist, no pollution exists, and the cost is low, etc. Since the difference of the degrees of corrosion, the rustiness removing time is generally within 1-5 minutes.

Owner:山西银河镀锌有限公司

Steel rust removing liquid

The invention provides a steel rust removing liquid which comprises the following components of oxalic acid, triethanolamine, phosphoric acid, hydrochloric acid, fatty alcohol-polyoxyethylene ether, hexamethylenetetramine and water. A buffering agent and an acid fog inhibiting agent are also added into the steel rust removing liquid provided by the invention besides using a few amount of organic acid. The steel rust removing liquid not only can well remove metal oxides, but also has the characteristics of retarding steel corrosion and inhibiting acid fog volatilization and the like.

Owner:陈瑜

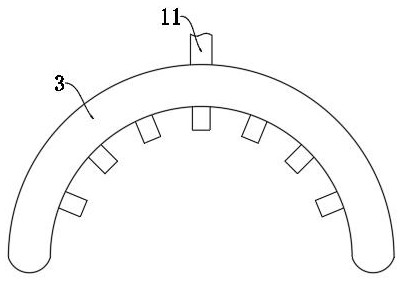

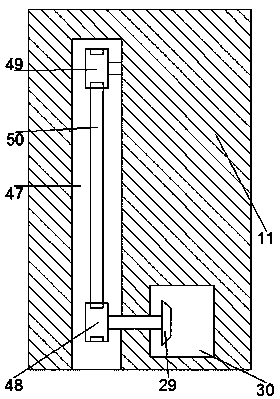

Pipeline inner wall derusting device

InactiveCN111702640AAchieve full coverageRealize all-round rust removal operationRevolution surface grinding machinesGrinding drivesElectric machineStructural engineering

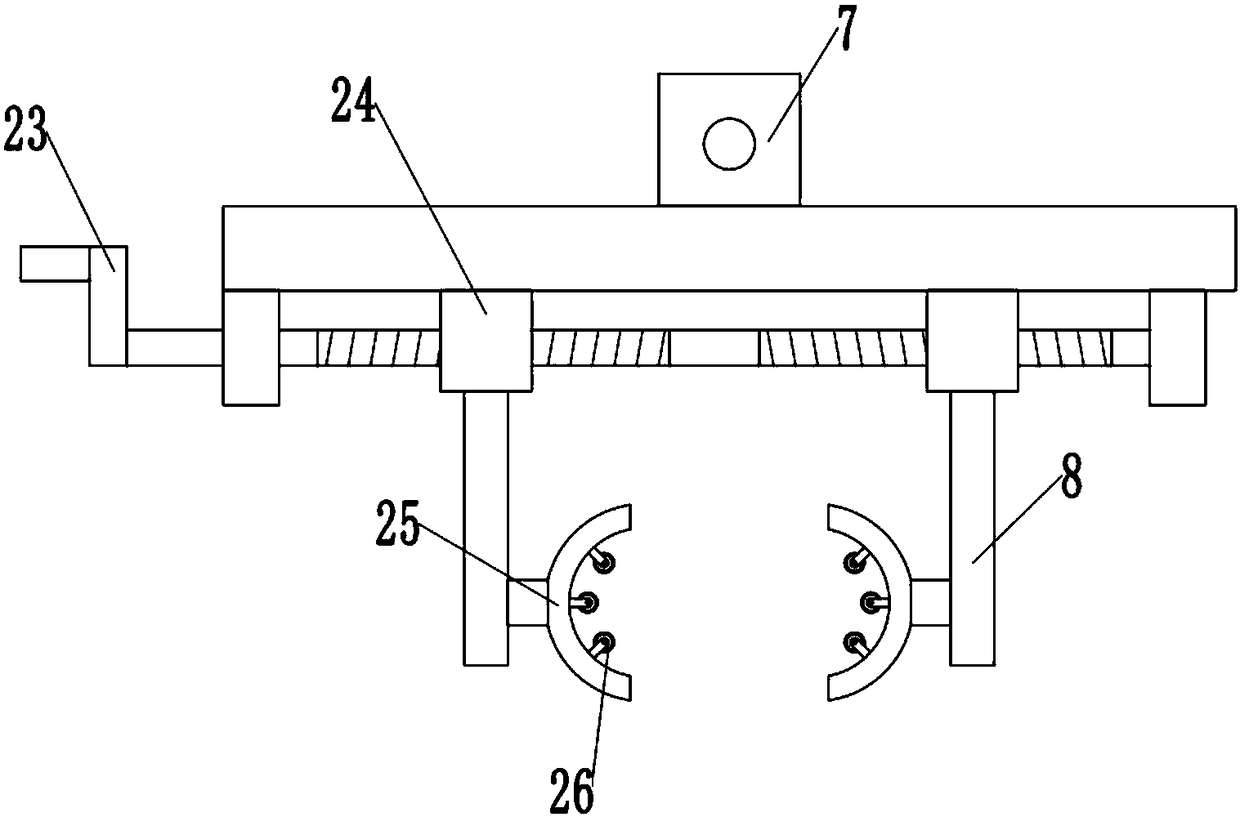

The invention discloses a pipeline inner wall derusting device. The pipeline inner wall derusting device comprises a fixing mechanism, a driving motor, a connection seat and two bilaterally-symmetrical derusting mechanisms with the connection seat as a center; the fixing mechanism comprises a fixing plate, two positioning plates, a conveying motor and a threaded conveying rod; the center positionof the right end surface of the driving motor is rotationally connected with the left end of the threaded conveying rod, the left end surface of the driving motor is connected with a hollow box with an inner cavity being of a hollow structure through two connection rods, the driving motor rotationally penetrates through the right end surface of the hollow box through a power shaft and is connectedwith a first bevel gear located in the inner cavity of the hollow box, and the side wall of the front side of the inner cavity of the hollow box is rotationally connected with a second bevel gear through a hinge pin; and the two derusting mechanisms each comprise a threaded rod, a threaded sleeve, a sliding sleeve, a plurality of adjusting blocks annularly and uniformly distributed at intervals,and a plurality of cleaning hairbrushes annularly and uniformly distributed at intervals. The pipeline inner wall derusting device can adapt to pipelines different in opening diameter conveniently, quickly conduct feeding and derusting and blow away removed iron rust.

Owner:缪静

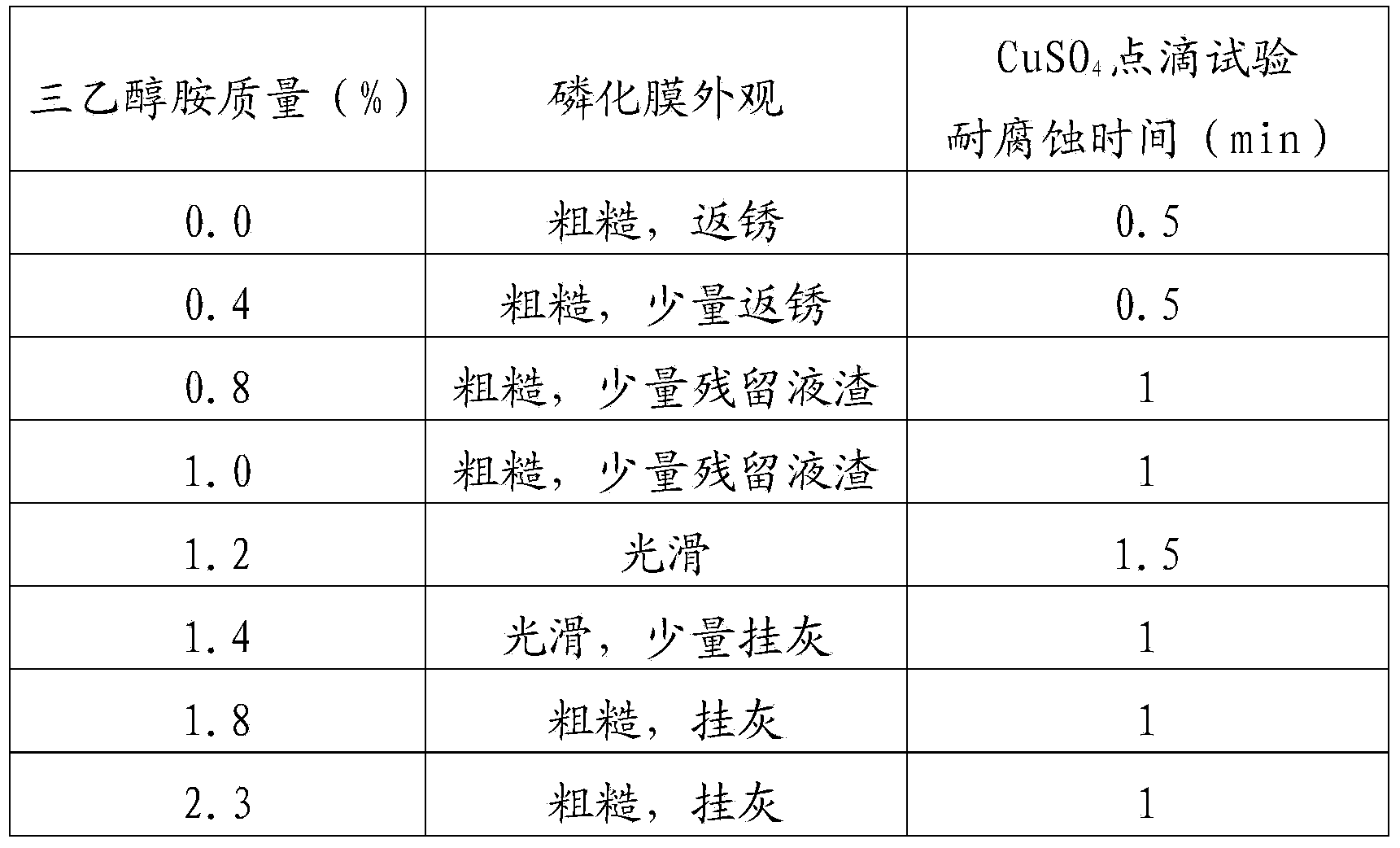

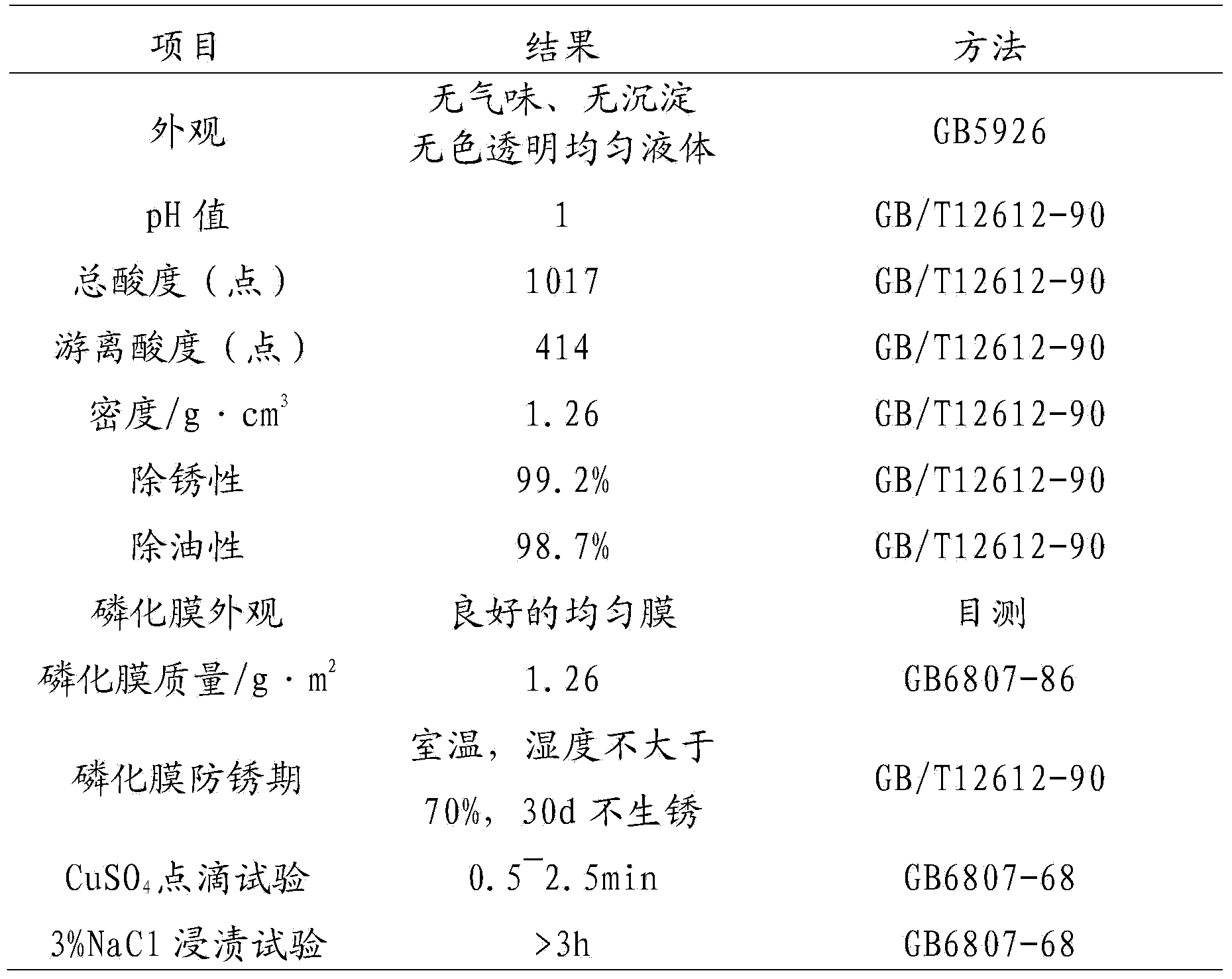

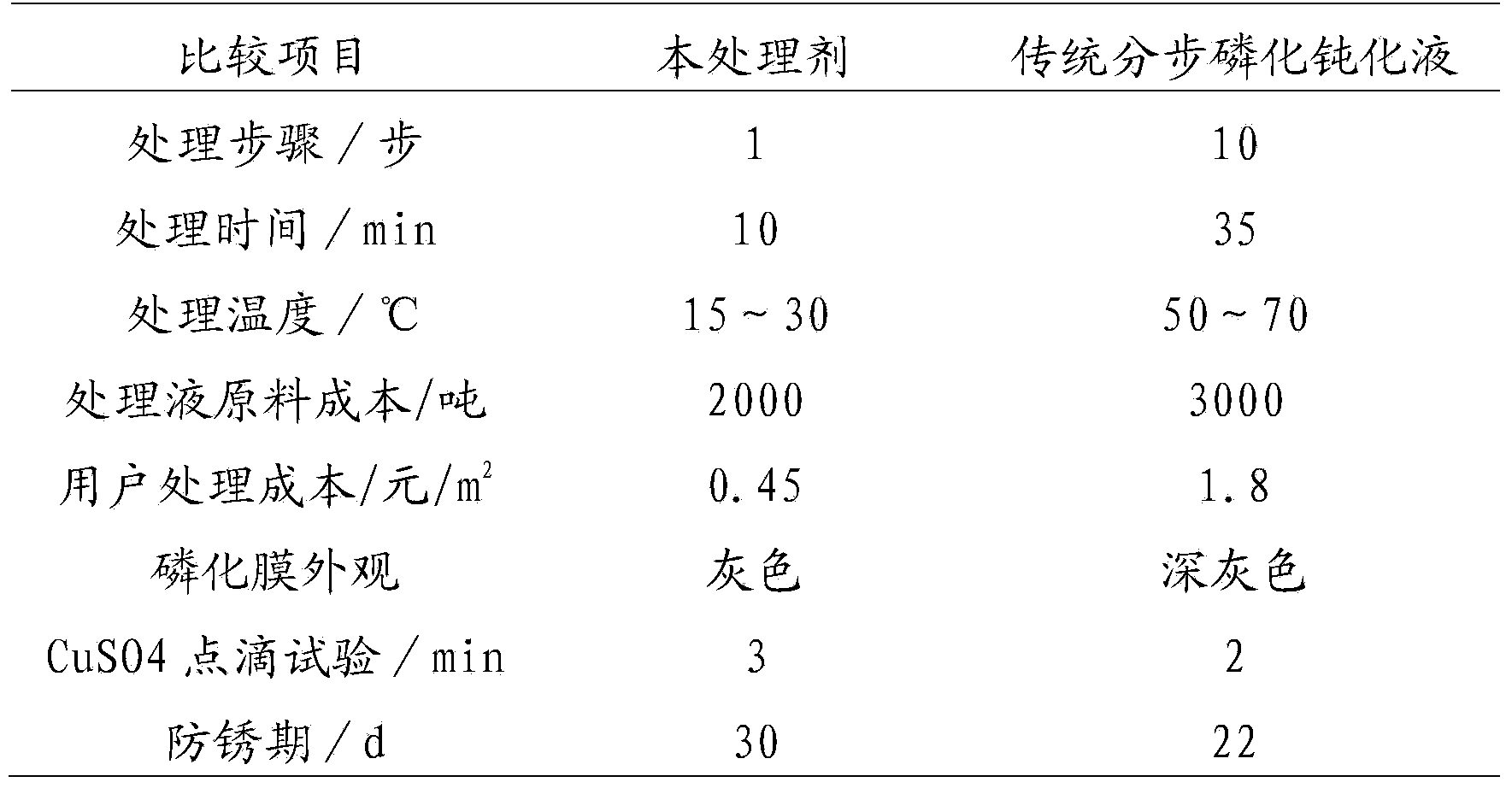

Comprehensive treatment agent and use method thereof

InactiveCN103436872AAvoid time costReduce processing costsMetallic material coating processesThioureaPhosphate

The present invention relates to a comprehensive treatment agent, which comprises, by mass, 25.0-30.0% of phosphoric acid, 1.0-3.0% of zinc oxide, 0.1-0.5% of sodium molybdate, 4.0-7.0% of zinc dihydrogen phosphate, 0.3-1.2% of potassium chlorate, 0.3-1.2% of a surfactant, 0.0-2.3% of triethanolamine, 0.8-2.3% of citric acid, 0.1-0.3% of thiourea, and 58.0-62.6% of water. According to the present invention, the treatment agent can be recycled, a treatment cost is low, and pollution on the environment can not be generated.

Owner:谢俊磊

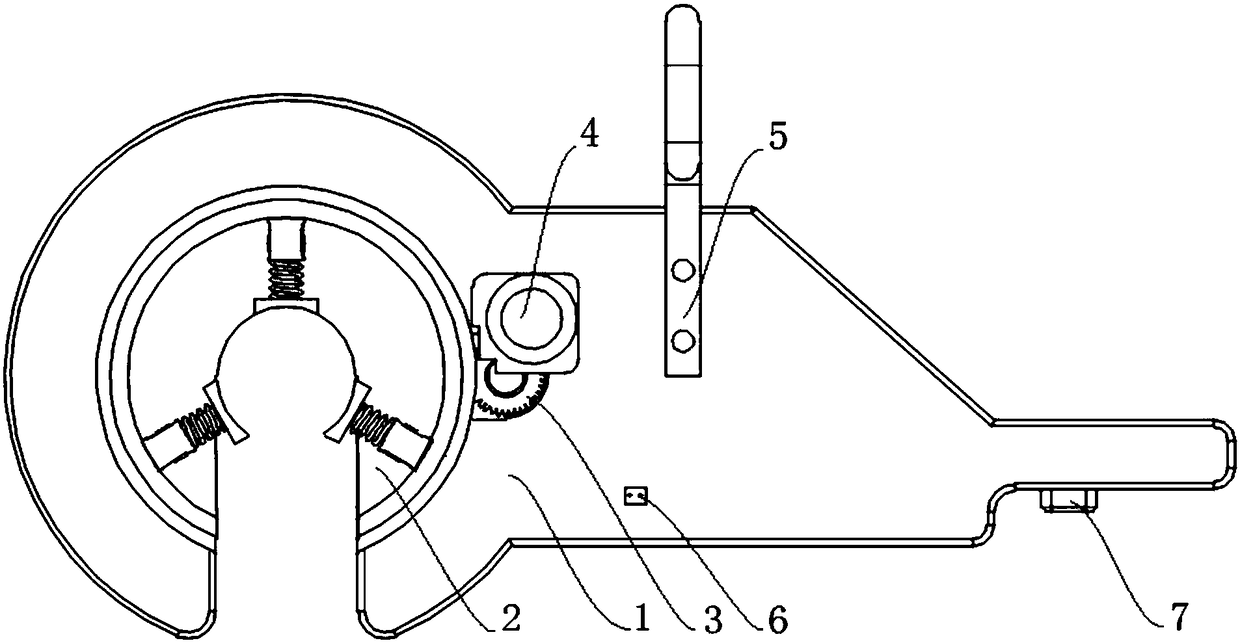

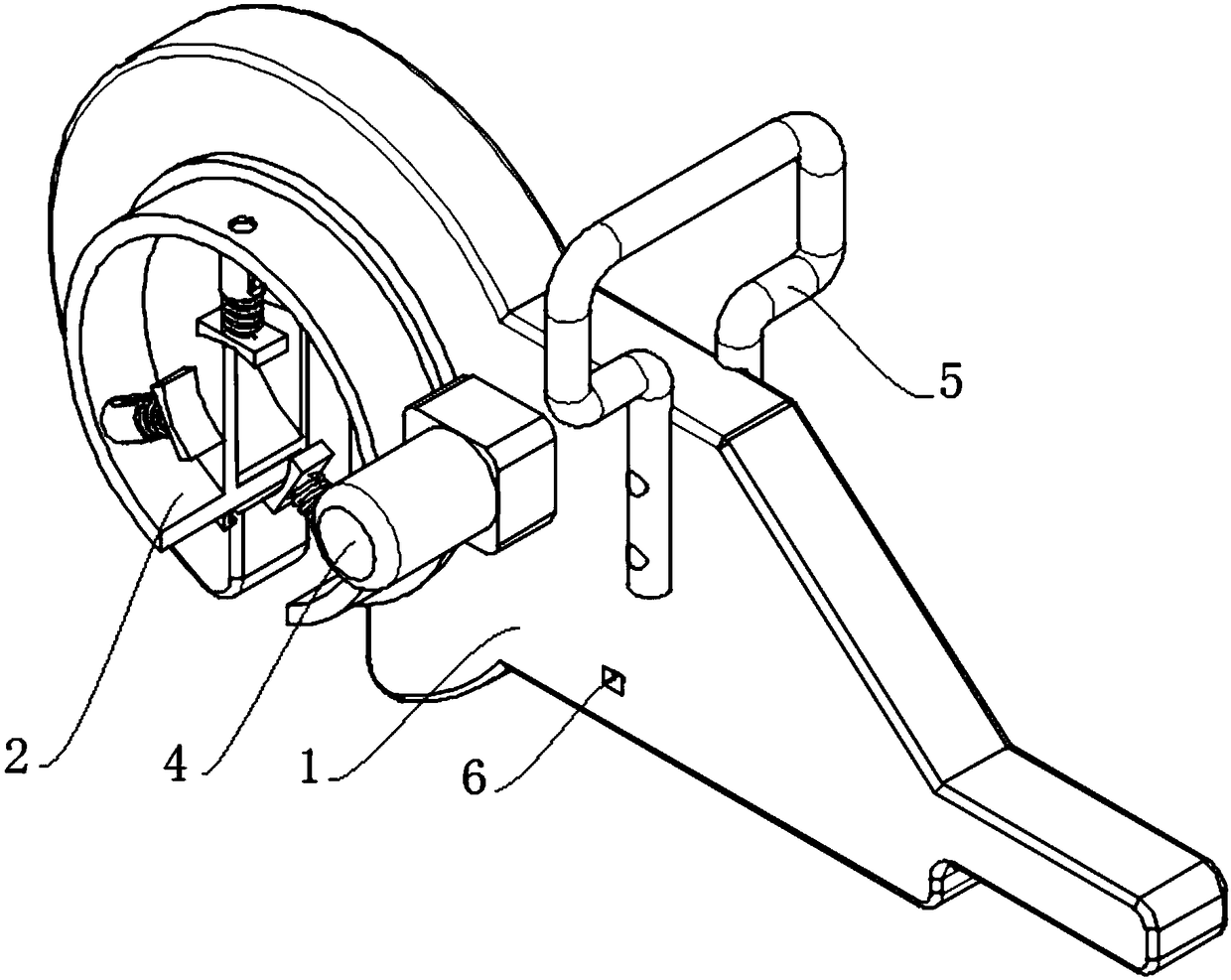

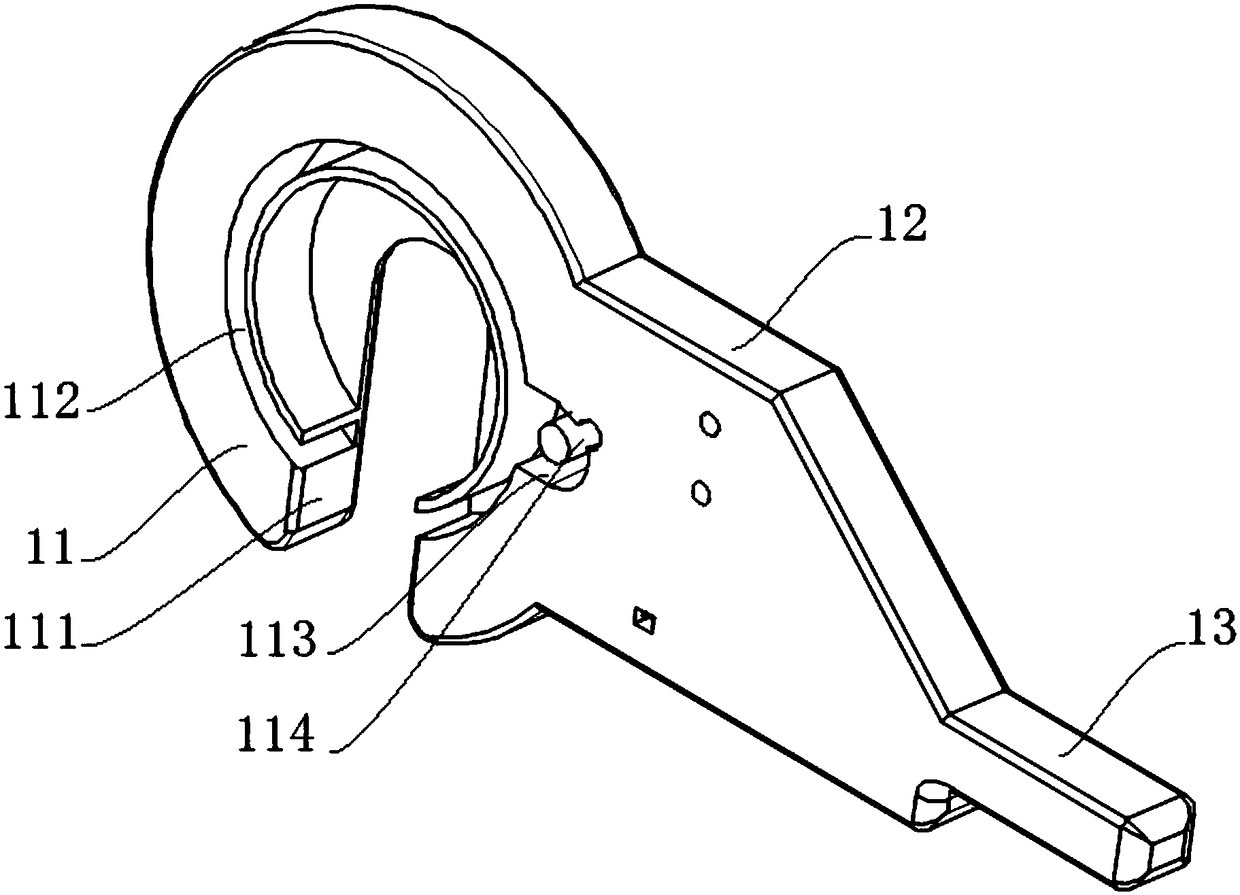

Hand-held petroleum drill rod rust remover

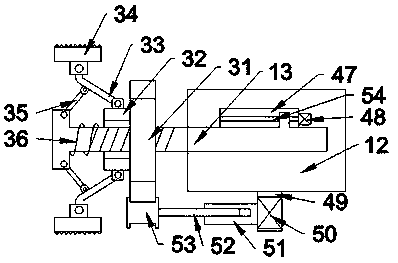

InactiveCN108115528AReduce labor intensityQuick rust removalPortable grinding machinesGear wheelHand held

The invention discloses a hand-held petroleum drill rod rust remover which includes a casing, a motor, a secondary gear, a rotating wheel and a grinding tool. The front end of the casing is provided with a transmission portion which is in a disc shape, the transmission portion is provided with a first U-shaped notch, one end face of the transmission portion is provided with an annular notch, the rotating wheel is mounted on the annular notch of the transmission portion and includes a circular pipe body and wheel teeth, a notch is formed between an outer circle and an inner circle of the circular pipe body, the plurality of wheel teeth are disposed evenly on the circumference of the outer circle of the circular pipe body, the wheel teeth of the rotating wheel are in meshing transmission with the secondary gear, a rotor output shaft of the motor is provided with a primary gear, the primary gear is in meshing transmission with the secondary gear, and the grinding tool is disposed in the circular pipe body of the rotating wheel. The hand-held petroleum drill rod rust remover can achieve the effect of rapid derusting only by operating the rust remover by hand to walk in the length direction of a petroleum drill rod, the labor intensity of workers' rust removal is reduced, and the derusting efficiency is greatly improved.

Owner:CHENGDU DAMO PETROLEUM TECH CO LTD

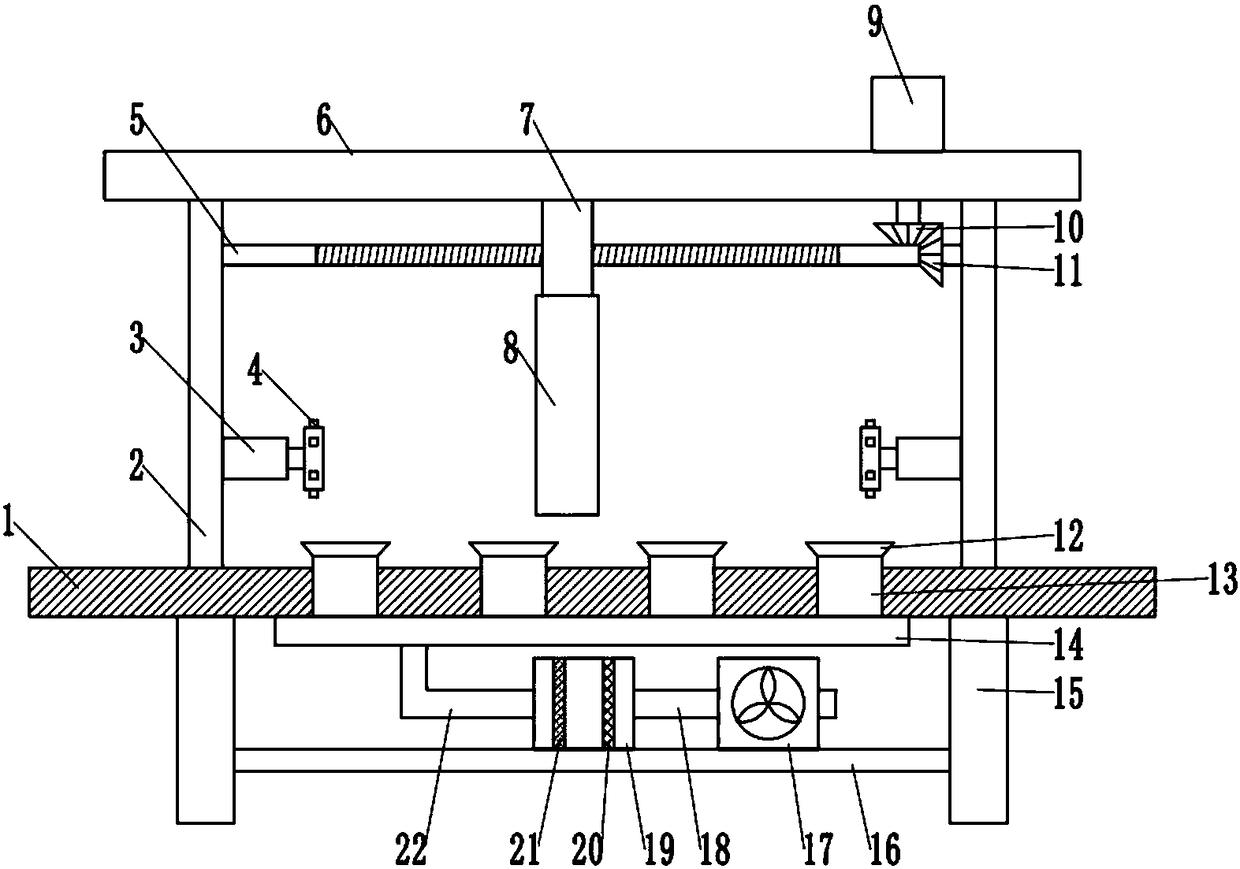

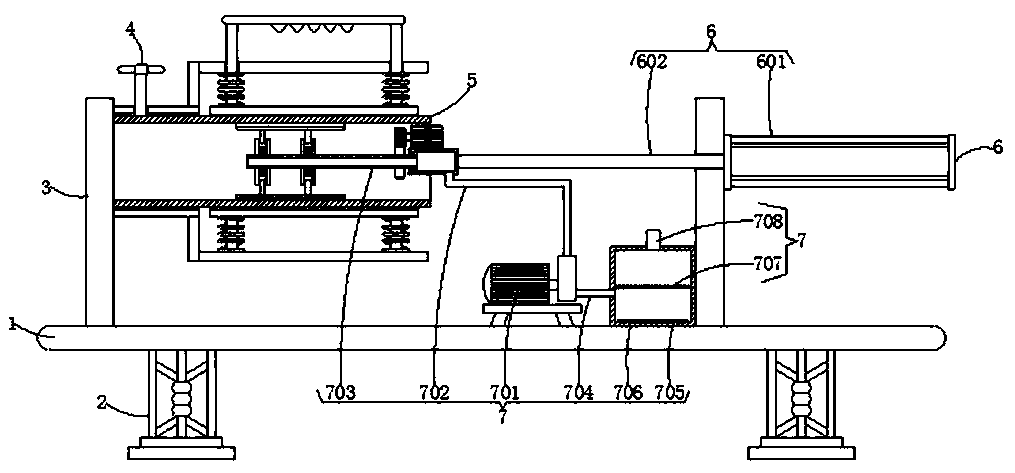

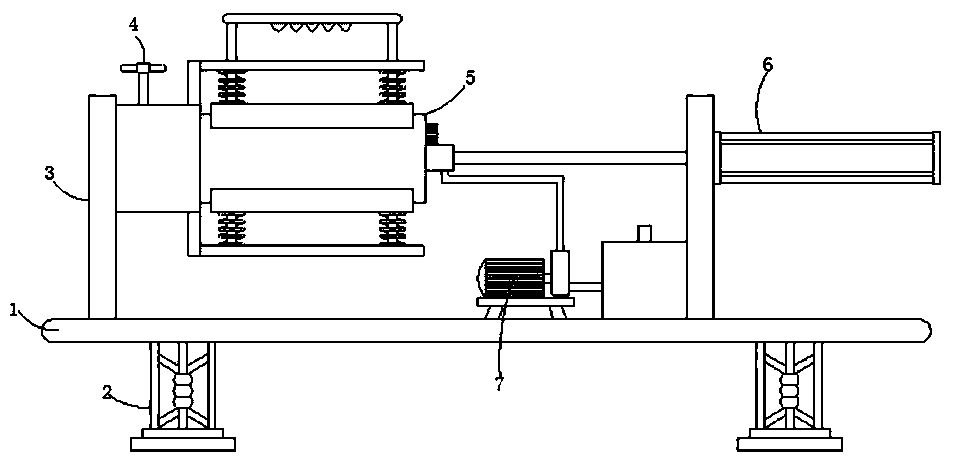

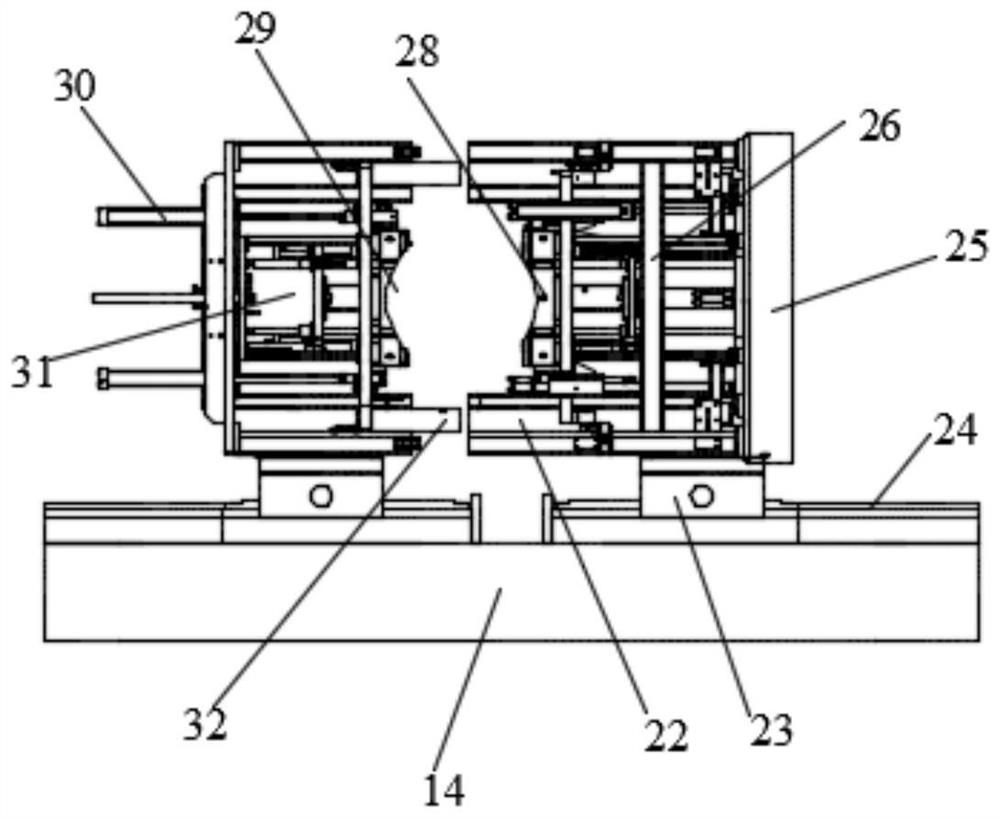

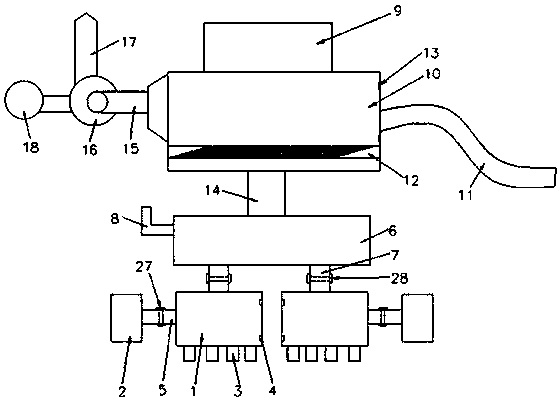

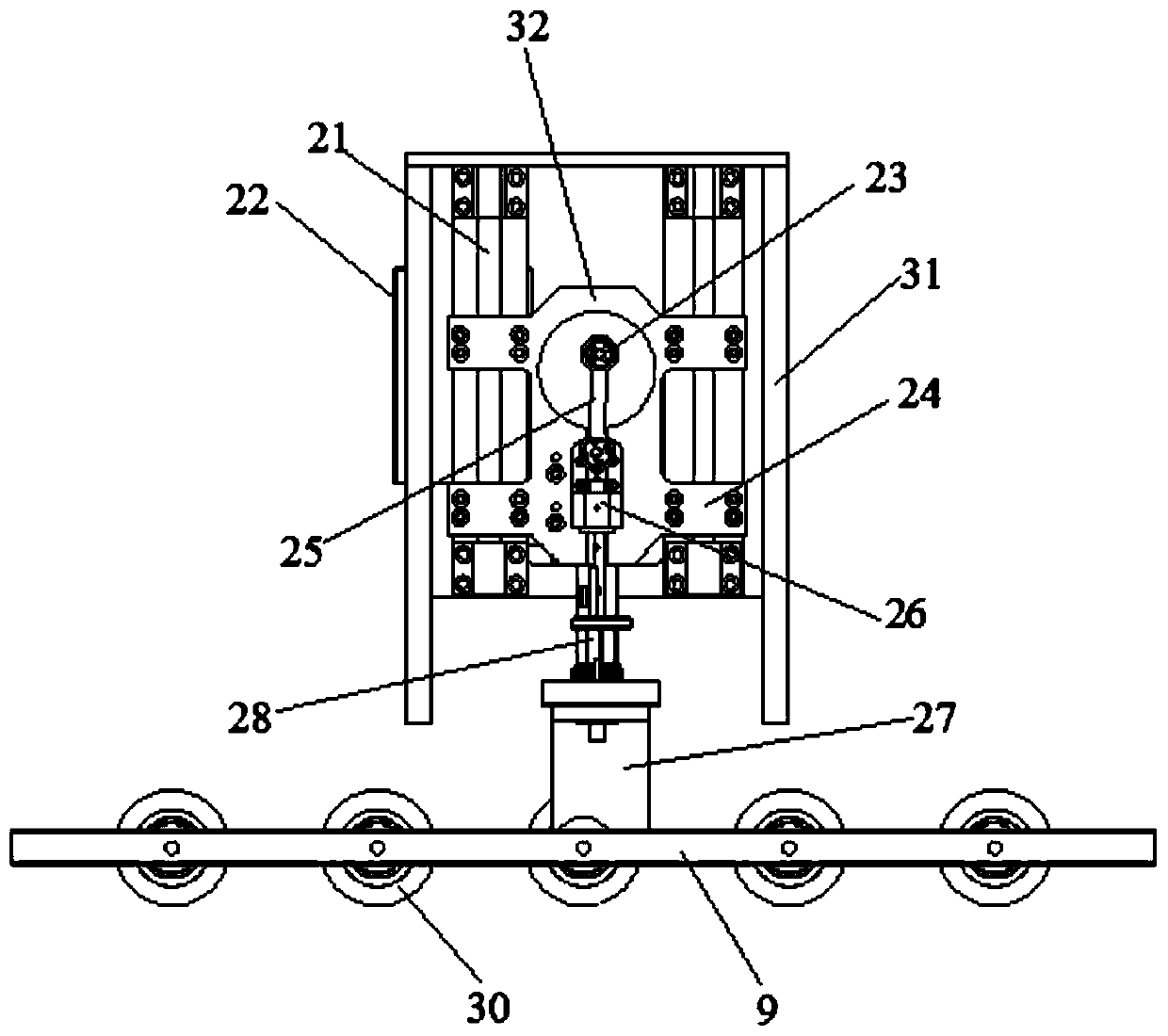

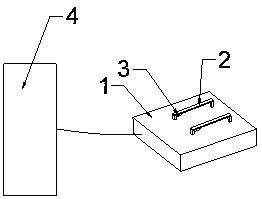

Steel pipe inner wall derusting equipment based on combined operation of grinding and dedusting

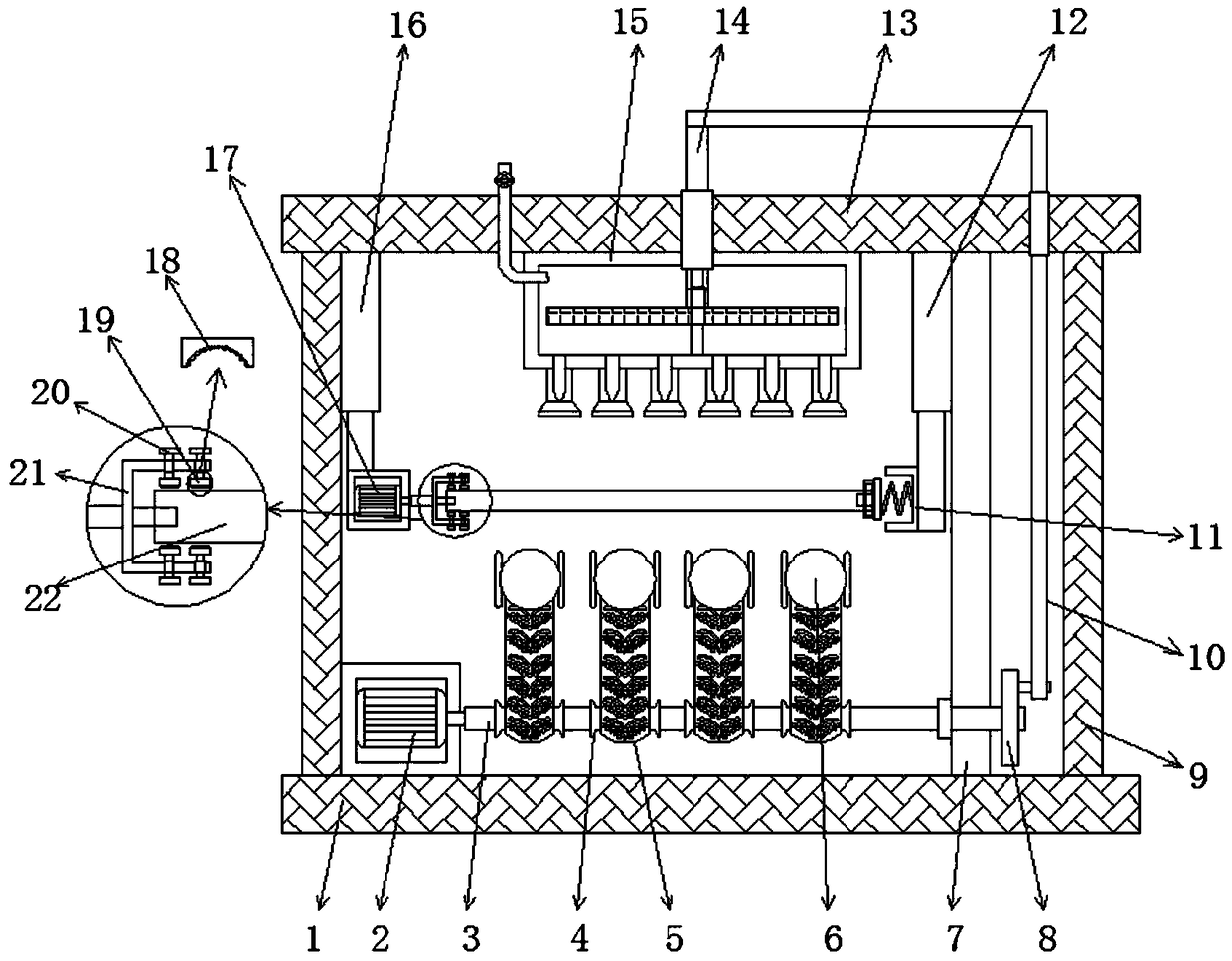

InactiveCN109434651APrecise positioningEasy to fixRevolution surface grinding machinesGrinding drivesOperation modeEngineering

The invention discloses steel pipe inner wall derusting equipment based on combined operation of grinding and dedusting, and relates to the technical field of steel pipes machining equipment. The steel pipe inner wall derusting equipment based on the combined operation of grinding and dedusting comprises a workbench, supporting legs, standing plates, a positioning device, a steel pipe body, a grinding device and a dedusting device, the top ends of the two supporting legs are fixedly connected with the two ends of the bottom surface of the workbench respectively, and the bottom ends of the twostanding plates are fixedly connected with the two ends of the top surface of the workbench respectively. According to the steel pipe inner wall derusting equipment based on the combined operation ofgrinding and dedusting, through usage of and cooperation among the positioning device, the grinding device and the dedusting device, the steel pipe body can be quickly positioned firstly, then grinding and derusting of the inner wall of the steel pipe can be rapidly completed, and operation mode of the device is very simple, so that labor intensity of workers is greatly reduced and practicabilityof the derusting equipment is further improved.

Owner:浙江工业大学上虞研究院有限公司

Hardware polishing technology

InactiveCN111761417AAccuracy is not affectedStrong and stable magnetic effectEdge grinding machinesPolishing machinesComputer hardwarePolishing

The invention discloses a hardware polishing technology. The hardware polishing technology comprises the following steps that pieces of hardware to be polished are detected, and the unqualified hardware is removed; the detected and qualified hardware is cleaned; a polishing solution is prepared, and appropriate polishing magnetic force steel needles are selected according to the specification of the hardware; the hardware, clear water, the polishing solution and the polishing magnetic force steel needles are put into a grinding barrel, a power source is connected, and polishing parameters of amagnetic force polishing machine are set according to the specification of the hardware; the magnetic force polishing machine is started, and therefore the grinding barrel is driven to rotate, and the hardware is ground and polished; after polishing operation is accomplished, the hardware is taken out, cleaned and dried; the dried hardware is subjected to passivation; and the passivated hardwareis packaged. According to the hardware polishing technology, no dead space exists in the polishing and grinding process, and all portions are completely ground; ground workpieces never deform, the damage is never damaged, and the accuracy is never affected; and the cost is low, the speed is high, the efficiency is high, the operation is easy and convenient, and the multi-machine operation can be conducted.

Owner:苏州邦仕威五金科技有限公司

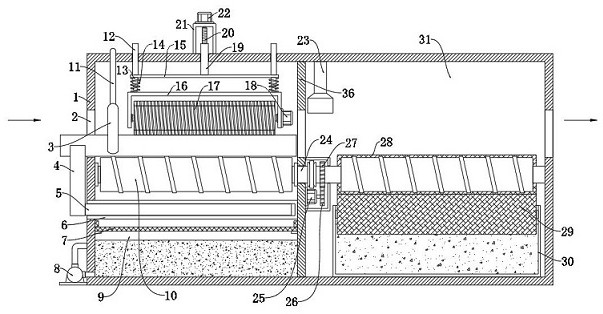

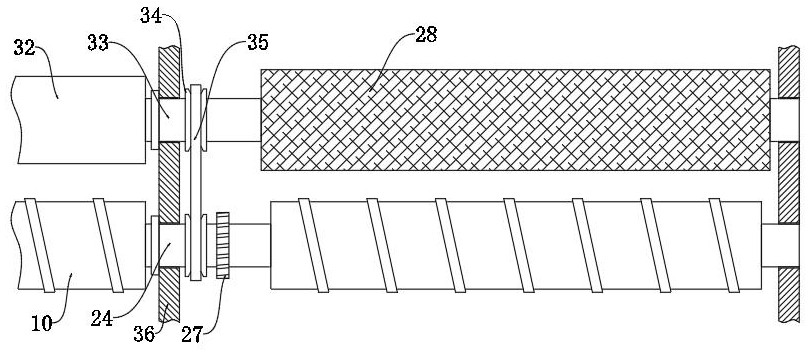

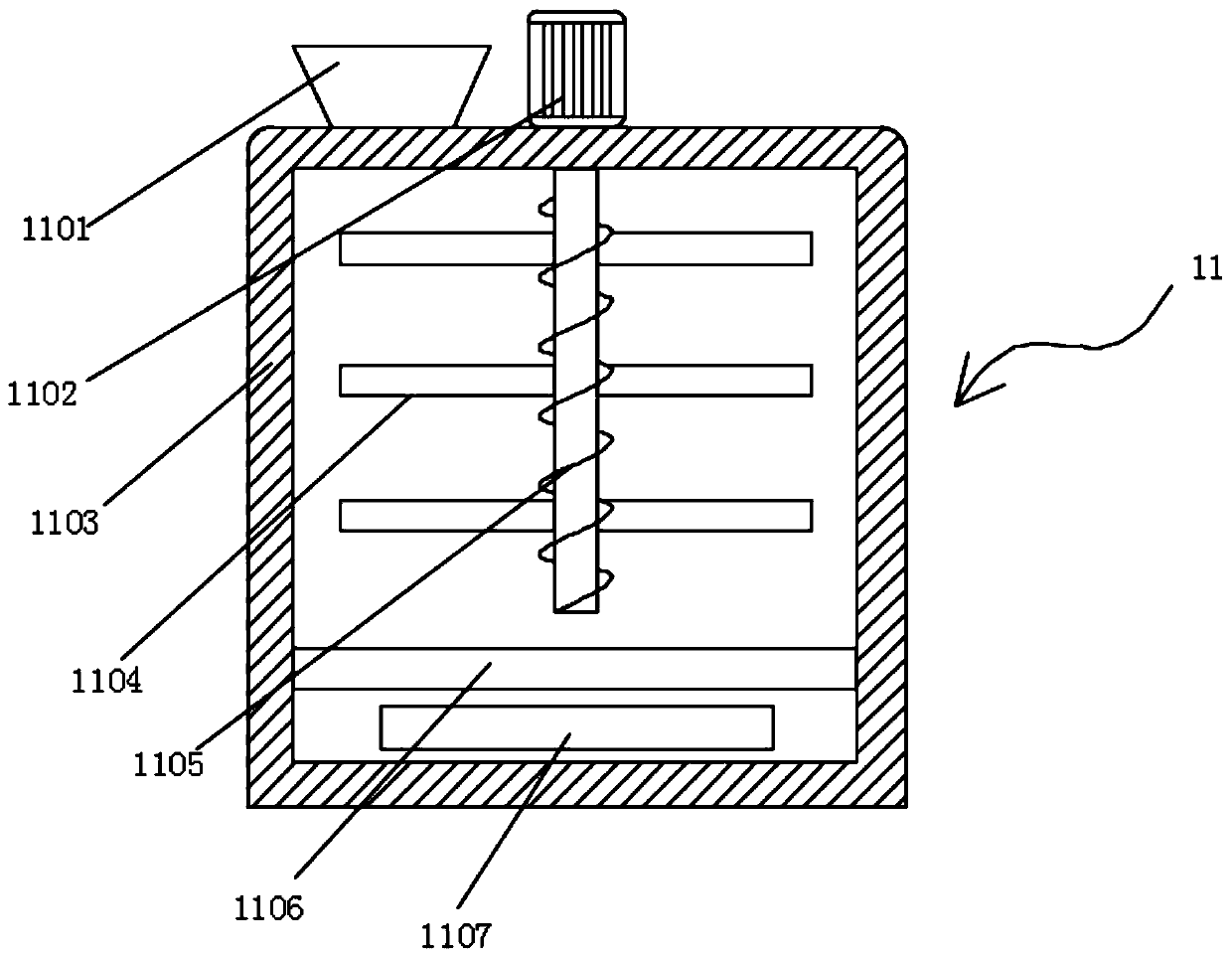

Large stainless steel pipe rolling type external force polishing and derusting mechanism

ActiveCN112338755AEfficient rust removalNo manual pushingLiquid surface applicatorsGrinding drivesSS - Stainless steelPipe

The invention discloses a large stainless steel pipe rolling type external force polishing and derusting mechanism comprising a box body, a partition plate is vertically arranged in the box body and divides the interior of the box body into a derusting chamber and a curing chamber which are arranged in the horizontal direction, and material passing openings are formed in the two side walls of thebox body and the partition plate correspondingly. A first rotating shaft and a second rotating shaft are arranged on the partition plate in a penetrating mode, the first rotating shaft and the secondrotating shaft are both rotationally connected with the partition plate, the ends of the first rotating shaft and the second rotating shaft are both rotationally connected to the inner wall of the boxbody, and the positions, located on the inner side walls of the derusting chamber and the curing chamber, of the first rotating shaft are both fixedly sleeved with feeding rollers. The large stainless steel pipe rolling type external force polishing and derusting mechanism is compact in structure and complete in function, rapid derusting, drying and curing of a stainless steel pipe can be achieved, manual pushing is not needed during derusting, time and labor are saved, the derusting efficiency is greatly improved, and the rust prevention performance of follow-up use of the steel pipe is improved.

Owner:浙江华鸣不锈钢有限公司

Water-based normal-temperature rust-removal rust-proof liquid and preparation method thereof

ActiveCN103882451AFast degreasingQuick rust removalMetallic material coating processesSODIUM METAPHOSPHATESodium phosphates

The invention relates to a water-based normal-temperature rust-removal rust-proof liquid, which is prepared from the following active ingredients in parts by weight: 1-2 parts of zinc oxide, 2-3 parts of manganese dioxide, 2-3 parts of citric acid, 22-24 parts of E-12 epoxy resin, 6-8 parts of sodium hexametaphosphate, 1-2 parts of dimethyl formamide, 2-3 parts of catechol, 1-2 parts of sodium dodecyl benzene sulfonate, 13-15 parts of bisphenol A epoxy acrylate, 1-2 parts of disodium edetate dihydrate, 4-5 parts of auxiliaries and 300 parts of water. The rust-proof liquid can fast remove oil and rust at normal temperature, and can be corrosion-resistant and antibacterial, a thin film can be formed on a metal surface by using organic polymer resin and a chelating agent so as to isolate air and achieve the oxidization prevention effect, and the corrosion-inhibition and rust-proof effects are better, the thin film is easy to remove with water, thus being energy-saving and environment-friendly.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

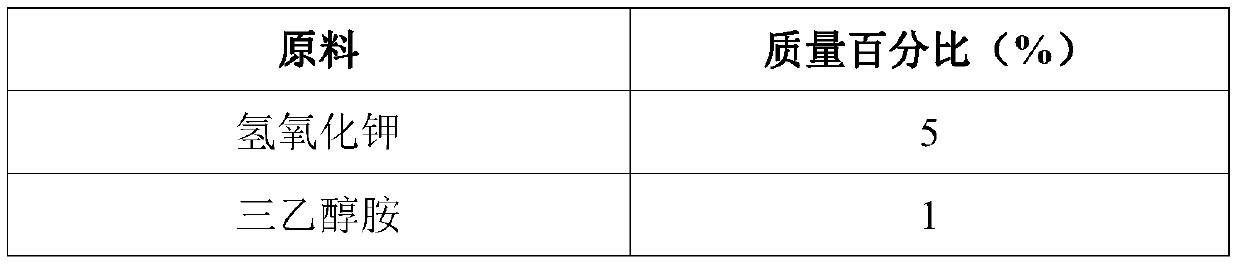

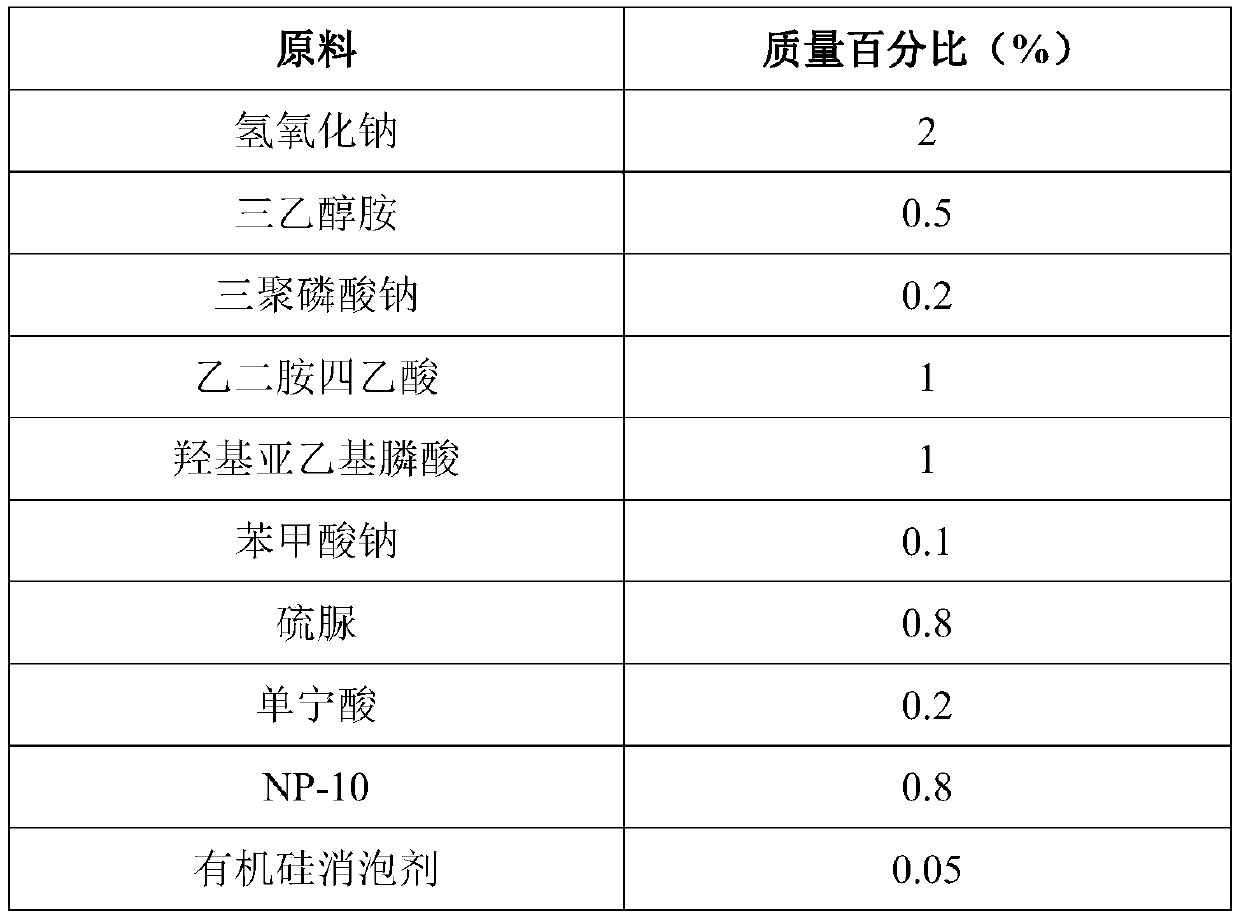

Alkaline steel rust remover and preparation method thereof

The invention discloses an alkaline steel rust remover and a preparation method thereof. The alkaline steel rust remover is prepared from the following components of, in percentage by mass, 0.1%-8% ofan alkali agent, 0.01%-5% of a complexing agent, 0.01%-3% of a corrosion inhibitor, 0.1%-3% of an emulsifier, 0.01%-0.05% of a defoaming agent, 0.02%-1% of a thickening agent and the balance water. The preparation method of the alkaline steel rust remover is very simple, and the components are mixed uniformly in batches; and the rust removal effect of the alkaline steel rust remover is good, steel is not corroded, acid mist is not generated, the hydrogen embrittlement phenomenon does not occur, the production process is simple, and safety and environmental protection are achieved.

Owner:广东中联邦精细化工有限公司

Rust removing and preventing liquid for steel and preparation method thereof

ActiveCN103614714ALow manufacturing process costGood rust resistanceMetallic material coating processesRosinChemistry

The invention discloses a rust removing and preventing liquid for steel. The rust removing and preventing liquid is prepared from the following raw materials in parts by weight: 1-2 parts of diallylamine, 2-3 parts of rosin-polythylene oxide ester, 1-2 parts of phosphoric acid, 1-2 parts of magnesium chloride, 2-3 parts of thiourea, 1-2 parts of sodium dodecyl sulfate, 6-9 parts of diethylene glycol dibenzoate, 1.5-2.5 parts of peregal, 1-2 parts of EDTA (ethylene diamine tetraacetic acid) disodium, 4-5 parts of additives, and 300 parts of water. The rust removing and preventing liquid for steel disclosed by the invention is rapid in rust removal; due to an adopted high-molecular polymer and a chelating agent, a layer of thin film is formed on the metal surface so as to achieve air-isolating and anti-oxidation effects, and the thin film is easily removed just by virtue of water washing. The rust removing and preventing liquid for steel disclosed by the invention is low in manufacturing process cost, and suitable for being used under the low temperature condition of 12-35 DEG C, and the film can be rapidly formed in 0.5-3 minutes, so that the rust prevention performance of the rust removing and preventing liquid for steel is good, and superior to GB6807 standards; the rust removing and preventing liquid for steel disclosed by the invention is small in environmental pollution, and beneficial to popularization and utilization.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

Oil and rust remover for metal surface

The invention discloses an oil and rust remover for a metal surface. The oil and rust remover is prepared from the following raw materials in parts by weight: 2-4 parts of hydrochloric acid, 3-6 partsof oxalic acid, 2-4 parts of citric acid, 3-5 parts of ascorbic acid, 3-6 parts of a complexing agent, 2-5 parts of a corrosion inhibitor, 2-4 parts of a permeability increasing agent, 2-6 parts of asurfactant and 50-90 parts of water, wherein the oil and rust remover is prepared from the following steps: S1, adding 400 mL of water into a reaction kettle of filling equipment; then slowly heatingthe solution to 30-50 DEG C by a heating element; and at the moment, driving a rotating motor to start to stir, adding the corrosion inhibitor while stirring, and stirring the solution for 10-15 minand fully dissolving the solution. The prepared oil and rust remover for the metal surface has the functions of deoiling, disacidifying, inhibiting corrosion and preventing oxidization. The rust removal time for light rust is about 2 min and the rust removal time for heavy rust is 5-6 min, and the deoiling rate can reach over 98%.

Owner:陈团英

Steel plate polishing and de-rusting device

InactiveCN111469036AQuick rust removalCollection will notGrinding carriagesGrinding drivesPhysicsSteel plates

The invention discloses a steel plate polishing and de-rusting device. The device comprises a device box body in which a supporting block cavity is formed, a polishing cavity is formed in an upper side of the supporting block cavity in a communicating mode, a supporting block is fixedly arranged in the supporting block cavity, a communicating cavity is formed in an upper side of the polishing cavity in a communicating mode, and a polishing stone capable of stretching up and down is arranged in the communicating cavity; an upper side of the communicating cavity is provided with a telescopic device for controlling the polishing stone to move up and down, the upper side of the communicating cavity is provided with a moving cavity in a communicating mode, a rear side of the moving cavity is provided with a moving device for controlling the moving block to slide left and right, a rear side of the polishing cavity is provided with a feeding cavity in a communicating mode, and a feeding device is arranged in the feeding cavity. Rusts on a steel plate can be removed through rotary moving polishing, double-sided polishing is conducted through overturning, and meanwhile, the rusts can be collected, and environment pollution is avoided.

Owner:福州市长乐区艾德利电子科技有限公司

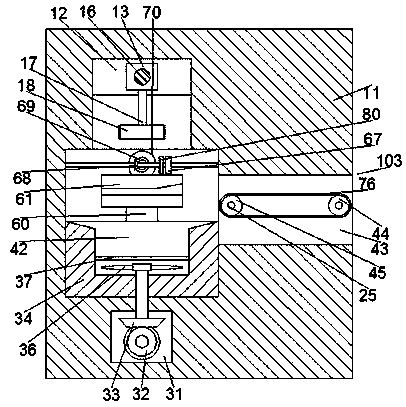

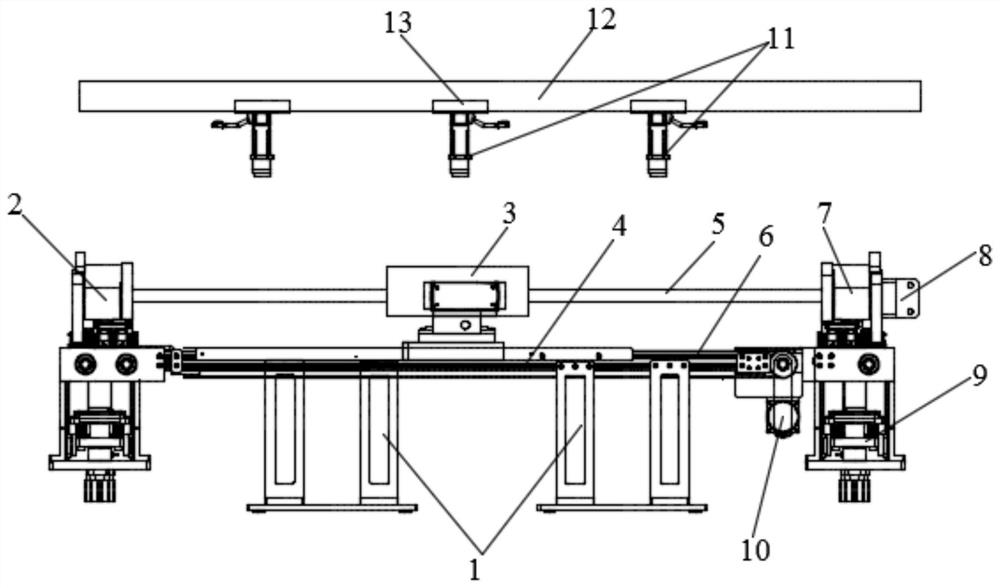

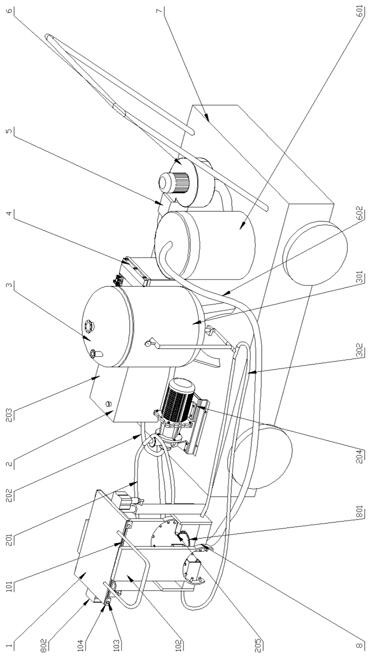

Rapid derusting and straightening equipment for oil field petroleum drilling drill rod

InactiveCN114273467AQuick rust removalImprove calibration accuracyGrinding carriagesGrinding drivesWell drillingOil field

The invention discloses rapid derusting and straightening equipment for an oil field petroleum drilling drill rod, which is provided with a first clamping mechanism, a second clamping mechanism, a visual inspection mechanism and a derusting and straightening mechanism, so that a controller can calculate each bent part of a contour and the bending degree of each bent part according to the contour of a vertical projection; the controller can control the derusting and straightening mechanism according to the bending part and the bending degree, so that the straightening efficiency and the straightening reliability are effectively improved, and the correction precision of the drill rod is improved; and the rust removal straightening mechanism straightens the bent part with the large bending degree firstly and then straightens the bent part with the small bending degree, so that the straightening efficiency and reliability are effectively improved, and the precision of the straightened drill rod is guaranteed.

Owner:黄增七

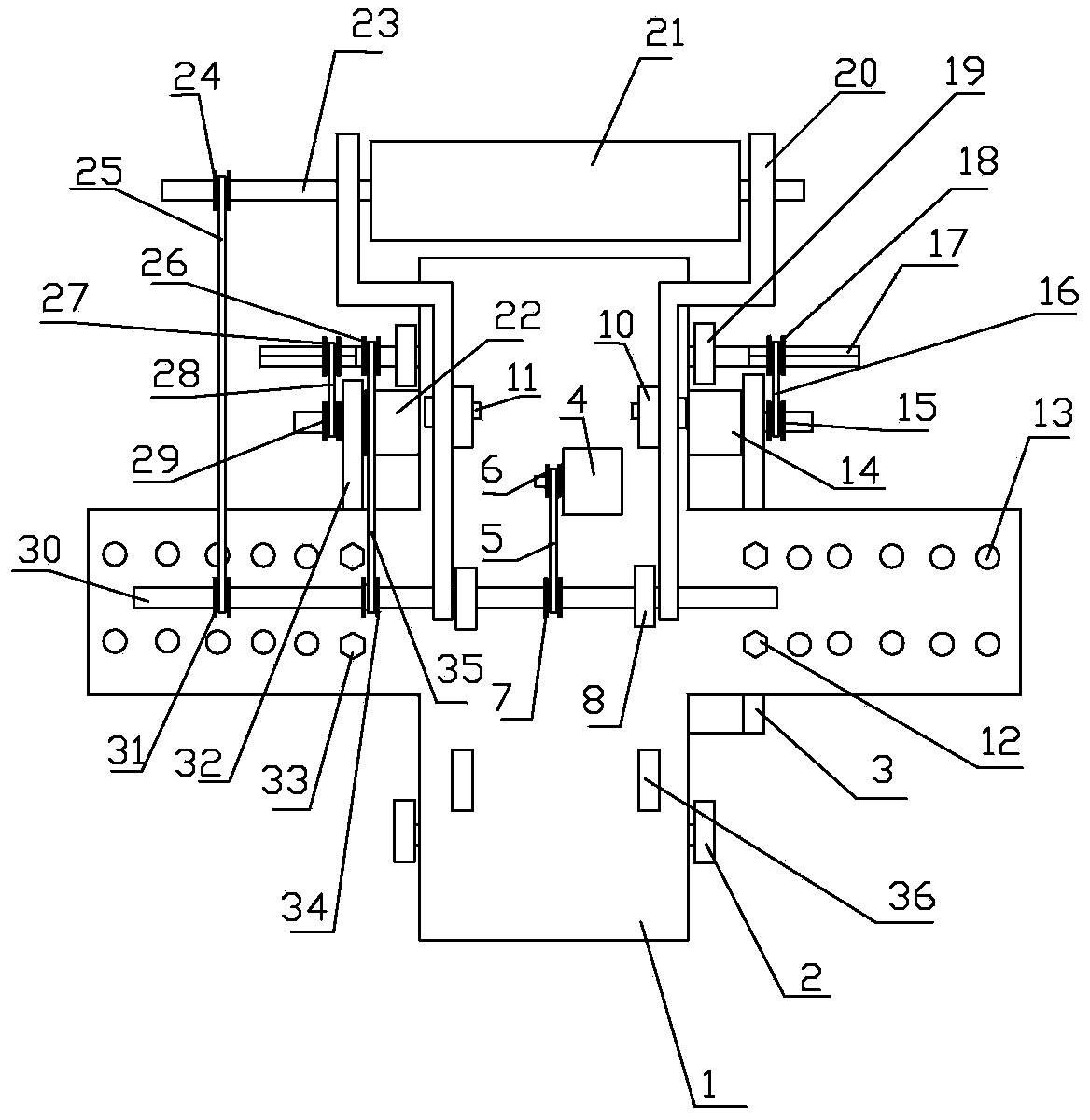

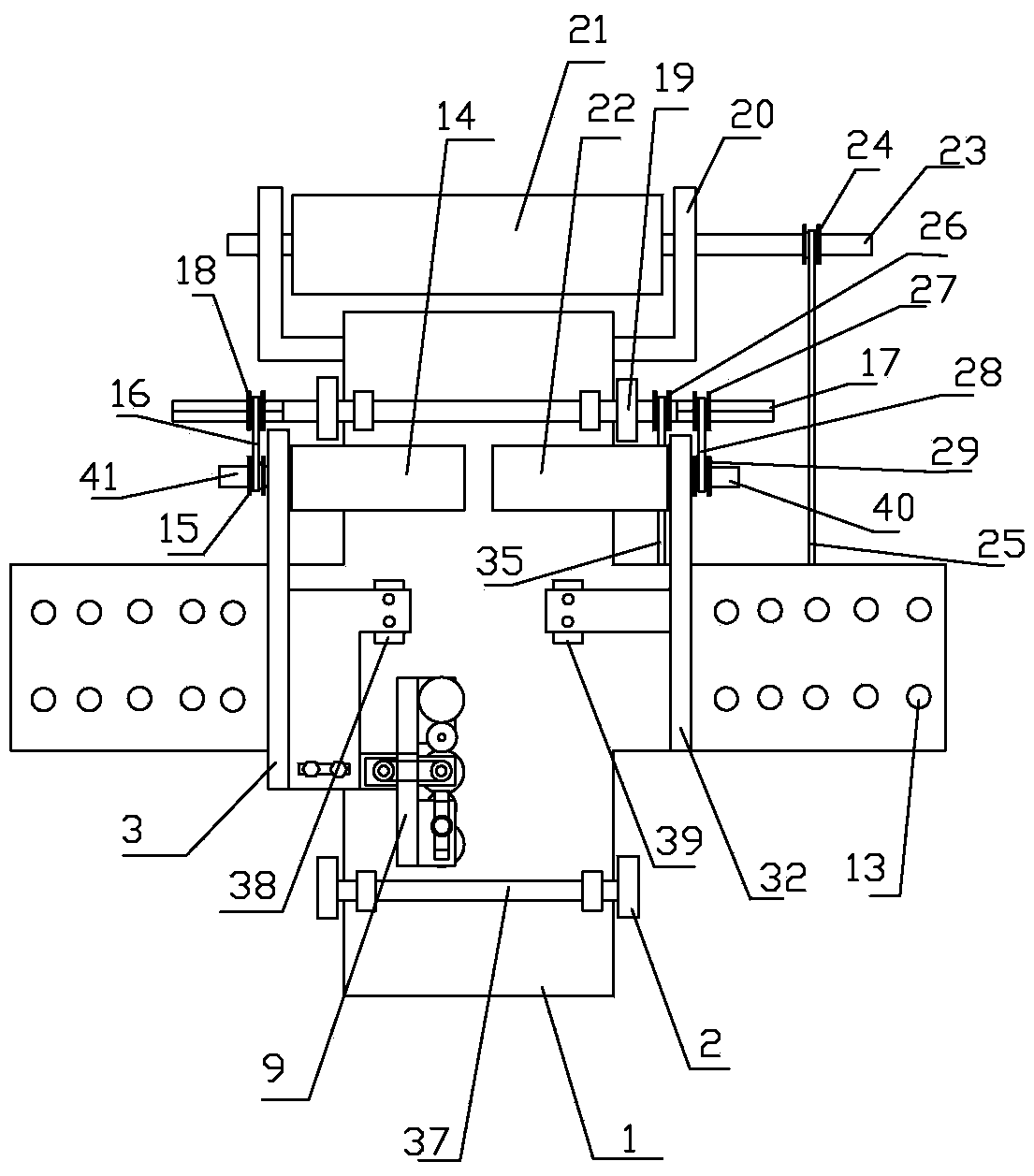

Hardware rust removing device

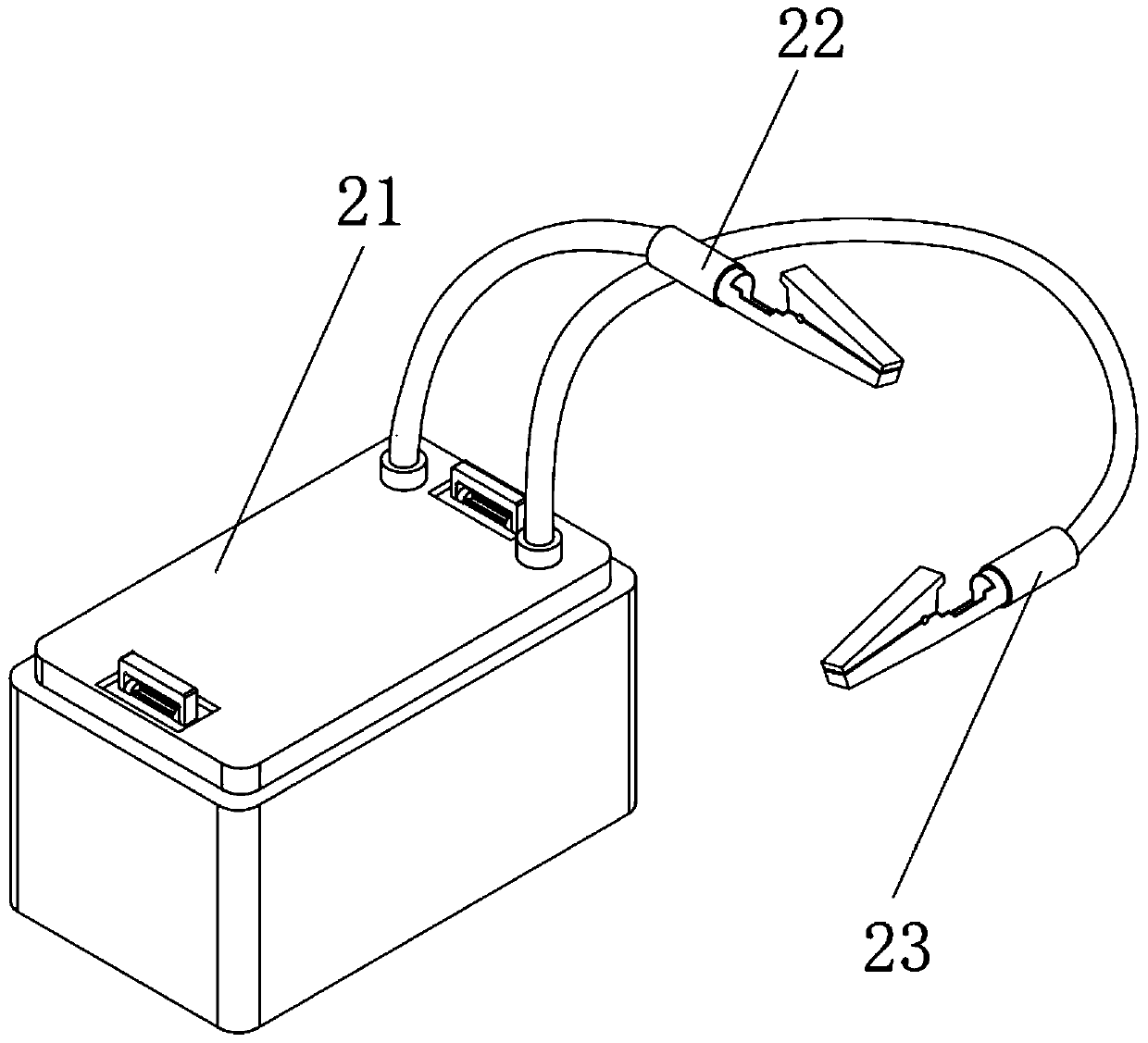

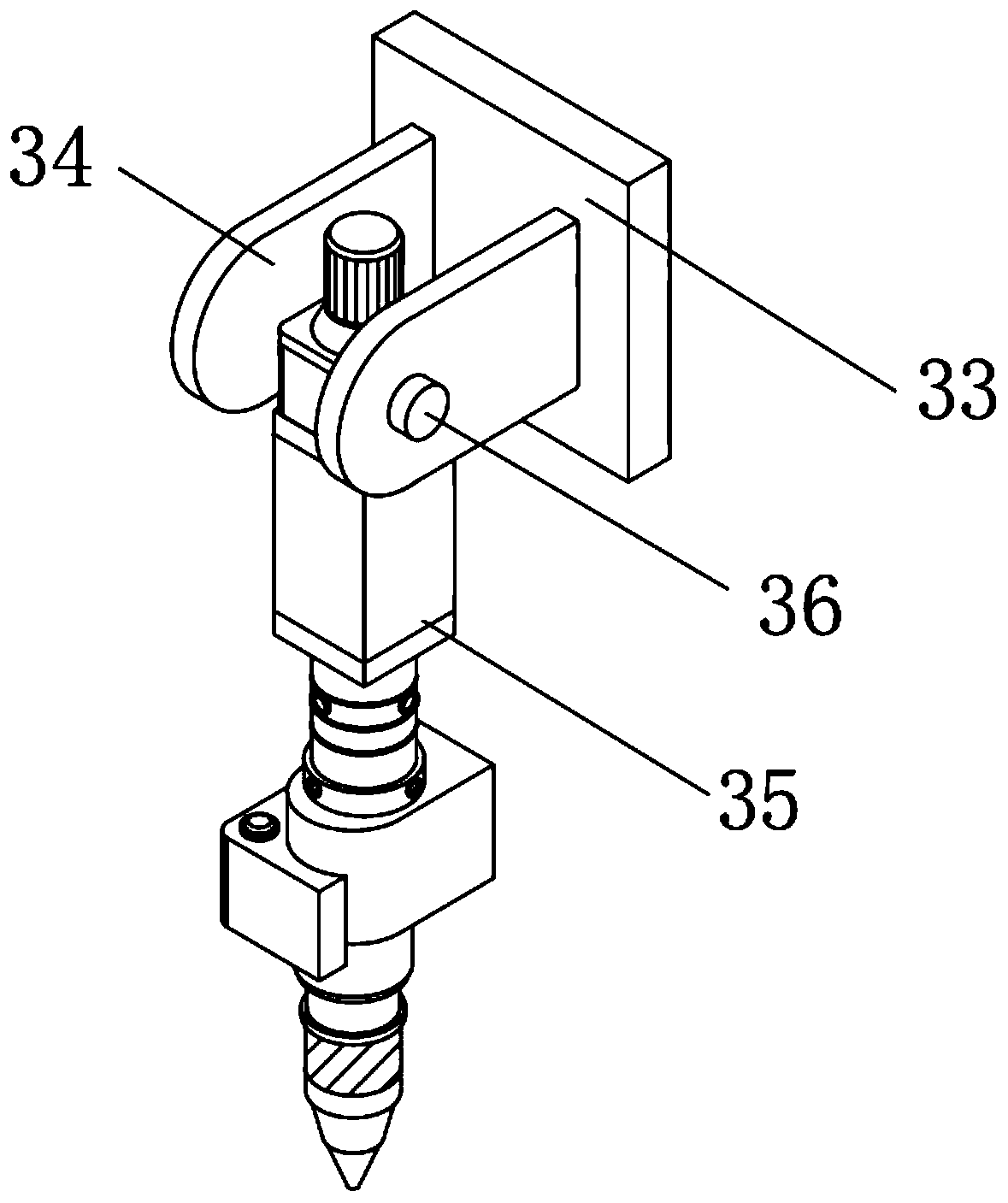

ActiveCN110592656AImprove rust removal effectDissolve fastElectrolysis componentsCleaning using liquidsEngineeringHigh pressure

The invention discloses a hardware rust removing device, and relates to the field of rust removing devices. The hardware rust removing device comprises a first box body; a rust removing module is arranged in the first box body, and comprises an accumulator; a positive output end and negative output end of the accumulator are connected with a positive terminal and a negative terminal through leads;an electrolyte rust removing pool is arranged at the top end of the accumulator; a high-pressure cleaning module is arranged at the top end of the electrolyte rust removing pool, and comprises a topplate; a stand column is arranged on one side of the top plate; a fixed plate is arranged at the bottom end of the top plate; two side arms are symmetrically welded on one side of the fixed plate; a water gun spraying head is arranged between the two side arms; and a locking bolt is arranged on one side of the water gun spraying head. Through cooperation of the rust removing module and the high-pressure cleaning module, the hardware rust removing device can quickly remove rust of hardware to prolong the service life of the hardware.

Owner:临沂未来科技城开发建设集团有限公司

Metal rust removing liquid and preparation method thereof

The invention discloses metal rust removing liquid and a preparation method thereof. The metal rust removing liquid comprises hexamethylenetetramine, triethanolamine, fatty alcohol-polyoxyethylene ether, sodium ethoxylated alkyl sulfate, polyethylene glycol, polyoxyethylene lauryl ether, triethanolamine oleate, sodium carboxymethylcellulose, lecithin and water. The preparation method comprises thesteps that the hexamethylenetetramine, the triethanolamine, the fatty alcohol-polyoxyethylene ether, the sodium ethoxylated alkyl sulfate, the polyethylene glycol and the sodium carboxymethylcellulose are dispersed in water, heating and stirring are carried out to achieve uniform dispersion, the polyoxyethylene lauryl ether, the triethanolamine oleate and the lecithin are added into the mixture,and after stirring and mixing, the metal rust removing liquid is obtained. The metal rust removing liquid is gentle in characteristics, and rust removing is easy and rapid.

Owner:SUZHOU HAOYAN PRECISION MOLD CO LTD

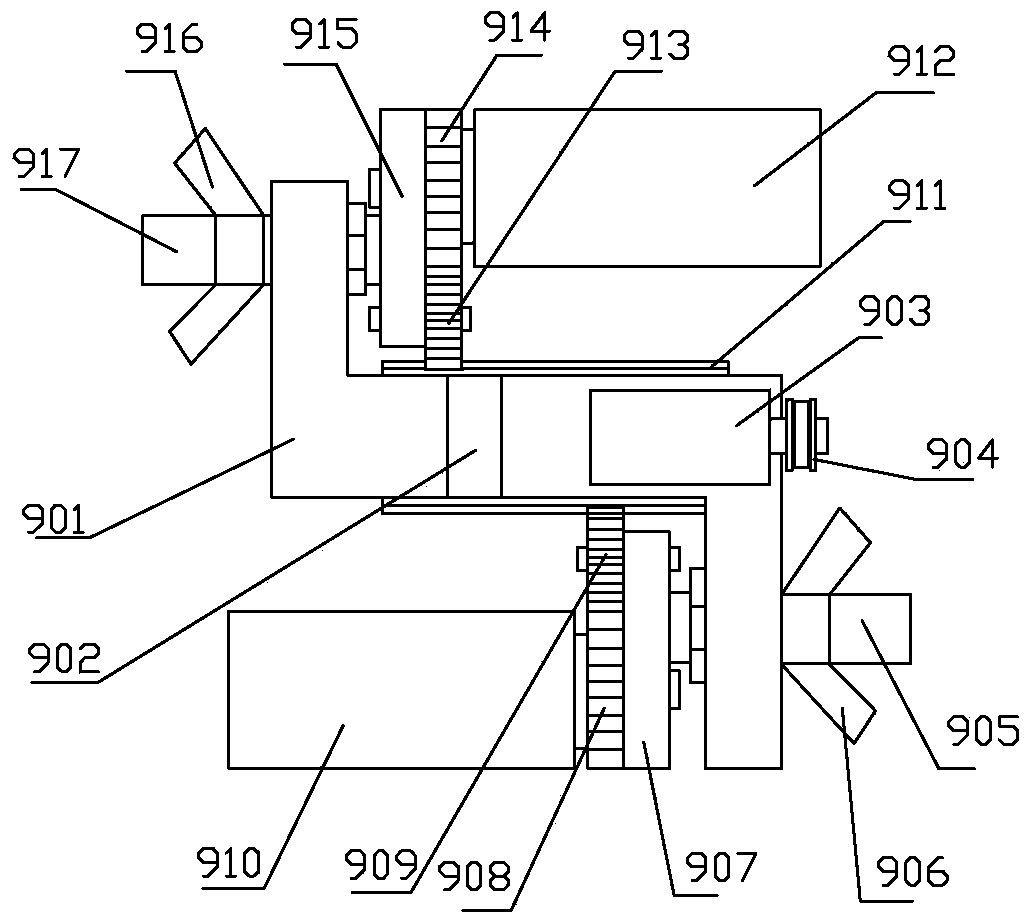

Vertical H-shaped steel four-face rust removal device

InactiveCN109277924AQuick rust removalReduce labor intensityGrinding carriagesGrinding machinesVehicle frameAgricultural engineering

The invention discloses a vertical H-shaped steel four-face rust removal device. The vertical H-shaped steel four-face rust removal device comprises a frame, a third rotary rod, a front wheel, a fourth rotary rod, a rear wheel, motors and brush rollers. The vertical H-shaped steel four-face rust removal device is characterized in that a first rotary rod is arranged in the middle of the frame, andthe first motor and the first rotary rod are in transmission; a second rotary rod is arranged at the front end of a clamping rod, the front brush roller is arranged on the second rotary rod, and the first rotary rod and the second rotary rod are in transmission; the first rotary rod and the third rotary rod are in transmission; a left rotary shaft is arranged at the front end of a left fixing plate of the frame, the left brush roller is arranged on the left rotary shaft, and the left rotary shaft and the third rotary rod are in transmission; a right rotary shaft is arranged at the front end ofa right fixing plate of the frame, the right brush roller is arranged on the right rotary shaft, and the right rotary shaft and the third rotary rod are in transmission; a left clamping wheel is arranged in the middle of the left fixing plate, and a right clamping wheel is arranged in the middle of the right fixing plate; and a web roll-brushing device is fixedly arranged on the rear portion of the right fixing plate. Standing H-shaped steel can be rapidly subjected to rust removal, the four faces of the H-shaped steel can be cleaned at a time, and therefore time and labor are saved.

Owner:LAIWU VOCATIONAL & TECHNICAL COLLEGE

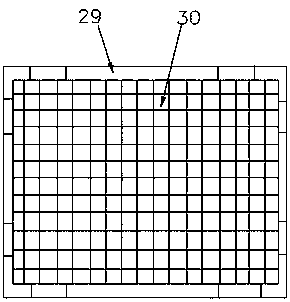

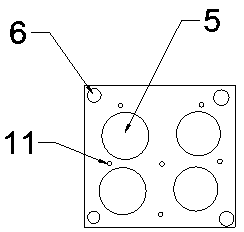

Steel grit descaling recovery and circulation system

PendingCN108098594AQuick rust removalReduce pollutionAbrasive machine appurtenancesAbrasive blastingEngineering

The invention discloses a steel grit descaling recovery and circulation system. The steel grit descaling recovery and circulation system includes a grit absorption mechanism, a grit storing mechanism,and a grit blasting mechanism. The grit blasting mechanism is arranged on the lowest side. The grit storing mechanism is arranged between the grit absorption mechanism and the grit blasting mechanism. The grit blasting mechanism includes two cubic grit cylinders, an air compressor, and a spraying gun. The two cubic grit cylinders are separately connected with the air compressor through air pipes.The spraying gun is connected with the cubic grit cylinders. The grit storing mechanism includes a grit storing cylinder. The grit absorption mechanism includes a grit absorption machine, a grit absorption cylinder, a grit absorption pipe, and a dust removing assembly. The steel grit descaling recovery and circulation system is novel in structural resign, simple in operation, and convenient to mount, descaling treatment can be conducted to the structural component surface rapidly; dust pollution can be reduced; continuous grit blasting can be achieved; gun stopping is not needed during grit adding; work efficiency is greatly improved; and effective guarantee can be achieved to the quality and the construction period of the whole project.

Owner:南通中远克莱芬船舶工程有限公司

Novel rust remover and production method thereof

The invention discloses a novel rust remover. The novel rust remover comprises 10-25wt% of acetic acid, 6-15wt% of citric acid, 5-18wt% of hexamethylene tetramine, 11-19wt% of sodium phosphate, 0.5-2.6wt% of a corrosion inhibitor, 5-10wt% of urotropine, 5-12wt% of triethanolamine, and the balance of water. A production method of the novel rust remover comprises the following steps: adding water, acetic acid, sodium phosphate and hexamethylene tetramine into a container at normal temperature under normal pressure, stirring until complete mutual dissolution, adding citric acid phosphonic acid, urotropine and triethanolamine, stirring, adding the corrosion inhibitor after complete dissolution, sampling, detecting, and packaging.

Owner:DALIAN KELINER CHEM TECH

Environmentally friendly metal rust remover and production method thereof

The invention discloses an environmentally friendly metal rust remover. The environmentally friendly metal rust remover comprises 10-20wt% of hydrochloric acid, 15-25wt% of tartaric acid, 5-13wt% of urea, 11-19wt% of sodium sulfite, 5-10wt% of sodium hydroxide, 0.5-2.5wt% of a corrosion inhibitor, and the balance of deionized water. A production method of the environmentally friendly metal rust remover comprises the following steps: adding deionized water, hydrochloric acid, sodium sulfite and urea into a container at normal temperature under normal pressure, stirring until complete mutual dissolution, adding tartaric acid and sodium hydroxide, stirring, adding the corrosion inhibitor after complete dissolution, sampling, detecting, and packaging.

Owner:DALIAN KELINER CHEM TECH

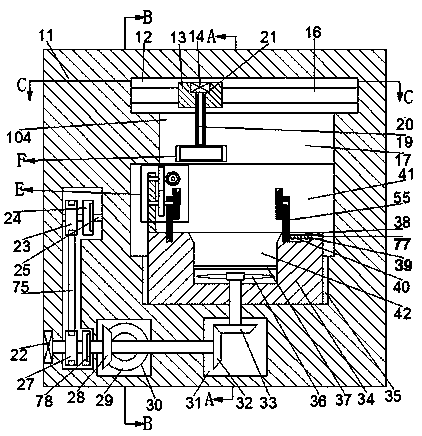

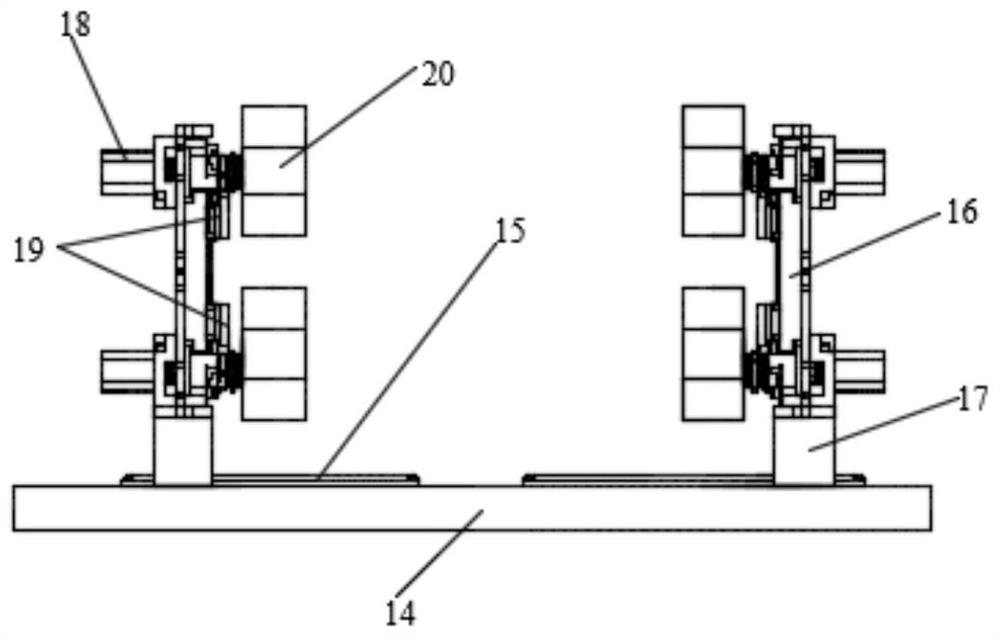

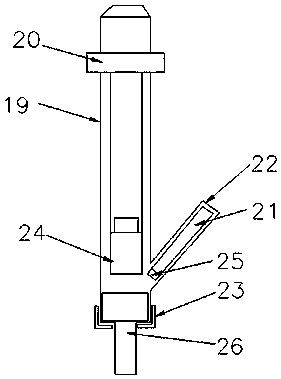

Surface rust removal device for petroleum drill rod

ActiveCN111318948AQuick rust removalQuick and thorough rust removalGrinding carriagesGrinding drivesReciprocating motionElectric machinery

The invention discloses a surface rust removal device for a petroleum drill rod. Automatic flow-type grinding rust removal for the petroleum drill rod can be achieved, moreover the rust removal effectis good, rapid and thorough rust removal for the petroleum drill rod can be achieved, during rust removal, while a high-speed grinding motor of a grinding rust-removal mechanism rotates at high speed, a swinging driving mechanism drives a swinging seat to swing, then while grinding steel wire bundles swing, a telescopic driving mechanism further drives the grinding steel wire bundles to reciprocate up and down slightly, rapid rust-removal treatment for the drill rod at all angles and in all areas can be guaranteed, and the thorough rust removal is guaranteed. During rust removal, the petroleum drill rod can rotate around the axial direction of the device, and thus, turnover rust removal can be achieved while conveying can be achieved automatically; and during rust removal, the petroleum drill rod can be jacked up and pressed with a pressing beam and a pressing wheel set, driving of a pressing rod driving mechanism is flexible, shifting of pressing down and lifting up of the pressing wheel set can be conveniently achieved, and the operation conveniences are improved.

Owner:XI'AN PETROLEUM UNIVERSITY

Handheld equipment suitable for steel plate rust removal

InactiveCN110450033AQuick rust removalExtended storage timePortable grinding machinesSheet steelSurface mounting

The invention provides handheld equipment suitable for steel plate rust removal. The handheld equipment suitable for the steel plate rust removal comprises a rust remover shell, a rust remover handle,a safety switch, a support cabinet, a transformer, a liquid tank, a liquid supply motor, main brush heads, auxiliary brush heads, a motor, a transmission shaft, a gearbox, a pressurization motor anda spraying opening, wherein the rust remover handle is fixedly connected to the upper surface of the rust remover shell, and the safety switch is arranged on the inner side surface of the rust removerhandle; the main brush heads are arranged on the lower surface of the rust remover shell, and the auxiliary brush heads arranged on the lower surface of the rust remover shell can achieve efficient rust removal of edges and corners; and the motor is arranged inside the rust remover shell, the pressurization motor is fixed inside the rust remover shell, and the gearbox is arranged inside the rustremover shell through screws. Steel plates with various sizes and shapes can be directly subjected to cleaning and rapid rust removal, steel storage time can be greatly prolonged with the assistant ofthe combination of the brush heads and a rust removal and antirust agent, and economic loss caused by rusting can be reduced.

Owner:徐州市茗尧机械制造有限公司

Pipe joint rust removing method

InactiveCN107937924ASimple processEasy to operateMetallic material coating processesWarm waterHigh pressure

The invention provides a pipe joint derusting method, comprising the following steps: a, removing slag, sanding the outer surface of the pipe joint to remove rust spots; b, cleaning, washing the workpiece with a high-pressure water gun of 5-10 MPa; c, immersing and derusting Oil for 1-2 hours; d, neutralization treatment, add the workpiece soaked in rust-removing oil to alkaline solution for neutralization treatment; e, cleaning, wash with warm water at 50-70°C for 20-30 minutes; f, drying , Dry the workpiece with a dryer. The rust removal method for the pipe joint of the present invention has simple process and convenient operation, can quickly remove rust, and simultaneously generates an oxidized coating to achieve better rust prevention effect.

Owner:NINGBO YINZHOU LUTONG HYDRAULIC PIPE FITTINGS FACTORY

A gear immersion derusting device

The invention relates to a soaking rust removal device for gears. The soaking rust removal device for gears comprises a bottom board, and a rust removal pool is arranged on the bottom board. A feed inlet is formed in the end of the rust removal pool. A filtering tank is arranged on each side of the end of the rust removal pool. An opening is formed in the end of each filtering tank, and a filtering screen is arranged inside each filtering tank. A solution drainage pump is arranged between each filtering tank and the end of the rust removal pool. Connecting plates are arranged on the inner side walls of the end of the rust removal pool. A magnetic attraction plate is arranged between the lower ends of the connecting plates. By means of the soaking rust removal device for gears, gears can be soaked in a rust removal solution, and rust can be removed conveniently and rapidly.

Owner:TAICANG BAODA RACK

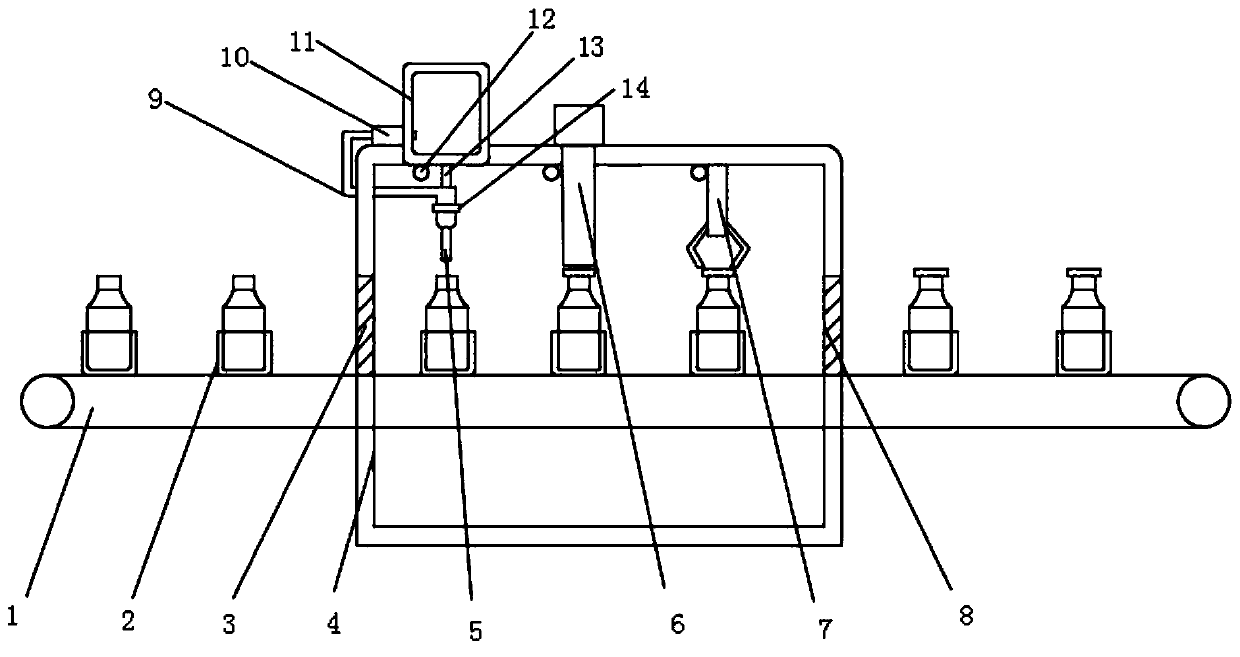

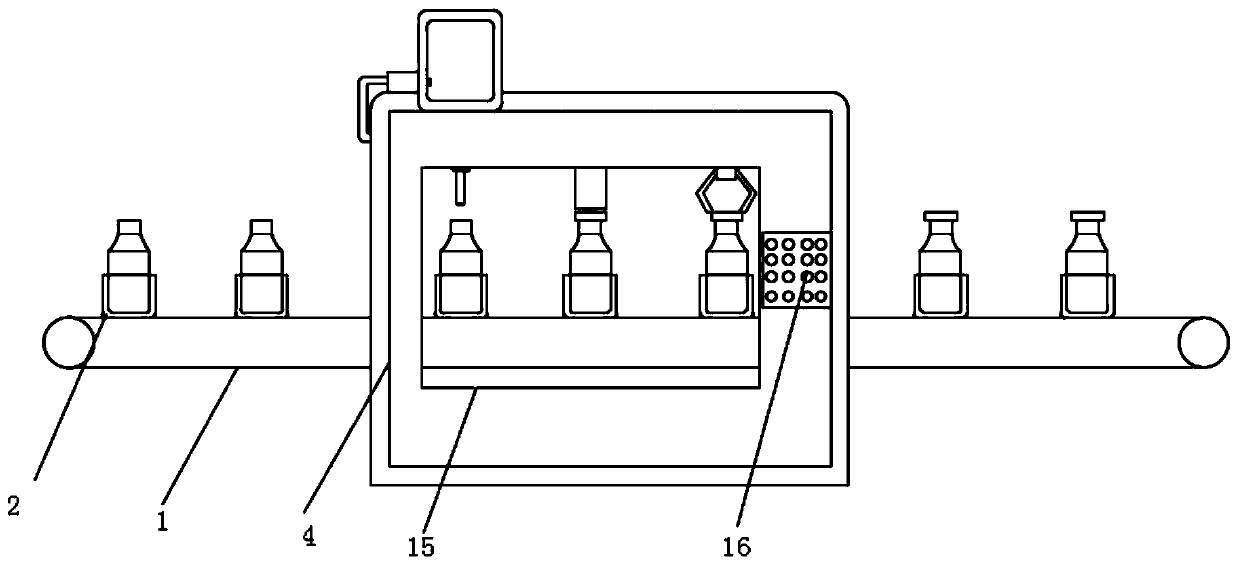

Rust removal and paint spraying device for bridge guardrail

InactiveCN112676090AQuick rust removalEffective absorptionPretreated surfacesAbrasive machine appurtenancesMetallurgyBridge maintenance

The invention provides a rust removal and paint spraying device for a bridge guardrail, and belongs to the technical field of bridge maintenance. The rust removal and paint spraying device is used for solving the problems of low efficiency and inconvenience during rust removal and paint spraying of a bridge. The rust removal and paint spraying device comprises an adjusting support and a vehicle body, wherein symmetrical sliding grooves are formed in the two sides of the adjusting support, symmetrical sliding plates are slidably arranged on the sliding grooves, guide rods are fixed to the lower sides of the sliding plates, lifting mechanisms are arranged on the sliding plates and the guide rods, symmetrical guide plates are fixed to the side end of the adjusting support, a paint spraying mechanism, a dust removal mechanism, a storage battery, a heating box and a dust suction mechanism are arranged on the vehicle body, the dust suction mechanism is connected with the air inlet end of the heating box, a hot air pipe is arranged at the air outlet end of the heating box, and the paint spraying mechanism, the rust removal mechanism, the hot air pipe and the dust collection mechanism are connected with the lifting mechanisms. According to the rust removal and paint spraying device, dust removal and paint spraying can be carried out on the bridge guardrail quickly and efficiently, the working efficiency is improved, and meanwhile, paint on the bridge guardrail is dried, sand grains generated during rust removal are effectively sucked, repeated utilization can be achieved, and influences on subsequent work are avoided.

Owner:安徽六安公路桥梁工程有限公司

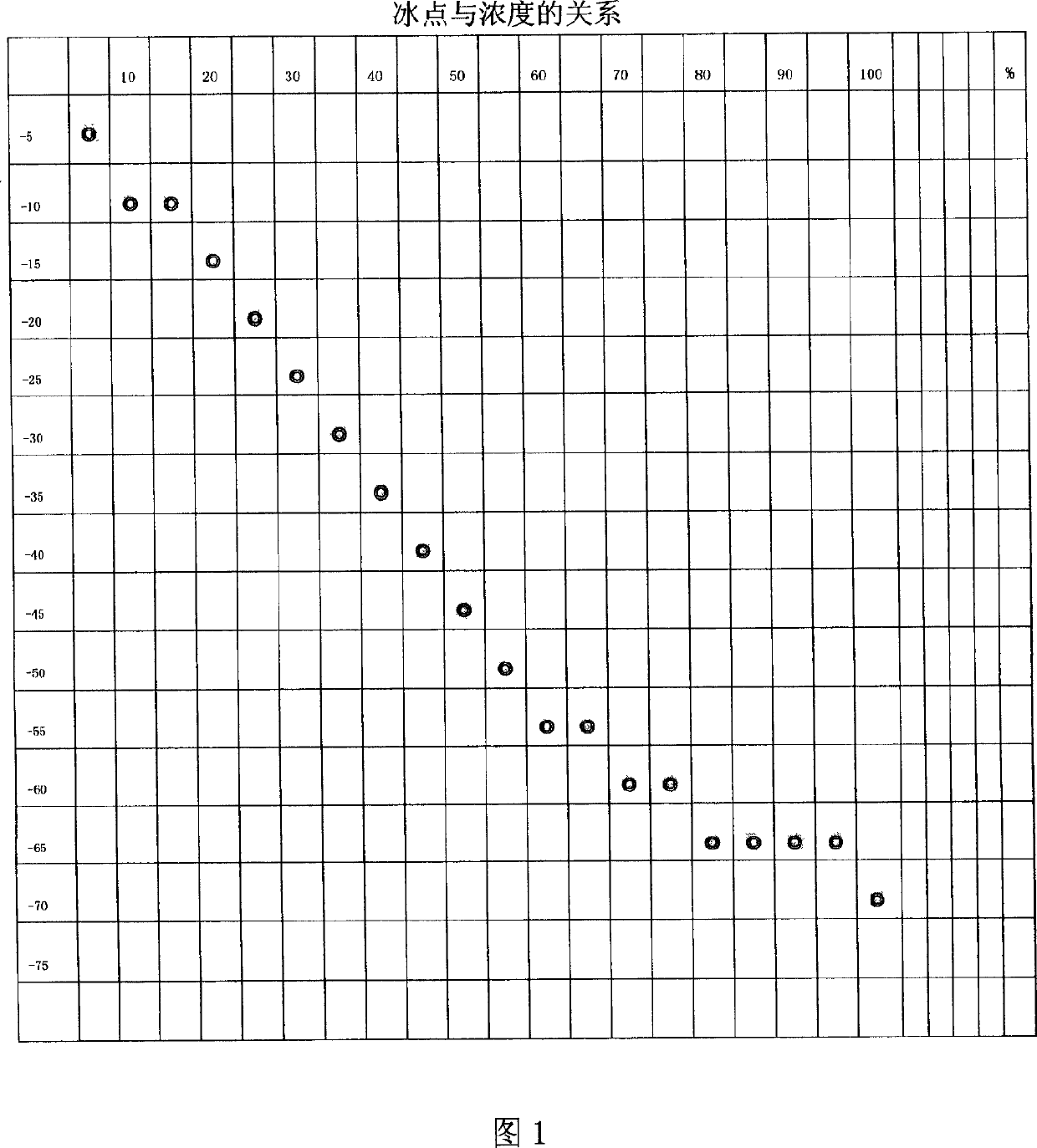

Multi-functional low temp. resisting corrosion-proof and anti-rust type freeze-proofing liquid and its products prepn. method

InactiveCN1831078AEasy to storeEasy to transportHeat-exchange elementsBenzoic acidTemperature resistance

This invention discloses multifunction low temperature resistance anticorrosion anti-rust anti-icing fluid and its preparation method. The base composition of the fluid is saturated organism ion activity water, xylene, tween, benzoic acid, methylene langley. The method is that the water is heated and toluene and benzoic acid are added in it, then fully agitated, the needed tween is added when the temperature is reduced, the agitated again, finally methylene Langley is added, the pH is 7.6-8.9 at the time, so it is the anti-icing fluid. The water can form a kind of bio-membrane at surface of the metal, the boiling point is high, dirty block is strong, strong rust removing ability, strong anticorrosion, super anti-freezing, non burning and explosion, non poisonous, it can be repeat use, its cost is low, heat capacity is large, also it is non-poison to human body and plant. It has great social and economic benefit to improve automobile performance.

Owner:AOERTAI SCI DEV

Preparation method of rust remover

The invention discloses a rust remover. The rust remover comprises the following components: sodium carbonate, sodium phosphate, sodium benzoate, citric acid, naphthenic acid, triethanolamine, mahogany petroleum sulfonate, hydrogen peroxide and water. According to the rust remover disclosed by the invention, all components are skillfully matched; a good rust removal effect is achieved; moreover, a preparation method of the rust remover disclosed by the invention is simple and easy to operate.

Owner:江苏绿科生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com