Patents

Literature

97results about How to "Efficient rust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

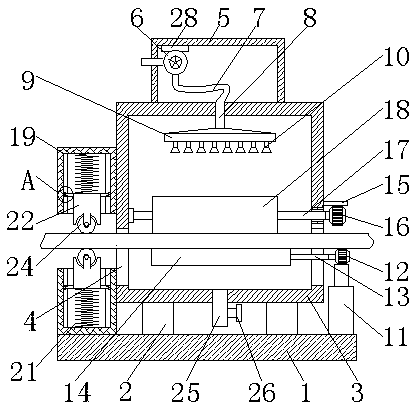

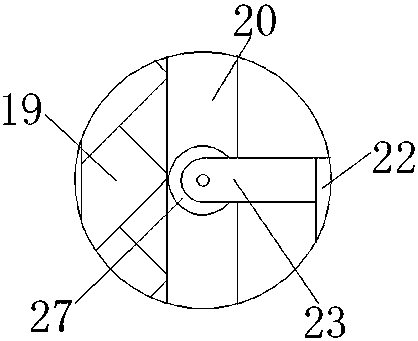

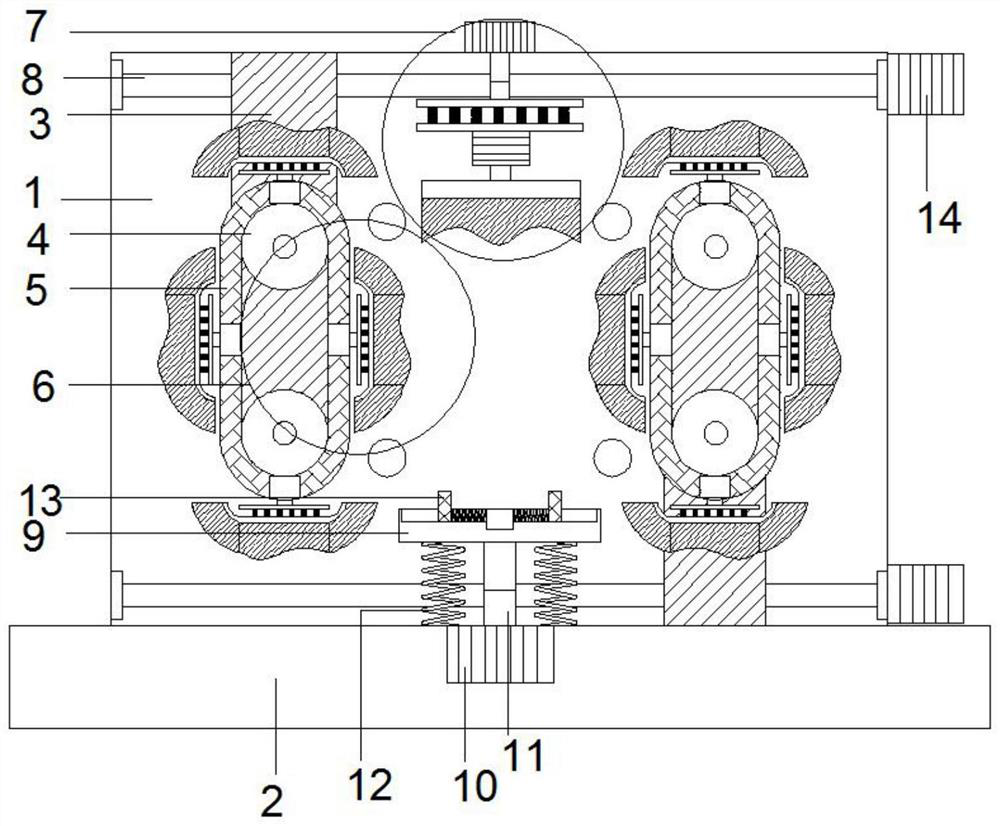

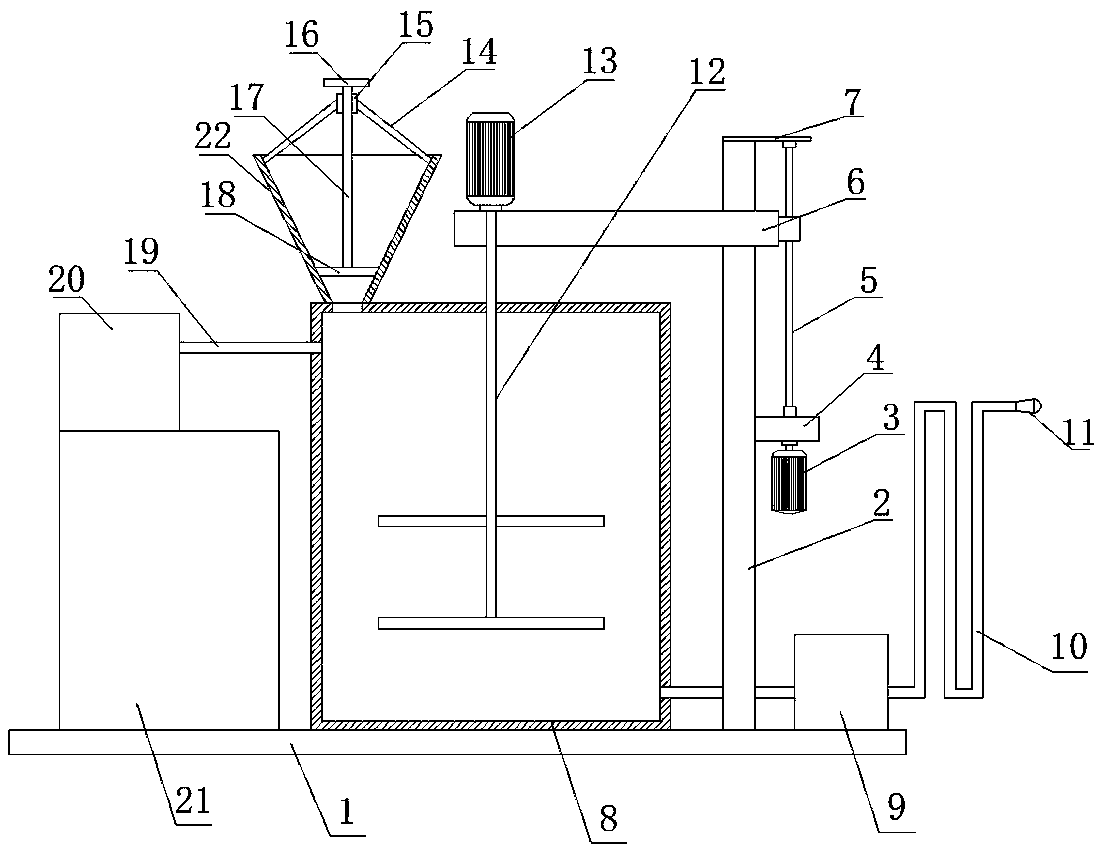

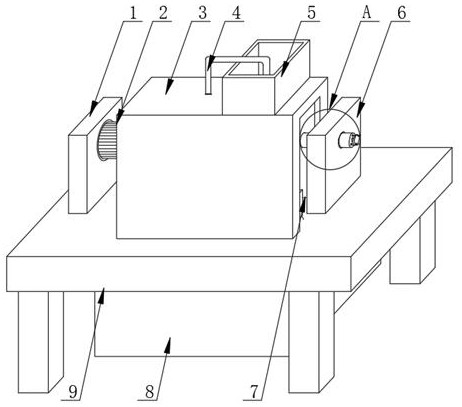

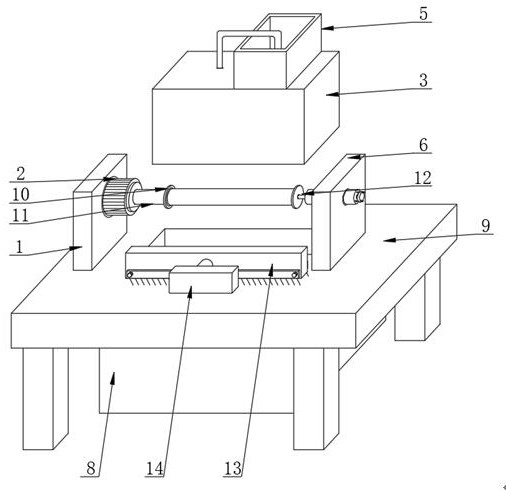

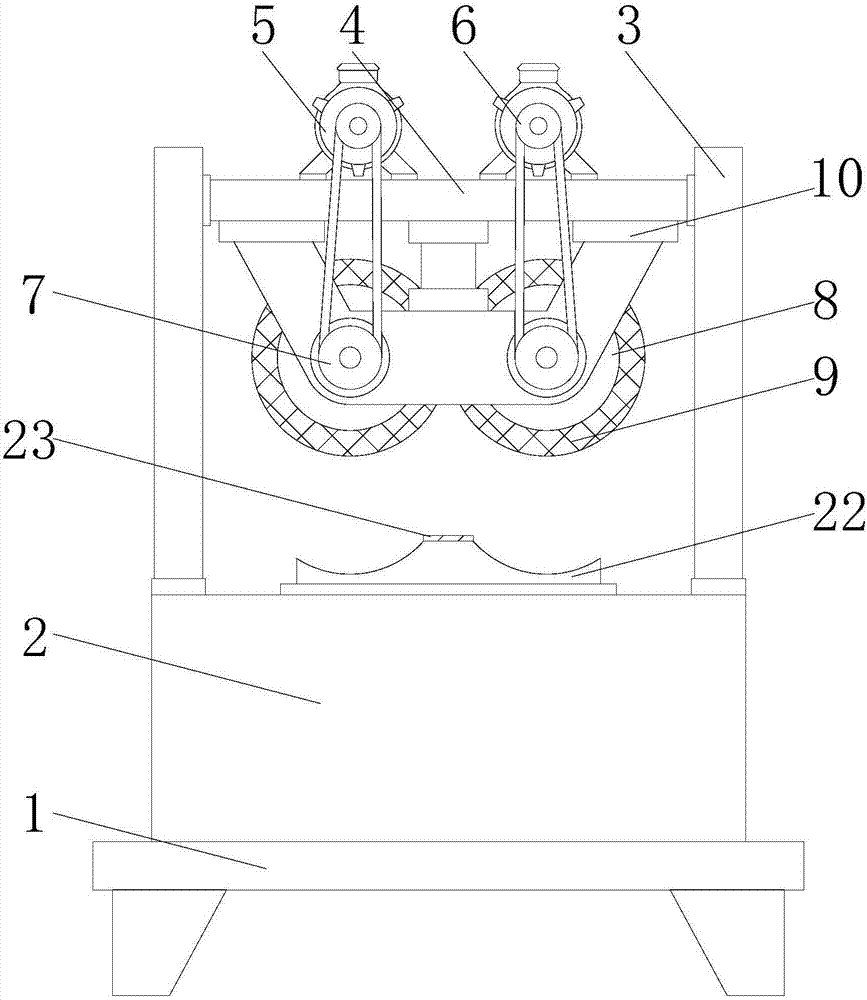

Reinforcing steel bar rust removal device

InactiveCN107775505AIncrease workloadIncrease frictionGrinding machinesCleaning using liquidsWire brushRebar

The invention discloses a steel bar derusting device, which comprises a base, a support column is fixedly connected to both sides of the top of the base, a box body is fixedly connected to the top of the support column, long holes are opened on both sides of the box body, and the top of the box body is fixed. A liquid storage tank is connected, and a water pump is arranged in the inner chamber of the liquid storage tank, and the water inlet pipe of the water pump runs through the liquid storage tank and extends to the left side of the liquid storage tank. The steel bar derusting device, through the box, the water pump, the hose, the standpipe, the shunt pipe, the nozzle, the electric telescopic rod, the first motor, the first rotating rod, the first wire brush, the second motor, the second rotating rod, The combined use of the second steel wire brush, casing, spring, bracket and grinding wheel has the advantages of efficient rust removal, and solves the problem that the existing steel bar rust removal device has a relatively single structure, and most of the steel bars are derusted by grinding, and cannot be rusted according to The size of the steel bar is fixed and cleaned, which not only increases the workload of the user but also reduces the practicality of the derusting device.

Owner:李鹏鹏

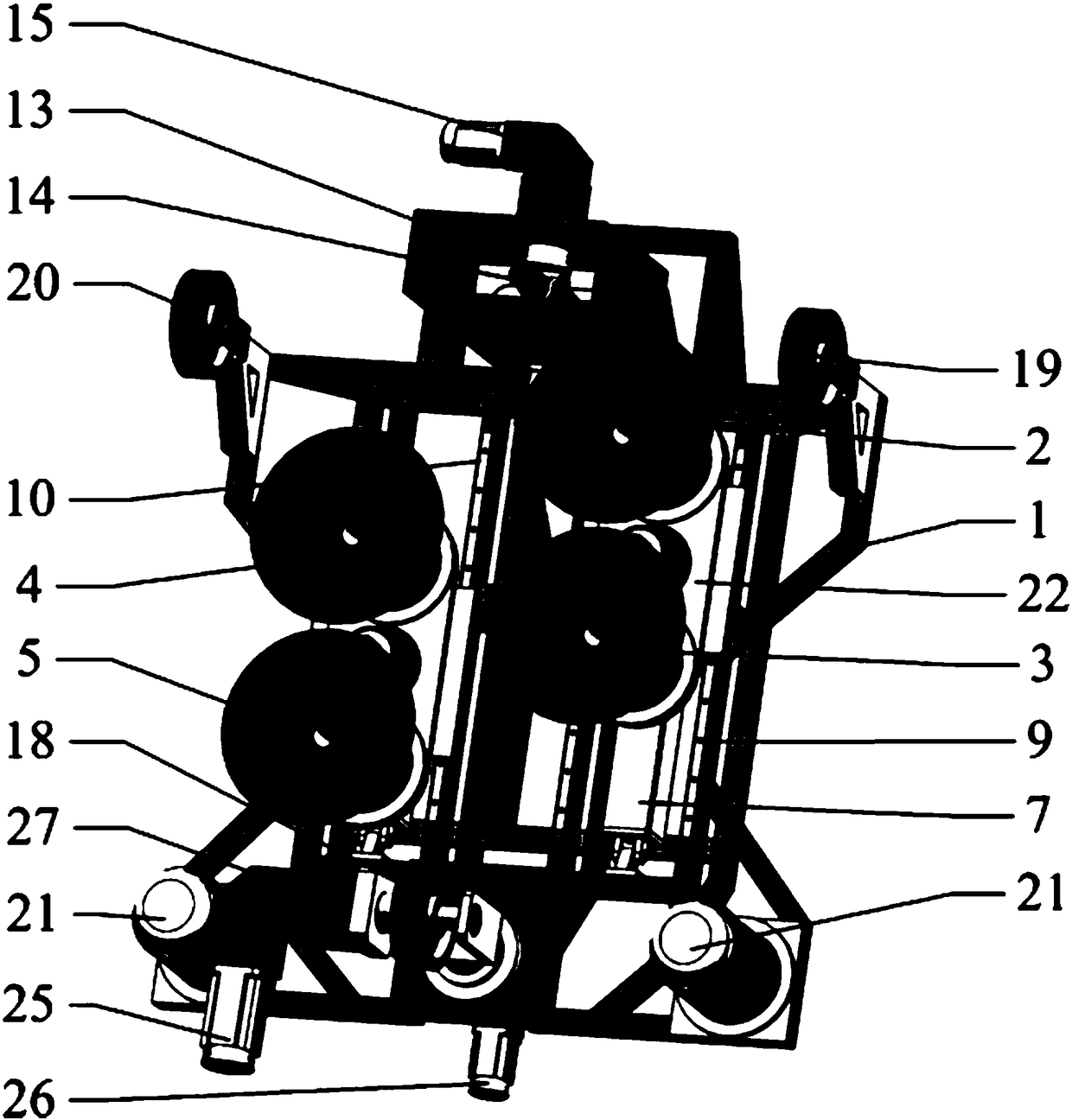

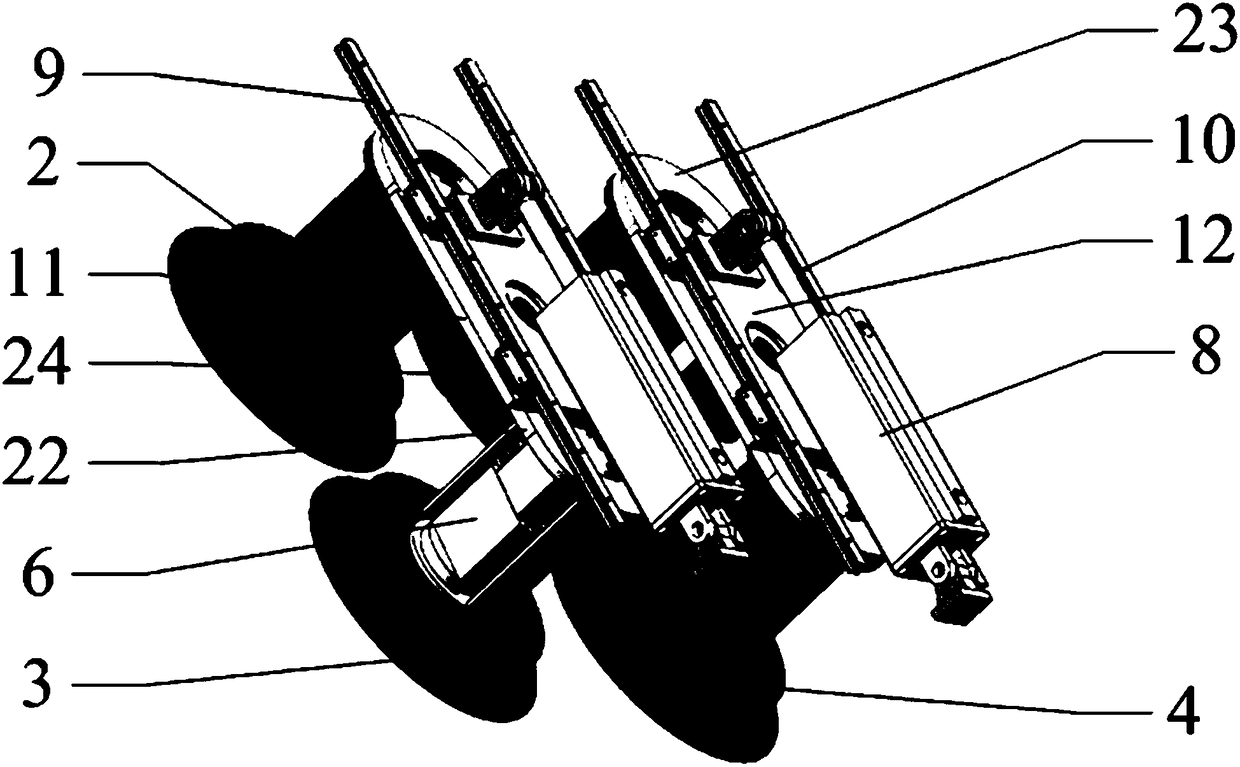

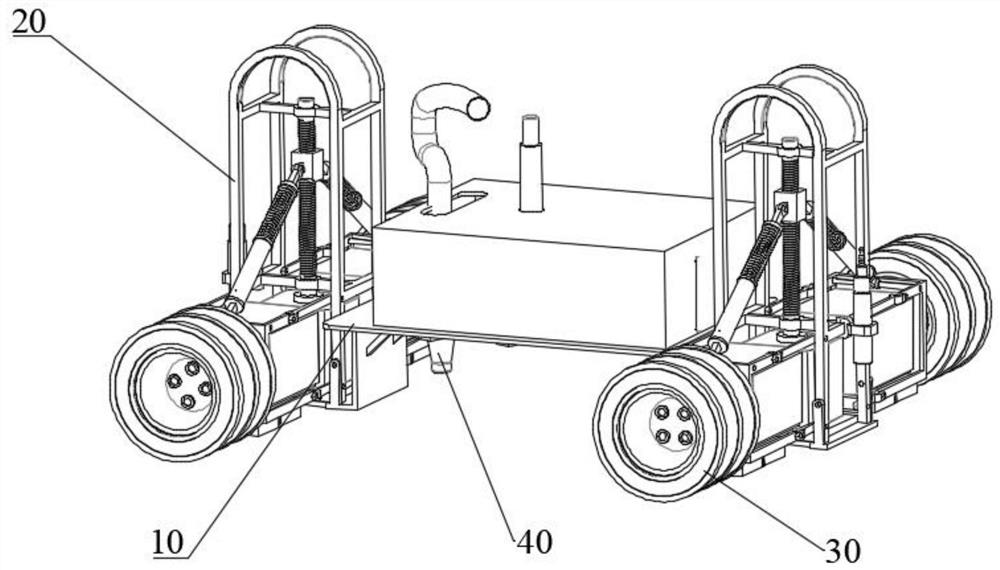

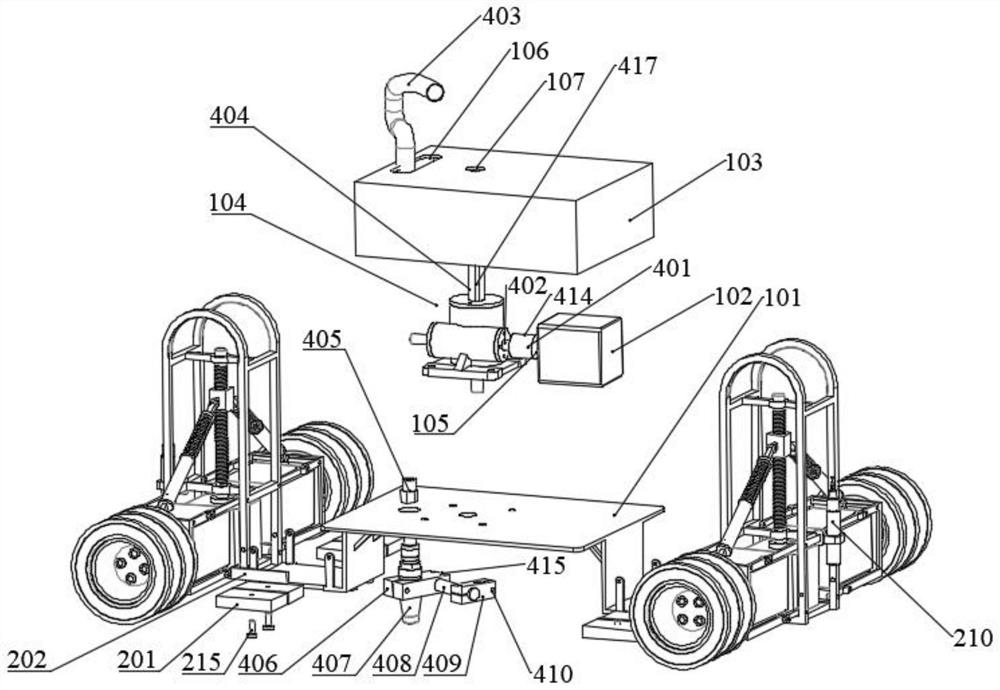

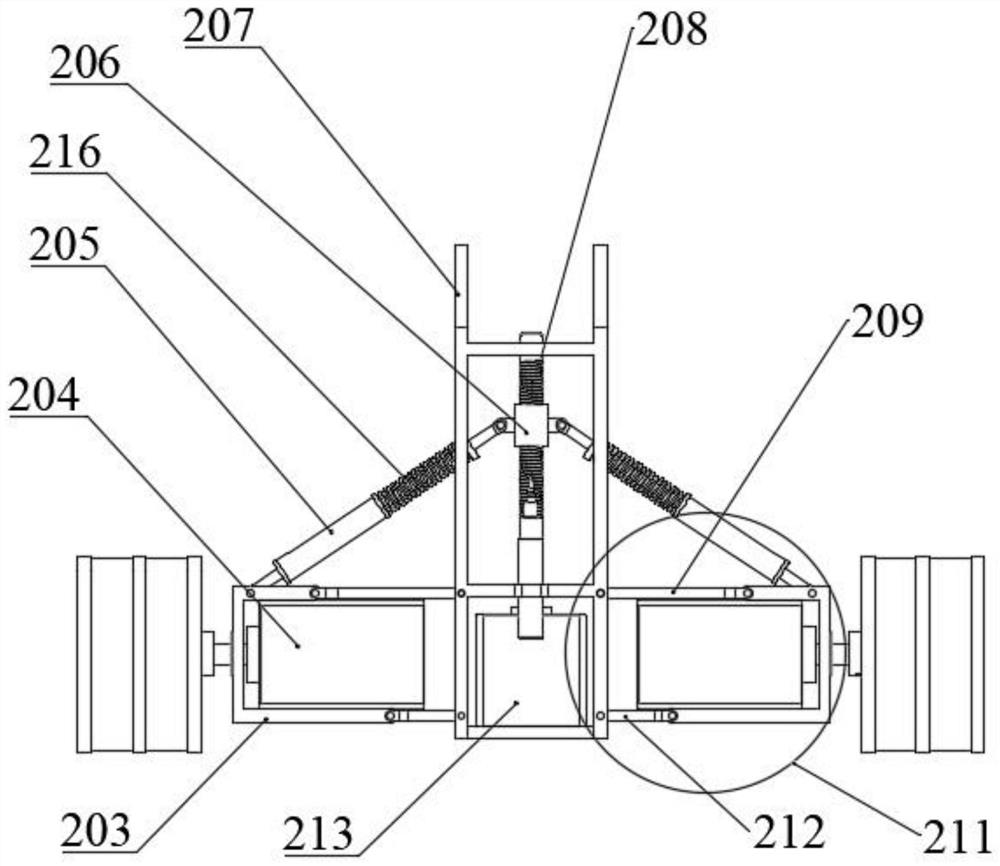

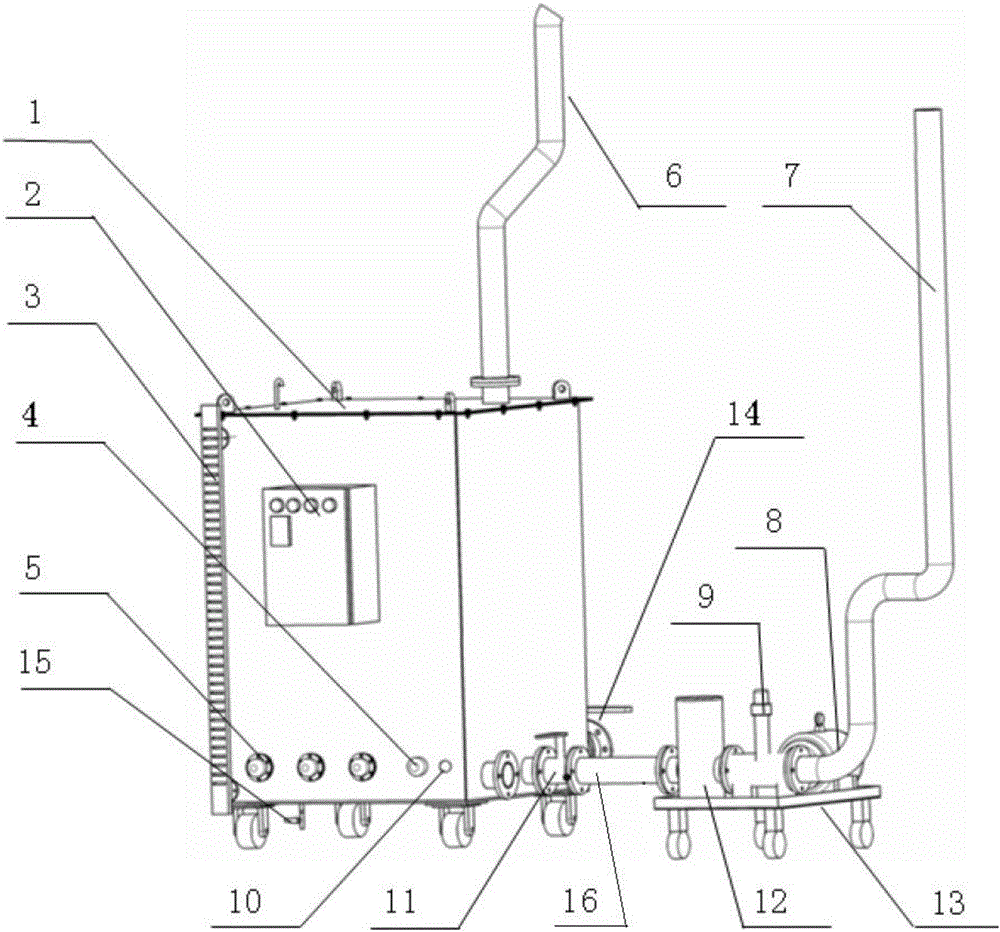

Wall-climbing type shot blasting robot

ActiveCN108326753AEfficient paint removalEfficient rust removalVessel cleaningHullsEngineeringFriction force

The invention discloses a wall-climbing type shot blasting robot, and belongs to the field of robots. According to the shot blasting robot, the problem that the efficiency of paint removal and rust mode for an existing ship surface is low is solved. The shot blasting robot is characterized in that under the action of corresponding air cylinders, a first sliding seat and a second sliding seat do reciprocating sliding motion on a first linear guide rail and the second linear guide rail respectively; the two linear guide rails are arranged on the bottom surface of a machine frame in parallel; a first vacuum sucker and a second vacuum sucker can slide along with the first sliding seat, and a third vacuum sucker and a fourth vacuum sucker can slide along with the second sliding seat; when a wheel type walking unit goes straight, the moving direction of the machine frame is parallel to the sliding direction of the first sliding seat; when a wheel type walking unit is turned, the first sliding seat rotates relative to the first vacuum sucker and the second vacuum sucker, and the second sliding seat rotates relative to the third vacuum sucker and the fourth vacuum sucker; the four vacuum suckers correspond to four cylinders respectively, wherein each air cylinder is used for adjusting the distance between the corresponding vacuum sucker and a to-be-sucked surface and sliding friction force of the wheel type walking unit; and the machine frame is provided with a shot blasting chamber.

Owner:黑龙江省工研院资产经营管理有限公司

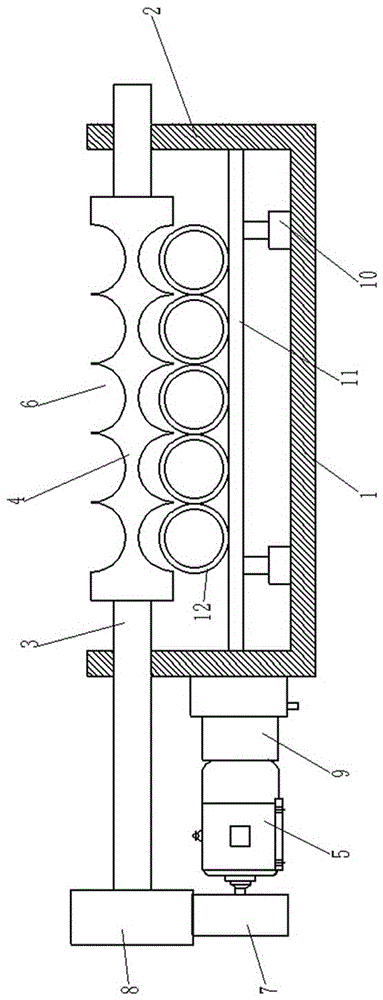

Steel tube derusting device

InactiveCN105817983ARealize no dead angle rust removalClean and even rust removalGrinding carriagesGrinding drivesElectric machinerySteel tube

The invention discloses a steel tube derusting device. The steel tube derusting device comprises a rack as well as a transmission mechanism, a derusting mechanism and a motor, which are mounted on the rack, wherein detachable type side frameworks are arranged at the two sides of the rack; the side frameworks are provided with fixed steel rings; the derusting mechanism is arranged between the two fixed steel rings; the derusting mechanism comprises at least two hard brushes, a soft brush and a roller, wherein the roller comprises a tube inlet and a tube outlet; the hard brushes are arranged on the surface of the roller, and are close to the tube inlet; the soft brush is arranged on the surface of the roller and is close to the tube outlet; and the derusting mechanism is connected with a motor through a transmission mechanism. The steel tube derusting device is clean and uniform in derusting effect, is concise in appearance, is small in size, is small in weight, and is convenient to move.

Owner:GUANGZHOU KOLLER REFRIGERATION EQUIP

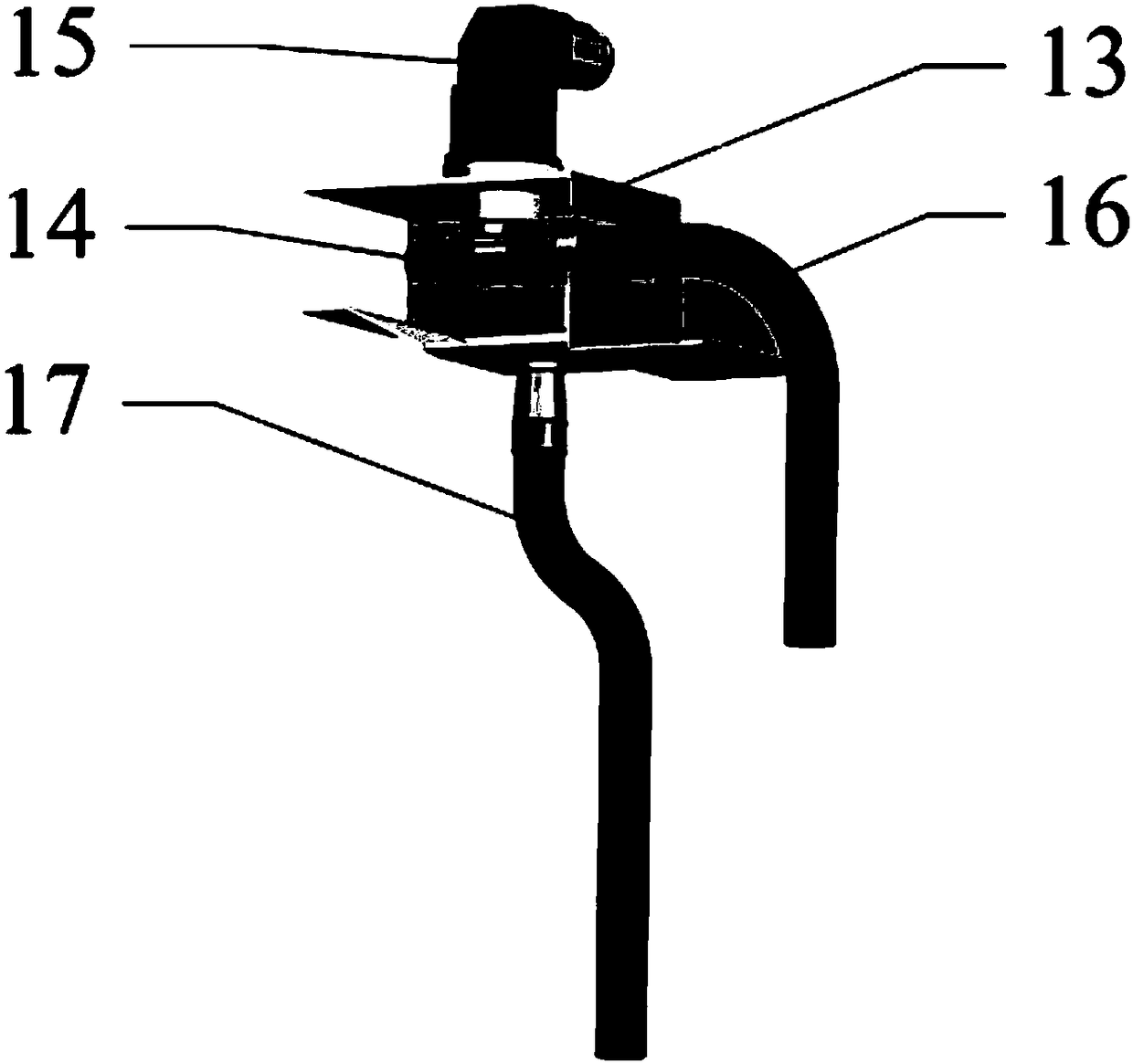

Rust-removing device for surface of mine wind and water pipeline

InactiveCN107900877AEfficient rust removalImprove work efficiencyGrinding carriagesGrinding drivesArchitectural engineeringSlide plate

The invention discloses a surface derusting device for a mine-used air-water pipeline, which comprises a bottom plate, a first telescopic rod is arranged on the upper side of the bottom plate, a connecting plate is arranged on the upper side of the first telescopic rod, and a first connecting rod is arranged on the left side of the connecting plate. There is a handle on the left side of the connecting rod, a connecting groove on the right side of the connecting plate, a screw rod inside the connecting groove, connecting sleeves at the upper and lower ends of the screw rod, and a third connecting rod on the right side of the connecting sleeve. The right side of the connecting rod is provided with a fixed block, the right side of the fixed block is provided with a semi-circular cover, the inside of the semi-circular cover is provided with a connecting cavity, the inside of the connecting cavity is provided with a second telescopic rod, the lower end of the second telescopic rod is provided with a semicircular sliding arc plate, and the semicircular sliding Ring-shaped bevel teeth are arranged at the front and rear ends of the arc plate, bevel gears are arranged at the outer upper end of the ring-shaped bevel teeth, a rotating shaft is arranged at the inner upper end of the bevel gear, and a motor is arranged at the upper end of the rotating shaft. The invention can effectively remove the rust on the surface of the installed geomantic pipe, thus effectively improving the working efficiency of the equipment and saving manpower and material resources.

Owner:王宏亮

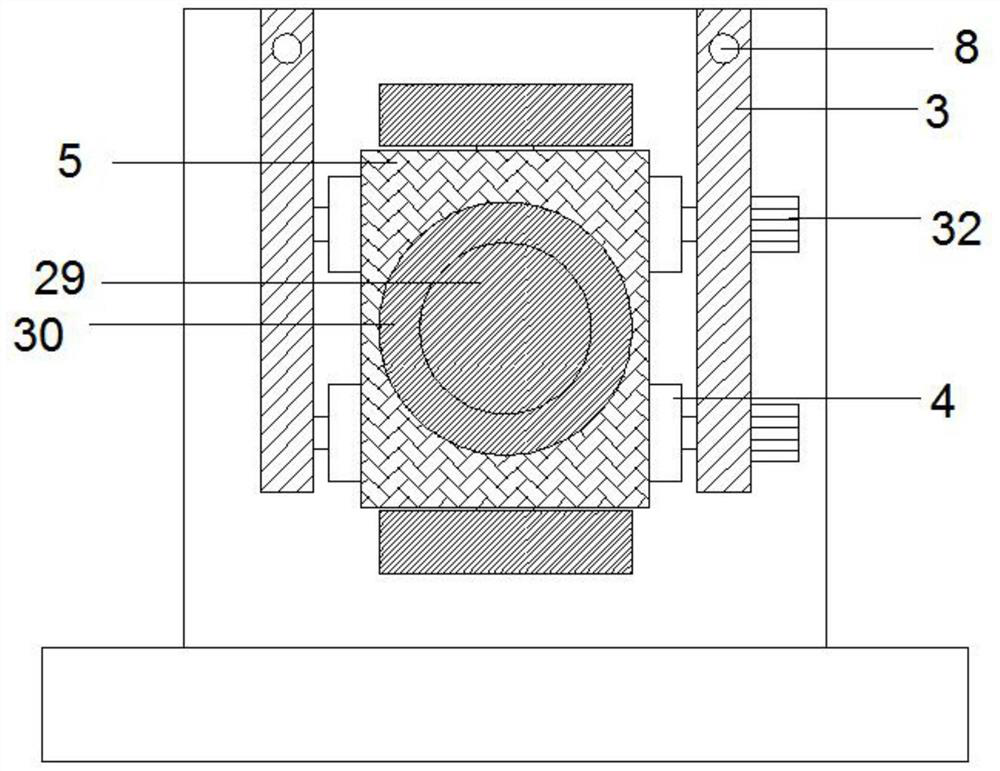

Industrial pipeline surface rust removal robot

ActiveCN111229745AEfficient rust removalGuaranteed uptimeHollow article cleaningControl engineeringStructural engineering

The invention discloses an industrial pipeline surface rust removal robot. The rust removal robot comprises a device machine body with a through cavity penetrating up and down in the bottom side end face, wherein the through cavity can wrap a pipeline, and adjustable moving wheel devices capable of clamping the pipeline and driving the device machine body to move forwards are symmetrically arranged at the upper position and the lower position of the inner wall of the through cavity. According to the rust removal robot, by arranging electric wheels capable of being adjusted according to the thickness of the pipeline, the device machine body can move on the pipeline for rust removal, compared with the process that a common rust removal device needs to detach the pipeline for rust removal, shutdown and production halt of the device in the rust removal maintenance period are avoided, normal operation of factory equipment is guaranteed, and by means of rotating wheel discs capable of beingmounted on and dismounted from the pipeline and rust removal devices capable of being adjusted according to the thickness of the pipeline in the rotating wheel discs, efficient rust removal can be carried out on the pipeline through rotation.

Owner:南京棠邑科创服务有限公司

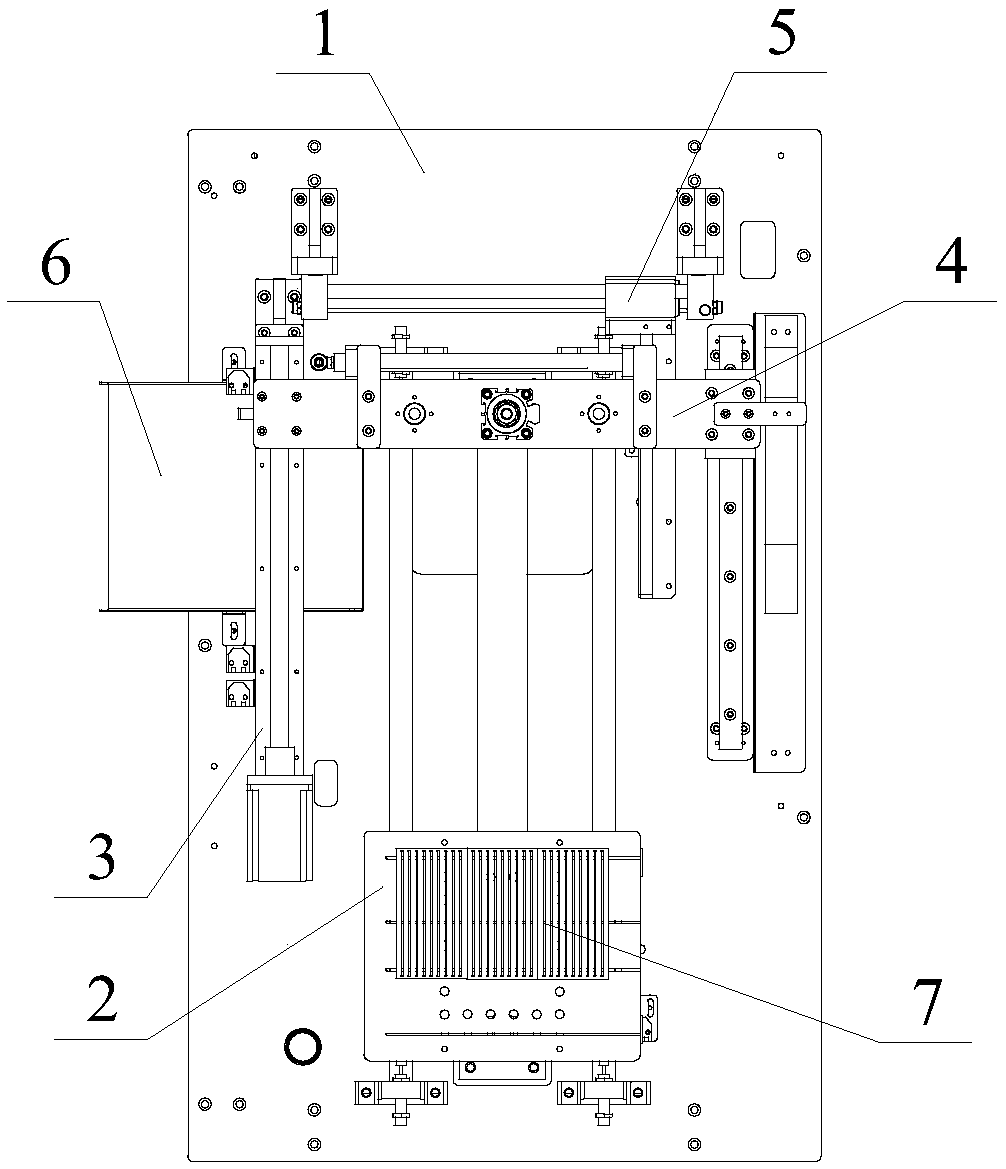

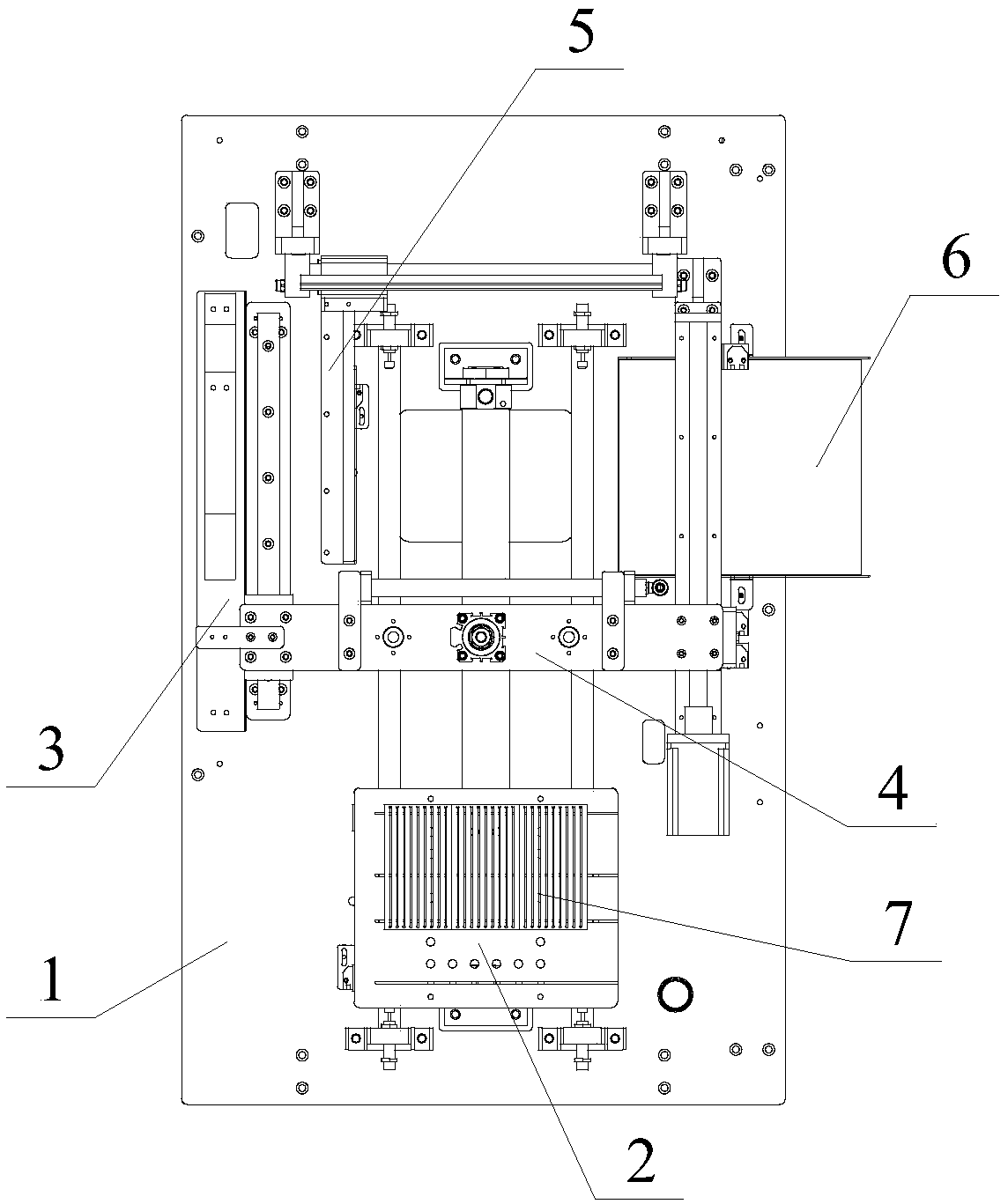

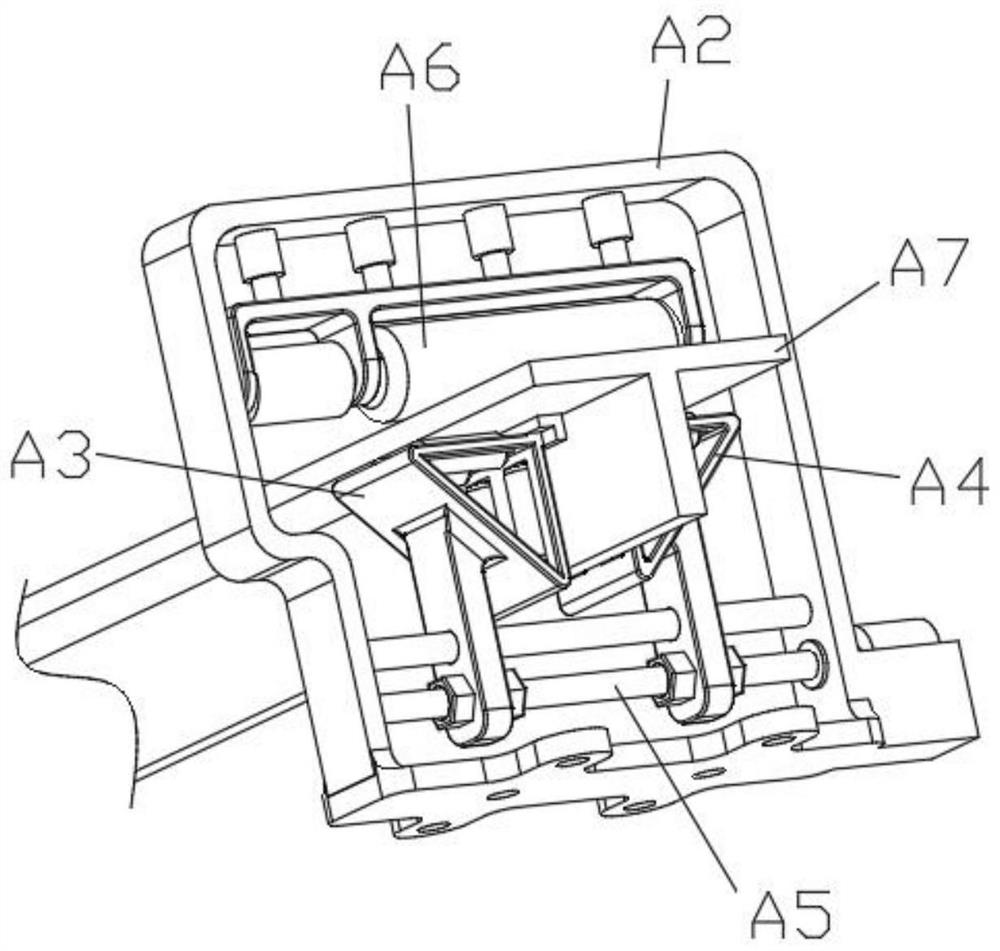

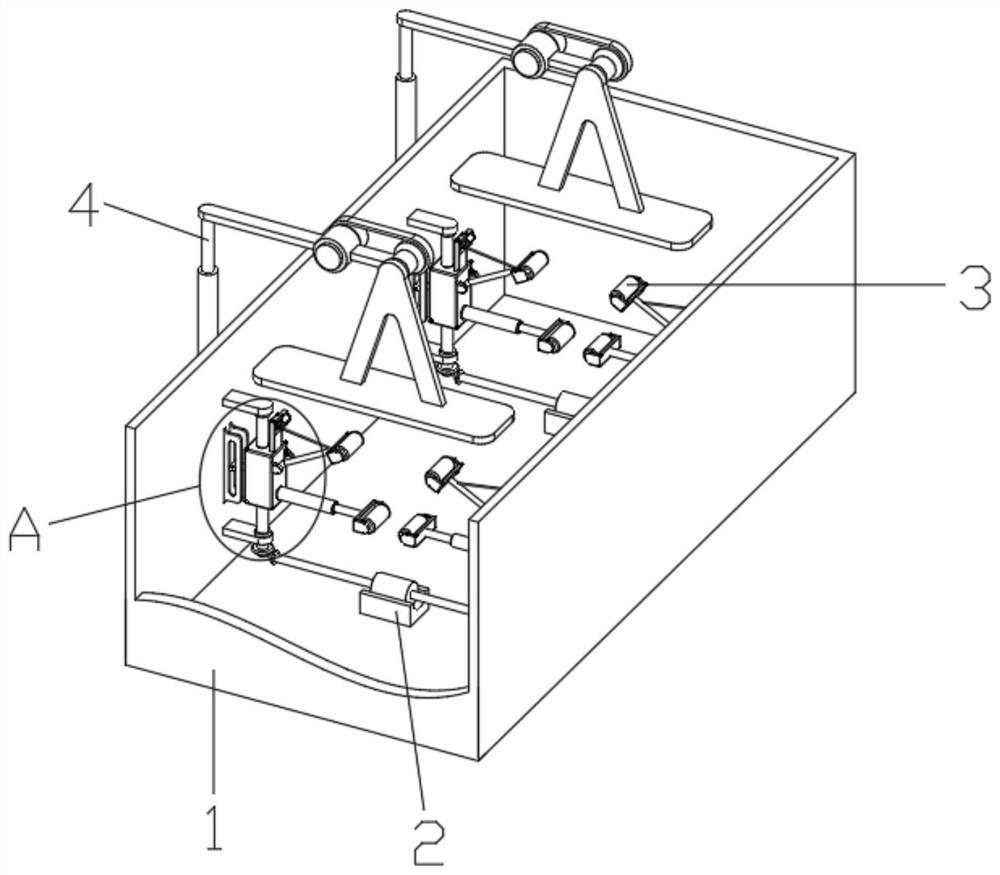

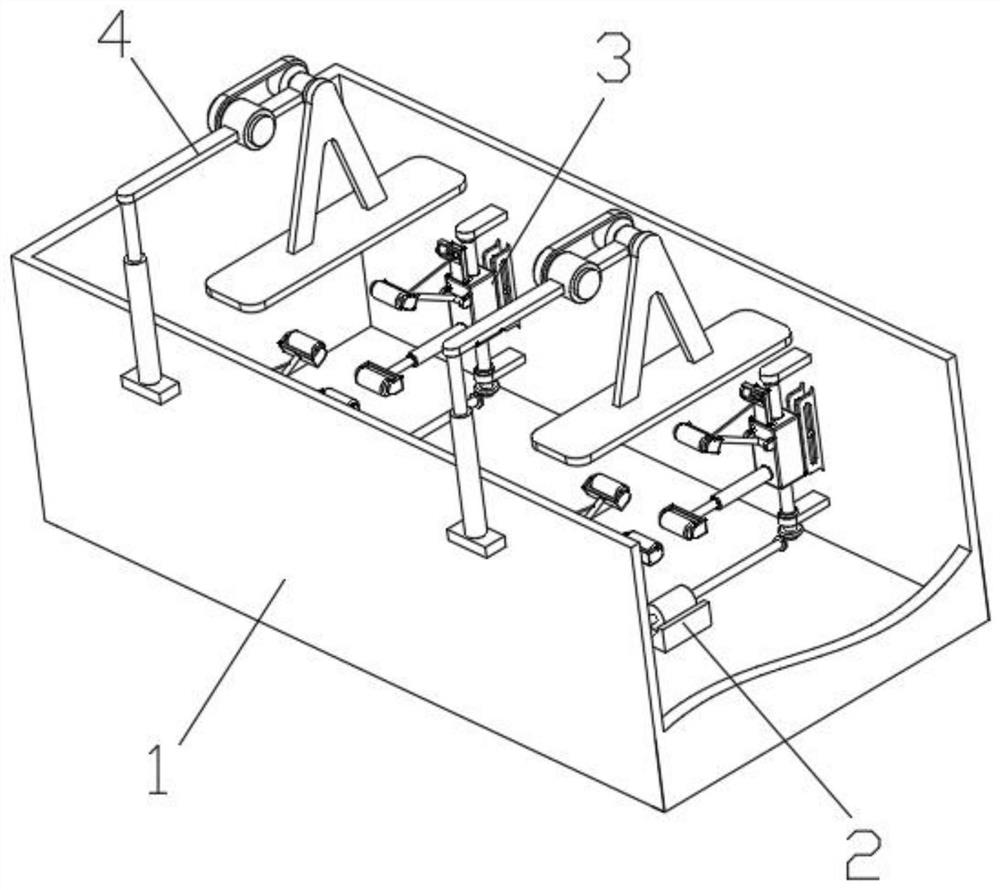

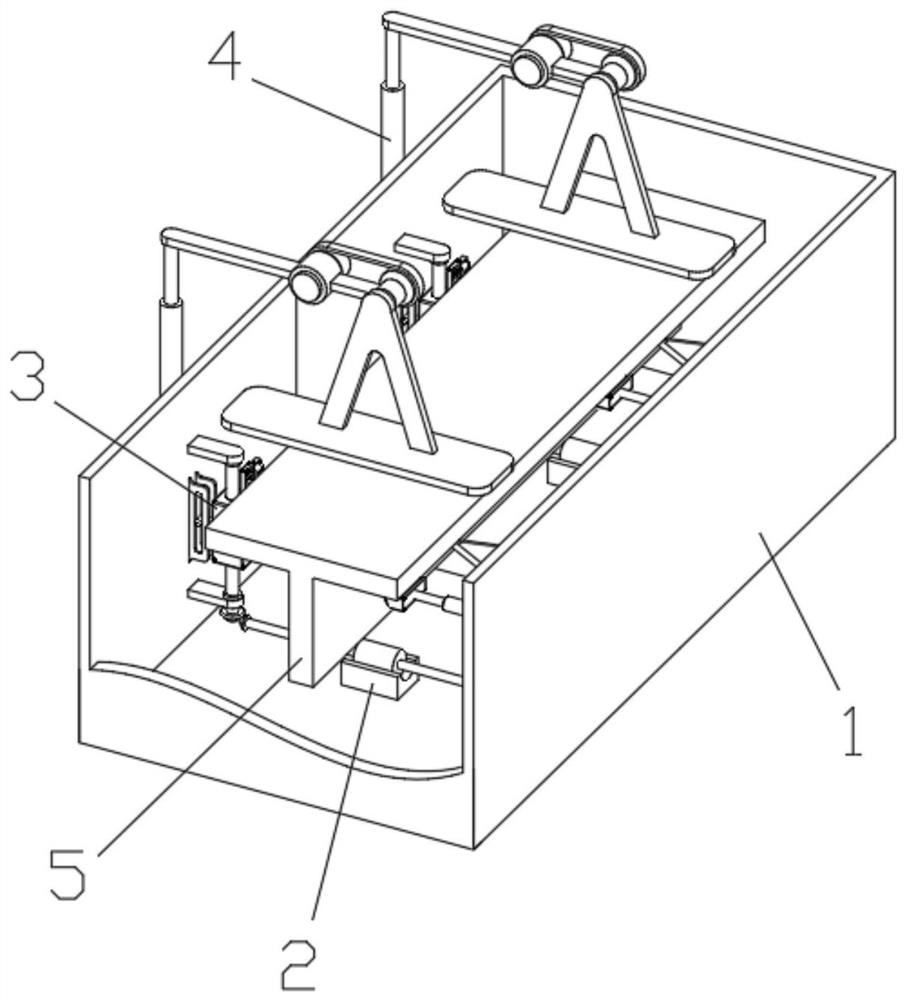

A PCB automatic derusting machine

InactiveCN108890497AEfficient rust removalImprove rust removal efficiencyGrinding machinesGrinding feedersMaterial resourcesEngineering

The invention discloses a PCB automatic derusting machine, which comprises a frame, wherein a feeding unit, a support moving unit, a derusting unit, a pushing unit and a discharging bin are arranged on the frame; The rust removing unit is arranged on the support moving unit, the rust removing unit is arranged above the feed unit to remove rust from the PCB board on the feed unit, The pushing unitis arranged behind the rust removing unit to push out the PCB board on the feeding unit from the feeding unit, the discharge bin is arranged on one side of the supporting mobile unit, and the PCB board enters the discharge bin after being pushed out from the feeding unit. The automatic rust remover of the PCB board of the invention has the advantages of reasonable functional division, simple structure and convenient operation, is not limited by the site, improves the rust removing and cleaning efficiency, strengthens the surface of the board, is favorable for maintenance, loading and unloading, saves manpower and material resources, and improves the working efficiency.

Owner:俞斌

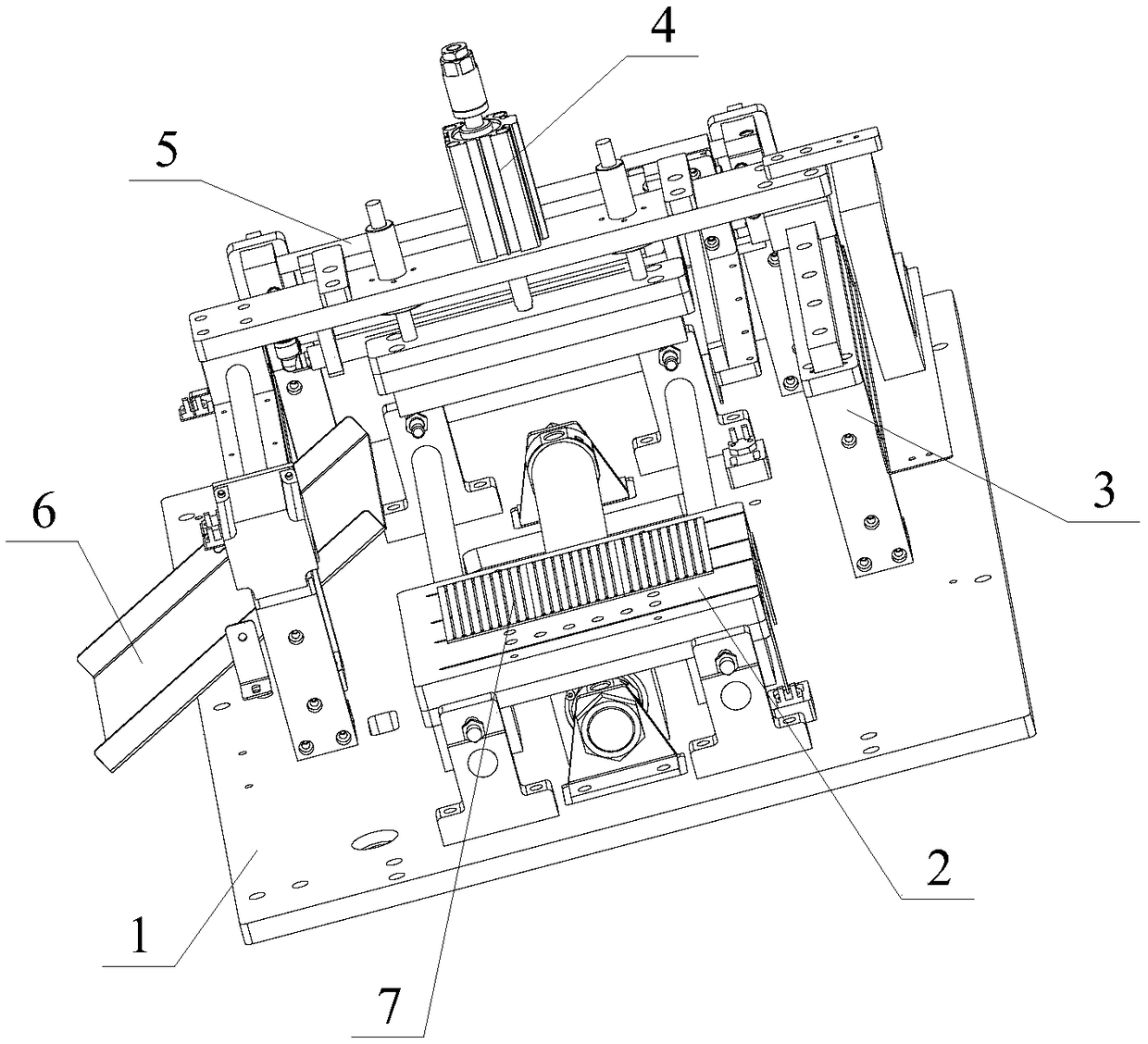

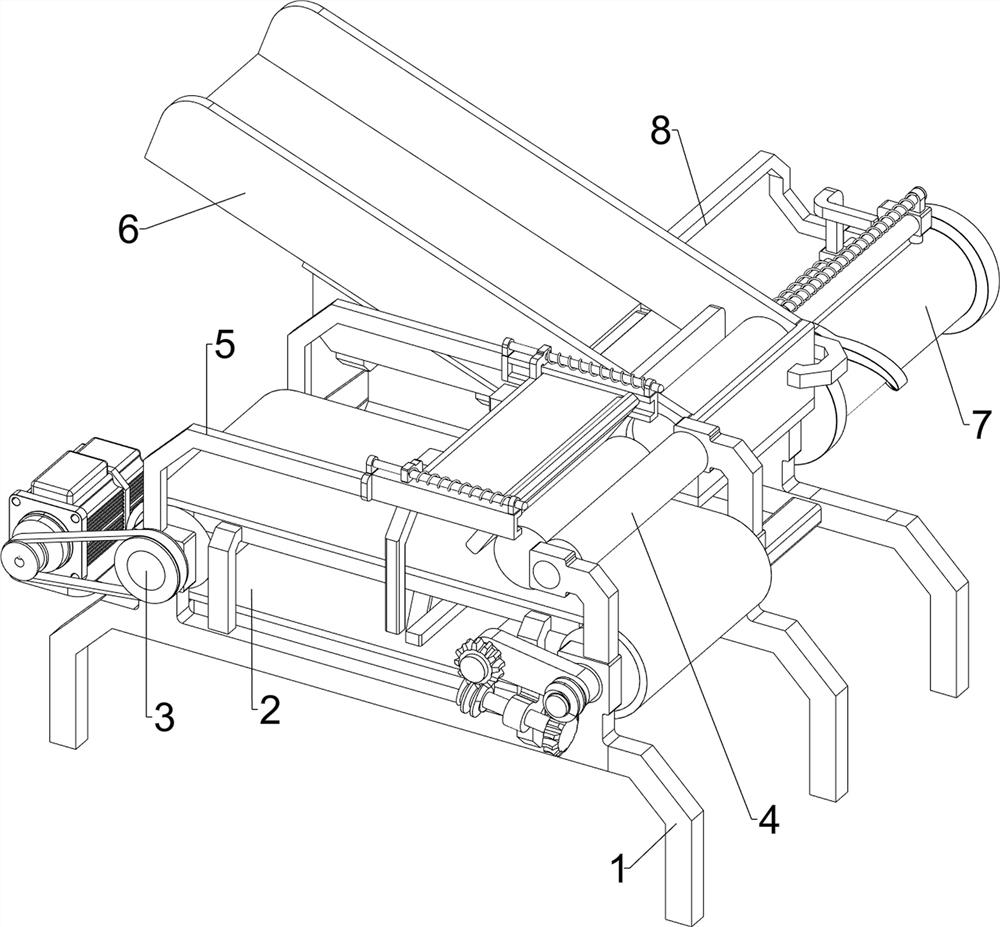

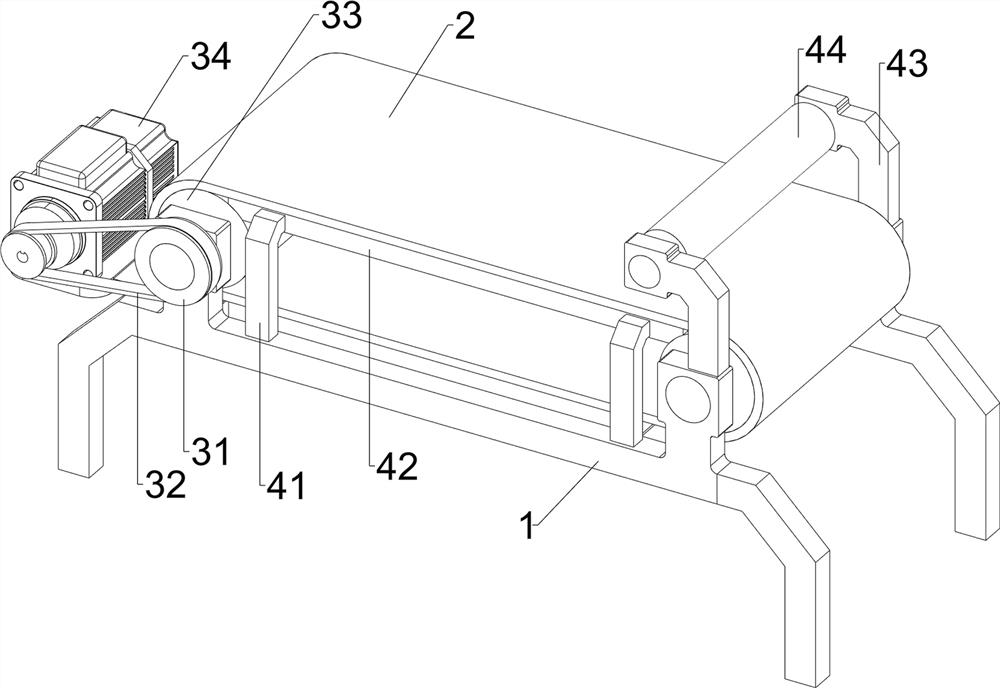

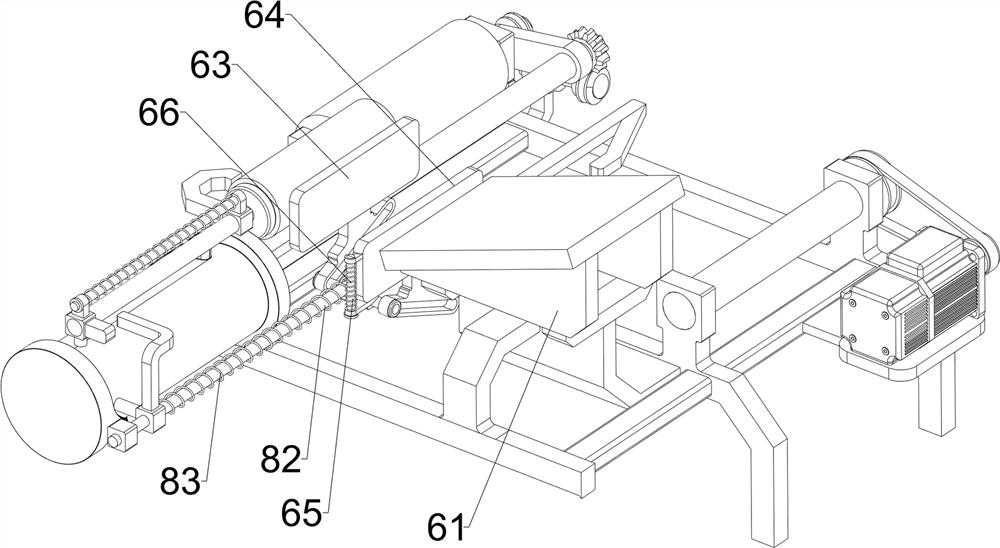

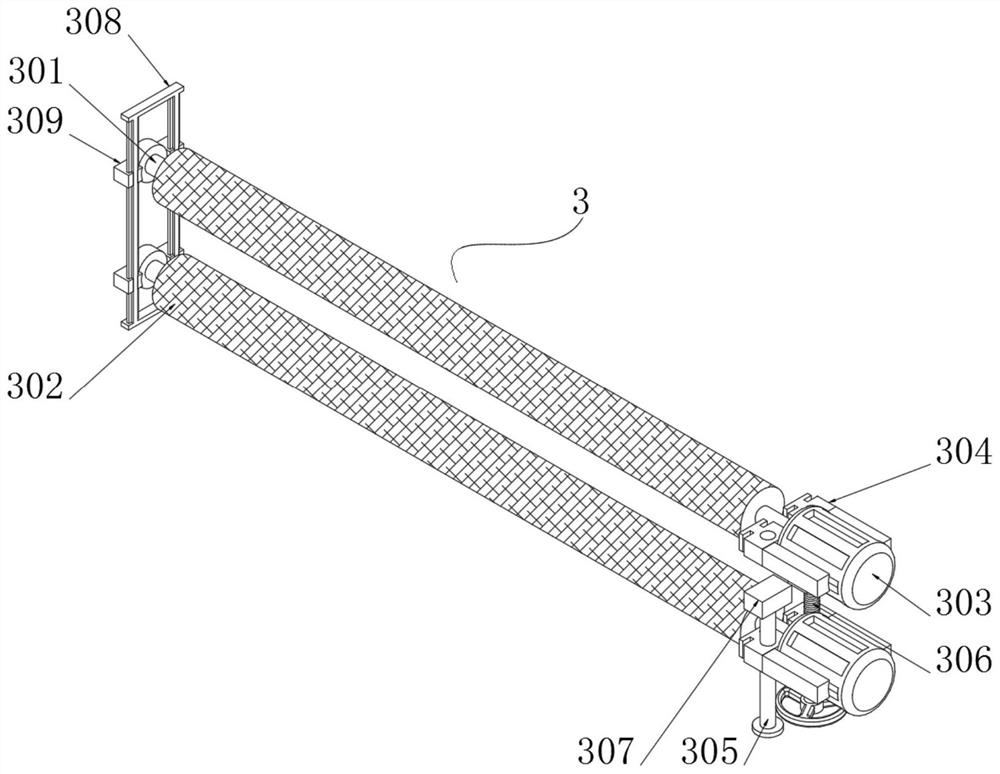

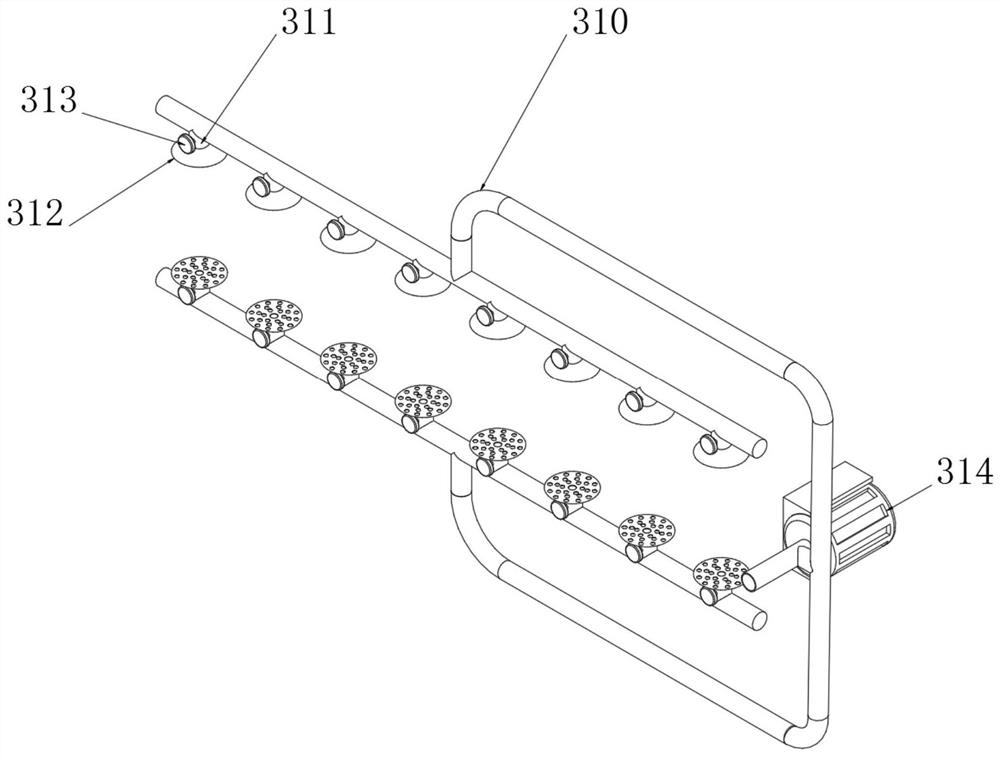

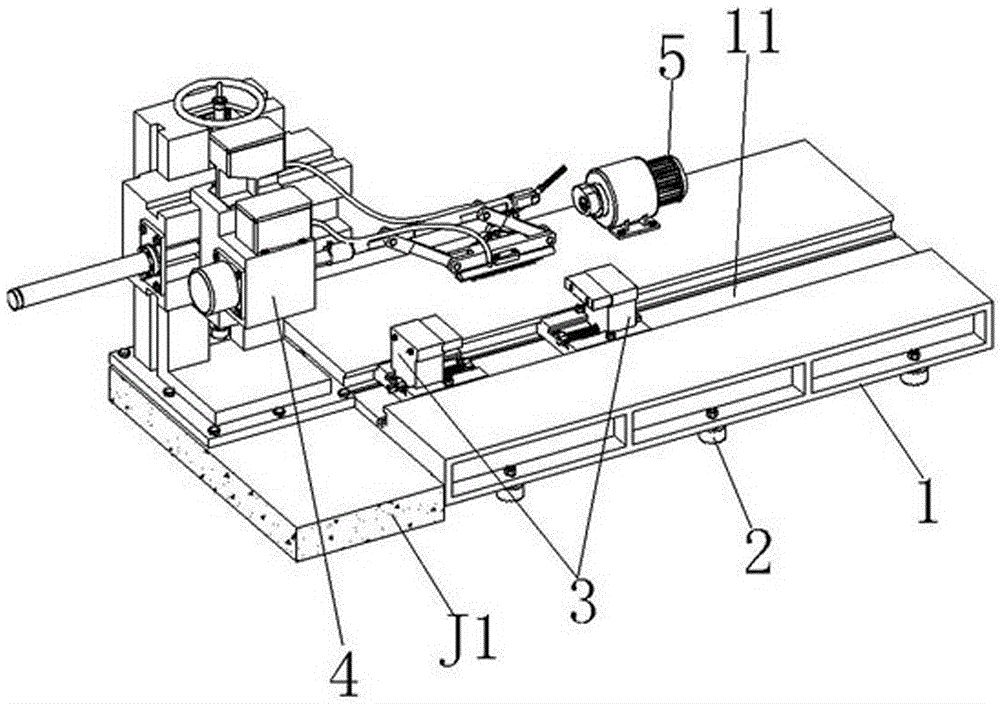

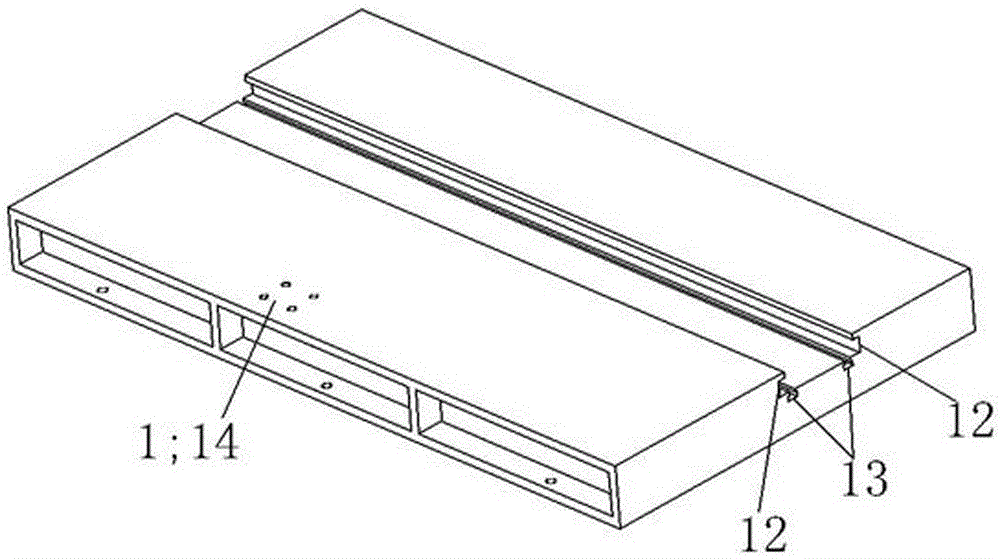

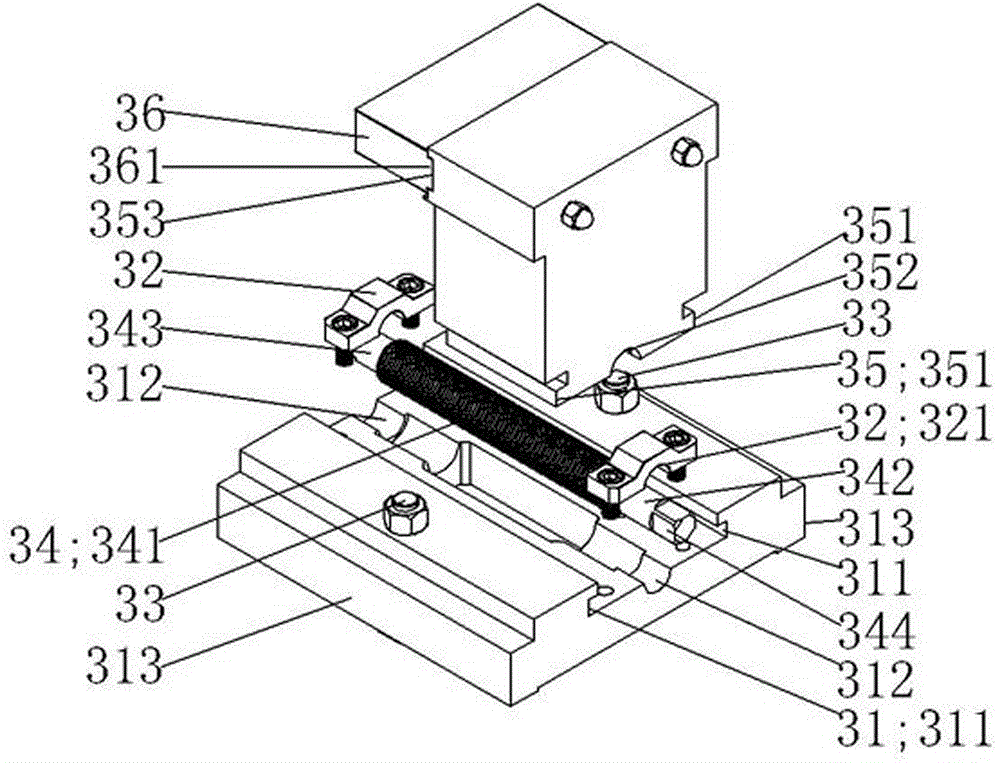

Steel pipe raw material surface rust removal equipment for intelligent manufacturing

ActiveCN112917334AEfficient rust removalImprove rust removal effectBelt grinding machinesGrinding feedersPipeSmart manufacturing

The invention relates to rust removal equipment, in particular to steel pipe raw material surface rust removal equipment for intelligent manufacturing. According to the steel pipe raw material surface rust removal equipment for the intelligent manufacturing, the working efficiency can be improved, the rust removal effect is improved, and the influence of steel pipe stacking on site construction is eliminated. According to the technical scheme, the steel pipe raw material surface rust removal equipment for the intelligent manufacturing comprises a base and a grinding mechanism, and the grinding mechanism is arranged at the top of the base; an abrasive belt arranged on the grinding mechanism; a supporting mechanism arranged on the base; and a clamping mechanism arranged on the grinding mechanism. According to the steel pipe raw material surface rust removal equipment for the intelligent manufacturing provided by the invention, firstly, people place a rusty steel pipe on the abrasive belt on the grinding mechanism, the clamping mechanism clamps and fixes the rusty steel pipe, the grinding mechanism is started to be matched with the supporting mechanism, the abrasive belt conducts rust removal on the surface of the rusty steel pipe, after rust removal of the steel pipe is completed, the grinding mechanism is closed, and the efficient rust removal effect is achieved.

Owner:佛山市添源钢管有限公司

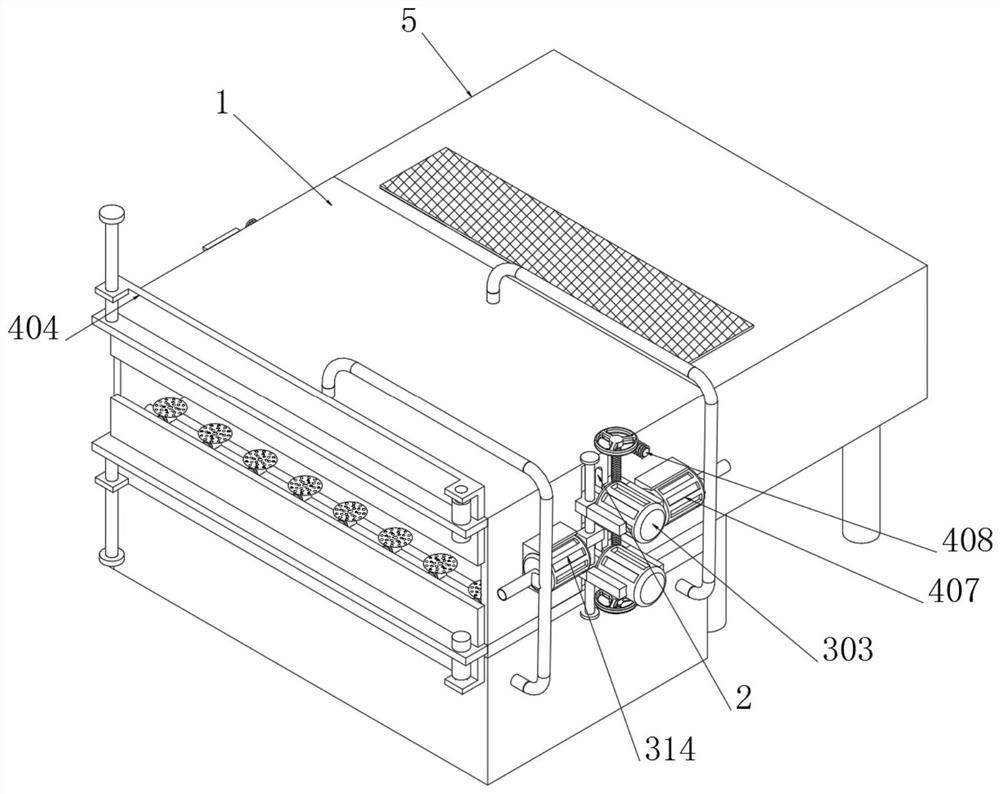

Device for efficiently derusting surfaces of steel pipes in batches

InactiveCN106002571AEfficient rust removalRevolution surface grinding machinesGrinding drivesEngineeringElectric motor

The invention provides a batch efficient surface rust removal device for steel pipes, a base, and two side plates perpendicular to the base. The batch high-efficiency surface derusting device for steel pipes also includes a grinding shaft, a grinding brush fixedly connected to the grinding shaft, and a motor. The motor is connected to one end of the grinding shaft by transmission. A semicircular annular groove, said annular groove matches the outer wall of the steel pipe. Beneficial effects of the present invention: the device can derust more efficiently, and the device can also derust several steel pipes in batches.

Owner:NANTONG YONGDA PIPE IND

Electric industrial brush device convenient to adjust

InactiveCN111701895AEasy to adjustEasy to controlGrinding carriagesGrinding drivesElectric machineryBrush device

The invention discloses an electric industrial brush device convenient to adjust, and relates to the technical field of processing of industrial brushes. The electric industrial brush device comprisesa brushing box, a base, a side edge cleaning mechanism and a top cleaning mechanism; the top cleaning mechanism comprises a second air cylinder, a second telescopic rod, a connecting plate, a secondmotor and an upper-end cleaning brush; the side edge cleaning mechanism comprises a rotating shaft and a rotating track; multiple third motors are arranged inside the rotating track; output shafts ofthe third motors are fixed to side edge brushes; two pairs of reciprocating screws are symmetrically arranged at the upper and lower ends of the brushing box; the side edge cleaning mechanism is fixedthrough a sliding block; and two groups of spraying openings are symmetrically formed in the upper and lower ends of a back plate inside the brushing box. According to the electric industrial brush device, defects in the prior art are overcome, the device is reasonable in design and convenient to use, cleaning and rust removal can be effectively performed on parts in different sizes, meanwhile, the positions of the industrial brushes can be adjusted conveniently, and the cleaning efficiency can be improved.

Owner:潜山卓越机电设备有限公司

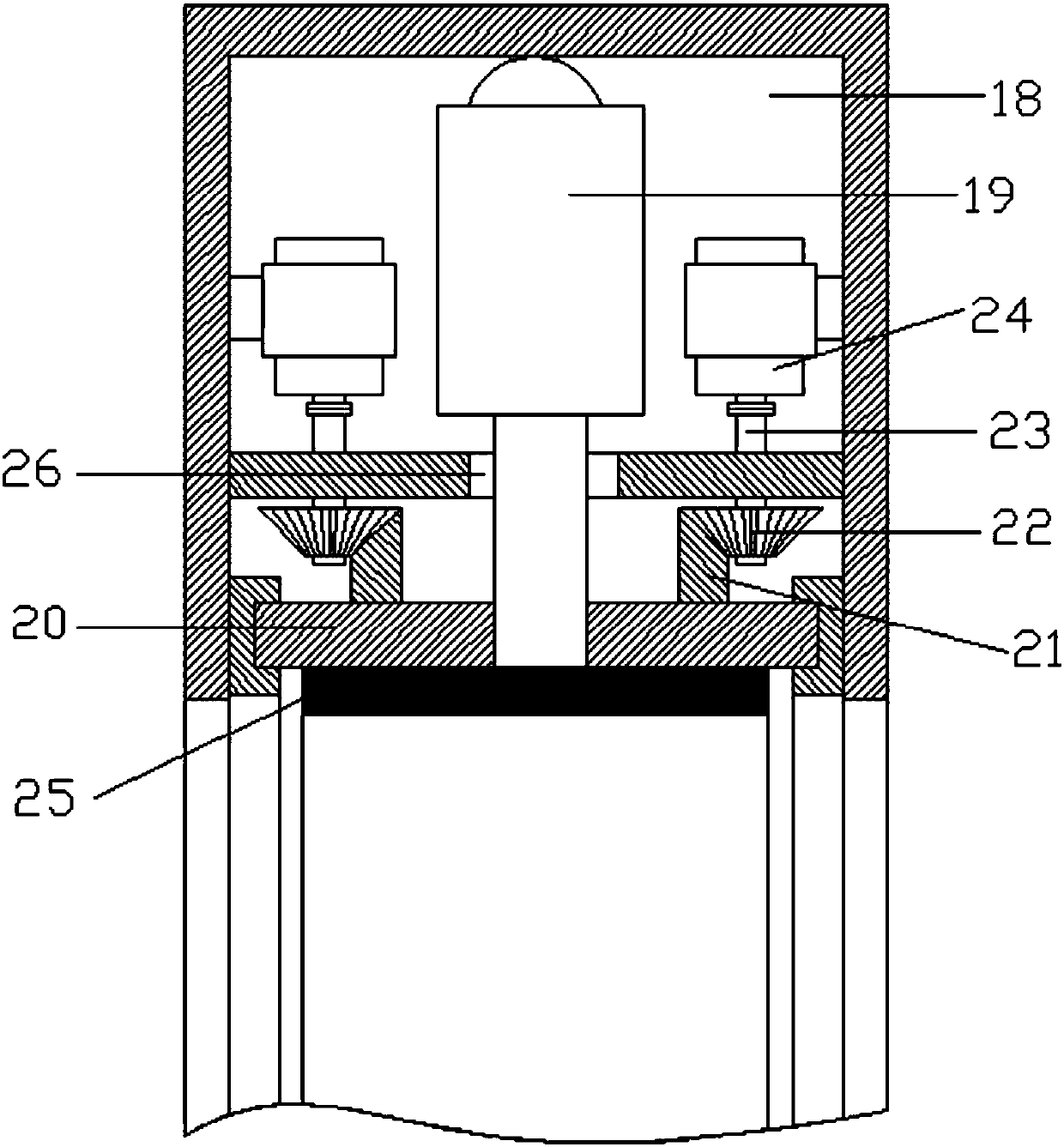

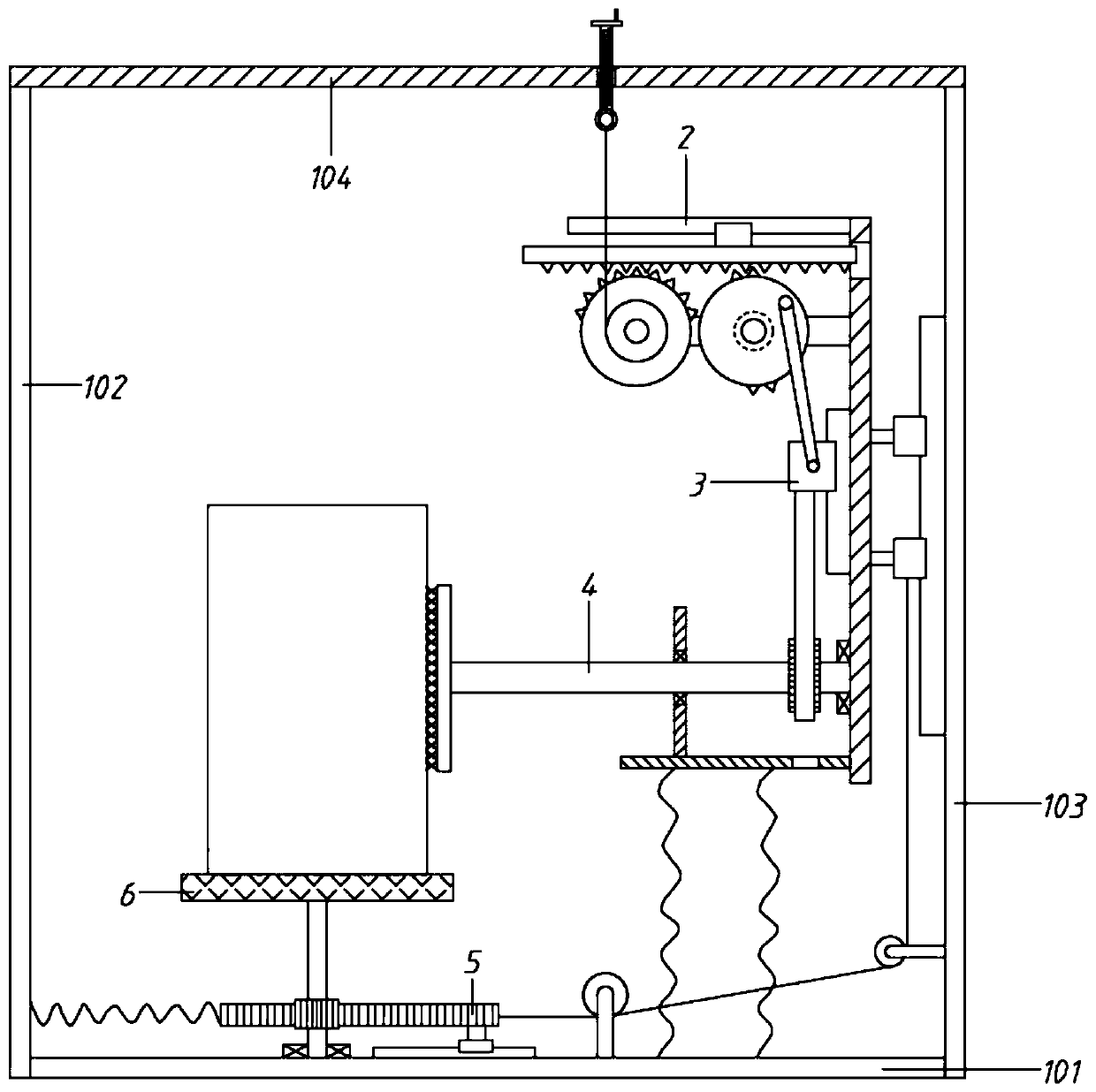

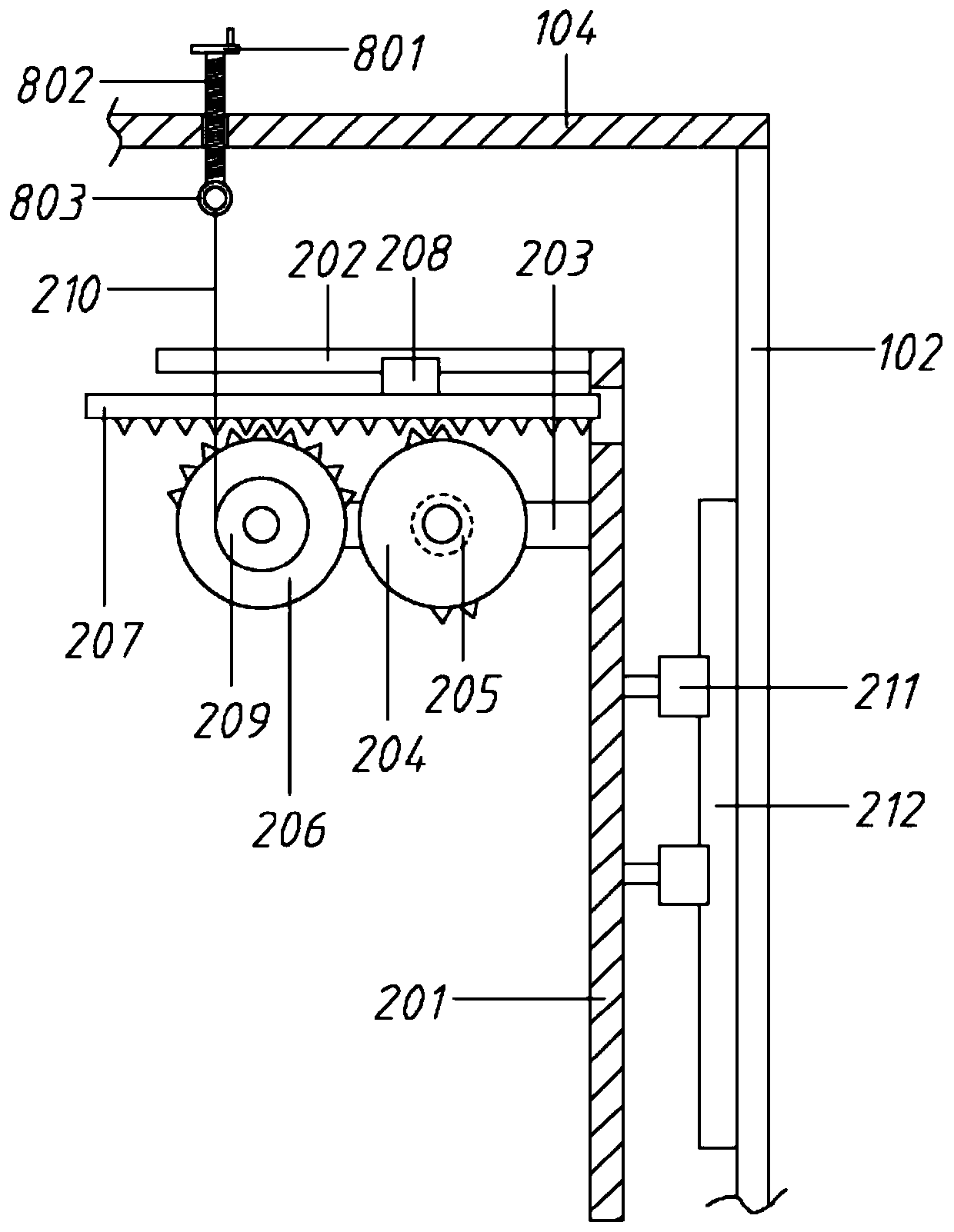

Automatic rust removal cleaning device for cylinder outer wall

ActiveCN111113230ARealize up and down changesRealize moving up and downGrinding drivesGrinding machinesGear driveGear wheel

The invention relates to the technical field of cylinder outer wall rust removal equipment, and particularly relates to an automatic rust removal cleaning device for a cylinder outer wall. A servo motor is adopted to drive a tooth-missing gear to rotate, and through cooperation of the tooth-missing gear, a half gear and a first rack, reciprocating rotation of the half gear and left-right movementof the first rack are achieved; the half gear drives a coaxial first take-up wheel to rotate in a reciprocating manner, due to the fact that the top of a first pull rope is fixed, the first pull ropedrives a lower component to move up and down through the action of a second sliding block and a second sliding rail, then a rust removal assembly moves up and down, and up-down changing of a rust removal area is achieved; and while a lifting assembly moves up and down, a second rack moves left and right through the action of a third pull rope and a first spring, a second gear is driven to drive asupporting shaft to rotate, and therefore a supporting base drives a cylinder to rotate, the rust removal acting face is enlarged, and comprehensive rust removal is conducted on the side wall of the cylinder.

Owner:苏州创小二智能科技有限公司

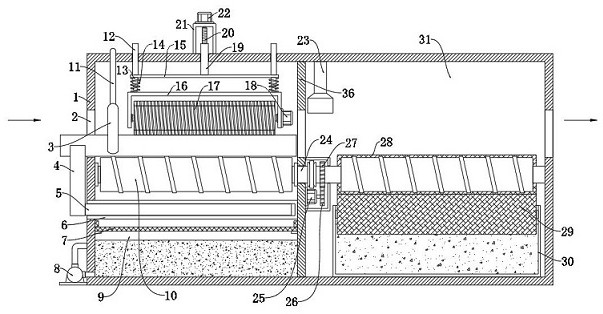

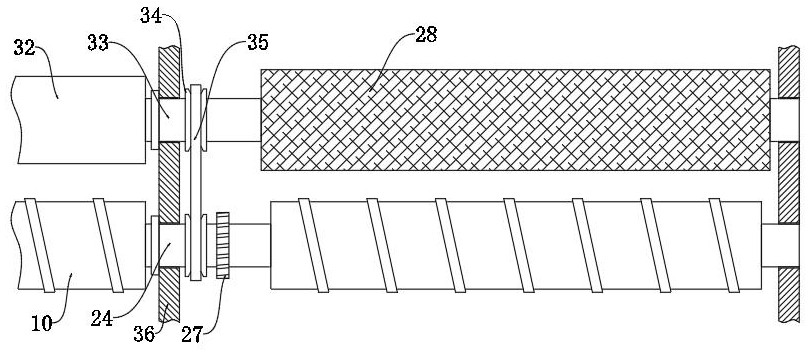

Large stainless steel pipe rolling type external force polishing and derusting mechanism

ActiveCN112338755AEfficient rust removalNo manual pushingLiquid surface applicatorsGrinding drivesSS - Stainless steelPipe

The invention discloses a large stainless steel pipe rolling type external force polishing and derusting mechanism comprising a box body, a partition plate is vertically arranged in the box body and divides the interior of the box body into a derusting chamber and a curing chamber which are arranged in the horizontal direction, and material passing openings are formed in the two side walls of thebox body and the partition plate correspondingly. A first rotating shaft and a second rotating shaft are arranged on the partition plate in a penetrating mode, the first rotating shaft and the secondrotating shaft are both rotationally connected with the partition plate, the ends of the first rotating shaft and the second rotating shaft are both rotationally connected to the inner wall of the boxbody, and the positions, located on the inner side walls of the derusting chamber and the curing chamber, of the first rotating shaft are both fixedly sleeved with feeding rollers. The large stainless steel pipe rolling type external force polishing and derusting mechanism is compact in structure and complete in function, rapid derusting, drying and curing of a stainless steel pipe can be achieved, manual pushing is not needed during derusting, time and labor are saved, the derusting efficiency is greatly improved, and the rust prevention performance of follow-up use of the steel pipe is improved.

Owner:浙江华鸣不锈钢有限公司

Water-based metal cleaning agent

The invention provides a water-based metal cleaning agent. The water-based metal cleaning agent comprises 70 g / L-100 g / L of glycollic acid, 10 g / L-18 g / L of malic acid, 5 g / L-10 g / L of sodium dodecyl benzene sulfonate, 5 g / L-8 g / L of sodium citrate, 6 g / L-10 g / L of sodium metasilicate pentahydrate, 0.8 g / L-1.6 g / L of peregal O-15 and 2.2 g / L-2.4 g / L of fatty alcohol-polyoxyethylene ether AEO-9. The water-based metal cleaning agent can achieve synchronous performing of oil removing and rust removing of the metal surface in the same acid solution under the heating-free normal-temperature state, raw materials are saved, the processing speed is high, and the cleaning effect is good.

Owner:LUOYANG LVREN ENVIRONMENTAL EQUIP

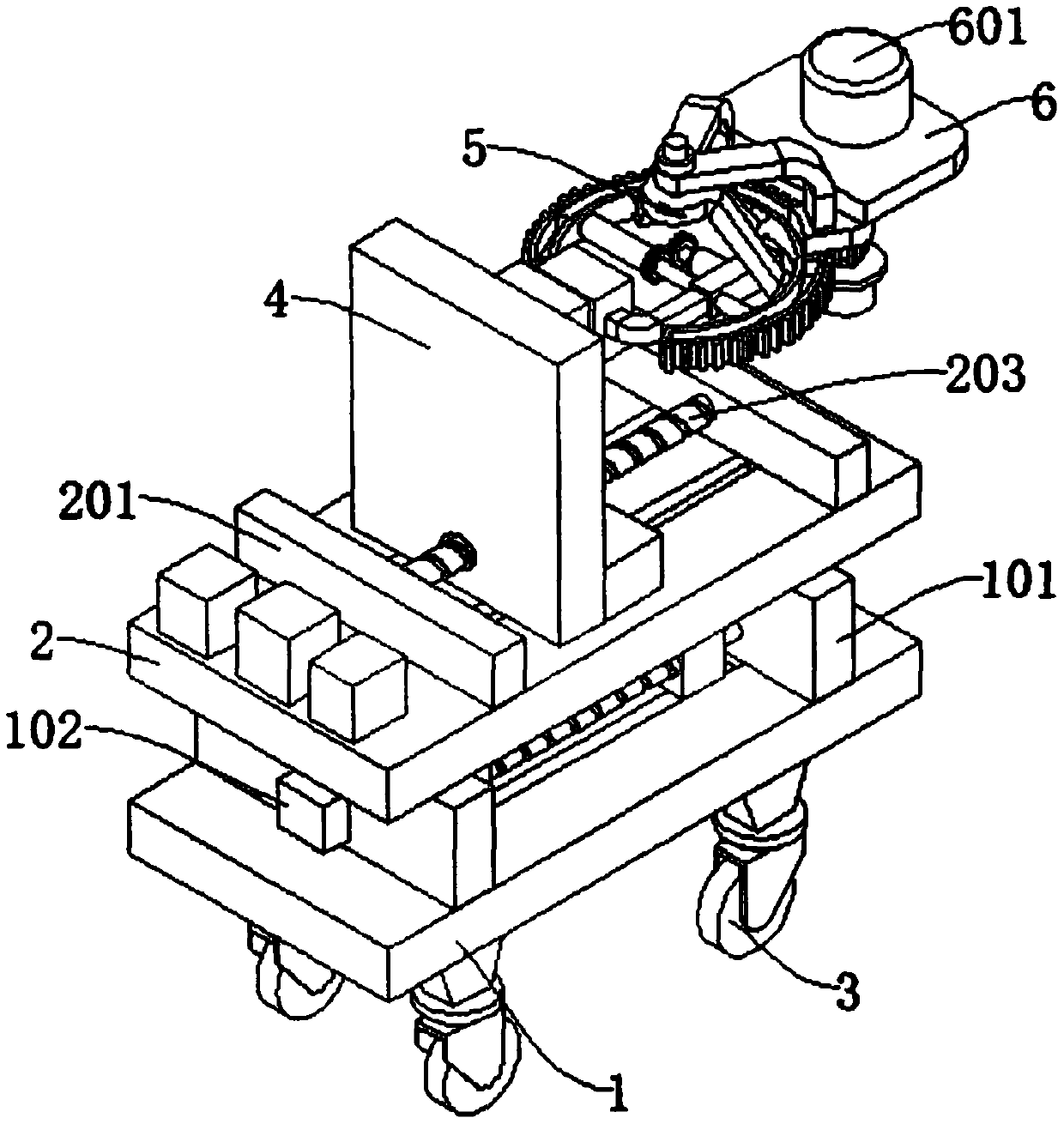

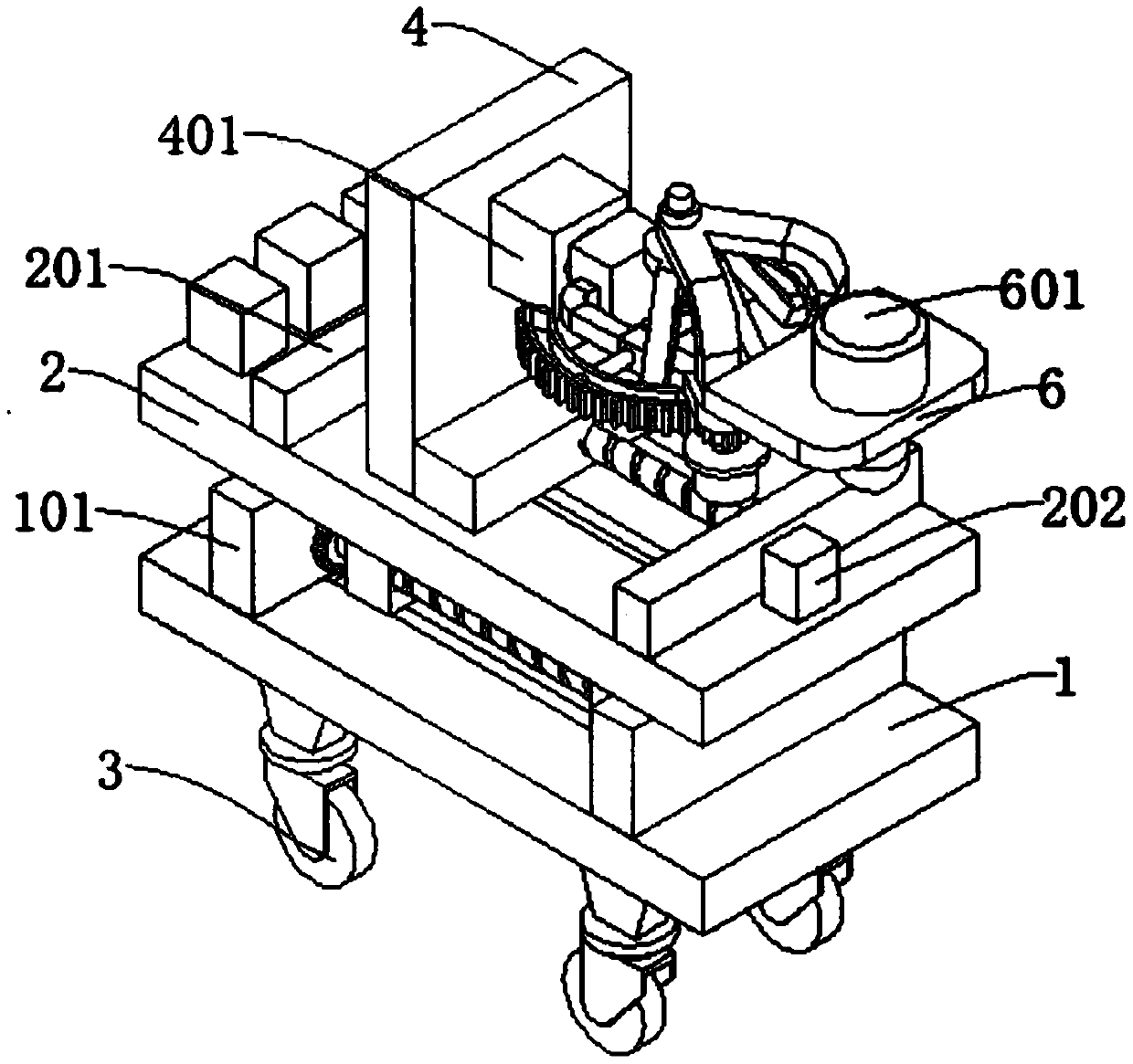

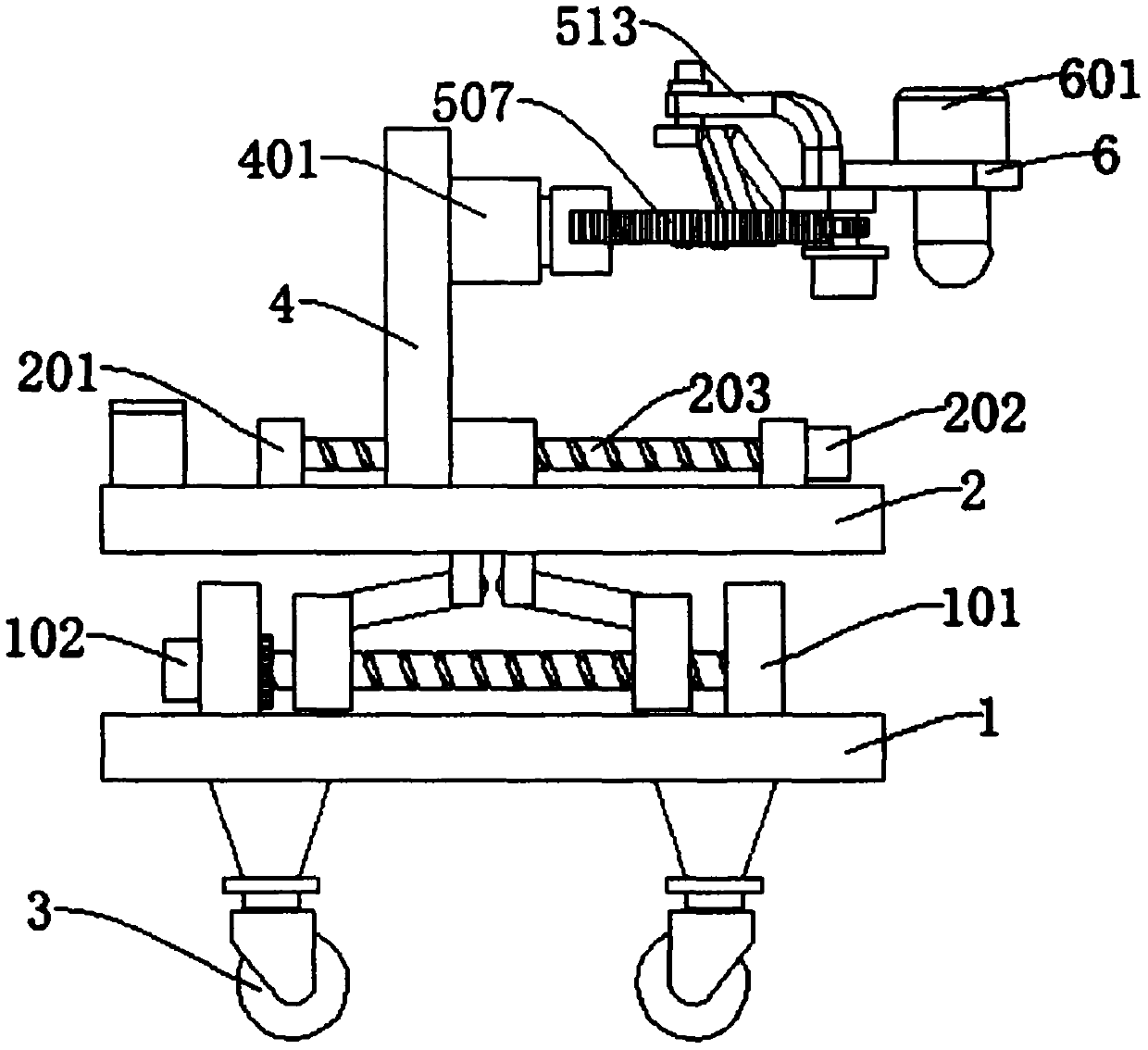

Intelligent and universal vehicle-mounted laser rust removing device

InactiveCN111203641AReduce labor intensityImprove work efficiencyLaser beam welding apparatusElectric machineryStructural engineering

The invention discloses an intelligent and universal vehicle-mounted laser rust removing device which comprises a bottom plate, a first supporting plate, universal wheels and a laser device. A first connecting plate is connected to the top wall of the bottom plate, and a first driving mechanism is connected to the inner wall of the first connecting plate. The first supporting plate is connected tothe output end of the first driving mechanism, and a second connecting plate is connected to the top wall of the first supporting plate. A second driving mechanism is connected to the inner wall of the second connecting plate, and the output end of the second driving mechanism is connected with a second supporting plate. The second supporting plate is connected to the top wall of the first supporting plate in a sliding manner, and a third motor is connected to the outer wall of the second supporting plate. The output end of the third motor is connected with a three-axis rotating mechanism, and the output end of the three-axis rotating mechanism is connected with a fourth supporting plate. By means of the intelligent and universal vehicle-mounted laser rust removing device, the three-axisrotating mechanism is arranged so that the laser device can be driven to rotate in a three-dimensional space, and therefore effective rust removing can be conducted on a special-shaped part conveniently, rust removing of the product is more thorough, and therefore the laser rust removing effect is improved.

Owner:JINAN G WEIKE SCI & TECH

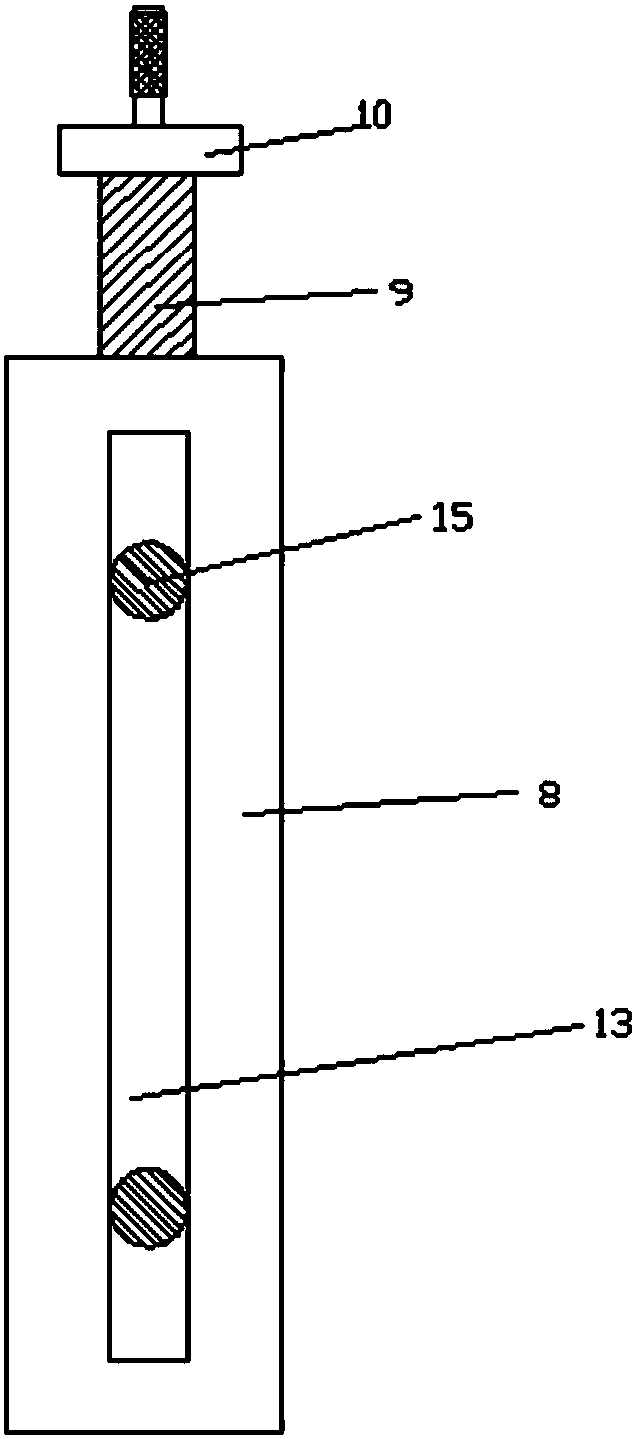

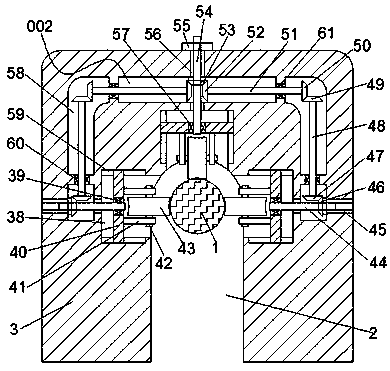

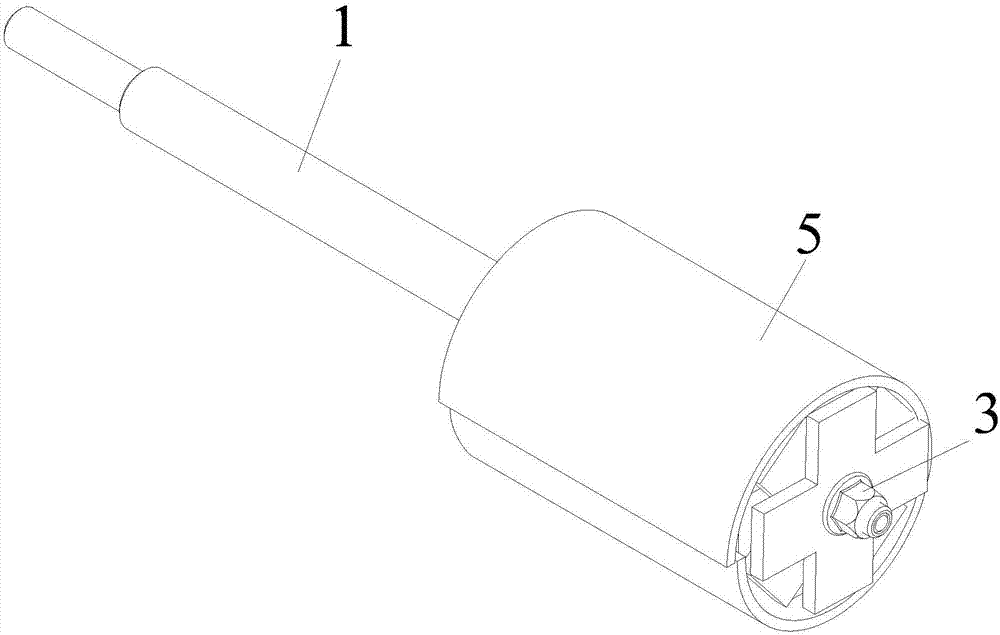

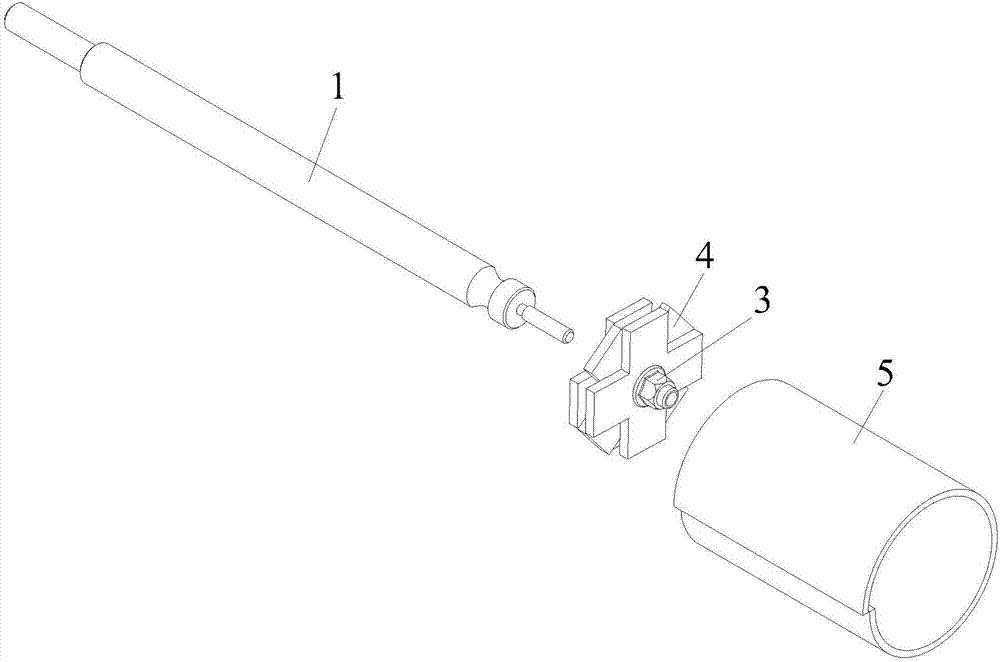

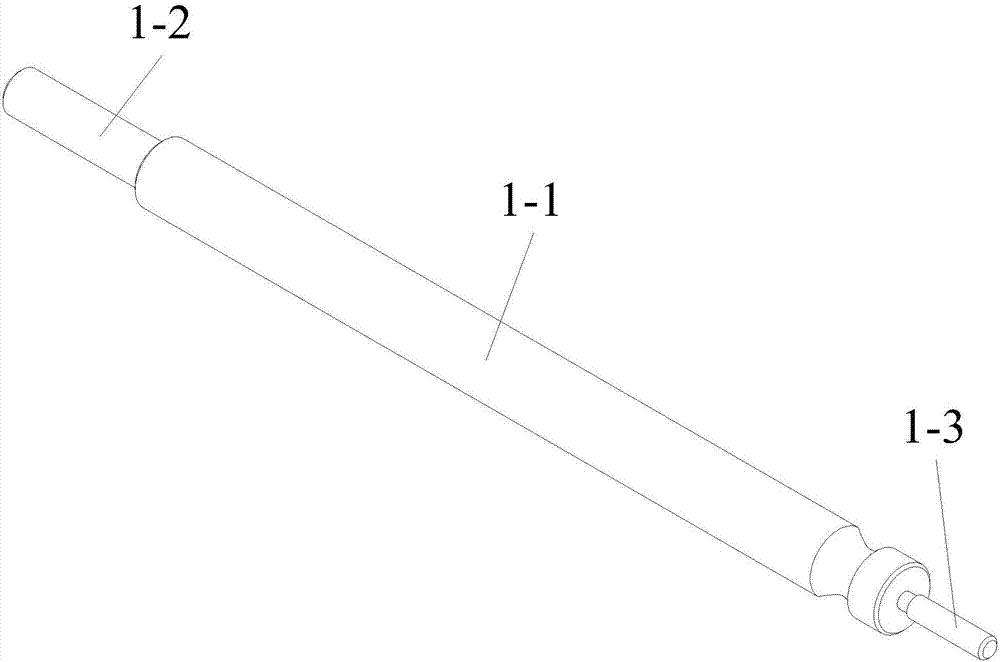

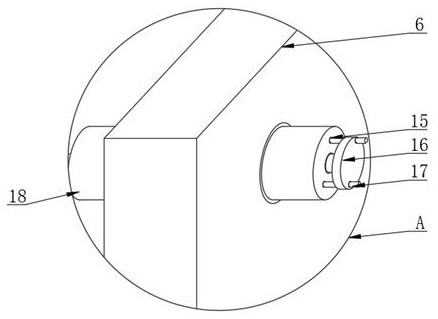

Inner surface polishing and derusting tool of hollow axle of CRH train

InactiveCN107571132ALow costMeet the needs of cleaning and rust removalRevolution surface grinding machinesButt jointEngineering

The invention discloses an inner surface polishing and derusting tool of a hollow axle of a CRH train, and belongs to the field of polishing devices for the inner surfaces of hollow axles of CRH trains. The tool comprises a lengthened rod, a polishing head base, an end nut, a polishing piece assembly and an outer-layer polishing piece. The outer-layer polishing piece and the polishing piece assembly of the polishing and derusting tool both adopt low-cost industrial scouring pads; the surface hardness satisfies the inner diameter cleaning and derusting demands of an axle hollow cylinder; the inner diameter of the hollow axle cannot be scratched; and the advantages of convenience to tailor, manufacture and replace are achieved; the polishing head base, the end nut and the polishing piece assembly form a polishing end; the outer-layer polishing piece is wound at the external of the polishing end to increase the outer diameter; a certain pressure can be applied to the inner side wall of the axle hollow cylinder to increase the slide friction force in cleaning and derusting; a butt joint base is used for coaxially and fixedly connecting the tool with an electric portable drill; and thetool is synchronously rotated along with the electric portable drill, so that the derusting operation on the inner side of the axle hollow cylinder is simple, convenient, labor-saved and efficient.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Efficient and convenient rust removal device for hardware machining

ActiveCN112139956AScientific and reasonable structureSafe to useGrinding carriagesGrinding drivesElectric machineryAgricultural engineering

The invention discloses an efficient and convenient rust removal device for hardware machining. A moving hole is formed in one side of a shell, a rust removal assembly is mounted on one side of the moving hole, rotating rods are symmetrically and slidably mounted on the inner side of the moving hole, one end of each rotating rod is connected to an output end of a transmission motor, a movable mounting block is mounted at one end of the shell, a movable lead screw is mounted at the top end of the movable mounting block, a rust removal drain pipe is mounted on the inner side of the shell, rust removal spray heads are mounted at a water outlet end of a connecting pipeline, a discharge limiting valve is embedded into one end of the connecting pipeline, and the rust removal drain pipe is connected to a booster water pump. By spraying a dust remover to the surface of a hardware plate by the spray head and brushing the hardware plate through a dust removal roller after spraying, rust is removed quickly and effectively. By adjusting the height of the dust removal roller, the device can be adjusted quickly and effectively, and it is convenient to remove dust for different hardware plates. By adjusting the limiting valve, the quantity of used spray heads is adjusted according to width of the hardware plate.

Owner:上海盈驰精密模具有限公司

High-pressure gravel rust removal device

InactiveCN108081154AChange the circulation gapQuick mixAbrasive feedersAbrasive machine appurtenancesBiochemical engineeringEngineering

The invention discloses a high-pressure gravel rust removal device. The high-pressure gravel rust removal device comprises a bottom plate, a guide rod is arranged on the upper end of the bottom platevertically, a screw is arranged on one side of the guide rod, a lifting motor is arranged at the lower end of the screw, the guide rod is sleeved with a lifting arm, the lifting arm can be up and downsliding connection along the guide rod, the lifting arm is in threaded fit connection with the screw, a stirring motor is arranged at the upper end of the lifting arm, a tank body is arranged above the bottom plate, an output shaft of the stirring motor extends into the tank body, multiple stirring blades are arranged, a water tank is arranged on the bottom plate, the water tank is provided witha water pump, the water pump and the tank body are communicated through a water pipe, a feeding opening is formed in the upper end of the tank body, a booster pump is arranged on the bottom plate, theinlet end of the booster pump is communicated with the bottom of the tank body through a pipeline, the outlet end of the booster pump is provided with a water spraying pipe, and the tail end of the water spraying pipe is connected with a high-pressure spraying gun. The device is beneficial to popularization and application.

Owner:达川区逸夫小学

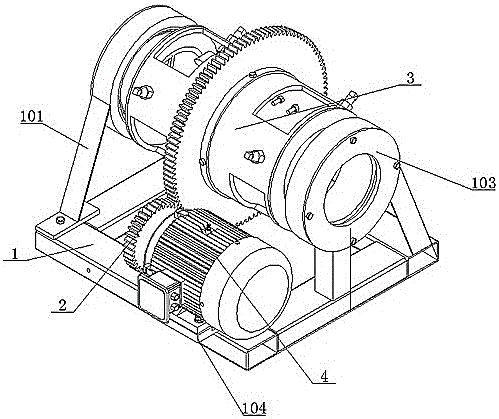

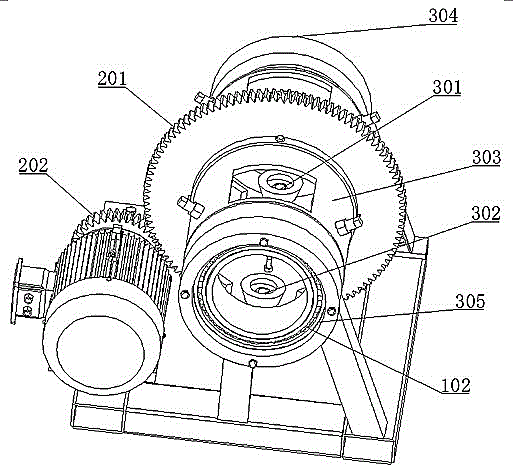

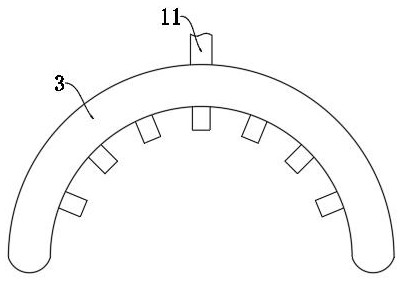

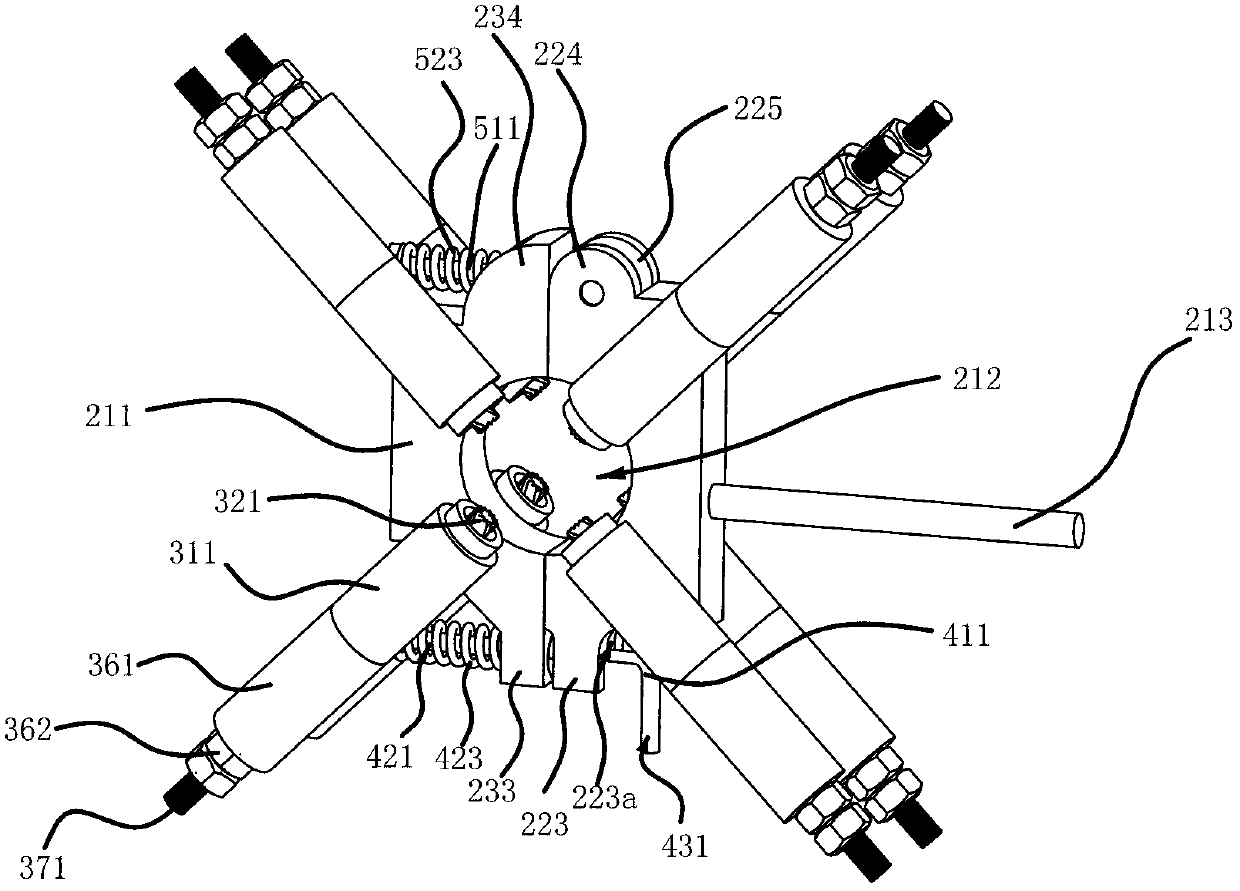

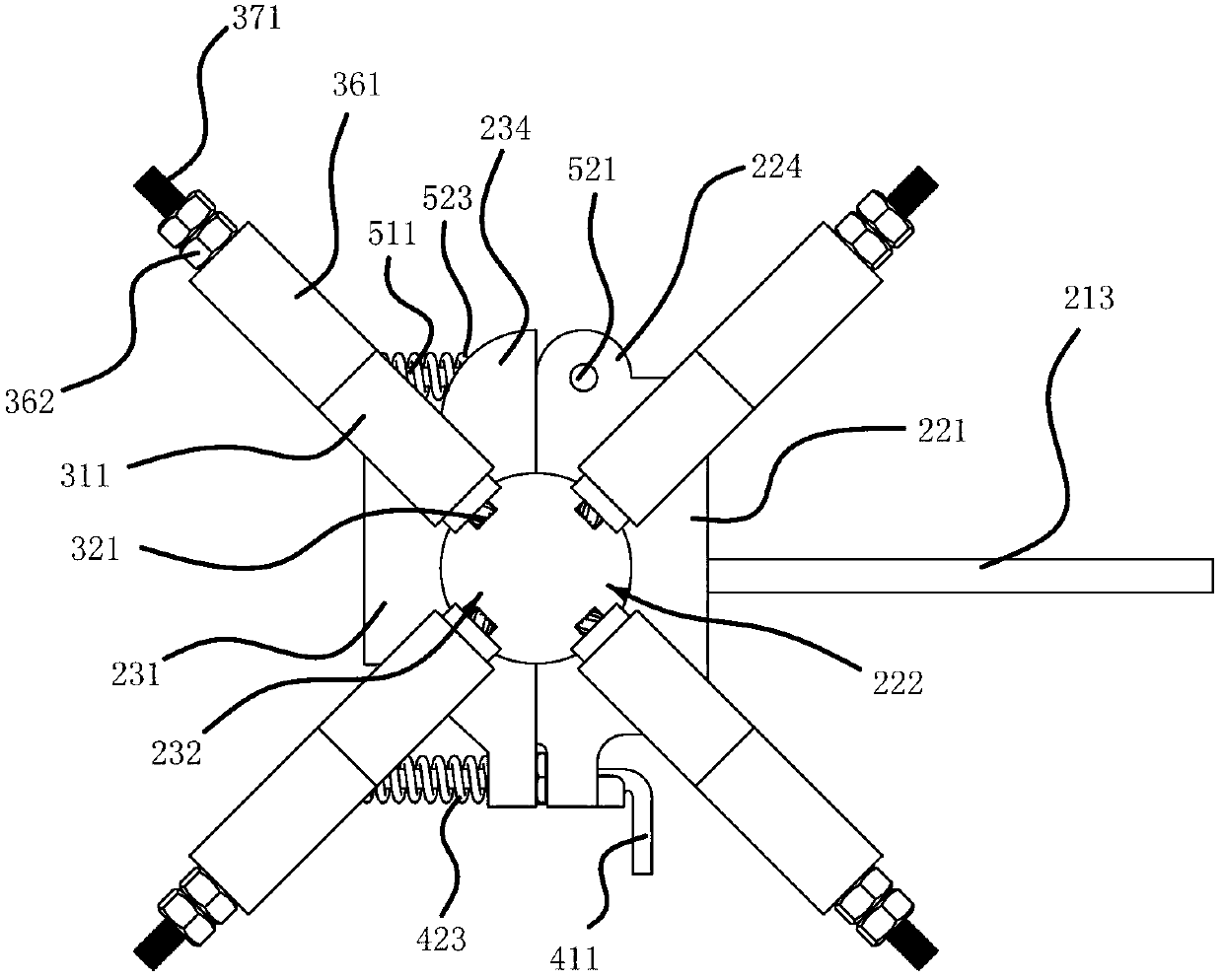

Bowl scaffold steel tube derusting machine

The invention provides a bowl scaffold steel tube derusting machine and belongs to the technical field of machinery. The bowl scaffold steel tube derusting machine solves the technical problems that rust cleaning of the whole bowl scaffold steel tube is unavailable for an existing bowl scaffold steel tube derusting machine and the like. The bowl scaffold steel tube derusting machine comprises a machine frame and a derusting ring. A speed reduction motor is fixed at one end of the machine frame. A fixing seat is arranged at the other end of the machine frame. A blocking rod is arranged on the lateral portion of the machine frame along the axial direction. A through hole is formed in the derusting ring and the steel tube passes through the through hole. A limiting rod which is capable of butting against the blocking rod is arranged on the periphery of the derusting ring. A plurality of fixing sleeves are fixed on the lateral sides of the derusting ring. The central axes of the fixing sleeves are parallel to the lateral sides of the derusting ring and intersect with the central axis of the through hole. Brush heads are arranged on the inner ends of the fixing sleeves. An adjusting component is arranged between each fixing sleeve and each corresponding brush head, wherein the adjusting component is capable of enabling the brush head to move along the direction of the axis of the fixing sleeve. The bowl scaffold steel tube derusting machine has the advantages of being capable of effectively cleaning rust on the bowl scaffold steel tube.

Owner:FANGYUAN CONSTR GRP REAL ESTATE DEVT CO LTD

Surface rust removal device for tubular mechanical part machining

ActiveCN112008576AFully derustedImprove rust removal effectGrinding carriagesGrinding drivesRotational axisElectric machine

The invention relates to the technical field of mechanical part surface rust removal, and discloses a surface rust removal device for tubular mechanical part machining. A first fixing plate and a second fixing plate are mounted on the upper surface of a workbench from left to right; a rotating motor is mounted in the first fixed plate; the driving end of the rotating motor is connected with a rotating shaft; one end of the rotating shaft is fixedly connected with a first limiting disc; a rotating column is rotationally mounted in the second fixed plate; and a first electric telescopic rod is mounted on the position, on the front surface of the groove, of the upper surface of the workbench, the telescopic end of the first electric telescopic rod is connected with a moving plate, a protective cover is mounted on the upper surface of the workbench, a rust removal box is fixedly mounted on the upper surface of the protective cover, and a collecting box is arranged on the lower surface of the workbench. Through the effect of the first electric telescopic rod, impurities generated on the workbench can be removed and recycled through the collecting box, and therefore the cleanliness of the workbench is guaranteed.

Owner:山东蒙阳机械制造有限公司

Derusting and strengthening method for flange electric pole

ActiveCN107013048APrevent re-corrosionExtended service lifeBuilding repairsMetallic material coating processesSodium molybdatePhosphoric acid

The invention relates to the technical field of flange electric poles and particularly discloses a derusting and strengthening method for a flange electric pole. The derusting and strengthening method comprises the following steps of cleaning preparation, derusting treatment, inner rust-proof layer and inner packing layer painting, strengthening layer arranging, middle packing layer and outer rust-proof layer painting, and outer packing layer and finishing coat painting. Derusting liquid is used in derusting treatment and comprises 85% phosphoric acid, zinc oxide, accelerants, sodium molybdate solutions, complexing agents, surfactants and the balance water. The derusting liquid forms a rust-proof phosphating film protective layer on the surface of the flange electric pole while derusting is completed, so that occurrence of rusting again is avoided. According to the derusting and strengthening method for the flange electric pole, the flange electric pole can be effectively subjected to derusting and strengthening, the service life of the electric pole is prolonged, the safety strength of the electric pole is strengthened, meanwhile, the derusting and strengthening method can operate under the normal using condition, the economic loss caused by power outage operation is avoided, and the economic cost brought by replacing a new electric pole is saved.

Owner:STATE GRID ZHEJIANG PINGHU POWER SUPPLY +1

Environmental protection rust removing and rust resistance cleaning agent and preparation method thereof

The present invention relates to an environmental protection rust removing and rust resistance cleaning agent and a preparation method thereof, and belongs to the technical field of metal surface treatments. The cleaning agent comprises the following raw materials, by weight, 120-150 parts of deionized water, 5-10 parts of triethanolamine, 2-5 parts of citric acid, 20-25 parts of phosphoric acid, 4-6 parts of sodium silicate, 1-2 parts of zinc dihydrogen phosphate, 5-12 parts of sodium tripolyphosphate, 3-8 parts of 1H-benzotriazole, 8-10 parts of sodium metasilicate pentahydrate, 7-10 parts of gamma-mercaptopropyltrimethoxysilane, 2-4 parts of triethanolamine oleate, 1-5 parts of APG, and 2-4 parts of sodium alpha-sulfo fatty acid methyl ester. The environmental protection rust removing and rust resistance cleaning agent has characteristics of effective oil stain cleaning, rust removing, and good rust resistance. In addition, the barium-free rust resistance agent is adopted, and the components of the cleaning agent do not contain sodium nitrite and other toxic components, such that harms of strong bases and strong acids on the human body and the environment are concurrently avoided, and characteristics of safety and environmental protection are provided.

Owner:SUZHOU XINQIXUN NETWORK CO LTD

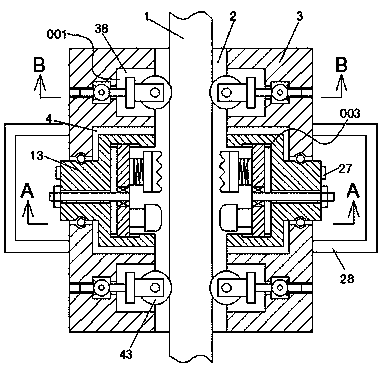

Self-adaptive curvature device and facade operation robot based on permanent magnet adsorption

InactiveCN111824283ARealize adaptive adjustmentIncreased curvature rangeVehiclesAcoustic wave reradiationEngineeringMotor control

The invention relates to a self-adaptive curvature device and a facade operation robot based on permanent magnet adsorption. The device comprises a frame structure, a damping spring, a first lead screw, a sliding block, an upper connecting rod, a lower connecting rod and two motion control boxes, the frame structure extends in the height direction, a second servo motor is fixedly installed in a lower frame of the frame structure, the output end of the second servo motor is fixedly connected with the first lead screw, and the upper portion of the first lead screw is fixed to the frame structure; the first lead screw is in threaded connection with the sliding block; each motion control box is of a semi-enclosed structure; the upper connecting rod and the lower connecting rod are respectivelyhinged above and below the open sides of the motion control boxes; the other ends of the upper connecting rod and the lower connecting rod are hinged at different heights of the frame structure; thedamping spring is hinged to the sliding block and the upper ends of the closed sides of the motion control boxes. Under the same condition, the robot is high in adsorption force, can adapt to curved surfaces and planes with large and small curvatures, can be completely attached to the curved surfaces, and can efficiently complete rust removal operation.

Owner:HEBEI UNIV OF TECH

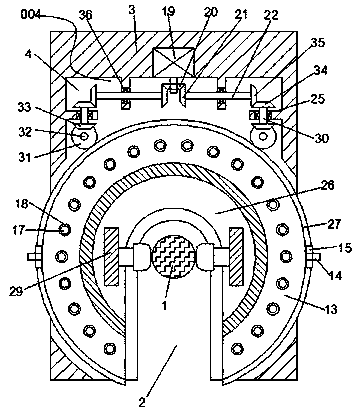

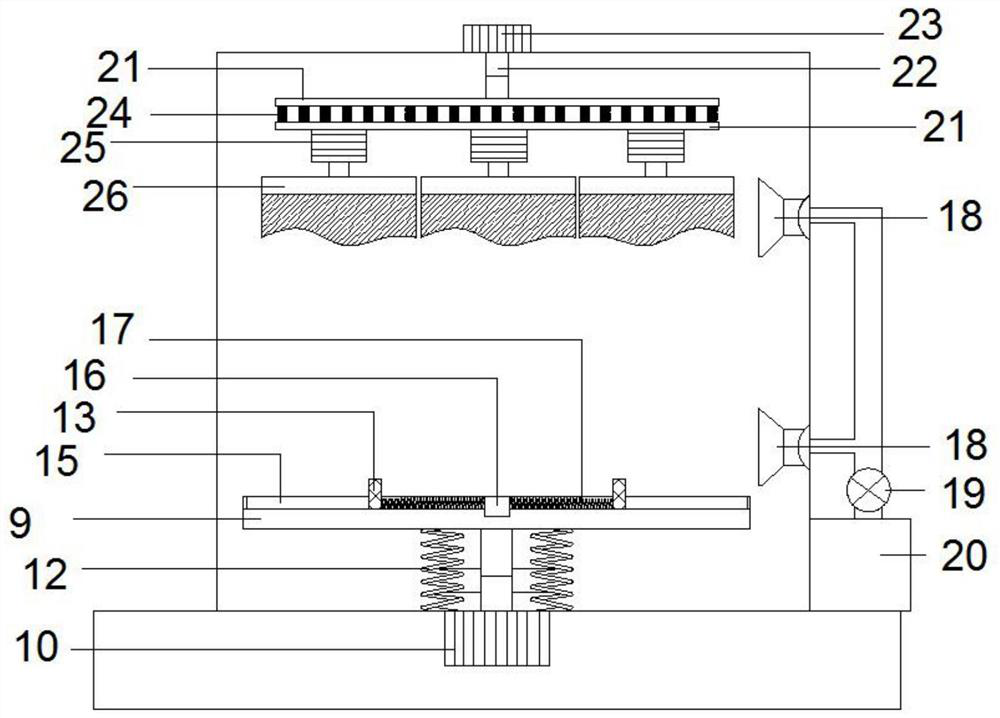

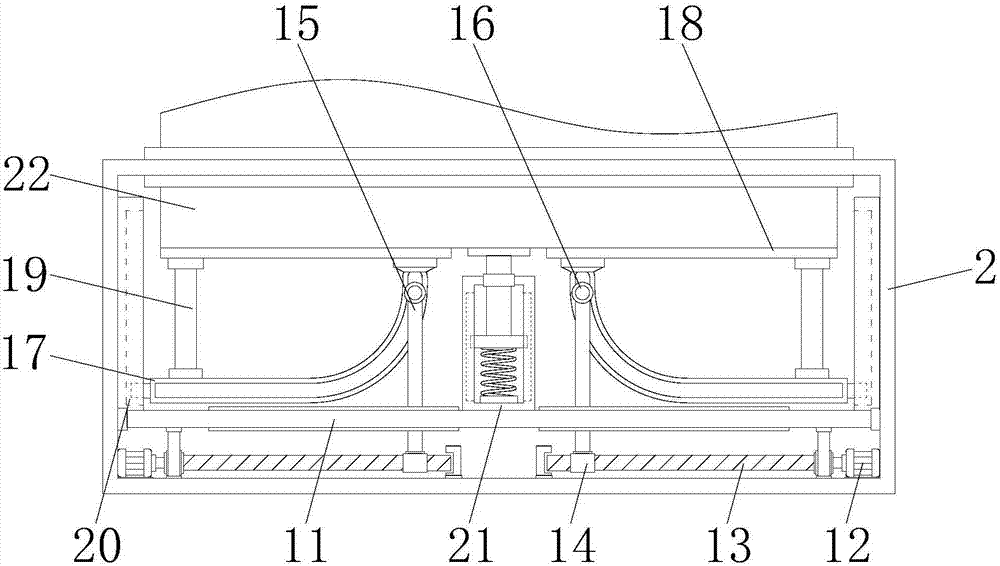

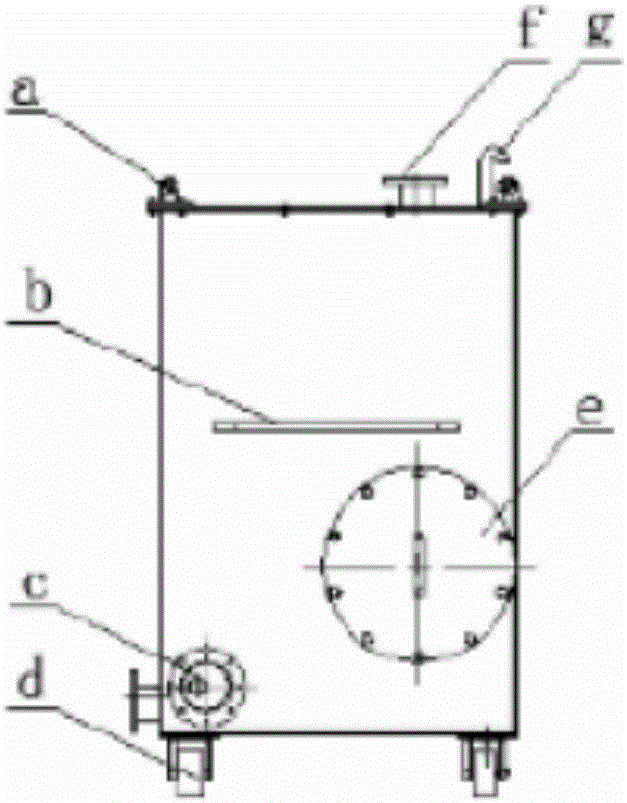

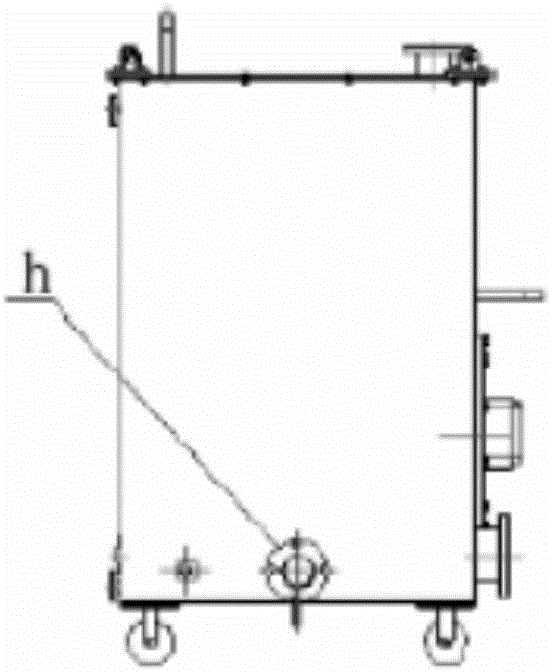

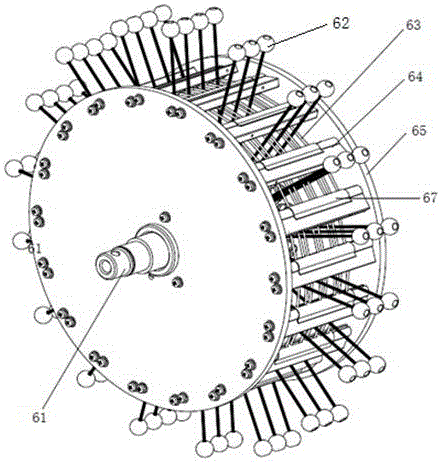

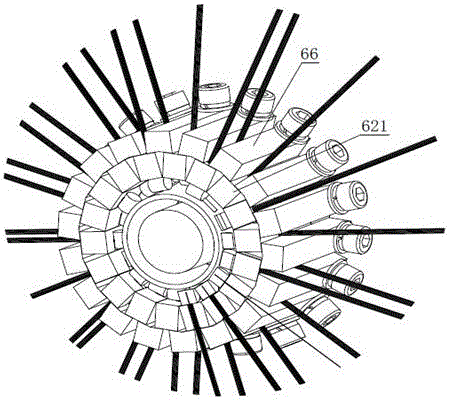

Large-scale Babbitt bearing casting machine

InactiveCN105772696AEfficient rust removalEfficient degreasingCasting cleaning apparatusMolten metal conveying equipmentsMechanical equipmentLayer removal

The invention discloses a large-scale Babbitt bearing casting machine and aims to provide casting mechanical equipment in the field of metal casting. The casting machine comprises a base, damping pads, two clamping pinchers, a painting device, and a vibrator, wherein the two clamping pinchers are horizontally arranged oppositely and fixedly connected in a middle groove formed in the base; the painting device is fixedly connected to a foundation; the vibrator is fixedly connected with a plane which is arranged on the base; the amount of the damping pads is six, and the damping pads are all arranged on the bottom face of the base. According to the technical scheme of the large-scale Babbitt bearing casting machine, wind pressure is used as the power, by means of the wiggle, rotation and reciprocating rectilinear movement of painting tools in the painting device, operations such as rust removal, oxide layer removal, degreasing and tin coating can be conducted efficiently; vibration casting is adopted, and the casting quality is improved. By means of the large-scale Babbitt bearing casting machine, casting efficiency can be improved effectively, and the working conditions of workers can be largely improved and labor intensity of the workers can be largely relieved; the casting machine is simple in structure, convenient to repair and low in equipment investment.

Owner:KUNMING UNIV

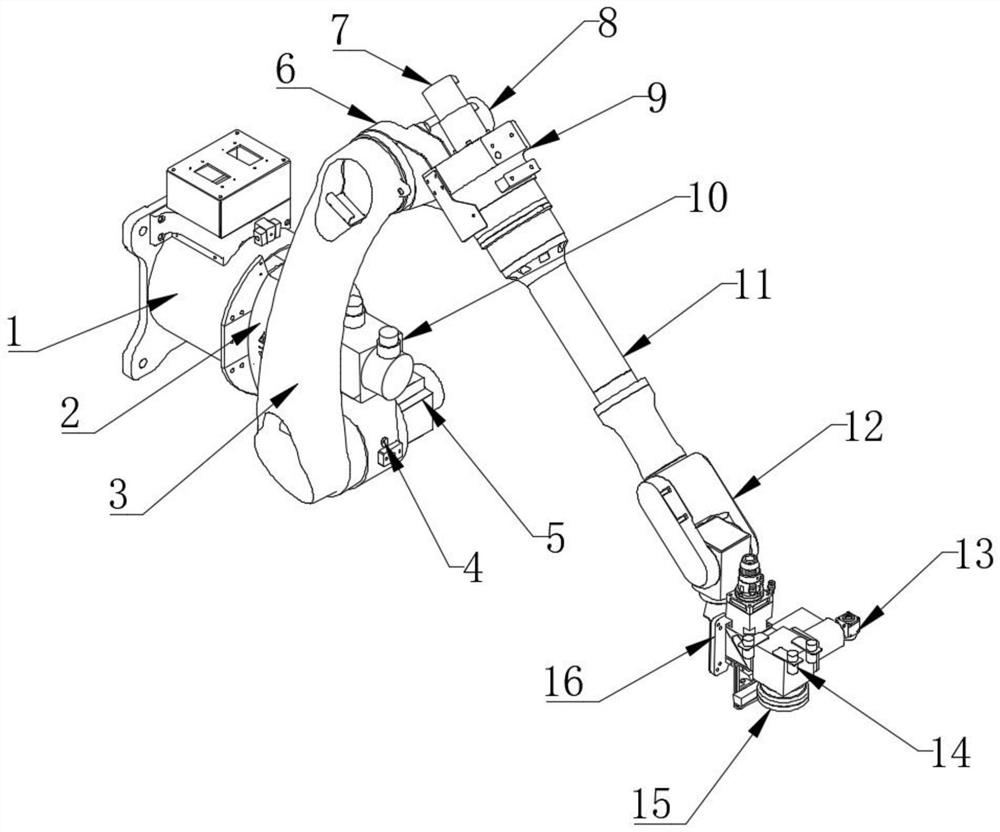

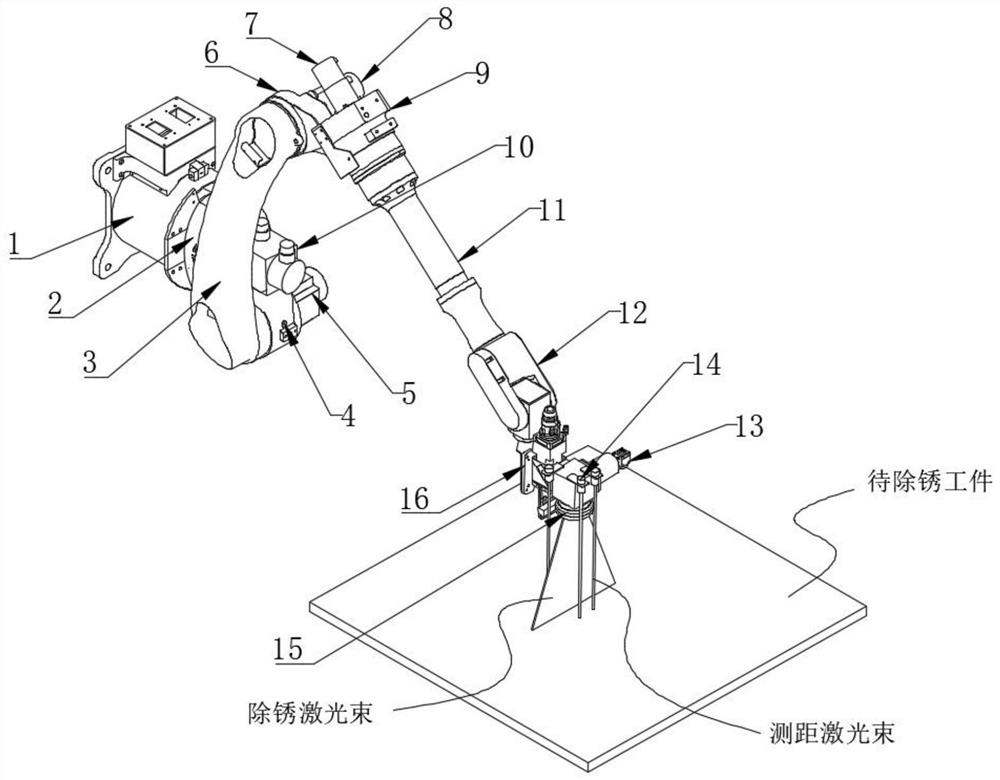

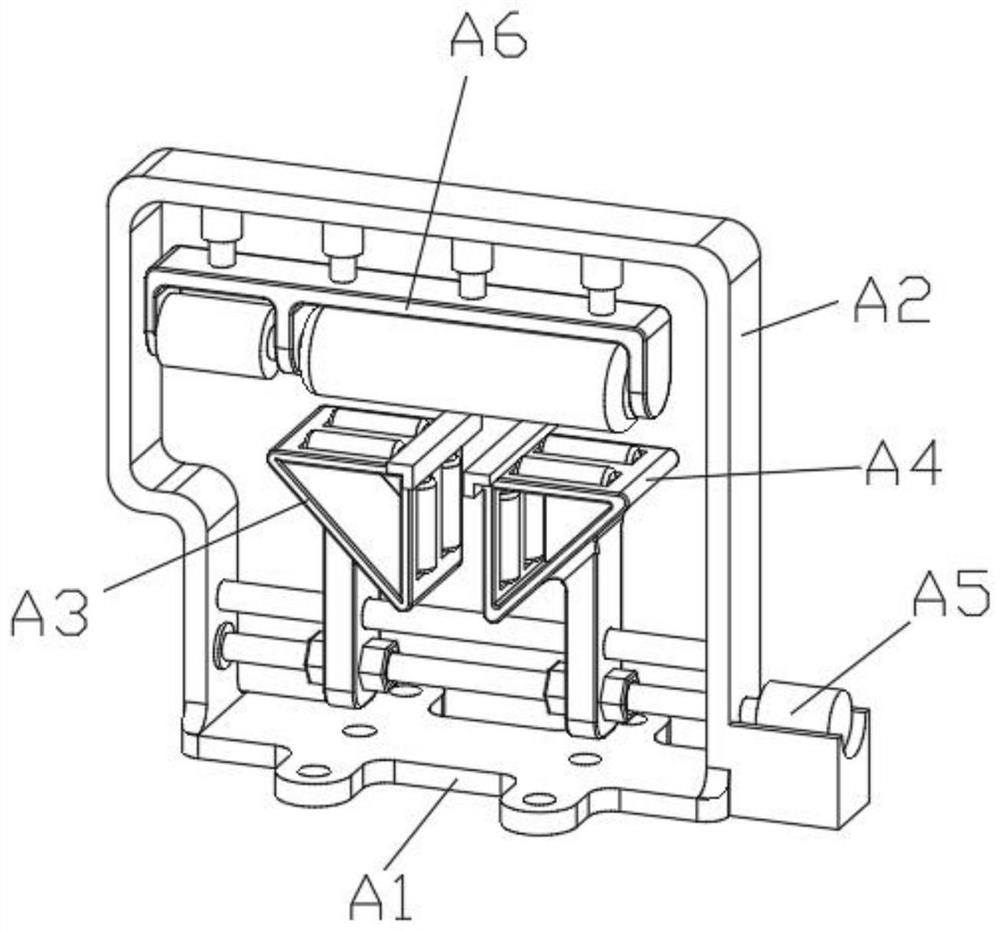

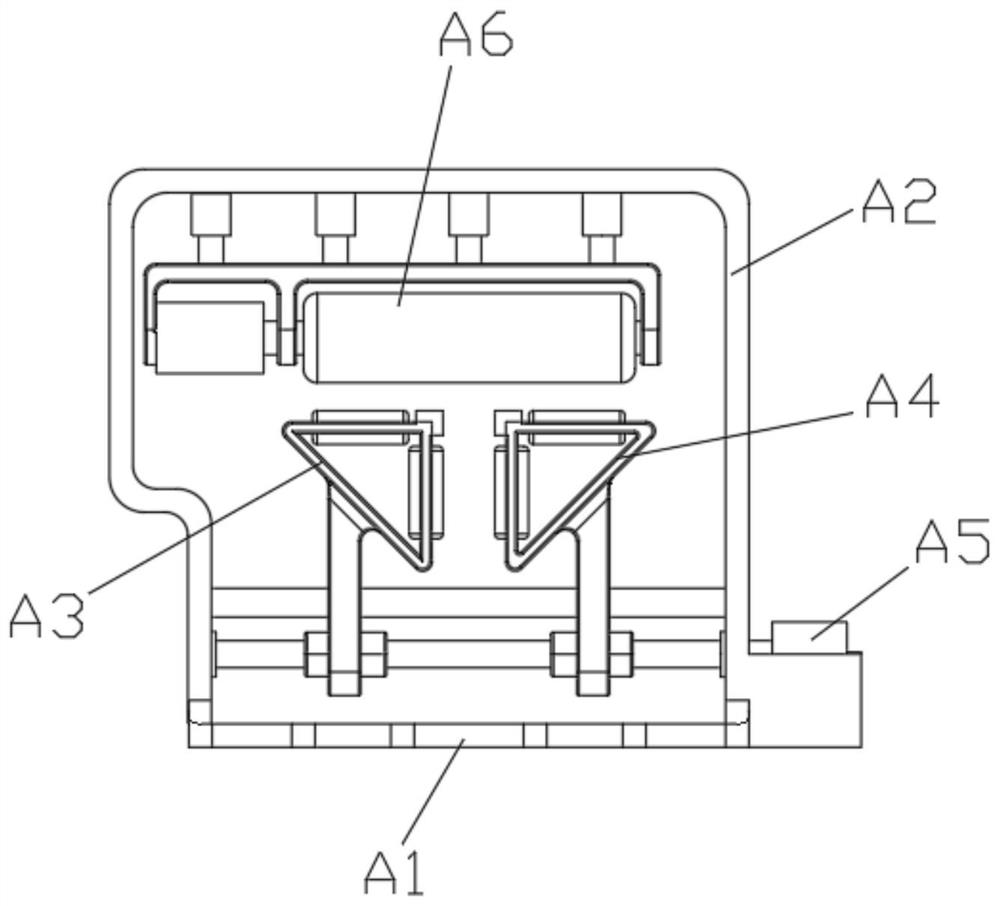

Intelligent focal length control system for laser rust removal

InactiveCN112008233AAvoid damagePosition controlCleaning processes and apparatusLaser beam welding apparatusControl systemElectric machinery

The invention relates to the technical field of laser rust removal, and discloses an intelligent focal length control system for laser rust removal. The system comprises a base, a first speed reduceris installed at the front end of the base, a focal length control box is installed at the lower end of the inner side of a clamp, a laser head is installed at the bottom end of the focal length control box, a camera is installed on one side of the focal length control box, and three displacement sensors are installed at the position, close to the outer side of the laser head, of the upper end of the focal length control box. According to the intelligent focal length control system, real-time shooting is carried out on a to-be-derusted workpiece by the camera; the size and shape of the workpiece and the rust position on the surface of the workpiece are obtained; real-time distance measurement is carried out on the two sides of a to-be-derusted position through the three displacement sensors; and the distance and angle of the laser head are adjusted through a first rotating joint motor, a second servo motor, a second rotating joint motor and a first servo motor, the position of the laserhead can be accurately controlled, optimal focal length control is achieved, the purpose of efficient rust removal is achieved, and damage to the workpiece is reduced as much as possible.

Owner:SHANGHAI JIANYE TECH ENG

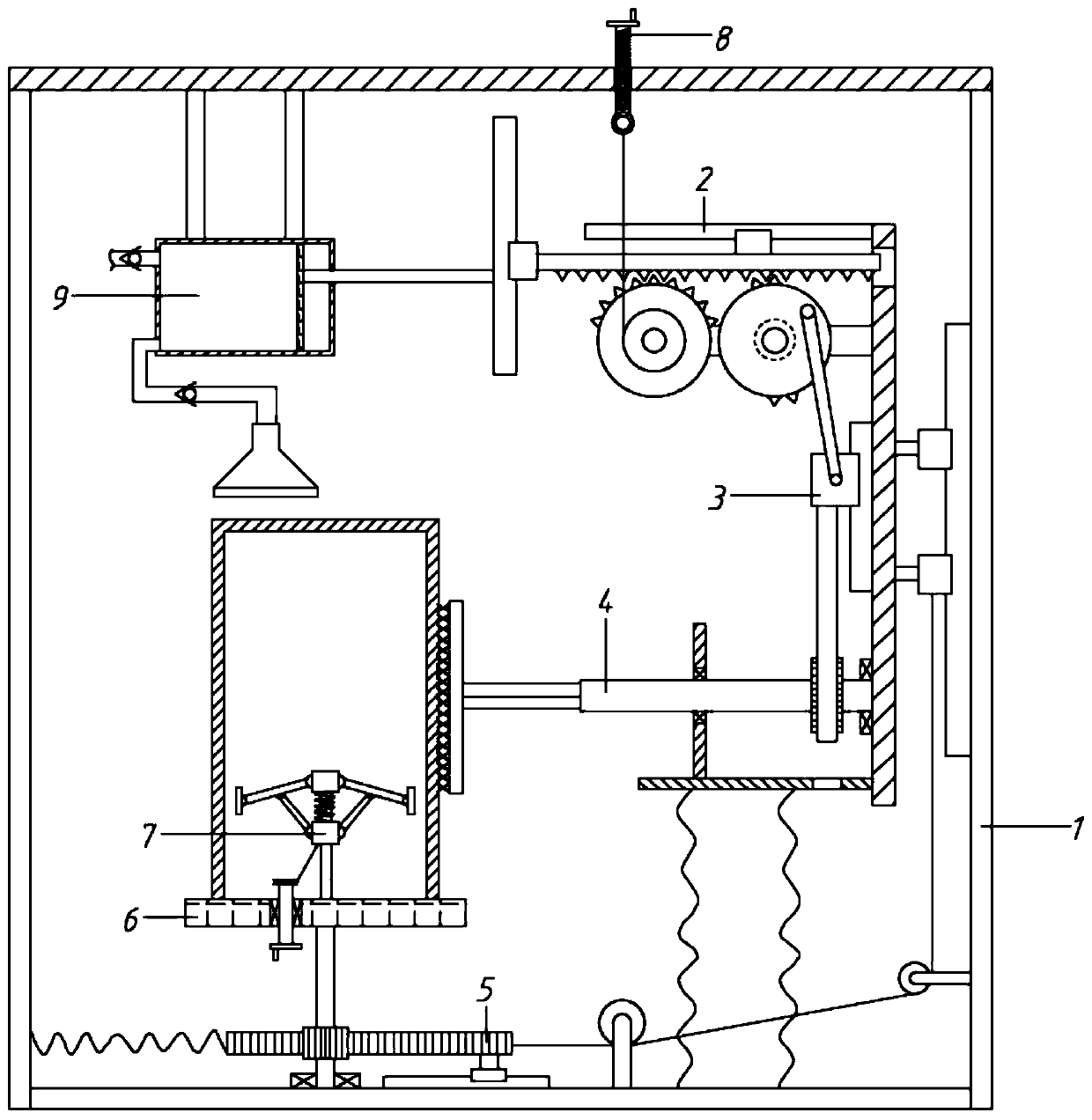

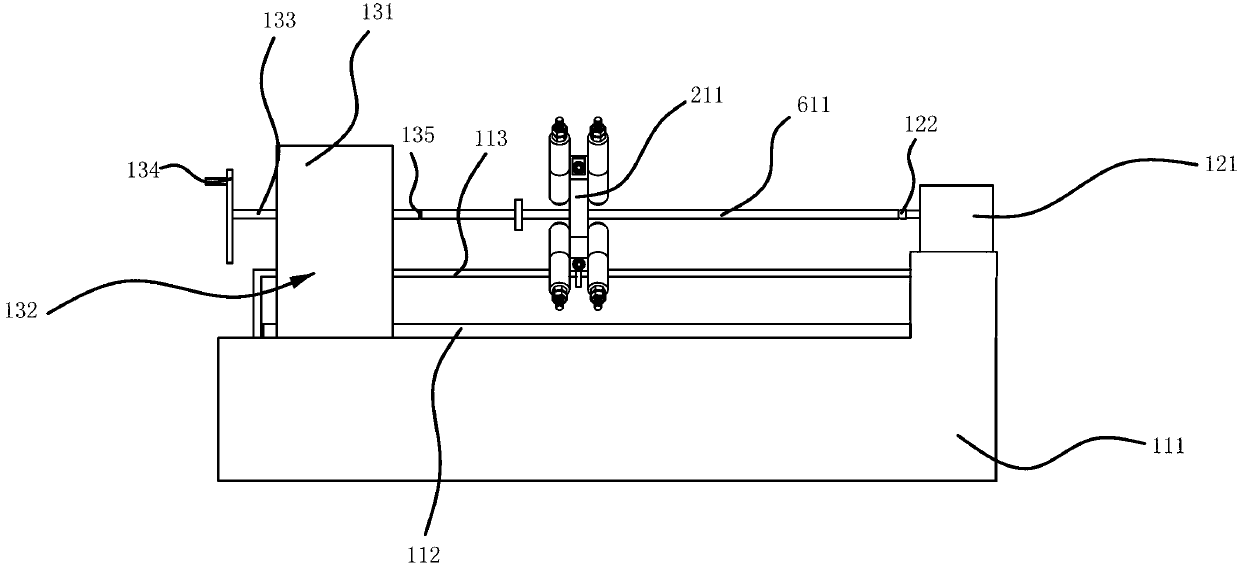

Production line of T-shaped steel for shipbuilding

ActiveCN112517672AImprove work efficiencyReduce labor intensityMetal-working feeding devicesCleaning using liquidsProduction lineEngineering

The invention provides a production line of T-shaped steel for shipbuilding. The production line comprises a correcting device, an operating device and a derusting device, the correcting device is used for correcting the bending deformation of the T-shaped steel, the derusting device is used for removing rust on the surface of the T-shaped steel, and the operating device is used for operating thecorrected T-shaped steel into the derusting device; the operating device comprises a clamping mechanism, a fourth telescopic piece, a width adjusting mechanism and a conveying belt, the width adjusting mechanism is arranged on the bottom surface of the conveying belt, the fourth telescopic piece is movably arranged on the width adjusting mechanism, and the clamping mechanism is arranged at the bottom end of the fourth telescopic piece; and the clamping mechanism comprises a first clamping plate, a second clamping plate, a vertical clamping plate and a transverse clamping plate, wherein the first clamping plate is horizontally distributed. According to the operating device, two first clamping rollers and a second clamping roller jointly clamp the top face and the bottom face of a top plateof the T-shaped steel, multiple clamping points are arranged, the clamping effect is good, and the potential safety hazard that the T-shaped steel falls off is eliminated.

Owner:DALIAN MARITIME UNIVERSITY

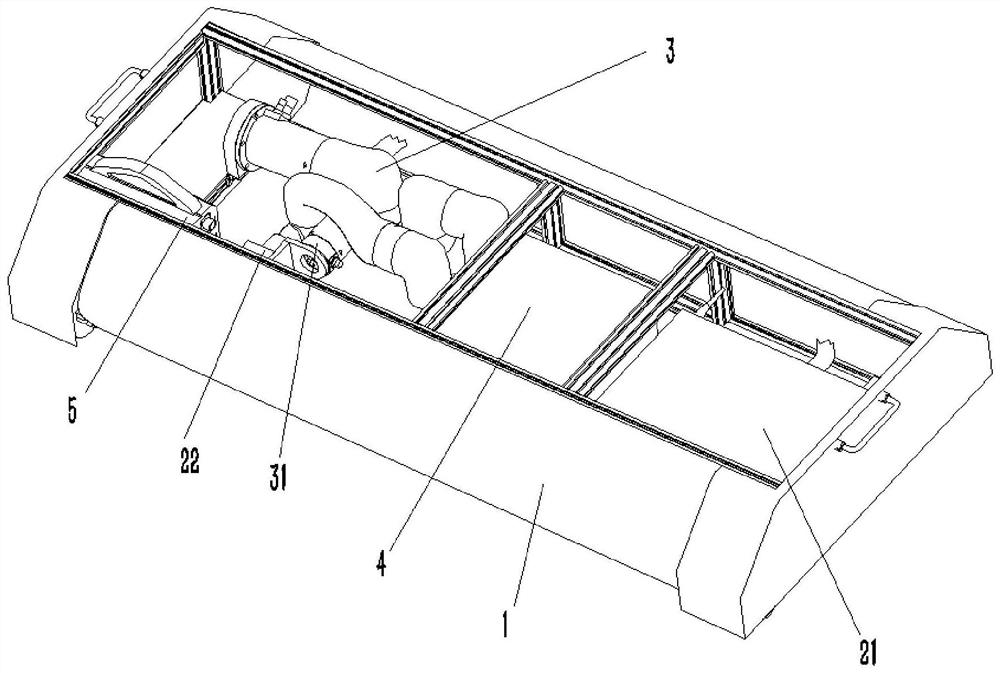

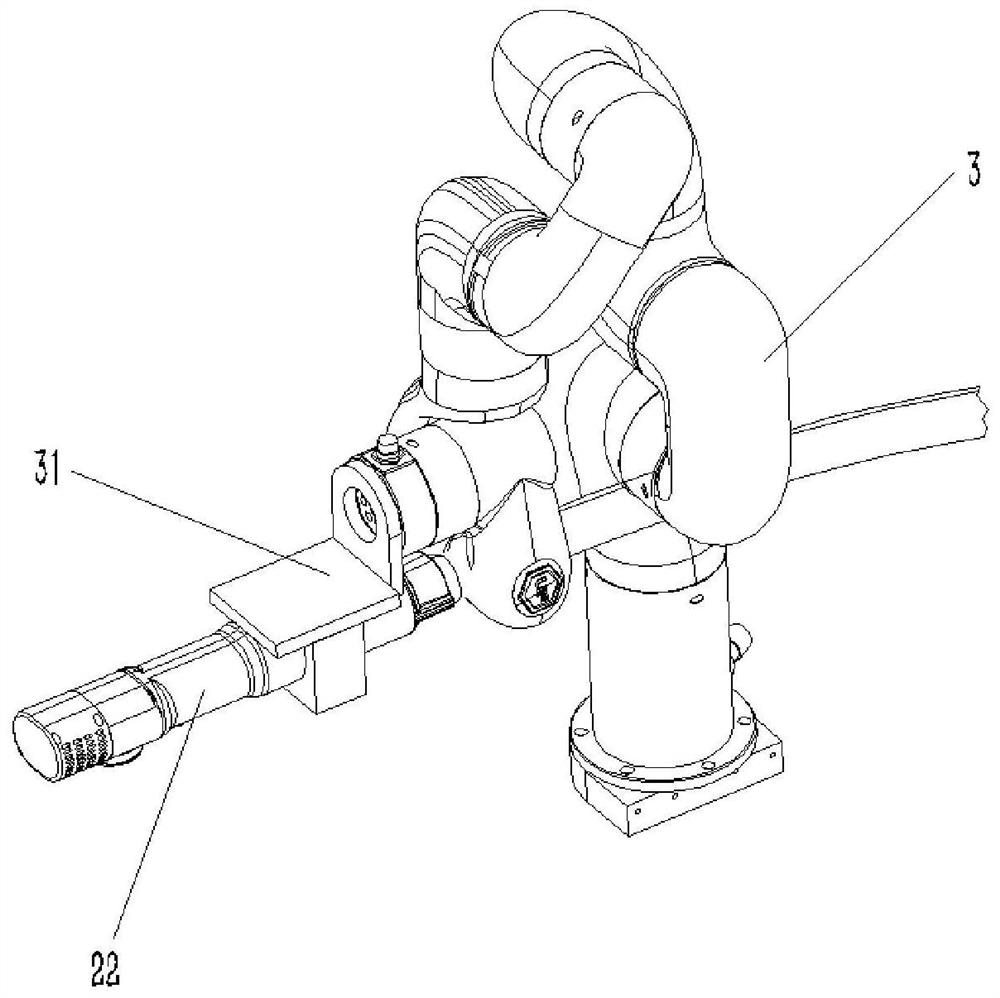

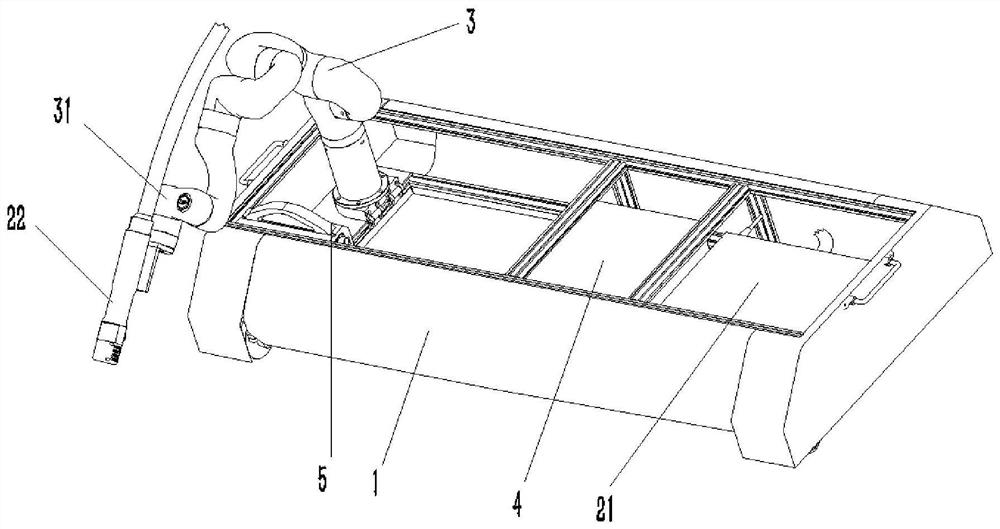

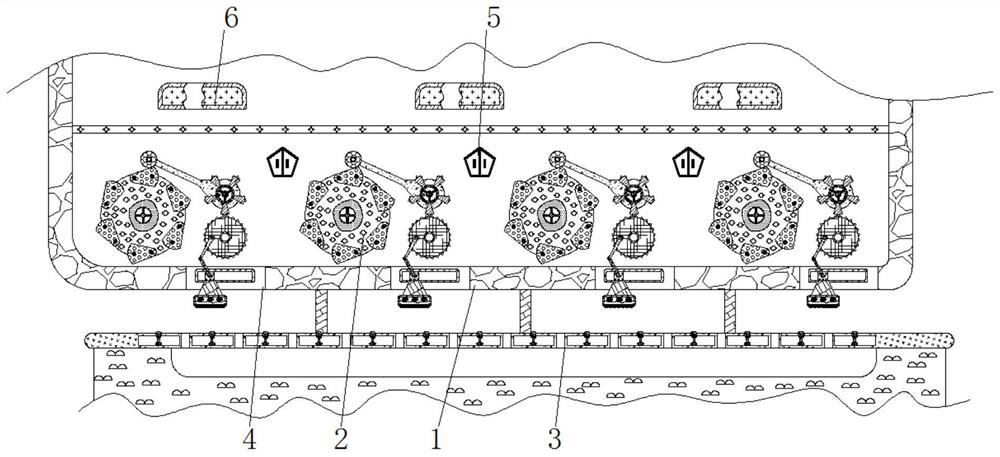

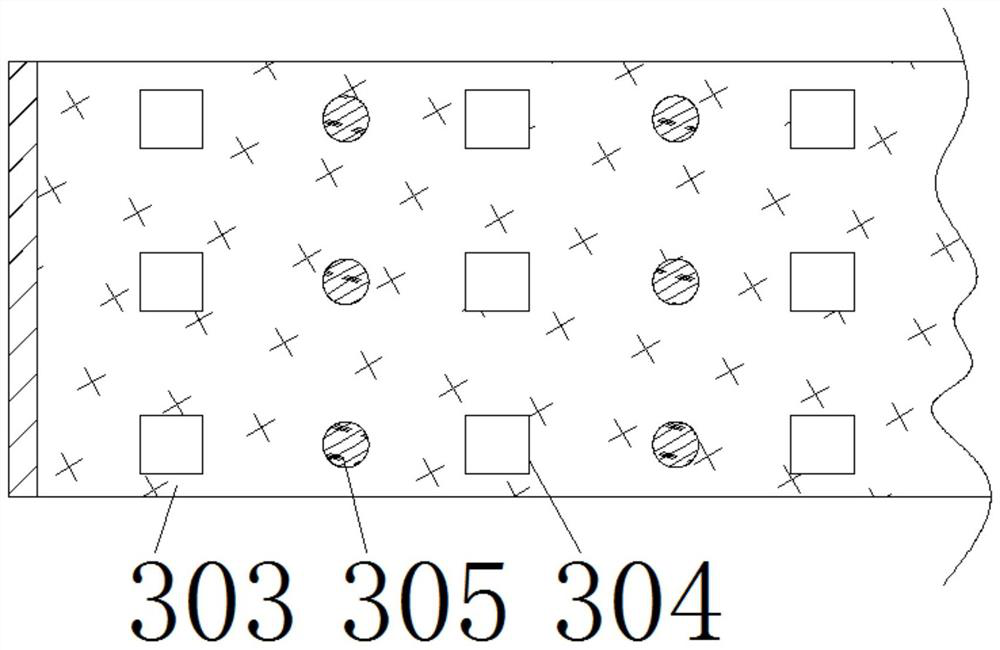

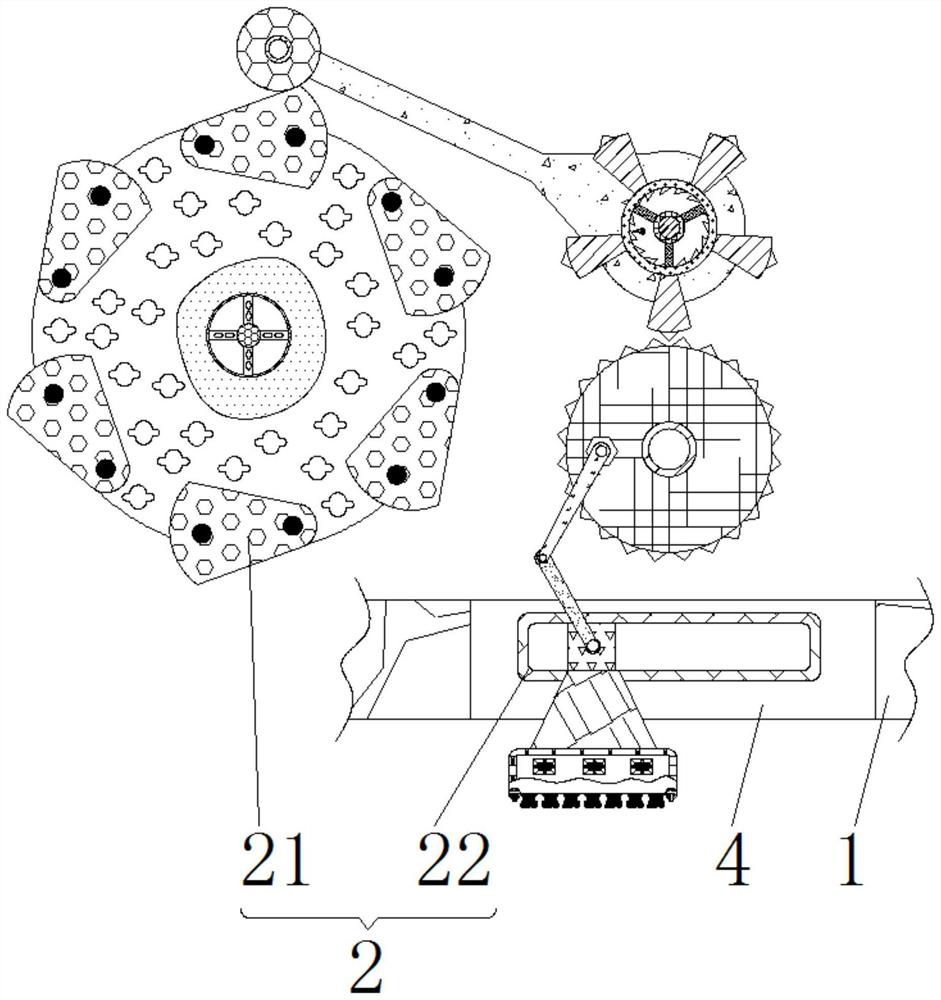

Rust removal device for ship manufacturing T-shaped steel and using method of rust removal device

ActiveCN112376063AComprehensive derusting treatmentChange the support positionCleaning using liquidsManufacturing engineeringMetallurgy

The invention provides a rust removal device for ship manufacturing T-shaped steel and a using method of the rust removal device. The rust removal device comprises a rust removal pool, a power mechanism, at least four supporting mechanisms and a grabbing mechanism, wherein the rust removal pool is used for accommodating rust removal liquid, the power mechanism is arranged between the inner bottomsurface and the side wall of the rust removal pool, the supporting mechanisms are movably arranged on the power mechanism, and can support the T-shaped steel, the grabbing mechanism is arranged on theouter side wall of the rust removal pool, and the grabbing mechanism can grab the T-shaped steel so as to place the T-shaped steel into the rust removal pool or take the T-shaped steel out of the rust removal pool; and the four supporting mechanisms are distributed at two ends of the bottom surface of the T-shaped steel correspondingly. According to the rust removal device, the rust removal liquid and ultrasonic waves can be in contact with an original supporting portion, so that rust removal operation can be effectively carried out on the supporting portion of the T-shaped steel, the operation is convenient and fast, the efficiency is high, and the time consumption of the rust removal operation is shortened.

Owner:DALIAN MARITIME UNIVERSITY

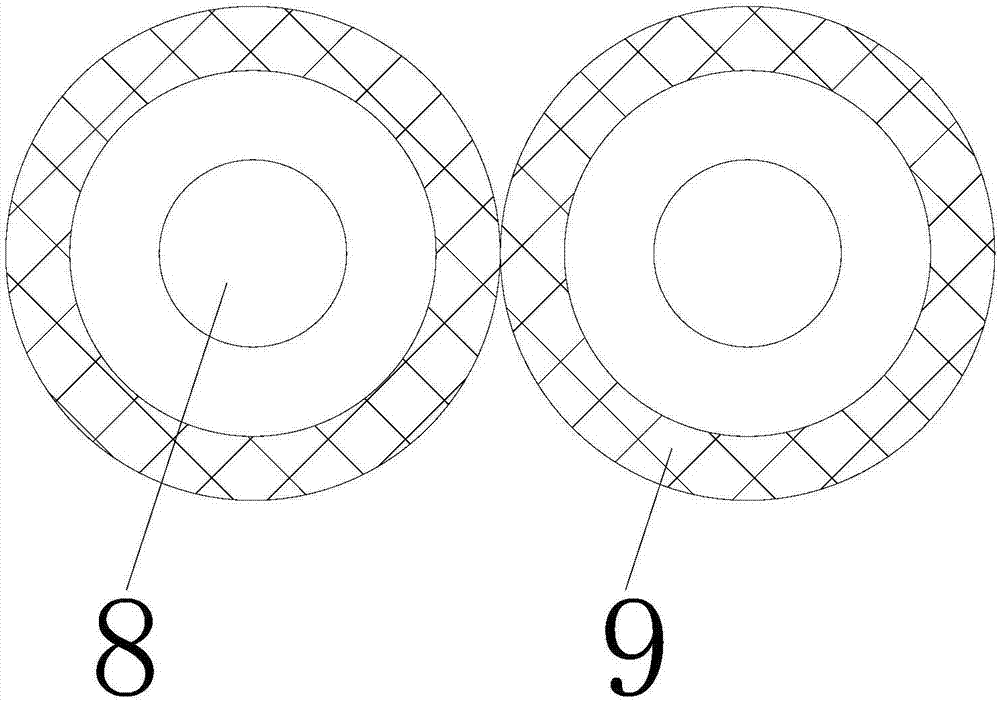

Iron faucet surface rust removing device

InactiveCN107877333AEfficient rust removalEfficient and fast rust removal workGrinding machinesElectric machineryEngineering

The invention discloses an iron faucet surface rust removing device comprising a bottom plate; a box body is fixedly connected to the top of the bottom plate, and two supporting rods are correspondingly and fixed connected with both sides of the top of the box body; a fixing plate is fixedly connected between the two supporting rods, and two first motors are fixedly connected with both sides of the top of the fixing plate; the surfaces of first belt pulleys are correspondingly connected with second belt pulleys in a driving mode through belts, grinding wheels are fixedly connected with one sides of the second belt pulleys through rotating shafts; and the top of a supporting frame is fixedly connected with the bottom of the fixing plate. The invention relates to the technical field of faucet surface rust removing. According to the iron faucet surface rust removing device, the box body is fixedly connected to the top of the bottom plate to efficiently and quickly remove rust on both sides of a faucet, and the rust removing work of the faucet can be completed quickly and the working speed can be improved; and the problem that uniform rust removing on both sides of the faucet of the existing iron faucet surface rust removing device cannot be carried out at the same time is solved.

Owner:WUXI HUIOU CERAMIC CO LTD

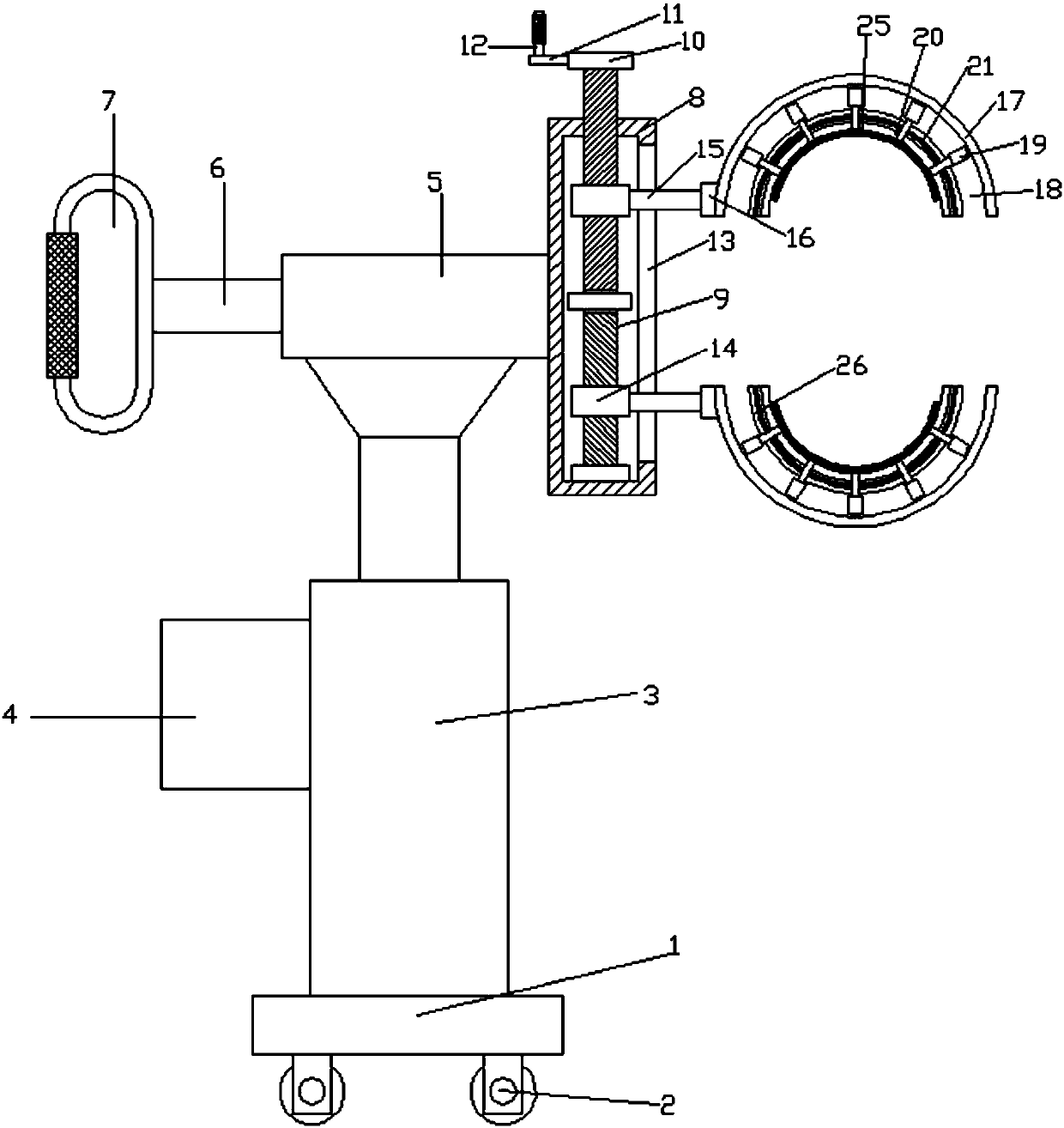

Cleaning and derusting device and method for water cavity system

InactiveCN106367769AEfficient rust removalComprehensive cleaning and rust removalWaste managementCentrifugal pump

Disclosed is a cleaning and derusting device for a water cavity system. The cleaning and derusting device is connected with a cooling water system of maintenance equipment to form an integrated loop. The cleaning and derusting device comprises a flushing water tank, a filter, a centrifugal pump and an electric unit, wherein the flushing water tank is provided with a water outlet and a return water opening, cleaning liquid containing a deruster is contained inside the flushing water tank, heating pipes for heating the cleaning liquid and a temperature sensor for detecting the temperature of the cleaning liquid are disposed on the lower portion of the flushing water tank, and the return water opening communicates with the cooling water system of the maintenance equipment; one end of the filter is connected with the flushing water tank; the centrifugal pump is driven by a motor so as to pressurize the cleaning liquid, one end of the centrifugal pump is connected with the other end of the filter, and the other end of the centrifugal pump communicates with the cooling water system of the maintenance equipment; and the electric unit controls the centrifugal pump to drive the pressurized warm cleaning liquid to circularly flow, so that no-dead-corner overall cleaning and derusting are performed on the cooling water system, and the residual cleaning liquid attached to the interior of the cooling water system after cleaning plays a subsequent antirust role. By means of the cleaning and derusting device for the water cavity system, thorough, overall and effective cleaning and derusting can be performed on the cooling water system provided with a complicated water cavity, and subsequent effective protection of the cooling water system is guaranteed.

Owner:CSSC MES DIESEL

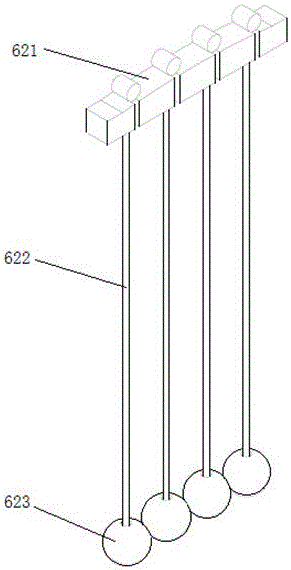

Fly ball wheel and hammering operation method

ActiveCN106758595AAvoid excessive collisionAvoid breakingRailway track constructionDrive shaftUltimate tensile strength

Owner:广州泽文通译文化传播有限公司

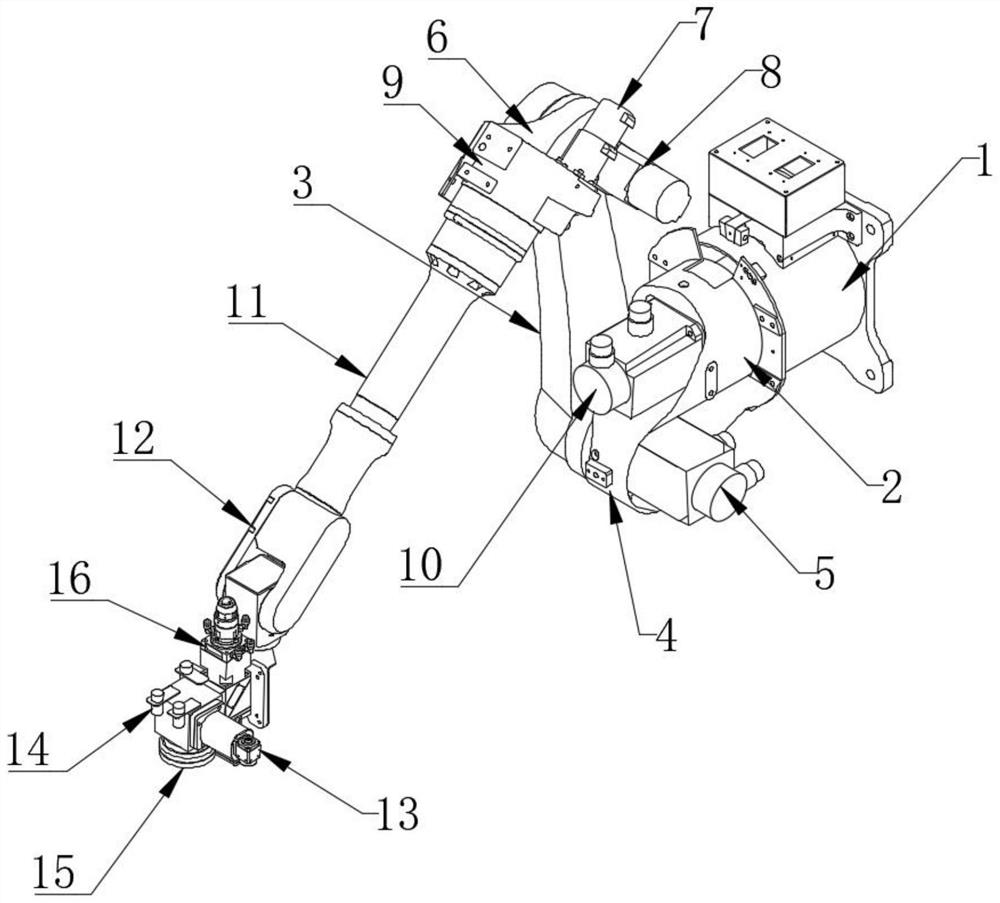

System for railway steel rail laser rust removal

PendingCN112475612AImprove work efficiencyHigh degree of integrationLaser beam welding apparatusCleaning processes and apparatusAutomotive engineeringElectrical and Electronics engineering

The invention relates to the railway rail rust removal technology, in particular to a system for railway steel rail laser rust removal. The system comprises a rail car and a laser generating device. Rail wheels are arranged on two sides of the bottom of the rail car, and the laser generating device comprises a laser generator and a laser head. The system further comprises a multiple-degree-of-freedom mechanical arm and a dust absorption device. A magnetic attraction device is arranged on the mechanical arm, the laser head is connected with the mechanical arm through a clamping block, the laserhead is electrically connected with the laser generator, and a storage bin, a power bin and a laser generation bin are sequentially arranged in the rail car. Multiple-angle rust removal of rails is achieved in the mode that the laser head and the mechanical arm are combined; and meanwhile, the mechanical arm can be attracted to the rails through the magnetic attraction device to complete dead-corner-free rust removal of the rails, rust removal is made more thorough, the operation time is saved, and the operation efficiency is improved. And meanwhile, rust dust and harmful gas generated in therust removal process can be absorbed through the dust absorption device, and it is guaranteed that the rust removal operation process is safe and reliable.

Owner:XIAN RAILWAY BUREAU SCI & TECH INST

Efficient metal component rust removal device for furniture manufacturing

The invention relates to the technical field of furniture production, and discloses an efficient metal component rust removal device for furniture manufacturing. The device comprises a shell, a rust removal mechanism is movably connected into the shell, and the rust removal mechanism comprises a movable assembly for motion adjustment and a cleaning assembly for removing rust on the surface of a metal component. The movable assembly is movably connected into the shell, and the cleaning assembly is movably connected to the inner side of the shell. A movable wheel rotates to enable a connecting plate to rotate, the connecting plate rotates to enable a gear to rotate, the gear rotates to enable a first connecting rod to rotate, the first connecting rod rotates to enable a second connecting rod to rotate to drive the cleaning assembly to do reciprocating motion to remove the rust, and meanwhile a protection shell moves to enable a rust removal brush to achieve rapid friction removal of the rust on the surface of the metal component; and a pickling solution is uniformly sprayed on the surface of the metal component by a spray head, so that efficient rust removal of the metal component is realized, the pickling operation time of the metal workpiece is effectively shortened, and the furniture production efficiency is also improved.

Owner:义乌市凌起家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com