Patents

Literature

51results about How to "Position control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

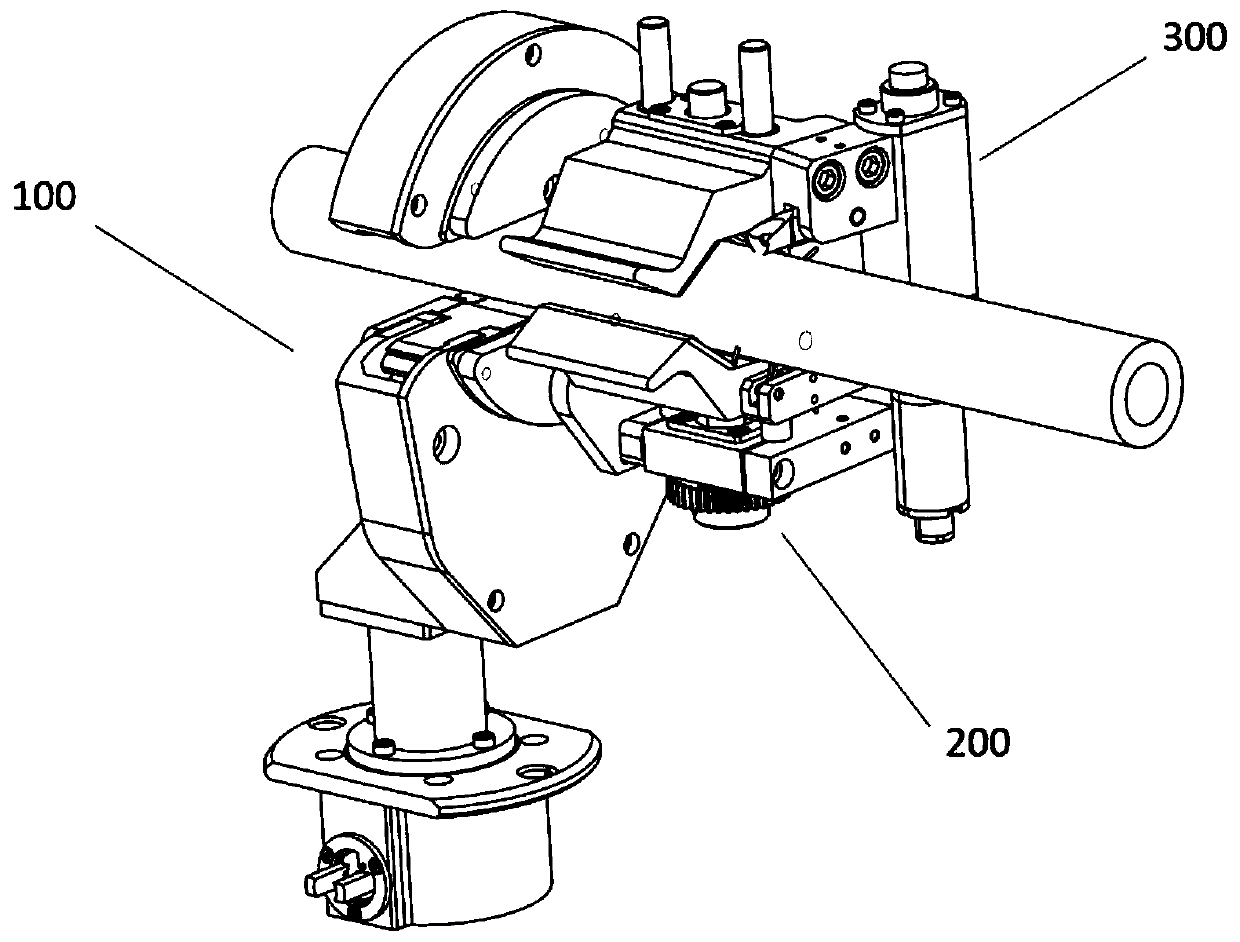

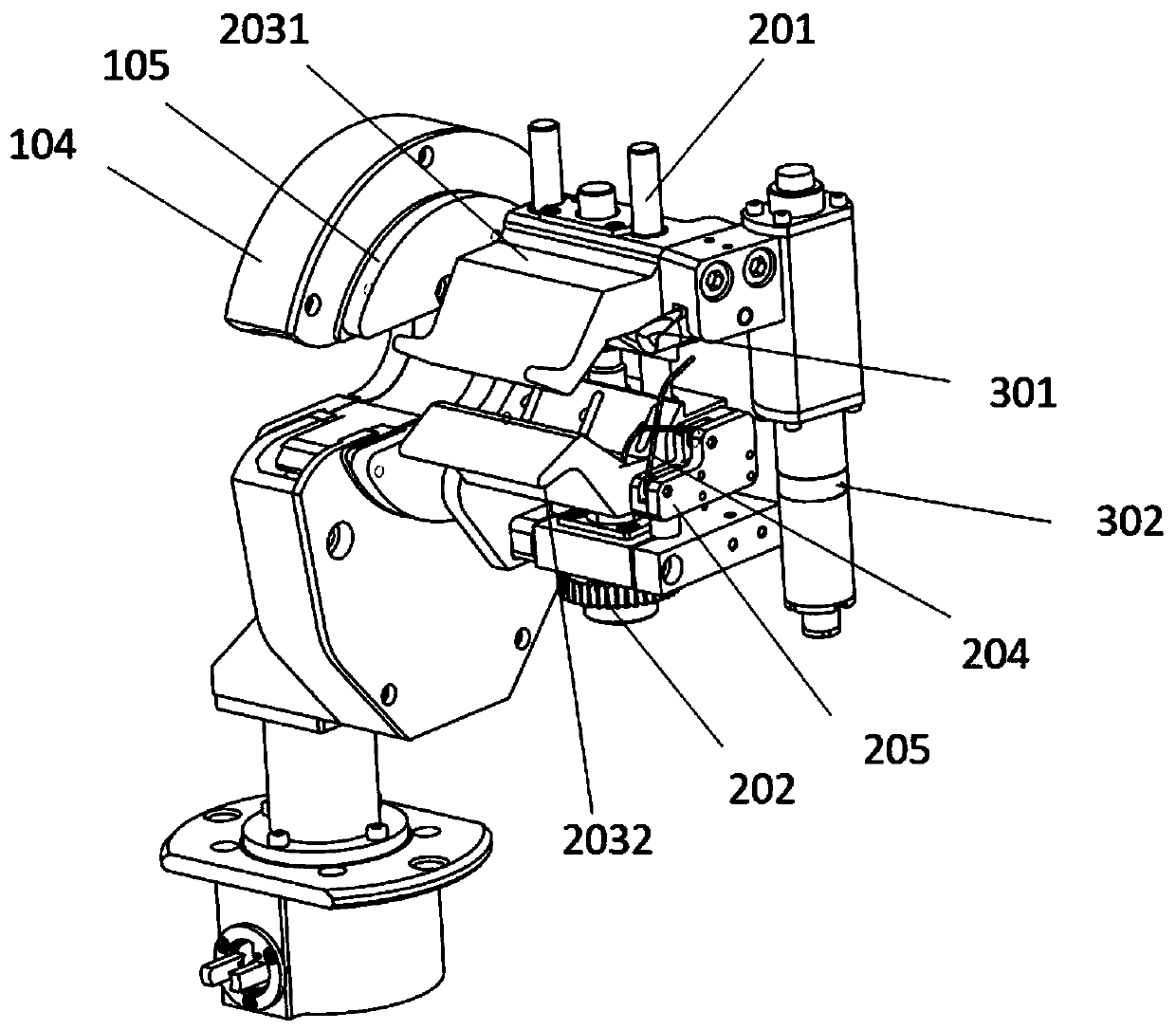

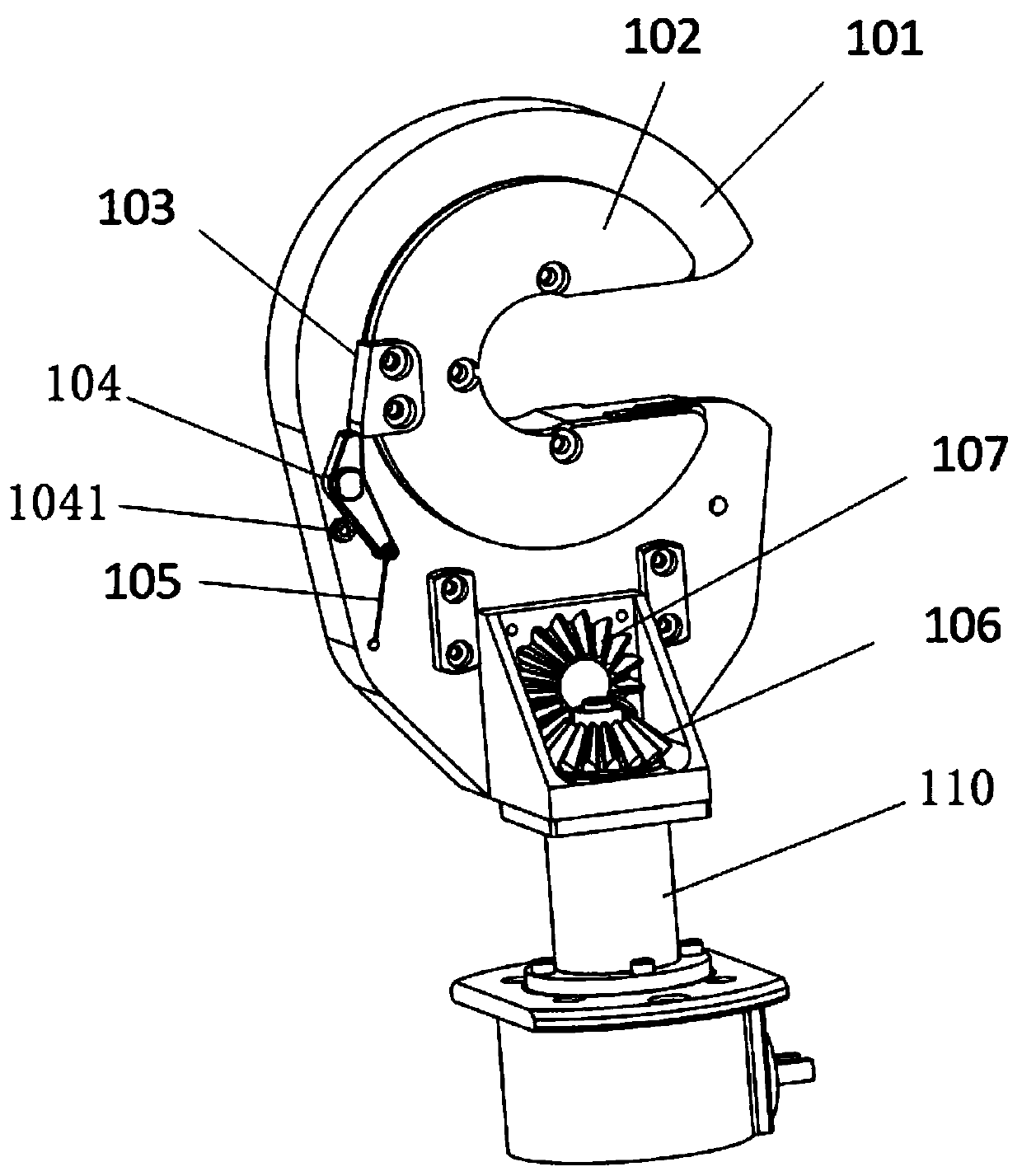

Wire stripper and wire stripping method thereof

ActiveCN111049069AEasy to controlPosition controlApparatus for removing/armouring cablesEngineeringTool bit

The invention discloses a wire stripper and a wire stripping method thereof. According to the wire stripper and the wire stripping method thereof, convex blocks with guiding functions are arranged inthe clamping opening of a wire clamp module, so that the wire stripper can be driven to rotate to strip wires and move forwards at the same time through friction forces between the convex blocks and the wires in the wire stripping process of the wire stripper, and the movement speed of the wire stripper is consistent with the stripping speed of the wire stripper. A detection part is arranged at the clamping opening of the wire clamp module, so that whether a tool bit cut insulating layers or not can be judged, and whether the tool bit cuts wire cores or not can also be judged; and the positionof the tool bit is continuously adjusted according to judgment results. Finally the stripping work of the wires is completed. According to the wire stripper and the wire stripping method thereof of the invention, the position of the tool bit can be conveniently controlled, and the tool bit can be timely adjusted after the tool bit cuts the wire cores.

Owner:YIJIAHE TECH CO LTD

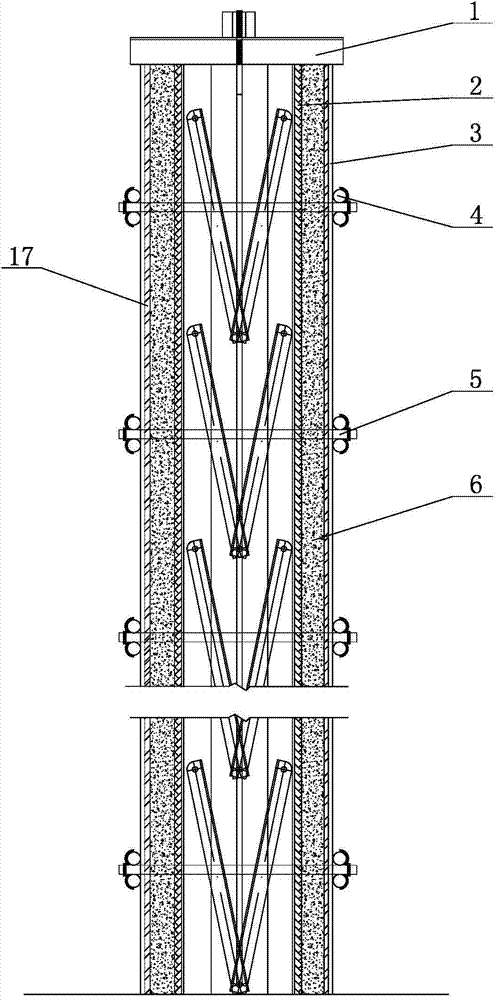

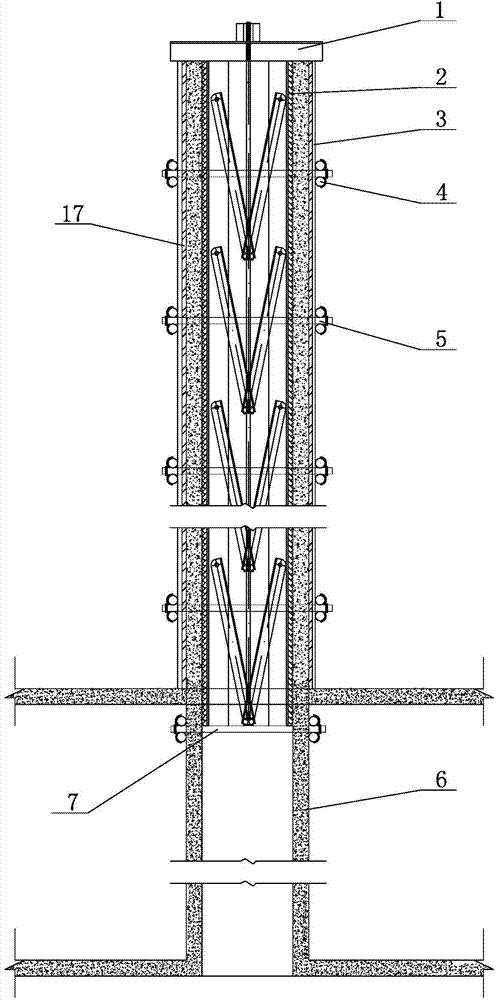

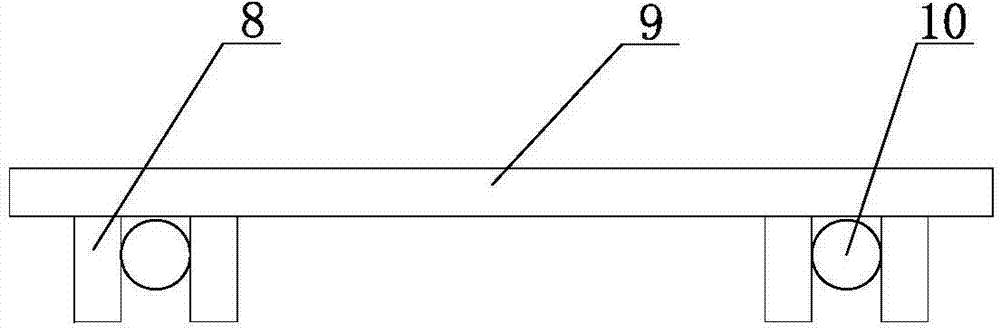

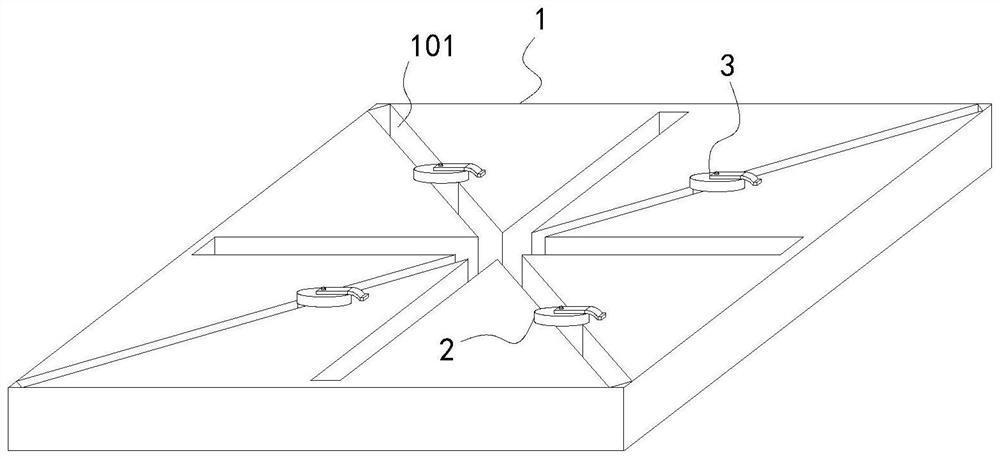

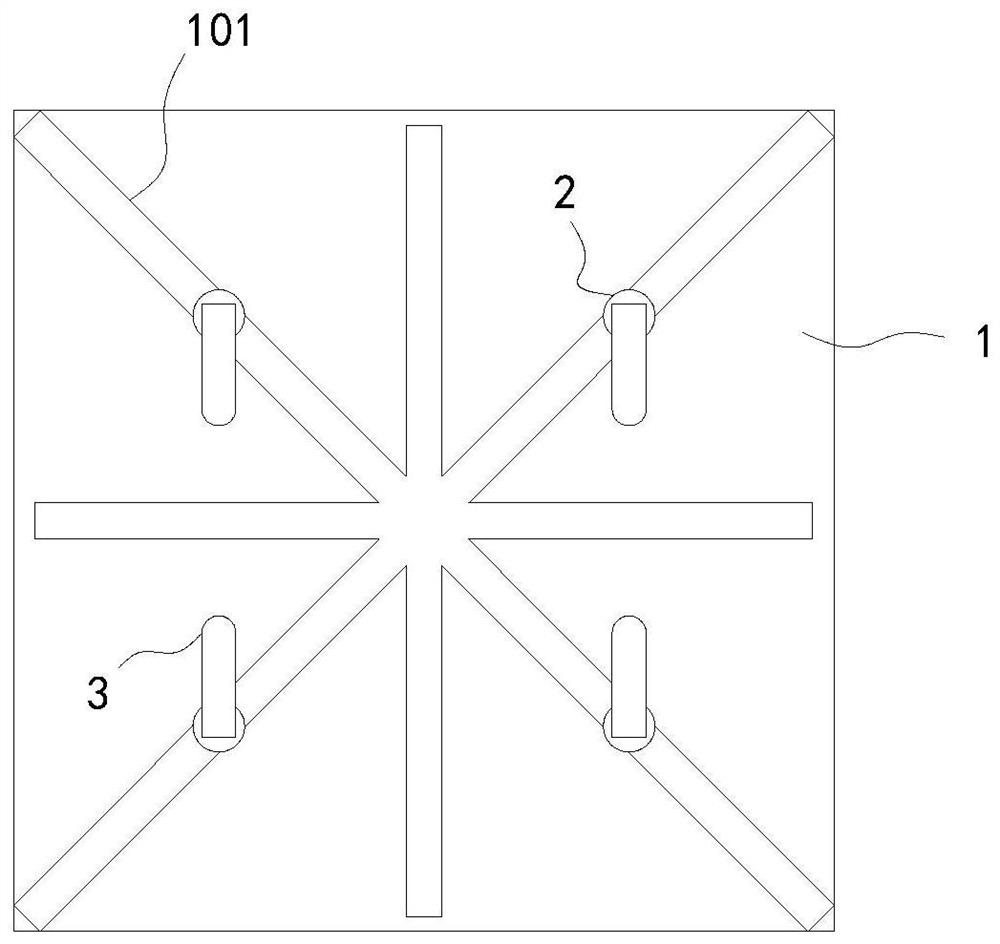

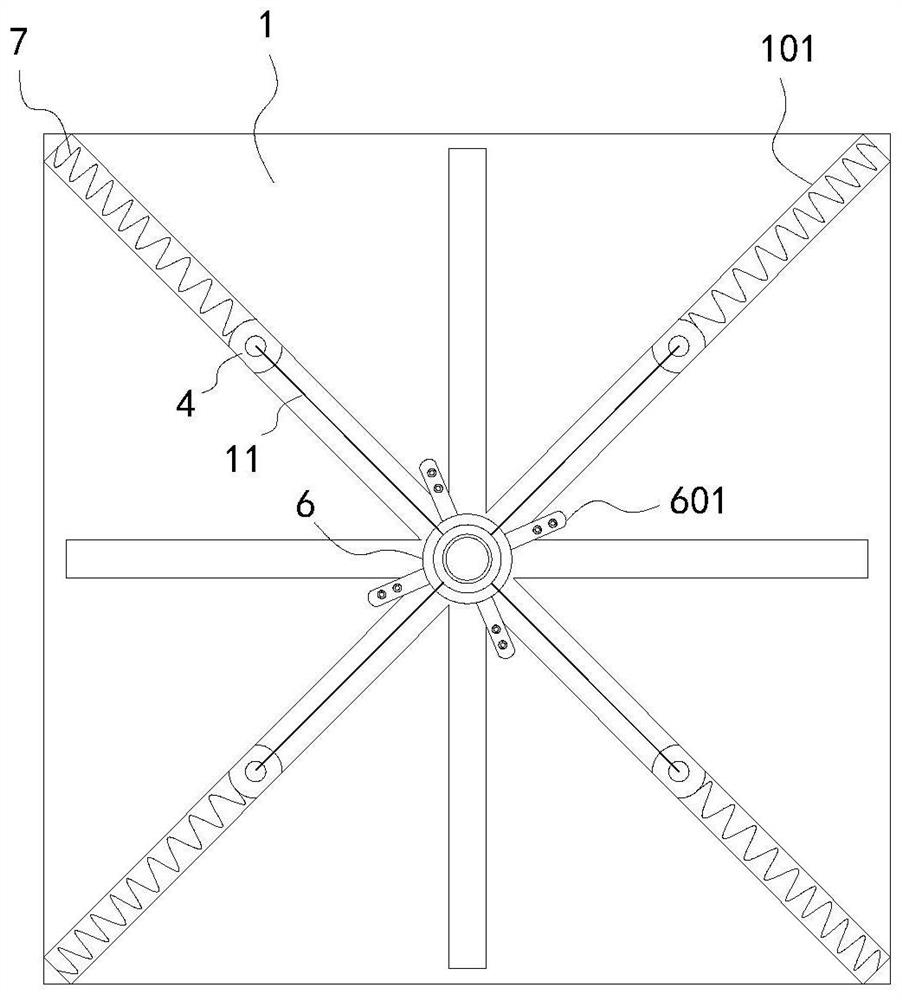

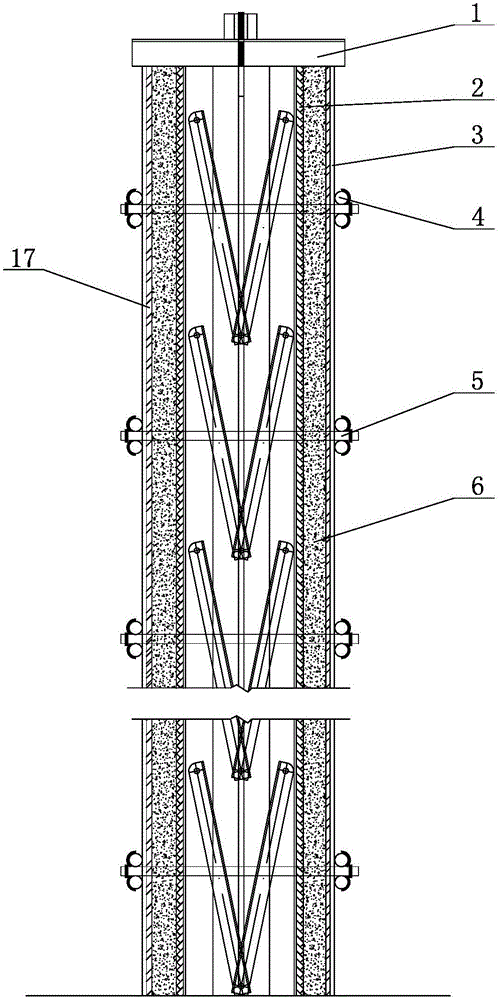

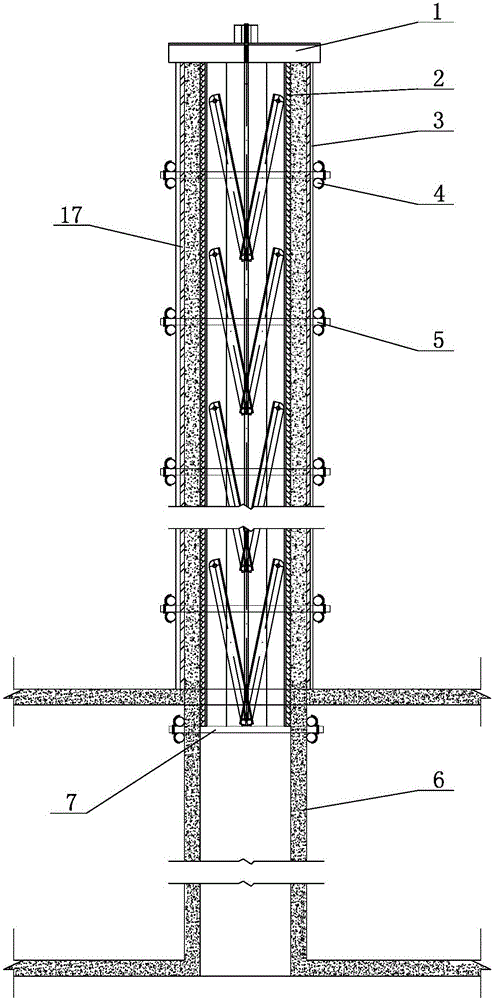

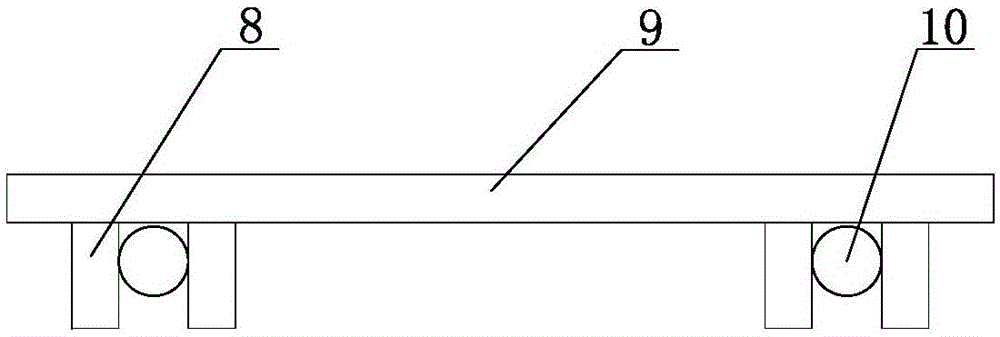

Construction technology for pouring concrete of walls on two sides of deformation joint

The invention belongs to the field of constructional engineering and particularly relates to a construction technology for pouring concrete of walls on two sides of a deformation joint. The construction technology comprises the following steps of 1 performing steel bar framework construction; 2 installing a wall board thickness control support; 3 performing positioning and paying-off; 4 installing a bottom-layer interior wall template and a scissors type connecting rod keel supporting system; 5 installing a wall outer-side template and a keel supporting system; 6 pouring the concrete; 7 template removal; 8 pouring the concrete of the walls on two sides of the upper-layer deformation joint; 9 repeating the step 8 till all of required floor pouring is finished. The construction technology is simple, convenient and efficient. Materials are saved. The quality accuracy is high. The root portion position control is good.

Owner:DONGHAI CONSTR GRP

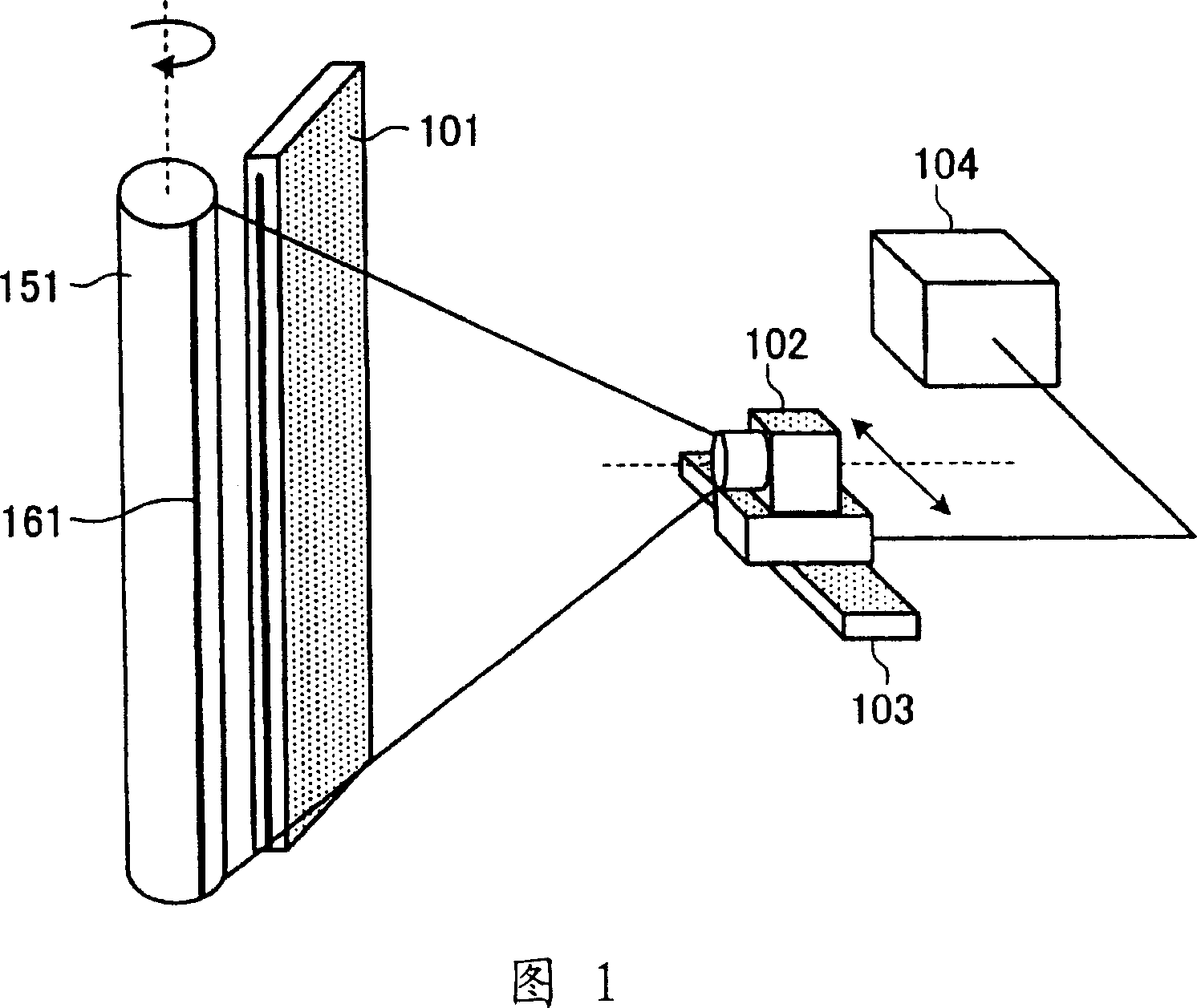

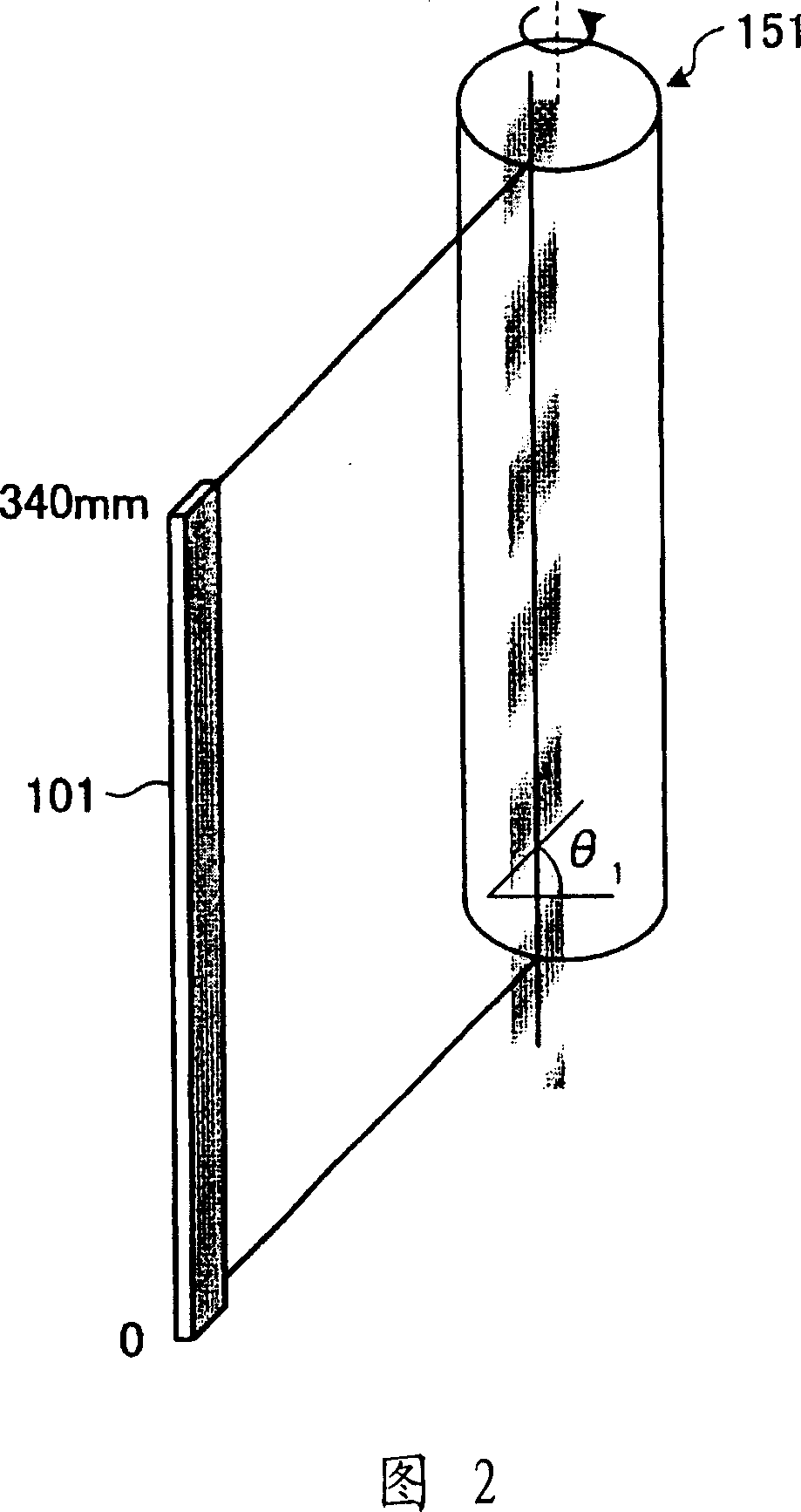

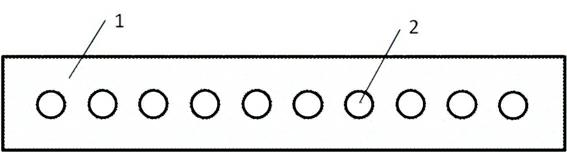

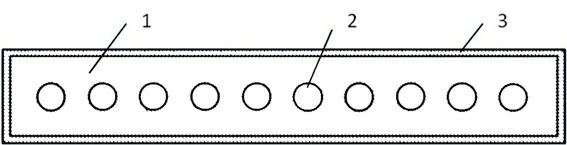

Surface defect inspection apparatus, surface defect inspection method, and surface defect inspection program

InactiveCN101013093AHigh-precision detectionConvenient distanceOptically investigating flaws/contaminationUsing optical meansLine sensorBrightness perception

A surface-defect inspection apparatus includes a line light source that irradiates a pattern light having brightness differentiated in a direction oblique to a sub-scanning direction of a rotating inspection target object; a line sensor that carries out a one-dimensional imaging of the inspection target object in a main scanning direction using an irradiated pattern light and reflected from the inspection target object; a phase detecting unit that detects a change of the phase of the brightness of a taken line image; and an control unit that controls the position of the line sensor to keep constant a relative distance between a position of the inspection target object and a position of the line sensor from a change of the phase.

Owner:RICOH KK

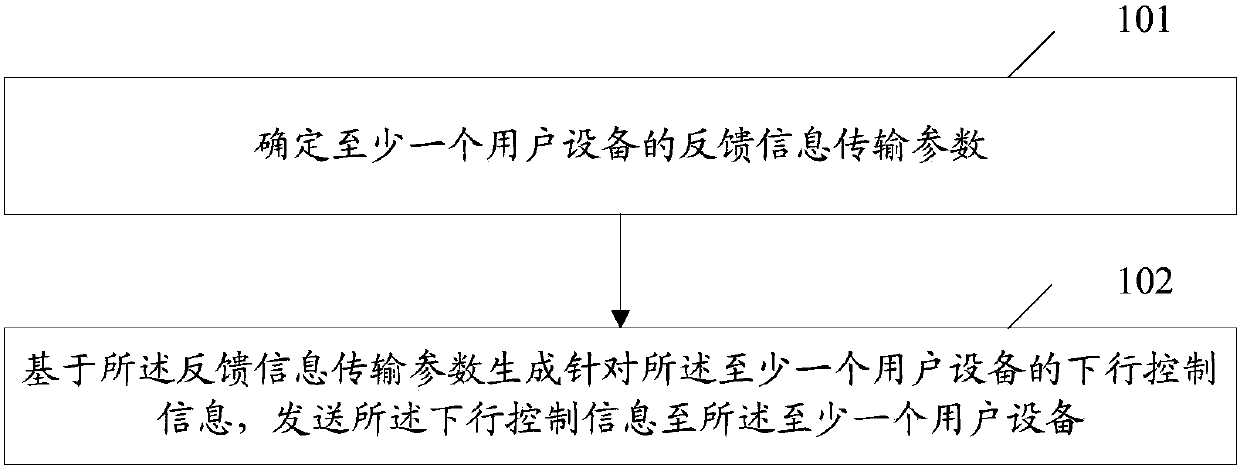

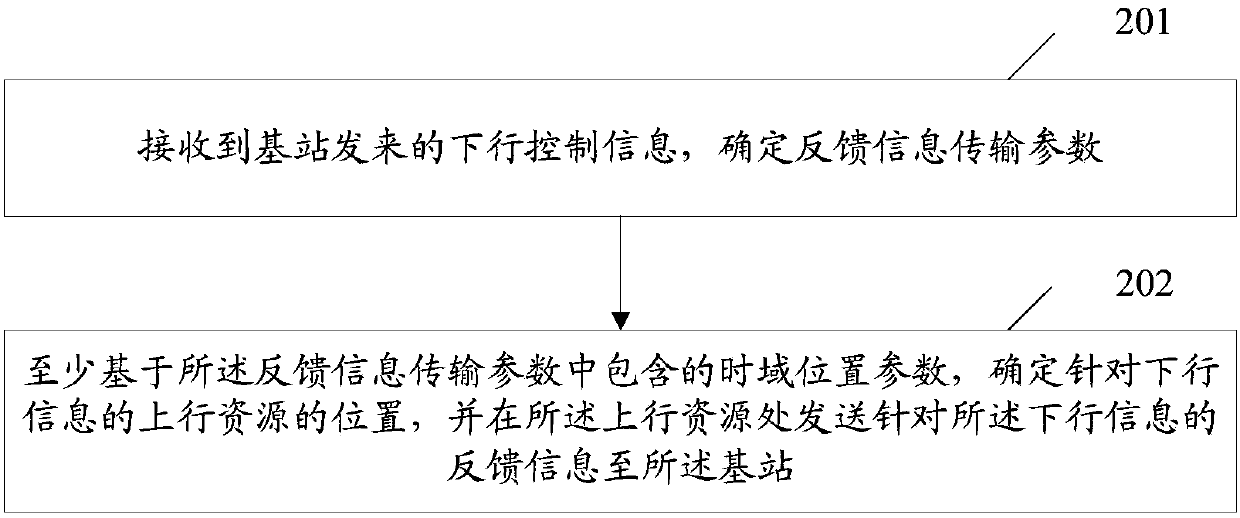

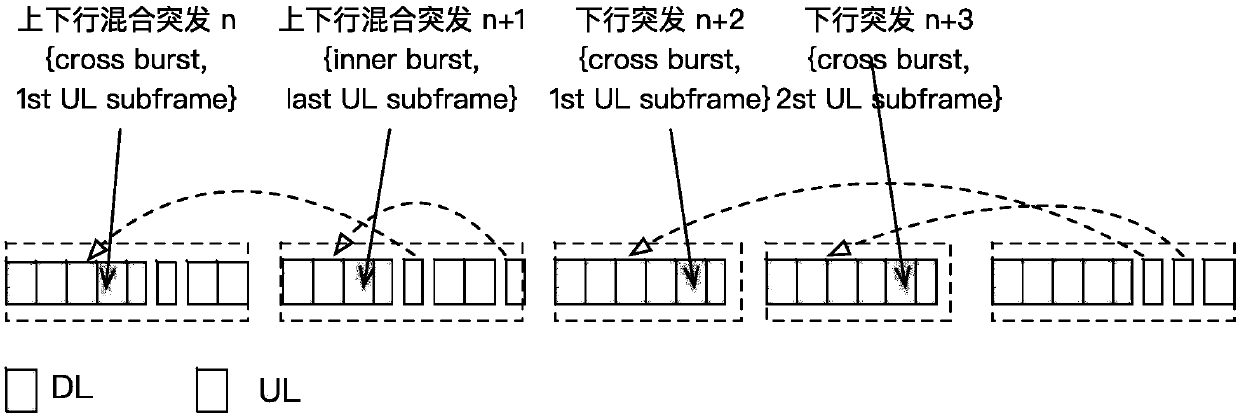

Information feedback method, base station and user equipment

ActiveCN107734653APosition controlSignal allocationWireless communicationInformation transmissionInformation feedback

The invention discloses an information feedback method, a base station and user equipment. The method comprises the steps of determining a feedback information transmission parameter of at least one piece of user equipment, wherein the feedback information transmission parameter is used for at least representing a time domain position parameter of feedback information aiming at downlink information; and generating downlink control information aiming at the at least one piece of user equipment based on the feedback information transmission parameter, and sending the downlink control informationto the at least one piece of user equipment.

Owner:CHINA MOBILE COMM LTD RES INST +1

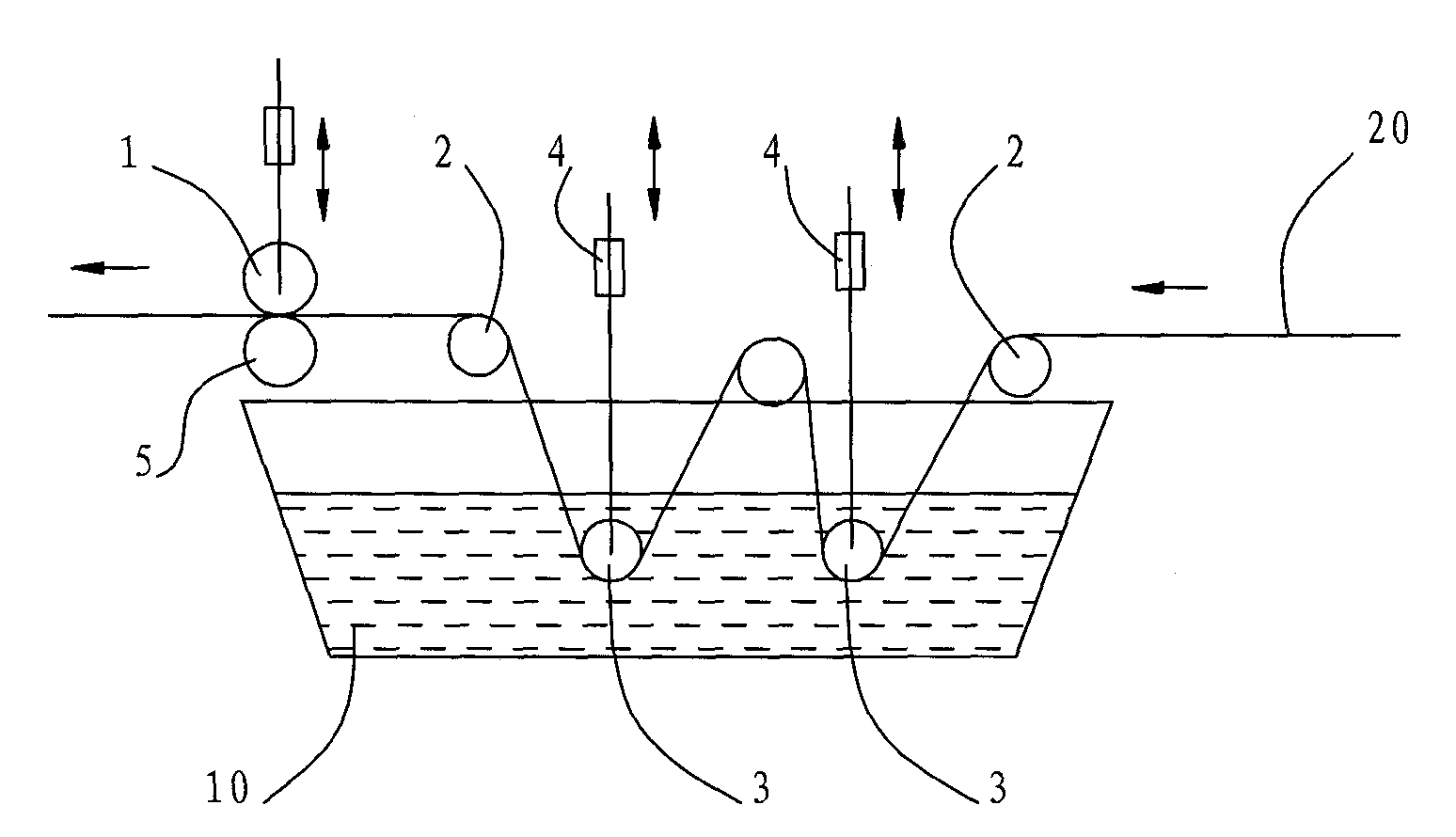

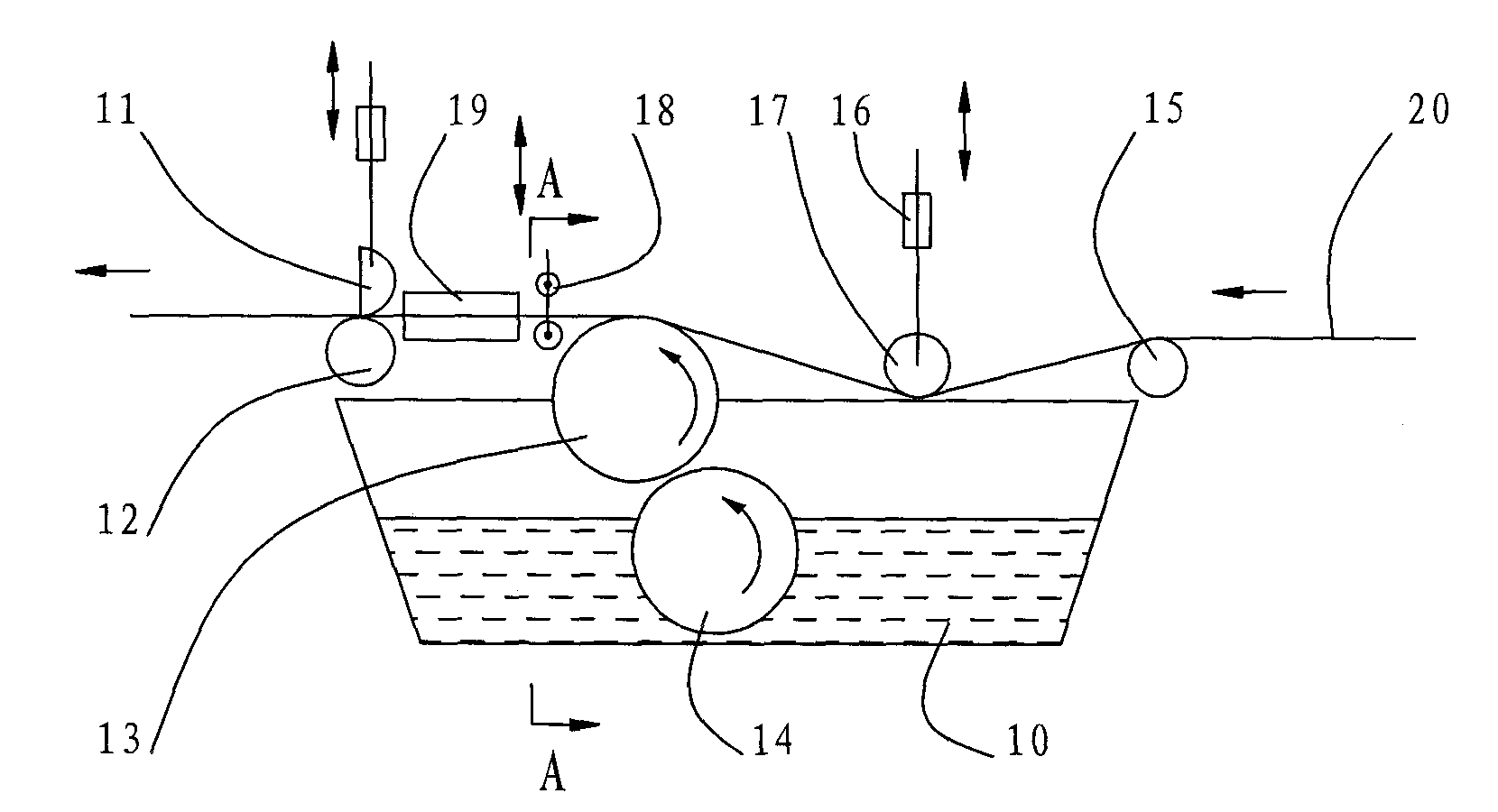

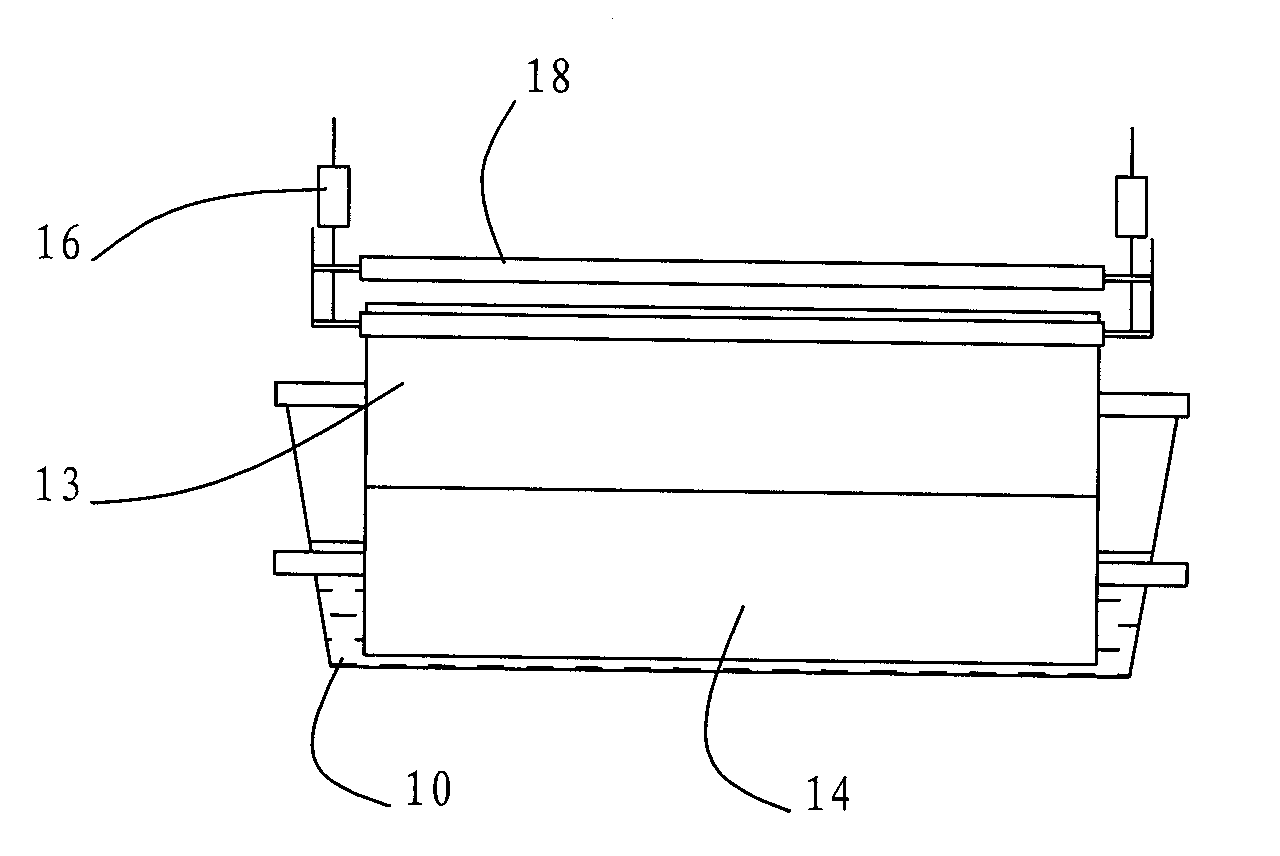

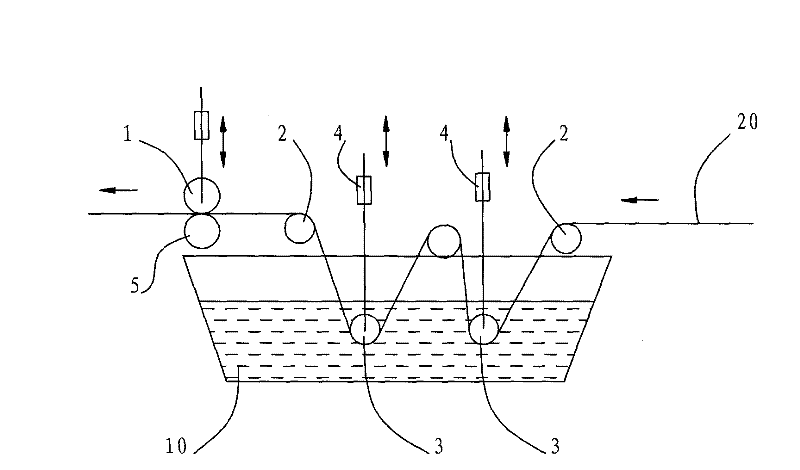

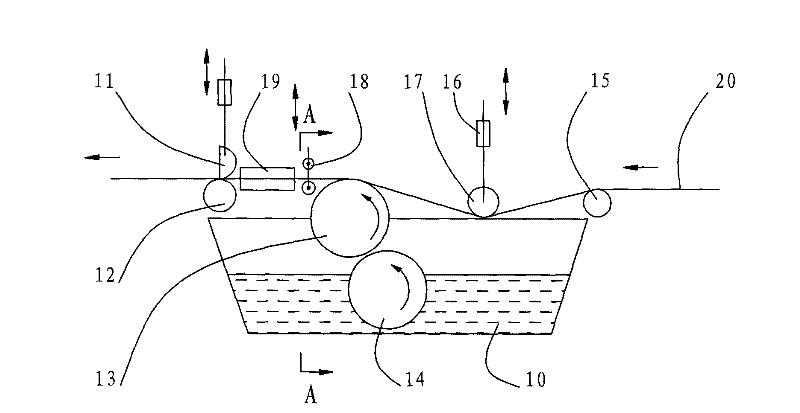

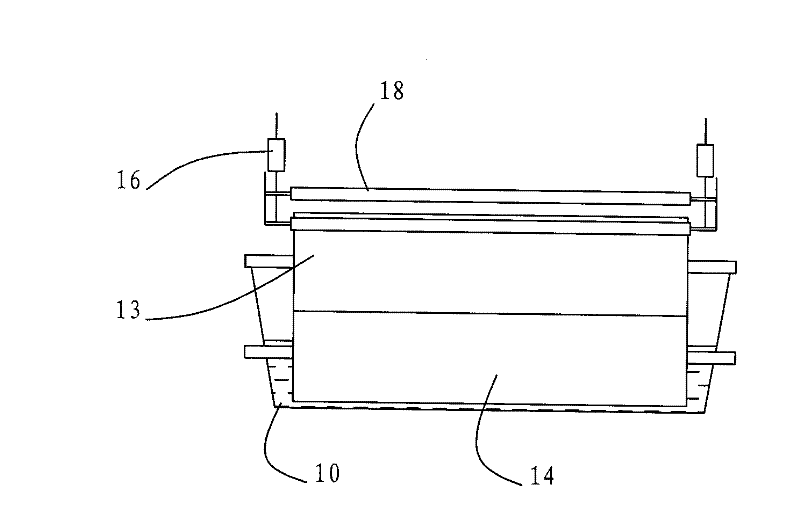

Processing device for dip-coating waterproof rolls

ActiveCN101831812ASolve the situation of scratched tire base fabricReduce work intensityTextiles and paperEngineeringDip-coating

The invention relates to a processing device for dip-coating waterproof rolls, which comprises a material pool and base fabric, the material pool is filled with coating, the side wall of the material pool and / or the bottom of the material pool are provided with a heating mechanism, the material pool is internally provided with a material delivering roll pair formed by an upper material picking-up roll and a lower material picking-up roll, the upper material picking-up roll is positioned above the coating, part of the lower material picking-up roll is soaked in the coating, the upper material picking-up roll and the lower material picking-up roll move in same direction or in opposite directions, the coating is delivered to the upper material picking-up roll through the lower material picking-up roll, and the base fabric is in connection with the surface of the upper material picking-up roll. One end of the material pool is a material inlet end which is provided with a guiding roll and a tensioning roll, and the guiding roll and the tensioning roll are positioned above the coating and are connected with a lifting mechanism; and one end of the base fabric is connected with the upper material picking-up roll after sequentially passing through the guiding roll and the tensioning roll. The invention has the characteristics of simple and reasonable structure, small whole machine volume and occupation, flexible operation, low manufacturing cost, low energy consumption, high production efficiency and wide application range.

Owner:鞍山科顺建筑材料有限公司

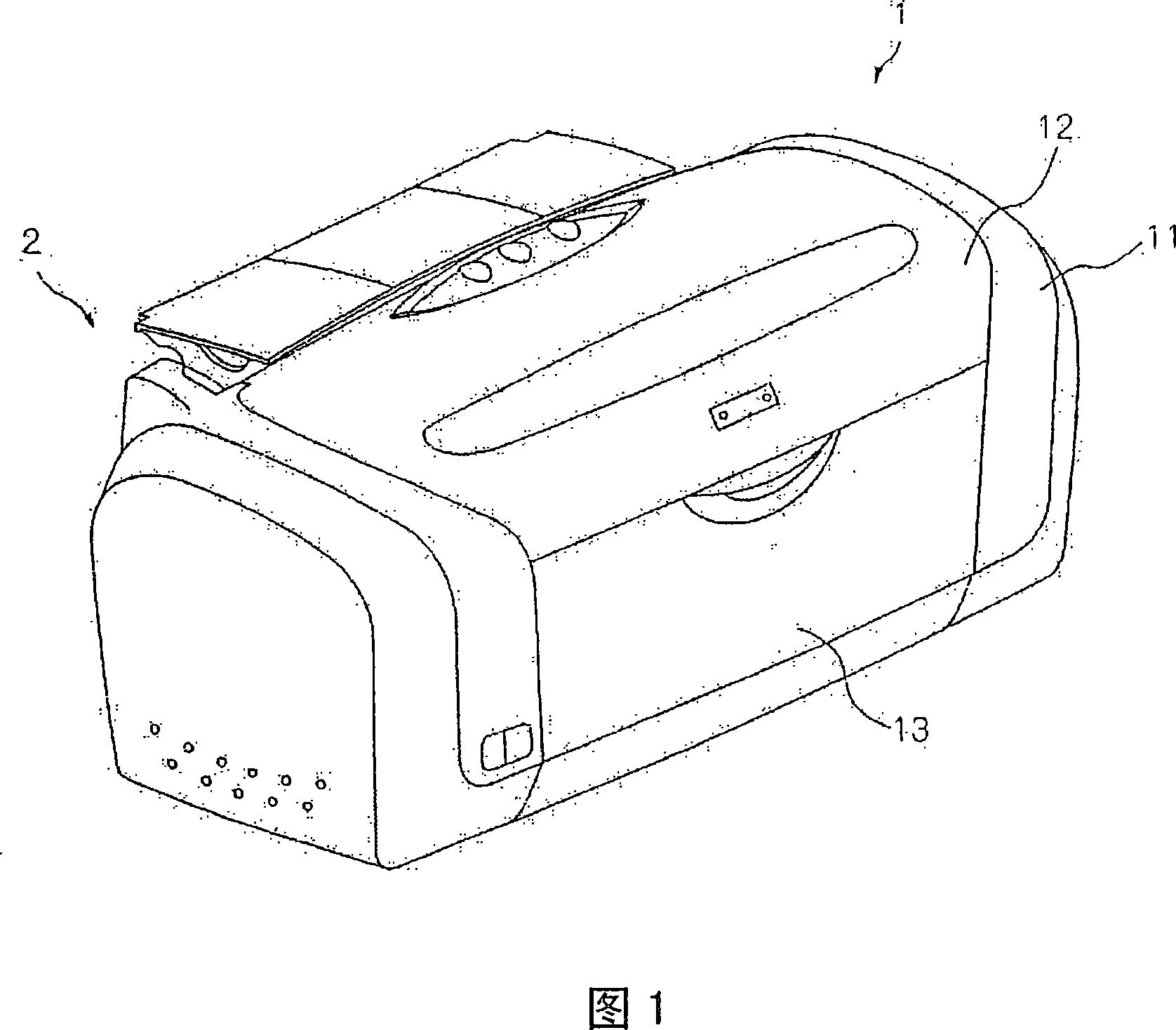

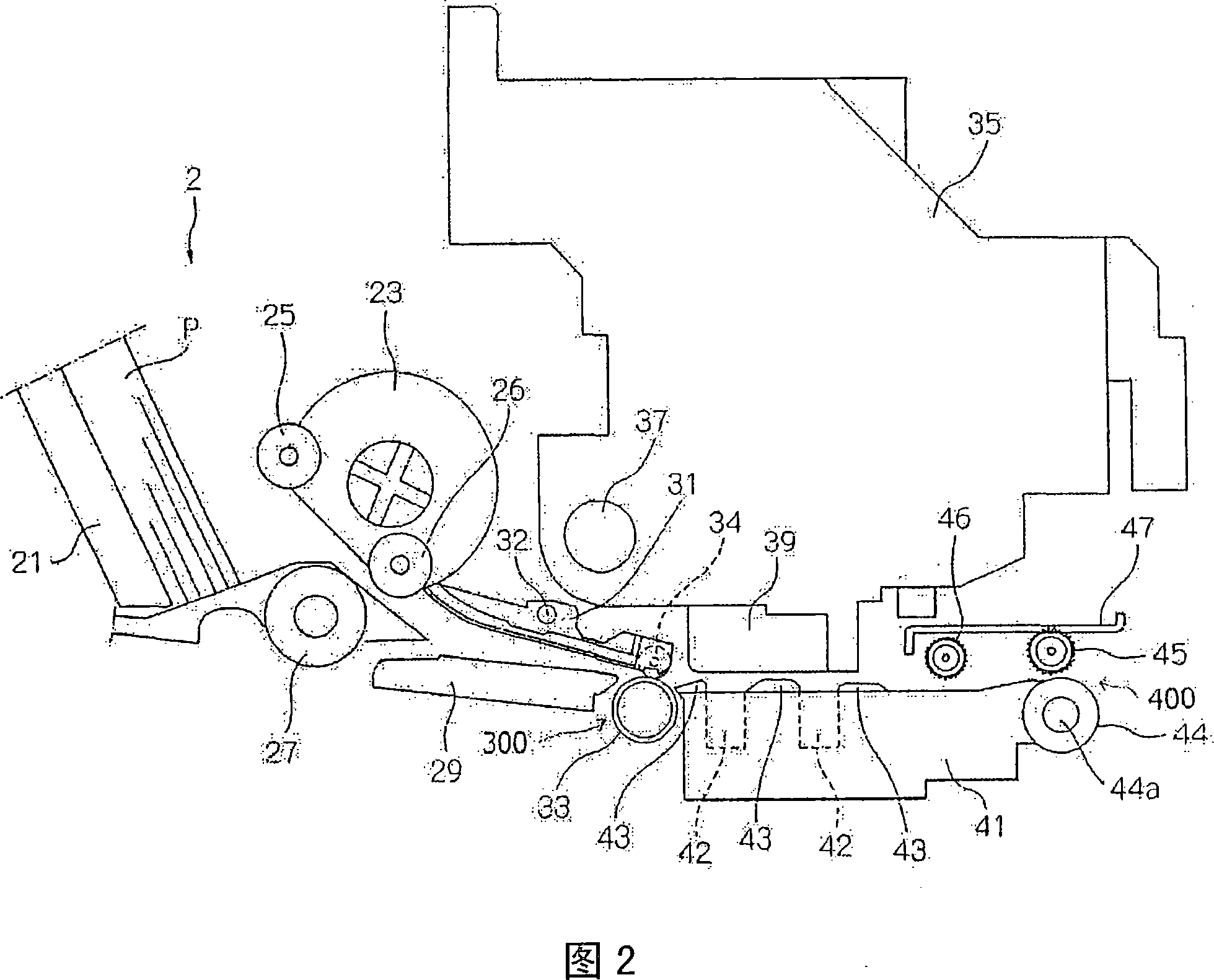

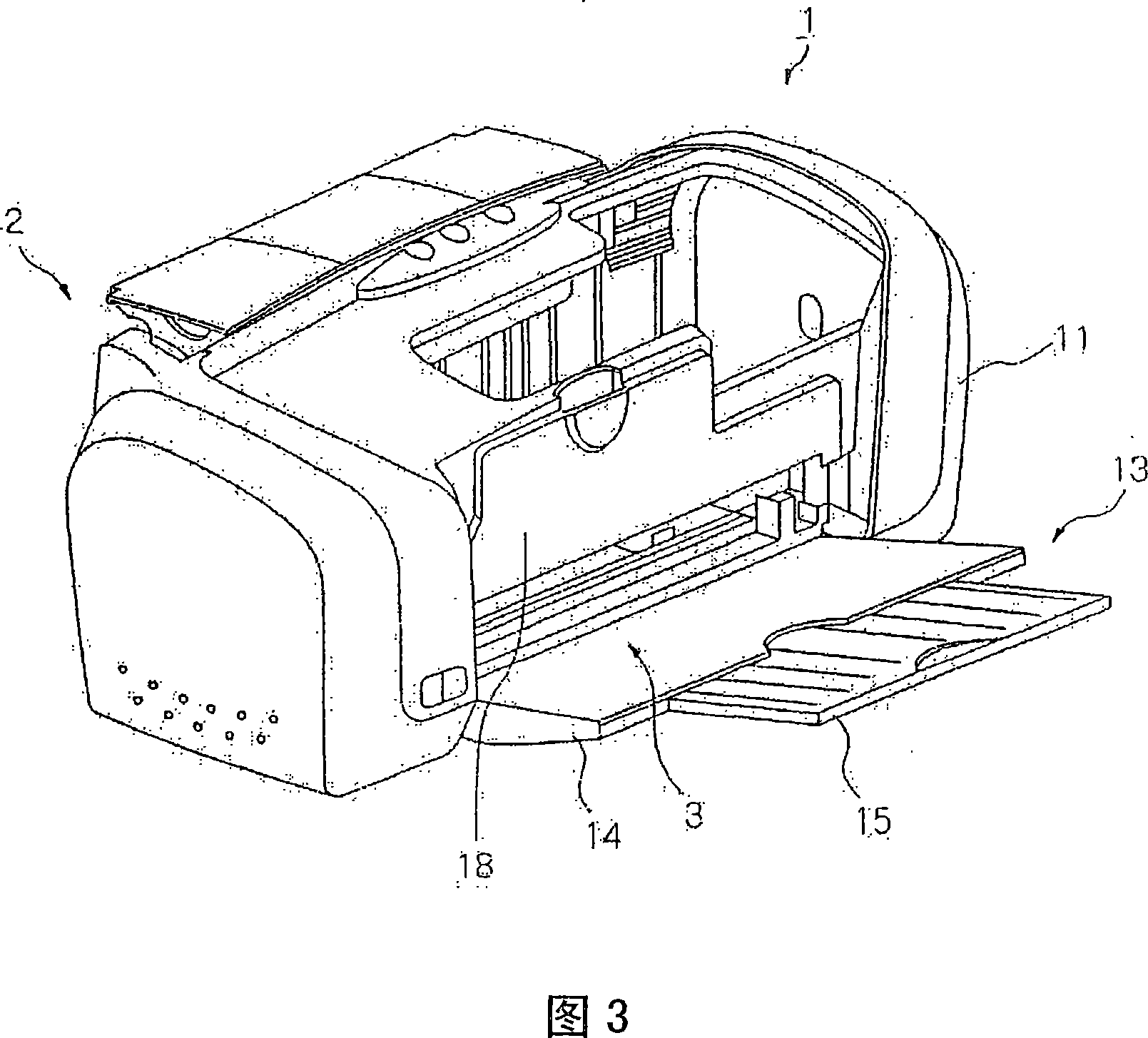

Recording apparatus and liquid ejection apparatus

InactiveCN101045376AEasy to operatePosition controlTypewritersOther printing apparatusPalletInjector

A liquid-spray devices, including: the liquid-spray head; transportation device; ejecting device, which can operation to eject the first aim medium to the out part of the device including the first and the second roll; the said first and second roll fit to clip the first aim medium transporting from the aiming position in the first direction; the shell body, the ejecting head, the transporting device and the ejecting part, which has the first front surface and the second surface with the later one in the front of the frontal one; the guiding part, which sets inner than the first front surface and comprise the guiding surface, the pallet part in the guiding position installed on the second aiming medium is aiming the aiming position, the second direction is opposite to the first direction; the guiding part used for closing the first position of the guiding surface and opening the guiding surface to support the second position of the pallet part and can rotate, wherein a depression is formed in the second front surface; and the guiding surface is set in the depression when the guiding part is set in the second position.

Owner:SEIKO EPSON CORP

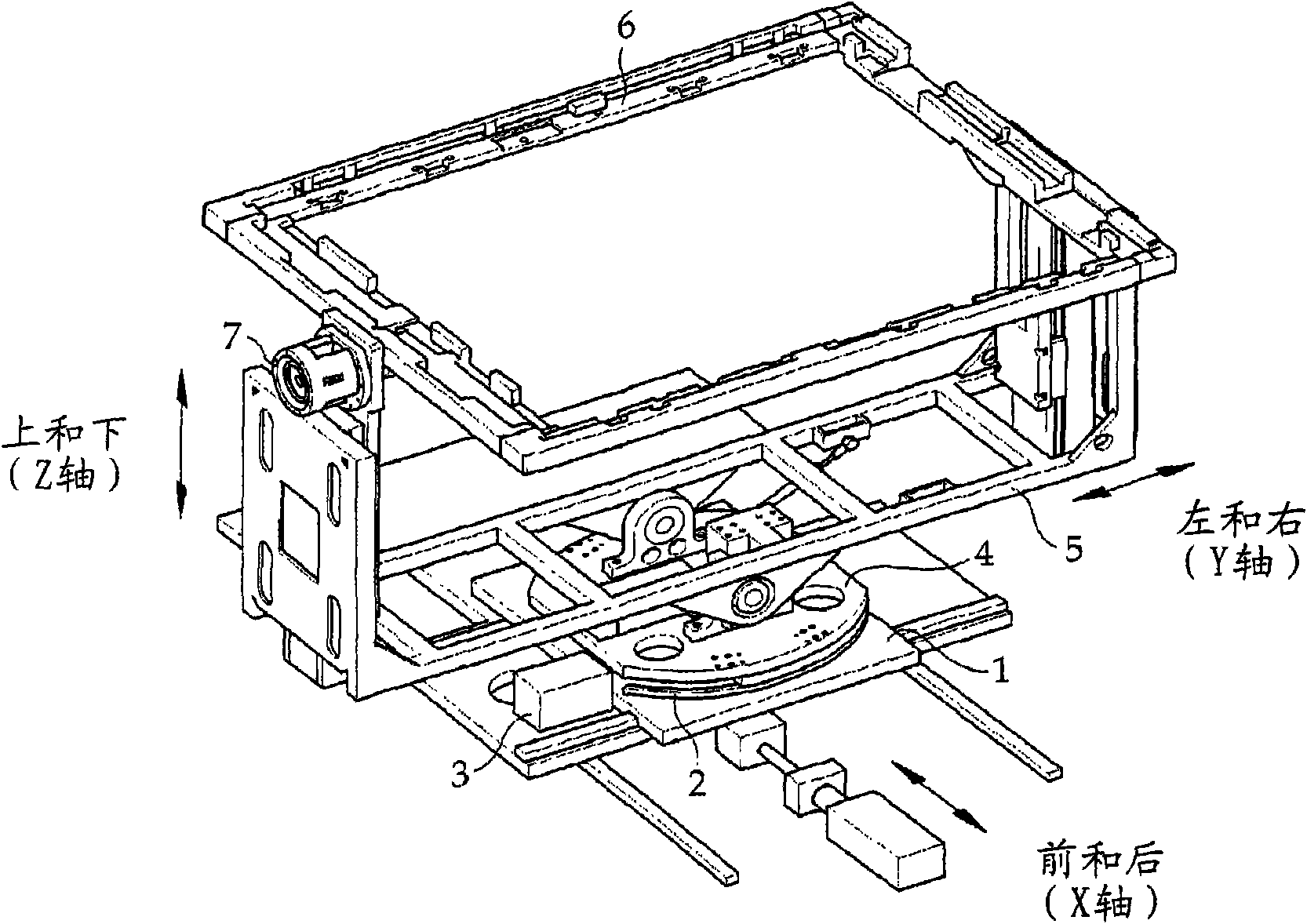

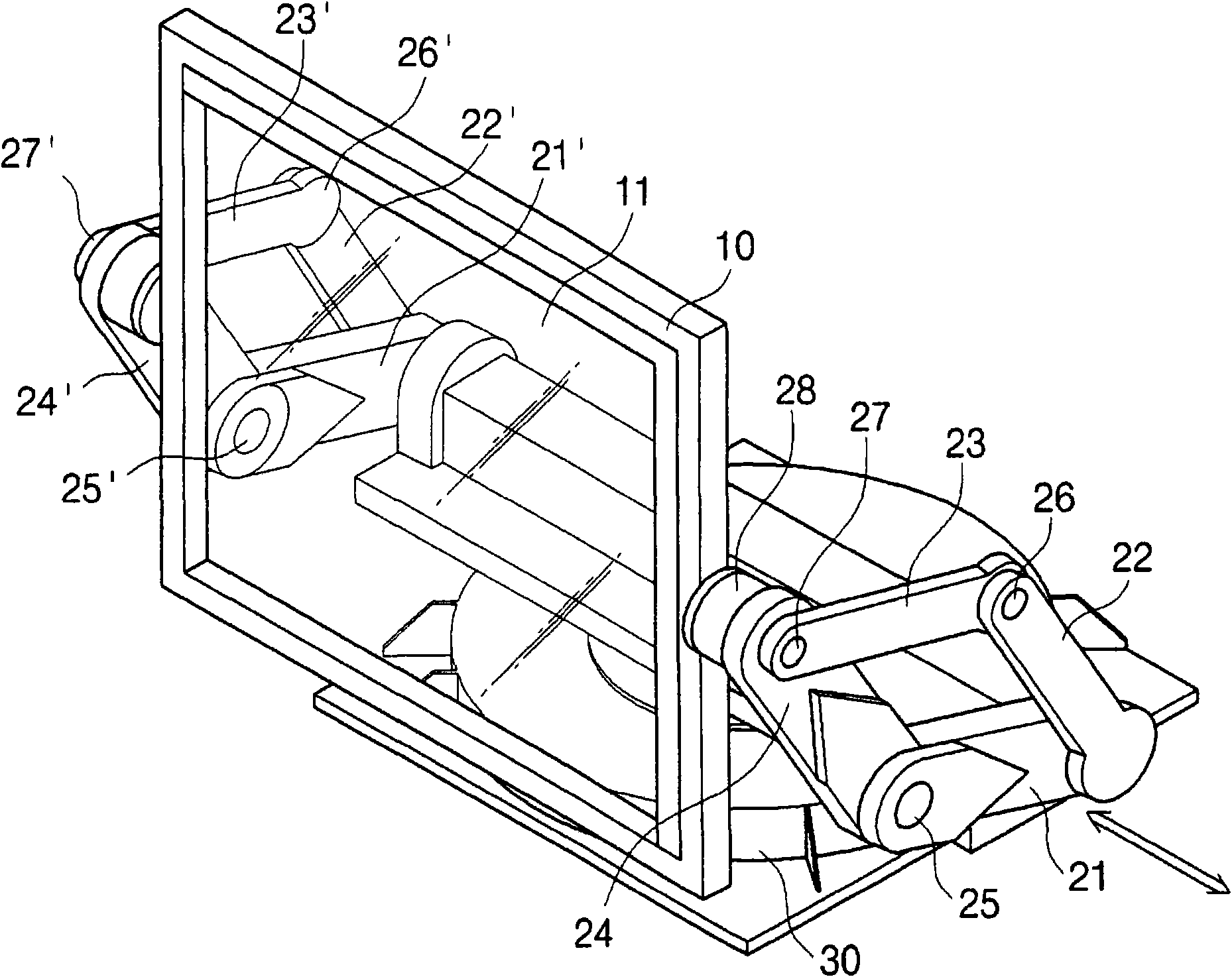

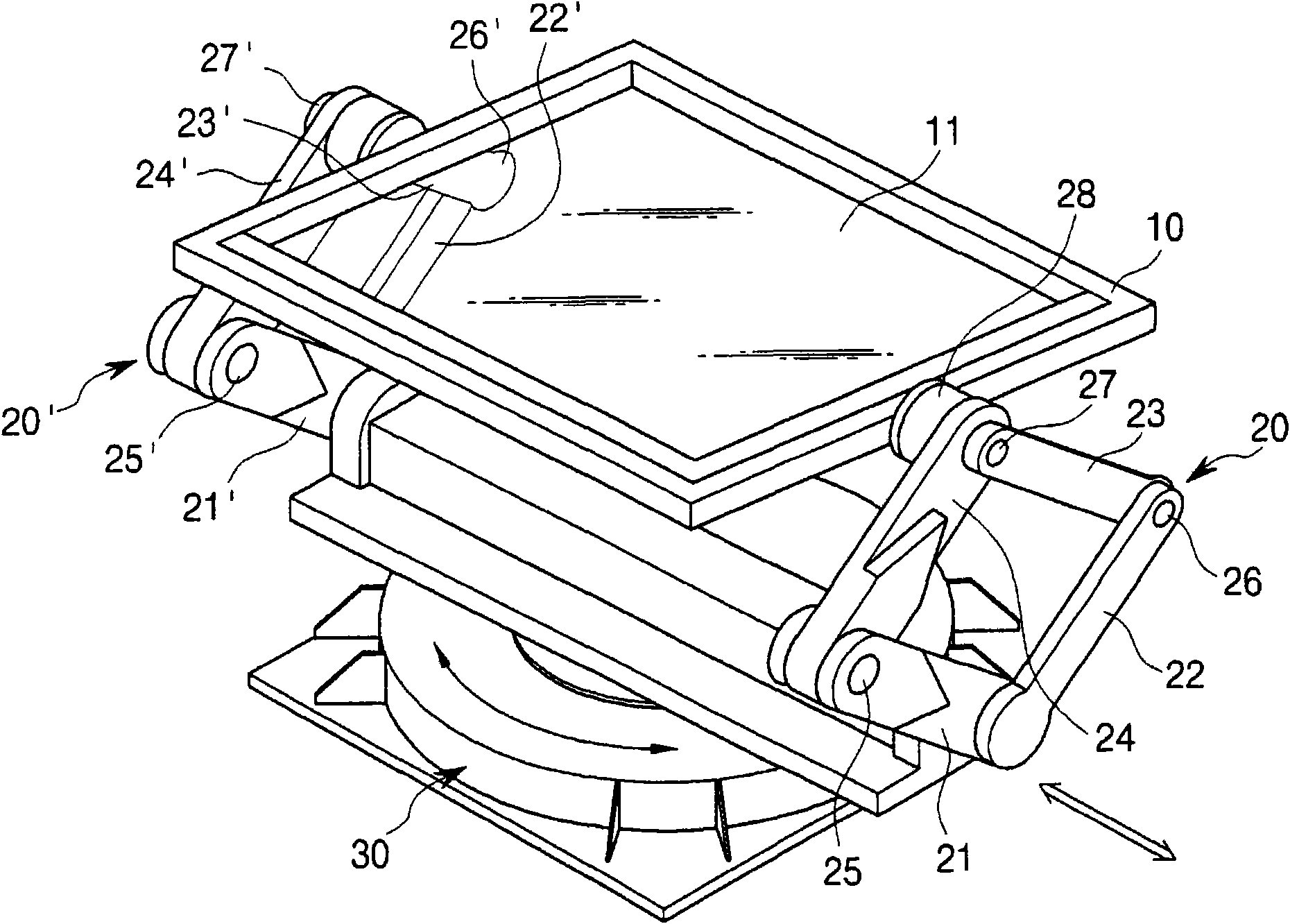

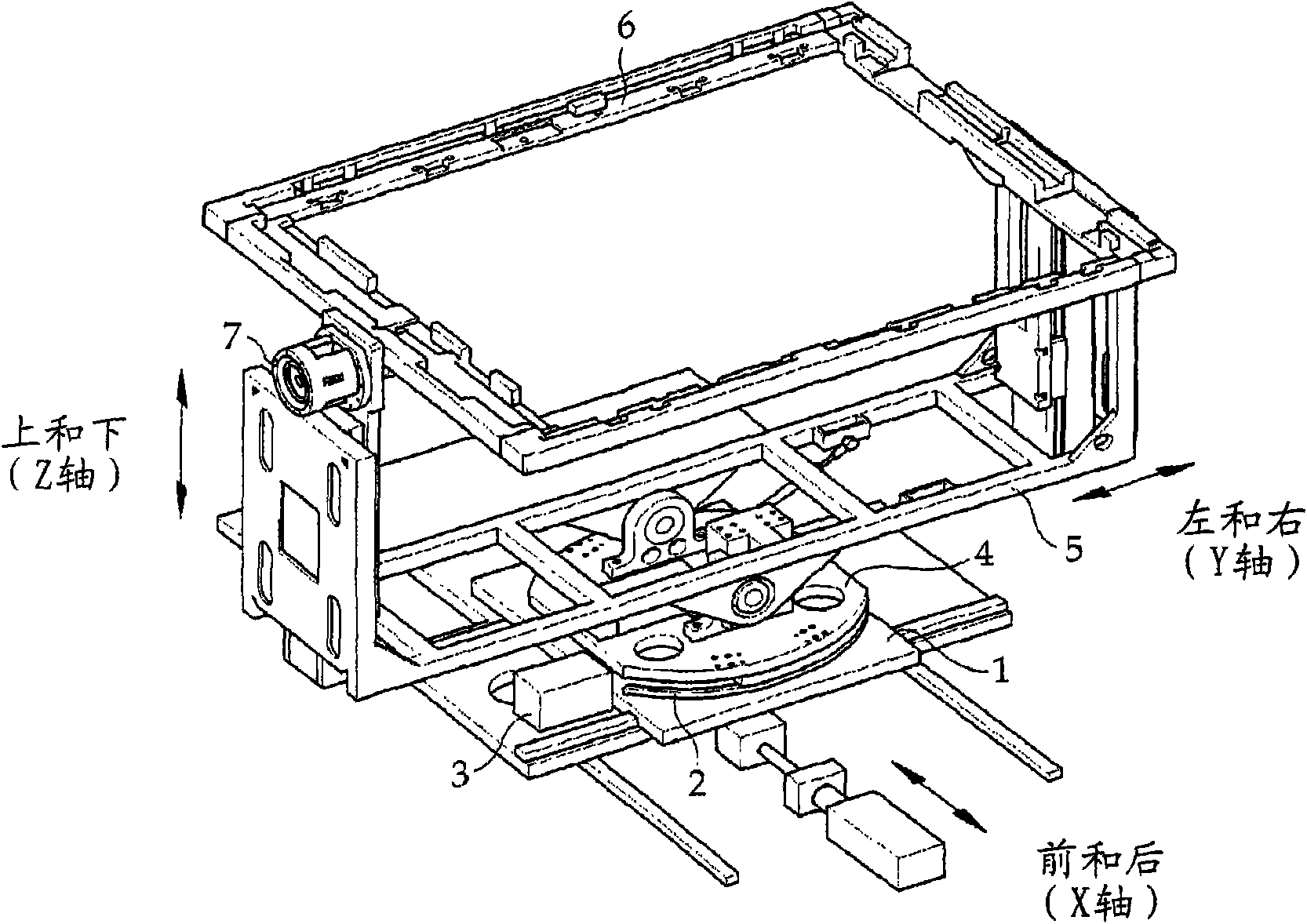

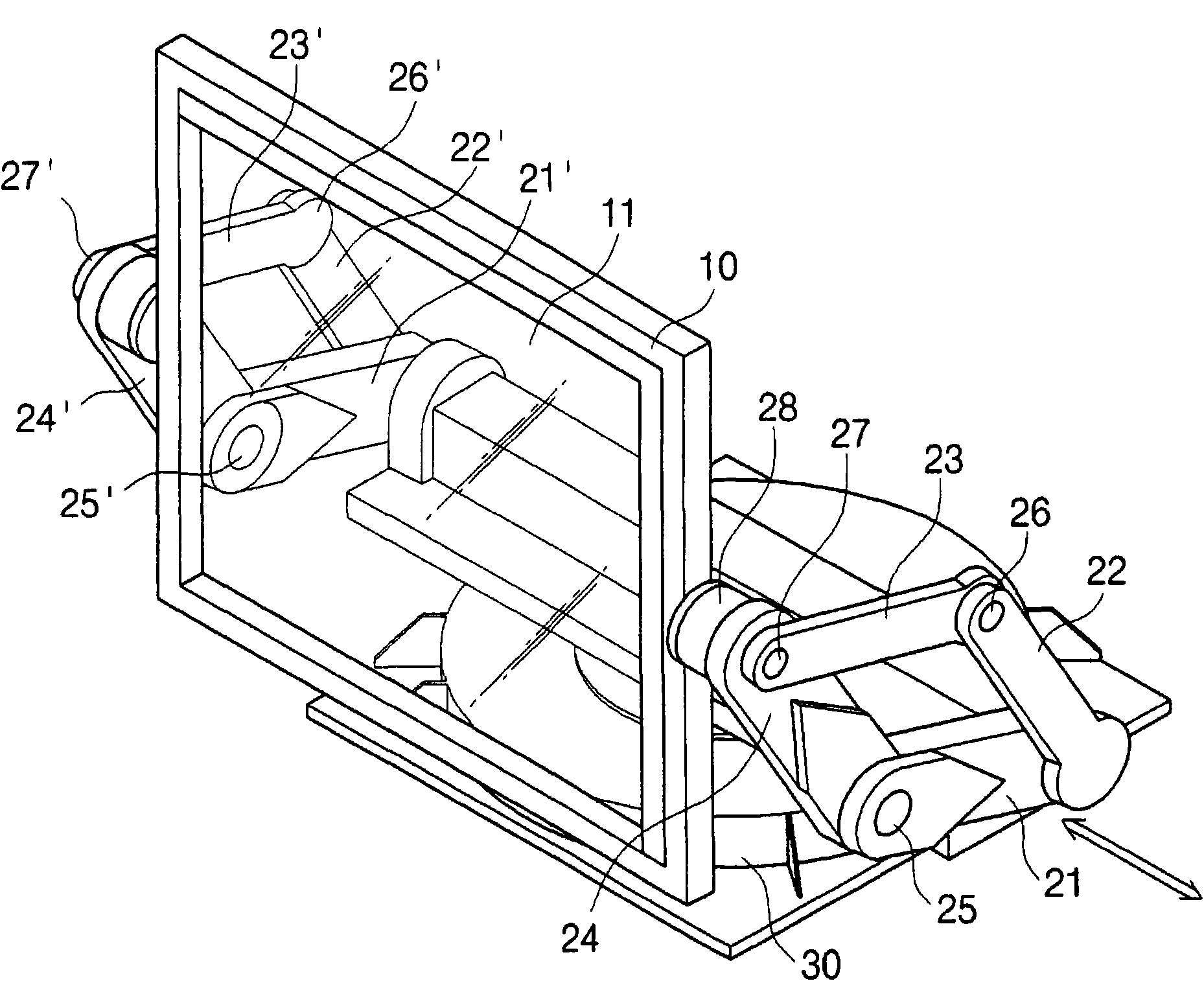

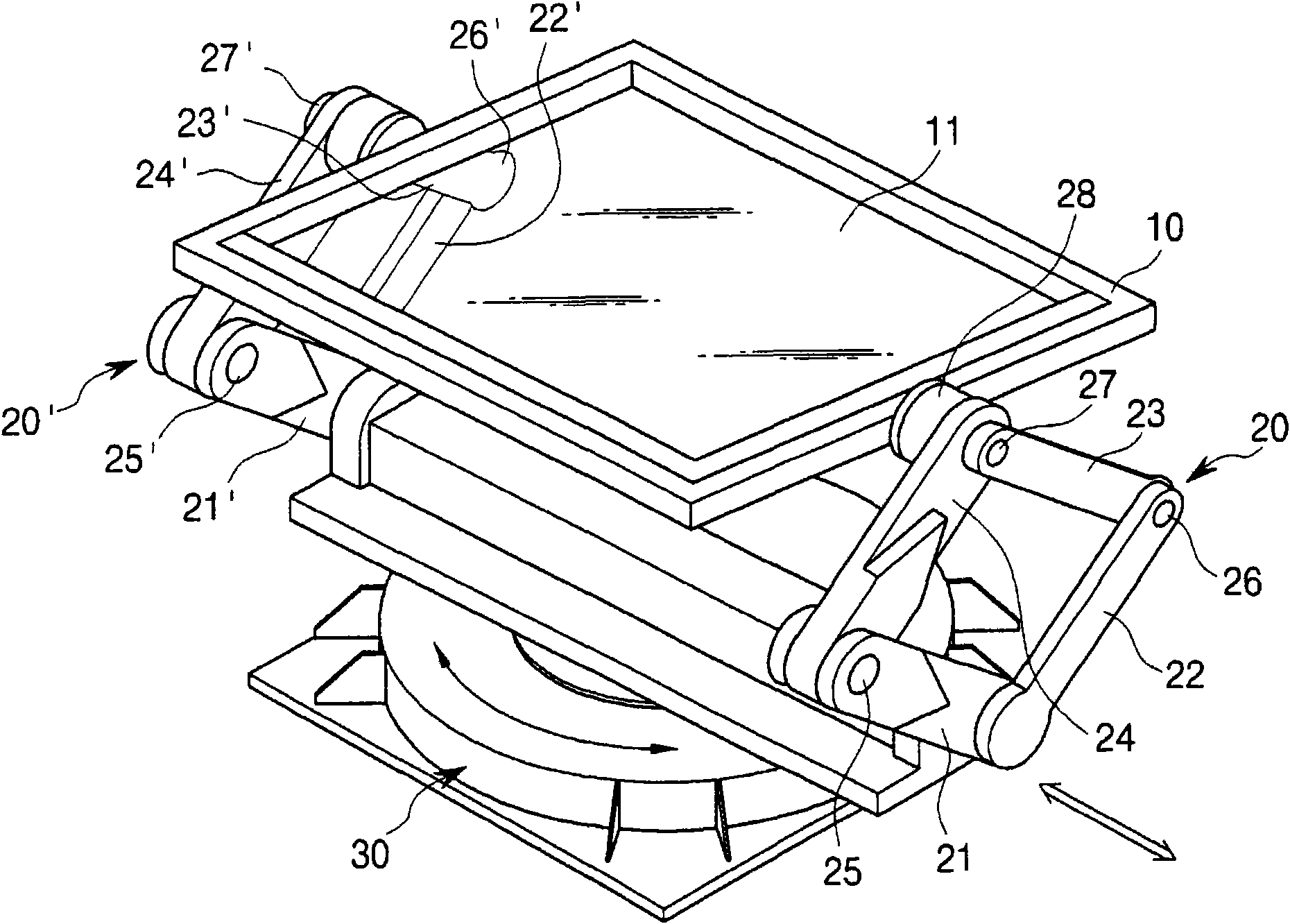

Macroscopic inspection equipment for LCD (Liquid Crystal Display) glass

InactiveCN101995674APosition controlReduce vibrationMaterial analysis by optical meansNon-linear opticsLinear motionLiquid-crystal display

The invention discloses macroscopic inspection equipment for LCD (Liquid Crystal Display) glass. Both sides of a glass retainer are supported by utilizing a pair of parallel hinging type connecting units so as to protect the LCD glass from vibration generated by driving macroscopic inspection equipment; and by adopting the parallel hinging type connecting units, the X-axis motion, Z-axis motion and inclination of the glass retainer are realized by a single electrode. The macroscopic inspection equipment comprises the LCD glass retainer, a pair of parallel hinging type connecting units, a rotating unit, an advancing shaft and a controller, wherein the pair of parallel hinging type connecting units are used for supporting the side surface of the glass retainer; the rotating unit is used forrotating a pair of connecting units; the advancing shaft is used for guiding the left and right linear motion of the inspection equipment; and the controller is used for controlling the position of the LCD glass retainer.

Owner:优视株式会社 +1

Cache-on-board (COB) technology-based integrated light emitting diode (LED) packing method

InactiveCN102437271ALower working temperatureFlexible thickness controlSemiconductor devicesCooking & bakingHeat resistance

The invention relates to a cashe-on-board (COB) technology-based integrated light emitting diode (LED) packing method, which comprises the following steps that: 1. thickness of a mould and diameter of a reserved hole are adjusted; 2. the reserved hole on the mould is aligned to an LED chip which is well fixed on an aluminum circuit board, and the mould covers the aluminum circuit board; 3. after fluorescent glue is sprayed on the aluminum circuit board, the aluminum circuit board is baked, then the mould is removed after the baking so as to obtain an LED packing unit. The method has followinng beneficial effects that: the shape, position, thickness and quantity of the fluorescent flue can be adjusted by adjusting the thickness of a silicone board and the diameter of the reserved hole, so the LED integrated packing procedures can be simplified, the heat resistance and the working temperature of the LED chip can be reduced, the shape, position, thickness and quantity of the fluorescent glue can be flexible to control, the light emitting efficiency and the consistency, stability and service life of the product can be improved, the packing efficiency also can be improved, the waste can be reduced, and the product cost can be reduced. The baking temperature is set as 140 to 160 DEG C, so the packing effect is better.

Owner:秦会斌 +6

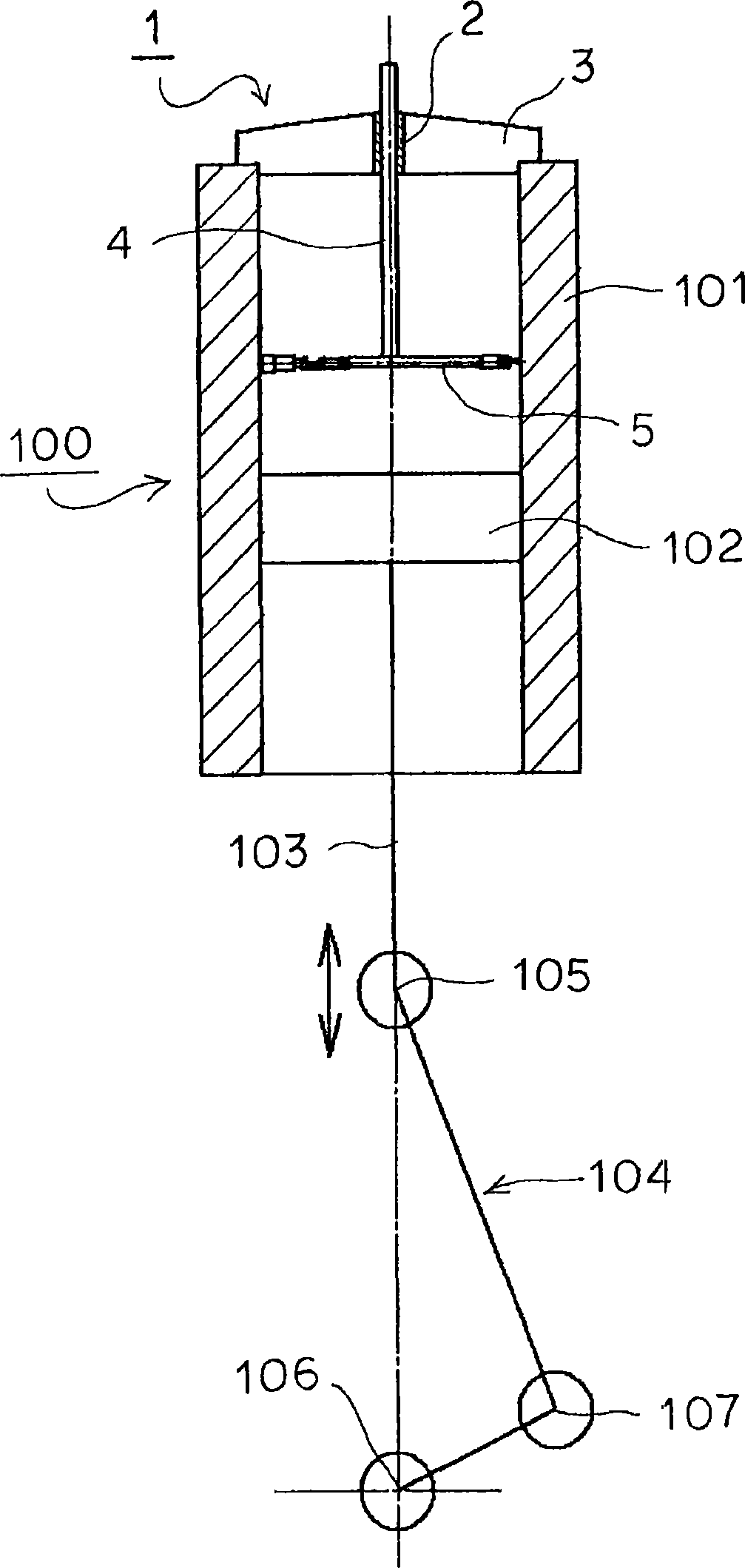

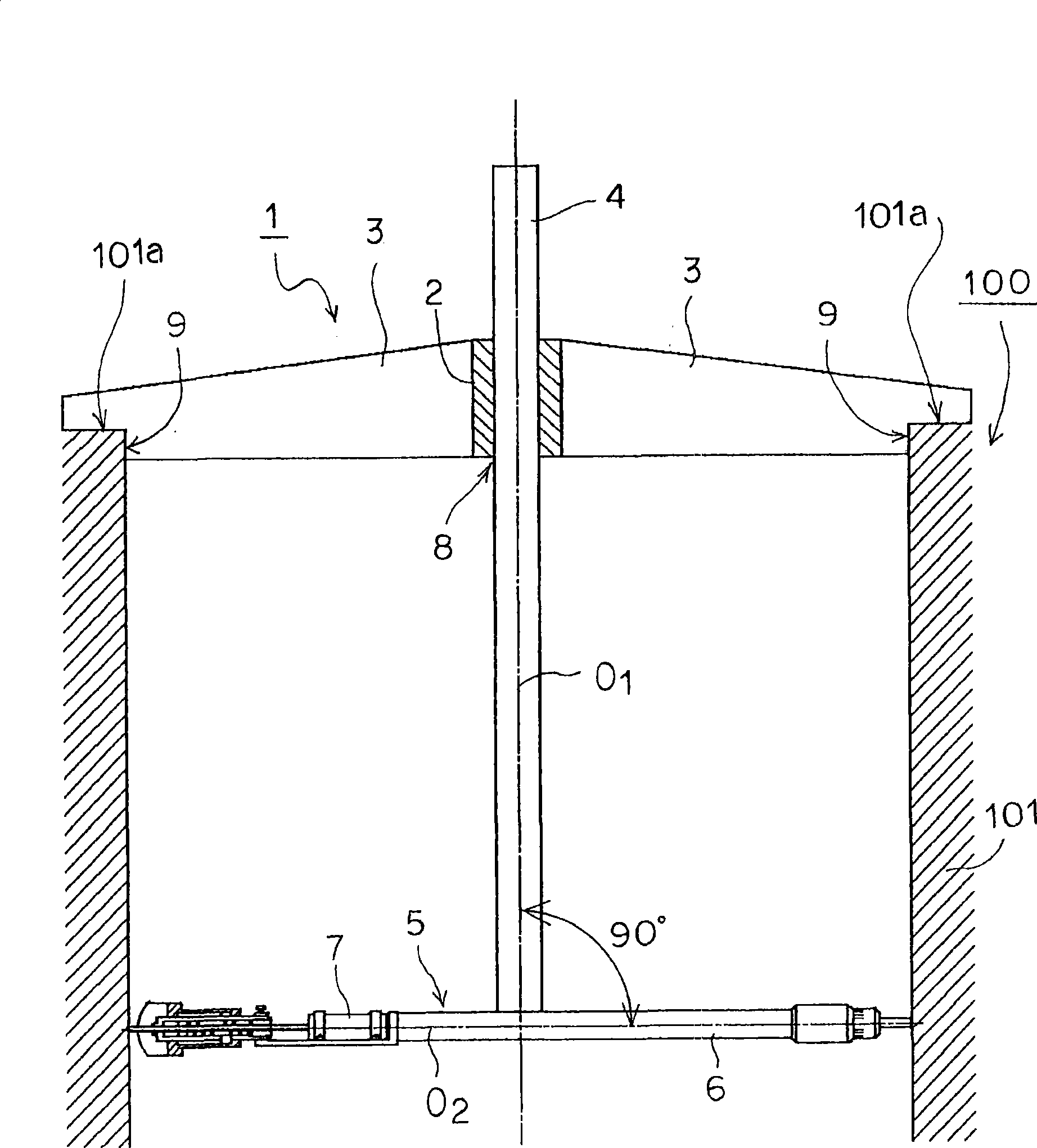

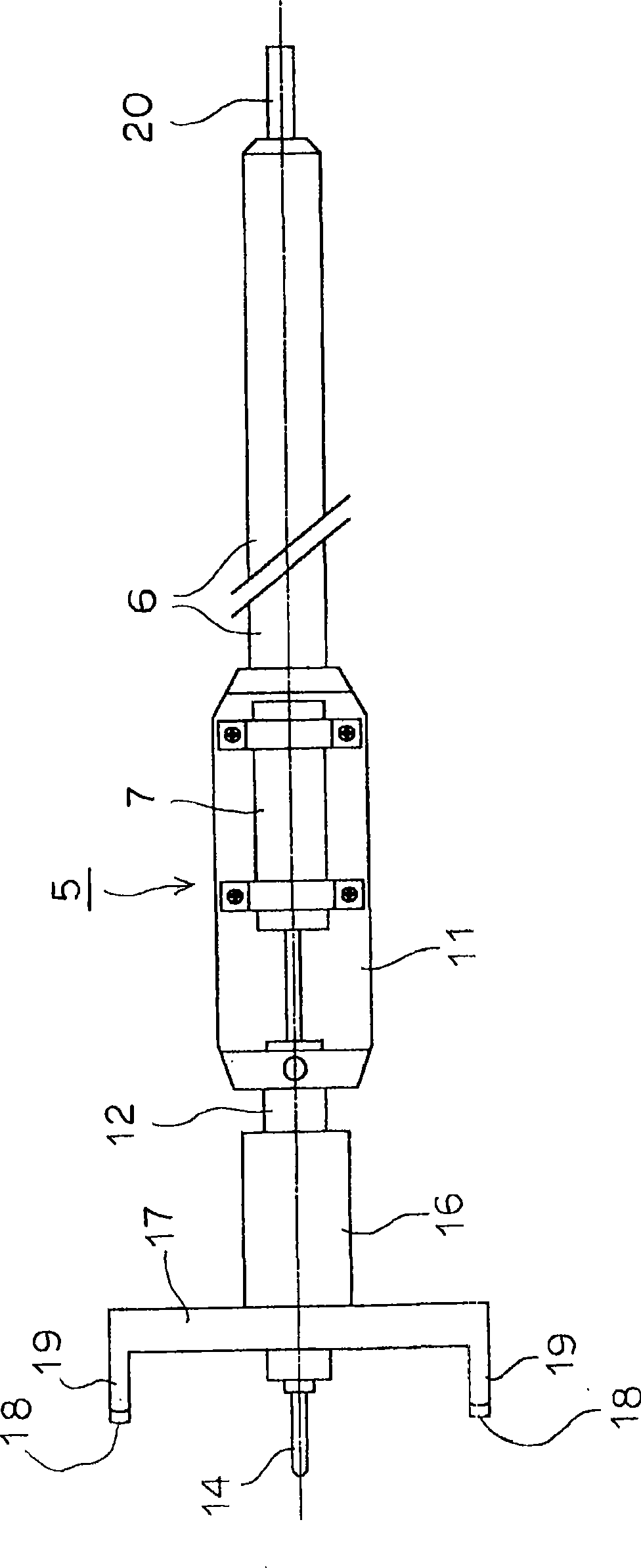

Cylinder diameter tester of reciprocating internal combustion engine

InactiveCN101482389ASimple structureEasy to operateMachine part testingCylinder headsContact typeEngineering

A cylinder diameter measuring device of reciprocating internal combustion engine includes: a guiding piece located at the shaft core of the cylinder; a bearing part holding the guiding piece; a long support rod penetrating the guiding piece; a length measurer provided on the support rod and in cross with the support rod, wherein, the length measurer includes a rod shaped measurer body; a contact or non-contact type displacement converter provided at the top of the measurer body for converting the measured values into electrical signals and then outputting.

Owner:MITSUI ENG & SHIPBUILD CO LTD

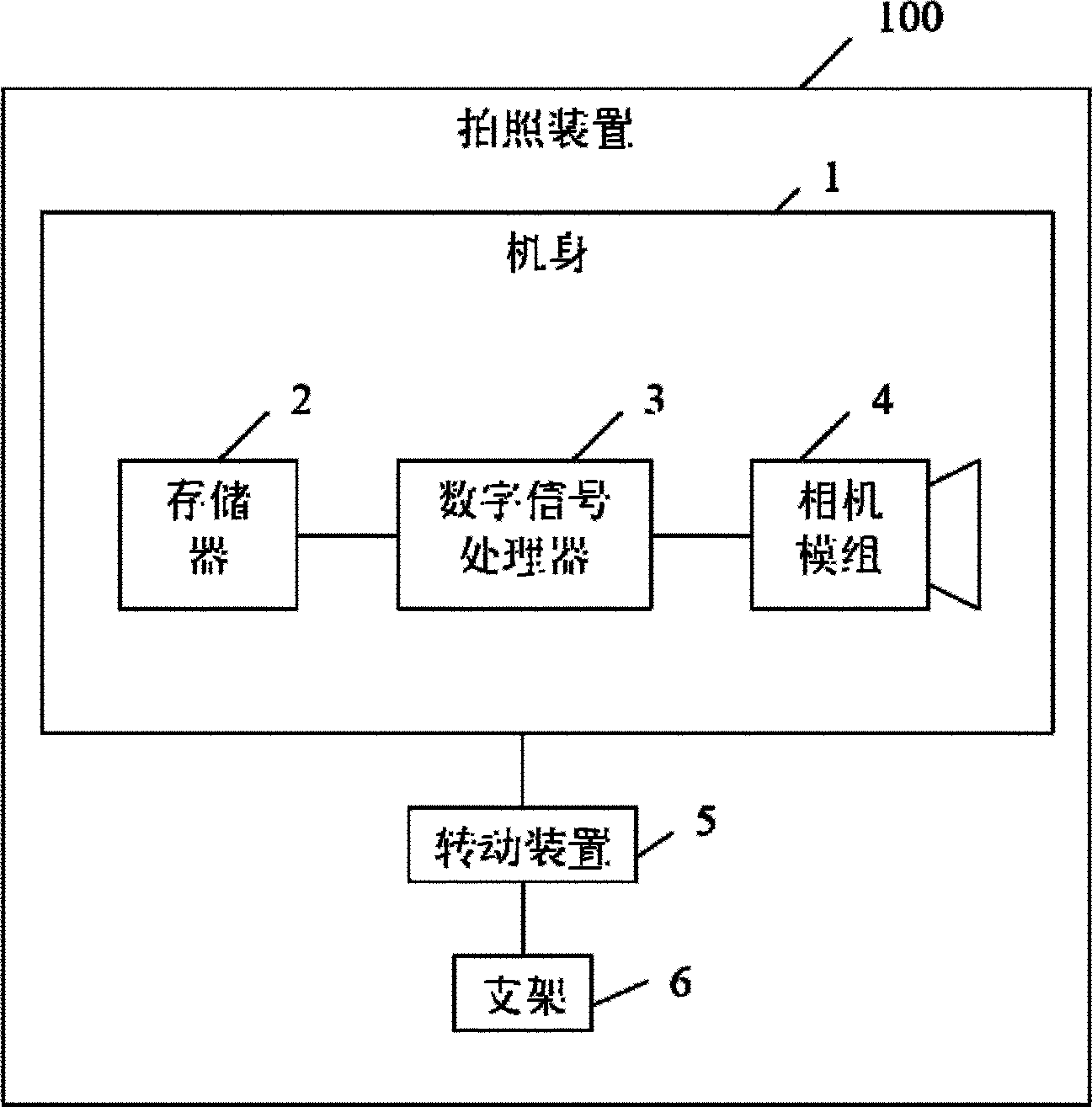

Photographing apparatus and method

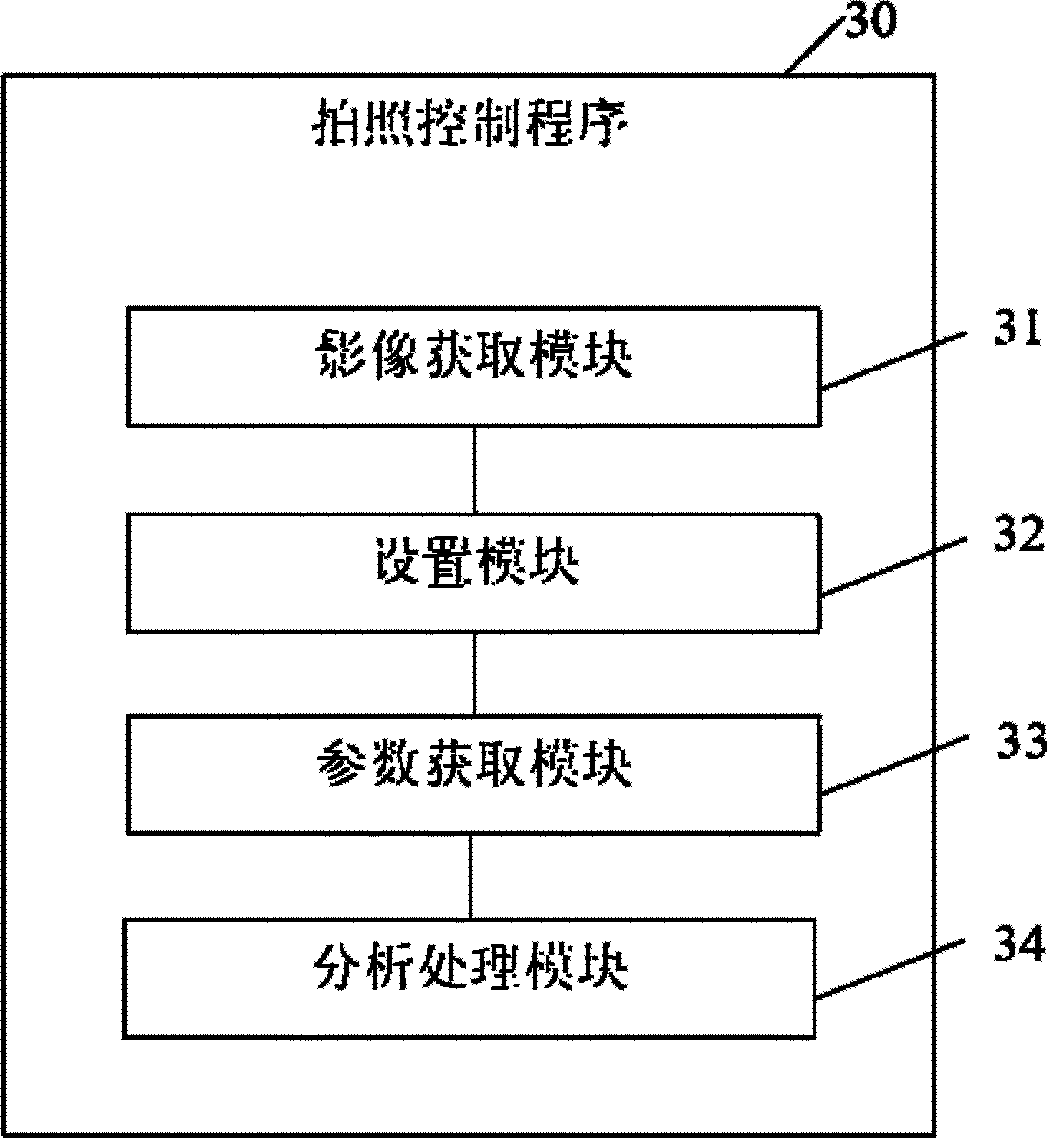

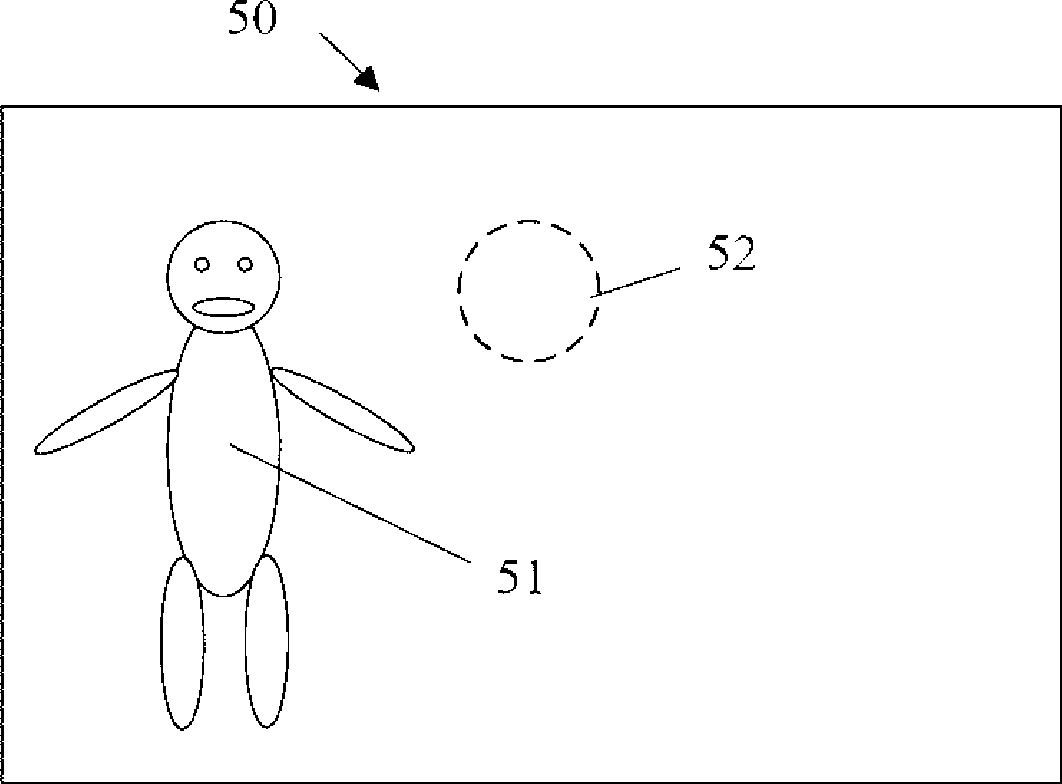

InactiveCN101420523APosition controlTelevision system detailsColor television detailsRotary actuatorImage acquisition

The invention provides a photographing device, which comprises a main frame, a rotary actuator and a bracket. The main frame is internally provided with a camera module, a digital signal processor, and a memory. The memory is internally stored with a photographing control program which comprises an image acquisition module, a setting module, a parameter acquisition module, and an analysis processing module. The image acquisition module is used for acquiring an image sensed by the camera module. The setting module is used for setting a preset graph and a preset position; wherein, the preset graph is the whole or the part planar graph of a main body to be shot; the preset position is the position of the preset graph in an image to be shot; the parameter acquisition module is used for acquiring the preset graph and the preset position stored in the memory. The analysis processing module is used for seeking the graph which is the same as the preset graph in an acquired image, controlling the rotary actuator to rotate so that the position of the sought graph in the sensed image is the same as the preset position and controlling the photographing device to take pictures. In addition, the invention also provides a photographing method.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

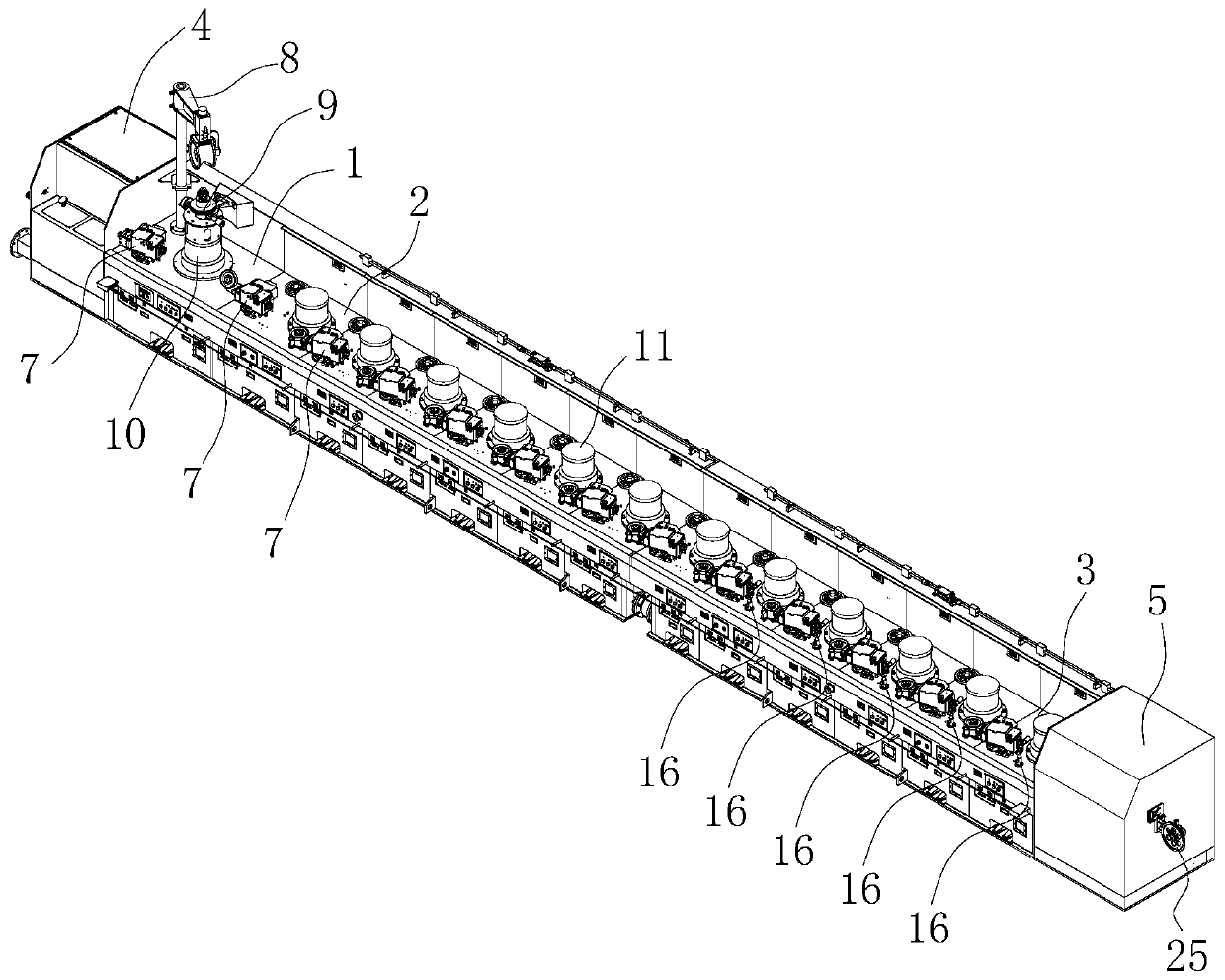

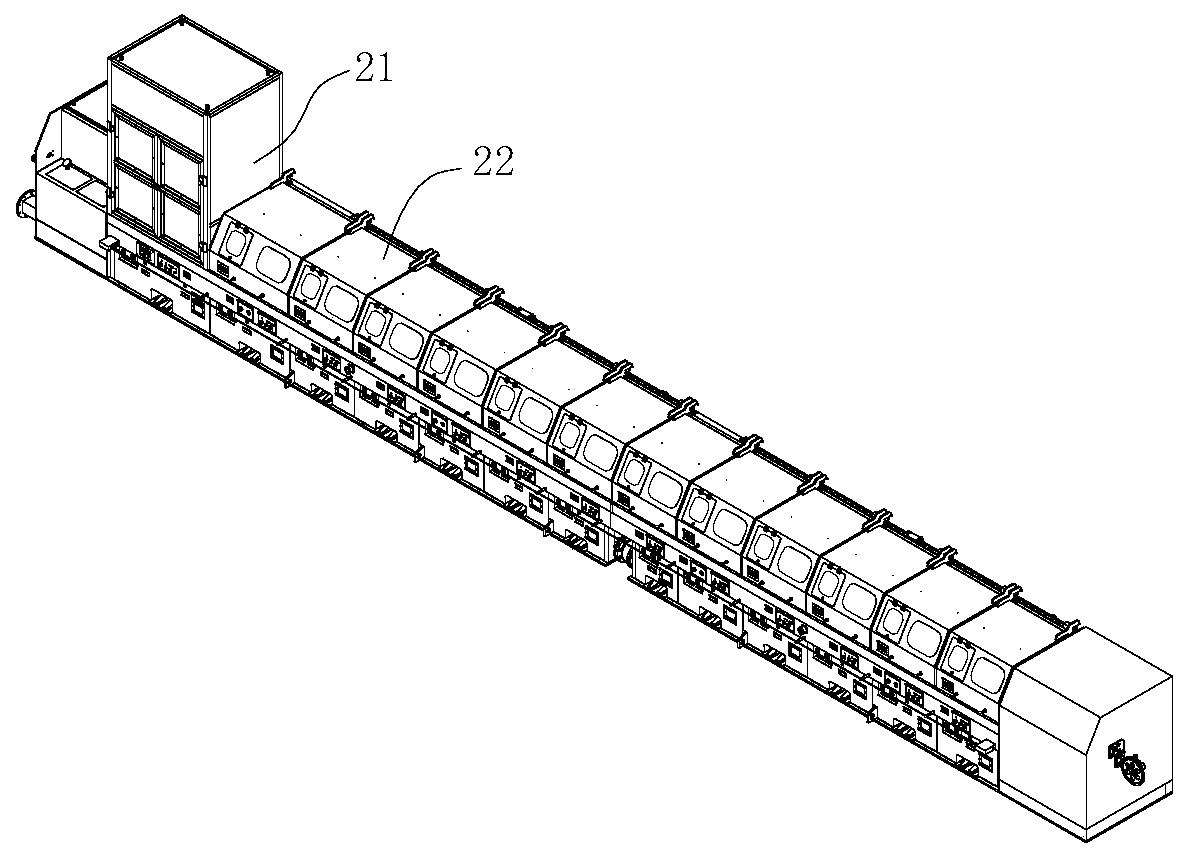

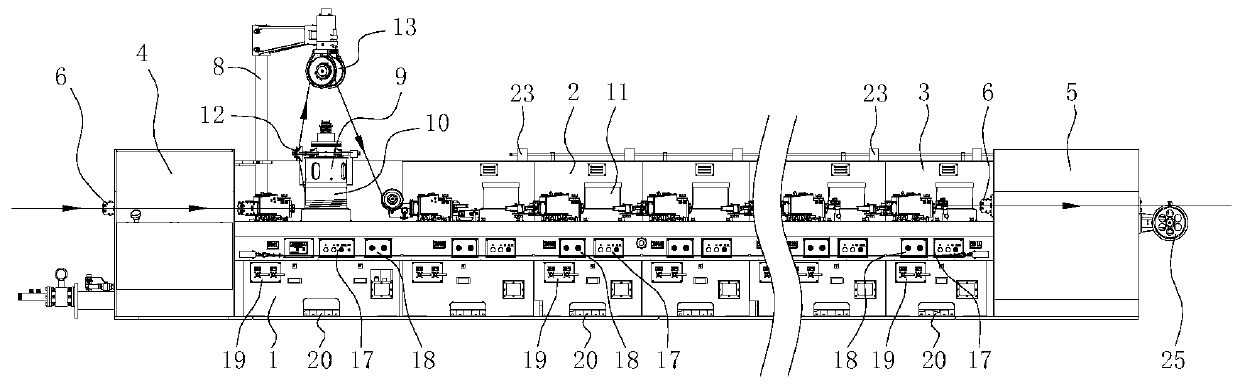

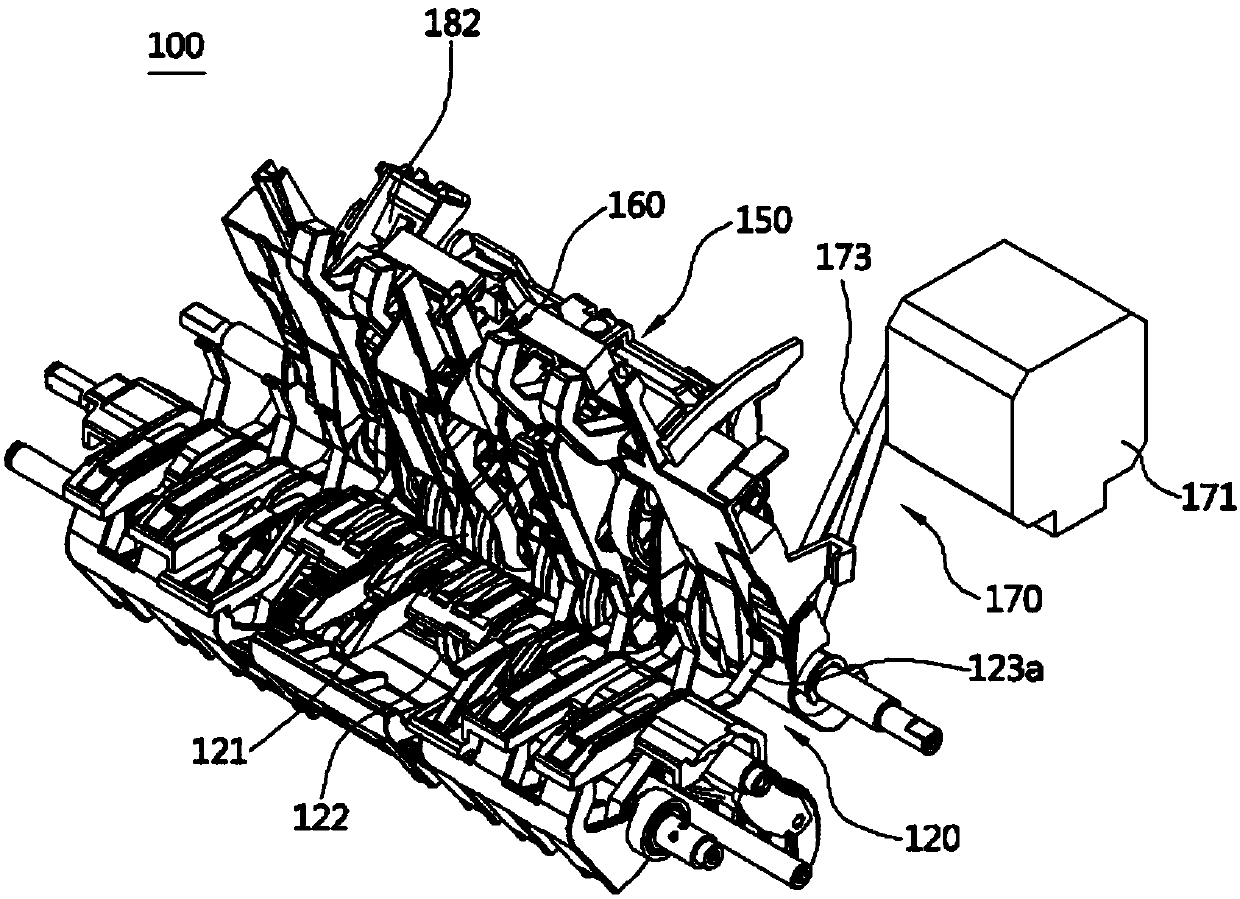

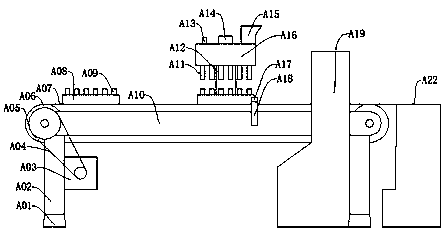

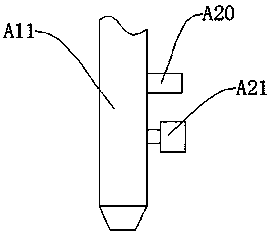

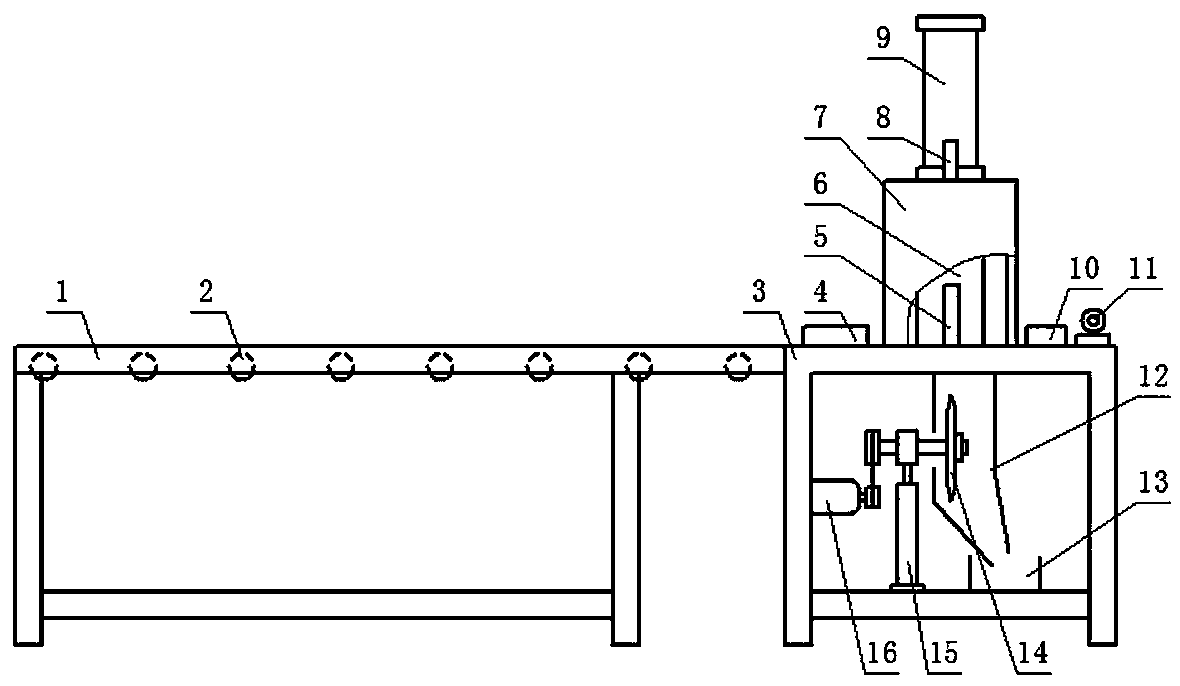

Loop type wire drawing machine

PendingCN110756605AReduce the degree of impactGuaranteed timelinessDrawing diesWater tanksWire drawing

The invention provides a loop type wire drawing machine. The loop type wire drawing machine comprises a first machine table, a plurality of second machine tables and a third machine table which are sequentially arranged from a wire inlet end of the drawing machine to a wire outlet end of the drawing machine, a water tank and an electric control cabinet, wherein the water tank is arranged at one end of the drawing machine, and the electric control cabinet is arranged on the other end of the drawing machine; the wire inlet end of the drawing machine and the wire outlet end of the drawing machineare both provided with herringbone rollers; a mold box, a hanging bracket device, a wire pulling device and a first winding drum are arranged on the first machine table; mold boxes, second winding drums and guide wheel devices are arranged on the second machine tables; and a mold box and a second winding drum are arranged on the third machine table. According to the loop type wire drawing machine, the multi-stage winding drums and the mold boxes are arranged, and the mold boxes are capable of lubricating and cooling metal wires, so that the drawing force of the metal wires between every adjacent winding drums is reduced, the drawing speed is increased, the drawing quality is improved, and the production efficiency is improved.

Owner:GUIZHOU AEROSPACE NANHAI SCI & TECH

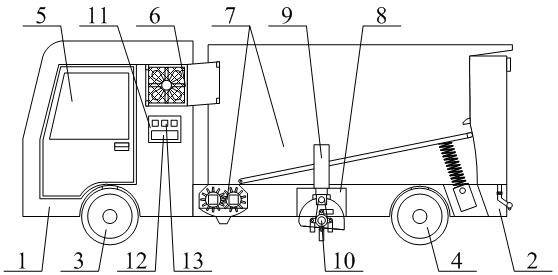

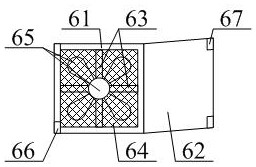

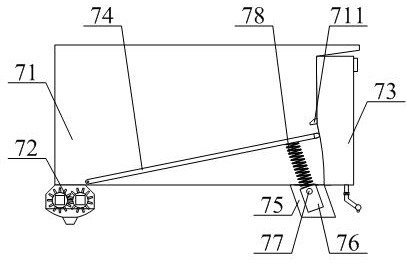

Engineering vehicle

InactiveCN111608053APrevent fallingAvoid affecting the surrounding environmentRoads maintainenceVehicle frameElectric machinery

The invention provides an engineering vehicle which comprises a vehicle head, a vehicle frame, front wheels, rear wheels, a vehicle door, cab heat dissipation and ventilation devices, a lime storage and discharge device, a hollow groove, a lifting air cylinder, a mixing and crushing device, a control console, a controller and a control button. The vehicle frame is welded to the lower part of the right side of the vehicle head; the front wheels are mounted at the lower part of the vehicle head; the rear wheel is mounted on the right side of the lower part of the vehicle frame; the vehicle dooris in pin shaft connection to the front side and the rear side of the vehicle head; the cab heat dissipation and ventilation devices are installed on the front portion and the rear portion of the upper right side of the vehicle head. The crushing and conveying baffles are welded to the outer sides of the rotating rollers correspondingly, the crushing and conveying baffles arranged on the left sideand the right side are engaged with each other, the crushing and conveying baffles are driven by the rotating motor through the rotating rollers to rotate towards the lower portion of the inner sideduring use, and therefore lime is evenly guided out downwards, and meanwhile the lime extruded into blocks can be pulverized.

Owner:辛秀

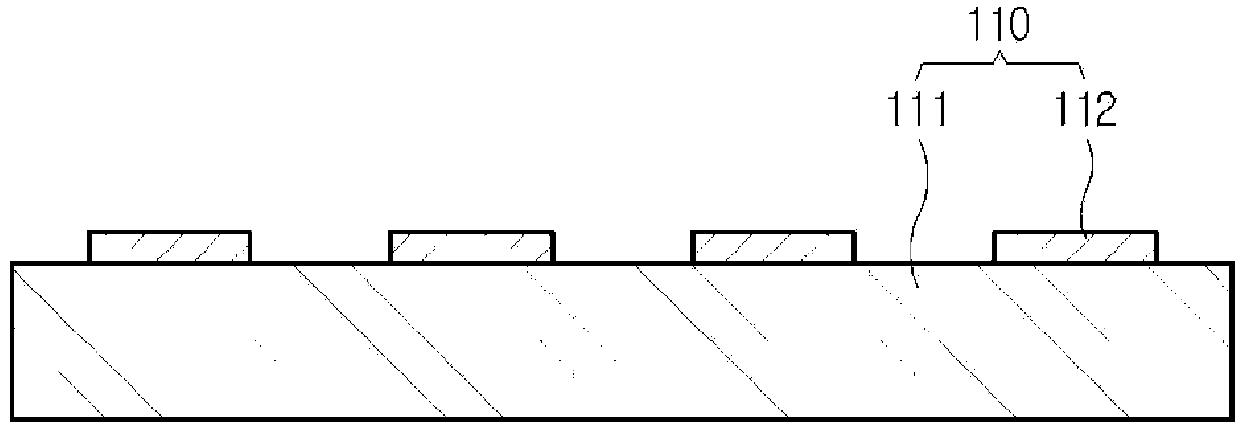

Method of manufacturing printed circuit board

InactiveCN103635032APosition controlAvoid condensationPrinted circuit assemblingSemiconductor/solid-state device detailsResistSolder ball

The present invention relates to a method of manufacturing printed circuit board. The method of manufacturing printed circuit board of the present invention includes the step of forming a solder resist in which a first opening is formed so that the step, and the upper portion of a bonding pad be exposed, the step of forming a mask in which a second opening is formed so that the upper portion of the bonding pad be exposed at the upper part of the solder resist, the step of setting up a solder ball at the upper part of the bonding pad, the step of coating a flux at the upper part of the solder ball, the step of performing the reflow and step of removing the mask, providing the base substrate including the bonding pad.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

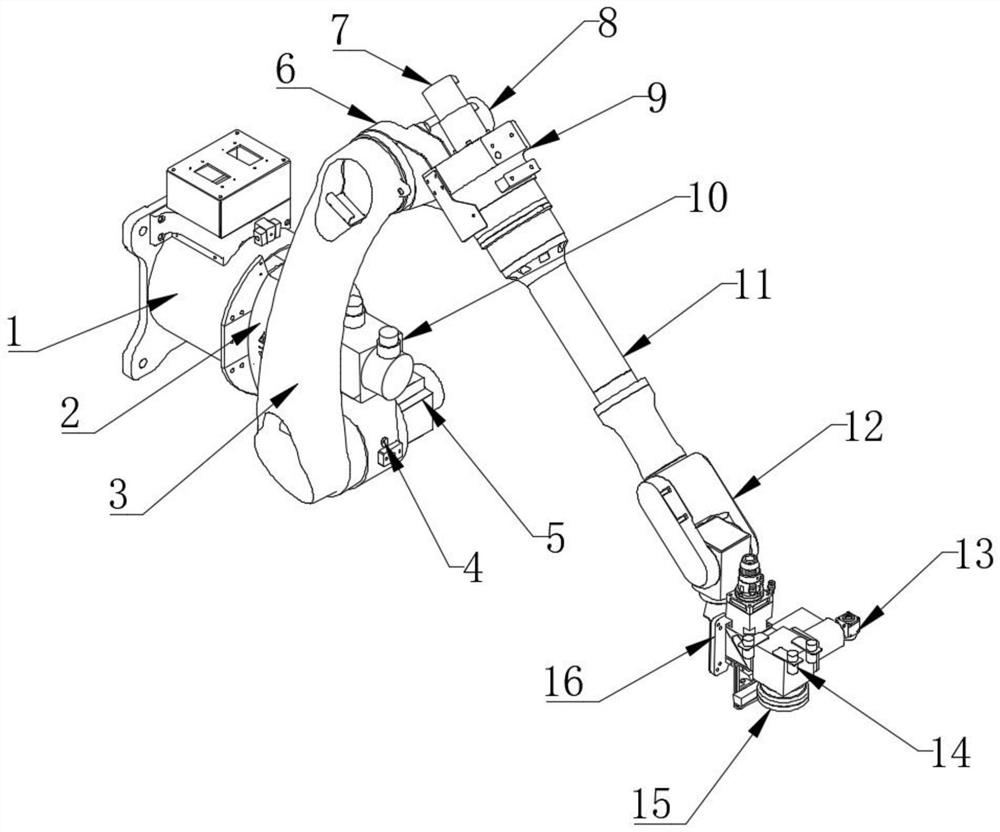

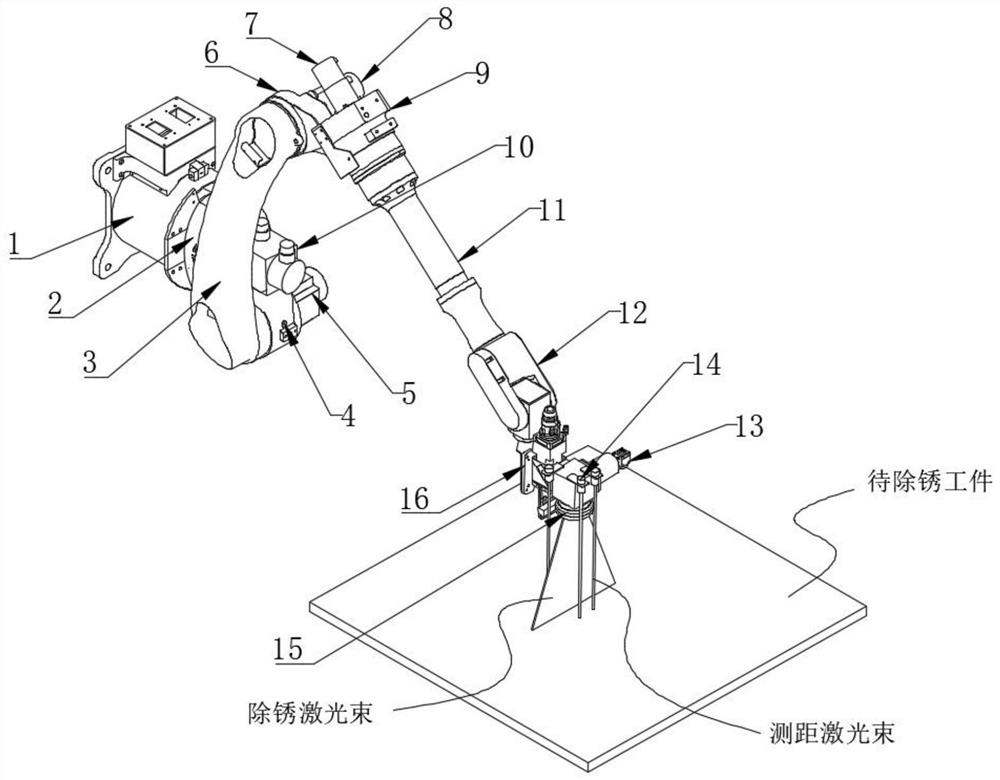

Intelligent focal length control system for laser rust removal

InactiveCN112008233AAvoid damagePosition controlCleaning processes and apparatusLaser beam welding apparatusControl systemElectric machinery

The invention relates to the technical field of laser rust removal, and discloses an intelligent focal length control system for laser rust removal. The system comprises a base, a first speed reduceris installed at the front end of the base, a focal length control box is installed at the lower end of the inner side of a clamp, a laser head is installed at the bottom end of the focal length control box, a camera is installed on one side of the focal length control box, and three displacement sensors are installed at the position, close to the outer side of the laser head, of the upper end of the focal length control box. According to the intelligent focal length control system, real-time shooting is carried out on a to-be-derusted workpiece by the camera; the size and shape of the workpiece and the rust position on the surface of the workpiece are obtained; real-time distance measurement is carried out on the two sides of a to-be-derusted position through the three displacement sensors; and the distance and angle of the laser head are adjusted through a first rotating joint motor, a second servo motor, a second rotating joint motor and a first servo motor, the position of the laserhead can be accurately controlled, optimal focal length control is achieved, the purpose of efficient rust removal is achieved, and damage to the workpiece is reduced as much as possible.

Owner:SHANGHAI JIANYE TECH ENG

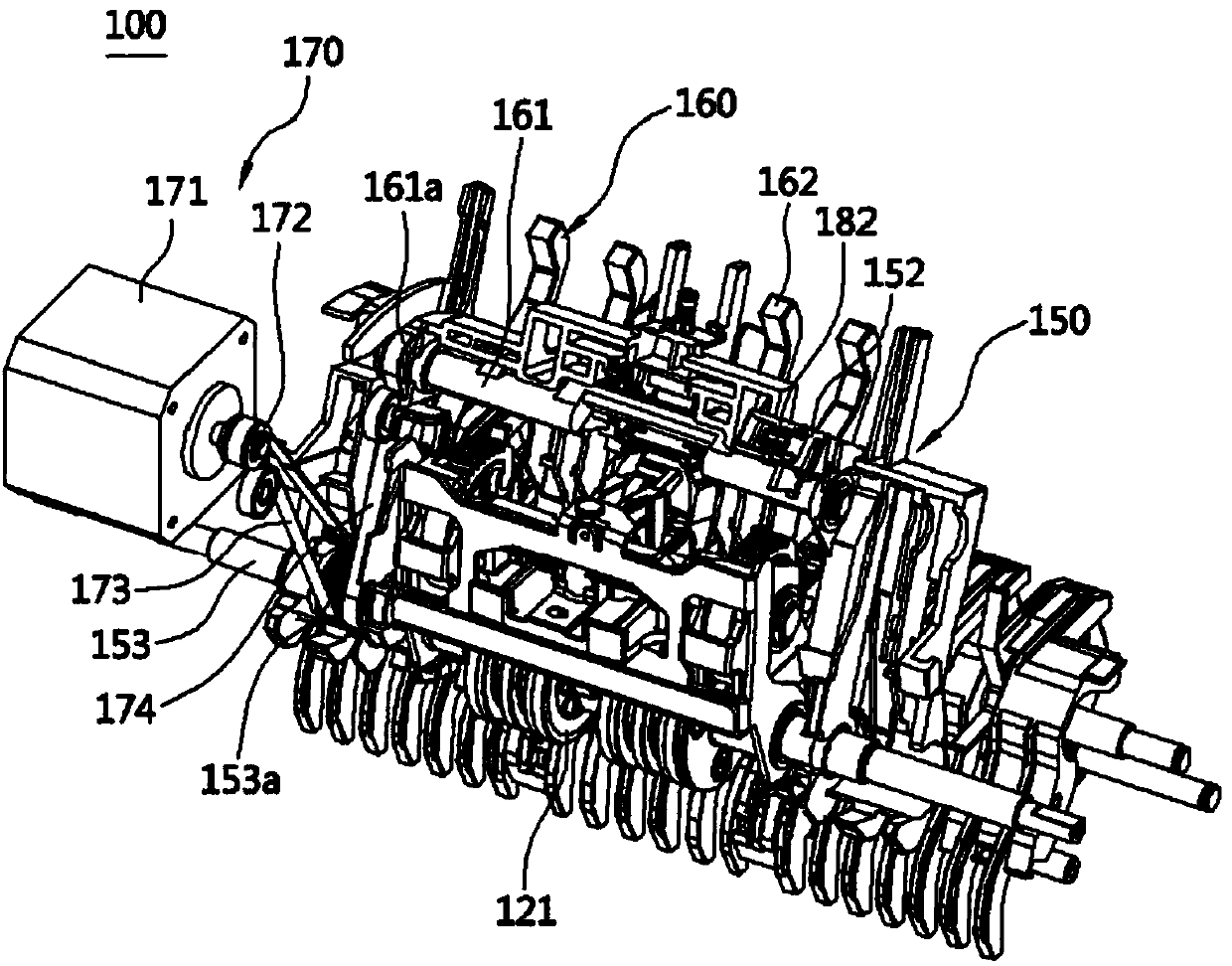

Banknote stacking apparatus

ActiveCN107871357APrevent flying phenomenonStack stableComplete banking machinesCoin/currency accepting devicesStacker

The present invention is directed to providing a banknote stacking apparatus capable of stably stacking banknotes even when various types of banknotes are stacked therein by preventing banknotes stacked in the banknote stacking space from being blown away. The banknote stacking apparatus includes a stacker for stacking banknotes in the banknote stacking space; a push plate provided to support thebanknotes stacked in the banknote stacking space and be movable in a reciprocating direction; a stack guide configured to guide the banknote which passes the stacker to be loaded into the banknote stacking space; a damper configured to press the banknote introduced into one side of the banknote stacking space toward the push plate located on the other side of the banknote stacking space and prevent the banknotes from being blown away; and a damper driver configured to operate the damper to move in a direction toward the banknote stacking space and a direction away from the banknote stacking space.

Owner:HYOSUNG TNS INC

Preparing device and use method of bee product soft capsules

The invention provides a preparing device and use method of bee product soft capsules. The preparing device comprises a machine base, a machine frame and capsule plates. A supporting leg is arranged at the upper end of the machine base and provided with a motor. A belt is arranged on the motor. The other end of the motor is provided with a rolling wheel. A transmission wheel is arranged outside the rolling wheel. A conveying belt is arranged outside the transmission wheel. The capsule plates are arranged on the conveying belt. A support is arranged at the upper portion of the machine frame. Amixing box is arranged on the support and provided with a filling pipe. A flow meter is arranged on the filling pipe. An electromagnetic valve is arranged at the lower end of the flow meter. Accordingto the capsule preparing device, automatic control and mechanical conveying are adopted, the flow meter is arranged to precisely control the amounts of raw materials in the capsules, all the preparedcapsules are the same in bee product content, the high-quality products are prepared and the plates are put away at a time, and efficiency is greatly improved.

Owner:MINGGUANG HAOHAO BEES

INFORMATION PROCESSING APPARATUS AND method

PendingCN108415676AAvoid excessive zooming outPosition controlGeometric image transformationLocation information based serviceComputer hardwareInformation processing

The invention provides an information processing apparatus and method. An information processing apparatus includes a display controller that changes a position indication of a movable object in accordance with a shape of a display region used for the position indication of the movable object.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Automatic cutting device of friction shoe of clutch

PendingCN108356894AHigh degree of automationReduce manual operationsMetal working apparatusClutchAutomatic control

The invention discloses an automatic cutting device of a friction shoe of a clutch. The automatic cutting device comprises a feeding mechanism and a cutting mechanism, wherein the feeding mechanism comprises a feeding rack and annular belts; the cutting mechanism comprises a rack and a lifting pressure cylinder; a support is arranged at the upper end of the rack; the lifting pressure cylinder is arranged on the support; a pressing block is arranged in the support; the upper end of the pressing block is connected with a piston rod of the lifting pressure cylinder; a cutting seam is formed in the lower end of the pressing block; a driving motor and a rotating shaft are arranged at the lower end of the rack; the rotating shaft is connected with the piston rod of the lifting pressure cylinderthrough a rotating sleeve; and a disc cutter is arranged at one end of the rotating shaft. According to the automatic cutting device, friction shoe conveying, friction shoe pressing and friction shoecutting are automatically controlled, the automation degree is high, manual operation is reduced, and cutting precision is improved.

Owner:HENAN DALIN RUBBER & TELECOMM APP

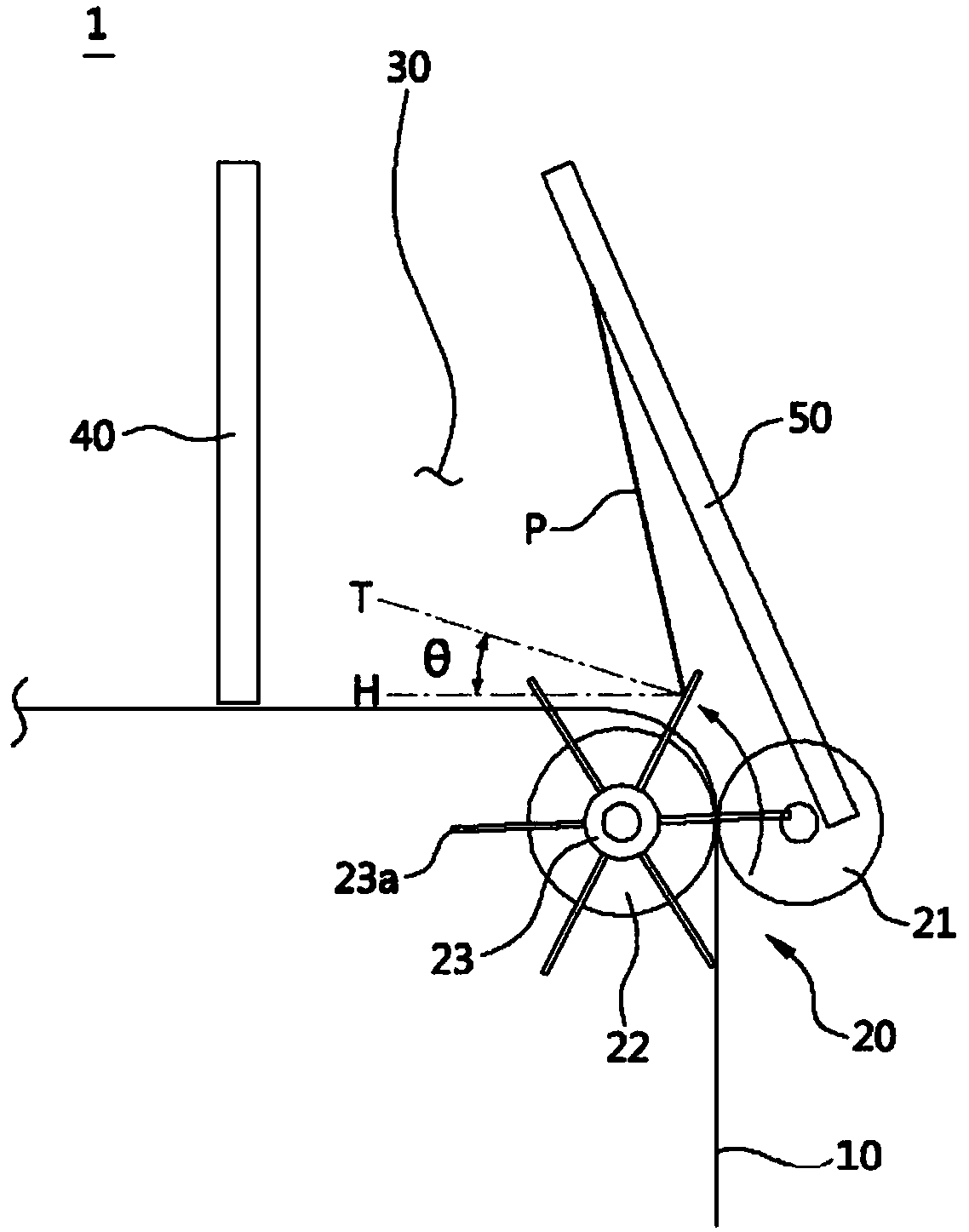

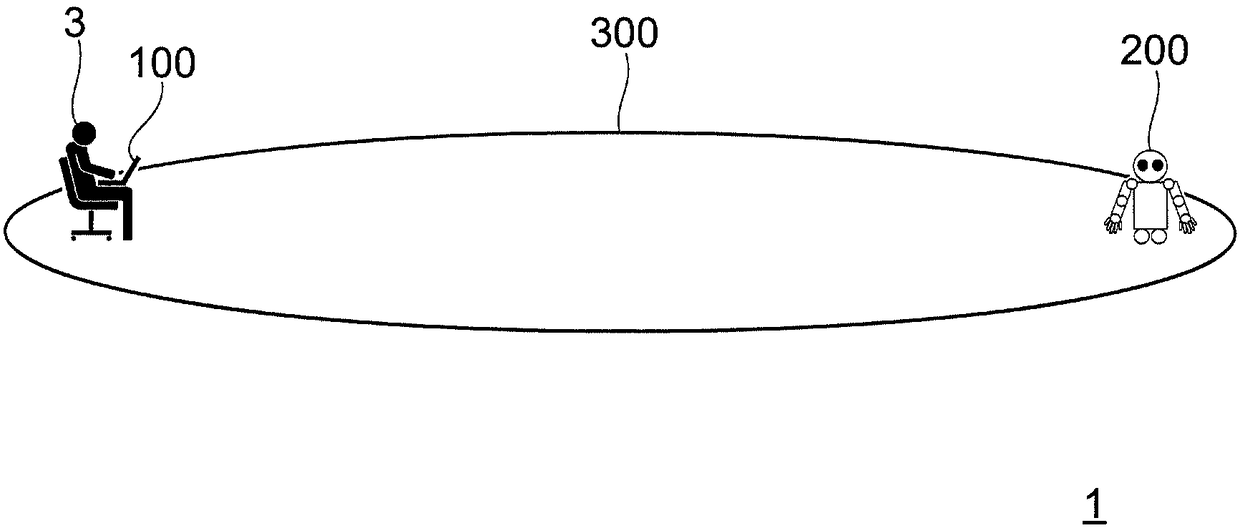

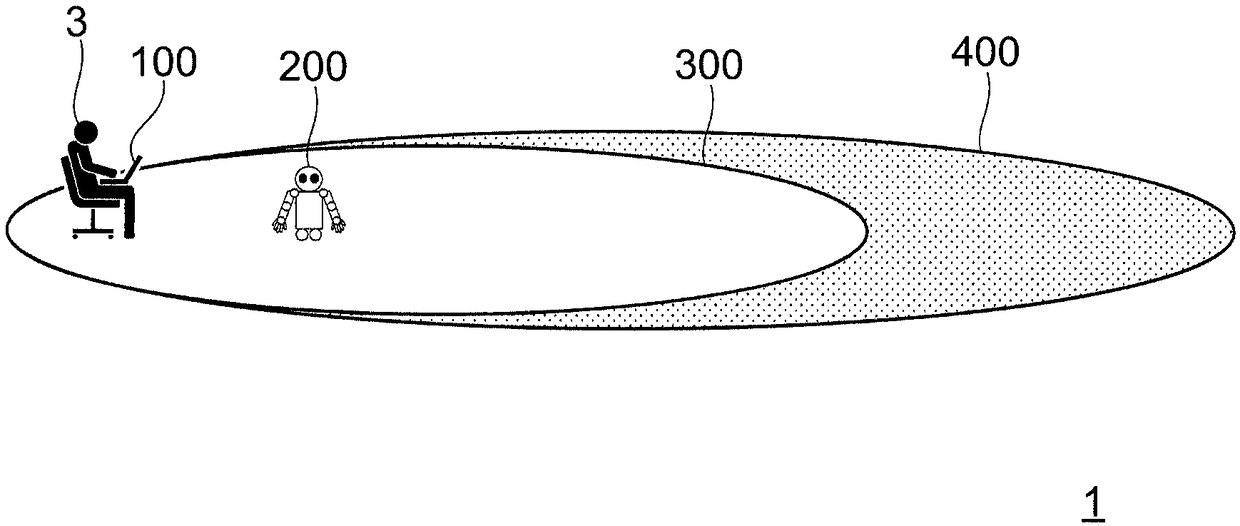

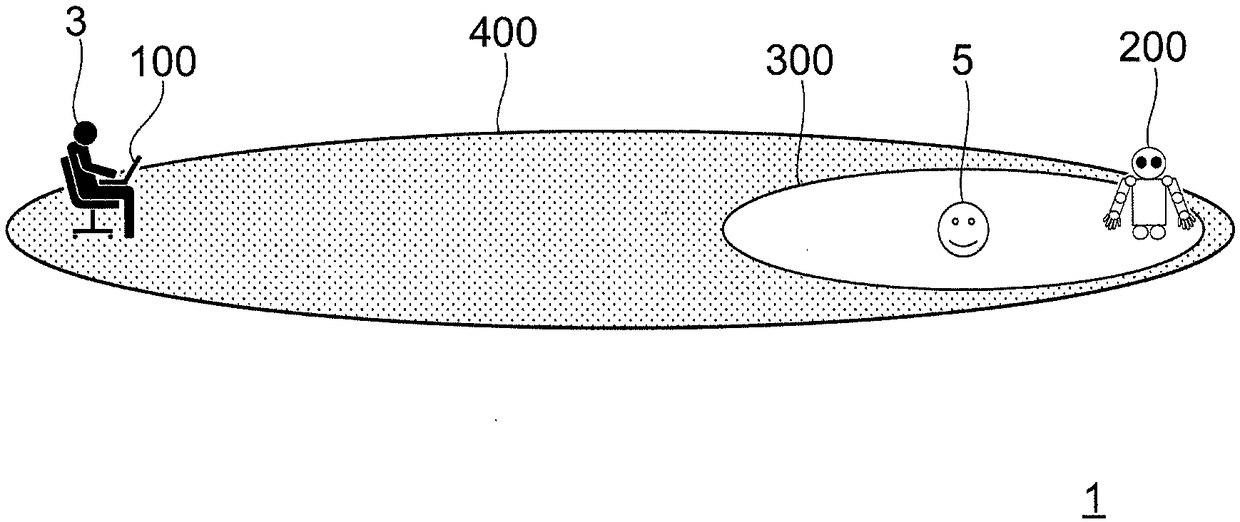

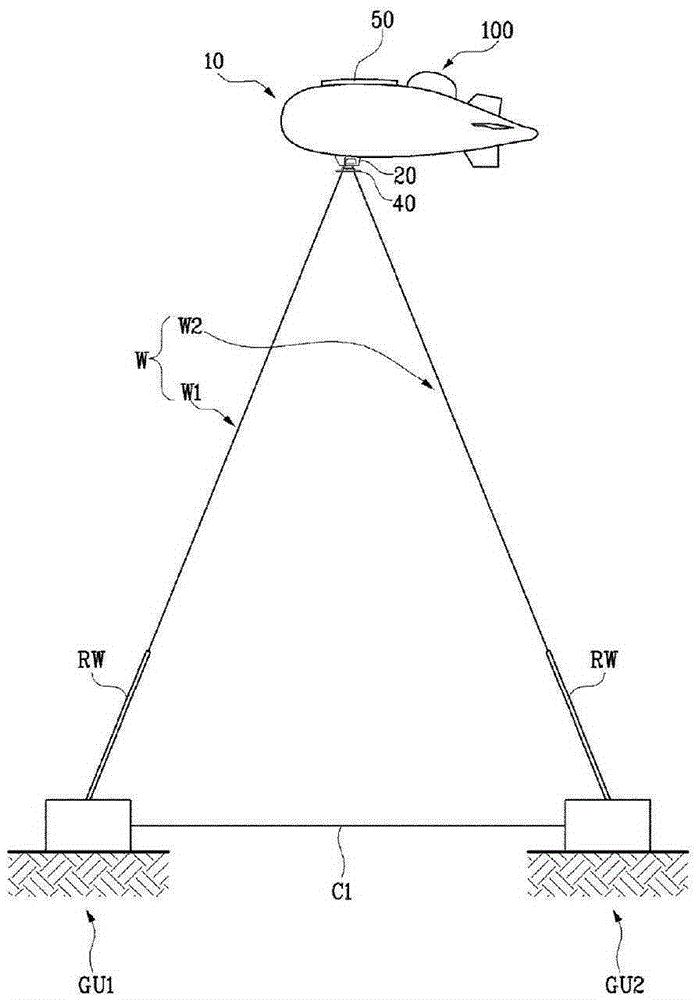

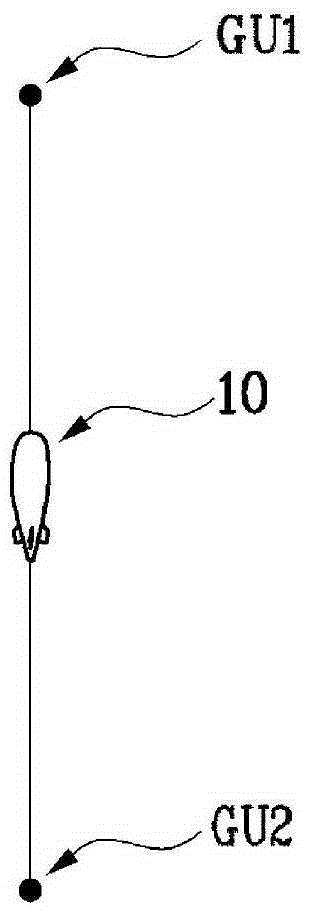

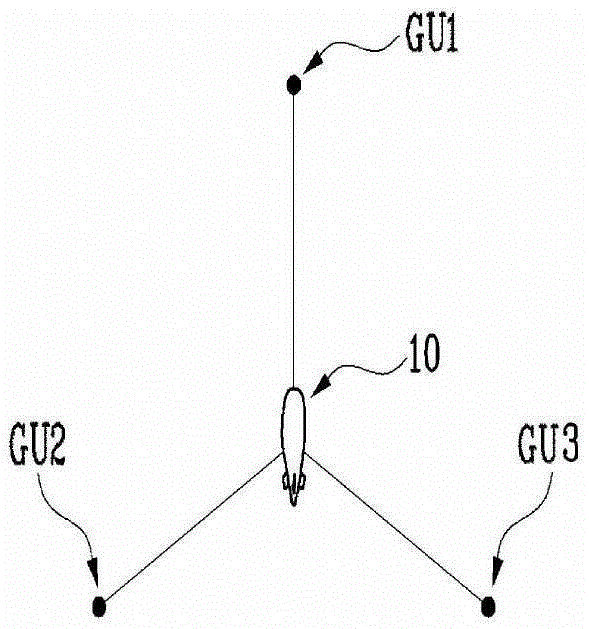

Flying object operating system

InactiveCN105283382AGuaranteed stabilityPosition controlTethered aircraftEnergy efficient operational measuresSkyWind force

The present invention relates to a system for operating a flying object that is flown from the ground. The flying object operation system includes a flying object that is filled with a gas therein to stay in the sky, a ground unit installed on the ground, a wire unit connecting the flying object to the ground unit, and a buoyancy-generation unit disposed on a side of the flying object to obtain buoyancy through friction with air, thereby transferring the obtained buoyancy to the flying object. In the present invention, since additional wind-derived buoyancy obtained by the buoyancy-generation unit connected to the flying object is further generated, sufficient buoyancy may be supplied to the flying object in a high-altitude environment to stably operate the flying object. Also, since power generated by using the wind power generation unit is transmitted to the ground through the wire unit, the flying object operation system may be utilized as wind power generation equipment.

Owner:章秀宁

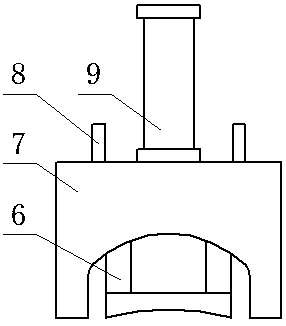

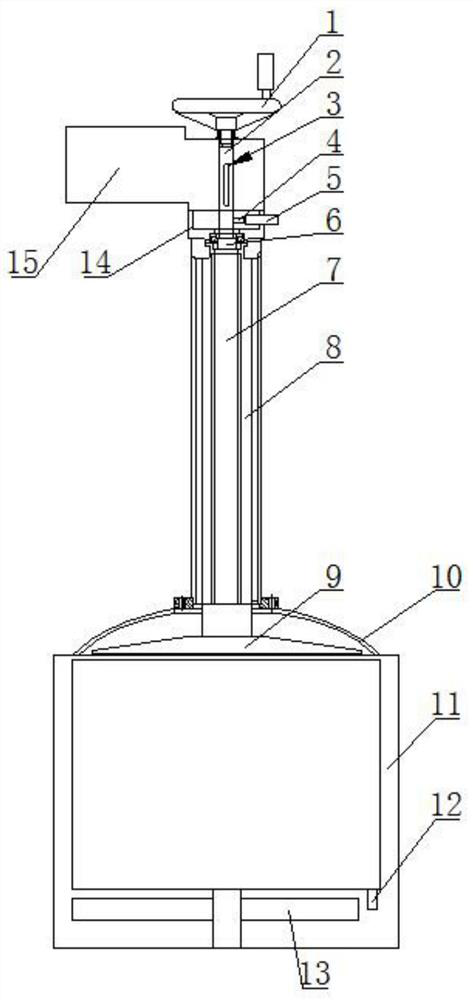

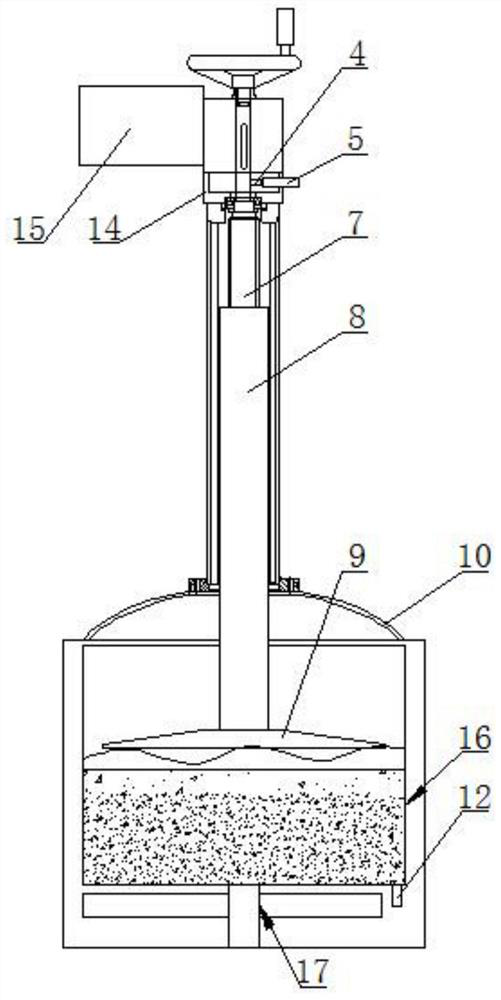

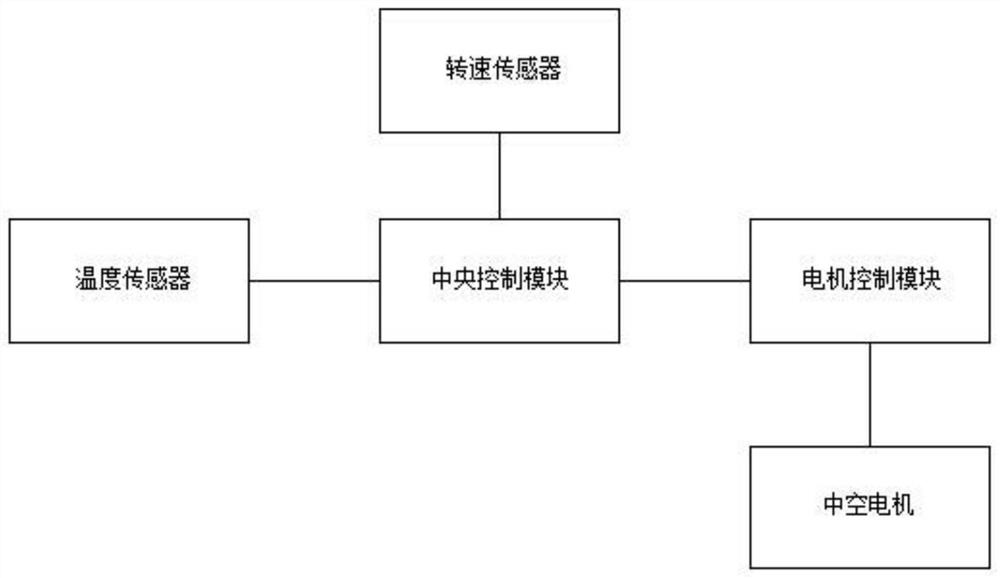

Automatic decoction device and decoction method thereof

ActiveCN107582392BChange positionPosition controlPharmaceutical product form changeMedicineDrive shaft

The invention relates to the field of traditional Chinese medicine decoction equipment, in particular to an automatic decoction device and a decoction method thereof, comprising a pot body, a sealing cover is installed on the upper end of the pot body, and a through hole is formed in the middle of the sealing cover, the A standpipe is integrally installed above the through hole, which is characterized in that a motor seat is integrally installed on the upper end of the standpipe, a through hole is formed in the middle of the motor stand, and a rotating shaft is rotatably installed in the through hole, and the rotating The upper end of the shaft is sleeved and fixed in a hand wheel, the lower end of the rotating shaft is integrally installed with a transmission shaft, the lower end of the transmission shaft is integrally installed with a lifting screw, and the lower end of the lifting screw is sleeved with a lifting sleeve, so A medicine pressing plate is installed at the bottom of the lifting sleeve, and the medicine pressing plate is located in the decoction cavity formed by the pot body. There is a rotational speed sensor, and a heating plate is installed at the bottom of the decoction chamber.

Owner:天津三延精密机械有限公司

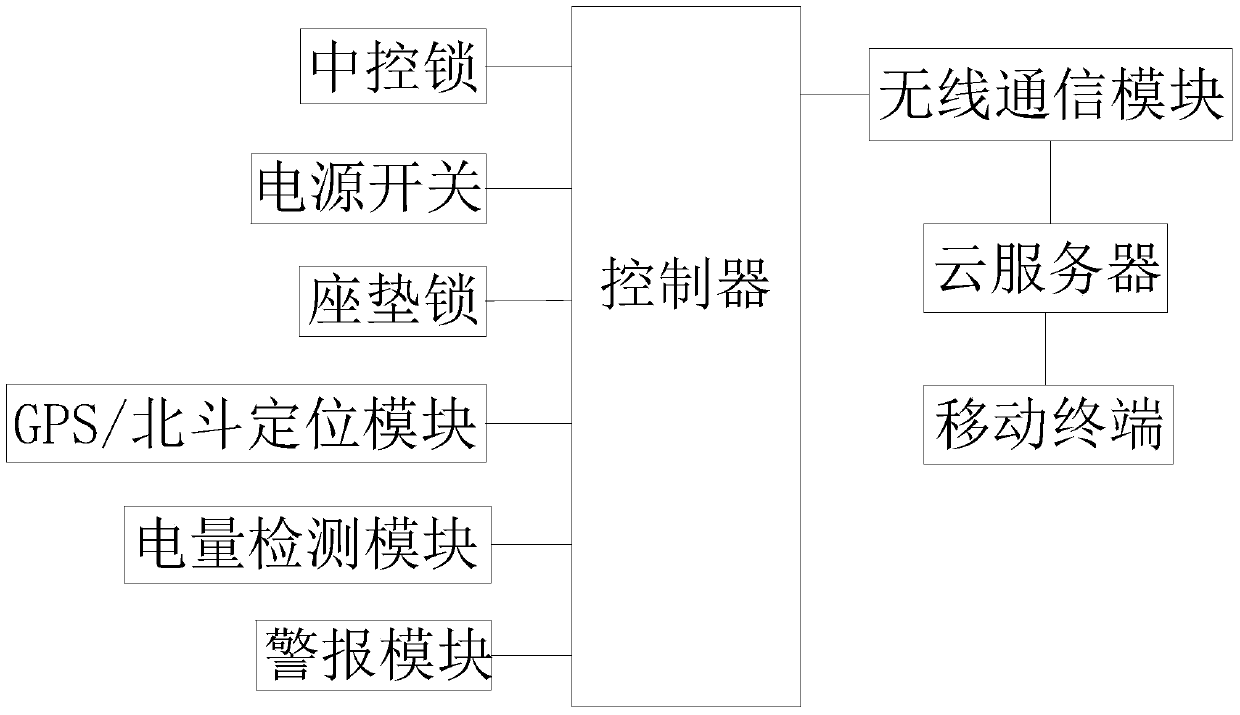

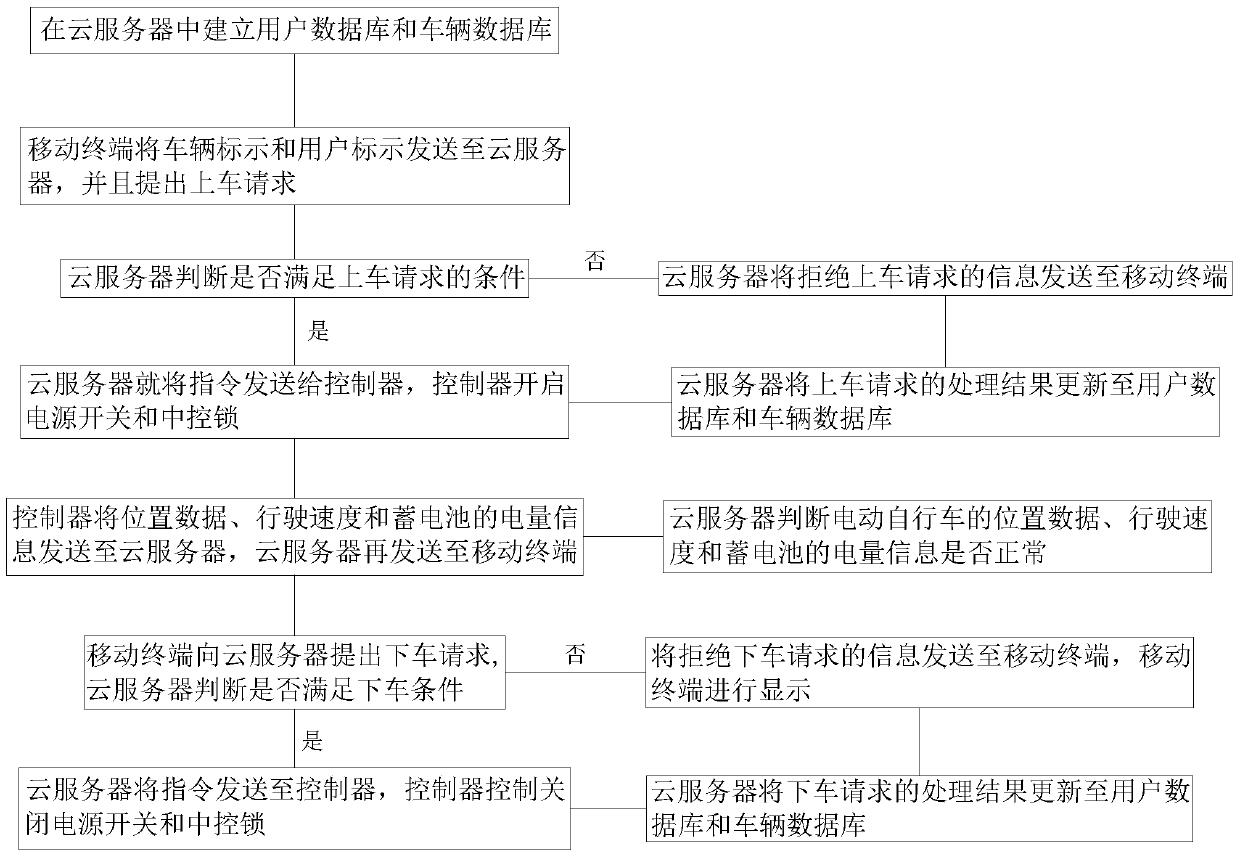

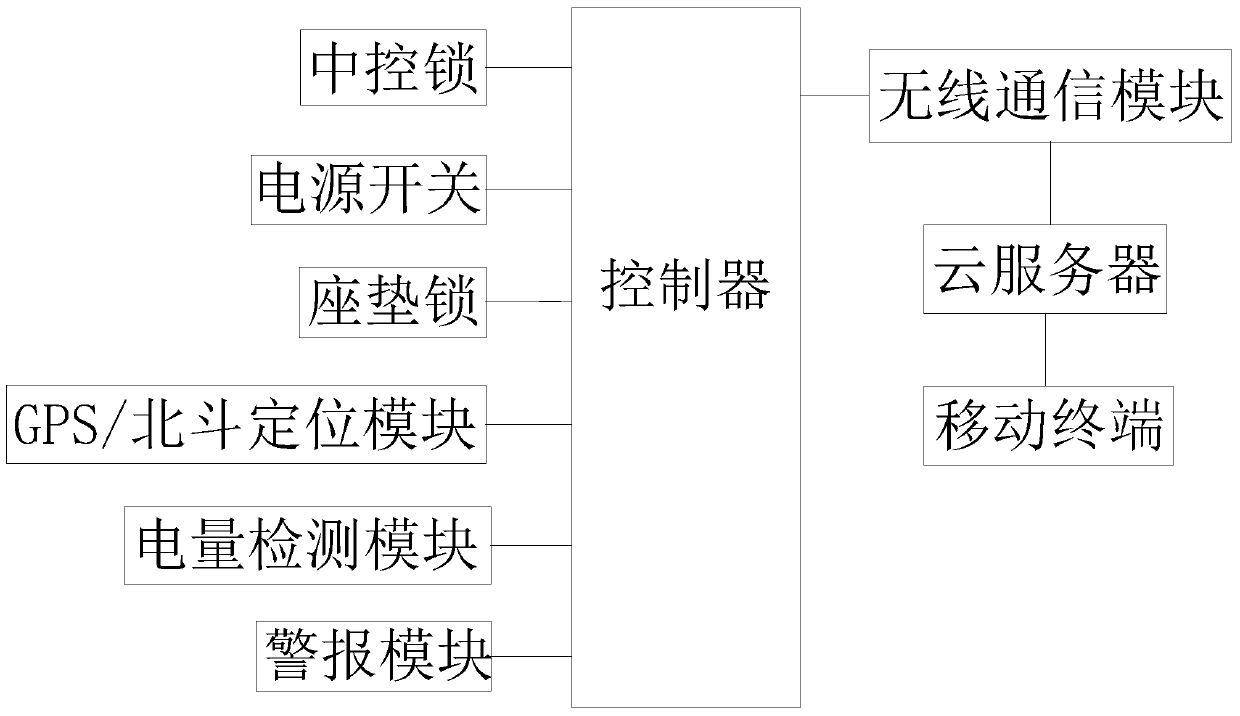

Control system and control method of electric bicycle

ActiveCN105711684BReal-time locationPosition controlAnti-theft cycle devicesAnti-theft devicesControl systemPower switching

The invention provides a control system of an electric bicycle.The control system comprises a controller, a central control lock and a wireless communication module which are connected with the controller, and the central control lock is used for locking a motor; the wireless communication module is used for enabling the controller to be connected into an internet in a wireless communication manner; the controller is used for acquiring a command by the internet and opening and closing the central control lock and a whole vehicle power switch according to the command.According to the control system and a control method of the electric bicycle, no key control is adopted, the whole electric bicycle can be controlled by a mobile terminal carried along, and the inconvenience of carrying a lot of keys is avoided; at the same time, when the electric bicycle is ridden, information of the position, the speed, the battery level and the like of the electric bicycle can be known in real time, the state of the whole electric bicycle is mastered, the electric bicycle use safety is improved, the position of the electric bicycle can be mastered in real time, and the electric bicycle can be found in the first time when stolen.

Owner:JIANGSU LVNENG ELECTRICAL BICYCLE TECH CO LTD

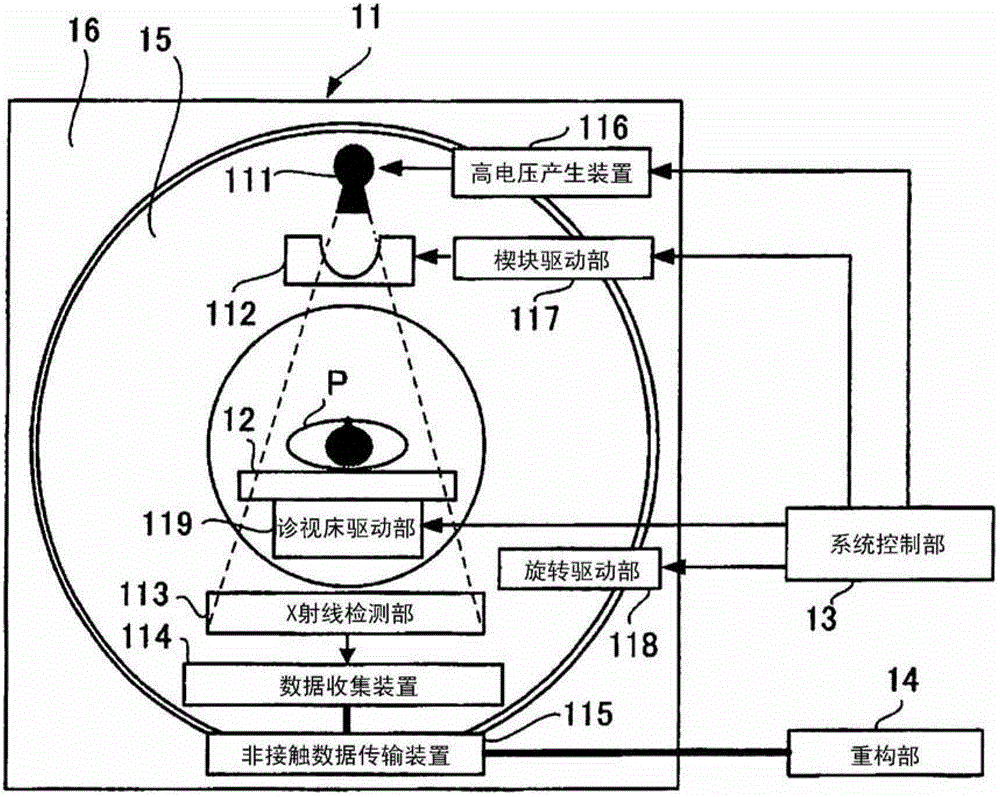

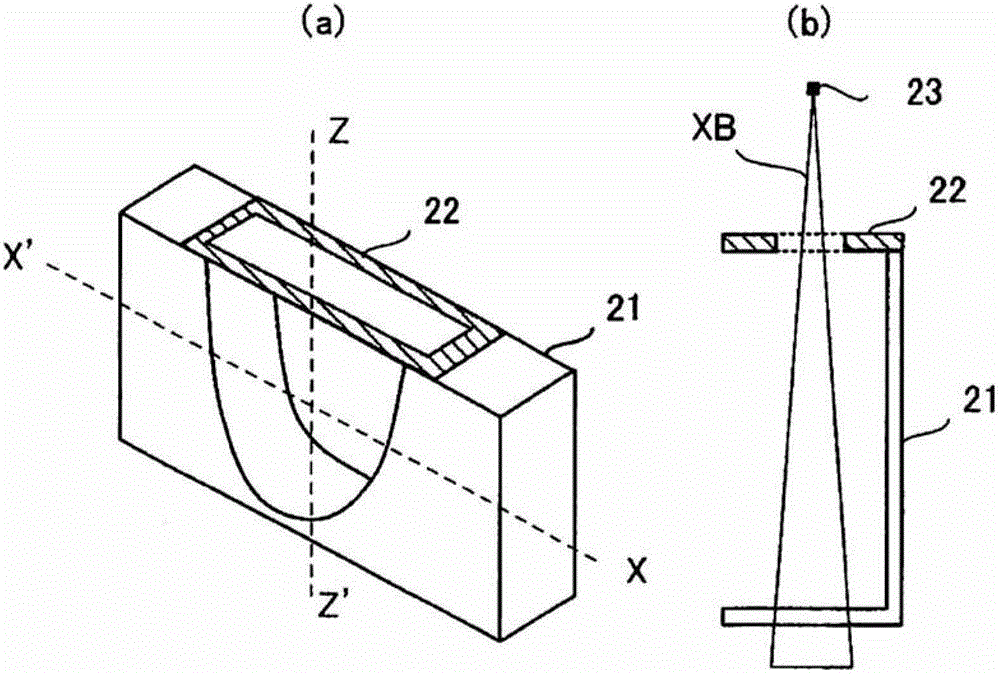

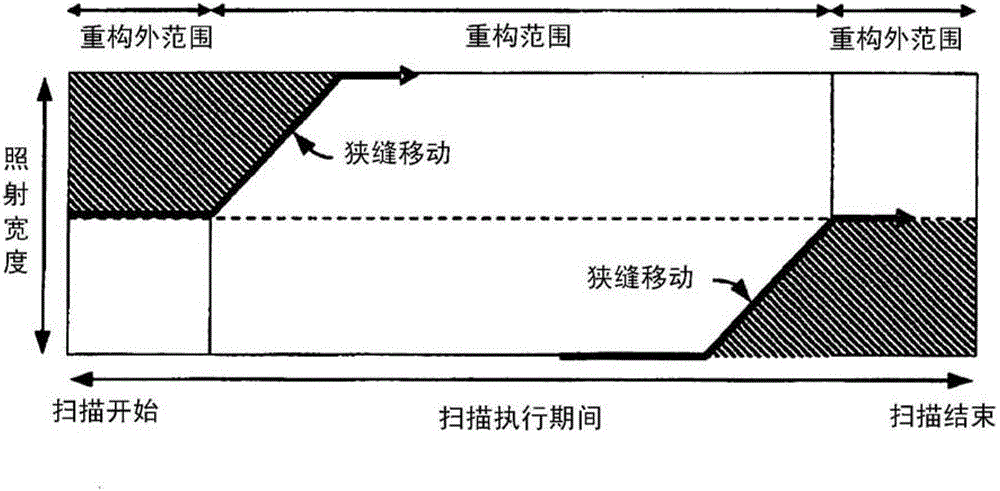

X-ray ct apparatus

ActiveCN102753099APosition controlHandling using diaphragms/collimetersComputerised tomographsPhysicsShielding block

There is provided an X-ray CT apparatus including: an X-ray source; a wedge which is disposed between the X-ray source and a subject and in which a shield blocking a part of an X ray is formed; a wedge driving unit for moving position of the wedge; and a system control unit controlling the wedge driving unit during a scan execution period to control the position of the wedge.

Owner:TOSHIBA MEDICAL SYST CORP

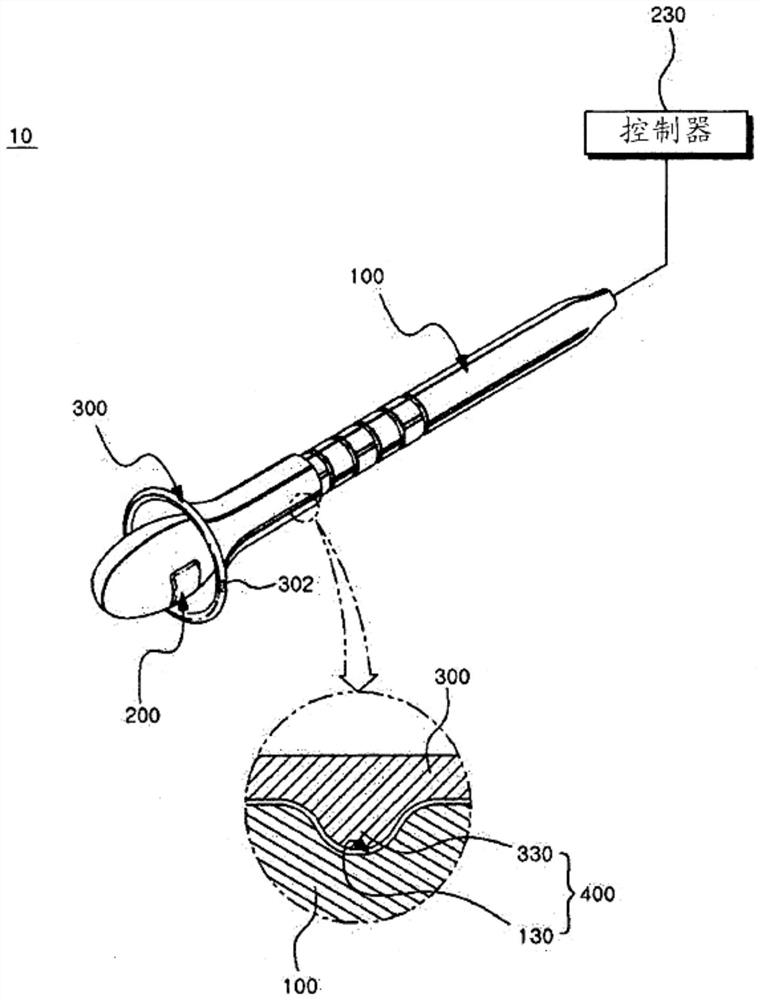

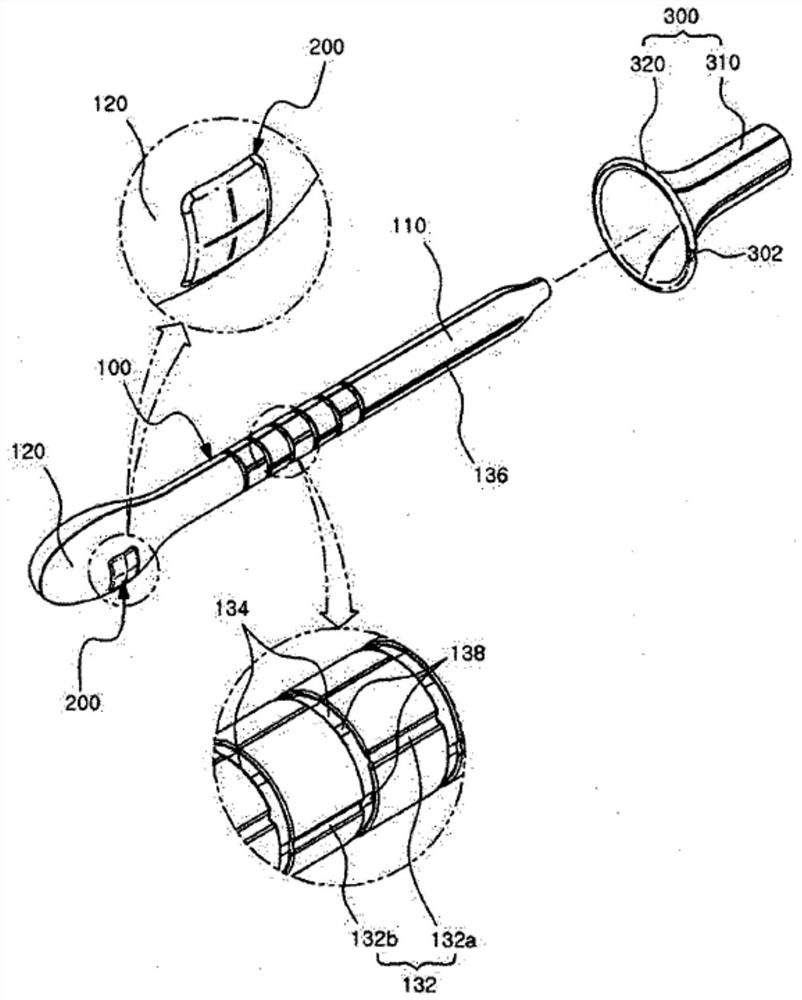

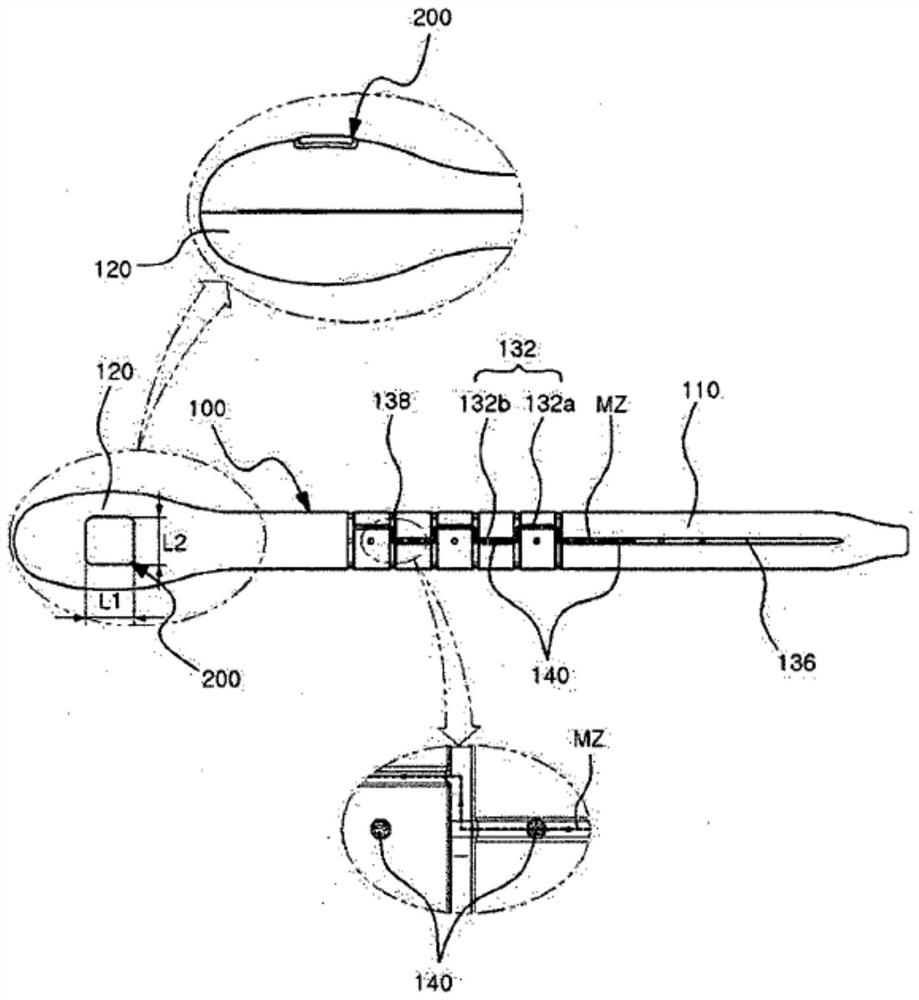

Device for treating submucosa

PendingCN111712294AMaintain contractilityIncrease elasticityHead electrodesSurgical instrument detailsSubmucosaBiomedical engineering

A device for treating a submucosa according to one embodiment of the present invention comprises: a probe member accessible to a mucosa of a treatment area; an electrode, provided on the probe member,for applying an electrical signal to a blood vessel of a submucosa of the mucosa; and a guide member, to which the probe member is movably received, for guiding a position of the electrode with respect to the mucous.

Owner:VIOL CO LTD

A jet printing machine

ActiveCN112874161BAchieve fixationAchieve compactionOther printing apparatusEngineeringPrinting press

The present invention relates to the technical field of inkjet printing machines, in particular to an inkjet printing machine, which includes a bottom plate, a plurality of sliding grooves are provided on the surface of the bottom plate, and at least one of the plurality of sliding grooves is provided with a The fixing assembly is used to fix the paper to be sprayed on the bottom plate; the fixing assembly includes a slider slidingly arranged in the sliding groove, and the top of the slider is fixed with a support plate, when pulled down The first pull cord moves the paddle downwards, and then fixes the paper to be sprayed on the base plate; the center of the bottom surface of the base plate is detachably installed with an adjustment assembly; the invention can quickly adjust the position of the paddle according to different paper sizes The position of multiple picks can be fixed, and then the picks can be moved downward to compress the paper; the entire paper pressing process can be completed by adjusting the components, and there is no need to adjust the positions of the picks one by one.

Owner:江苏瑞彩包装有限公司

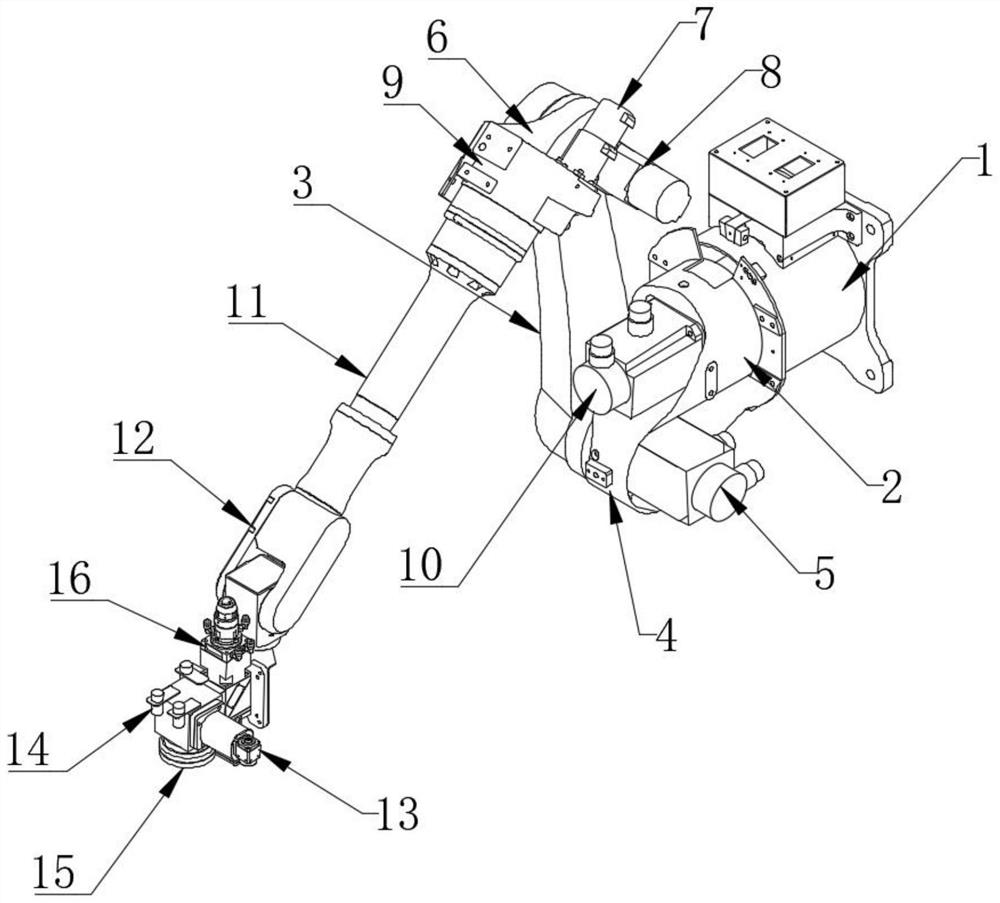

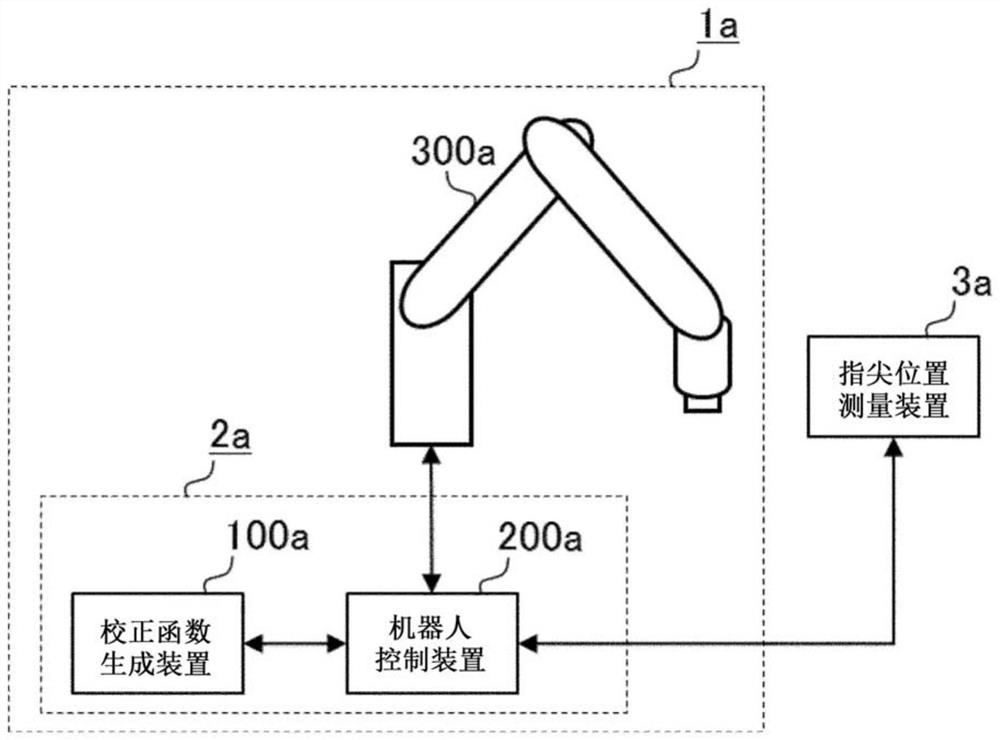

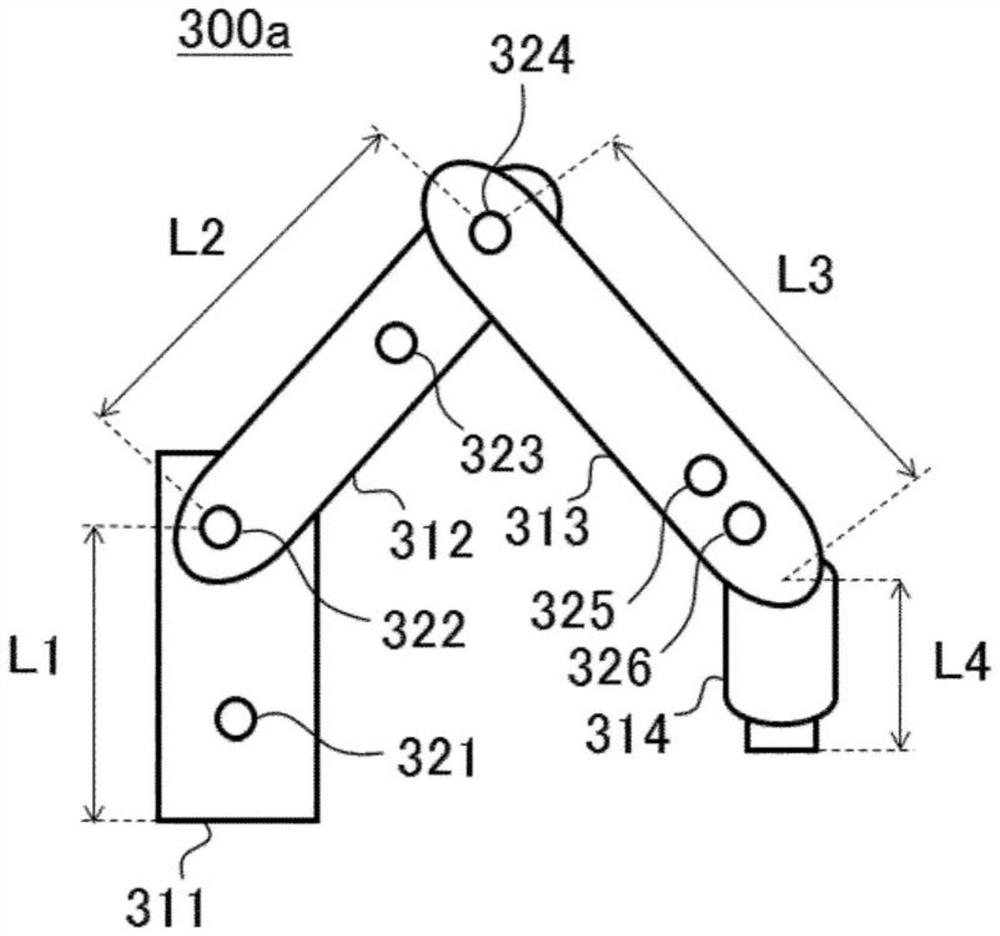

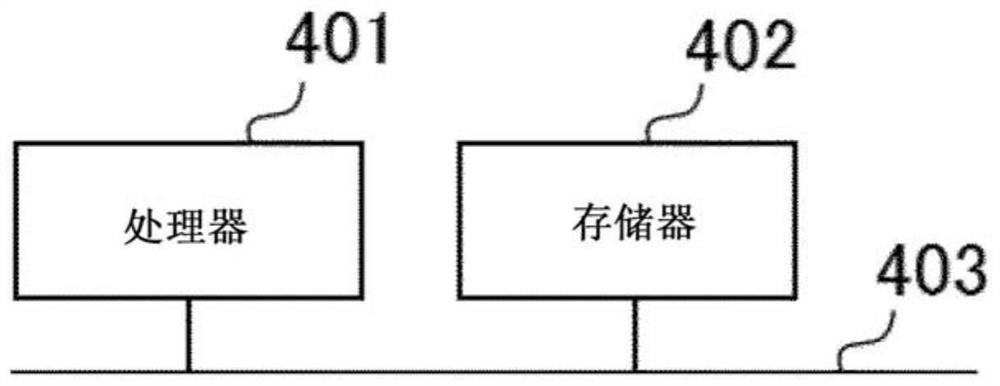

Correction function-generating device, robot control system, and robot system

ActiveCN111819037APosition controlProgramme controlProgramme-controlled manipulatorRobotic systemsTip position

The present invention makes it possible to control the position of the tip of a robot arm with high precision without increasing the points for which the position is measured. A correction function-generating device (100a) for generating a correction function to be used for controlling the position of the tip of a jointed robot arm is provided with: an information-acquiring unit (110a) for acquiring temperature information measured at a specified position of the robot arm and a measured position obtained by measuring the angle of a joint at the time point at which the temperature information was measured and the position of the tip at the time point at which the temperature information was measured; a tip position-estimating unit (120a) for determining an estimated position by estimating the position of the tip at the time point at which the temperature information was acquired on the basis of the acquired joint angle; and a correction function-determining unit (130a) for determining acorrection function, which is a function that has temperature information as a variable, on the basis of the results of comparing the measured position with the estimated position.

Owner:MITSUBISHI ELECTRIC CORP

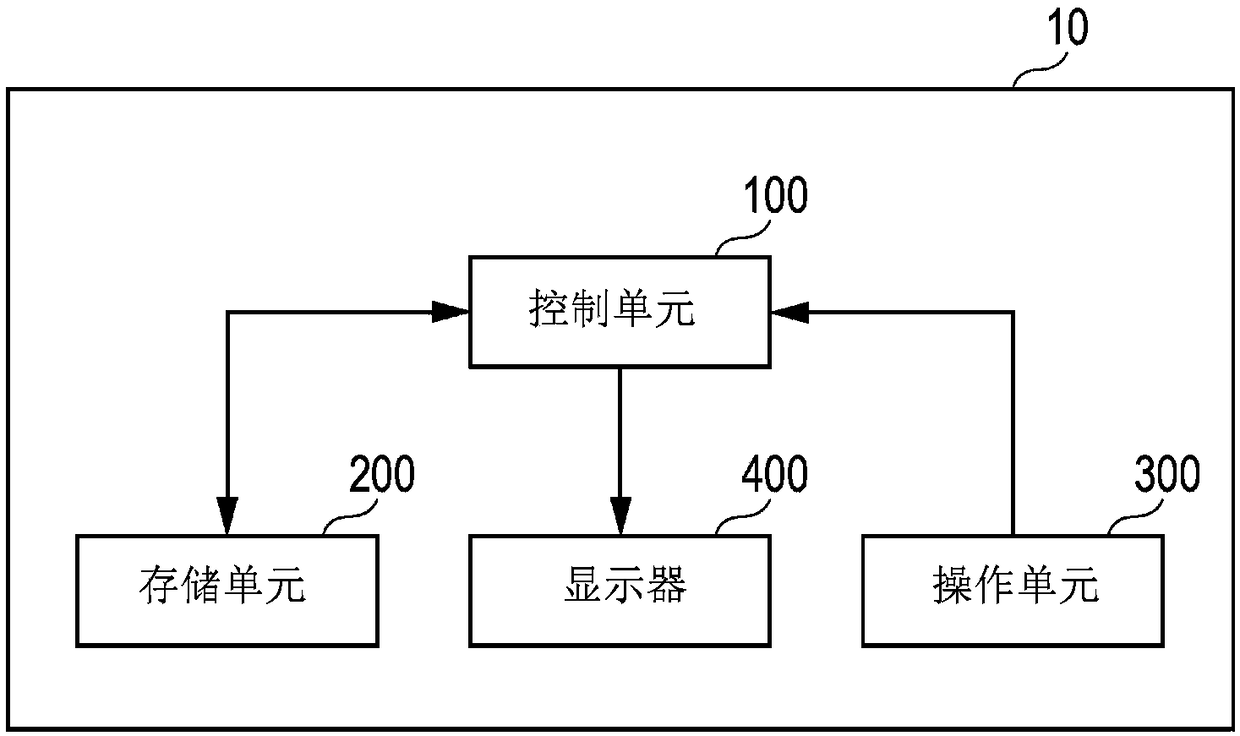

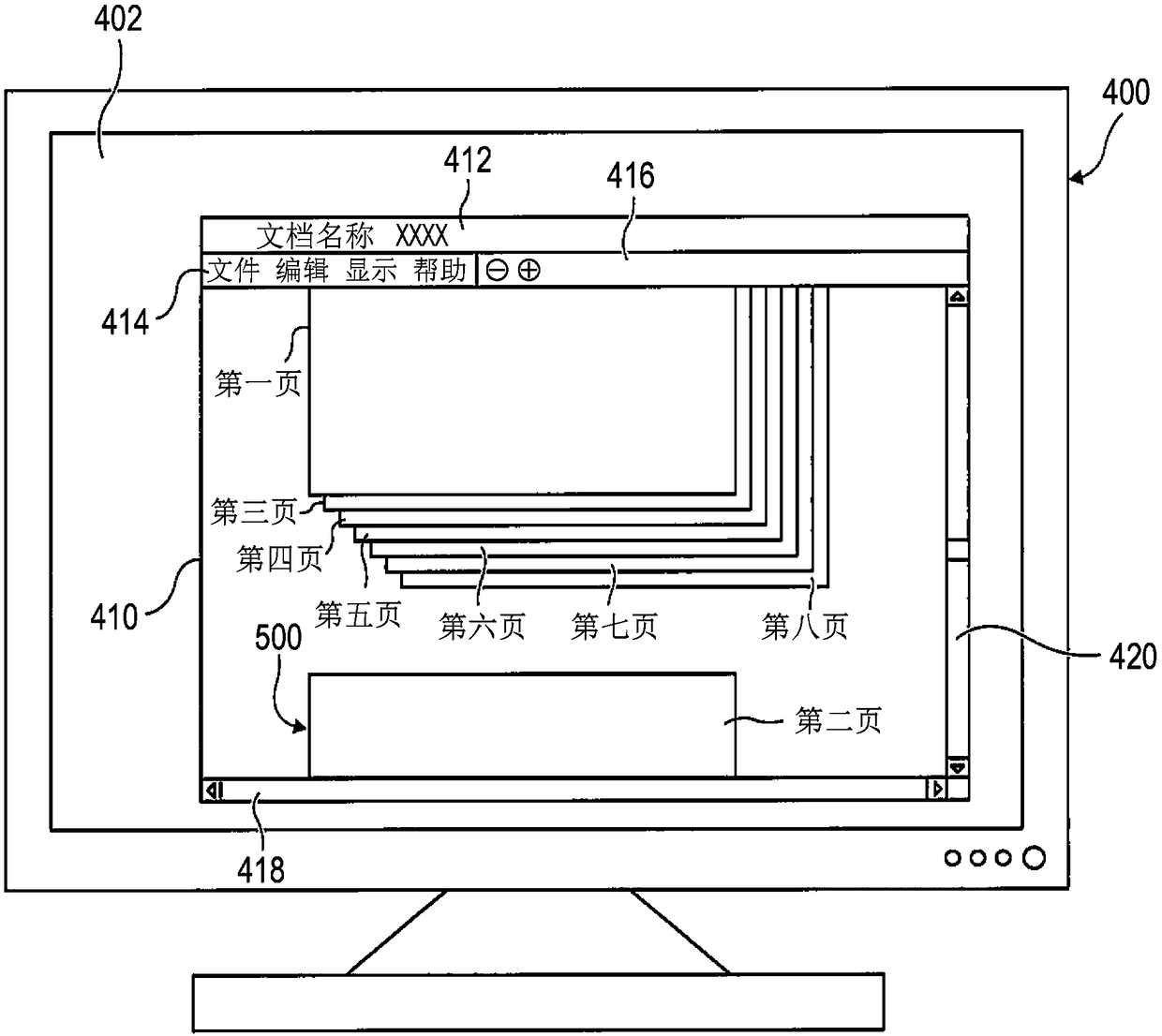

Document display device

PendingCN108388392AEx situ masteryGrasp the positionNatural language data processingDigital output to display deviceComputer graphics (images)Display device

Provided is a document display device. The document display device includes a controller. The controller controls a display for displaying document data constituted by a plurality of pages. The controller controls the display to display pieces of content of at least two consecutive pages of the document data side by side and to display one or more of content-displayed pages, which are the pages for which the pieces of content of the pages are displayed side by side, and one or more of pages other than the content-displayed pages among the plurality of pages so as to overlap.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Macroscopic inspection equipment for LCD (Liquid Crystal Display) glass

InactiveCN101995674BPosition controlReduce vibrationMaterial analysis by optical meansNon-linear opticsLinear motionLiquid-crystal display

The invention discloses macroscopic inspection equipment for LCD (Liquid Crystal Display) glass. Both sides of a glass retainer are supported by utilizing a pair of parallel hinging type connecting units so as to protect the LCD glass from vibration generated by driving macroscopic inspection equipment; and by adopting the parallel hinging type connecting units, the X-axis motion, Z-axis motion and inclination of the glass retainer are realized by a single electrode. The macroscopic inspection equipment comprises the LCD glass retainer, a pair of parallel hinging type connecting units, a rotating unit, an advancing shaft and a controller, wherein the pair of parallel hinging type connecting units are used for supporting the side surface of the glass retainer; the rotating unit is used forrotating a pair of connecting units; the advancing shaft is used for guiding the left and right linear motion of the inspection equipment; and the controller is used for controlling the position of the LCD glass retainer.

Owner:优视株式会社 +1

Concrete Pouring Construction Technology of Walls on Both Sides of Deformation Joint

The invention belongs to the field of constructional engineering and particularly relates to a construction technology for pouring concrete of walls on two sides of a deformation joint. The construction technology comprises the following steps of 1 performing steel bar framework construction; 2 installing a wall board thickness control support; 3 performing positioning and paying-off; 4 installing a bottom-layer interior wall template and a scissors type connecting rod keel supporting system; 5 installing a wall outer-side template and a keel supporting system; 6 pouring the concrete; 7 template removal; 8 pouring the concrete of the walls on two sides of the upper-layer deformation joint; 9 repeating the step 8 till all of required floor pouring is finished. The construction technology is simple, convenient and efficient. Materials are saved. The quality accuracy is high. The root portion position control is good.

Owner:DONGHAI CONSTR GRP

Waterproof membrane dip coating processing device

ActiveCN101831812BSolve the situation of scratched tire base fabricReduce work intensityTextiles and paperEngineeringSmall footprint

A dip-coating processing device for waterproof coiled material, comprising a material tank and a tire base cloth, the material tank is filled with paint, the side wall of the material tank and / or the bottom of the material tank is provided with a heating mechanism, and the material tank is provided with an upper belt roller It is a pair of feeding rollers composed of the lower belt roller, the upper belt roller is located above the paint, the lower belt roller is partially immersed in the paint, the upper belt roller and the lower belt roller rotate in the same direction or in the opposite direction, and the paint passes through The lower belt material roll is transferred to the upper belt material roller, and the tire base cloth is in contact with the surface of the upper belt material roller. One end of the material pool is the feed end, which is provided with a guide roller and a tension roller, which are located above the paint, and the tension roller is connected with the lifting mechanism; one end of the tire base cloth passes through the guide roller in turn. After the roller and the tension roller, it is connected with the upper belt material roller. The invention has the characteristics of simple and reasonable structure, small overall volume, less land occupation, flexible operation, low production cost, low energy consumption, high production efficiency and wide application range.

Owner:鞍山科顺建筑材料有限公司

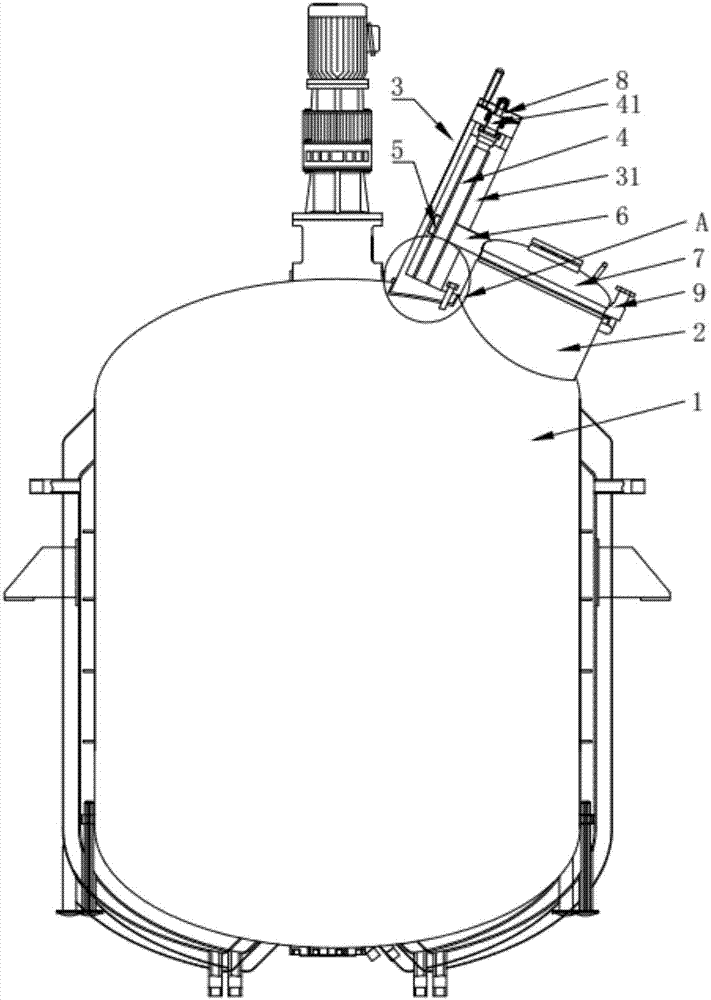

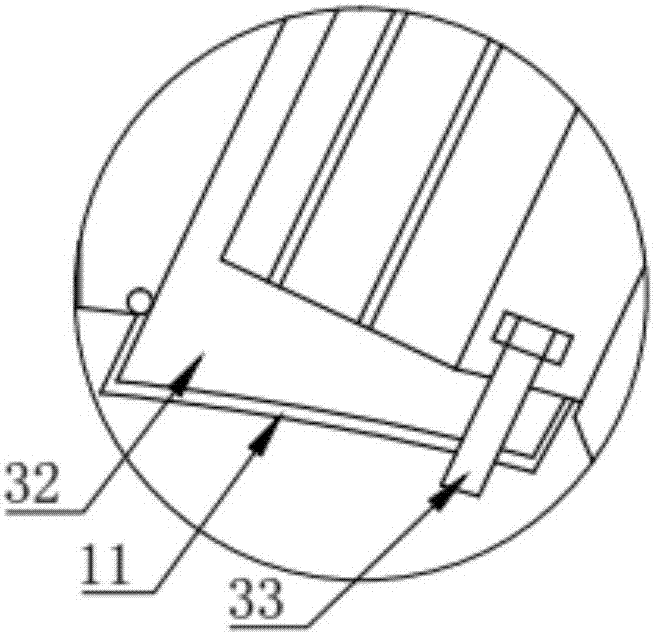

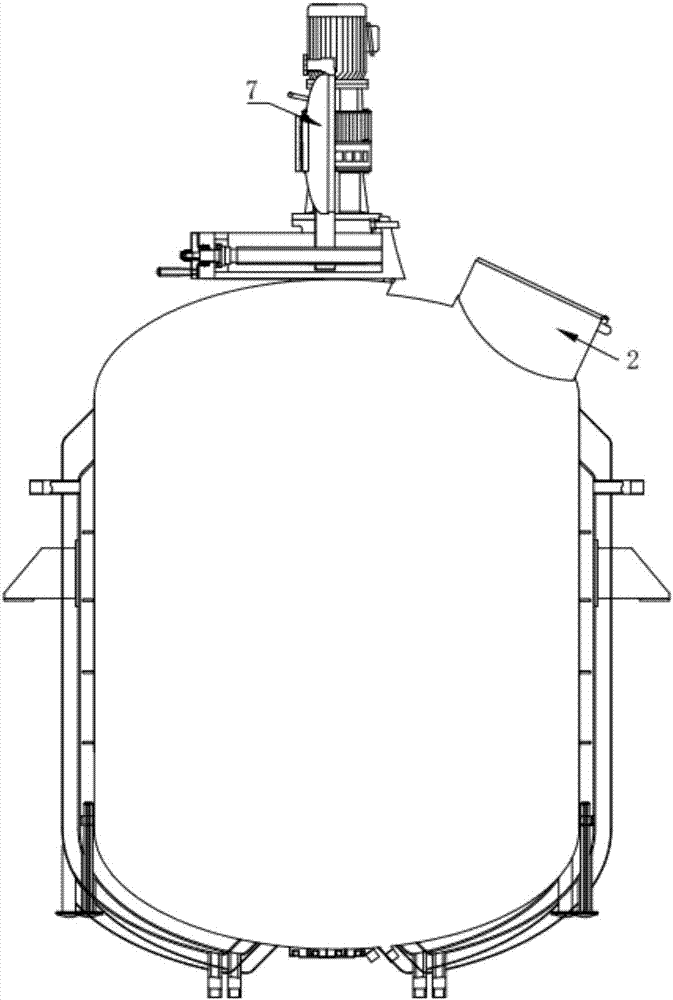

Manhole cover opening and closing apparatus of reaction vessel

InactiveCN107138109ASmooth turningEasy to operateChemical/physical/physico-chemical processesClosure operationEngineering

The invention belongs to the technical field of chemical equipment, and provides a manhole cover switch device for a reaction kettle, including a kettle body, a manhole and a support frame are arranged on the top of the kettle body, the position of the support frame matches the position of the manhole, and the support frame It is a cuboid component. One side of the support frame is hinged with the kettle body, and the other side is detachably connected with the kettle body. There is a lead screw connected to the support frame in rotation, and the screw nut is threaded on the lead screw. , the lead screw nut is connected to the manhole cover through the connecting piece, the support frame is provided with a sliding groove matching the lead screw nut and the connecting piece, the lead screw has an extension extending out of the support frame, and the extension is connected with a rotating handwheel; A locking mechanism is provided between the hole cover and the feed inlet. The invention reduces the problem of equipment damage caused by the opening and closing of the manhole cover of the reaction kettle, facilitates stable opening and closing operations of the manhole cover, and improves the convenience of use.

Owner:HENGYANG YISHUN CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com