Engineering vehicle

A technology for engineering vehicles and frames, applied in the field of engineering vehicles, can solve problems such as humidifying the cab, high inconvenient spillage, inconvenient soil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

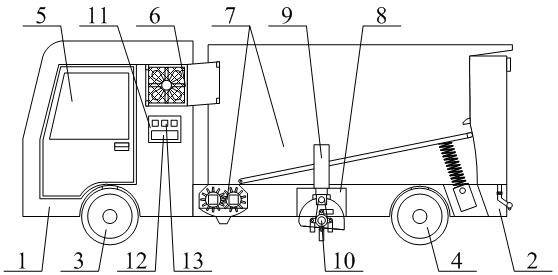

[0043] As attached figure 1 And image 3 Shown

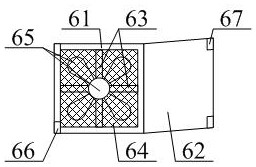

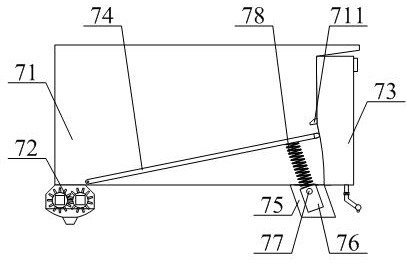

[0044] The present invention provides an engineering vehicle, including a front 1, a frame 2, a front wheel 3, a rear wheel 4, a door 5, a cab heat dissipation and ventilation device 6, a lime storage and discharge device 7, a hollow tank 8, a lifting cylinder 9, and mixed crushing The device 10, the console 11, the controller 12 and the control buttons 13, the frame 2 is welded on the lower right side of the front head 1; the front wheels 3 are installed on the lower part of the front head 1, and the rear wheels 4 are installed In the lower right position of the frame 2; the door 5 pins are connected to the front and rear sides of the front 1; the cab heat dissipation and ventilation device 6 is installed on the front and rear of the upper right side of the front 1; the lime The storage and discharge device 7 is installed on the upper part of the frame 2; the hollow groove 8 is opened in the middle and lower part of the frame 2; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com