Macroscopic inspection equipment for LCD (Liquid Crystal Display) glass

A macro inspection, glass technology, applied in optics, measuring devices, material analysis by optical means, etc., can solve problems such as glass or glass holder damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

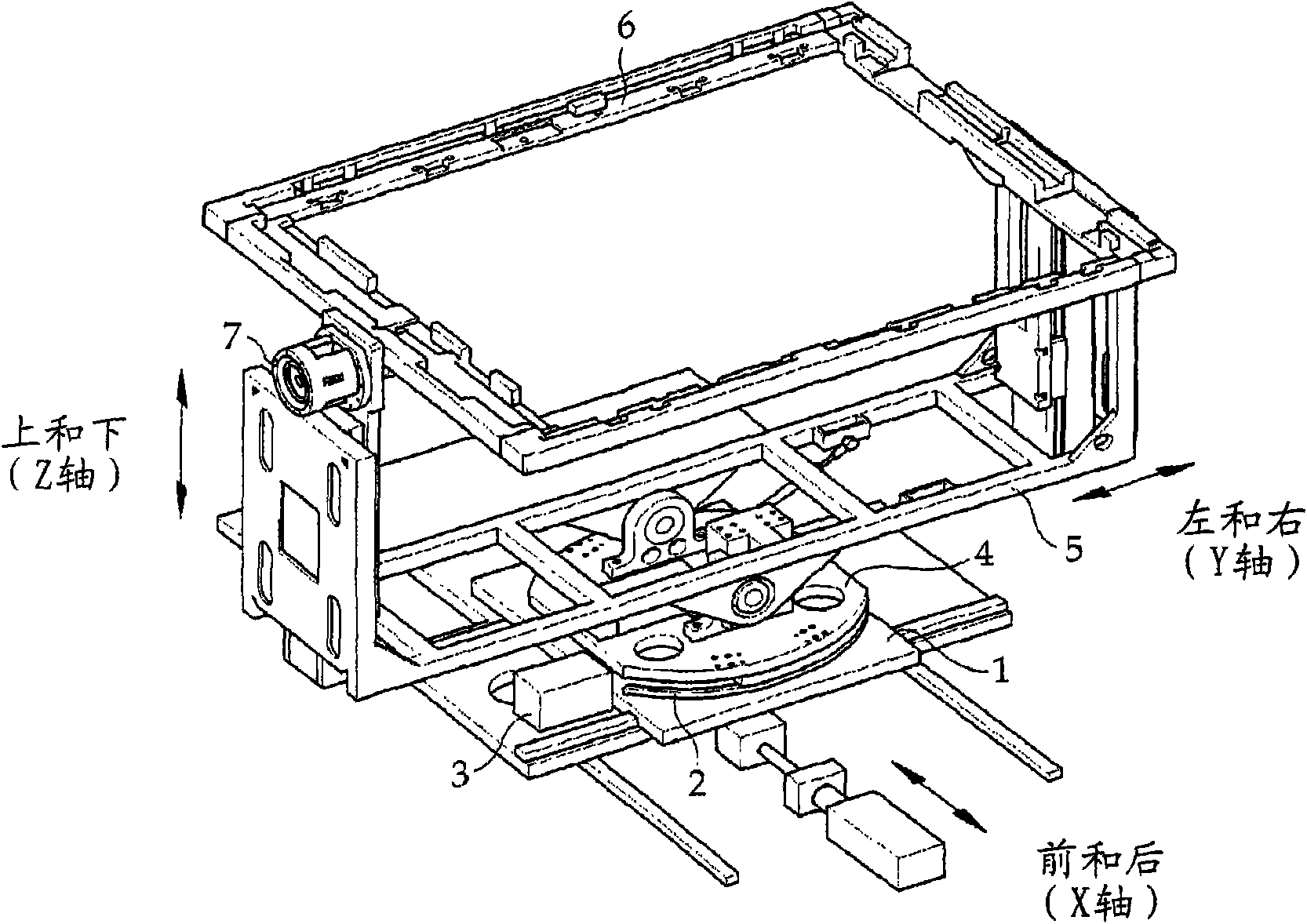

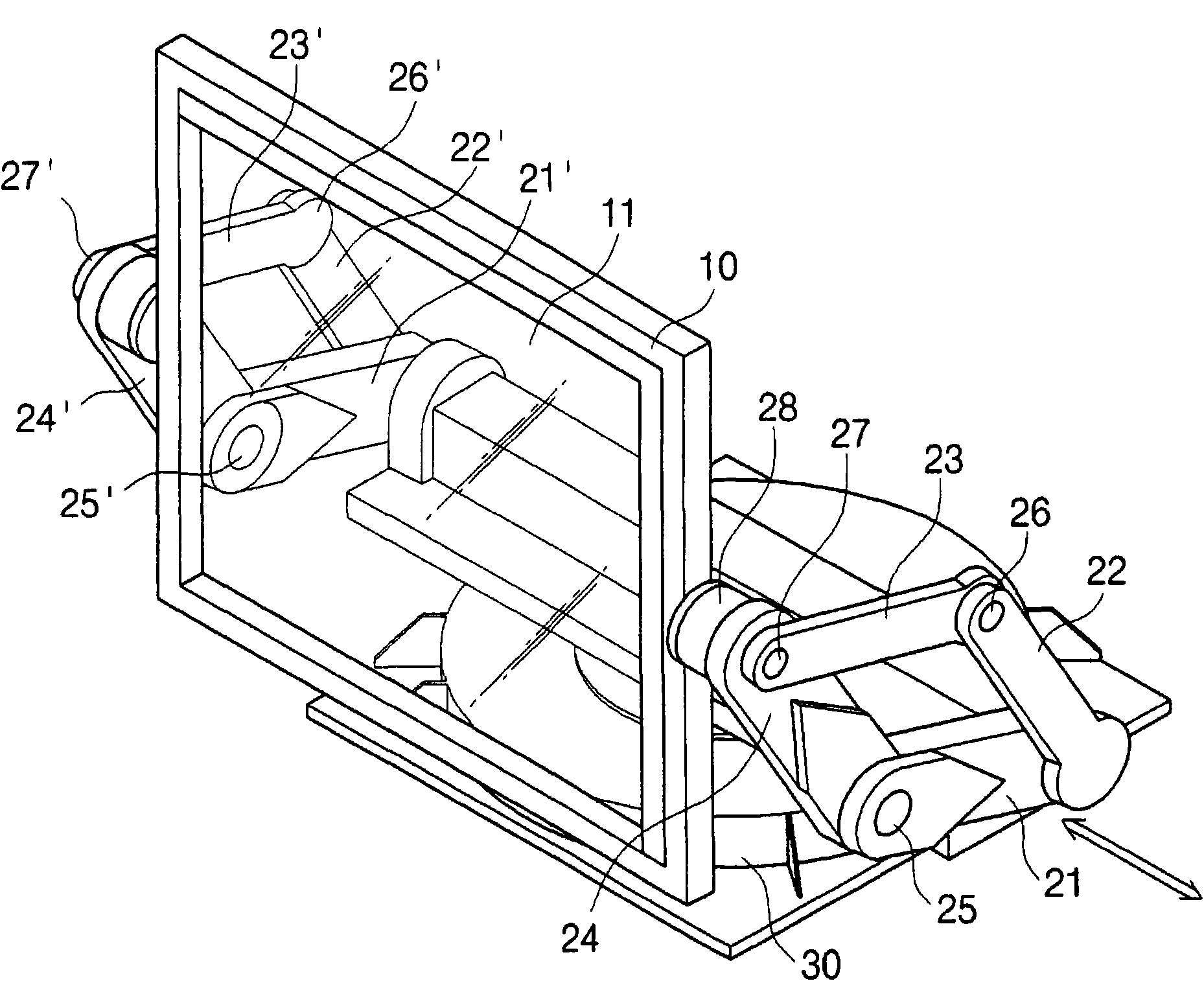

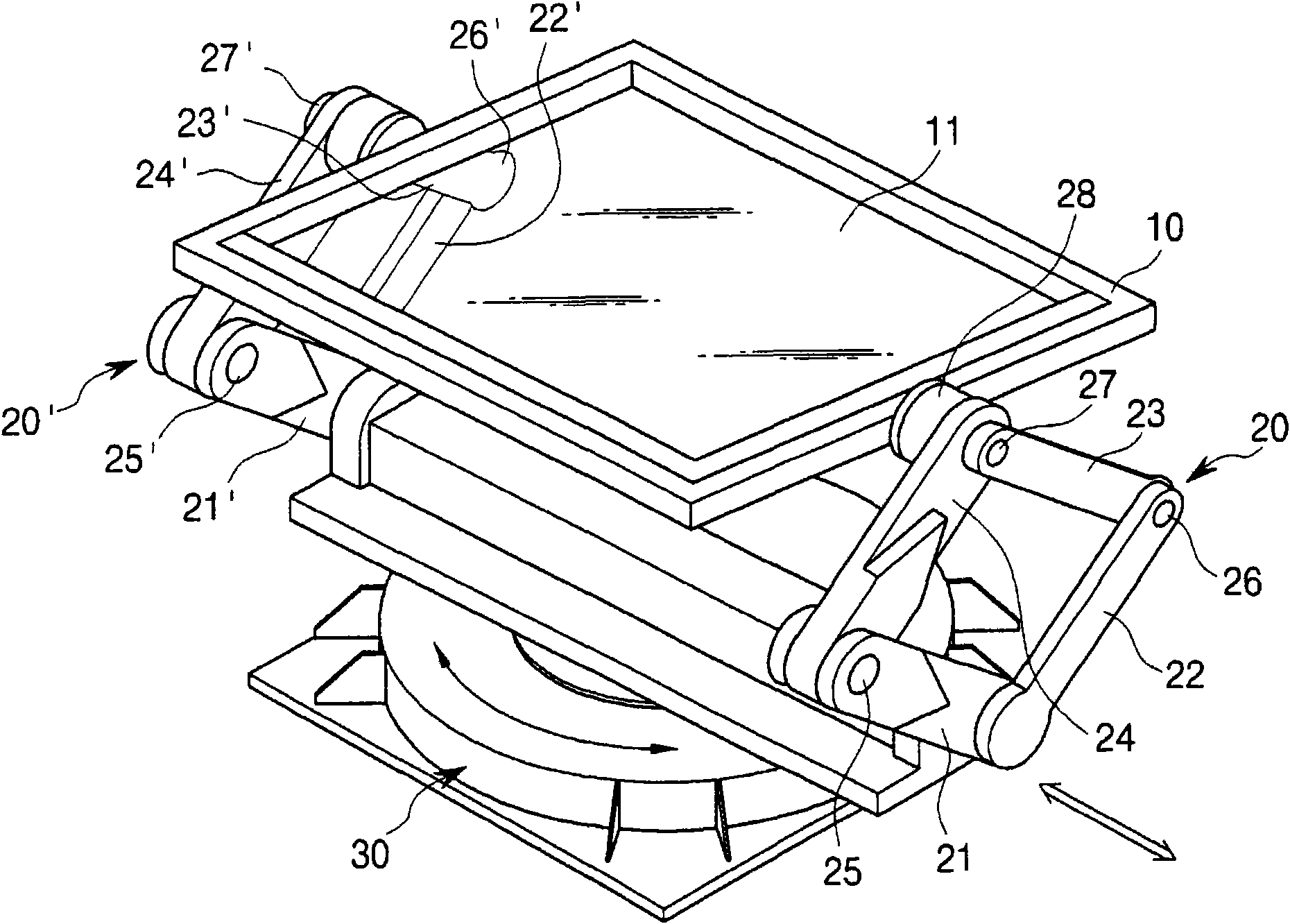

[0017] Reference Figure 2a with 2b , The macro inspection apparatus for LCD glass according to the present invention includes an LCD glass holder 10, a pair of parallel hinged connection units 20 and 20' for supporting the side surface of the glass holder 10, a rotating connection unit 20 and A 20' rotating unit 30, a traveling axis for guiding the left and right linear movement of the macroscopic inspection equipment, and a controller for controlling the position of the LCD glass holder.

[0018] As LCD glass becomes larger, the macro inspection equipment becomes larger. Therefore, both sides of the LCD glass holder of the large-scale macro inspection device are supported to form a stable structure of the inspection device. Such as Figure 2a with 2b As shown, a pair of connecting units 20 and 20' having a parallel hinged connection structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com