Construction technology for pouring concrete of walls on two sides of deformation joint

A construction technology, concrete technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of small construction area, difficult construction, difficult demolition, etc., and achieve the effect of high quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

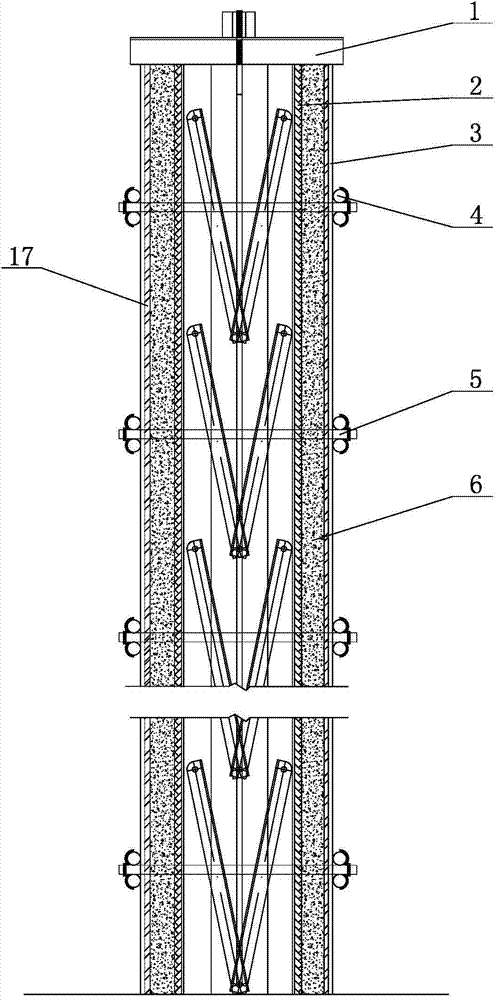

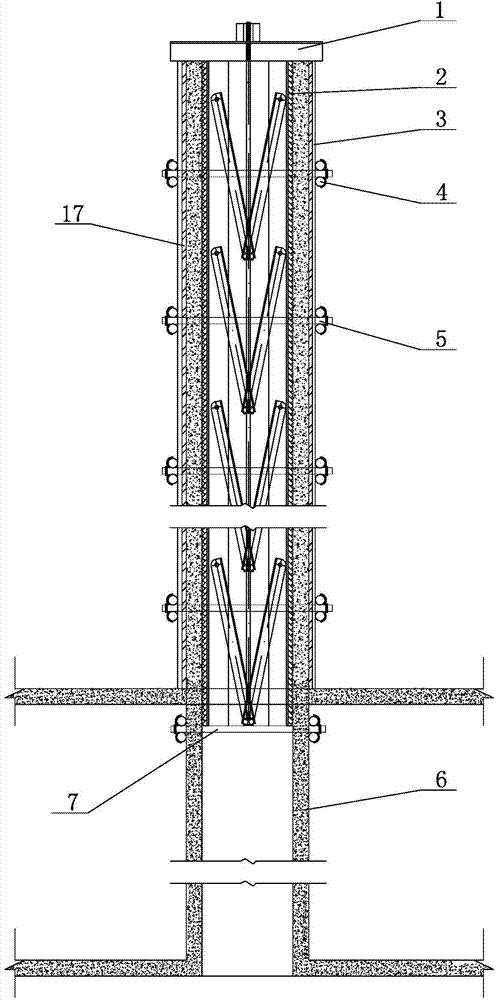

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as Figure 1 ~ Figure 4 As shown, the wall concrete pouring construction technology on both sides of the deformation joint of the present invention comprises the following steps:

[0028] 1) Steel skeleton construction;

[0029] 2) Install the wall panel thickness control support: use the shear wall steel bar positioning fixture to be clamped between the two horizontal bars of the steel skeleton, and the positioning fixtures between the adjacent horizontal bars are inserted into the space, and the positioning fixtures in the same column The distance between them is not more than 1000mm;

[0030] 3) Positioning and setting out: release the inner and outer edge lines of the walls on both sides of the deformation joint respectively;

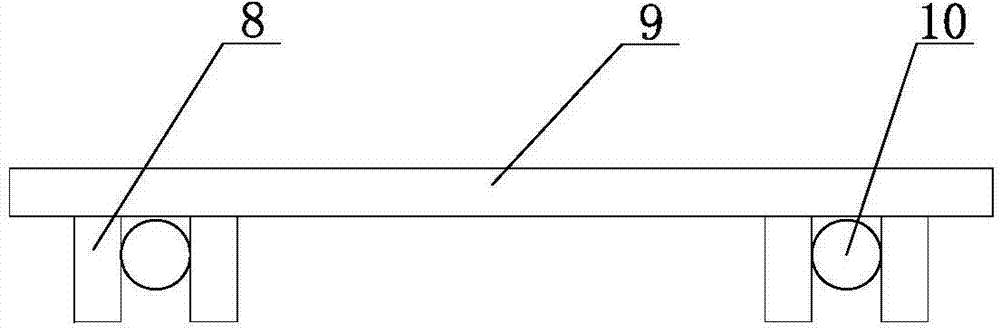

[0031] 4) Install the bottom interior wall formwork and the scissor-type connecting rod keel support system: install the interior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com