Patents

Literature

99results about How to "Save template" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method for large-area concrete weighbridge

ActiveCN102691401AOvercome the technical problem that the flatness is difficult to controlOvercome the problem of too much usageFlooringWater flowEngineering

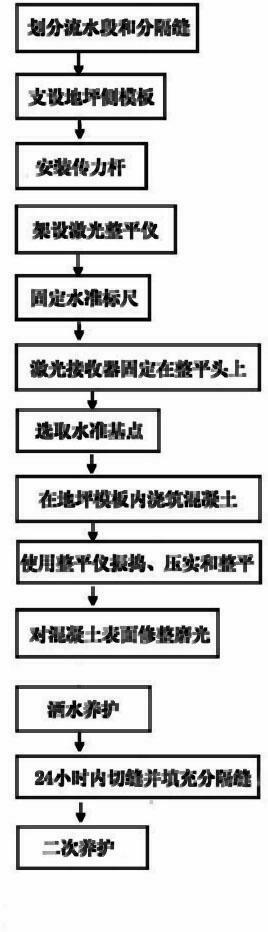

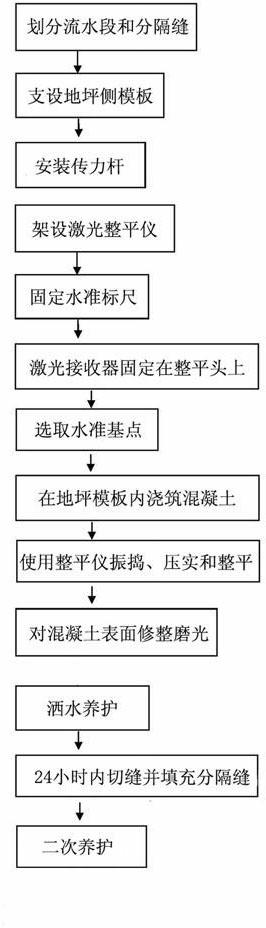

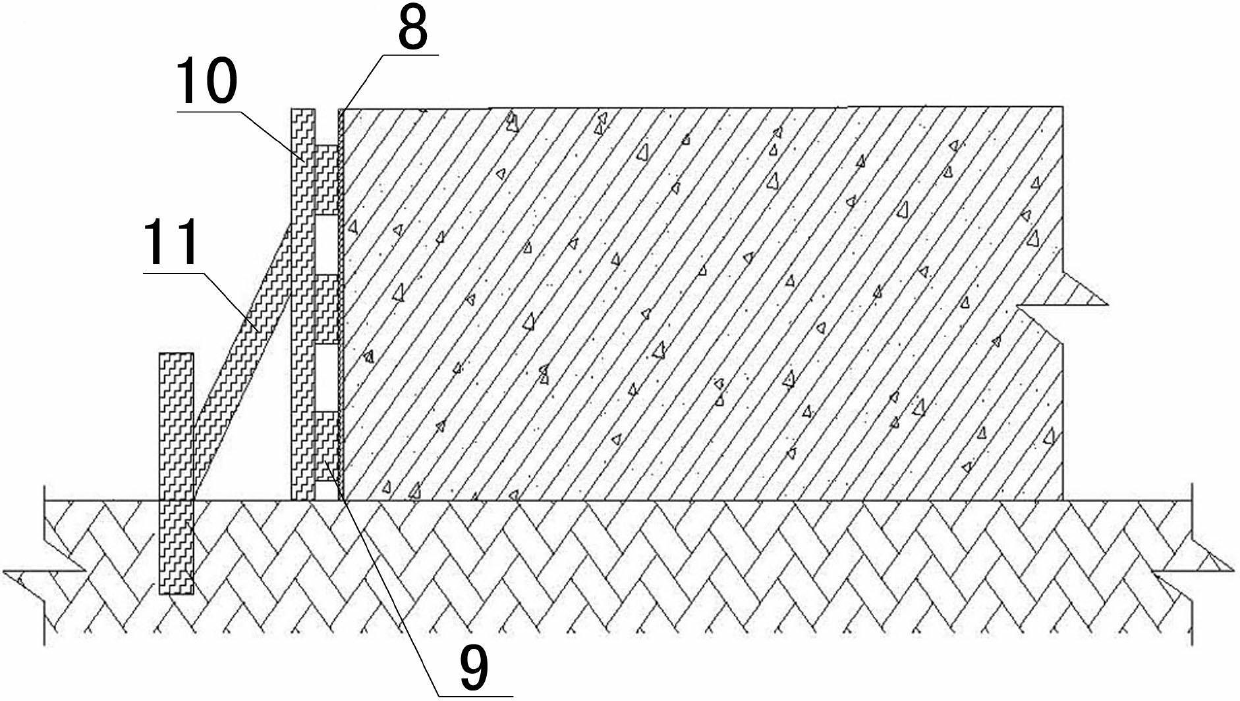

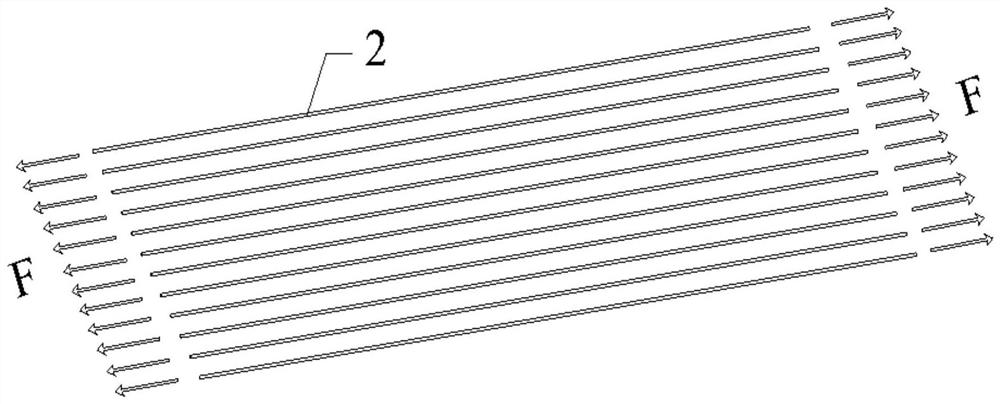

The invention discloses a construction method for a large-area concrete weighbridge. The construction method comprises the steps of: dividing the locations of a construction water flowing section and a construction separation joint, erecting a weighbridge side template, installing a force transmission rod at a junction of the water flowing section, erecting a laser leveller, fixing a levelling staff, selecting a levelling base point, pouring concrete in a space surrounded by weighbridge templates, vibrating, compacting and levelling the weighbridge by the leveller, finishing surface conditioning and polishing of the concrete weighbridge before the final solidification of the concrete, maintaining the concrete weighbridge, cutting the construction separation joint within 24h, stuffing the construction separation joint and carrying out secondary maintenance. By the construction method, the technical problem that the whole levelling degree of the large-area weighbridge is very difficult to control is solved; the problems that the cost of later maintenance of the ground and the use quantity of the templates are very high since the construction joint of the large-area concrete weighbridge is very prone to breakage is solved; and the problems such as breakage along a warehouse dividing joint on the large-area concrete weighbridge, easy hollowing in the layered pouring of the weighbridge, easy cracking and the like are solved.

Owner:北京城建建设工程有限公司

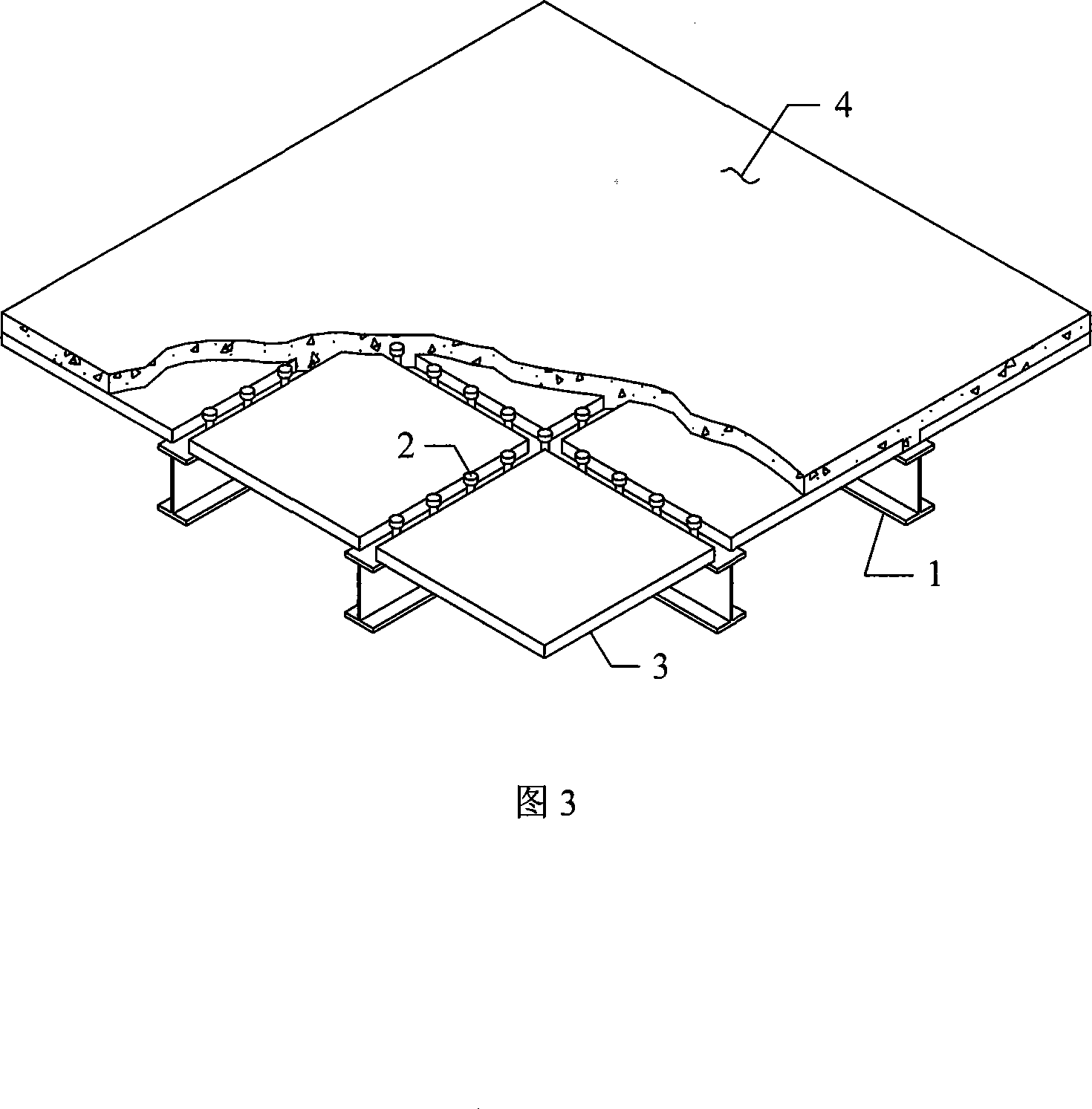

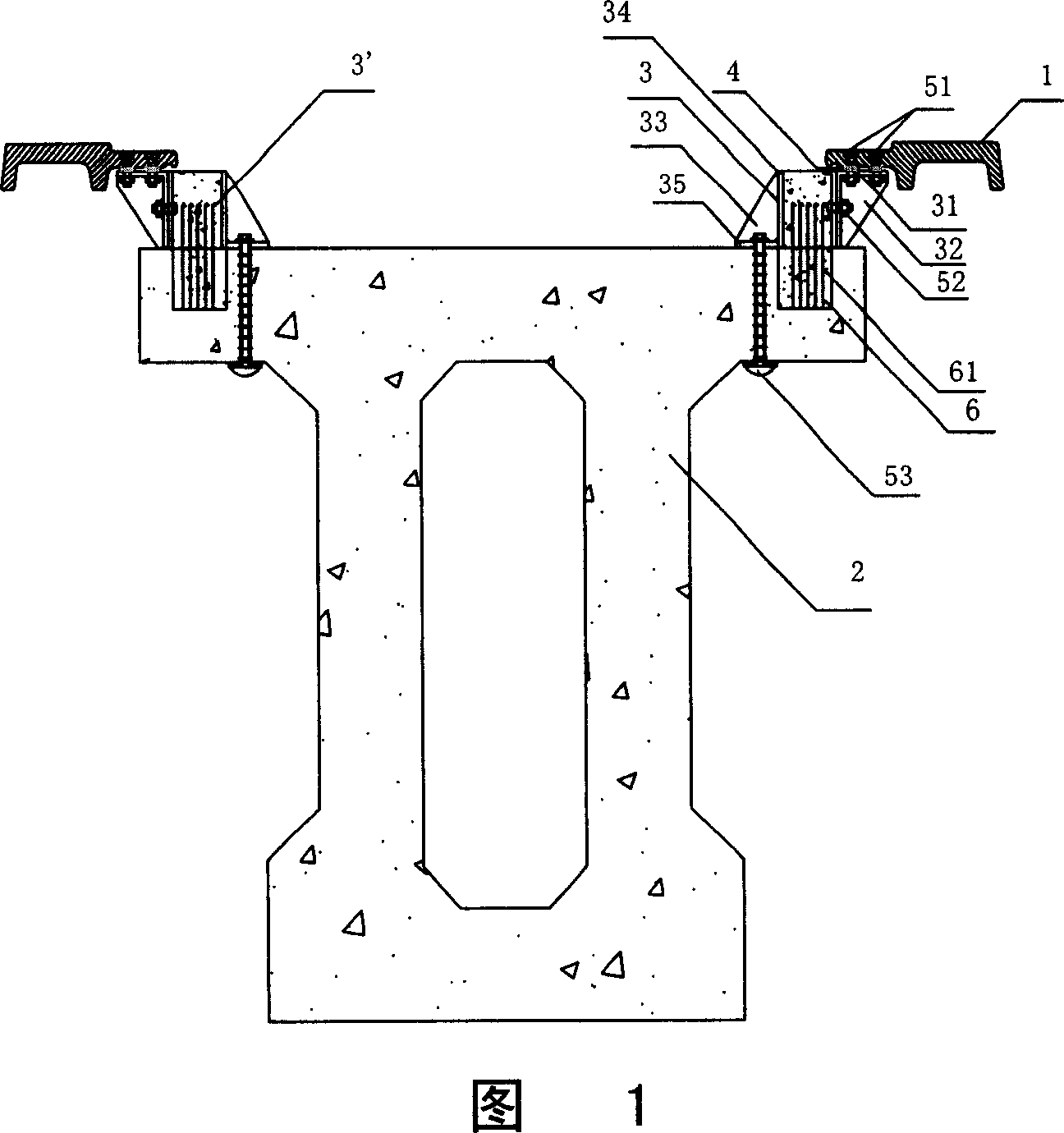

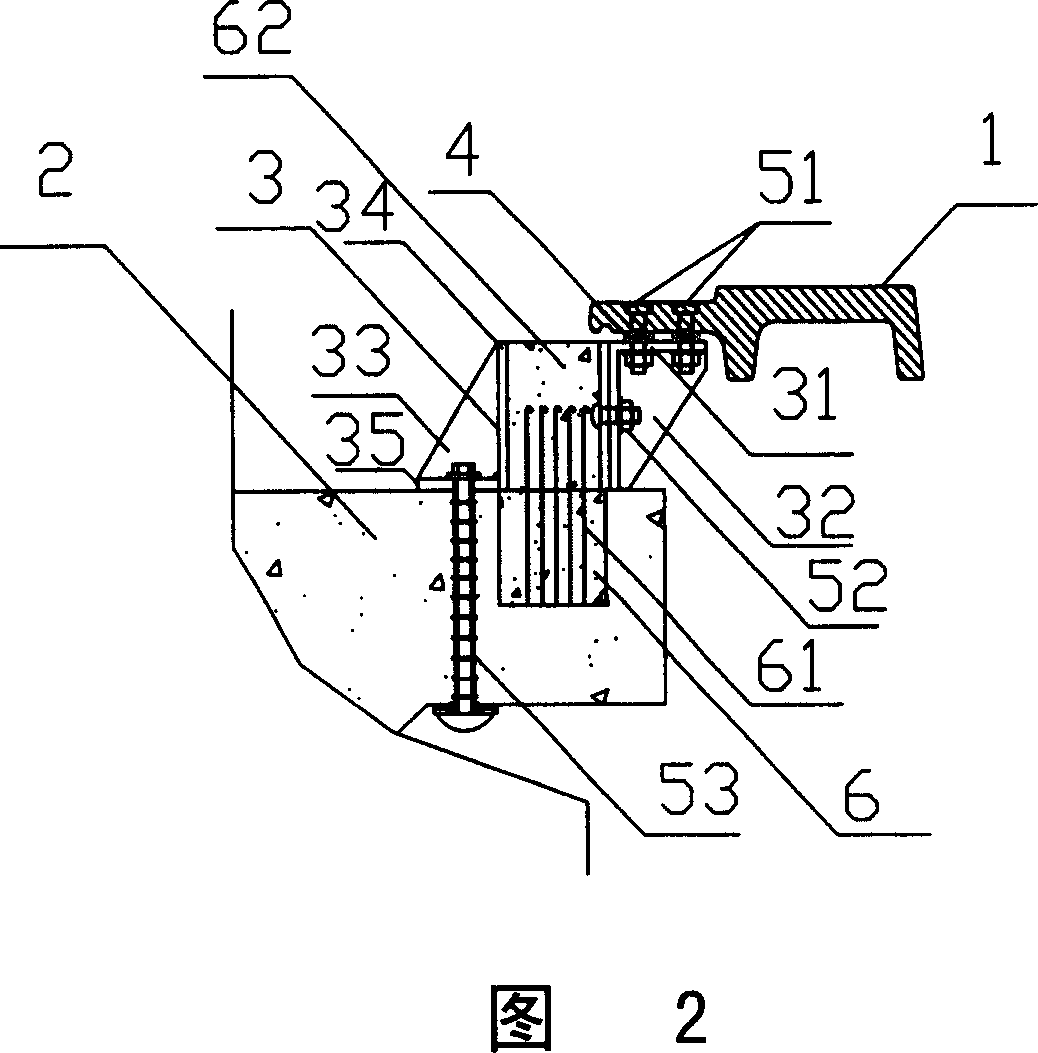

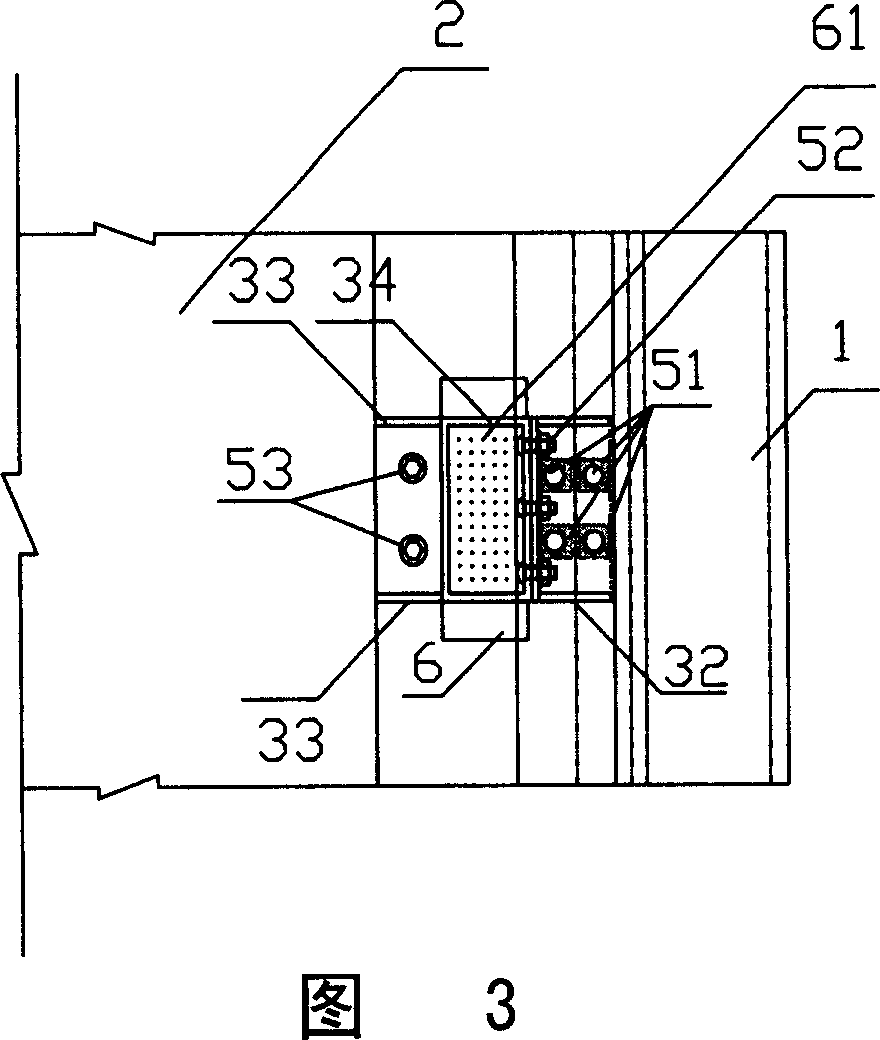

Bidirectional steel-stacked plate concrete composite building roof

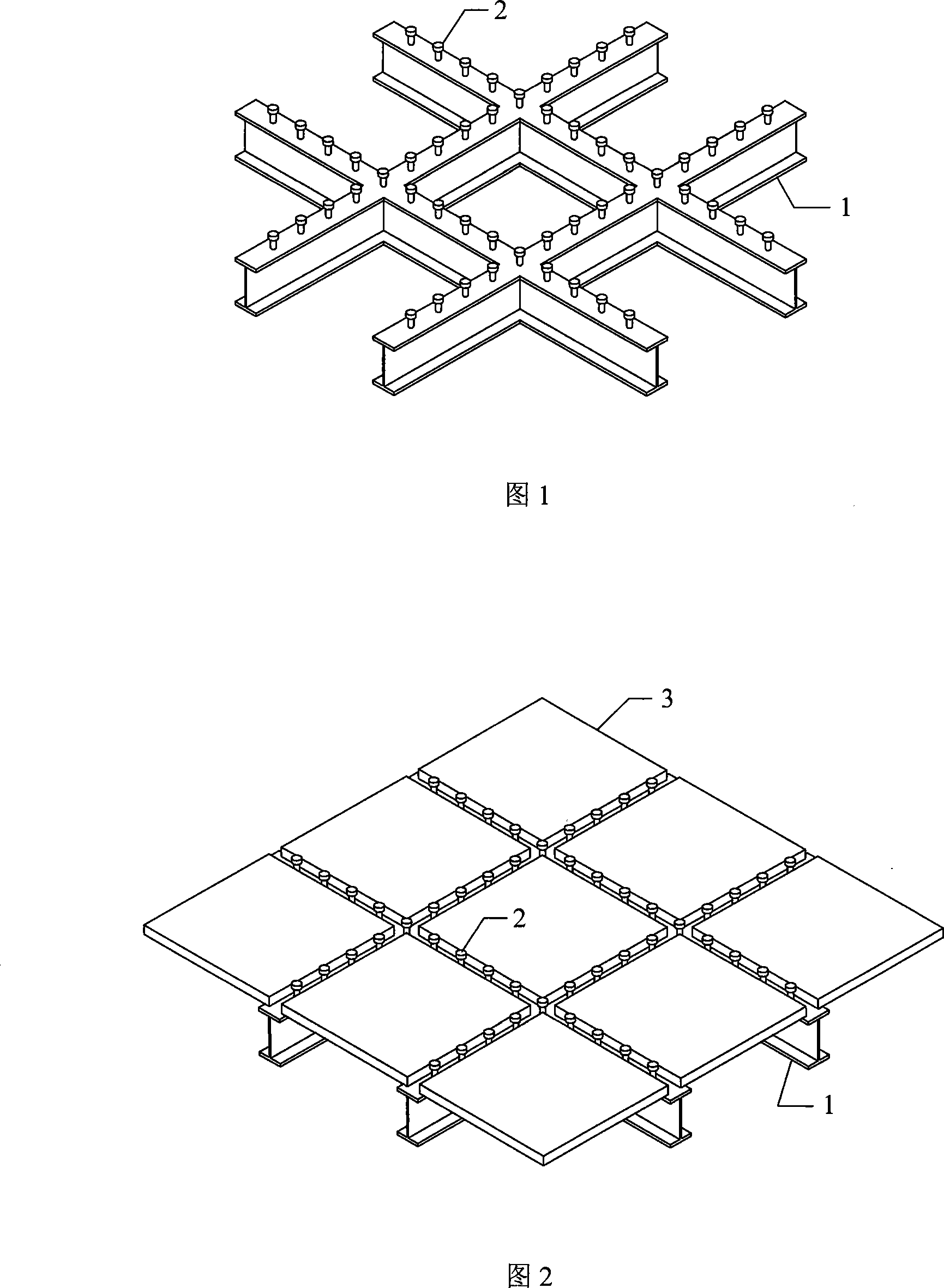

The invention relates to a dual-way steel-laminated slab concrete composite floor, belonging to a new large span floor structure, comprising a cross steel beam, a prefabricated slab and a later pouring concrete layer, wherein the cross steel beam is an I shaped cross section or box section steel beam; the prefabricated slab, a common reinforced concrete slab or a prestressed concrete slab, is held on the cross steel beam and covered on the grids between the steel beams; the later pouring concrete layer is concrete poured on the prefabricated slab and the steel beam. The invention has the advantages of low structure height, high bearing capacity, stiffness, bilateral support effect, saved forming procedure and formwork, reduced the wet work amounts of site concrete, favorableness to the three-dimensional construction, and shortened construction period.

Owner:TSINGHUA UNIV

Track structure of magnetic floating traffic and manufacturing method therefor

The invention provides a track structure of magnetic floating traffic, comprising a track beam, a track at two sides of the upper face of the track beam, and a connecting structure connecting aforementioned two parts, wherein the connecting structure comprises a fixer and a block between the track beam and the track as one structure connector. The invention also provides a relative production. The invention has uniform track beam type, saved template, reduced production complexity, easy track adjustment via arranging the curvature track all on the block, with simple method and low cost. And the invention uses industry tool to form a track distributor to position the track, thereby adjusting the track linearity easily and improving working efficiency.

Owner:TONGJI UNIV

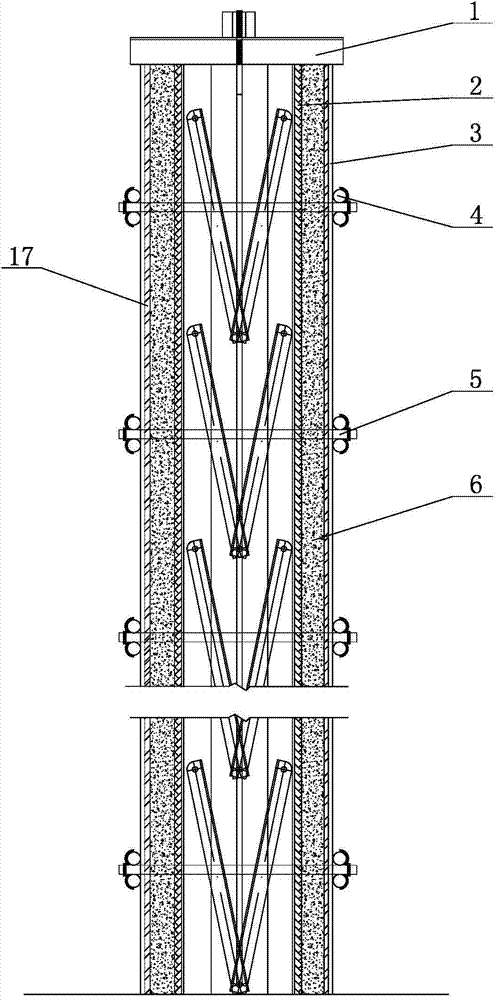

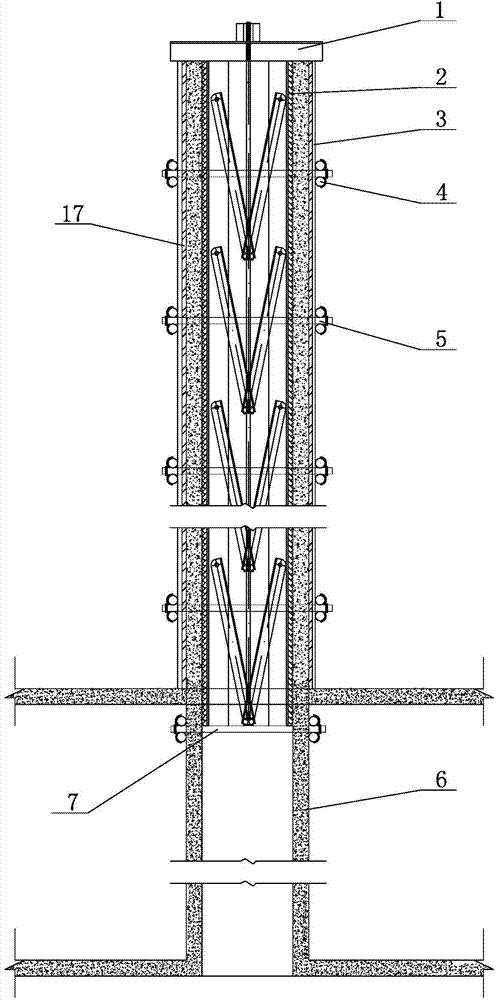

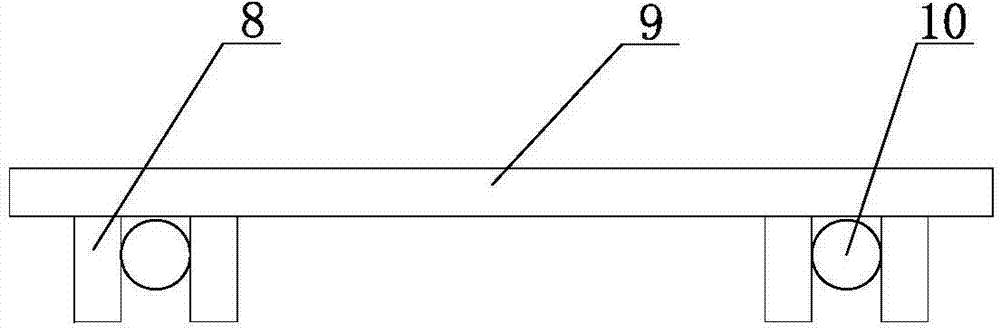

Construction technology for pouring concrete of walls on two sides of deformation joint

The invention belongs to the field of constructional engineering and particularly relates to a construction technology for pouring concrete of walls on two sides of a deformation joint. The construction technology comprises the following steps of 1 performing steel bar framework construction; 2 installing a wall board thickness control support; 3 performing positioning and paying-off; 4 installing a bottom-layer interior wall template and a scissors type connecting rod keel supporting system; 5 installing a wall outer-side template and a keel supporting system; 6 pouring the concrete; 7 template removal; 8 pouring the concrete of the walls on two sides of the upper-layer deformation joint; 9 repeating the step 8 till all of required floor pouring is finished. The construction technology is simple, convenient and efficient. Materials are saved. The quality accuracy is high. The root portion position control is good.

Owner:DONGHAI CONSTR GRP

Airbag core mold component cast hollow floor construction method

InactiveCN105908887AMulti-building use spaceFlexible layoutFloorsBuilding material handlingSupporting systemSurface layer

The invention provides an airbag core mold component cast hollow floor construction method, and belongs to the field of construction methods. The airbag core mold component cast hollow floor construction method comprises the following steps: I, erecting a support system; II, paving bottom tendons and rib tendons; III, mounting a fixing device, wherein the fixing device is used for fixing airbag core mold components; IV, paving the airbag core mold components, and fixing the airbag core mold components through the fixing device; V, paving surface-layer reinforcing steel ribs; VI, casting concrete. By adopting the construction method, the self weight of floors can be reduced, the construction cost can be lowered, and the utilization rate of lands can be increased.

Owner:CHONGQING DAOTONG BUILDING MATERIAL CO LTD

Steel plate concrete column and construction method

InactiveCN102061780AImpact resistantFatigue resistantStrutsBuilding material handlingShock resistanceRebar

The invention discloses a steel plate concrete column and a construction method, and the method is characterized in that a plastic skin aluminum core lead wire is built in on a steel bar before concrete is poured, unhardened concrete is heated by utilizing an electromagnetic inductive method, and when the concrete is hardened, the shrinkage of a steel plate is greater than that of the concrete, i.e., prestressing force is applied to a steel tube by the concrete. Before the concrete is poured, an inbuilt conducting tube is connected with an anode power supply, the steel bar is connected with a negative power source, the power source is switched on in the process of pouring the concrete, and free water in the concrete is discharged through different electric potential distributions formed in the concrete. The steel plate concrete column provided by the invetnion has the advantages of high intensity, light weight, good plasticity, shock resistance, fatigue resistance, and the like; and the construction method provided by the invention has the characteristics that templates are omitted, labor and materials are saved, the construction is convenient, no season restriction exists, and the like.

Owner:虞建放

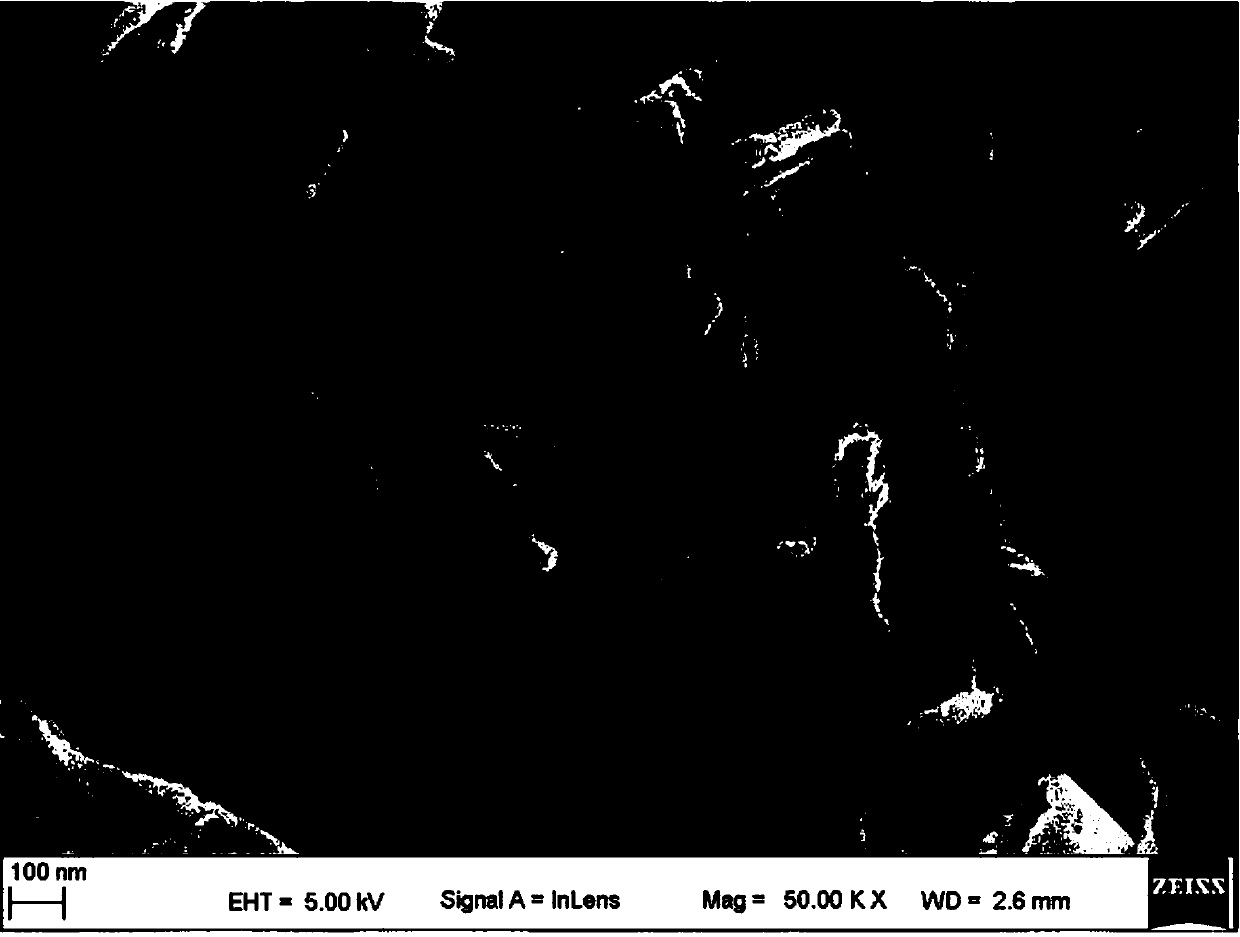

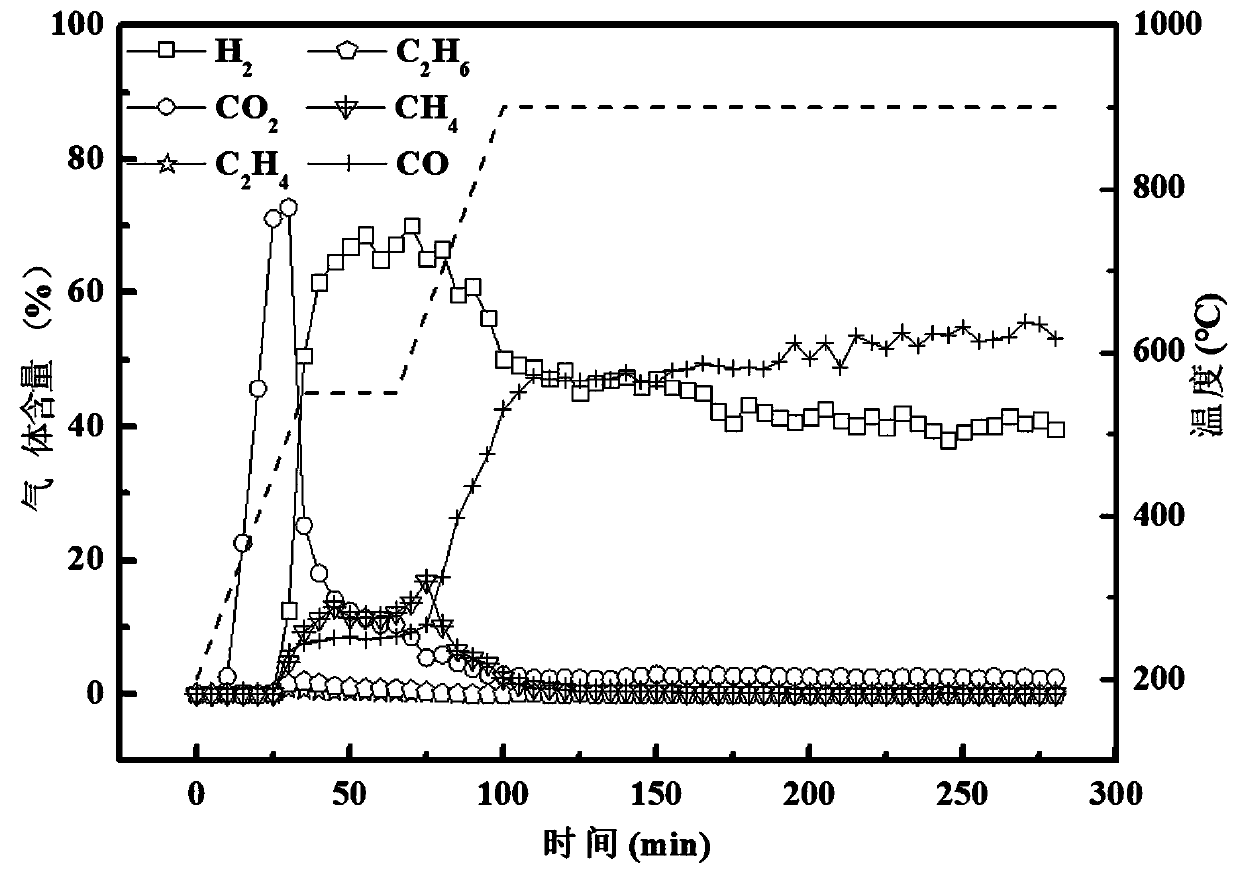

Preparation and purification method of coal-based carbon nanotubes

Owner:TAIYUAN UNIV OF TECH

Prefabricated concrete bottom plate with stiffening cold-bending thin wall type steel ribs and made composite slab

InactiveCN108468401AImprove bearing capacityEasy constructionConstruction materialFloorsHigh strength concreteComposite slab

The invention discloses a prefabricated concrete bottom plate with stiffening cold-bending thin wall type steel ribs and a made composite slab. The prefabricated sconcrete bottom plate comprises prefabricated bottom plate transverse structural reinforcement, prefabricated bottom plate longitudinal stress reinforcement, longitudinal stiffening cold-bending thin wall type steel ribs and stiffening cold-bending thin wall type steel rib structural reinforcement; the two longitudinal stiffening cold-bending thin wall type steel ribs same in shape penetrate through holes reserved in the lower portions of the ribs through the transverse structural reinforcement and are connected with the upper portions of the two ribs through the stiffening cold-bending thin wall type steel rib structural reinforcement, and the prefabricated bottom plate transverse structural reinforcement, the prefabricated bottom plate longitudinal stress reinforcement and the longitudinal stiffening cold-bending thin walltype steel ribs are embedded in high-strength concrete to form the prefabricated concreted bottom plate. Accordingly, manufacturing is easy and convenient, rigidity is large, industrial production isfacilitated, and the made composite floor with the stiffening cold-bending thin wall type steel ribs has the advantages that convenience is brought to construction, the bearing capacity is large, theanti-seismic property is good, forms are saved, the floor mass is reduced, and the floor heat preservation, therm insulation and sound insulation functions are added.

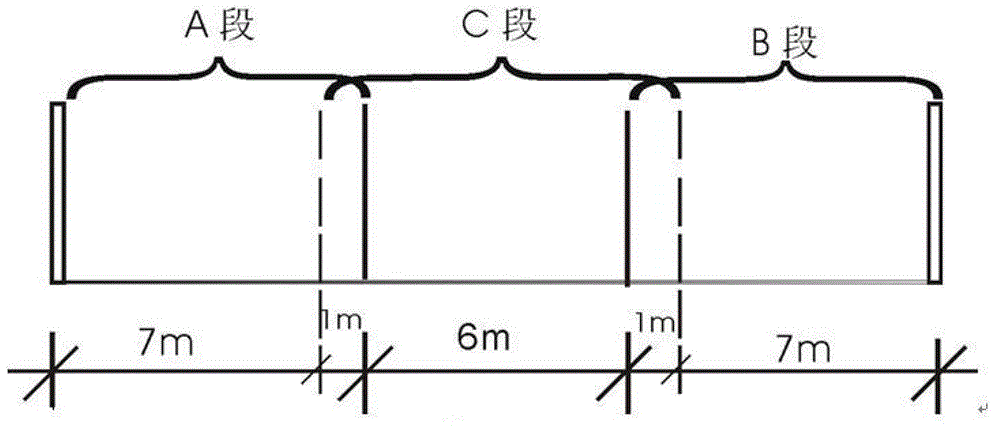

Underground engineering mixed construction method

ActiveCN103334452AShorten the construction periodSave formwork and support systemArtificial islandsUnderwater structuresRebarReinforced concrete

The invention discloses an underground engineering mixed construction method which comprises the following steps that (1) the surface of a road is transversely divided into a section A, a section B and a section C, the section A is sealed, reinforced concrete construction is carried out on the section A, and an underground continuous wall is obtained; (2) the surface layer earthwork is excavated to obtain a basement top slab of the section A; (3) earth is backfilled to recover the traffic of the road face of the section A; (4) the section B is sealed, and reinforced concrete construction is carried out on the section B to obtain an underground continuous wall; (5) the surface earthwork is excavated to obtain a basement top slab of the section B; (6) earth is backfilled to recover the traffic of the road face of the section B; (7) the section C is sealed, the surface earthwork is excavated, and basement bottom slabs of the section A, the section B and the section C are obtained; (8) a basement top slab of the section C is obtained and connected with the top slab of the section A and the top slab of the section B; (9) earth is backfilled, and the road face traffic is recovered. By means of the underground engineering mixed construction method, efficient and safe construction on the road face is achieved, bi-directional traffic is achieved, and the problems that a cover and cut-top down method is limited by excavation depth and is low in excavation speed are solved.

Owner:李涛 +2

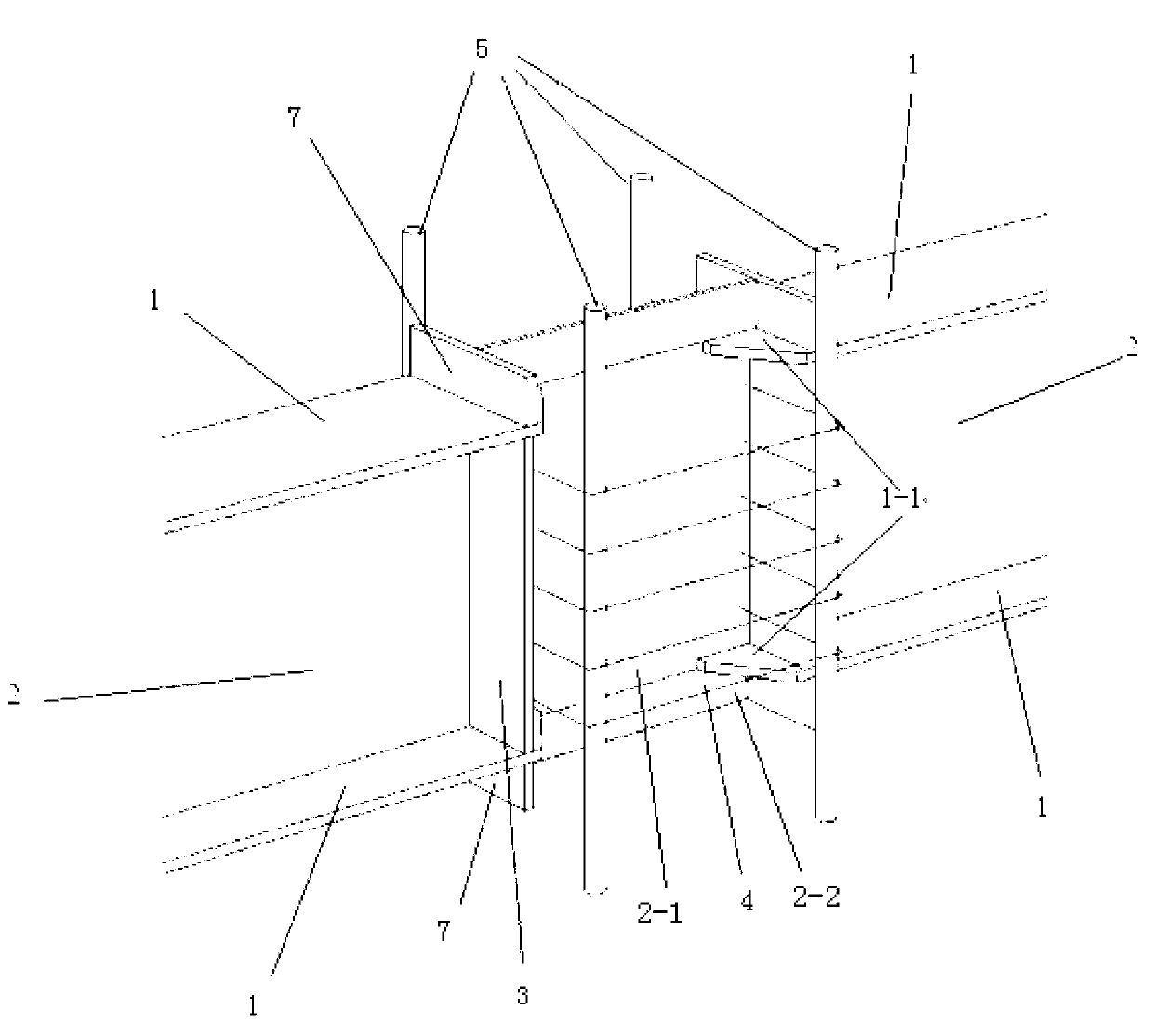

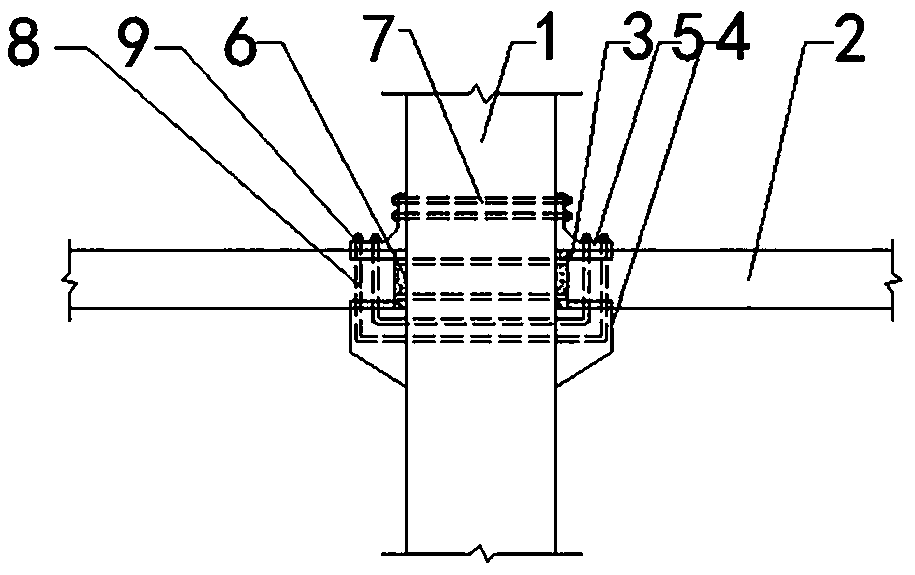

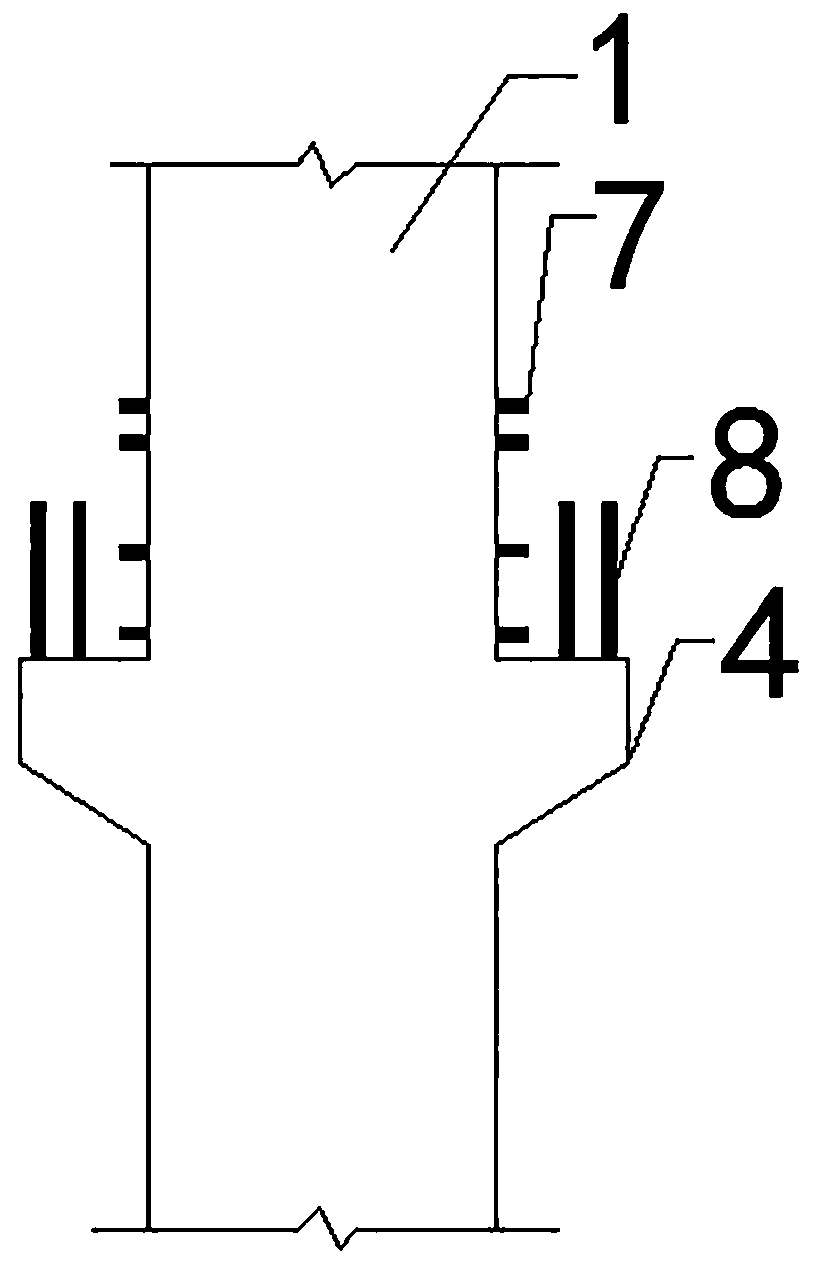

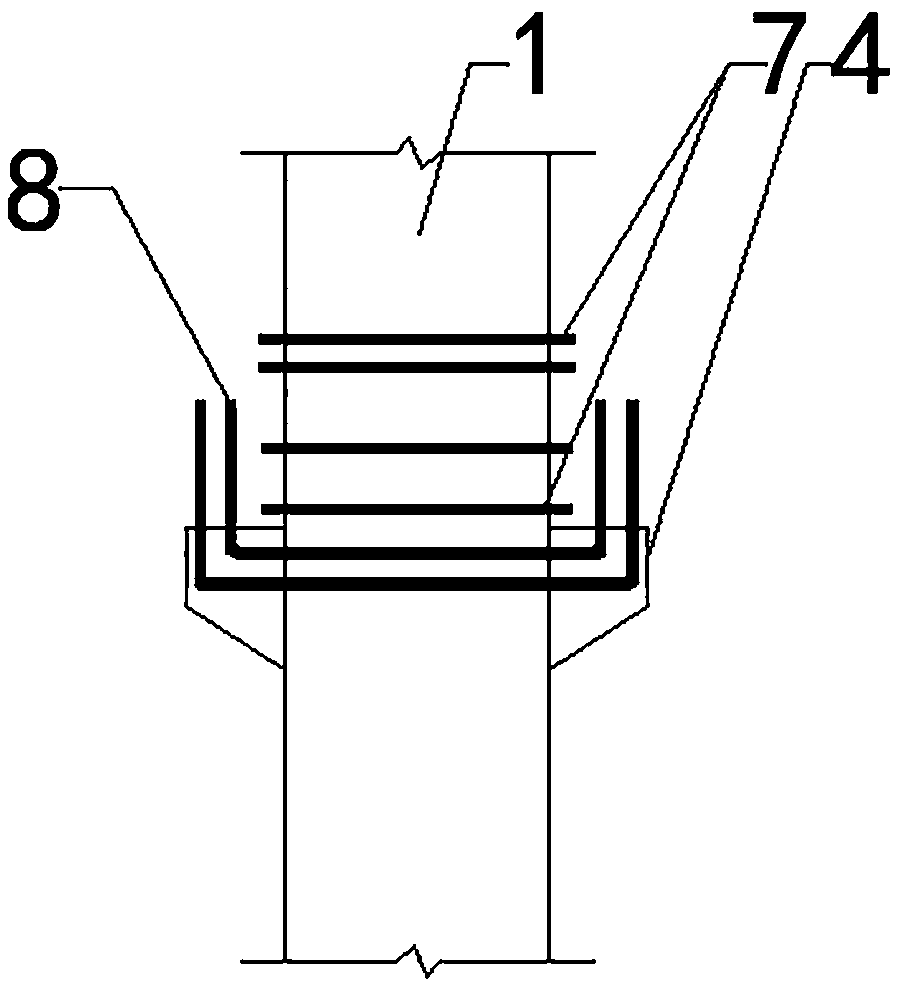

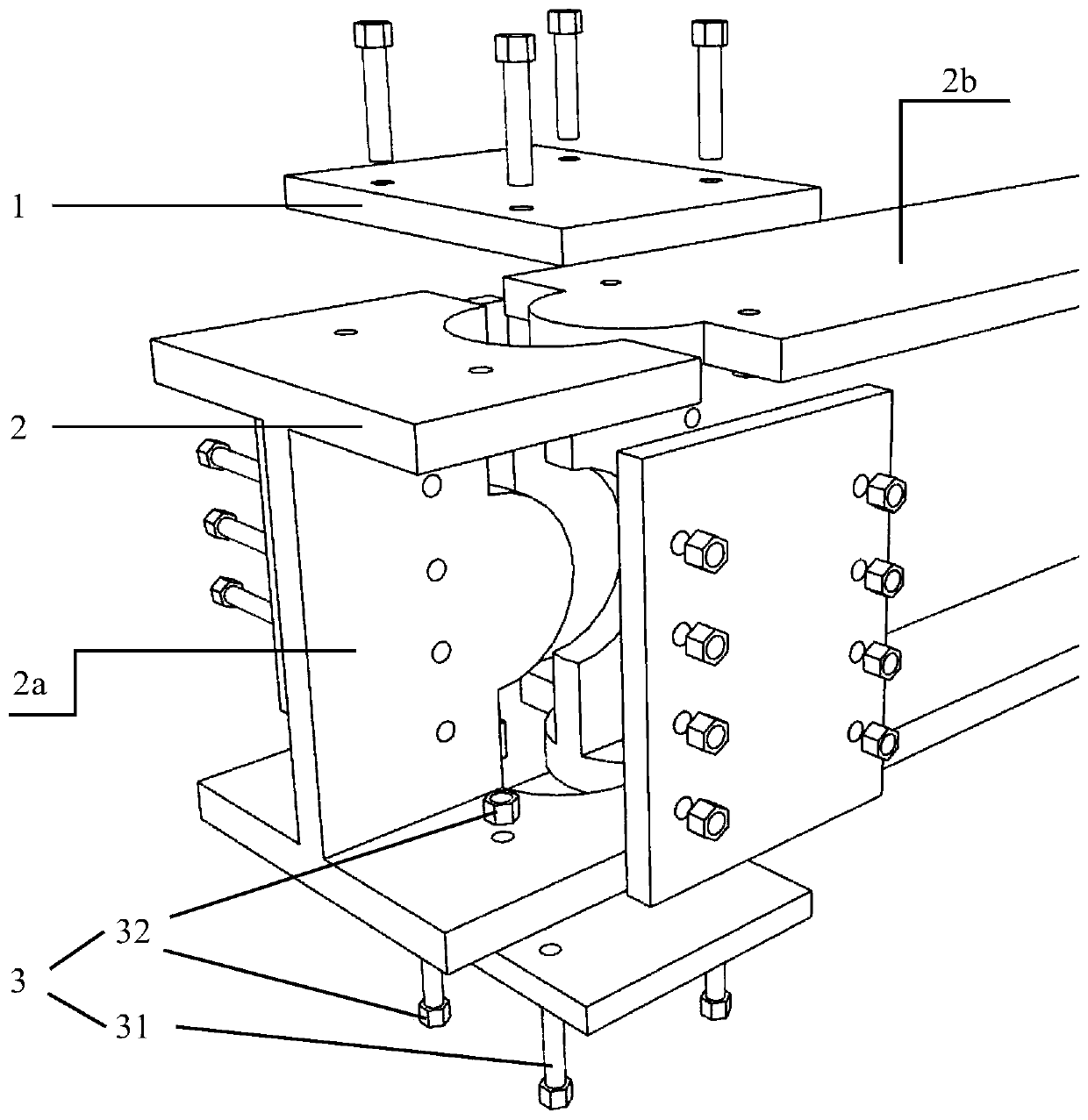

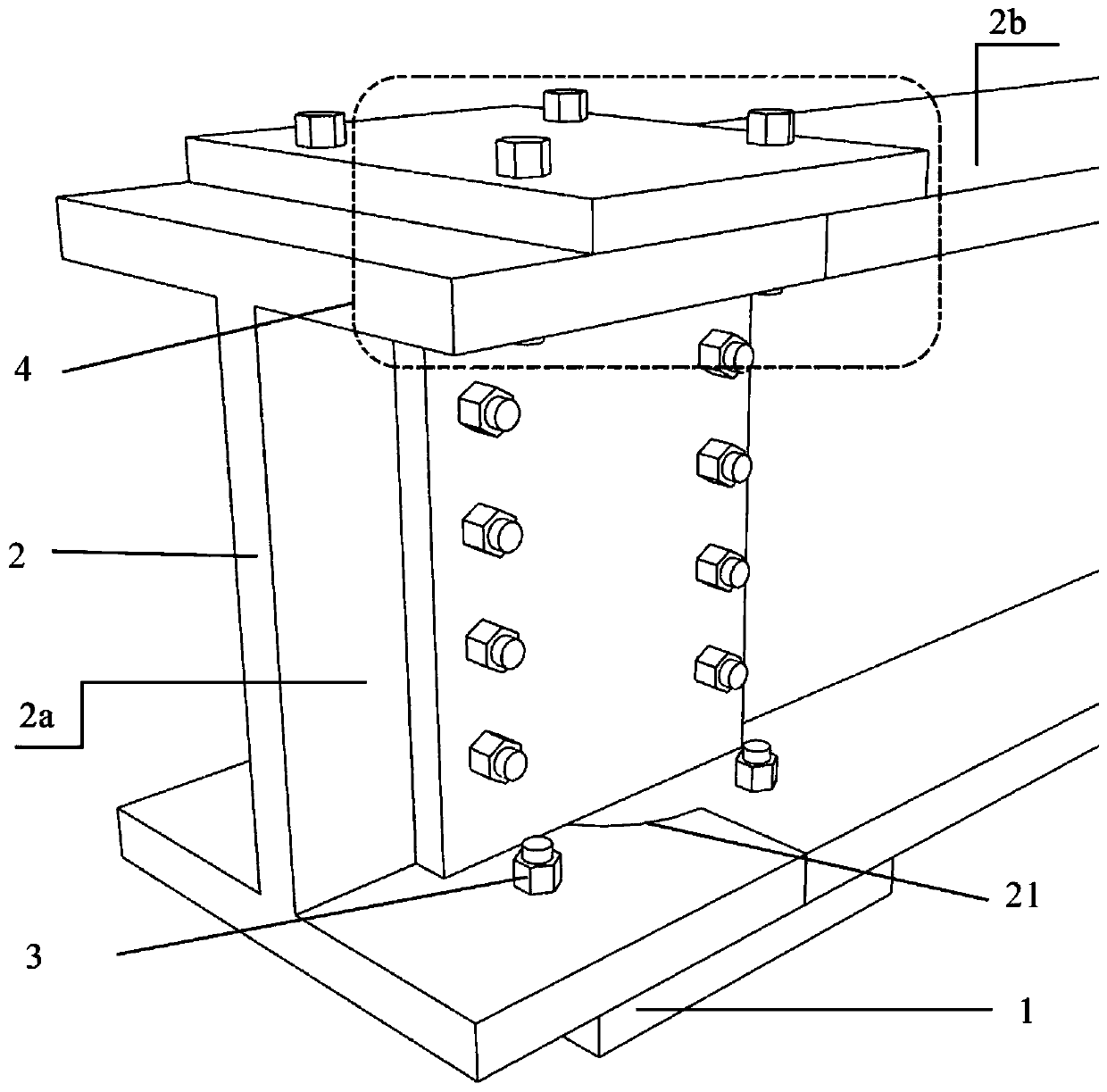

RCS (reinforced concrete structure) combined node with continuous webs and partially-cut flanges

InactiveCN102995755ALower the altitudeLose weightBuilding constructionsReinforced concrete columnSteel bar

The invention discloses an RCS (reinforced concrete structure) combined node with continuous webs and partially-cut flanges, comprising a reinforced concrete column, and a steel beam which vertically penetrates through the reinforced concrete column, wherein the steel beam is formed by vertically connecting a steel beam web with steel beam flanges on the two end parts; the reinforced concrete column is composed of a longitudinal reinforcement, a plurality of layers of horizontally-distributed stirrups clinging to and surrounding the longitudinal reinforcement, and inter-column pouring concrete, the steel beam flanges which vertically penetrate through the reinforced concrete column are partially cut off, the stirrups penetrate through a node web which is connected with the steel beam web, and surface bearing plates are vertically distributed at the both ends of the node web; and a core node is composed of the longitudinal reinforcement in the reinforced concrete column, the stirrups surrounding the longitudinal reinforcement, the two surface bearing plates, the node web and steel beam flange extending ends of the partially-cut steel beam flanges. The steel web at the core node is mainly used for bearing a shearing force, the steel beam flange extending ends and the surface bearing plates are used for restraining concrete at the core node, so that the anti-shearing bearing force of the node is greatly improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

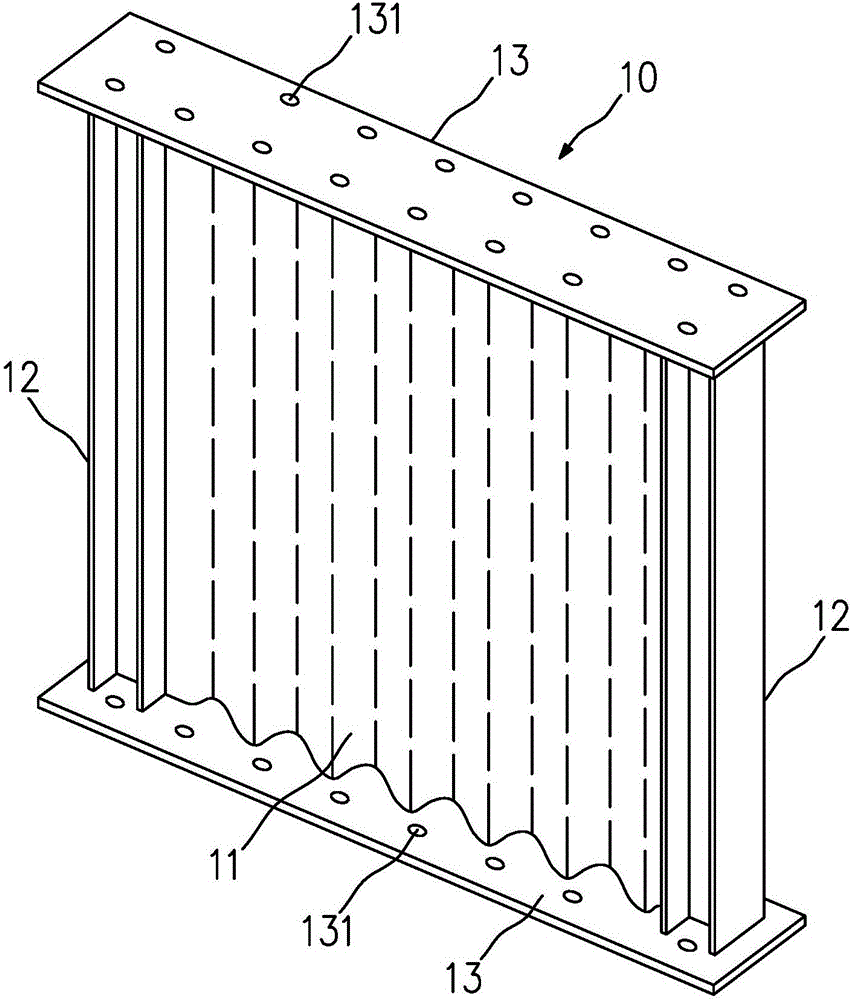

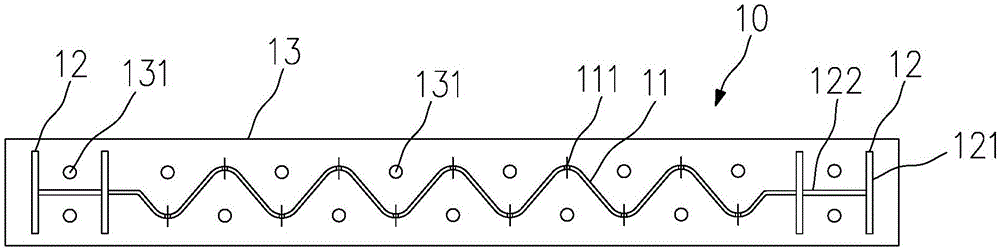

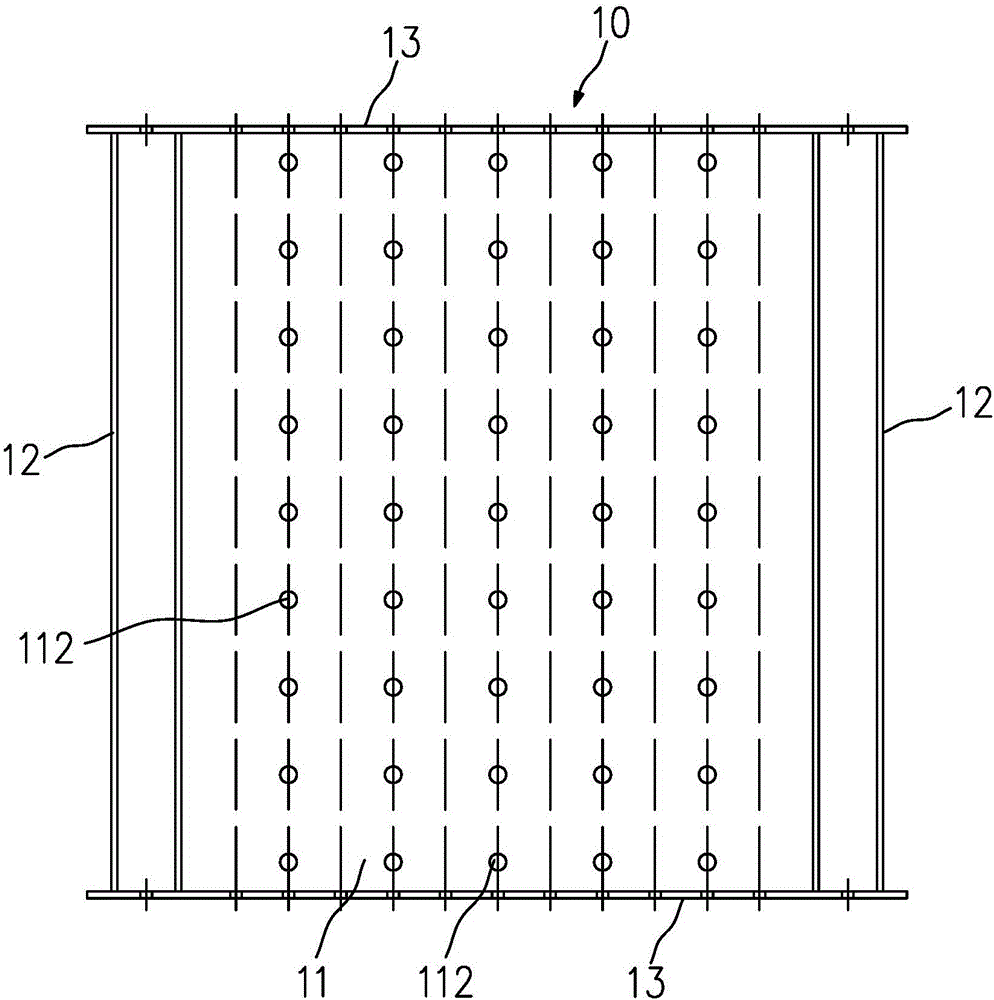

Antinode core-board precast concrete prefabricated composite wall

ActiveCN106193435AOvercome the thicknessOvercome the disadvantage of heavy weightConstruction materialWallsHorizontal forceFloor slab

The invention relates to an antinode core-board precast concrete prefabricated composite wall comprising an antinode core-board unit. The antinode core-board unit comprises an antinode core board, edge reinforcing columns and end boards; the board surface of the antinode core board is wavy; the edge reinforcing columns are fixedly arranged on two sides of the antinode core board, the length direction of the edge reinforcing columns is parallel to the direction of wave crests or wave troughs of the antinode core board, and the upper and lower ends of each edge reinforcing column are parallel to the upper and lower ends of the antinode core board; the end boards are respectively and fixedly arranged on the upper and lower sides of the antinode core board and the edge reinforcing columns; a reinforced concrete board covers the outer sides of the antinode core board and the edge reinforcing columns. The antinode core-board precast concrete prefabricated composite wall is high in field fabrication degree, fast in construction and high in industrialization and commercialization degree, and is more convenient to connect with steel beams and floor slabs. Advantages of various existing lateral force resistance members can be integrated in the composite wall, and the composite wall can bear vertical load as well as resist horizontal force and can play an important role in aseismic design of multi-story and super-high-rise building structure systems.

Owner:HEFEI UNIV OF TECH

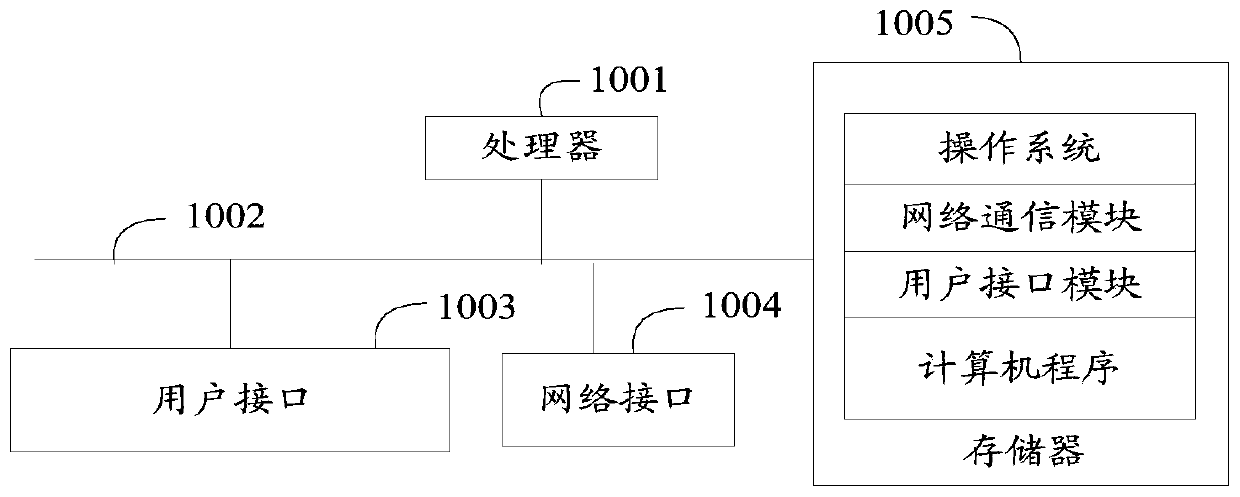

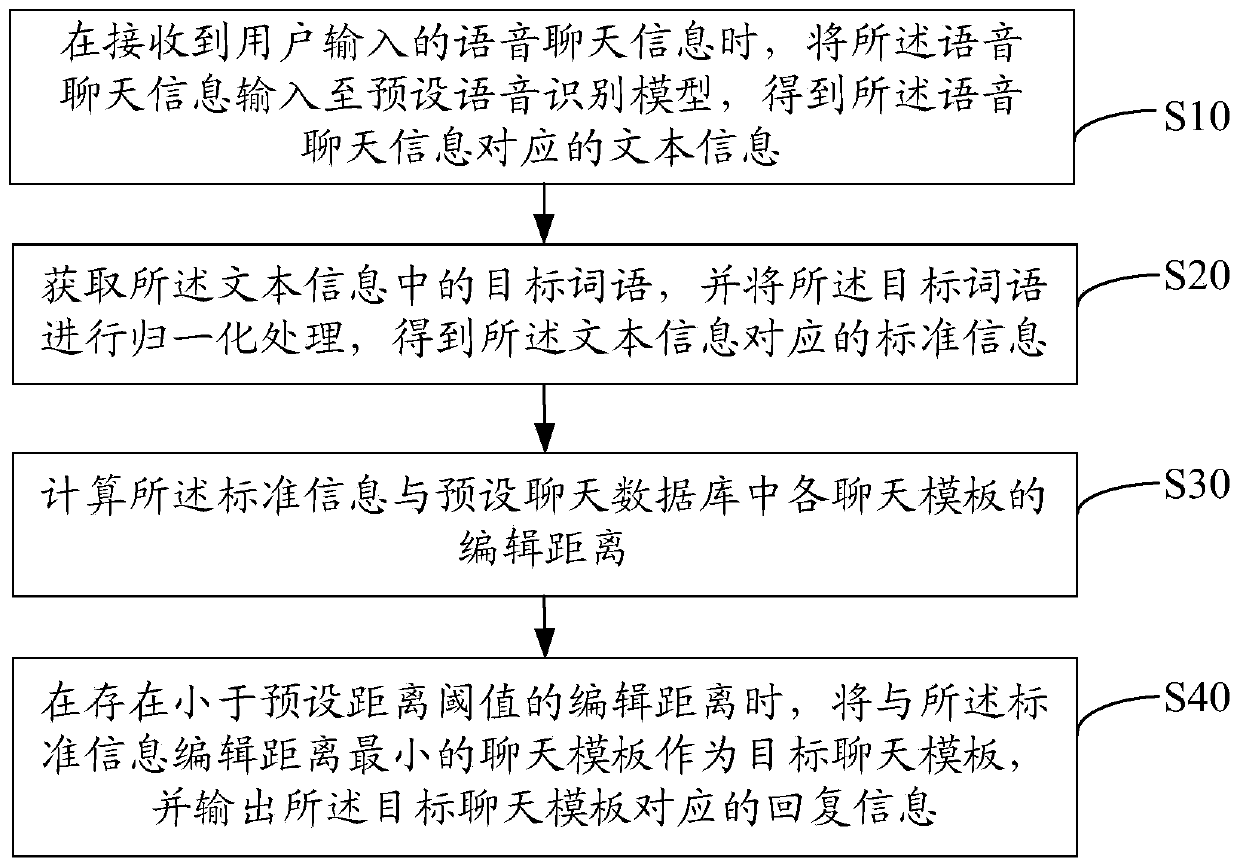

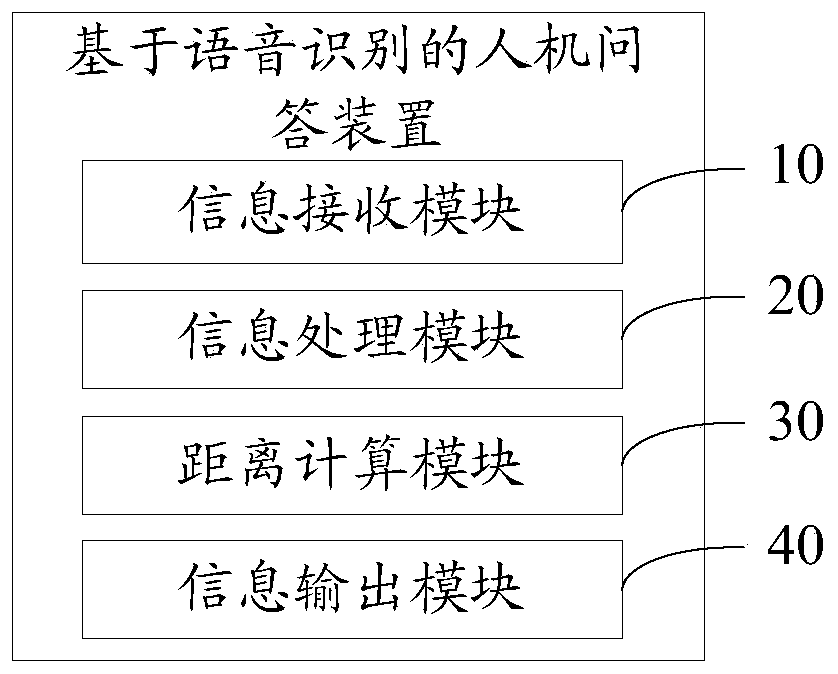

Voice recognition based man-machine question and answering method, device, equipment and storage medium

PendingCN109920415AReduce database templatesImprove search efficiencySpeech recognitionSpeech identificationSpeech sound

The invention discloses a voice recognition based man-machine question and answering method. The method comprises the following steps: inputting voice chat information to a preset voice recognition model when user input voice chat information is received, so as to obtain text information corresponding to the voice chat information; acquiring target terms from the text information, and normalizingthe target terms, so as to obtain standard information corresponding to the text information; calculating editing distances between the standard information and all chat templates in a preset chat database; taking a chat template, which has the smallest editing distance from the standard information, as a target chat template when an editing distance smaller than a preset distance threshold valueis present, and outputting answering information corresponding to the target chat template. The invention further discloses a voice recognition based man-machine question and answering device, equipment and a storage medium. According to the voice recognition based man-machine question and answering method, the device, the equipment and the storage medium, through processing the voice chat information of a user, a chat intent of the user is accurately recognized.

Owner:PINGAN CITY CONSTR TECH SHENZHEN CO LTD

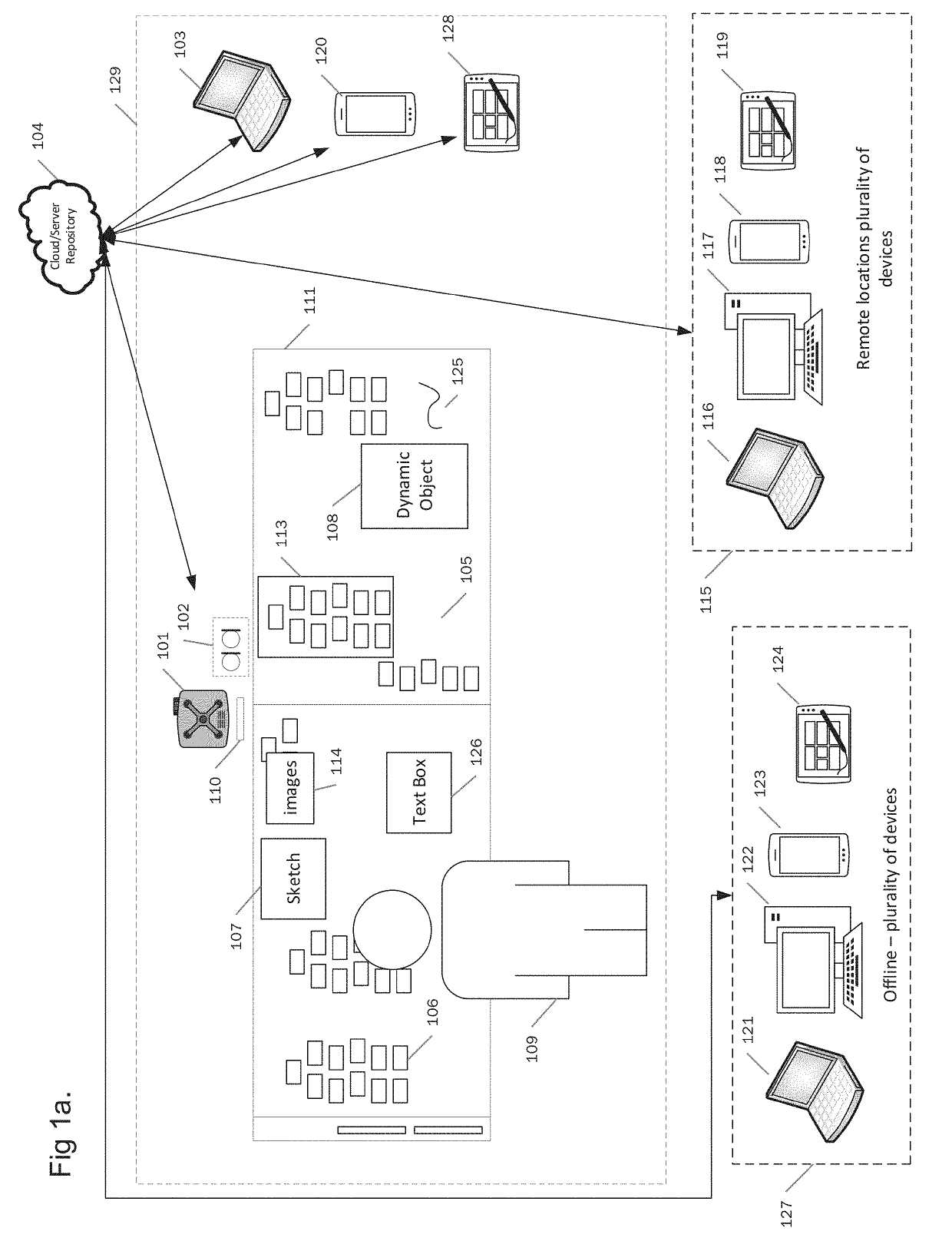

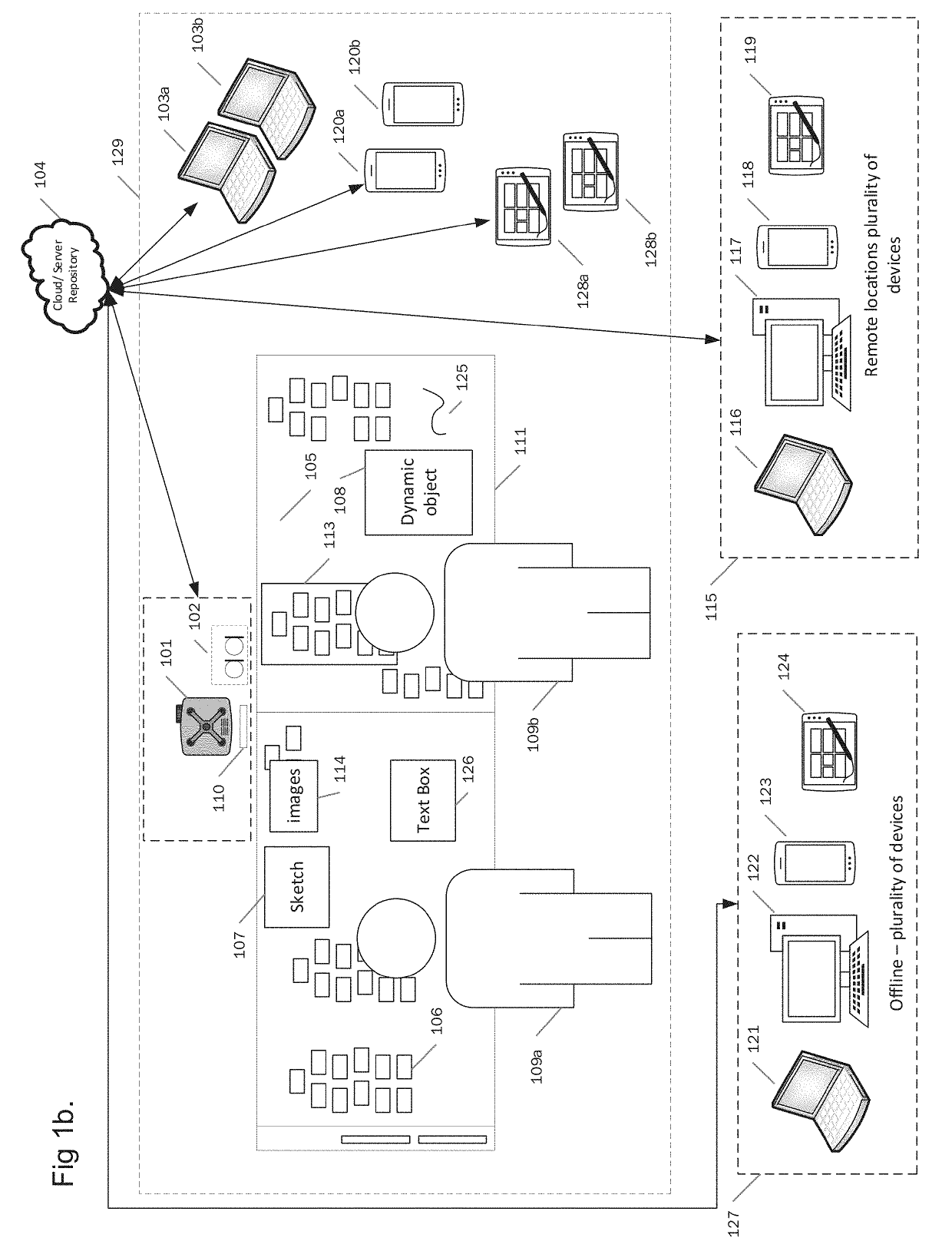

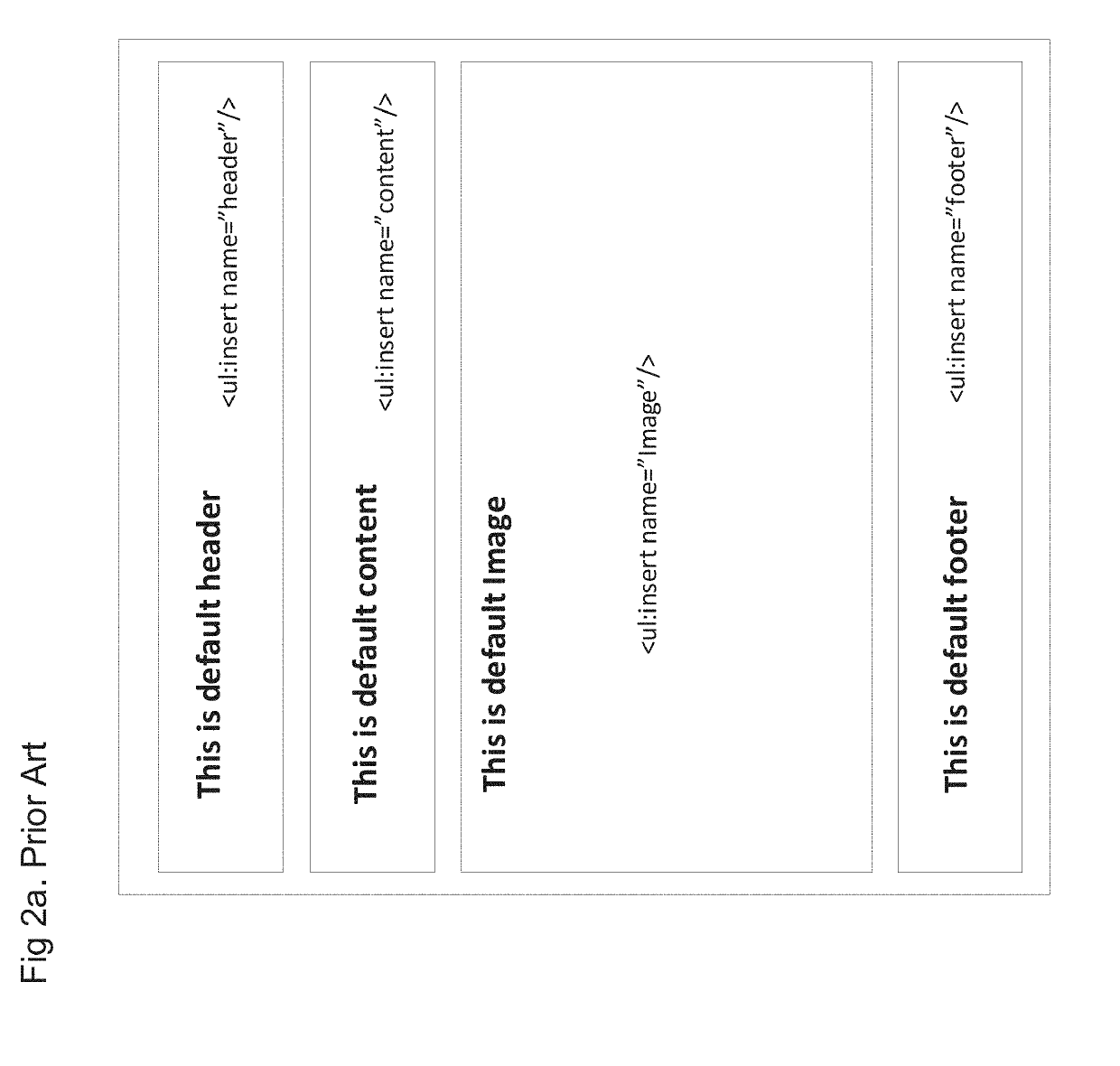

Method, apparatus and computer-readable media for converting static objects into dynamic intelligent objects on a display device

ActiveUS20190236125A1Overcome limitationsAccurate representationText processingWebsite content managementComputer graphics (images)Display device

Method, apparatus, and computer-readable media for converting static objects into dynamic intelligent object templates preferably provides structure and / or function whereby a first user displays a static object on a display. The user converts the static object into a dynamic template object having attributes of a group, the group including at least two of (i) notes, (ii) text boxes, (iii) images, (iv) sketches, (v) embedded links, (vi) inking objects, and (vii) sub-groups. Objects of the group inherit behaviors and attributes of the group including at least two of (i) color, (ii) naming convention, and (iii) positional attributes. The conversion occurs when the attributes and behaviors of the group are added to the static object, or when another underlying behavior is made available through interaction with the object. The dynamic template object is stored in a template library. Preferably, a second user can have the same conversion rights as the first user.

Owner:NUREVA INC

Dike underwater concrete paving construction method

InactiveCN105908676ASave engineering effortSave investmentCoastlines protectionSoil textureUltimate tensile strength

The invention discloses a dike underwater concrete paving construction method. The dike underwater concrete paving construction method comprises the steps that after offshore slope riprapping is conducted through a ship, a riprap surface is flattened; geotextile cloth bags are sewn, and the length of the geotextile cloth bags is equal to the sum of the length of an underwater paving and the length of an overwater paving of a soil texture dike; the geotextile cloth bags are sequentially laid in the shoreline construction direction; concrete is started to be poured to the bottoms of the geotextile cloth bags, and the pouring length corresponds to the designed slop length; concrete pouring is sequentially conducted from underwater tail end pouring sleeving openings of the geotextile cloth bags towards the overwater direction; the concrete flows in the geotextile cloth bags in a filling mode, all the geotextile cloth bags are filled with the concrete, and after the concrete is solidified and hardened, an underwater concrete paving is formed in a preset designed position and plays a function of protecting the underwater portion of the soil texture dike; after the concrete in the geotextile cloth bags reaches the designed strength, concrete pouring of a pressing top or an anchoring groove is conducted, and slope toe riprap pressing foot construction is carried out; and construction is not limited by seasons and can be conducted in both the low flow period and the high flow period.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG +1

Novel built concrete structure building wall and construction method thereof

ActiveCN102086666AImprove seismic performanceEasy to set upConstruction materialWallsEngineeringRebar

The invention discloses a novel built concrete structure building wall and a construction method thereof, and belongs to the technical field of buildings. The wall is mainly formed by piling up bearing self-insulation main building blocks, at least one structural column formed by pouring concrete into a U-shaped cavity formed by self-insulation auxiliary building blocks is also arranged in the wall, and a vertical steel bar connected with a bottom ring beam is arranged in the structural column; the bearing self-insulation main building blocks are in cuboid structures, the building block body is provided with two cavities communicated with the upper and lower surfaces thereof along the width direction, and insulation materials are filled in the cavities respectively; and the self-insulation auxiliary building blocks form U-shaped insulation on the outer side of the structural column. Organic combination of an invisible framework formed by the structural column and the ring beam in an outer masonry and a building internal framework structure can be realized, the seismic resistance of the building can be greatly improved, and simultaneous construction of insulation and structure is realized, so the construction process is reduced, a template is saved, the construction efficiency is improved, and the project cost is reduced.

Owner:山东七星实业有限公司

Open-cut construction method for assembly type flat-top column-contained underground structure

PendingCN110080287AImprove mechanical performanceShorten the construction periodArtificial islandsExcavationsFalseworkStructure of the Earth

The invention belongs to the field of underground engineering construction and relates to an open-cut construction method for an assembly type flat-top column-contained underground structure. The construction method comprises the following steps: (1) after an enclosure structure is constructed, constructing by adopting an open-cut method, and excavating while erecting three inner supports; (2) constructing a concrete cushion layer, a waterproof layer and a second laminate after excavating to the bottom, and detaching the lowest inner support; (3) completing the construction of a second side wall and completing the construction of a second middle vertical column and a second middle longitudinal beam; (4) completing the construction of a first laminate, and removing the middle inner support;(5) completing the construction of a first side wall, and completing the construction of a first middle vertical column and a first middle longitudinal beam; and (6) completing the construction of aflat-top board, and then removing the uppermost inner support. By adopting the construction method, the fabricated underground structure is well achieved, the application range is wide, a superposed structure is formed through part of a prefabricated part and a cast-in-place layer, on-site erecting of temporary facilities such as part of a formwork and a scaffold can be omitted, and the waterproofperformance and the overall structural stress performance of the fabricated underground structure can be effectively improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

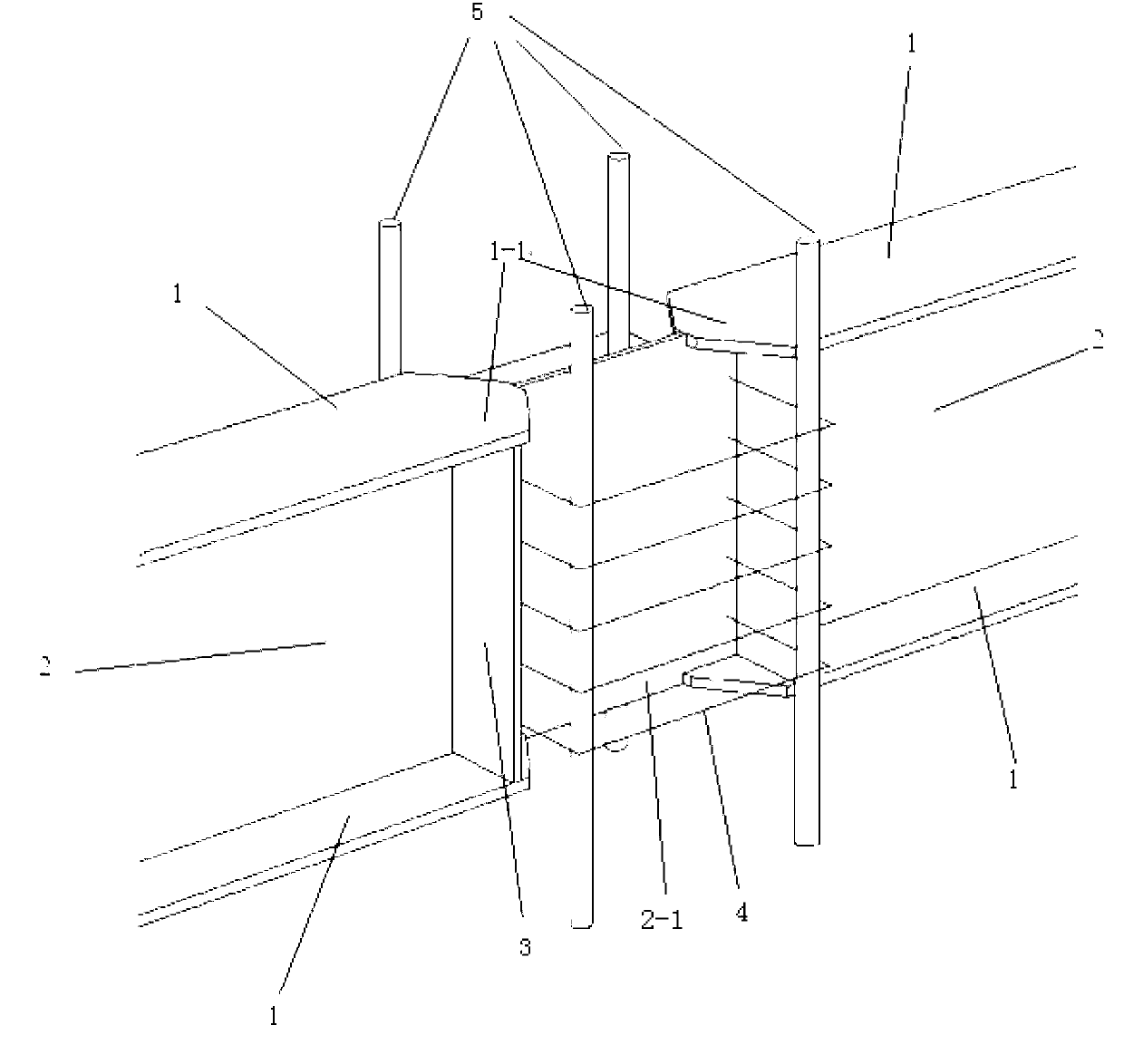

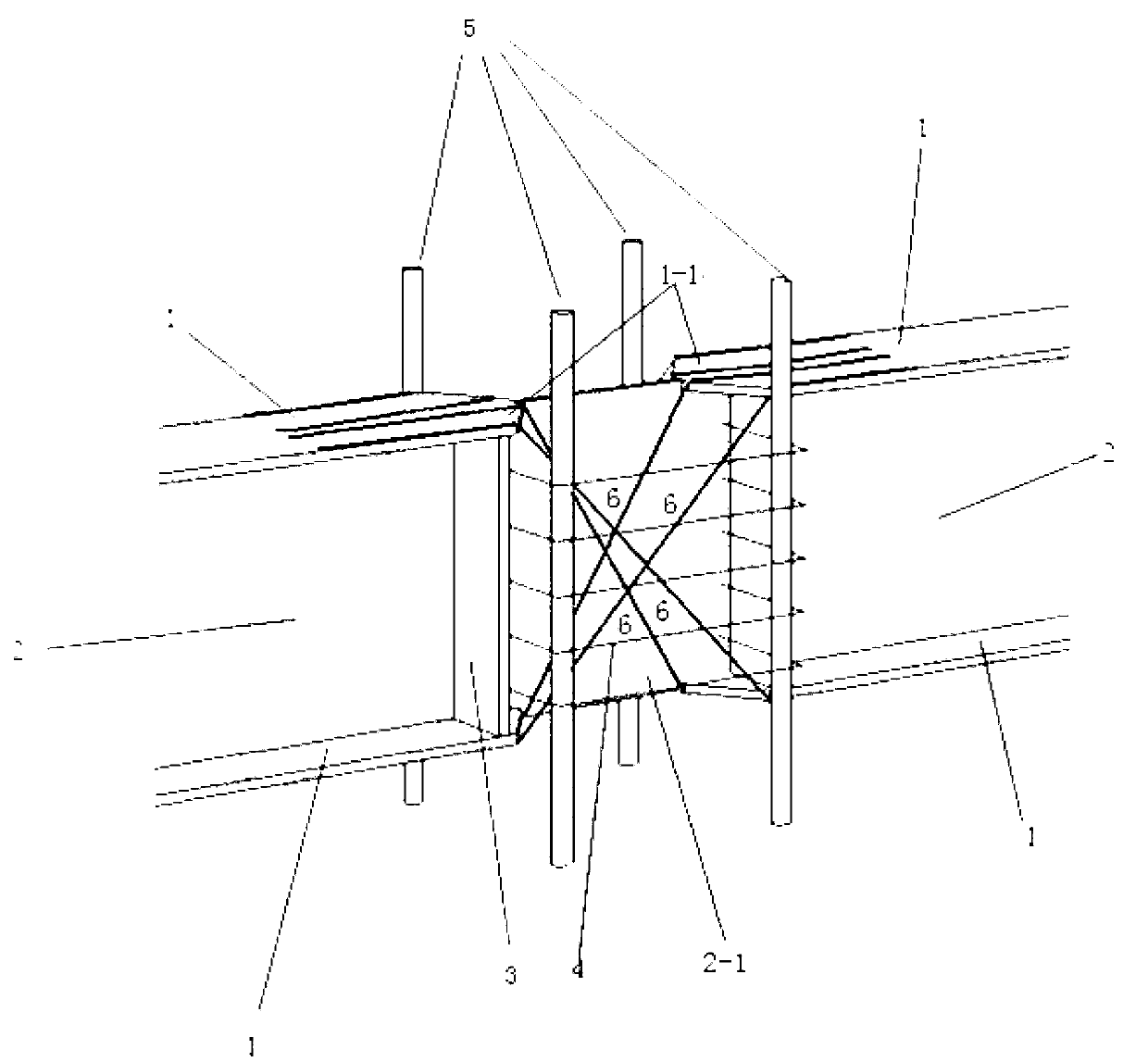

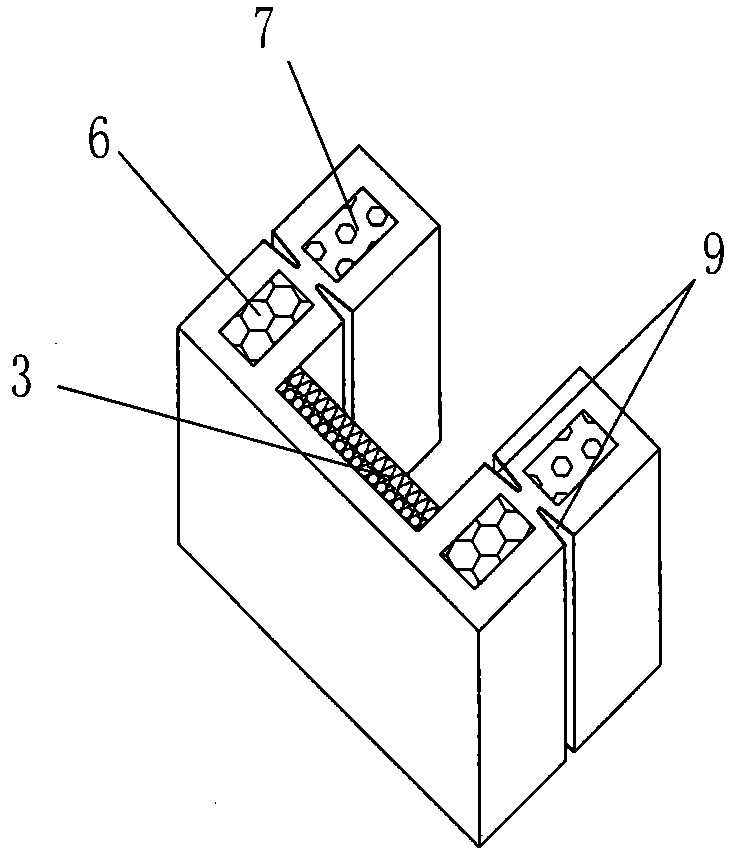

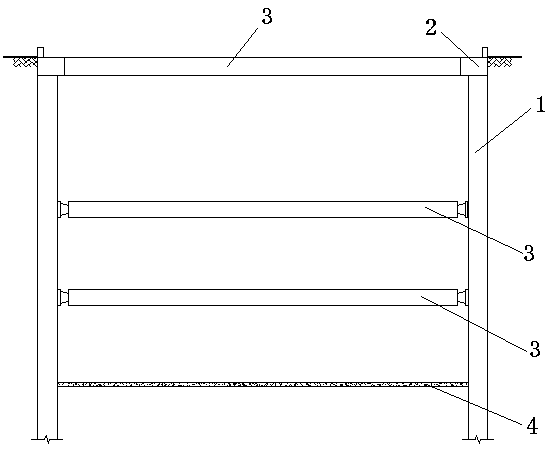

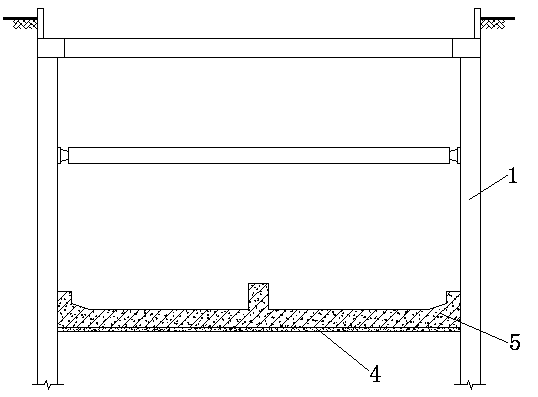

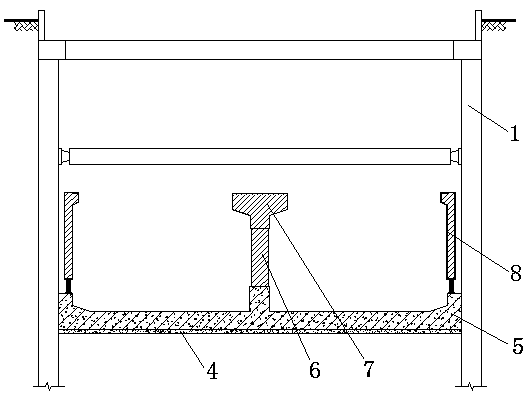

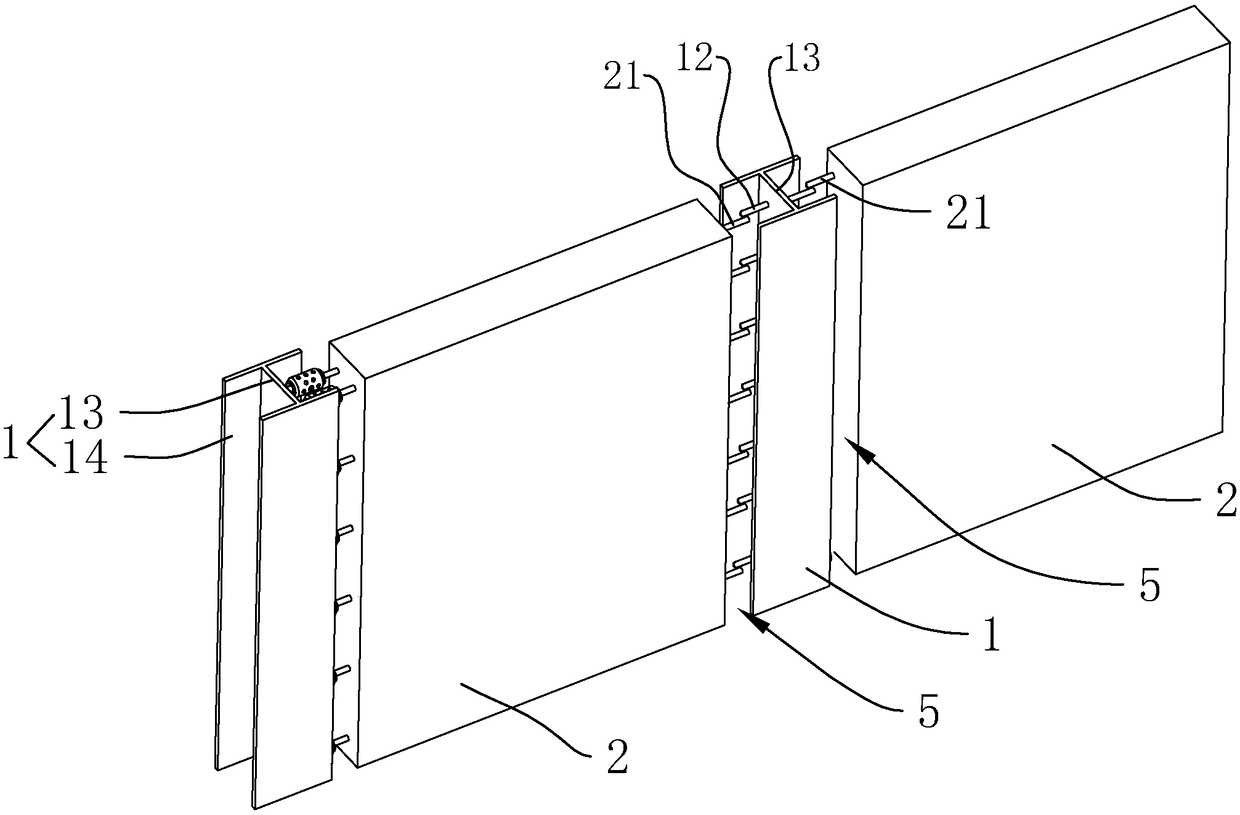

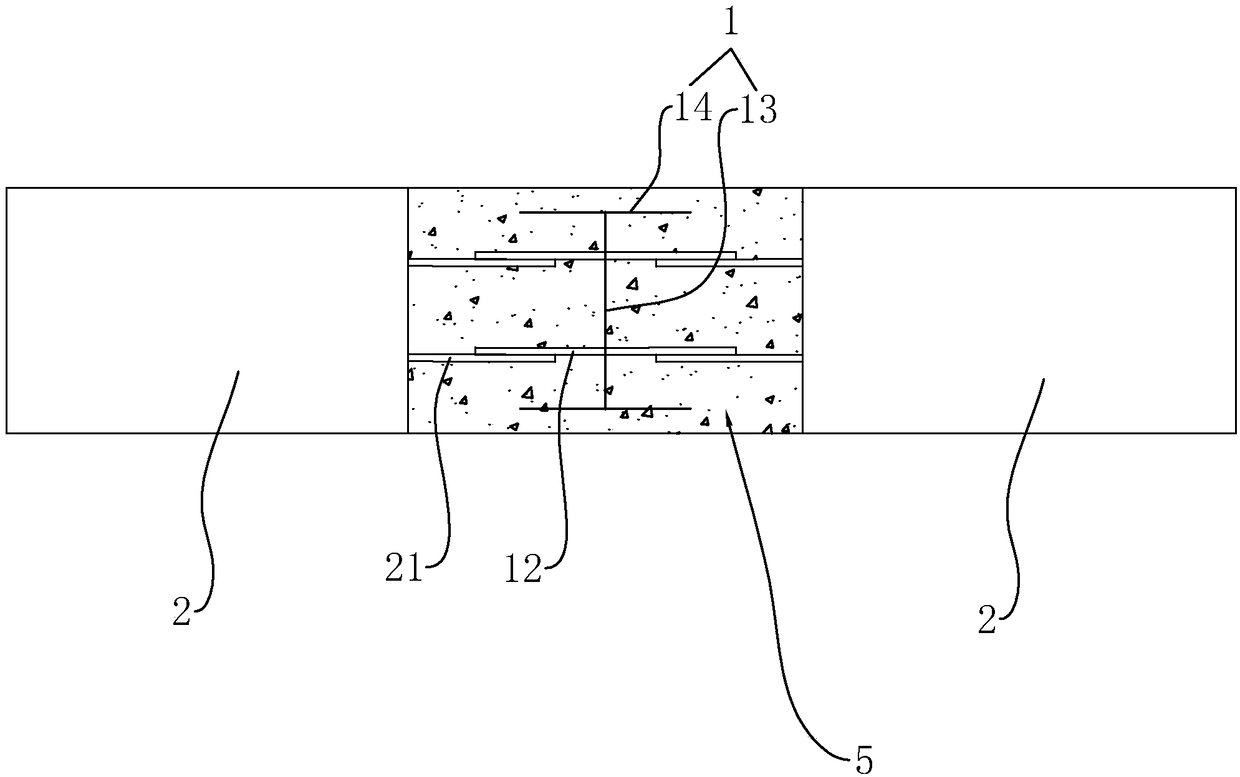

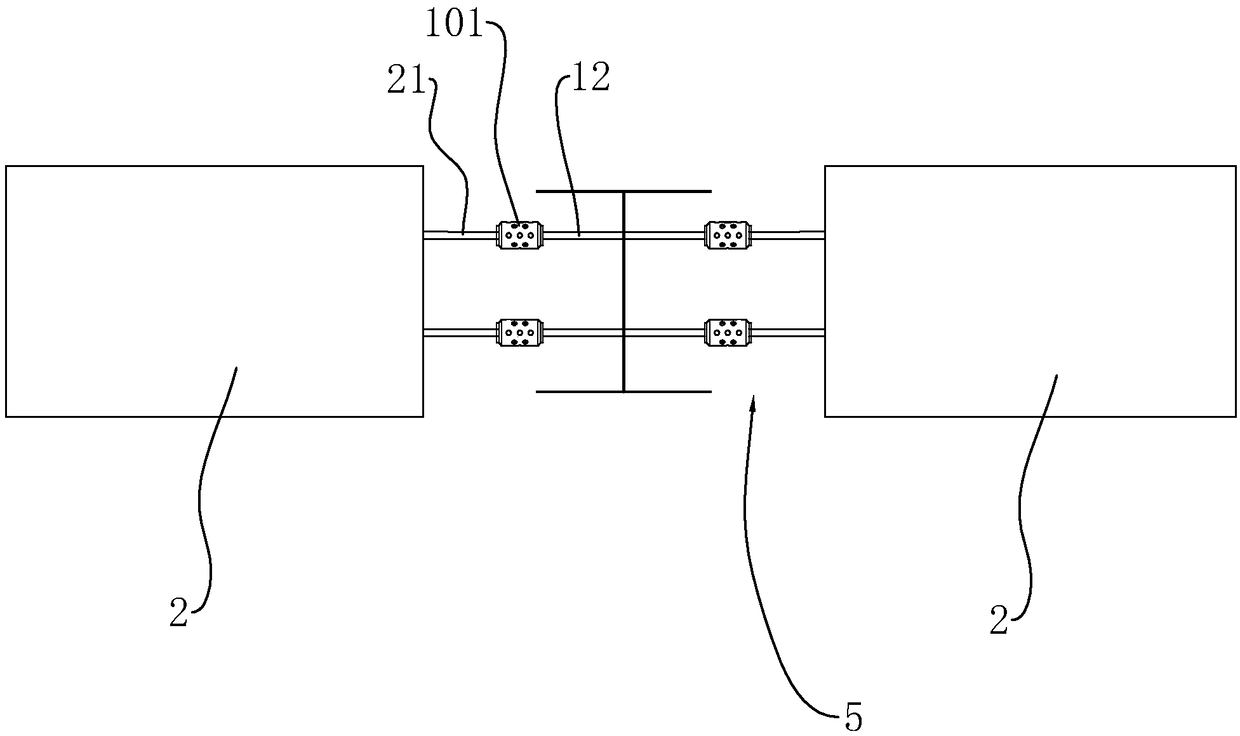

Connecting structure for prefabricated concrete wall panels and steel columns and construction method thereof

The invention discloses a connecting structure for prefabricated concrete wall panels and steel columns. The key point of the technical scheme is as follows: the connecting structure comprises sectionsteel columns and the prefabricated concrete wall panels, the section steel columns are vertically arranged, the prefabricated concrete wall panels are arranged in at least two directions of four side faces of each section steel column, and the prefabricated concrete wall panels and the section steel columns compose a straight, L-shaped, T-shaped or cross wall structure; post-cast strips are arranged between the section steel columns and the prefabricated concrete wall panels; connecting rebars which horizontally extend out are perpendicularly and fixedly connected to the four side faces of each section steel column, embedded rebars are arranged in the end surface, which is close to the section steel column, of each prefabricated concrete wall panel, part of each embedded rebar is locatedin a wall, and the other part extends into the post-cast strip; and after being fixedly connected, the connecting rebars and the embedded rebars are buried in concrete of the post-cast strips. The connecting structure ensures that the connection between the prefabricated concrete wall panels and the steel columns has good integrity and is steadier.

Owner:李藏柱

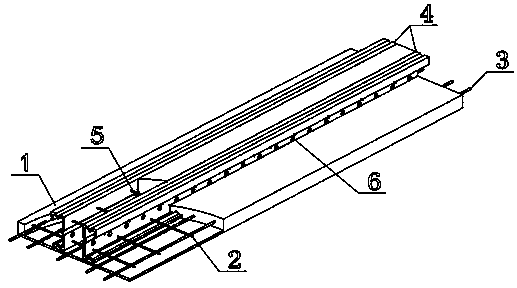

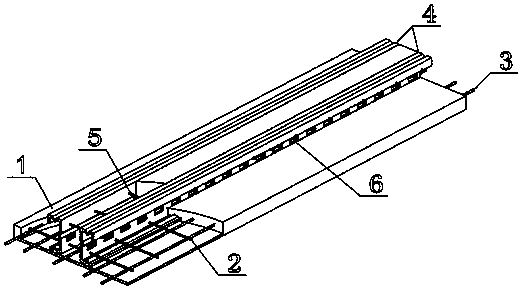

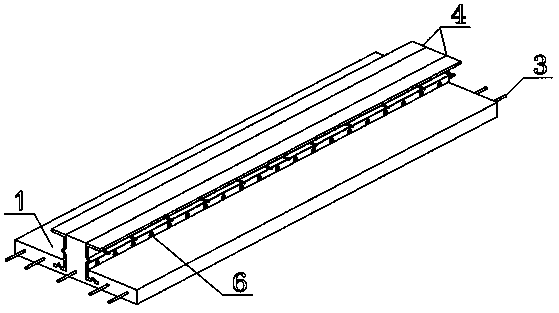

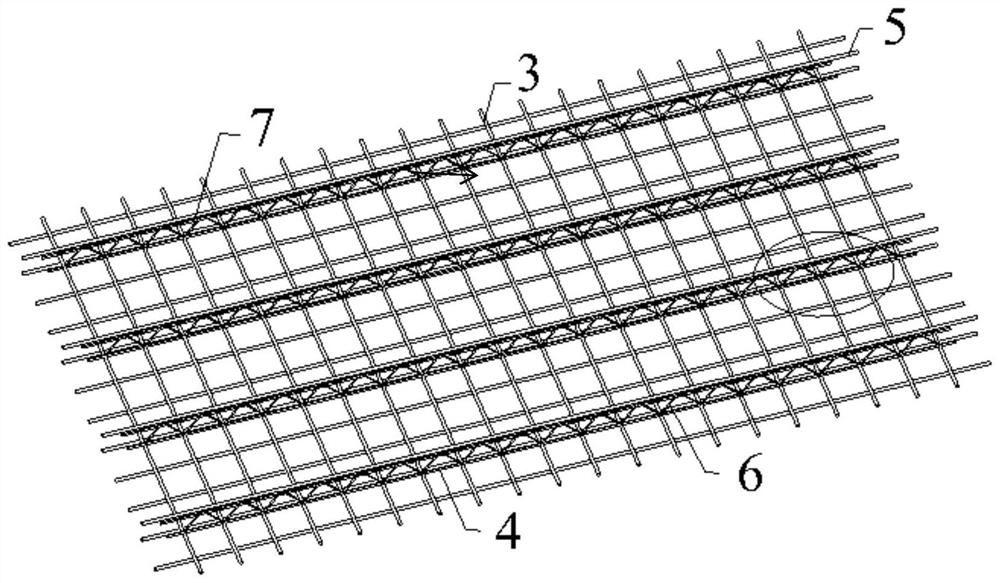

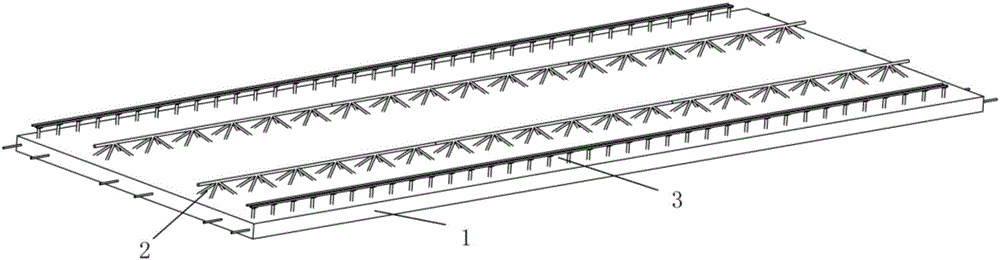

Support-free medium-long prefabricated rib truss rib composite plate structure and preparation method thereof

The invention discloses a support-free medium-long prefabricated rib truss rib composite plate structure and a preparation method thereof. The support-free medium-long prefabricated rib truss rib composite plate structure comprises a horizontal reinforcing mesh and truss reinforcing steel bars arranged on the horizontal reinforcing mesh; the horizontal reinforcing mesh comprises longitudinal reinforcing steel bars and transverse reinforcing steel bars connected to the longitudinal reinforcing steel bars in a lap joint mode; each truss reinforcing steel bar comprises an upper chord reinforcing steel bar, two lower chord reinforcing steel bars and a web member reinforcing steel bar, wherein the web member reinforcing steel bar is connected with the upper chord reinforcing steel bar and the two lower chord reinforcing steel bars to form an umbrella-shaped structure unit, the two lower chord reinforcing steel bars are arranged on the two sides of the longitudinal reinforcing steel bars in parallel respectively, and a concrete prefabricated rib is arranged between every two adjacent truss reinforcing steel bars; and a first concrete layer is poured on the lower portion of the horizontal reinforcing mesh and the lower portions of the truss reinforcing steel bars, and a second concrete layer is poured on the upper portions of the truss reinforcing steel bars. The support-free medium-long prefabricated rib truss rib composite plate structure has the advantages of being convenient to construct, convenient and fast to assemble, low in carbon, environmentally friendly, excellent in performance and the like, is suitable for plate structures of medium-long span fabricated concrete buildings and support-free construction, and greatly reduces construction cost.

Owner:SHENYANG JIANZHU UNIVERSITY

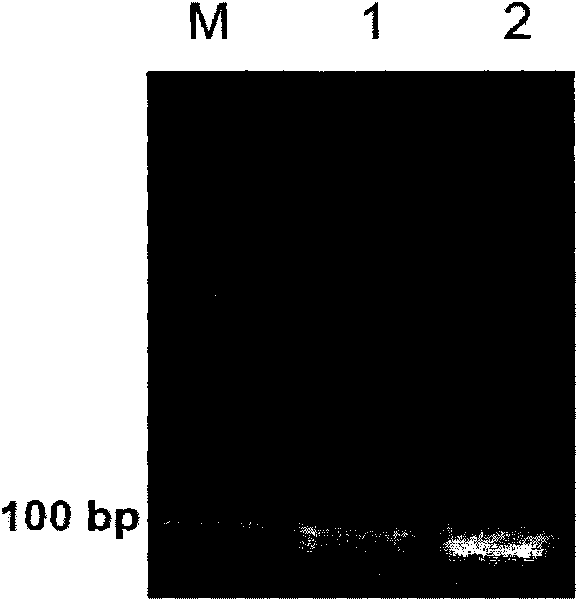

High-efficiency separation method for lower molecular multiplex PCR-amplified fragments

InactiveCN101705225AHigh purityHigh sensitivityMicrobiological testing/measurementDNA preparationElectrophoresisCapillary electrophoresis

The invention provides a high-efficiency separation method for lower molecular multiplex PCR-amplified fragments, which comprises: firstly, purifying lower molecular multiplex PCR-amplified fragments by using a magnetic bead purification method; and secondly, separating the lower molecular multiplex PCR-amplified fragments by using a capillary electrophoresis method. The method combining a multiplex PCR method and capillary electrophoresis can quickly screen transgenic plants. The multiplex PCR has high template-saving, reagent-saving and time-saving performance; when used to process the products of the multiplex PCR, the magnetic bead method can effectively remove the impurities from a PCR reaction system to make the PCR reaction system more suitable for performing capillary electrophoresis; and the capillary electrophoresis has the characteristics of low detection limit, high sensitivity and short detection time. The method can be safely used, successfully separate and identify the lower molecular multiplex PCR-amplified fragments, keep the detection time within 10.6 minutes and be widely used in fields such as food sanitation quarantine and clinical examination.

Owner:CHINA AGRI UNIV

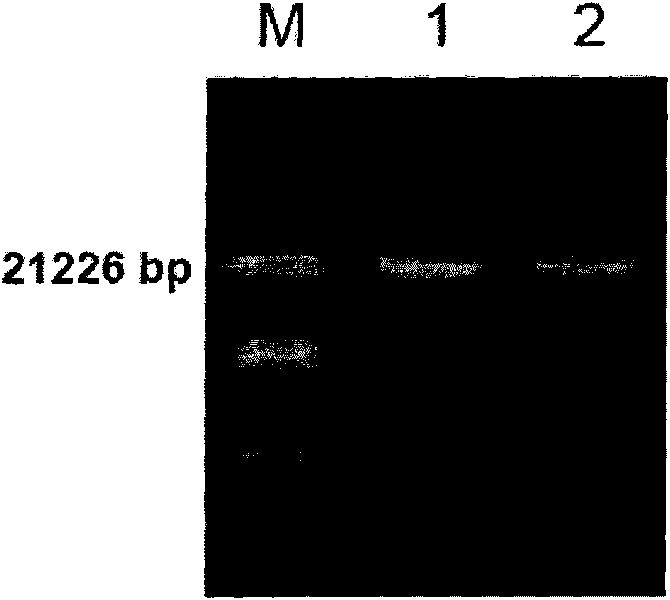

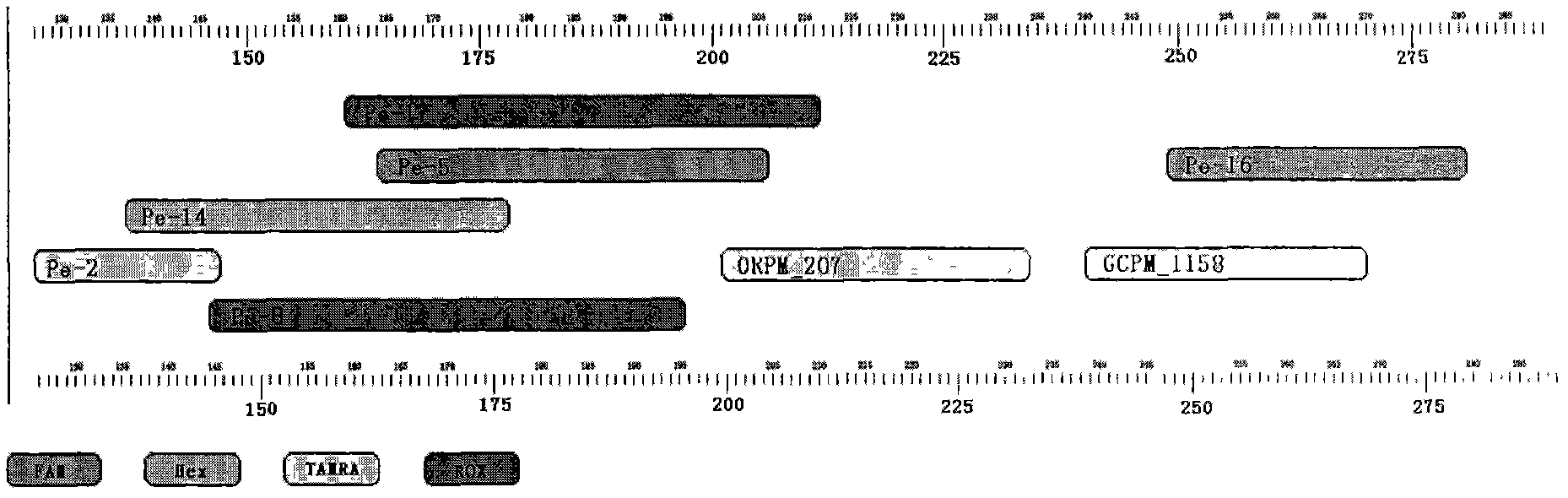

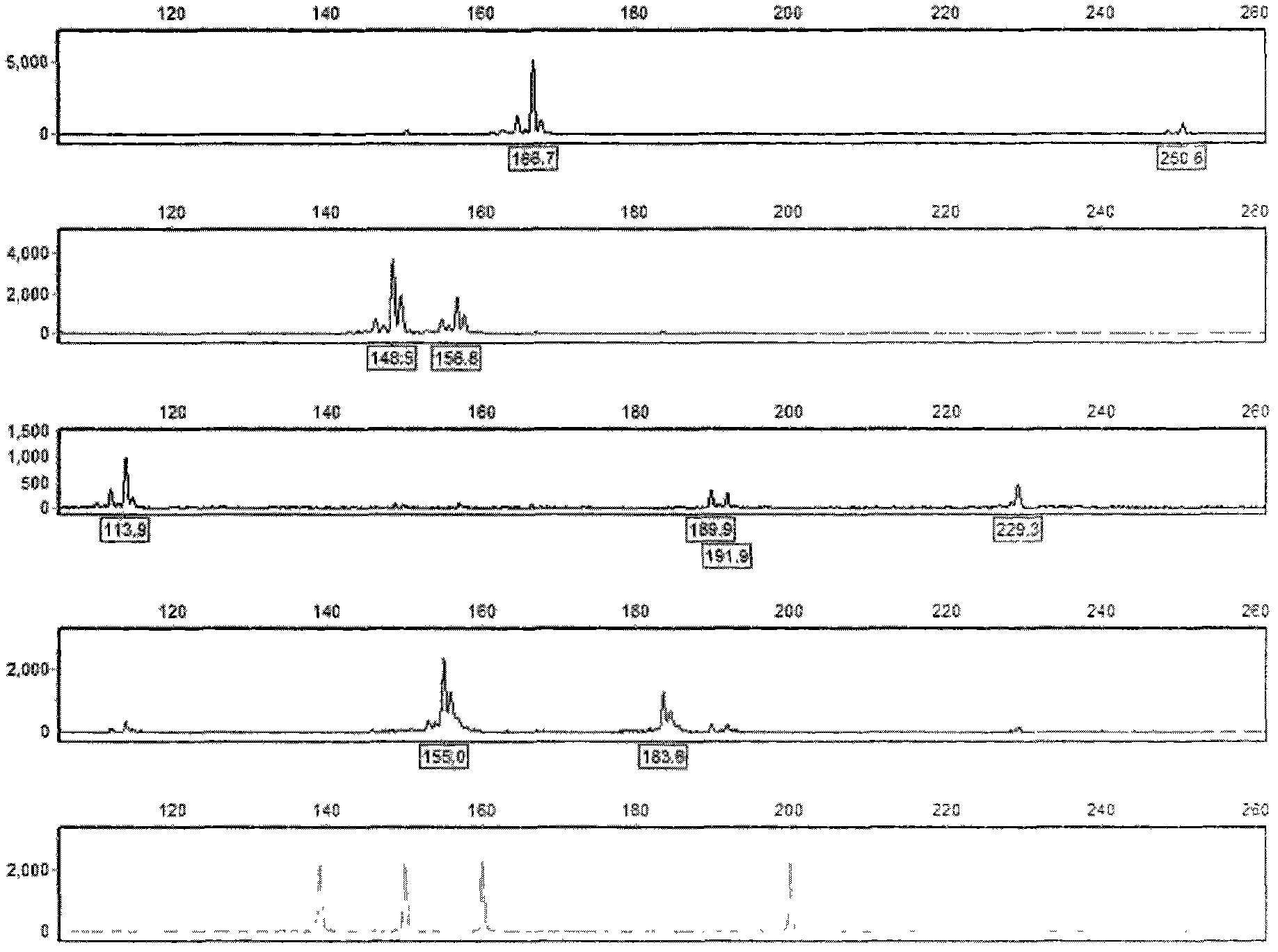

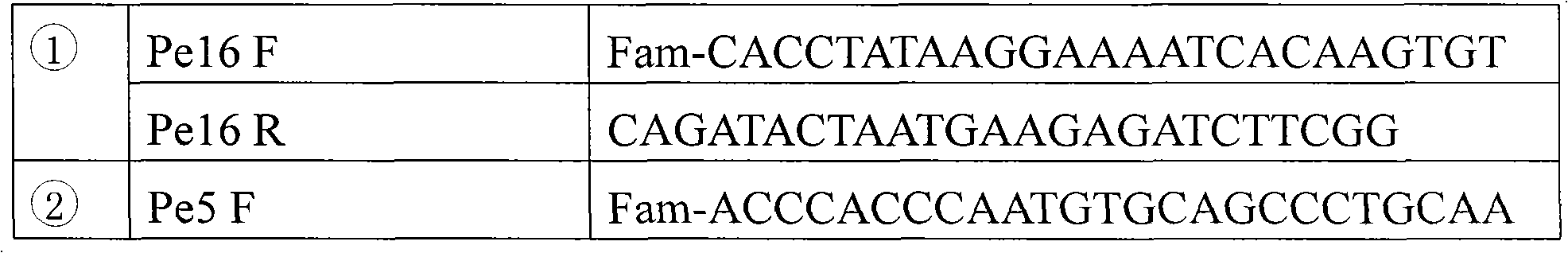

Method for carrying out genetic analysis and paternity test of diversifolious poplar colony by 8-plex PCR (polymerase chain reaction)

InactiveCN102676682AImprove efficiencyReduce stepsMicrobiological testing/measurementDNA/RNA fragmentationMultiplex pcrsGenetic analysis

The invention discloses a method for carrying out genetic analysis and paternity test of diversifolious poplar colony by 8-plex PCR (polymerase chain reaction). According to the method provided by the invention, one group of primers are used for multiplex PCR reactions, meanwhile, eight sites are amplified, and the primers comprise primers with sequences of SEQ ID NO: 1-SEQ ID NO: 8. The invention further relates to a primer group formed by the primers with the sequences of SEQ ID NO: 1-SEQ ID NO: 8, and a kit comprising the primer group and application of the primer group. According to the invention, eight pairs of primers with high polymorphism incapable of interacting in pairs are screened, and the multiplex PCR reaction is carried out by optimizing the primer concentration and adjusting amount of DNA (deoxyribonucleic acid) templates. The method provided by the invention is quick and efficient, suitable for extremely trace DNA, easy for automation and wide in application prospects of genetic analysis, paternity test and variety protection of diversifolious poplar.

Owner:BEIJING FORESTRY UNIVERSITY

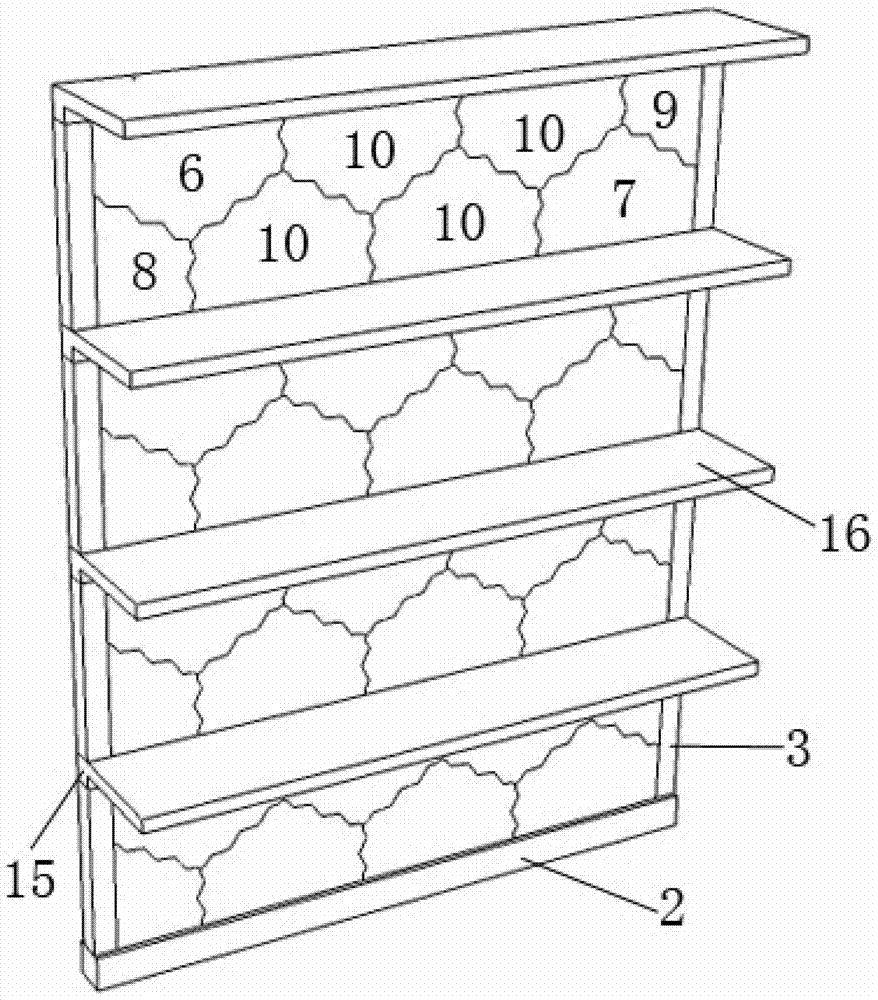

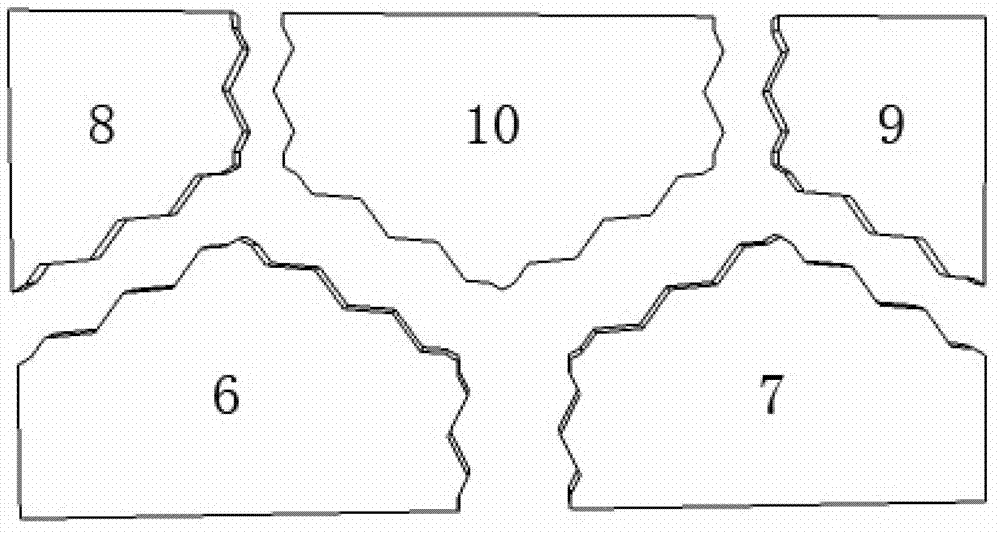

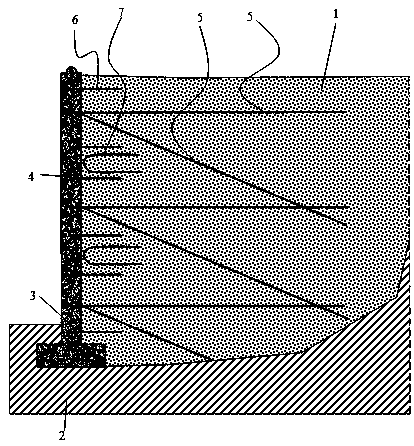

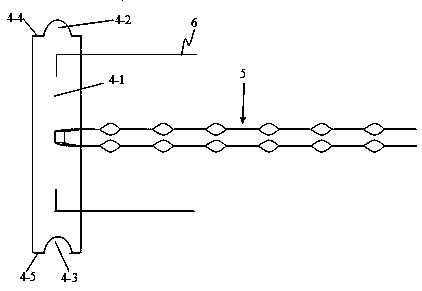

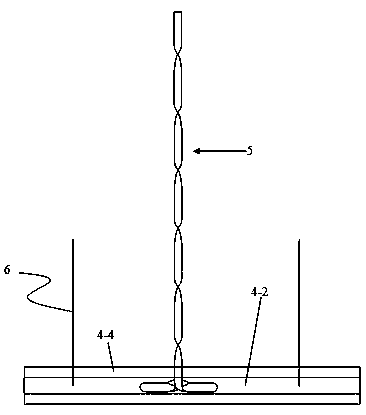

Assembly interlocking prestressing force shear wall system and construction method thereof

ActiveCN103088939AGood shock resistanceReduce wall cracksWallsBuilding material handlingFloor slabWall plate

The invention discloses an assembly interlocking prestressing force shear wall system which comprises prestressing tendons 1, a cast-in-place foundation beam 2, sighting telescopes 4, combination wallboards 5, cast-in-place columns 3, a cast-in-place beam 15 and a cast-in-place floor slab 16. A concave-shaped frame is formed by the cast-in-place foundation beam 2 with a through hole 12 reserved and the cast-in-place columns 3. The combination wallboards 5 are embedded into the concave-shaped frame through the prestressing tendons 1. The sighting telescopes 4 are installed after the prestressing tendons are stretched and pulled. Then, the cast-in-place beam 15 and the cast-in-place floor slab 16 on a first floor and the cast-in-place columns 3 on a second floor are poured. A new concave-shaped frame is formed. Then, the combination wallboard 5 on the second floor is assembled. Construction of other floors is repetition of the process. Provided is a construction method of the assembly interlocking prestressing force shear wall system. The construction method comprises the steps of (a) preparation work, (b) foundation excavation, (c) pouring of foundation, the cast-in-place foundation beam 2 and the cast-in-place columns 3 on the first floor, (d) assembly of the combination wallboard 5 on the first floor, (e) pouring of the cast-in-place beam 15 and the cast-in-place floor slab 16 on the first floor and the cast-in-place columns 3 on the second floor, (f) assembly of the combination wallboard 5 on the second floor, and (g) construction on other floors.

Owner:HUNAN YUBAN CONSTR GRP CO LTD

Overlapped plate with enhanced bidirectional force transfer performance

InactiveCN106088437AImprove adhesionImprove shear resistanceFloorsBuilding reinforcementsFloor slabEngineering

The invention discloses an overlapped plate with enhanced bidirectional force transfer performance, and belongs to building section bars. The overlapped plate structurally comprises a prefabricated bottom plate, at least one reinforcing steel bar truss, at least two anti-pulling connectors and bidirectional configuration reinforcing steel bars. One end of each reinforcing steel bar truss and one end of each anti-pulling connector are respectively positioned in the prefabricated bottom plate, the bidirectional configuration reinforcing steel bars are positioned on the lower portions of the anti-pulling connectors and are arranged in the prefabricated bottom plate, the reinforcing steel bar trusses and the anti-pulling connectors are respectively positioned on two sides of the prefabricated bottom plate and are vertically arranged, each reinforcing steel bar truss is positioned between the two corresponding anti-pulling connectors, and the reinforcing steel bar trusses and the anti-pulling connectors are respectively arranged along the length direction of the prefabricated bottom plate. The overlapped plate has the advantages that tripping damage to new and old concrete joint surfaces at butted seams can be effectively prevented, and integral overlapped and spliced floor slabs are assuredly provided with excellent bidirectional force transfer mechanisms; the floor slabs are built in direct butted seam splicing modes during site construction, cast-in-situ zones with certain widths can be omitted, accordingly, the overlapped plate is high in construction speed, and the like.

Owner:山东省建筑科学研究院有限公司 +2

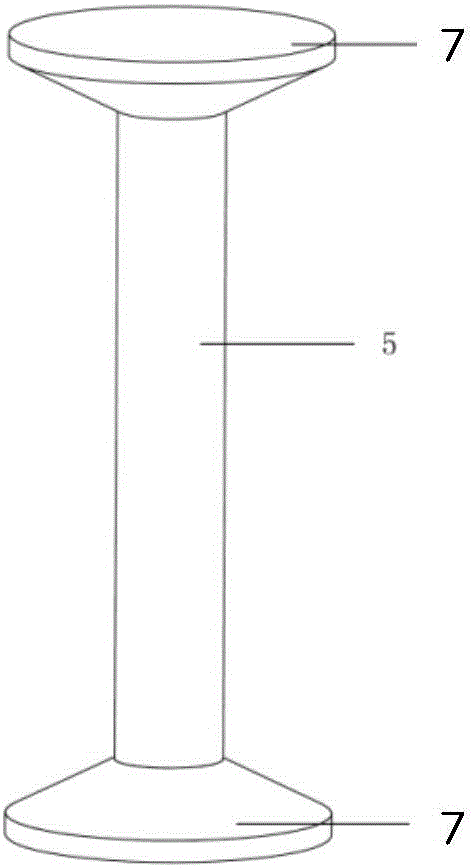

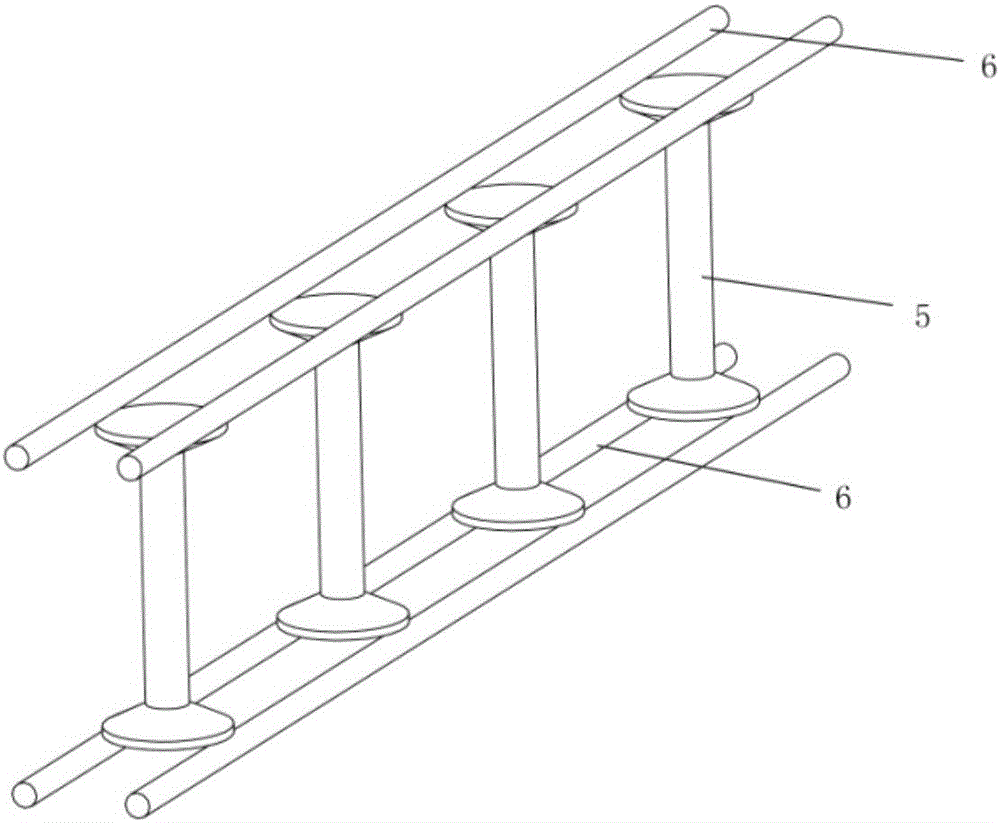

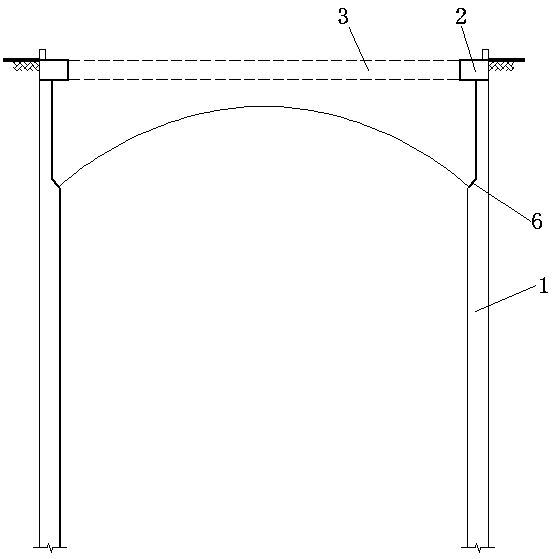

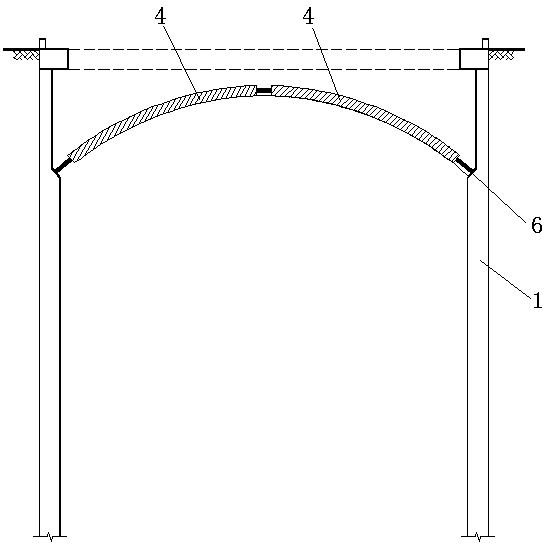

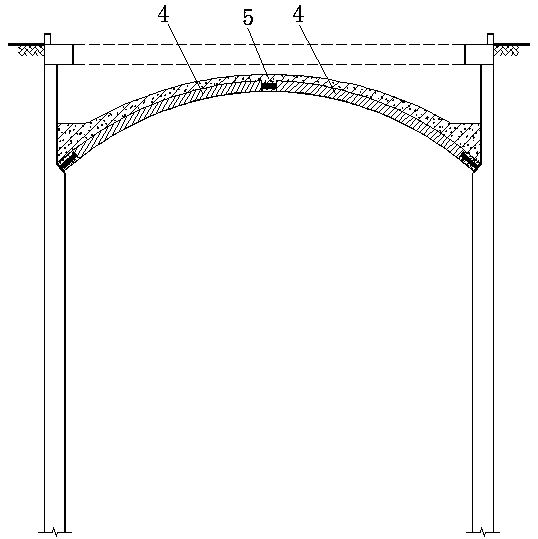

Cover-excavation semi-inverse construction method for assembly type arch top large-span column-free underground structure

PendingCN110080294APromote recoveryShort time on the roadArtificial islandsUnderwater structuresFalseworkClerestory

The invention belongs to the field of underground engineering construction, and relates to a cover-excavation semi-inverse construction method for an assembly type arch top large-span column-free underground structure. The method comprises the following steps: 1) after an enclosure structure is constructed, erecting an inner support, and excavating to the bottom surface of a foundation pit of an arch top board; 2) completing the construction of a arch top layer board, dismantling the inner support, and backfilling covering soil; 3) excavating the lower edge of the arch top layer board while supporting, erecting two inner supports, constructing a concrete cushion layer and a waterproof layer after excavating to the bottom, completing the construction of a second layer board, and removing the inner supports at the lower part; 4) completing the construction of a second side wall, a middle stand column and a middle longitudinal beam; 5) completing the construction of a first layer board, and removing the remaining inner support; and 6) completing the construction of a first side wall. By adopting the method, the assembly type underground structure is well achieved, the visual effect ofthe building is good, erecting of part of temporary facilities such as an on-site formwork and a scaffold can be omitted by forming a superposed structure through part of a prefabricated piece and acast-in-place layer, and the waterproof performance and the overall stress performance of the assembly type underground structure can be effectively improved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

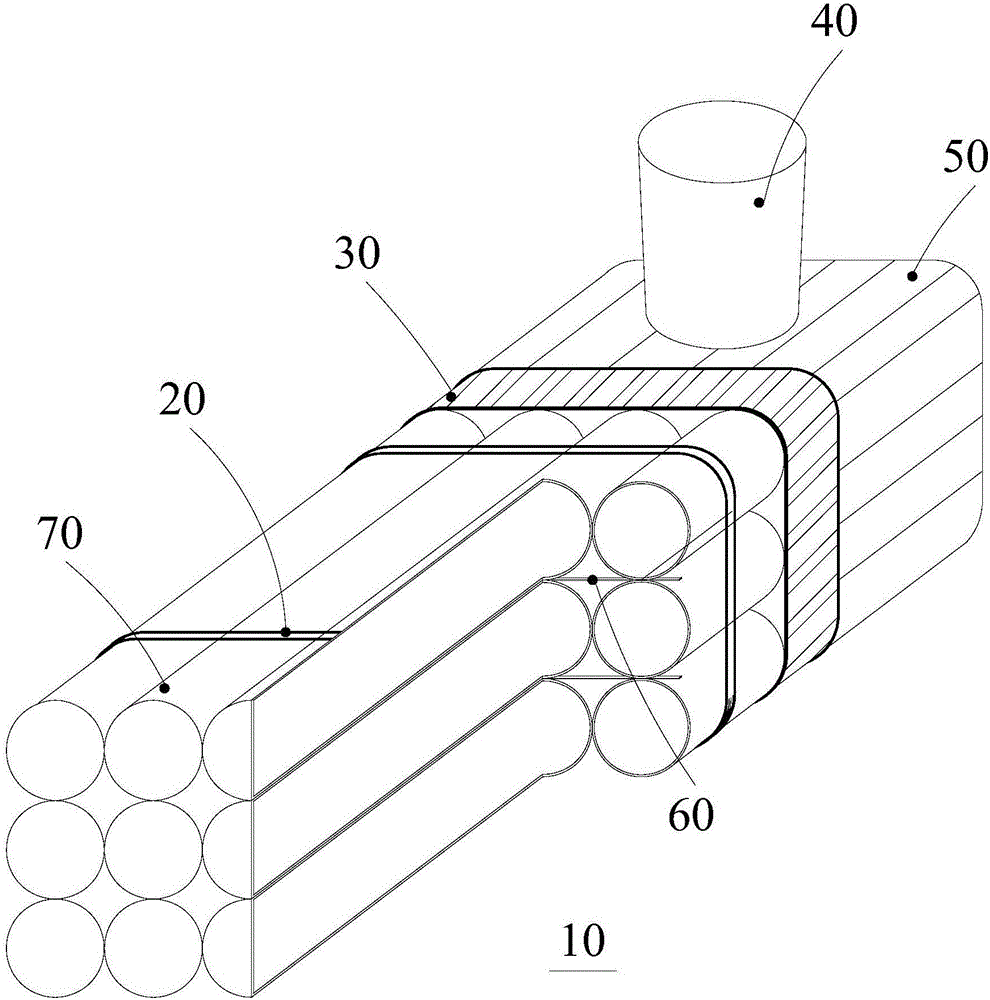

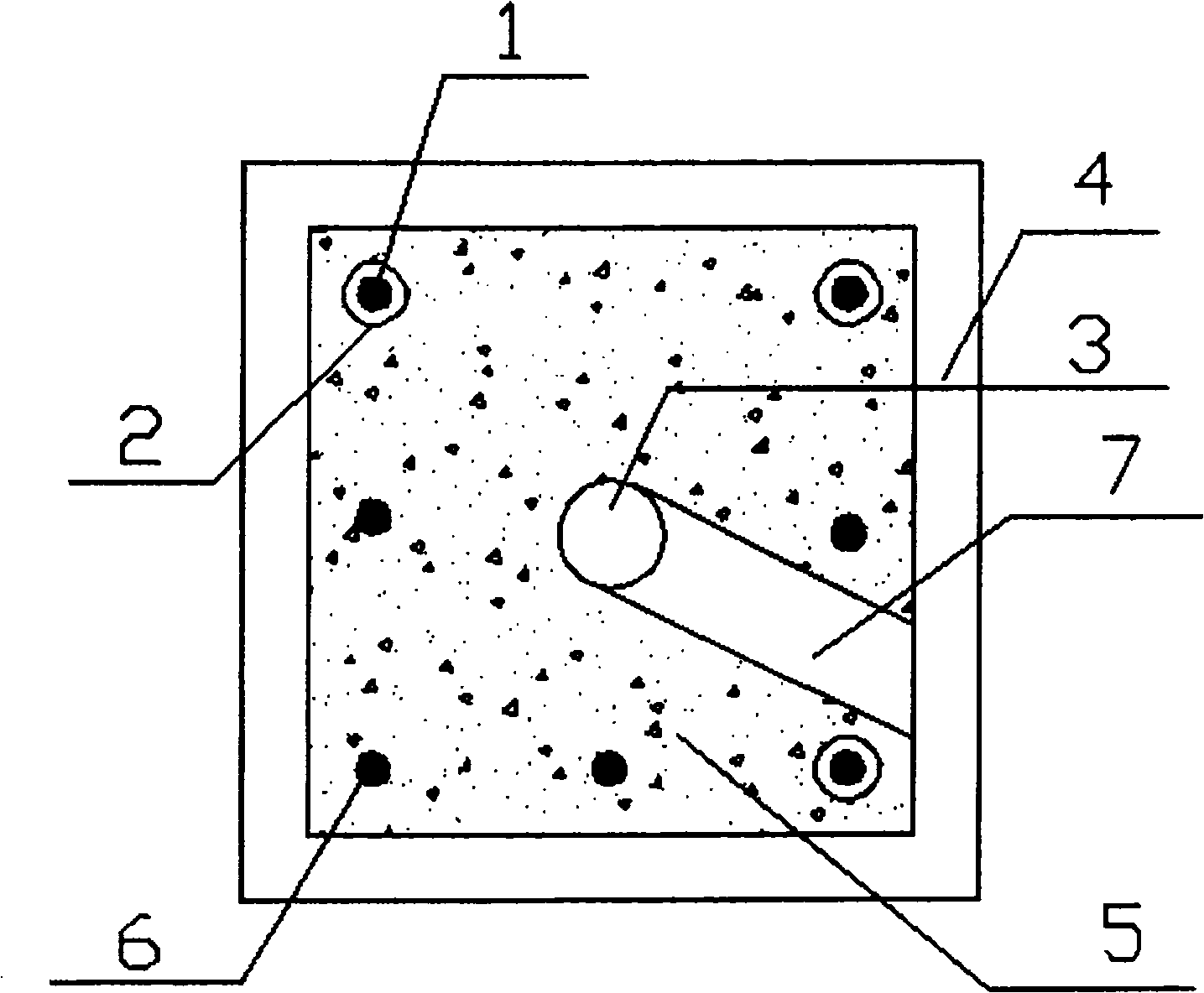

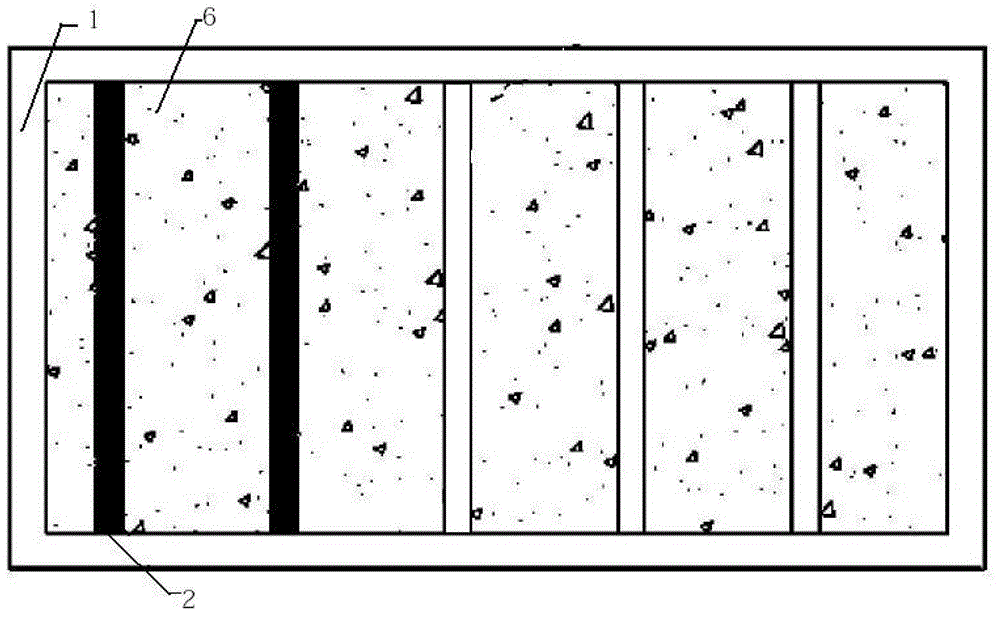

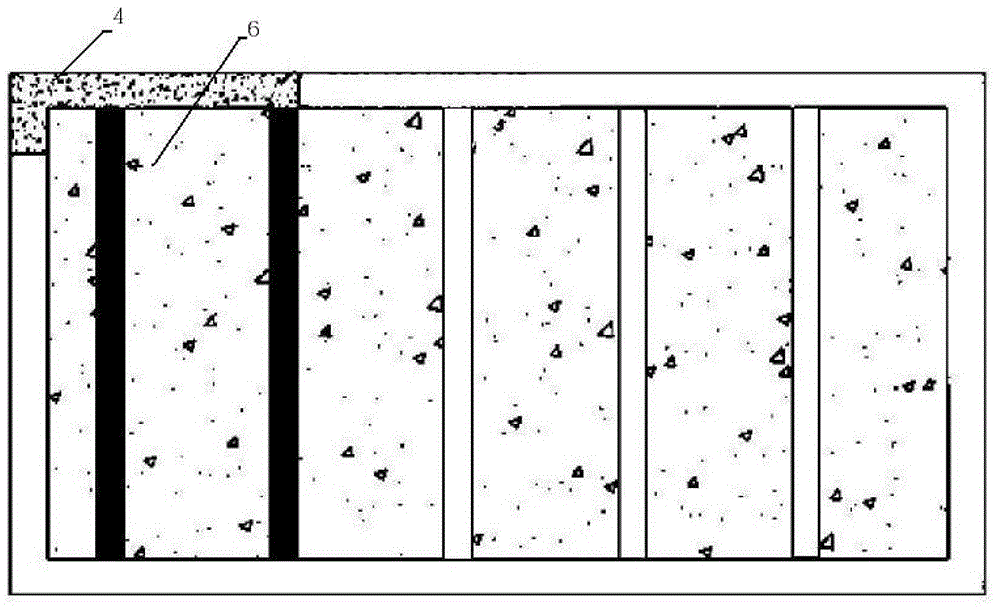

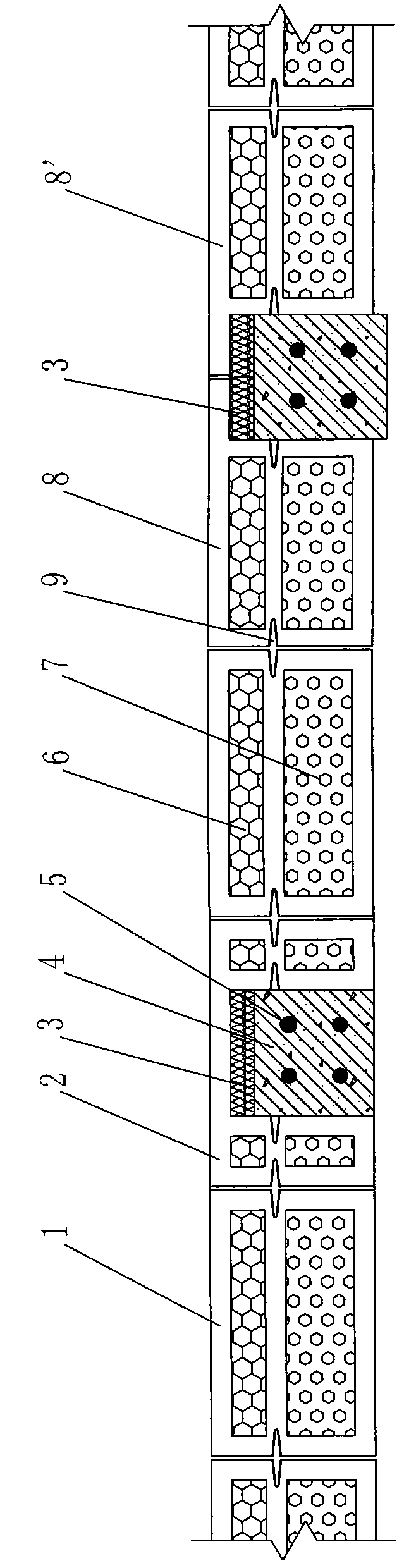

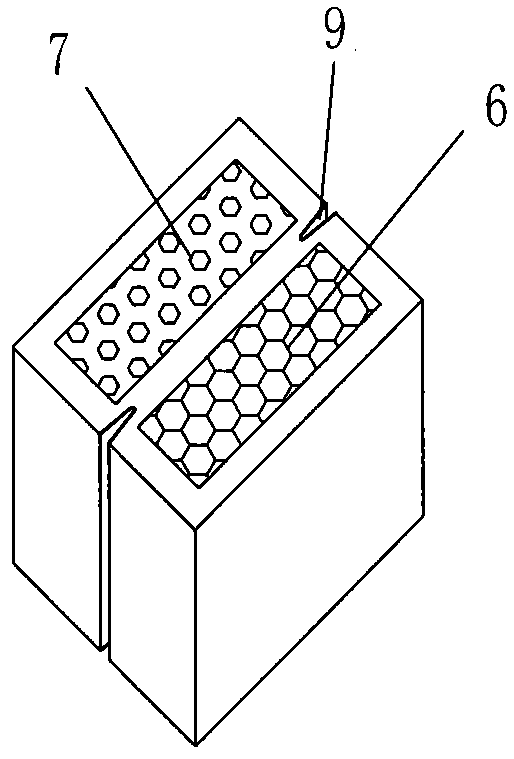

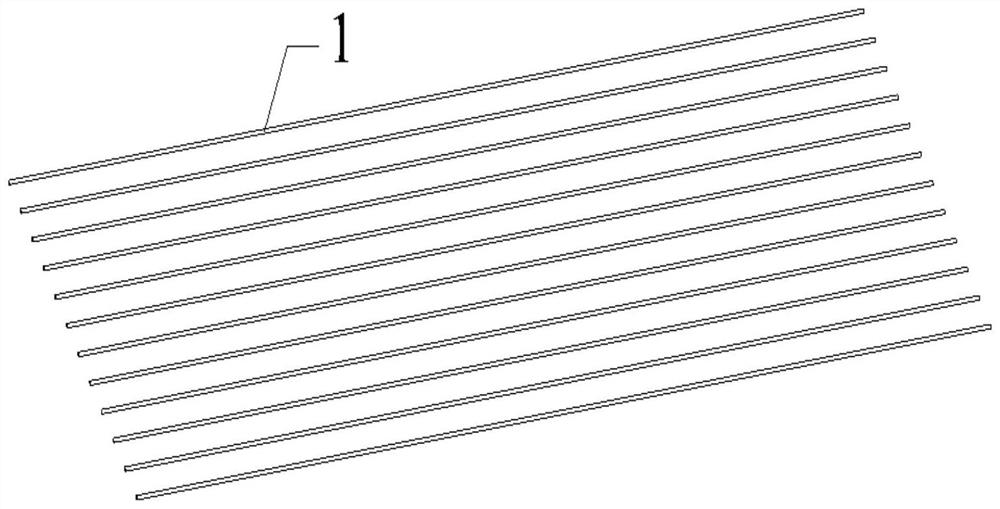

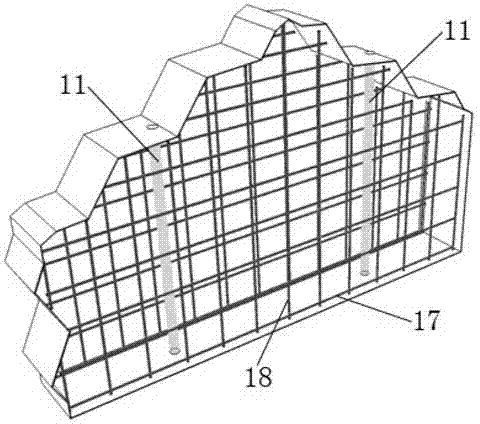

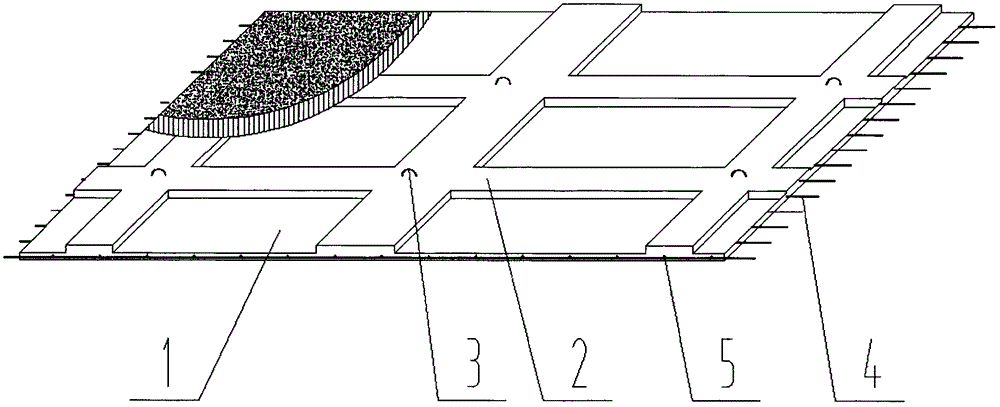

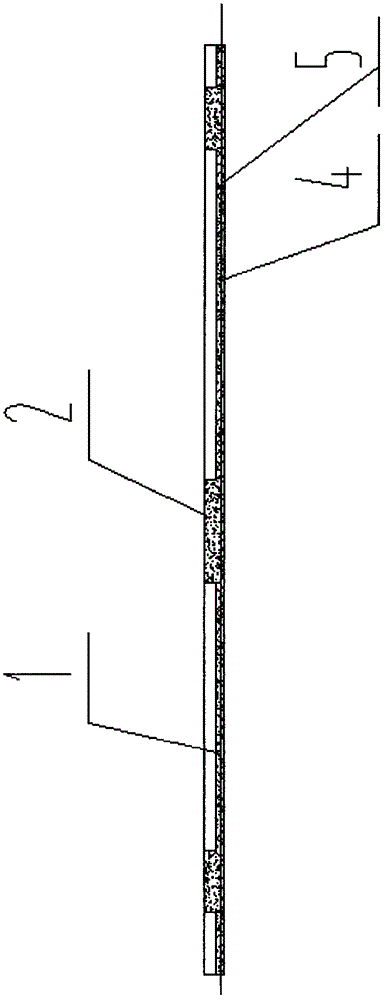

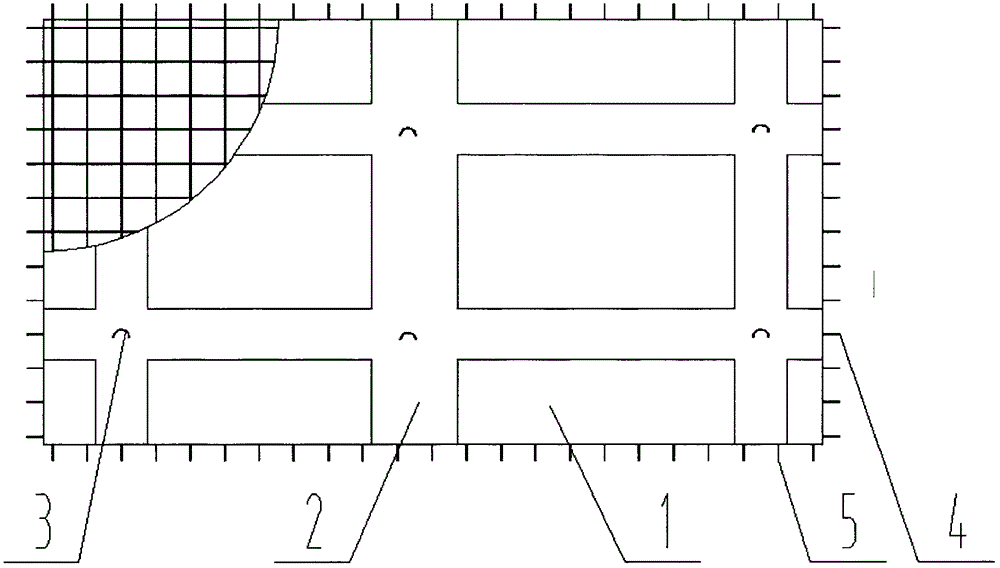

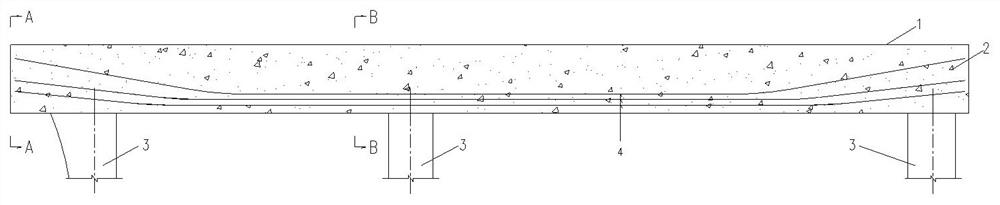

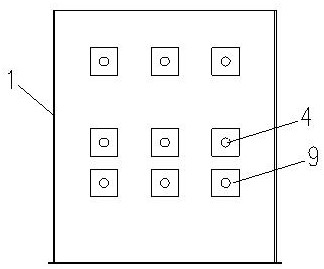

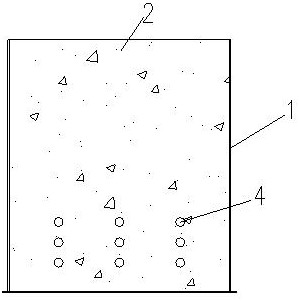

Concrete laminated slab prefabricated part with two-way ribs

A concrete laminated slab prefabricated component with two-way ribs relates to the field of concrete prefabricated parts technology and prefabricated structures in the construction industry. The thin plate (1) is made of a group of horizontally stressed steel bars (4) and a group of vertically stressed steel bars (5) bound together and then poured concrete, and the two sets of reinforcing ribs (2) are respectively arranged on the thin plate (1) in two directions perpendicular to each other, and the set of suspension rings (3) are respectively fixedly installed on the two sets of reinforcing ribs (2). Two-way ribs increase the stiffness of the component, reduce the deformation of the prefabricated component and the stress of the steel bar during construction; it is convenient to ensure the thickness of the protective layer for laying the steel bar on the slab; the thin concrete slab reduces the weight of the prefabricated component, which is conducive to the transportation and hoisting of the component; Tensile steel bars can be prestressed steel bars, which can save a lot of steel.

Owner:赵洪波

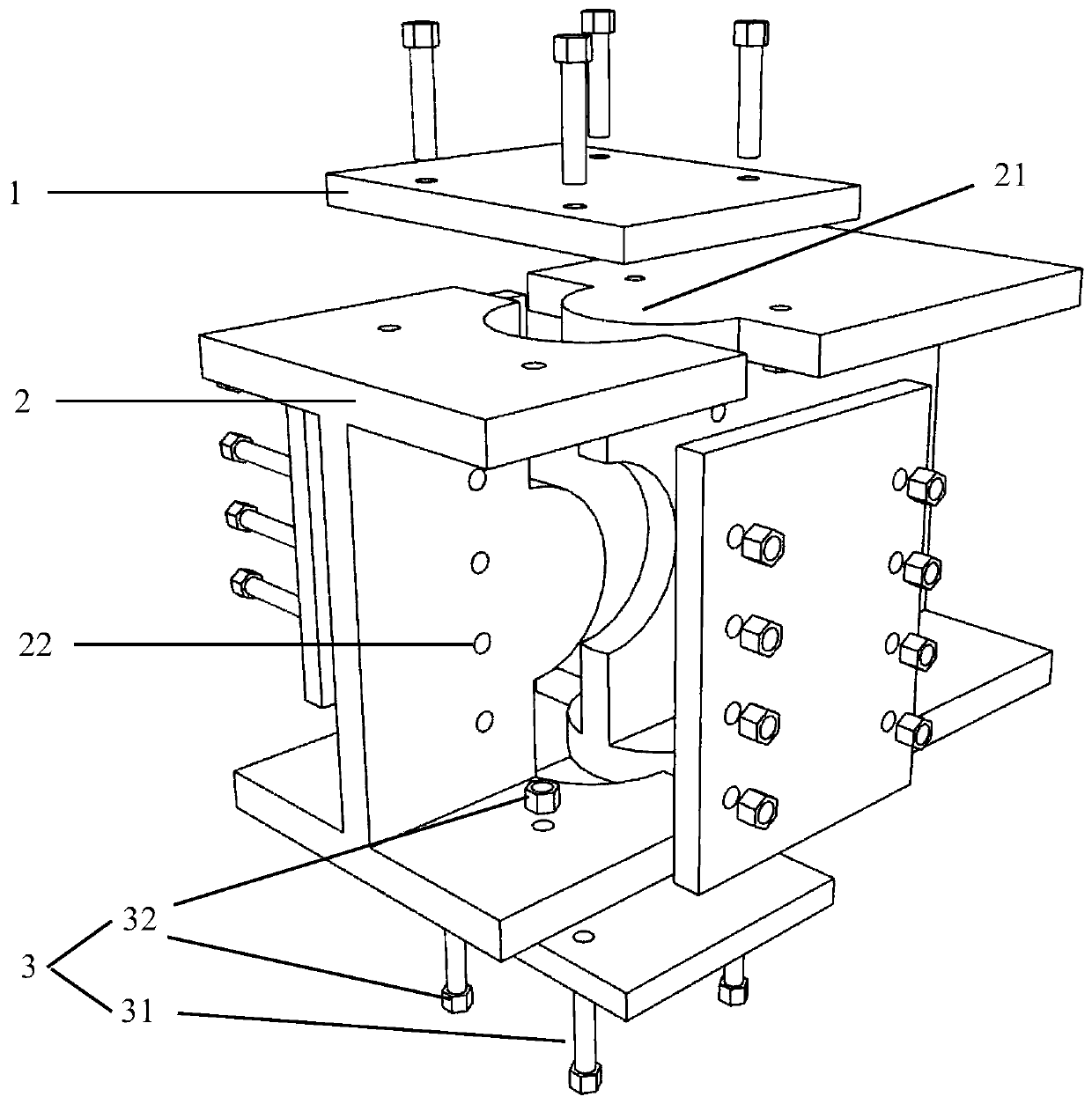

Fabricated beam column connection joint and installation method thereof

InactiveCN108018944AImprove construction efficiencyAvoid problems such as complex structuresBuilding constructionsReinforced concrete columnEngineering

The invention belongs to the field of prefabricated structures in civil engineering, and particularly relates to a fabricated beam column connection joint and an installation method thereof. The fabricated beam column connection joint comprises a prefabricated reinforced concrete column, prefabricated reinforced concrete beams, pre-buried steel plates, brackets, upper end fixed angle irons, mortarlayers, pre-buried prick post steel bars, pre-buried beam-passing steel bars, bolted caps, longitudinal steel bars in beam, a reinforcement sleeve, and reserved beam-passing reinforced holes; four pre-buried prick post steel bars and four pre-buried beam-passing steel bars are respectively arranged in the prefabricated reinforced concrete column and the brackets; two beam-passing reinforced holesare respectively reserved at the left side and the right side of the prefabricated reinforced concrete beams; and the side walls of the prefabricated reinforced concrete column are provided with thebrackets and the upper end fixed angle irons. The fabricated beam column connection joint and the installation method thereof is simple in structure, the construction efficiency of beam column structure is effectively improved, the construction technology is simplified, and the problems of complex reinforcement structure in the beam column joint area while ensuring the bending and shear bearing capacity of the joints are avoided.

Owner:SHENYANG JIANZHU UNIVERSITY

Fabricated structure connection piece

PendingCN110318469AImprove bending abilityLight weightBuilding constructionsEngineeringShock resistance

The invention discloses a fabricated structure connection piece. The fabricated structure connection piece comprises a prefabricated steel member, wherein the prefabricated steel member comprises at least two prefabricated special-shaped components which are sequentially arranged in the left-right direction, multiple special-shaped nodes are correspondingly arranged on end portions, close to eachother, of each two adjacent special-shaped components, and each pair of the special-shaped nodes are connected with a matched prefabricated steel sheet through a fastening device. In assembly, the fabricated structure connection piece can be used in node connection for connecting fabricated members such as pillars and pillars, beams and beams, the beams and the pillars and walls and walls, and iswide in application range. By designing the I-shaped structure and the special-shaped nodes, the assembly type structure connection piece guarantees assembly accuracy and flatness on the premise of facilitating rapid fabricating construction for constructors, and prevents secondary calibration for the constructors, and the special-shaped nodes are high in shock resistance and reliable in structure, and guarantee construction quality on the premise of improving efficiency. The fabricated structure connection piece avoids the problems that an existing fabricated structure connection piece adoptsa grout sleeve connection mode for connection, and therefore construction difficulty is large and huge potential safety hazard exists.

Owner:HENAN UNIV OF URBAN CONSTR

Thin-wall open steel box-prestressed reinforced concrete combined cover beam and construction method

PendingCN113279323ASimple stitchingOptimal Section DesignBridge structural detailsBridge erection/assemblyReinforced concretePre stress

The invention relates to a thin-wall open steel box-prestressed reinforced concrete combined cover beam and a construction method. The combined cover beam comprises a thin-wall open steel box and a pier column. An internal reinforcement cage is arranged in the thin-wall opening steel box, and concrete is poured; a pier top pre-embedded wedge-shaped steel block is arranged at the top of the pier column, a bent cap bottom reinforcing steel plate is fixedly welded to the position, corresponding to the pier column, of the bottom of the thin-wall open steel box, and the pier top pre-embedded wedge-shaped steel block is fixedly welded to the bent cap bottom reinforcing steel plate, so that connection between the pier column and the thin-wall open steel box is achieved. The steel box disclosed by the invention has the characteristics of high strength, light weight, easiness in splicing and the like, can form a steel-concrete structure with internal prestressed reinforced concrete, and also can be used as a template of internal post-pouring concrete, so that the amount of labor used for supporting and disassembling the template is saved, the construction progress is accelerated, and the influence on passing under a bridge is reduced; an effective and reasonable solution is provided for solving the problems of green, assembly and quick construction of the long and large bent cap at present.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

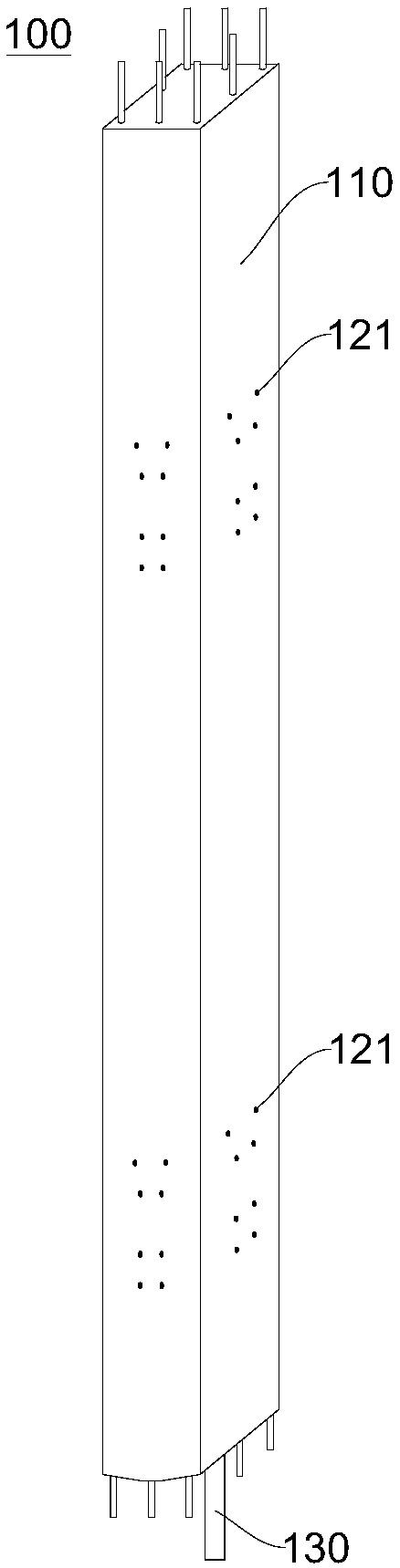

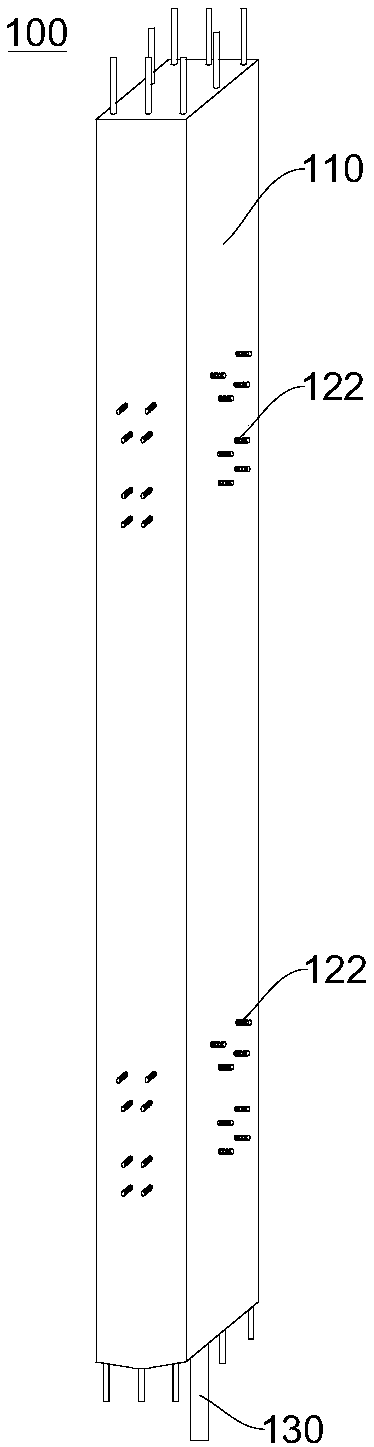

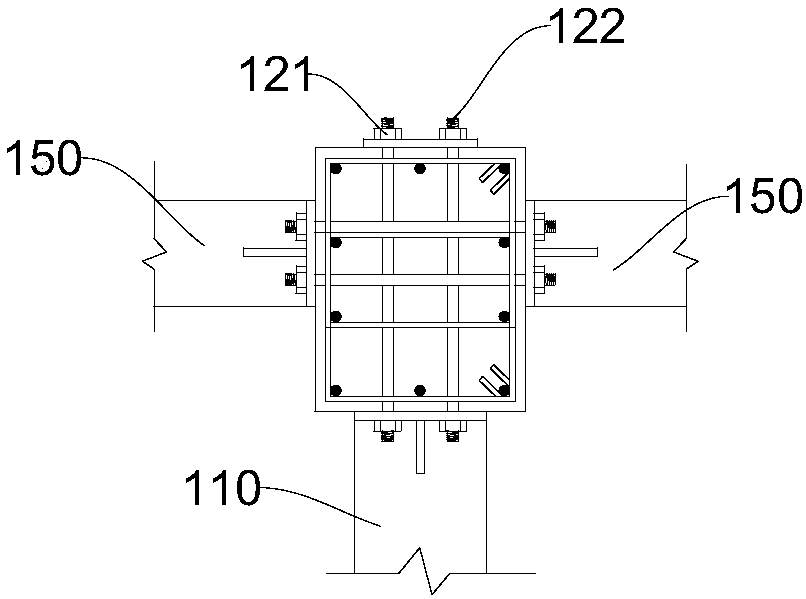

Fabricated precast reinforced concrete column and fabricated mixed frame building system

PendingCN107654021AImprove the compressive bearing capacityImprove carrying capacityStrutsProtective buildings/sheltersReinforced concrete columnArchitectural engineering

The invention provides a fabricated precast reinforced concrete column and a fabricated mixed frame building system, and relates to the field of construction. The fabricated precast reinforced concrete column comprises a pre-embedded casing and precast reinforced concrete with a connecting joint position. The precast reinforced concrete includes a concrete body and steel bars prefabricated in theconcrete body. The pre-embedded casing is arranged at the connecting joint position of the concrete body. The pre-embedded casing is embedded in the concrete body. The pre-embedded casing is of a hollow tubular structure, wherein a through hole is formed in the hollow tubular structure. The fabricated mixed frame building system comprises the fabricated precast reinforced concrete column. The fabricated precast reinforced concrete column can give full play to the excellent compression resistance bearing performance of reinforced concrete and the excellent tensile and flexural properties of structural steel. Concrete formworks are saved through a steel connecting part, the bearing capacity and ductility of the structure are increased, and large span assembly is realized. The assembly rate is increased while the bearing capacity and ductility of the fabricated precast reinforced concrete column are increased.

Owner:程丹松

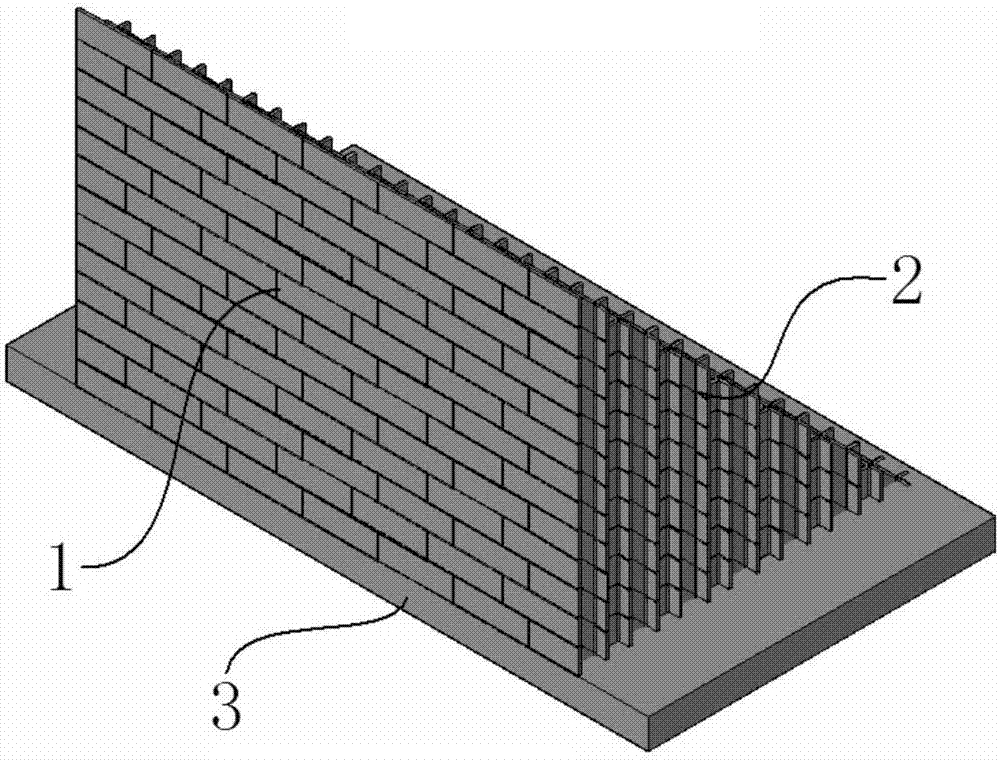

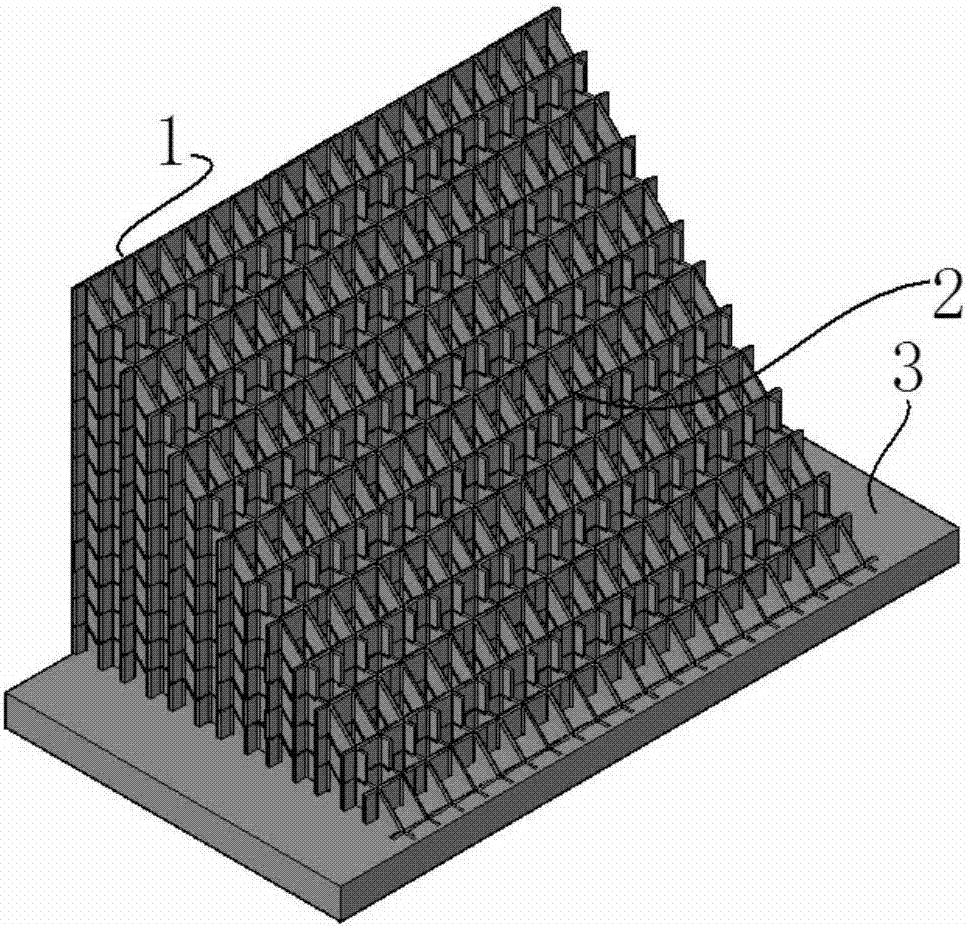

Strengthened anchoring fabricated type concrete retaining wall

InactiveCN108951694AImprove the anchoring effectImprove integrityArtificial islandsUnderwater structuresRoad engineeringPublic Facility

The invention provides a strengthened anchoring fabricated type concrete retaining wall, and belongs to the technical field of city underground road engineering and public facilities. Convex opening concrete prefabricated T-shaped plates are located on original soil, and arc-shaped concave connectors of concave-convex opening concrete fabricated flat plates are matched with arc-shaped convex connectors of the convex opening concrete prefabricated T-shaped plates; and a spiral long extending arm provided with a strengthening anchoring tie bar is horizontal, and the other one inclines downwardsby 30 degrees-45 degrees to be crossed with the horizontal spiral long extending arm on the lower layer. The strengthened anchoring fabricated type concrete retaining wall has the beneficial effects that mold plates can be saved, the construction condition during manufacturing is improved, the labor productivity is improved, the construction progress is accelerated, and the construction quality isguaranteed. Standardization, light and thin making and universalization of the fabricated type concrete retaining wall are achieved. The anchoring performance, the integrality, the stability and thesafety performance of the concrete retaining wall are obviously improved, cost is low, and project quality is easily guaranteed.

Owner:SHENYANG JIANZHU UNIVERSITY

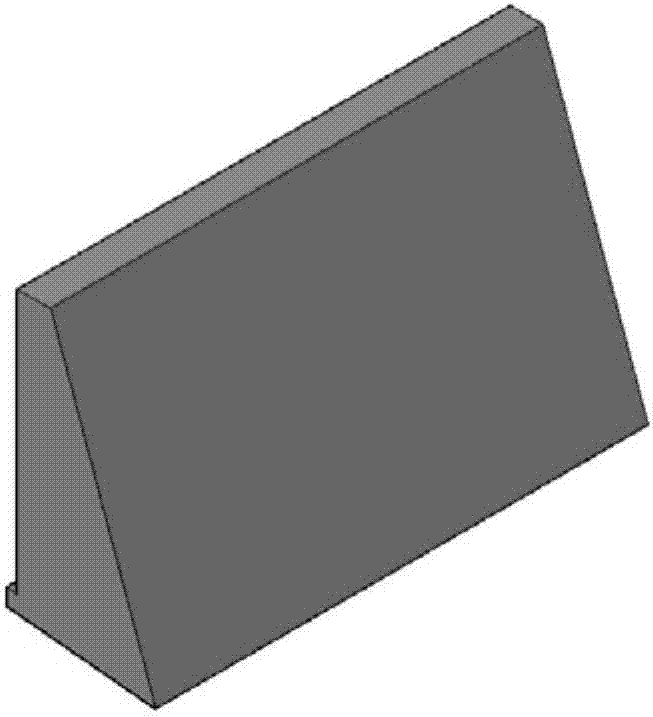

Prefabricated gravity type barrier wall

ActiveCN107288153AReduce dosageLow costArtificial islandsUnderwater structuresArchitectural engineeringRebar

The invention provides a prefabricated gravity type barrier wall. The prefabricated gravity type barrier wall comprises multiple wall face prefabricated blocks, multiple wall body prefabricated blocks, a barrier wall foundation plate and multiple reinforcing steel bars. The wall face prefabricated blocks and the wall body prefabricated blocks are designed into concrete grids which can be overlapped with one another for construction and mounted on the barrier wall foundation plate. Then, all the constructed prefabricated blocks are fixedly connected together through the reinforcing steel bars and mortar. Meanwhile, grid holes are filled with sandy soil so that the weight of the barrier wall can be increased. By means of the prefabricated gravity type barrier wall, the requirement for the bearing capacity of a foundation is low; concrete consumption is greatly saved; a scrapped soil body at site is fully converted into a wall body backfill construction material for the barrier wall; construction cost of a project is greatly saved; the construction period of the project is shortened; and the wall face ecological afforestation environment can be improved conveniently.

Owner:易朋莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com