Prefabricated gravity type barrier wall

A gravity-type retaining wall technology, applied in construction, artificial islands, infrastructure engineering, etc., can solve problems such as long construction period and poor economic performance of retaining walls, reduce project cost, improve slope greening effect, build Convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

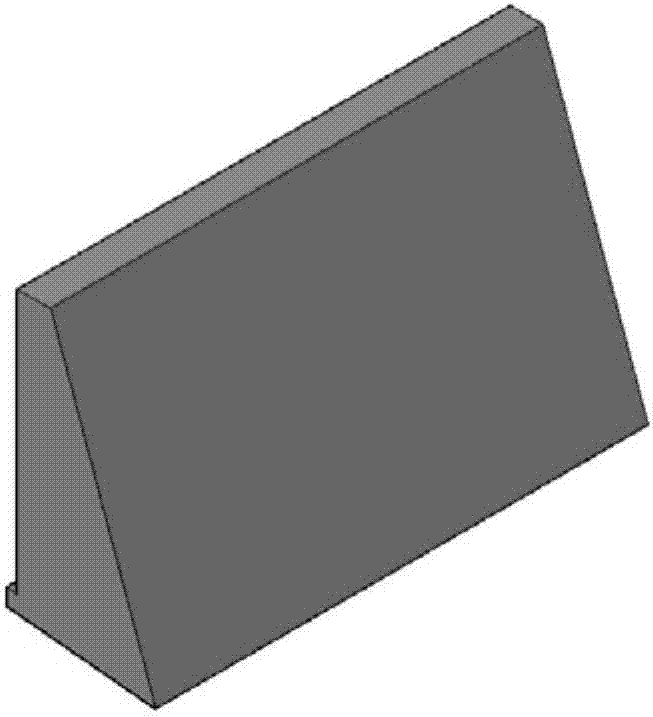

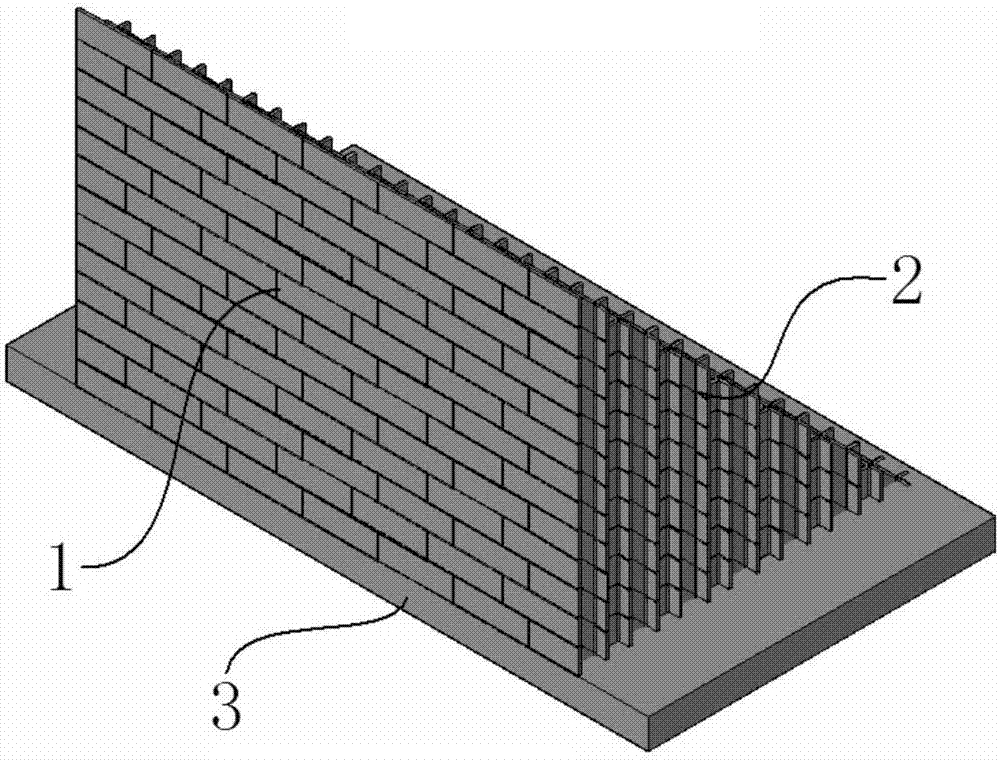

[0039] A prefabricated gravity retaining wall includes several wall prefabricated blocks 1, several wall prefabricated blocks 2, retaining wall foundation boards 3 and several steel bars.

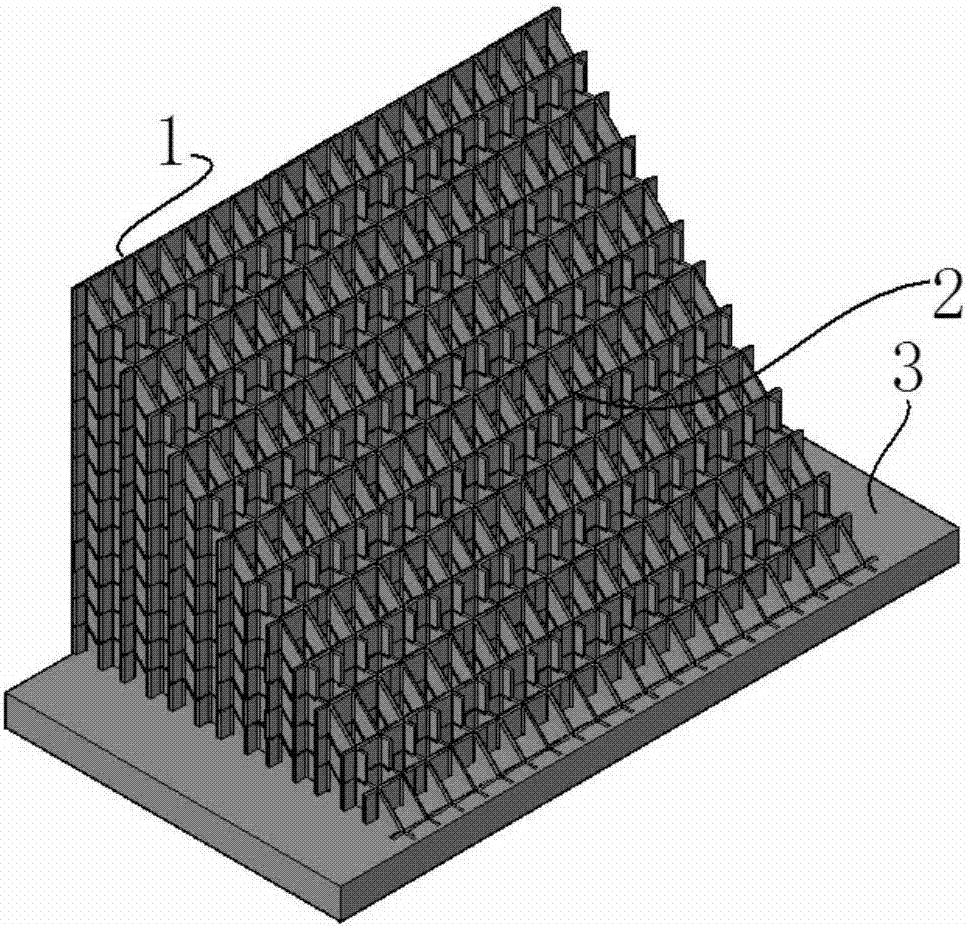

[0040] The wall prefabricated block 1 includes a vertical wall 101 and several concrete spacers 102 . The wall surface 101 and these concrete partition boards 102 are cast-in-place as an integral structure. The surfaces of the concrete partition boards 102 are vertical and interlaced with each other to form a plurality of hollow sash holes. The intersections of these concrete spacers 102 are provided with vertically through reserved holes 103 . One side of the prefabricated wall block 1 is a wall surface 101, and the peripheral grids on the other three circumferential sides are spliced grids. When two adjacent wall prefabricated blocks 1 on the same horizontal plane are spliced together, the spliced sashes around them are combined to form a complete sash hole.

[0041] In this embo...

Embodiment 2

[0048] The main structure of this embodiment is substantially the same as that of Embodiment 1. Wherein the wall prefabricated block 1 and the wall prefabricated block 2 are both in the shape of steps. Their plan view and embodiment 1 Figure 8 , Figure 9 Not much difference. while the side view see Figure 11 and Figure 16 , between each step is a standard step surface perpendicular to each other, that is, one step corresponds to a vertical step surface.

[0049] That is to say, the prefabricated wall block 1 and the prefabricated wall block 2 of the present invention may be designed to be able to assemble each other. Their specific prototypes can be found in Figure 12 and Figure 17 , that is, the concrete sash at the same horizontal position, these concrete partitions 102 are arranged in a criss-cross pattern to form a rectangular sash, and when building masonry, as long as the joints are staggered from each other and the sash holes are connected to each other, it...

Embodiment 3

[0053] This embodiment provides a process installation method for a retaining wall, which specifically includes the following steps:

[0054] 1) According to the design of the retaining wall, the wall prefabricated block 1 and the wall prefabricated block 2 are made in the prefabrication yard.

[0055] 2) Prepare the mortar for the assembly of the above prefabricated blocks, and the connecting steel bars to be installed in the reserved holes.

[0056] 3) Excavate the foundation groove on site, pour the retaining wall foundation plate 3, embed the connecting steel bars, and install the first layer of prefabricated wall blocks 1 and 2. 1 / 3-1 / 2 of the lower ends of these prefabricated blocks on the first floor are embedded in the base plate 3 of the retaining wall.

[0057] 4) After the strength of the base plate 3 of the retaining wall meets the construction requirements, backfill the soil in the grid hole, and compact the filled soil. Connect the reserved holes to connect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com