Support-free medium-long prefabricated rib truss rib composite plate structure and preparation method thereof

A technology of laminated slab and prefabricated rib, applied in the direction of structural elements, floor slabs, building components, etc., can solve the problems of insignificant improvement of slab rigidity, difficulty in fabrication, etc., and achieve the effect of good integrity, good crack resistance, and template saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

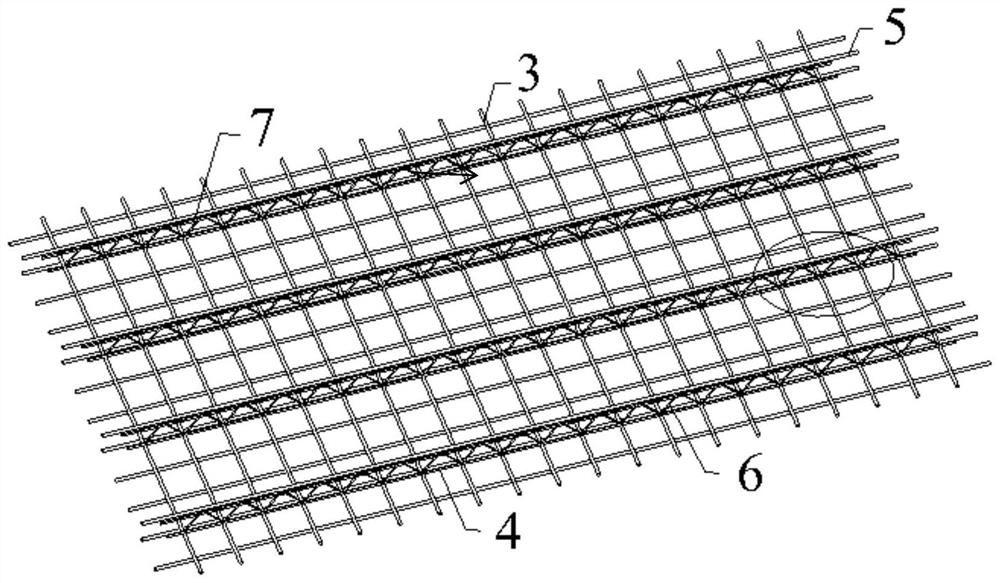

[0052] The present invention provides a support-free mid-length prefabricated rib truss bar laminated slab structure, such as image 3 , Figure 4 and Figure 5 As shown, it includes: a horizontal reinforcement mesh and a truss reinforcement 7 arranged thereon, the horizontal reinforcement mesh includes a longitudinal reinforcement and a transverse reinforcement 3 overlapped thereon, each of the truss reinforcements 7 includes an upper chord reinforcement 5, two A lower chord reinforcement 4 and a web reinforcement 6, the web reinforcement 6 connects the upper chord reinforcement 5 and the two lower chord reinforcements 4 to form an umbrella-shaped structural unit, and the two lower chord reinforcements 4 are respectively arranged in parallel on the Both sides of the longitudinal reinforcement, such as Figure 11 As shown, concrete prefabricated ribs 9 are arranged between the adjacent truss bars 7, the first concrete layer 16 is poured on the lower part of the horizontal re...

Embodiment 2

[0068] The present invention provides a support-free mid-length prefabricated rib truss bar laminated slab structure, such as image 3 , Figure 4 and Figure 5 As shown, it includes: a horizontal reinforcement mesh and a truss reinforcement 7 arranged thereon, the horizontal reinforcement mesh includes a longitudinal reinforcement and a transverse reinforcement 3 overlapped thereon, each of the truss reinforcements 7 includes an upper chord reinforcement 5, two A lower chord reinforcement 4 and a web reinforcement 6, the web reinforcement 6 connects the upper chord reinforcement 5 and the two lower chord reinforcements 4 to form an umbrella-shaped structural unit, and the two lower chord reinforcements 4 are respectively arranged in parallel on the On both sides of the longitudinal reinforcement, concrete prefabricated ribs 9 are arranged between the adjacent truss reinforcement 7, the first concrete layer 16 is poured on the lower part of the horizontal reinforcement mesh a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com