Strengthened anchoring fabricated type concrete retaining wall

A technology of concrete and strengthening anchors, which is used in water conservancy projects, artificial islands, underwater structures, etc., to achieve the effect of speeding up construction progress, low cost, and saving formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

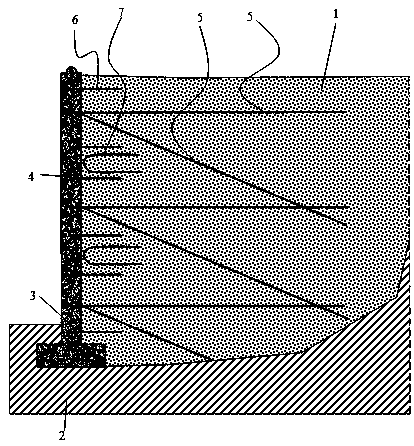

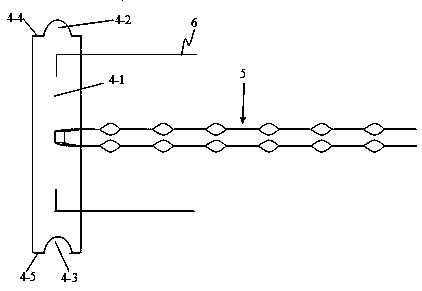

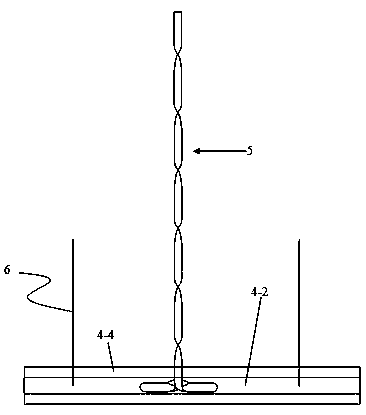

[0033] Such as Figure 1~Figure 6 As shown, a reinforced and anchored assembled concrete retaining wall includes filling soil 1, original soil 2, convex concrete prefabricated T-shaped plate 3, concave and convex concrete prefabricated flat plate 4, reinforced anchorage tie bars 5, horizontal short steel bars 6, Interface U-shaped steel bar 7, the convex concrete prefabricated T-shaped plate 3 is located at the bottom, and the reinforced horizontal feet 4-6 of the convex concrete prefabricated T-shaped plate 3 are located on the original soil 2; the original soil 2 on one side is higher than the reinforced level Feet 4-6, the other side is filling soil 1; the arc-shaped concave interface 4-3 of the concave-convex concrete prefabricated slab 4 matches the arc-shaped convex interface 4-2 of the convex concrete prefabricated T-shaped plate 3 below; and The arc-shaped convex interface 4-2 of the concave-convex concrete prefabricated slab 4 matches the arc-shaped concave interface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com