Prestressed steeling reinforcement method for concrete column

A concrete column and prestressing technology, which is applied in the structural engineering field of civil engineering disciplines, can solve problems such as the low stress state of the pasted angle steel, cannot fully play its role, and is difficult to achieve the expected purpose, so as to improve the earthquake resistance level and achieve good anchorage Effect, the effect of low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

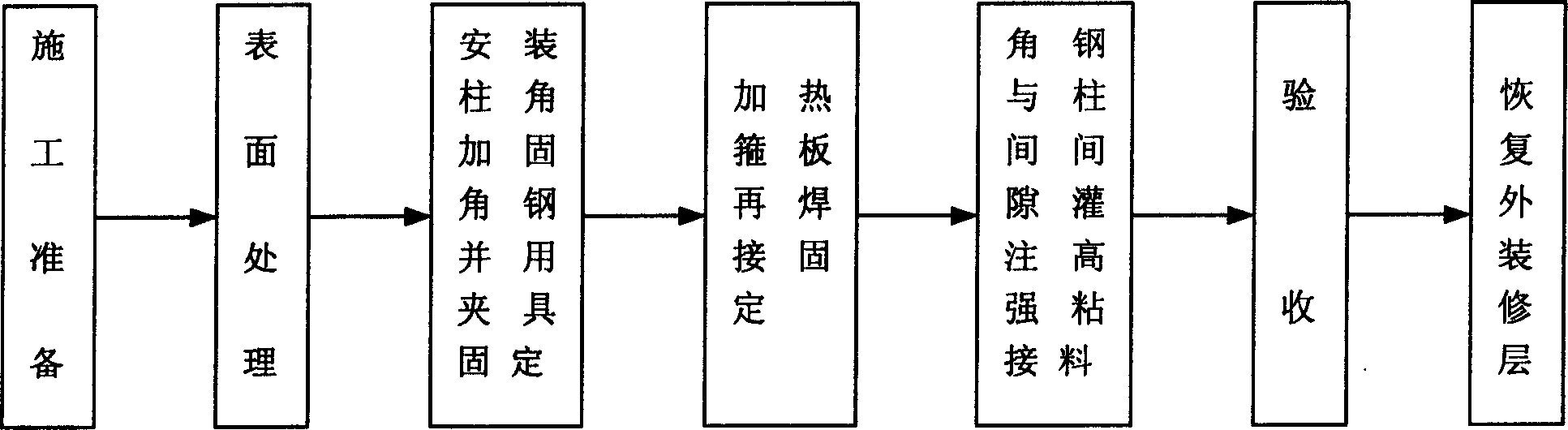

Method used

Image

Examples

Embodiment 1

[0029] The cross-section of a central column in a workshop is 400×600mm, equipped with 8Φ22+2Φ18 longitudinal steel bars, and the cross-sectional area of the steel bars is 3550mm 2 , the height of the column from the top of the foundation to the floor of the second floor is 4.5m, the maximum axial force is 3200kN, the bending moment is 250kN*m, and the measured strength grade of the original concrete is C15. Reinforcement material: 4∠100×8, cross-sectional area 6256mm 2 , A3 steel, compressive strength 235N / mm 2 , the short side hoop plate is selected -80×6, the cross-sectional area is 480mm 2 , the long side hoop plate is selected -60×6, the cross-sectional area is 360mm 2 , 16Mn steel, strength 295N / mm 2 , the spacing is 250mm, the heating temperature of the hoop plate on the long side is calculated to be 131°C, and the heating temperature on the short side is 136°C. Construction: Chisel out the crisp concrete at the column corners, grind the column surface flat with a...

Embodiment 2

[0031] In a dormitory building, it was found that the concrete compressive strength of the first floor column was low, which did not meet the design requirements. The structural review showed that the concrete strength of some columns was too low. The original column data is: the cross section of the central column is 500×600mm, with 8Φ25+4Φ20 longitudinal Steel bar, steel bar cross-sectional area 5183mm 2 , the height of the column from the top of the foundation to the floor of the second floor is 3.8m, and the measured strength of the original concrete is at least 15.6MPa. Reinforcement material: 4∠80×8, cross-sectional area 5100mm 2 , A3 steel, compressive strength 235N / mm 2, the short side hoop plate is selected -60×6, the cross-sectional area is 360mm 2 The long side hoop plate is selected -50×6, the cross-sectional area is 300mm 2 , 16Mn steel, strength 295N / mm 2 , with a spacing of 250mm, the calculated heating temperature of the hoop plate on the long side is 131°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com