BDAPOPP type silicone-containing adhesive and preparation method thereof

A technology of adhesives and organic solvents, applied in the direction of adhesives, etc., can solve the problems of high price, unfavorable large-scale popularization and application, and high cost of polyetherimide resin, and achieve the effect of convenient operation, good market application prospects, and industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

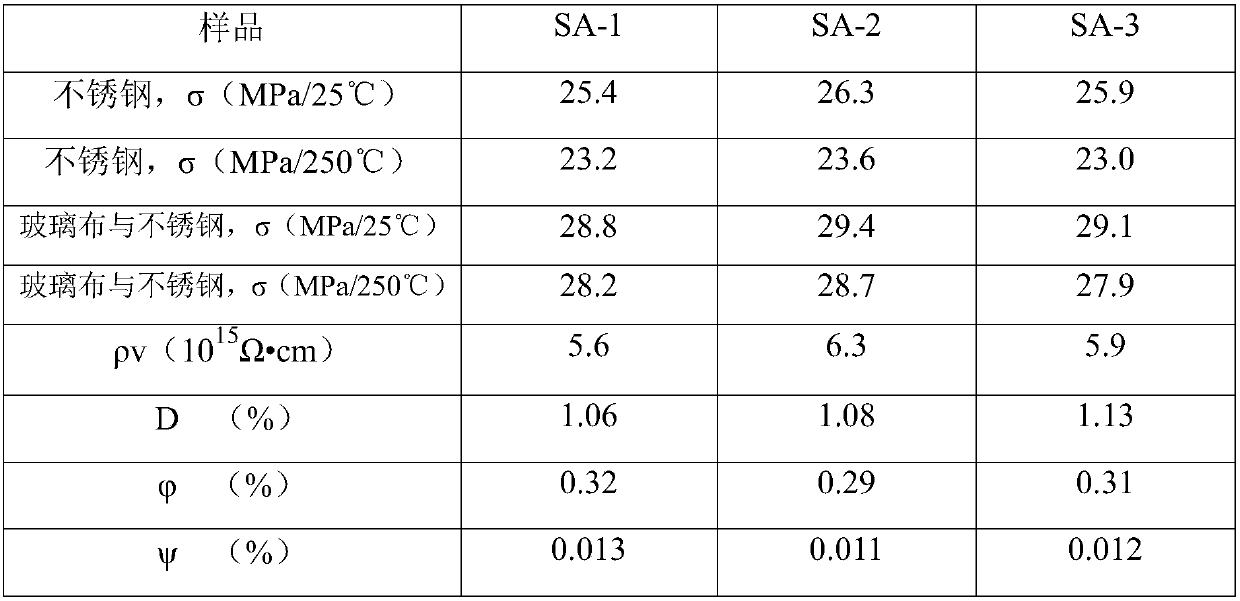

Embodiment 1

[0039] Put 44.0 grams (0.1 mol) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane (BDAPOPP) and 1300 grams of N,N dimethylacetamide into the reactor After stirring and dissolving at room temperature, 19.6 g (0.2 mol) maleic anhydride was added. After stirring and dissolving, after stirring and reacting at room temperature for 15 min, 40.0 g (0.2 mol) 3,4'-diaminodiphenyl ether and 58.4 g ( 0.2 mol) 1,4-bis(4-aminophenoxy)benzene and 41.0g (0.1 mol) 2,2-bis[4-(3-aminophenoxy)phenyl]propane, stir to dissolve, add 209.3g (0.65mol) of 3,3',4,4'-tetracarboxybenzophenone dianhydride, stirred and dissolved at room temperature, after stirring and reacting for 1.0 hour, 22.1g (0.1mol) of 3-aminopropyltriethyl was added Oxysilane, stirred and reacted at room temperature for 2 hours to obtain 1734.4 grams of viscous, transparent and homogeneous BDAPOPP type silica gel adhesive, denoted as SA-1.

Embodiment 2

[0041] 44.0 grams (0.1 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane (BDAPOPP), 1200 grams of N,N dimethylacetamide and 900 grams of N- Put ethyl-2-pyrrolidone into the reaction kettle. After stirring and dissolving at room temperature, 19.6 g (0.2 mol) of maleic anhydride was added. After stirring and dissolving, after stirring and reacting at room temperature for 30 min, 29.0 g (0.1 mol) 4,4 '-Diamino-4"-hydroxytriphenylmethane, 160.0 g (0.8 mole) 3,3'-diaminodiphenyl ether and 41.0 g (0.1 mole) 2,2-bis[4-(4-aminophenoxy) After stirring to dissolve, add 186.0 g (0.6 mole) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride and 193.2 g (0.6 mole) of 3,3',4,4 '-Tetracarboxybenzophenone dianhydride, stir to dissolve at room temperature, stir and react for 4.0 hours, add 44.2 g (0.2 mol) of 3-aminopropyltriethoxysilane, stir and react at room temperature for 0.5 hours to obtain 2817.0 Grams of viscous, transparent and homogeneous BDAPOPP-type silicone adhesive is denote...

Embodiment 3

[0043] 44.0 g (0.1 mole) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane (BDAPOPP), 3000 g N,N dimethylformamide and 1800 g N- Put ethyl-2-pyrrolidone into the reaction kettle, stir and dissolve at room temperature, add 19.6 g (0.2 mole) of maleic anhydride, stir and dissolve, stir and react at room temperature for 25 minutes, add 140.0 g (0.7 mole) 3,4 '-Diaminodiphenyl ether, after stirring to dissolve, add 155.0g (0.5mol) 3,3',4,4'-tetracarboxydiphenyl ether dianhydride, 182.0g (0.35mol) 2,2-bis[4 -(3,4-Dicarboxyphenoxy)phenyl]propane dianhydride, stir to dissolve at room temperature, after stirring and reacting for 2.0 hours, add 22.1g (0.1mol) of 3-aminopropyltriethoxysilane and 17.9g (0.1 mol) 3-Aminopropyltrimethoxysilane was stirred and reacted at room temperature for 1.5 hours to obtain 5380.6 g of a viscous, transparent and homogeneous BDAPOPP type silica gel adhesive, denoted as SA-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com