BAHPP-type silicon-containing adhesive and preparation method thereof

An adhesive and organic solvent technology, applied in adhesives and other directions, can solve the problems of high price, unfavorable large-scale popularization and application, high cost of polyetherimide resin, and achieve the effect of convenient operation, good market application prospects, and industrialized production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

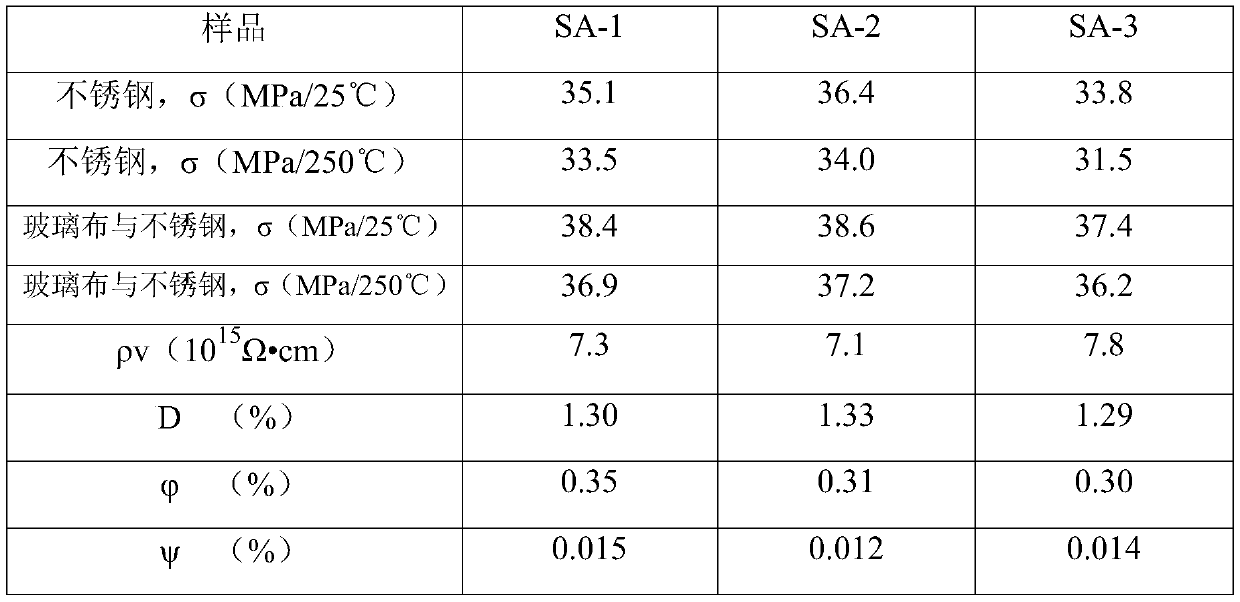

Embodiment 1

[0040] Put 25.8 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl)propane (BAHPP) and 1380 grams of N,N dimethylformamide into the reaction kettle, stir and dissolve at room temperature , add 120.0 g (0.3 mol) 4,4'-bis(4-aminophenoxy) diphenyl sulfide, 20.0 g (0.1 mol) 3,4'-diaminodiphenyl ether and 41.0 g (0.1 mol) 2,2-bis[4-(4-aminophenoxy)phenyl]propane, after stirring and dissolving, add 209.3 grams (0.65 moles) of 3,3',4,4'-tetracarboxybenzophenone dianhydride , stirring and dissolving at room temperature, after stirring and reacting for 1.0 hour, 22.1 grams (0.1 moles) of 3-aminopropyltriethoxysilane was added, stirred and reacted for 2 hours at room temperature, and then 23.6 grams (0.1 moles) of γ-(2, 3-Glycidoxy)propyltrimethoxysilane was stirred and reacted at 80° C. for 15 minutes to obtain 1841.8 grams of a viscous, transparent and homogeneous BAHPP-type silicone-containing adhesive, designated as SA-1.

Embodiment 2

[0042] 25.8 grams (0.1 mol) of 2,2-bis(3-amino-4-hydroxyphenyl)propane (BAHPP), 2000 grams of N,N dimethylacetamide and 1000 grams of N-ethyl-2-pyrrolidone Put it into the reaction kettle, stir and dissolve at room temperature, add 22.4 grams (0.1 moles) of 2-(4-aminophenyl)-5-aminobenzimidazole, 100.0 grams (0.5 moles) of 3,4'-diaminobis Phenyl ether, 51.8 g (0.1 mol) 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane and 120.0 g (0.3 mol) 4,4'-bis(4-aminophenoxy base) diphenyl sulfide, after stirring and dissolving, add 186.0 grams (0.6 moles) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride and 193.2 grams (0.6 moles) of 3,3',4,4 '-Tetracarboxybenzophenone dianhydride was stirred and dissolved at room temperature, and after stirring for 4.0 hours, 44.2 grams (0.2 moles) of 3-aminopropyltriethoxysilane was added, stirred and reacted for 0.5 hours at room temperature, and then 23.6 gram (0.1 mole) of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, stirred and reacted at 90°C ...

Embodiment 3

[0044] 25.8 grams (0.1 mol) of 2,2-bis(3-amino-4-hydroxyphenyl)propane (BAHPP), 5000 grams of N,N dimethylformamide and 1200 grams of N-ethyl-2-pyrrolidone Put the organic solvent in the reaction kettle, stir and dissolve at room temperature, add 280.0 grams (0.7 moles) of 4,4'-bis (4-aminophenoxy) diphenyl sulfide, stir and dissolve, add 225.4 grams (0.7 mol) 3,3',4,4'-tetracarboxybenzophenone dianhydride, 78.0 g (0.15 mol) 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane Dianhydride, stirring and dissolving at room temperature, after stirring for 2.0 hours, add 22.1 grams (0.1 mole) of 3-aminopropyltriethoxysilane and 17.9 grams (0.1 mole) of 3-aminopropyltrimethoxysilane, Stir the reaction for 1.5 hours, then add 47.2 grams (0.2 moles) of γ-(2,3-glycidoxy) propyltrimethoxysilane, and stir and react at 85°C for 15 minutes to obtain 6896.4 grams of viscous, transparent and homogeneous BAHPP type Contains silicone adhesive, denoted as SA-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com