Track structure of magnetic floating traffic and manufacturing method therefor

A manufacturing method and track technology, which is applied to tracks, roads, buildings, etc., can solve problems such as the complexity of track beam manufacturing, and achieve the effects of convenient adjustment of line alignment, simple method, and reduced manufacturing complexity and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

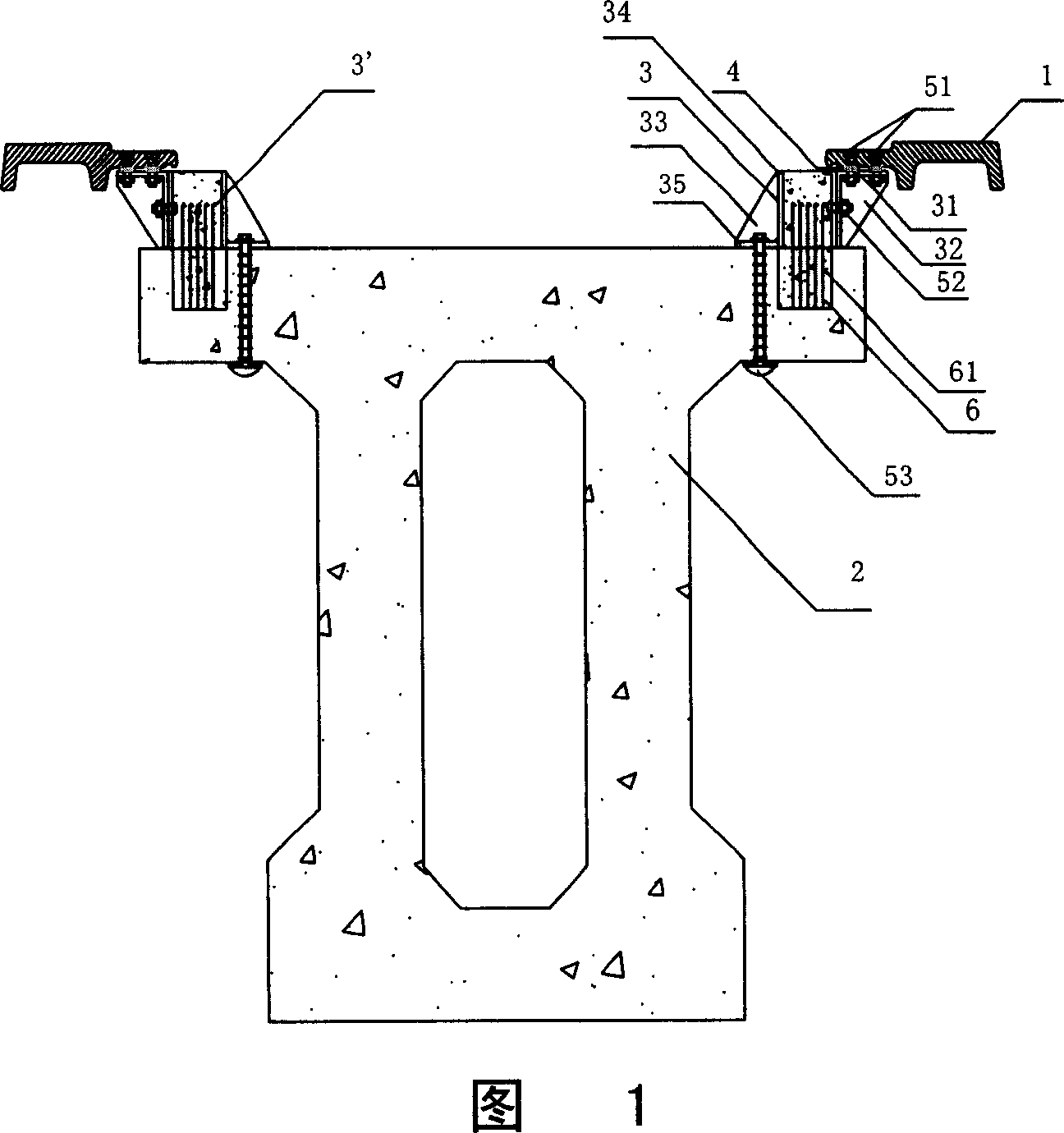

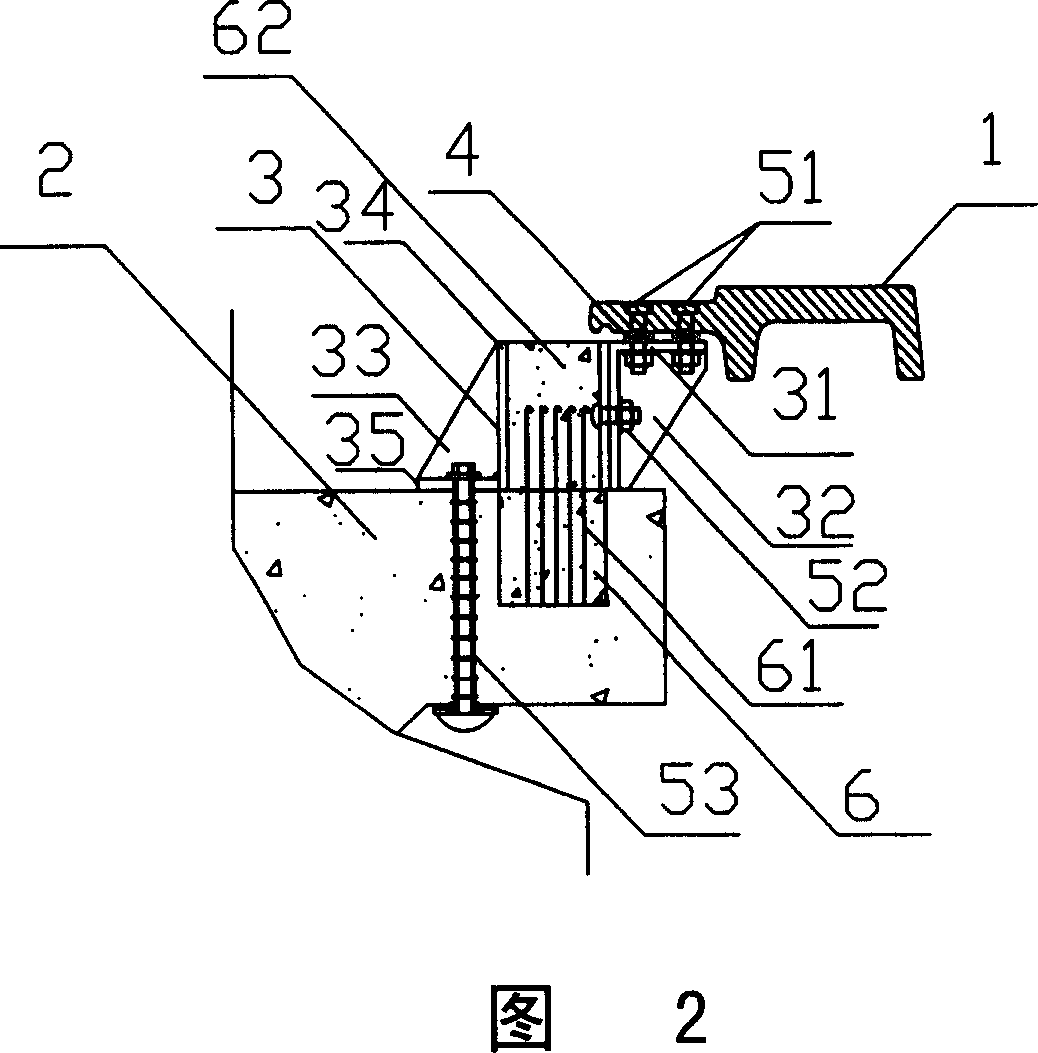

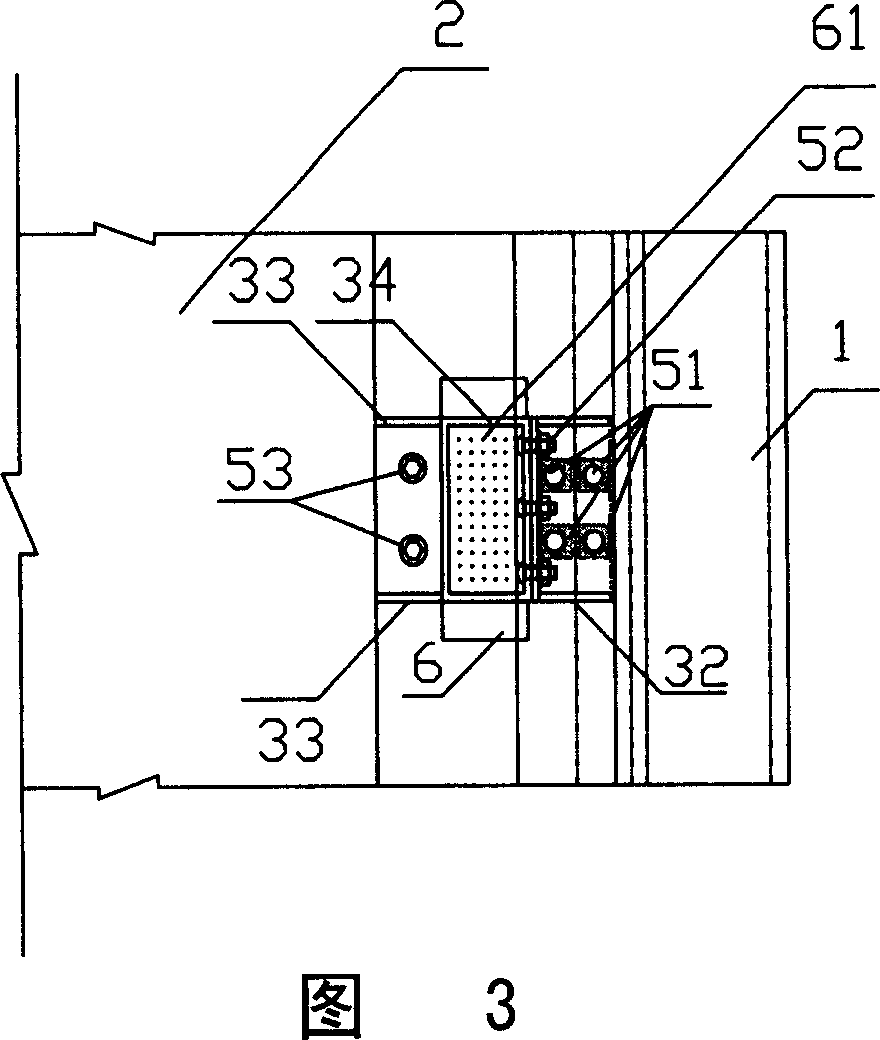

[0032] Please refer to Figs. 1-8, all the same components are represented by the same symbols among the figures. It can be seen from the figures that the track structure of the present invention mainly includes: track beam 2, guide rails 1 located on both sides of the upper surface of track beam 2, and a connecting structure connecting these two parts. The connection structure mainly includes pads 3 and fasteners such as bolts, and gaskets 4 can also be provided according to adjustment requirements. The difference between the present invention and the prior art is that pads 3 are arranged between the track beam 2 and the guide rail 1 . The so-called "block 3" here is different from the padding member for adjustment used in the past, but a structural connecting piece that connects the guide rail 1 and the track beam 2 .

[0033] 1 to 4 show a track structure according to a first embodiment of the present invention. In this embodiment, the block 3 is a prefabricated steel comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com