Novel vibration damper of clutch driven plate, with rotation angle added

A vibration damping device and clutch technology, applied to clutches, friction clutches, mechanical drive clutches, etc., to achieve the effects of alleviating idling vibration and noise, improving driving comfort, and optimizing vehicle matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

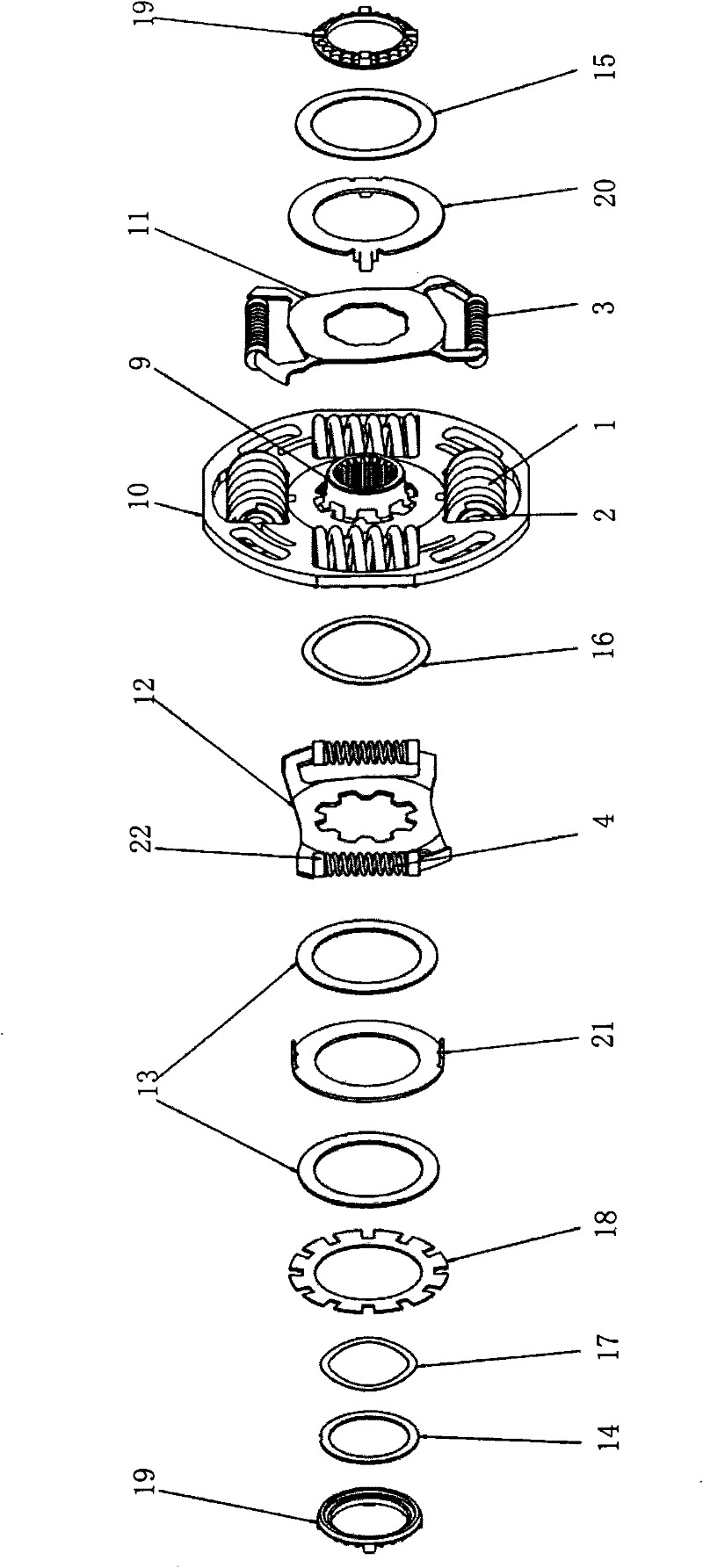

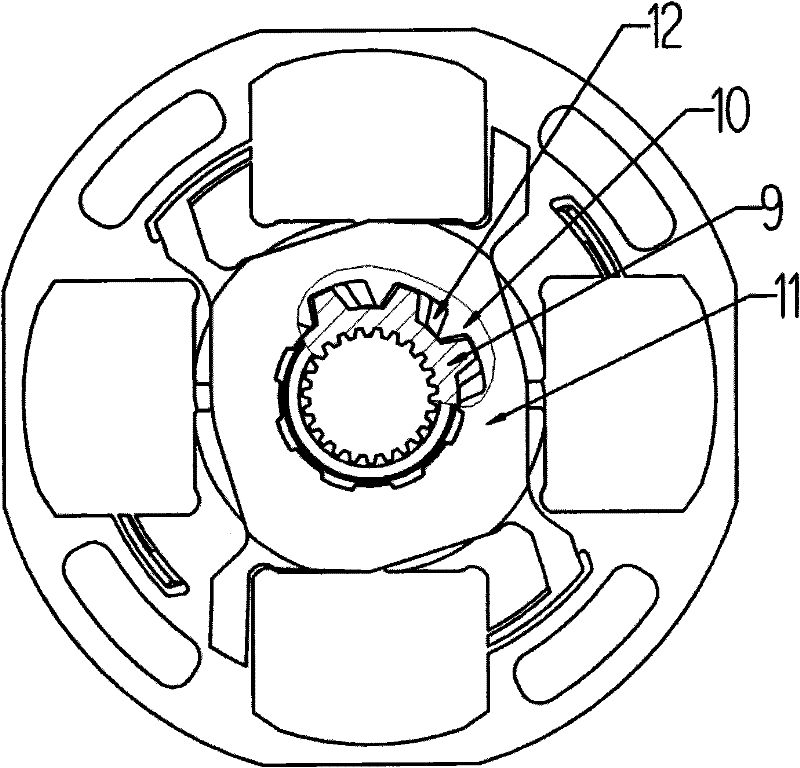

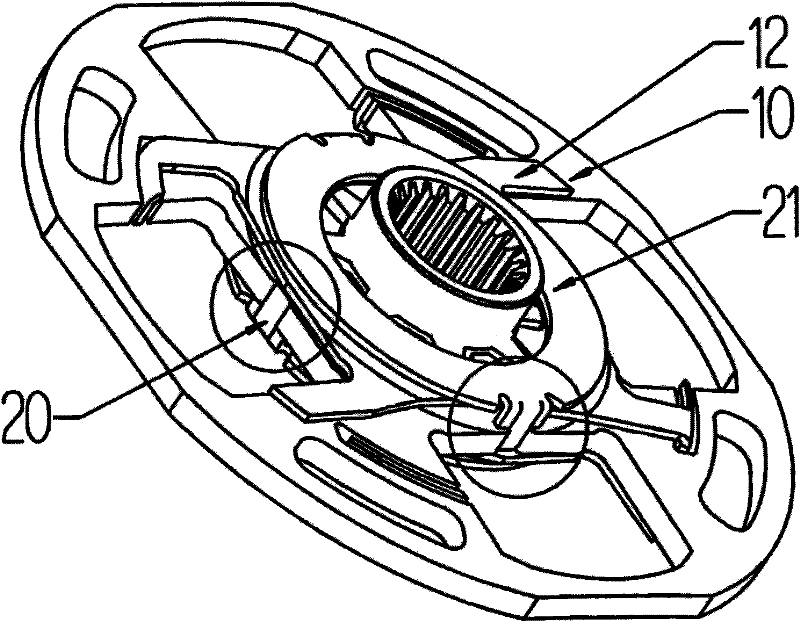

[0037] Please refer to the accompanying drawings for a further description of the present invention.

[0038] Such as figure 1 As shown, the present invention provides a novel clutch driven disc that can increase the rotation angle and damping device, including the main shaft sleeve plate 10 and the spline shaft sleeve 9, and it is characterized in that, on both sides of the main shaft sleeve plate 10, It is equipped with a first-level bushing plate 11 with a small spring A3, a second-level bushing plate 12 with a small spring B4, two limiting plates, a primary bushing plate 11 and a limiting plate E20, and a main shaft bushing plate 10 1. The secondary sleeve plate 12 and the limit plate F21 are connected in series with the spline sleeve 9 in the form of spline teeth, and the spline sleeve 9 is connected with the input shaft of the gearbox.

[0039] Such as figure 2 As shown, the tooth profile of the first-stage bushing plate 11 is exactly the same as that of the spline b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com