Antinode core-board precast concrete prefabricated composite wall

A technology of prefabricated concrete and composite walls, which is applied in the direction of walls, household walls, and layered products of hydraulic substances, which can solve problems such as lack, and achieve the effects of increasing energy consumption capacity, flexible layout, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

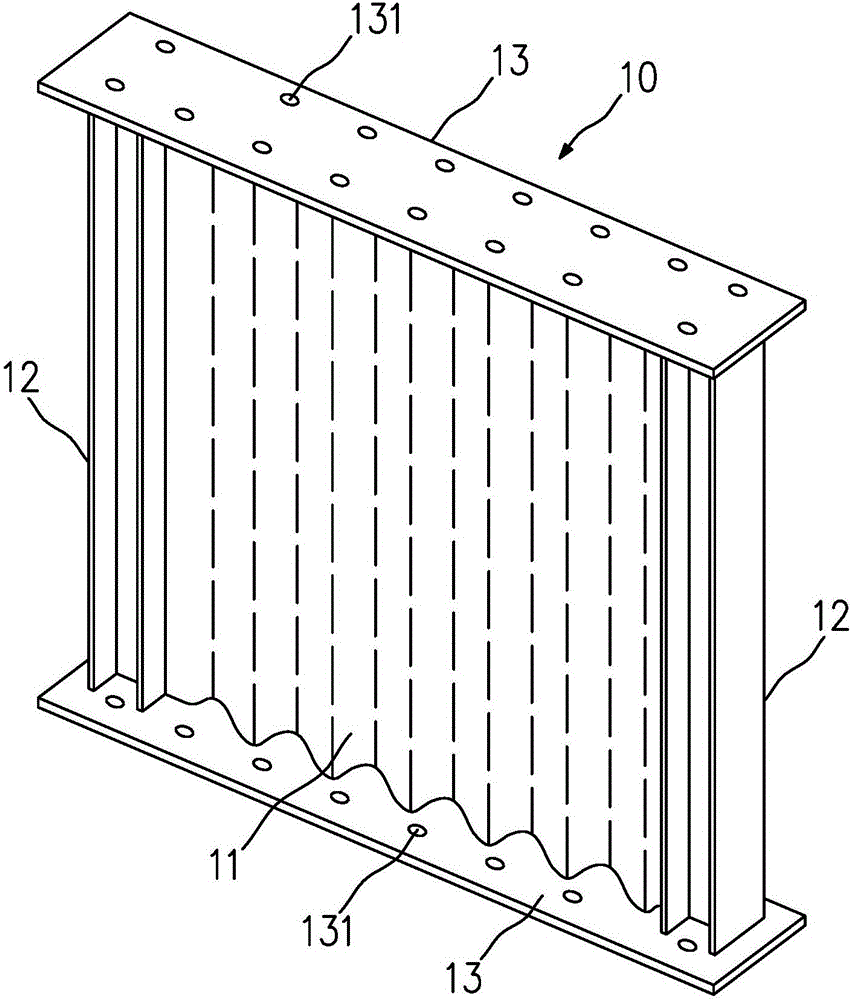

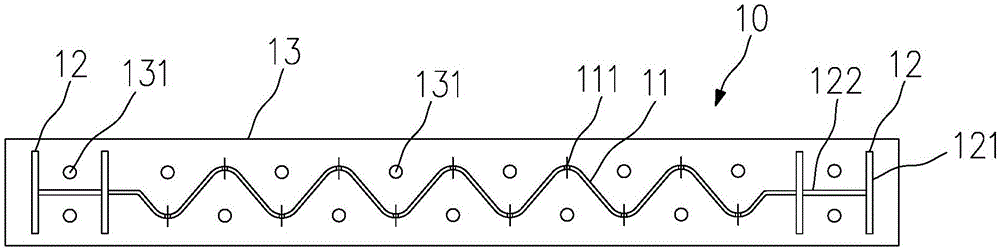

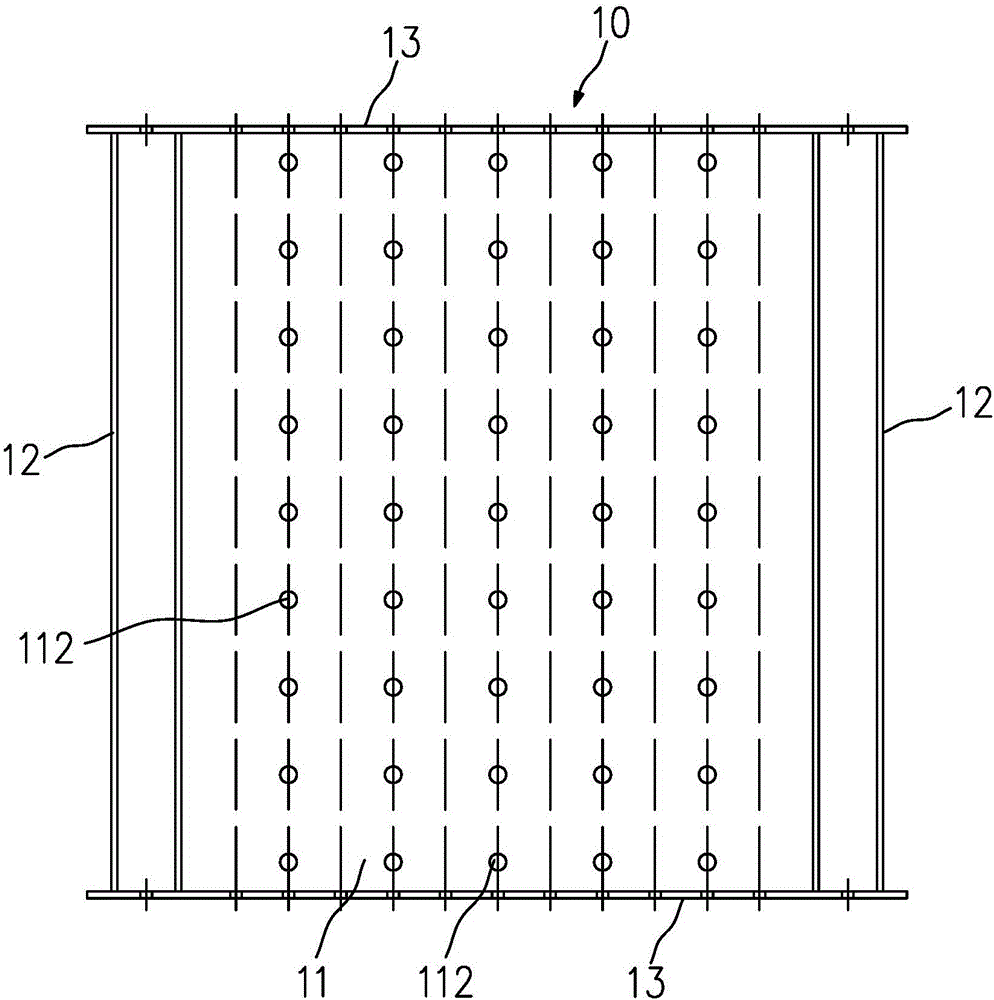

[0040] Such as Figure 1-7 As shown, a prefabricated concrete prefabricated composite wall with an antinode core plate is composed of an antinode core plate unit 10 and a reinforced concrete slab 20 covering the outside of the antinode core plate unit 10 .

[0041] Such as Figure 1~5 As shown, the antinode core plate unit 10 is a unit component composed of an antinode core plate 11, an edge reinforcement column 12 and an end plate 13; Figure 1~3 As shown, the surface of the antinode core plate 11 is wavy; the edge reinforcement column 12 is fixedly arranged on both sides of the antinode core plate 11, and the column length direction of the edge reinforcement colum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com