Method for preparing large-size high-temperature superconducting film

A high-temperature superconducting film and large-scale technology, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of difficulty in preparing large-scale high-temperature films with thickness, uncontrollable, and low surface roughness and other issues, to achieve the effect of meeting the requirements of commercial application, low production cost and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

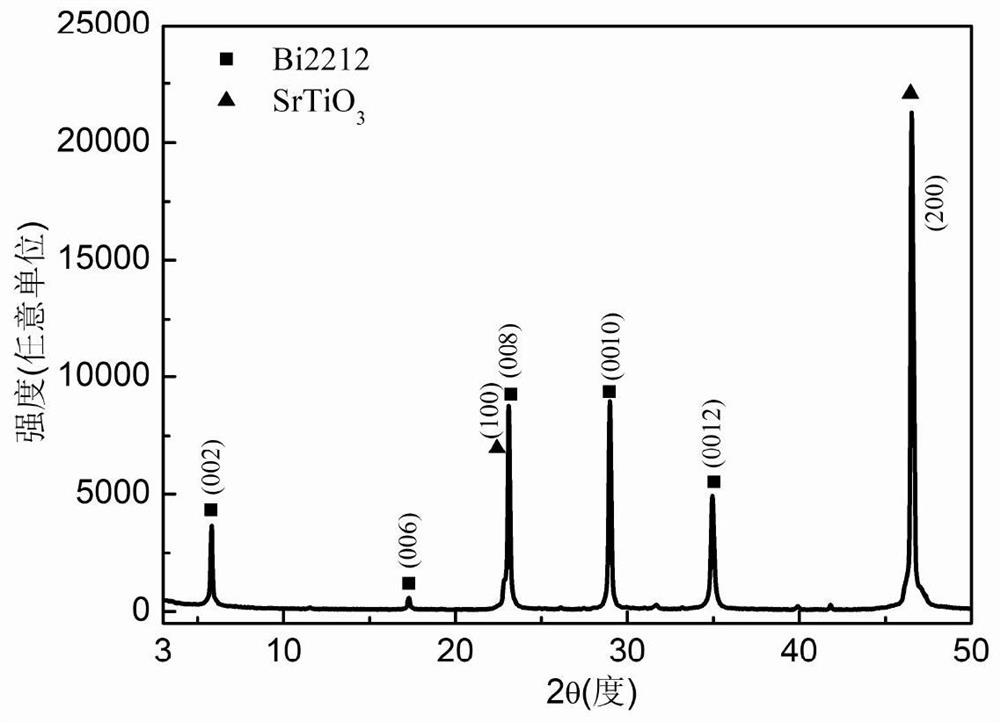

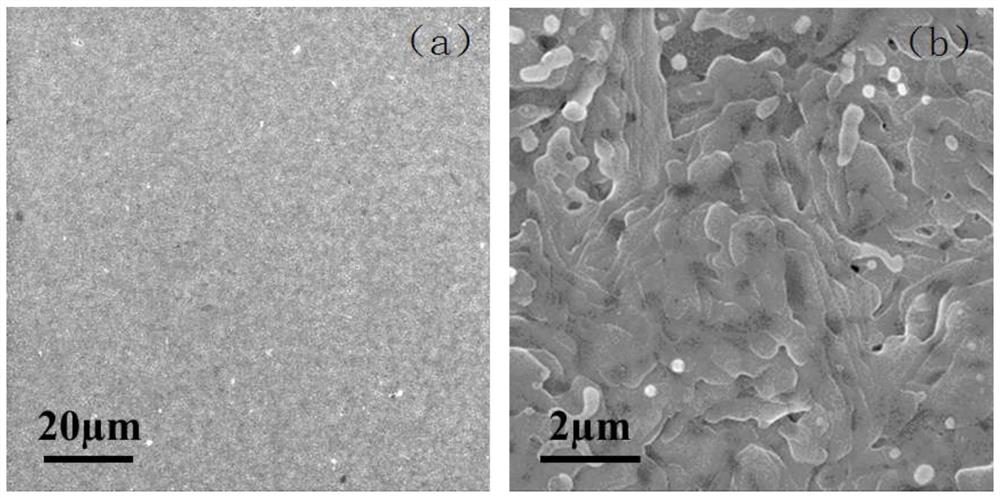

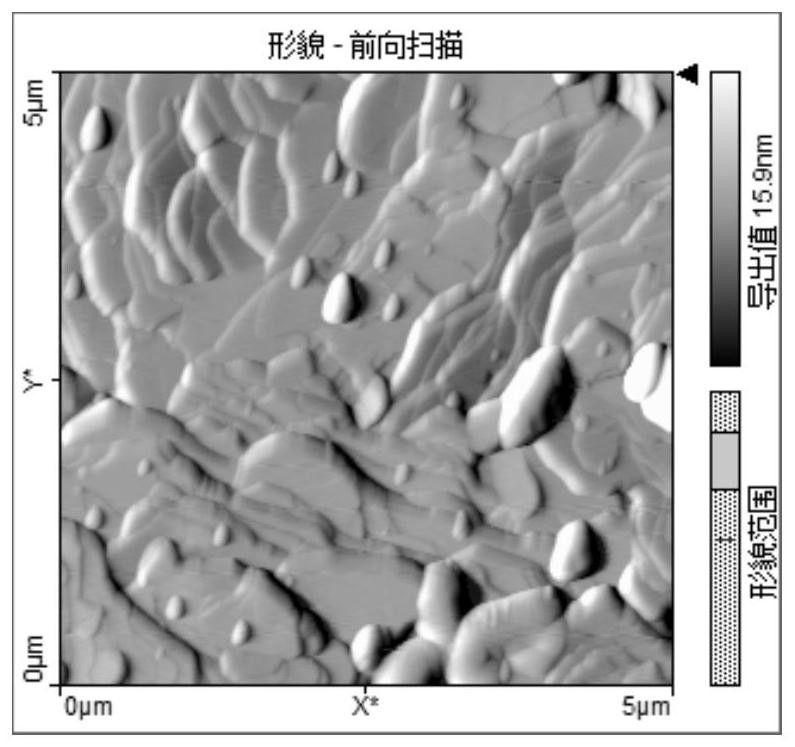

Image

Examples

Embodiment 1

[0028] (1) Configure the reaction solution

[0029] First weigh 0.2g of polyvinylpyrrolidone PVP and put it into a beaker, then weigh 10ml of propionic acid solution and add it to the beaker, stirring is required during the addition. Then stir on a magnetic stirrer for 8 hours until the PVP is completely dissolved in the propionic acid solution to form a uniform and transparent mixed solution. Finally, according to the molar ratio of high-temperature superconducting material elements 2:2:1:2 converted into the corresponding mass, weigh bismuth acetate (1.12g), strontium acetate (0.63g), calcium acetate (0.26g) and copper acetate (0.58 g) Afterwards, the above-mentioned mixed solution was added one by one, and stirred on a magnetic stirrer for 8 hours at room temperature to obtain a precursor sol.

[0030] (2) Preparation of precursor film by dipping and pulling method

[0031] First the SrTiO 3 , MgO or LaAlO 3 The single crystal substrate was put into deionized water, alc...

Embodiment 2

[0035] (1) Configure the reaction solution

[0036] First weigh 0.3g of polyvinylpyrrolidone PVP and put it into a beaker, then weigh 10ml of propionic acid solution and add it to the beaker, stirring is required during the addition. Then stir on a magnetic stirrer for 8.5 hours until the PVP is completely dissolved in the propionic acid solution to form a uniform and transparent mixed solution. Finally, according to the molar ratio of high-temperature superconducting material elements 2:2:1:2 into the corresponding mass, weigh bismuth acetate (1.13g), strontium acetate (0.64g), calcium acetate (0.26g) and copper acetate (0.59 g) Afterwards, the above mixed solution was added one by one, and stirred on a magnetic stirrer for 8.5 hours at room temperature to obtain a precursor sol.

[0037] (2) Preparation of precursor film by dipping and pulling method

[0038] First the SrTiO 3 , MgO or LaAlO 3 The single crystal substrate was put into deionized water, alcohol with a puri...

Embodiment 3

[0041] (1) Configure the reaction solution

[0042]First weigh 0.1g of polyvinylpyrrolidone PVP and put it into a beaker, then weigh 10ml of propionic acid solution and add it to the beaker, stirring is required during the addition. Then stir on a magnetic stirrer for 7.5 hours until the PVP is completely dissolved in the propionic acid solution to form a uniform and transparent mixed solution. Finally, according to the molar ratio of high-temperature superconducting material elements 2:2:1:2 into the corresponding mass, weigh bismuth acetate (1.12g), strontium acetate (0.64g), calcium acetate (0.25g) and copper acetate (0.58 g) Afterwards, the above mixed solution was added one by one, and stirred on a magnetic stirrer for 7.5 hours at room temperature to obtain a precursor sol.

[0043] (2) Precursor film prepared by dipping and pulling method

[0044] First the SrTiO 3 , MgO or LaAlO 3 The single crystal substrate was sequentially put into deionized water, alcohol with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com