Preparation method of micro-nano double-scale composite porous material

A porous material, two-scale technology, applied in the field of porous metal materials, can solve the problems of long preparation period and complex driving process, and achieve the effect of overcoming extremely high brittleness, overcoming technical bottlenecks, and expanding specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The preparation method of this micro-nano dual-scale composite porous material comprises the following steps:

[0021] (1) Put 400g of Mg and Zn mixture (metal Zn accounts for 70% of the mixture's mass) into the melting crucible in the high-pressure induction furnace, cover the furnace cover tightly, lock the furnace body, and evacuate to a vacuum degree of 10 -2 Pa;

[0022] (2) Fill in 0.1MPa hydrogen, heat the metal mixture in the melting crucible, melt the mixture to 20°C above the melting point, and then keep it warm for 30 minutes to fully dissolve the hydrogen in the alloy solution;

[0023] (3) Pour the metal melt into a crucible cooled by water at the bottom to obtain a directional arranged micron-scale regular through-hole material with a thickness of 90 mm and a porosity of the micron-level regular through-hole material of 34%;

[0024] (4) Use 1mol / L hydrochloric acid to dealloy the porous material until no obvious air bubbles are generated on...

Embodiment 2

[0025] Embodiment 2: The preparation method of this micro-nano dual-scale composite porous material comprises the following steps:

[0026] (1) Put 500g of Mg and Ag mixture (metal Ag accounts for 50% of the mass of the metal mixture) into the melting crucible in the high-pressure induction furnace, cover the furnace cover tightly, lock the furnace body, and evacuate until the vacuum degree is 10 -2 Pa;

[0027] (2) Fill in 0.5MPa hydrogen, heat the metal mixture in the melting crucible, melt the mixture to 30°C above the melting point, and keep it warm for 20 minutes to completely dissolve the hydrogen into the alloy solution;

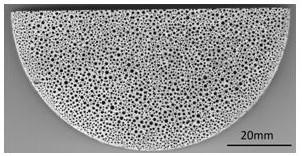

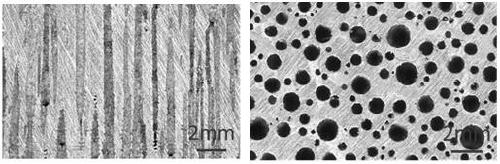

[0028] (3) Pour the metal melt into a crucible cooled by water at the bottom to obtain a material with oriented micron-scale regular through holes; the macroscopic morphology of the longitudinal section of the Mg-Ag porous alloy is shown in figure 1 , the cross-sectional macroscopic topography is shown in figure 2 , and the partial enlargement of t...

Embodiment 3

[0030] Embodiment 3: The preparation method of this micro-nano dual-scale composite porous material comprises the following steps:

[0031] (1) Put 600g of Mg, Ag and Pd mixture (metal Ag accounts for 40% of the mass of the metal mixture) into the melting crucible in the high-pressure induction furnace, close the furnace cover, lock the furnace body, and evacuate until the vacuum degree is l0 -2 Pa;

[0032] (2) Fill in 1.5MPa hydrogen, heat the metal mixture in the melting crucible, melt the mixture to 20°C above the melting point, and then keep it warm for 30 minutes to fully dissolve the hydrogen in the alloy solution;

[0033] (3) Pour the metal melt into a crucible cooled by water at the bottom to obtain a directional arranged micron-scale regular through-hole material with a thickness of 110 mm and a porosity of micron-scale regular through-hole material of 47%;

[0034] (4) The obtained porous material was corroded by the electrochemical corrosion method, the electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com