Installation and leveling method of prefabricated short floating slab in floating track bed

A floating track bed and prefabricated technology, which is applied in the field of rail transit, can solve the problems affecting the construction progress and the time-consuming installation and leveling of prefabricated short floating slabs, etc., so as to improve the construction speed, have broad market application prospects, and overcome technical bottlenecks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

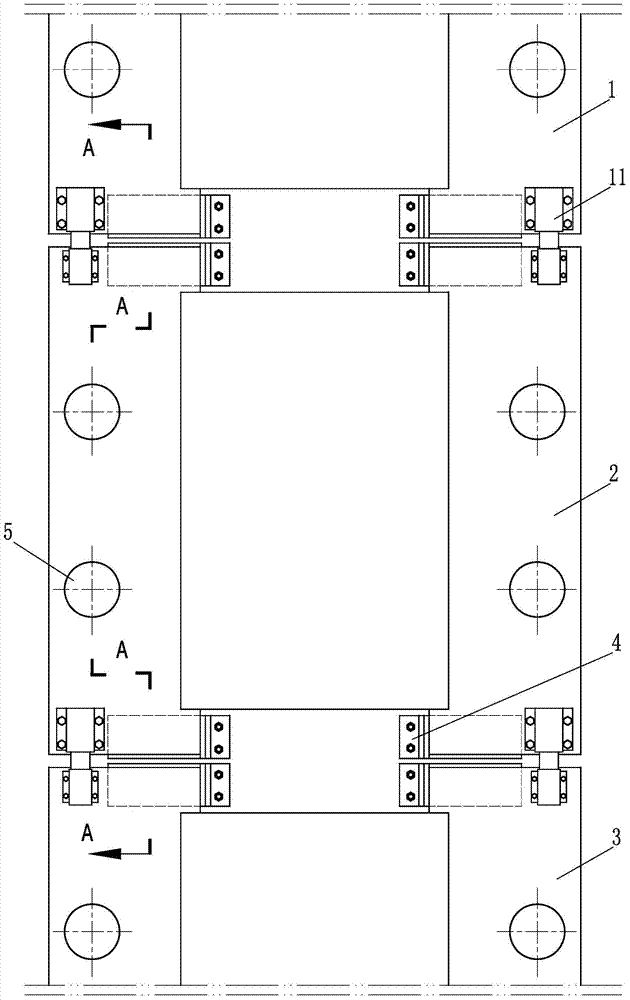

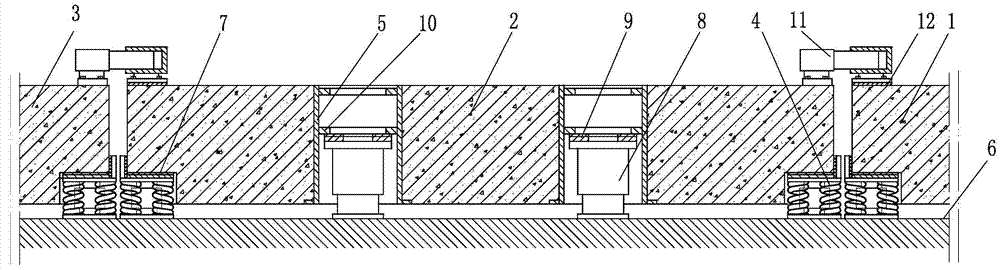

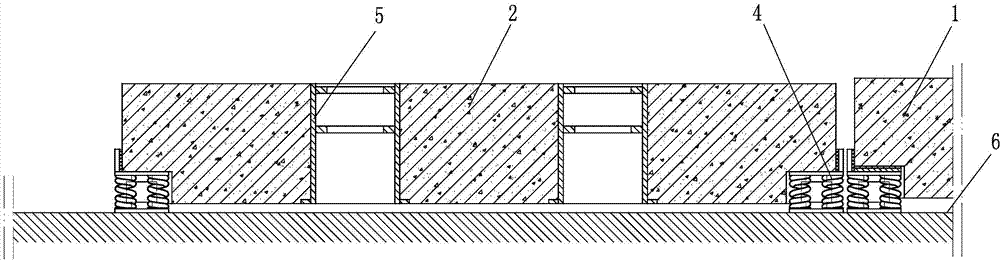

[0030] Taking each prefabricated short floating slab in the floating ballast bed as an example, the prefabricated short floating slab in the floating ballast bed of the present invention is jointly supported by four plate end vibration isolation devices and four built-in elastic vibration isolators. The operation process of the installation and leveling method is given specific instructions. For the convenience of understanding the method of the present invention, the basic structure of the involved floating ballast bed is firstly explained. The typical structure of the floating ballast bed is as follows figure 1 and figure 2 As shown, taking the prefabricated short floating slab 2 as an example, it is jointly supported by four plate end vibration isolators 4 and four built-in elastic vibration isolators 8, separated from the surface of the foundation 6, and the elastic vibration isolators 8 are placed on In the connecting sleeve 5 fixedly arranged in the prefabricated shor...

Embodiment 2

[0064] Still taking the floating ballast bed described in Embodiment 1 as an example, each prefabricated short floating slab is jointly supported by four plate end vibration isolation devices and four built-in elastic vibration isolators. Different from Embodiment 1, this embodiment In the installation and leveling method of the prefabricated short floating slab in the floating track bed of the present invention, when placing the prefabricated short floating slab in step (1), place and adjust in sequence according to the method described in step (1). The plane positions of many prefabricated short floating slabs constitute at least one installation section, and then carry out initial jacking and leveling, second jacking and leveling and precise jacking for each prefabricated short floating slab in the installation section Leveling, so as to realize the installation and leveling of the prefabricated short floating slab in the floating ballast bed.

[0065] In the installation a...

Embodiment 3

[0068] Still taking the floating ballast bed with the structure described in Embodiment 1 as an example, based on the technical principles of Embodiment 1 and Embodiment 2, the installation and leveling method of the prefabricated short floating slab in the floating ballast bed of the present invention can also be evolved as follows, The specific operation process is as follows:

[0069] (1) According to the plane positions of the prefabricated short floating slab and the four plate end vibration isolation devices marked by the dashed line on the ballast bed foundation, place the plate end vibration isolation devices at the predetermined positions respectively, and then place the prefabricated prefabricated Place the prefabricated short floating slabs on the vibration isolation device at the end of the slab by hoisting and transporting equipment, adjust the plane position of the prefabricated short floating slabs, and place and adjust the plane positions of multiple prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com