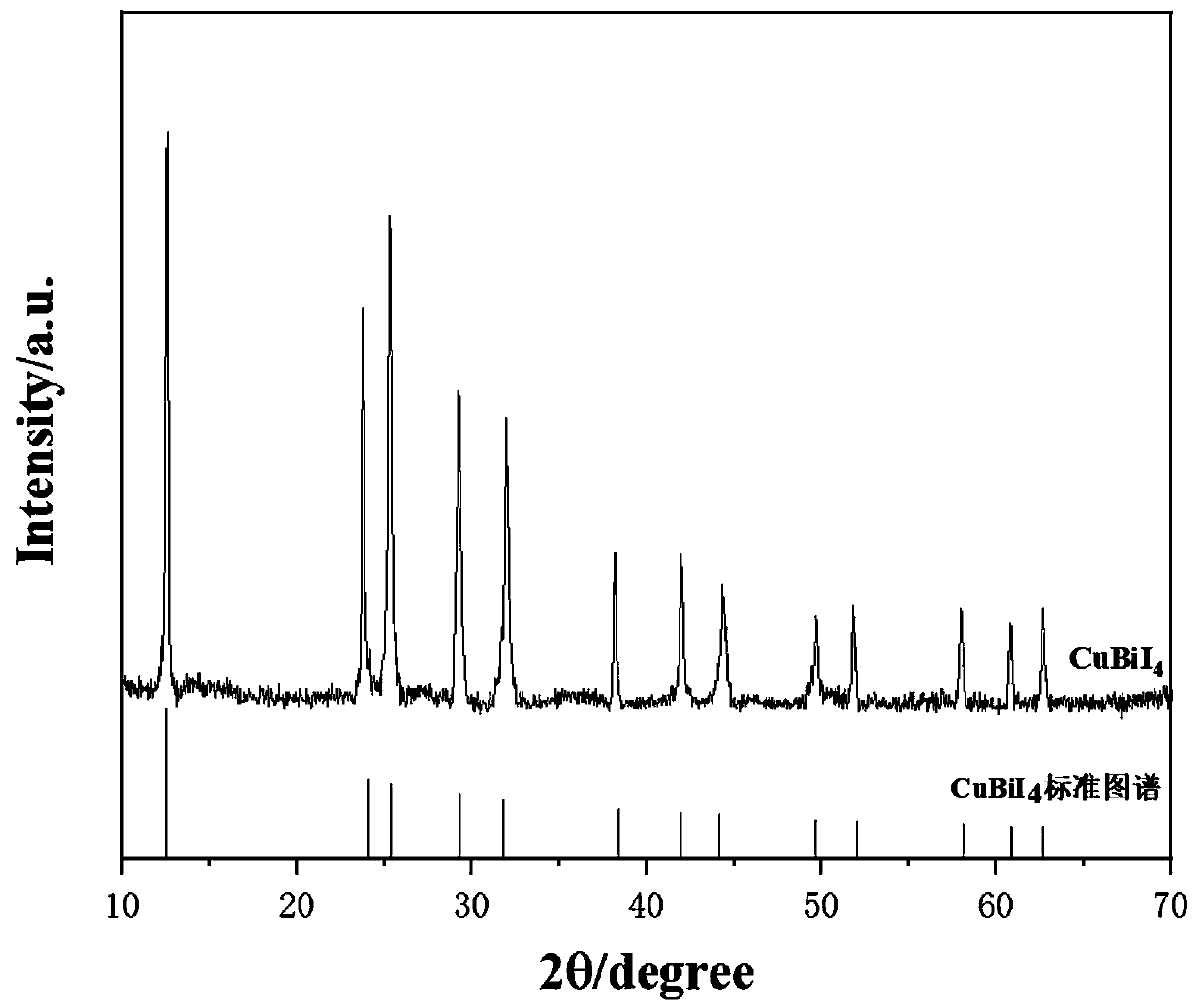

Preparation method of bismuth copper iodide crystal

A technology of copper crystal and crystal furnace, which is applied in the field of preparation of iodine-bismuth-copper crystals, can solve problems such as explosions and a large number of exothermic crucibles, and achieve the effects of overcoming technical bottlenecks, reducing component segregation, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of iodine bismuth copper crystal, comprising the steps of:

[0032] 1) Preparation of iodine bismuth copper polycrystalline material; the preparation process includes the following steps:

[0033] ①Weigh copper powder, bismuth powder and iodine particles with a purity greater than or equal to 99.99% in a dark room according to the molar ratio Cu:Bi:I=1:1:4.

[0034] ②In the darkroom, mix 5.7019g copper powder and 18.7516g bismuth powder evenly, put 45.5465g iodine particles into the mortar for grinding, then put the copper-bismuth mixture into the bottom of the quartz crucible, put the ground iodine particles into The upper layer of the quartz crucible; wrap the outside of the quartz crucible with tin foil to avoid light, and then vacuumize and seal the quartz crucible with the raw materials, so that the vacuum degree in the quartz crucible is 1×10 -1 Pa. The quartz crucible used has a wall thickness of 1 mm and a tip with an angle of 30° at the b...

Embodiment 2

[0041] A preparation method of iodine bismuth copper crystal, comprising the steps of:

[0042] 1) Preparation of iodine bismuth copper polycrystalline material; the preparation process includes the following steps:

[0043] ①Weigh copper powder, bismuth powder and iodine particles with a purity greater than or equal to 99.99% in a dark room according to the molar ratio Cu:Bi:I=1:1:4. The raw materials are cuprous iodide and bismuth iodide. A quartz crucible with a wall thickness of 1.2 mm is prepared, and a tip with an angle of 40° is provided at the bottom thereof, and a seed well for placing a seed crystal is also provided at the bottom of the quartz crucible. The iodine-bismuth-copper crystal that spontaneously nucleates and grows is ground into a cylinder with a length of 60 mm and a diameter of 2 mm in the direction of as a seed crystal, and the seed crystal is placed in the seed well of a quartz crucible in advance.

[0044] ②In the darkroom, mix 5.7019g copper powde...

Embodiment 3

[0051] A preparation method of iodine bismuth copper crystal, comprising the steps of:

[0052] 1) Preparation of iodine bismuth copper polycrystalline material; the preparation process includes the following steps:

[0053] ① Weigh cuprous iodide and bismuth iodide with a purity greater than or equal to 99.99% at a molar ratio of Cu:Bi=1:1 in a dark room. Prepare a quartz crucible with a wall thickness of 1.5 mm, and a tip with an angle of 45° is provided at the bottom of the quartz crucible, and a seed well for placing a seed crystal is also provided at the bottom of the quartz crucible. The iodine-bismuth-copper crystal that spontaneously nucleates and grows is ground into a cylinder with a length of 60 mm and a diameter of 2 mm in the direction of as a seed crystal, and the seed crystal is placed in the seed well of a quartz crucible in advance.

[0054] ②In the darkroom, put the weighed cuprous iodide under the quartz crucible, put the weighed bismuth iodide into the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com