Light polyether-ether-ketone or composite material thereof with different degrees of crystallinity and preparation method thereof

A composite material board and polyetheretherketone technology, which is applied in the field of polymer material preparation, can solve the problems of difficult gas saturation, single cell size, and small foam expansion ratio, and achieve enhanced foam strength, improved bottlenecks, and high foaming The effect of magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Put polyetheretherketone pellets (Changchun Jida Special Plastic Engineering Research Co., Ltd., MFI=25g / 10min) into a mold with a size of 4cm×10cm×3mm, and press molding at a temperature of 365°C and 5MPa to obtain a plate , and cut to size.

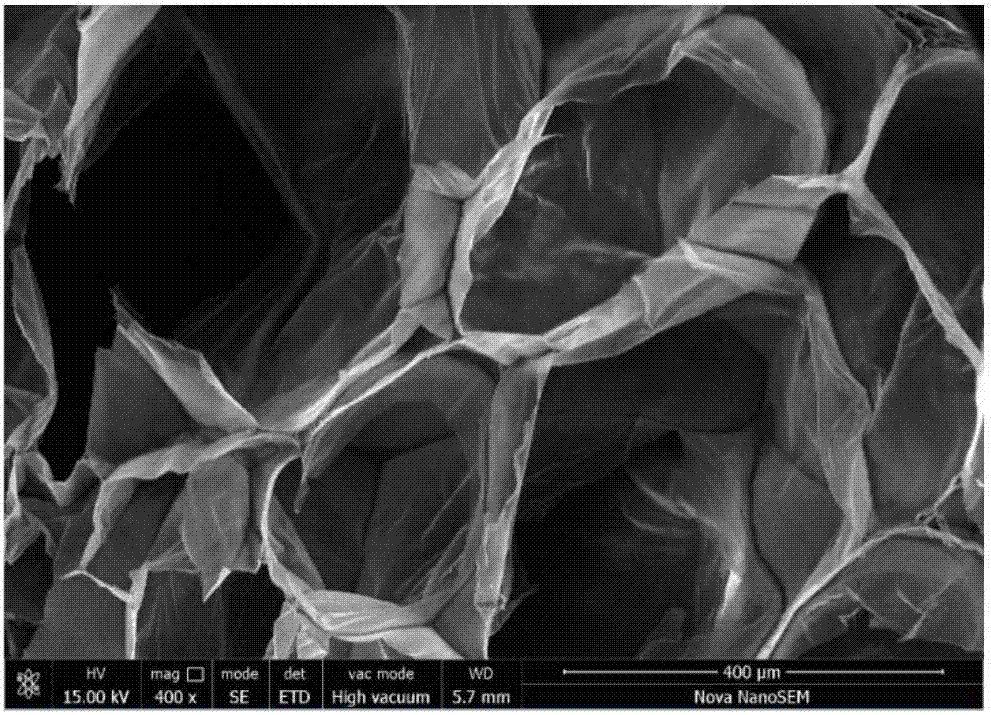

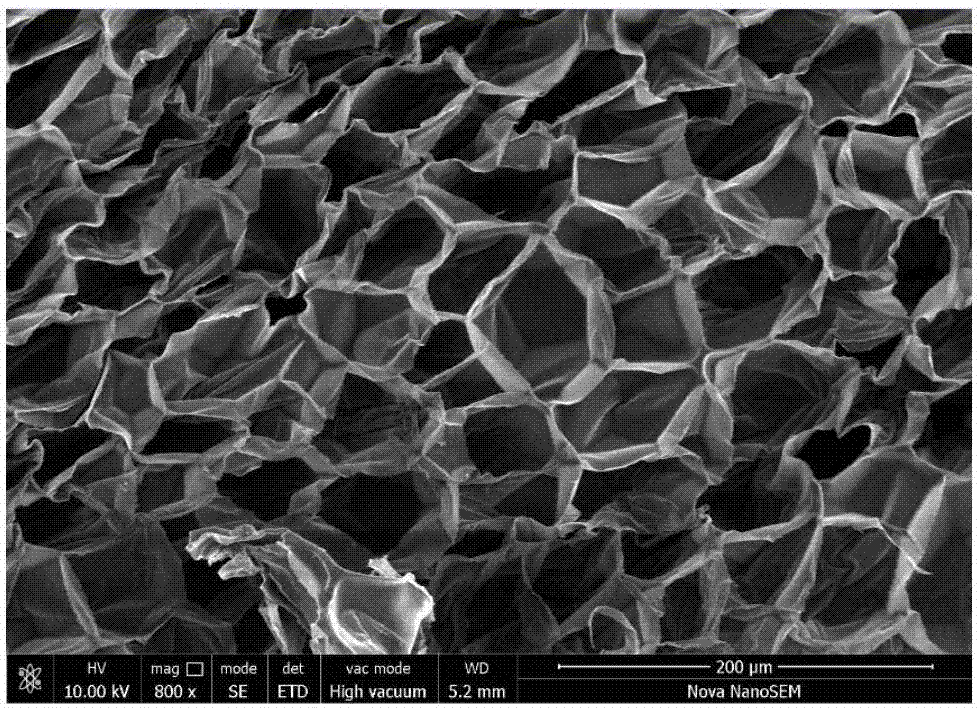

[0029] A polyetheretherketone plate (MFI=25g / 10min, crystallinity 26%, the size of the plate is 3cm×3cm×3mm) was placed in the autoclave, and the autoclave was sealed after being fixed. Inject CO into the autoclave using a high-pressure metering pump 2 Gas and exhaust the air in the autoclave until the autoclave is filled with CO 2 gas, and make the pressure in the kettle reach the set saturation pressure of 15MPa. Put the autoclave into the heating jacket, and turn on the temperature controller to make the temperature of the autoclave reach the set saturation temperature of 330° C., and the saturation time is 1 h. Control the pressure relief rate through the pressure relief valve to remove CO in the kettle 2Gas, the depressu...

Embodiment 2

[0032] Put polyetheretherketone pellets (Changchun Jida Special Plastic Engineering Research Co., Ltd., MFI=16g / 10min) into a mold with a size of 4cm×10cm×3mm, and press molding at a temperature of 365°C and 5MPa to obtain a plate , and cut to size.

[0033] A polyetheretherketone sheet (MFI=16g / 10min, crystallinity 26%, size of the sheet is 3cm×3cm×3mm) was placed in an autoclave, and the autoclave was sealed after being fixed. Inject CO into the autoclave using a high-pressure metering pump 2 Gas and exhaust the air in the autoclave until the autoclave is filled with CO 2 gas, and make the pressure in the kettle reach the set saturation pressure of 20MPa. Put the autoclave into the heating jacket, and turn on the temperature controller to make the temperature of the autoclave reach the set saturation temperature of 330°C. The saturation time is 1h, and the pressure relief rate is controlled by the pressure relief valve to remove the CO in the kettle 2 Gas, the depressuri...

Embodiment 3

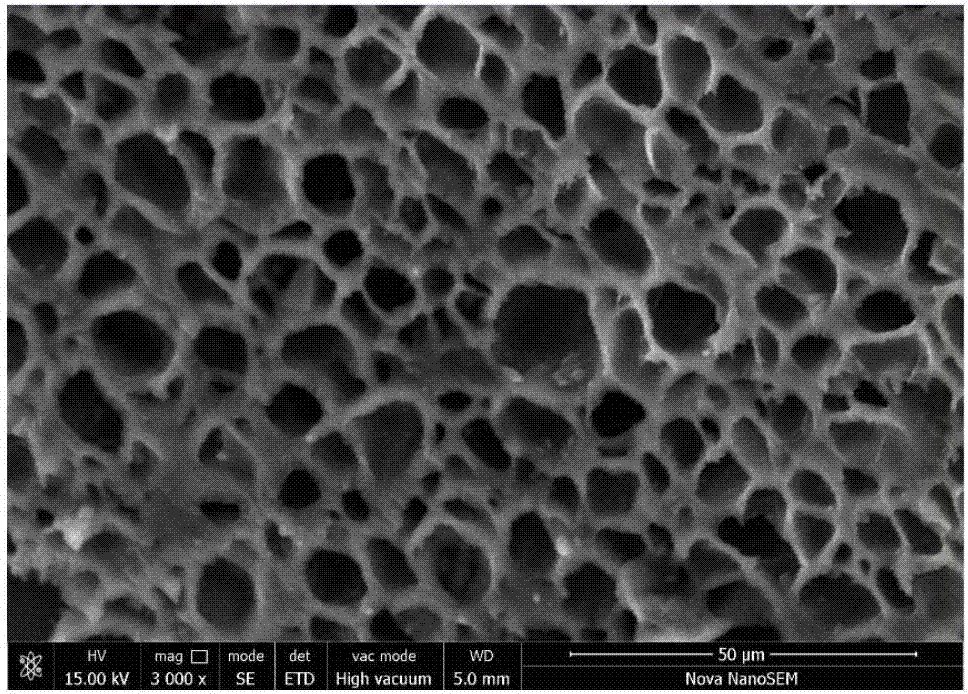

[0036] 0.1 g of polyethersulfone resin (PES) was dissolved in 50 mL of N,N-dimethylacetamide (DMAc) solvent. 8 g of multi-walled carbon nanotubes (MCNTs) were dispersed in 300 mL of N,N-dimethylacetamide (DMAc) to form a suspension. The two solutions were mixed under stirring, and ultrasonicated at 50° C. for 8 h. The ultrasonic suspension was discharged into distilled water and washed 8 times with distilled water. After suction filtration, the filter cake was dried under vacuum at 120°C for 4 hours to obtain polyethersulfone resin-coated modified multi-walled carbon nanotubes (PES @MWCNTs).

[0037] Weigh 3wt% PES@MWCNTs and 97wt% PEEK powder ((Changchun Jida Special Plastic Engineering Research Co., Ltd., MFI=45g / 10min), fully premix in a high-speed mixer (26000r / min), use Huck Extruder (HAAKEMiniLab) carries out melt blending and extrudes granulation. Setting processing temperature is 380 ℃, and screw speed is 80r / min. Then pellet is put into a mold that size is 4cm * 10c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com