Filter and preparation method thereof

A filter and bulk acoustic wave resonator technology, applied in electrical components, impedance networks, etc., can solve the problems of many process steps, high production cost, long production process, etc., and achieve simplified process, light weight, and small thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

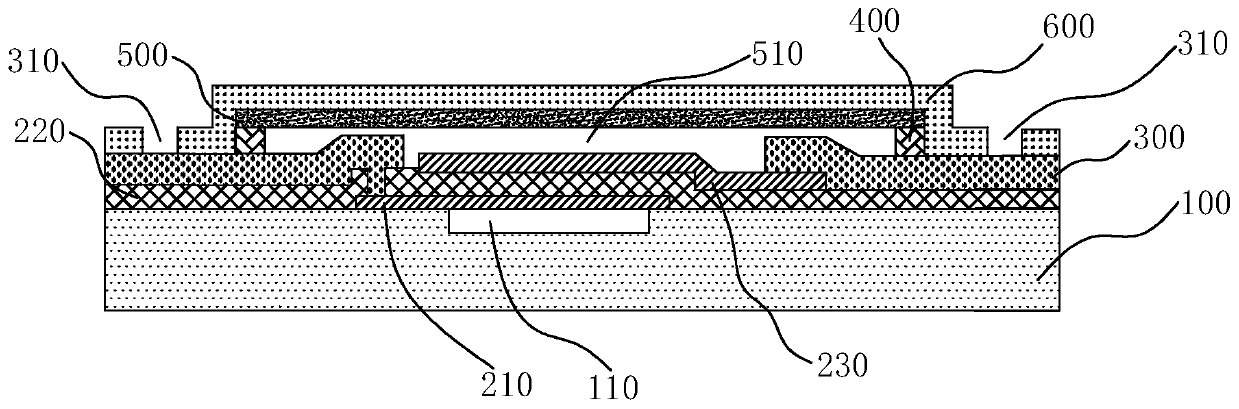

[0031] Embodiment 1 provides a kind of BAW filter, refer to figure 1 , figure 1 The BAW filter structure is shown, including: a substrate 100 , bulk acoustic wave resonators ( 210 , 220 , 230 ), an electrical connection layer 300 , a sealing layer 400 , a capping layer 500 and a protective layer 600 .

[0032] In this embodiment, the substrate 100 can be made of material Si or SiC, the substrate has a lower cavity 110, the lower cavity 110 is arranged on the upper surface of the substrate, and a bulk acoustic wave resonator (210) is arranged on the lower cavity. , 220 , 230 ), the bulk acoustic wave resonator includes a lower electrode 210 , a piezoelectric layer 220 and an upper electrode 230 , and the piezoelectric layer 220 is located between the lower electrode 210 and the upper electrode 230 .

[0033] The electrical connection layer 300 formed on the piezoelectric layer 220 includes a metal connection, and two ends of the metal connection are respectively connected to t...

Embodiment 2

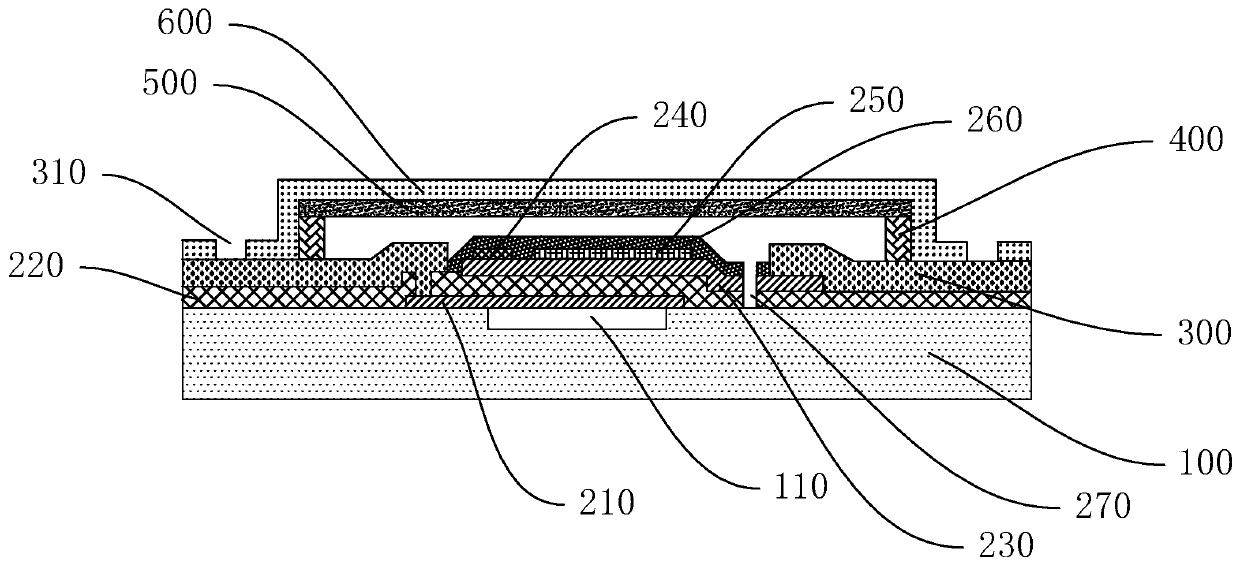

[0035] Embodiment 2 provides another BAW filter, refer to figure 2 , figure 2 Another BAW filter structure is shown, which not only includes the substrate 100, bulk acoustic wave resonators (210, 220, 230), electrical connection layer 300, sealing layer 400, capping layer 500 and protective layer in Embodiment 1 600, further comprising a mass load 240 for frequency adjustment, a thin film layer 250 for temperature compensation of the filter, a passivation layer 260 for protecting the resonator, and a stray wave suppression structure 270.

[0036] Wherein, the difference from Embodiment 1 is that the sealing layer 400 of the BAW filter in this embodiment is made of a photosensitive dry film.

[0037] The mass load 240 is used to adjust the frequency of the mass load, that is, by setting a load on the upper electrode 230, the frequency of the bulk acoustic wave resonator (210, 220, 230) is fine-tuned to meet the design requirements of the filter. Mass loads are generally met...

Embodiment 3

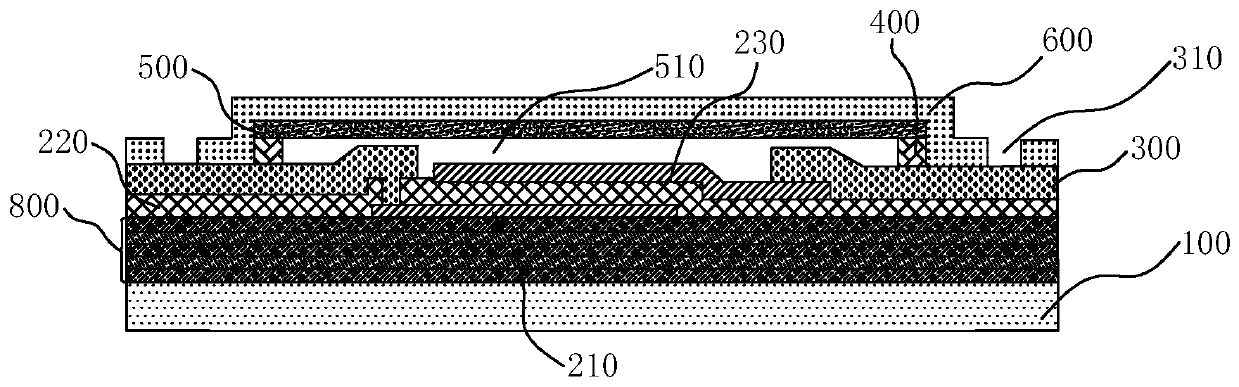

[0042] Embodiment 3 provides a kind of BAW-SMR filter, refer to image 3 , image 3 A schematic diagram of the structure of the BAW-SMR filter is shown. The BAW-SMR filter structure of the present invention includes: a substrate 100 , a Bragg reflector 800 , bulk acoustic wave resonators ( 210 , 220 , 230 ), an electrical connection layer 300 , a sealing layer 400 , a capping layer 500 and a protective layer 600 .

[0043]Specifically, the substrate 100 can be made of material Si or SiC, in image 3 In the described embodiment, the substrate does not have a lower cavity. A Bragg reflector 800 composed alternately of two materials with different acoustic impedances is disposed on the substrate 100, and the Bragg reflector 800 can effectively reduce the acoustic wave propagating to the substrate. Bulk acoustic wave resonators (210, 220, 230) are arranged on the Bragg reflector 800, and the bulk acoustic wave resonators (210, 220, 230) include a lower electrode 210, a piezoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com